Fault Monitoring of Electromagnetic Vibration Damping System Based on Magnetic Flux Density Signals

-

摘要:

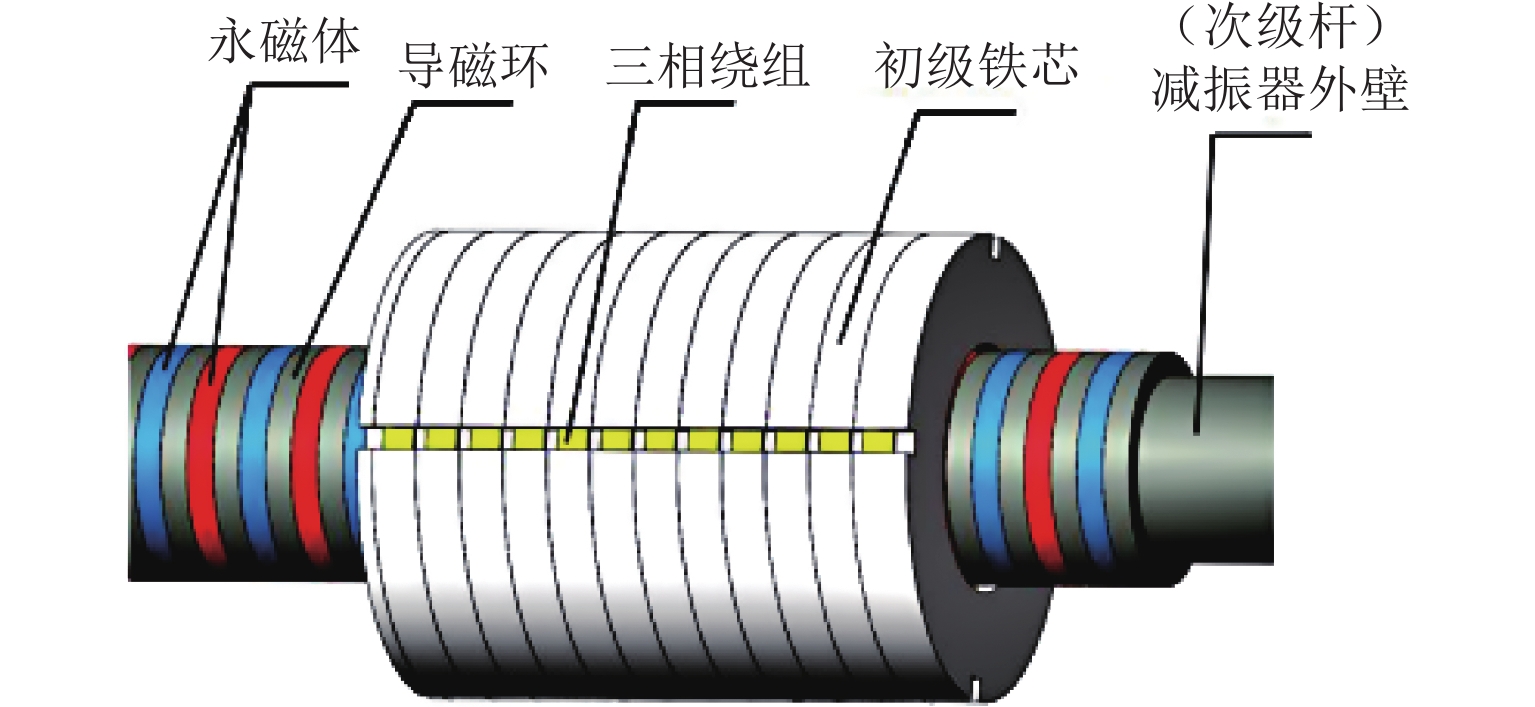

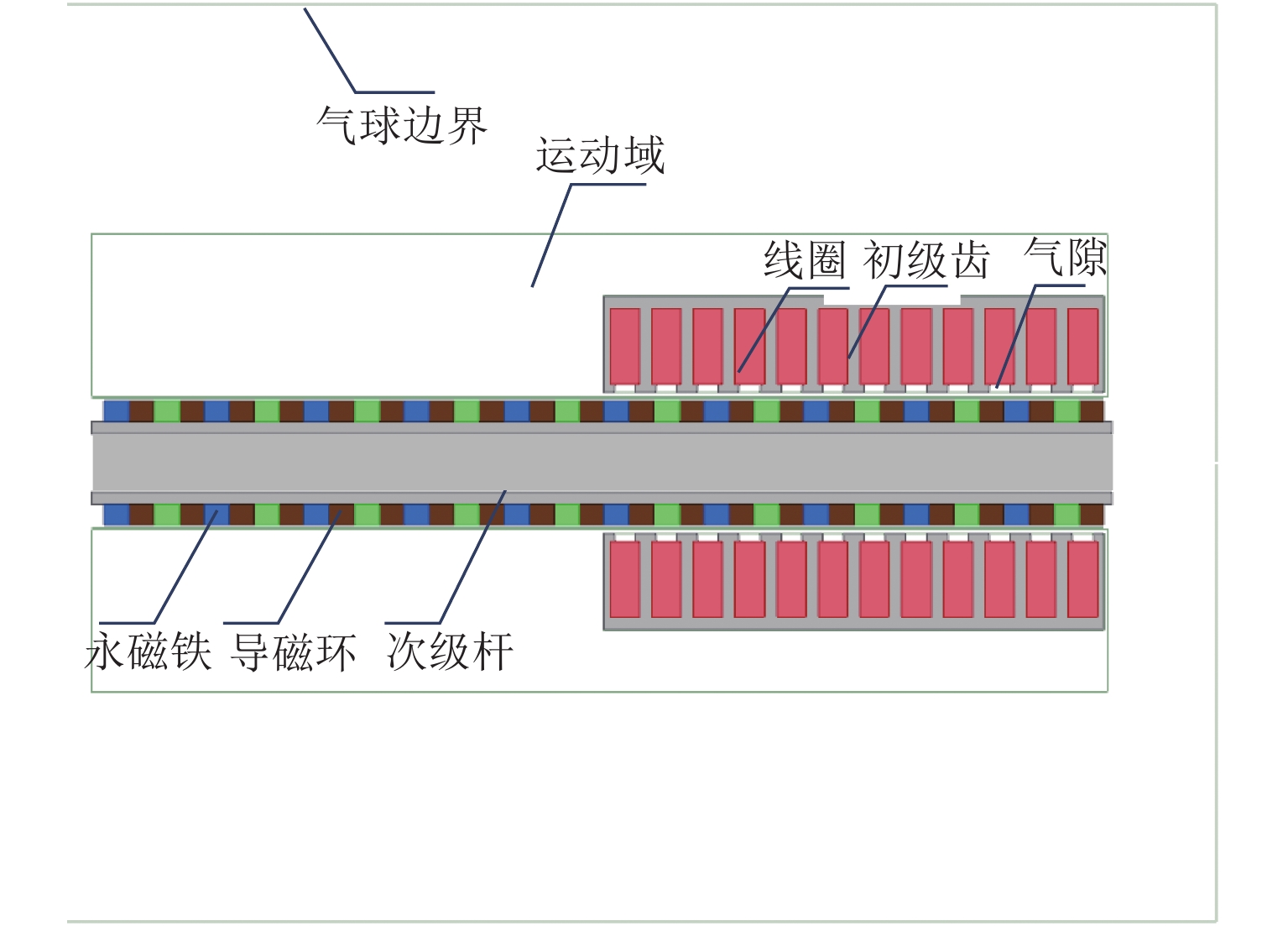

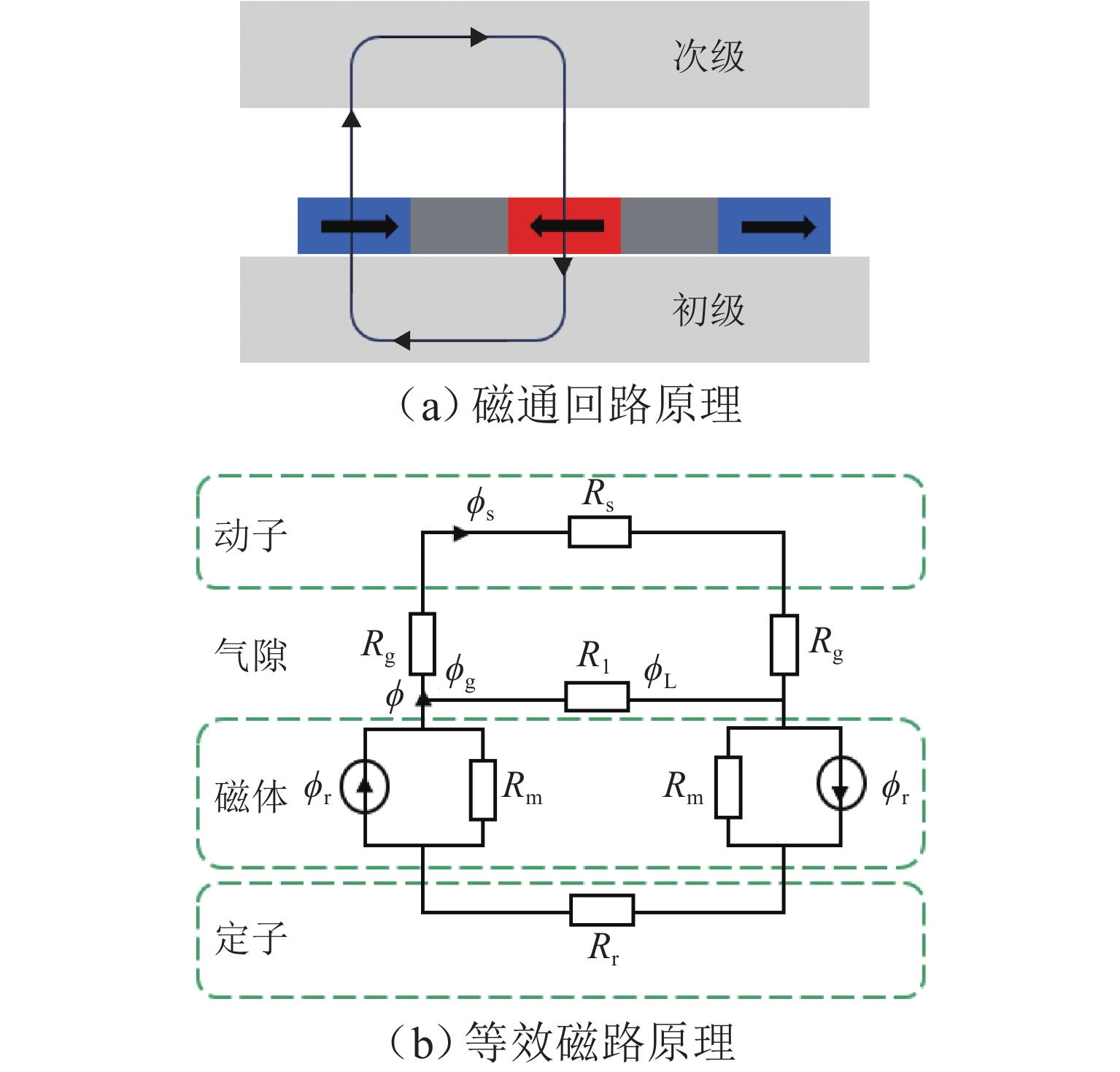

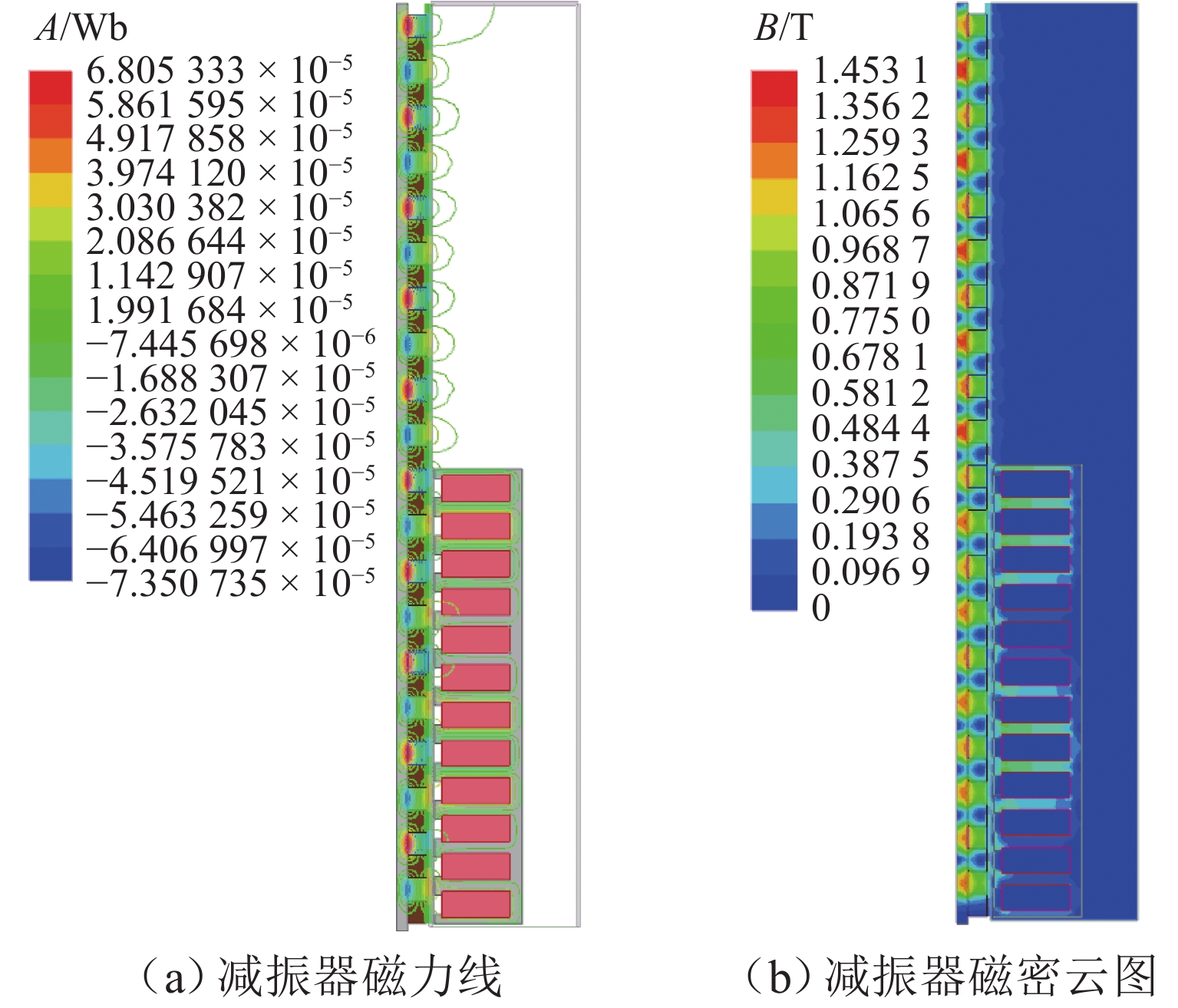

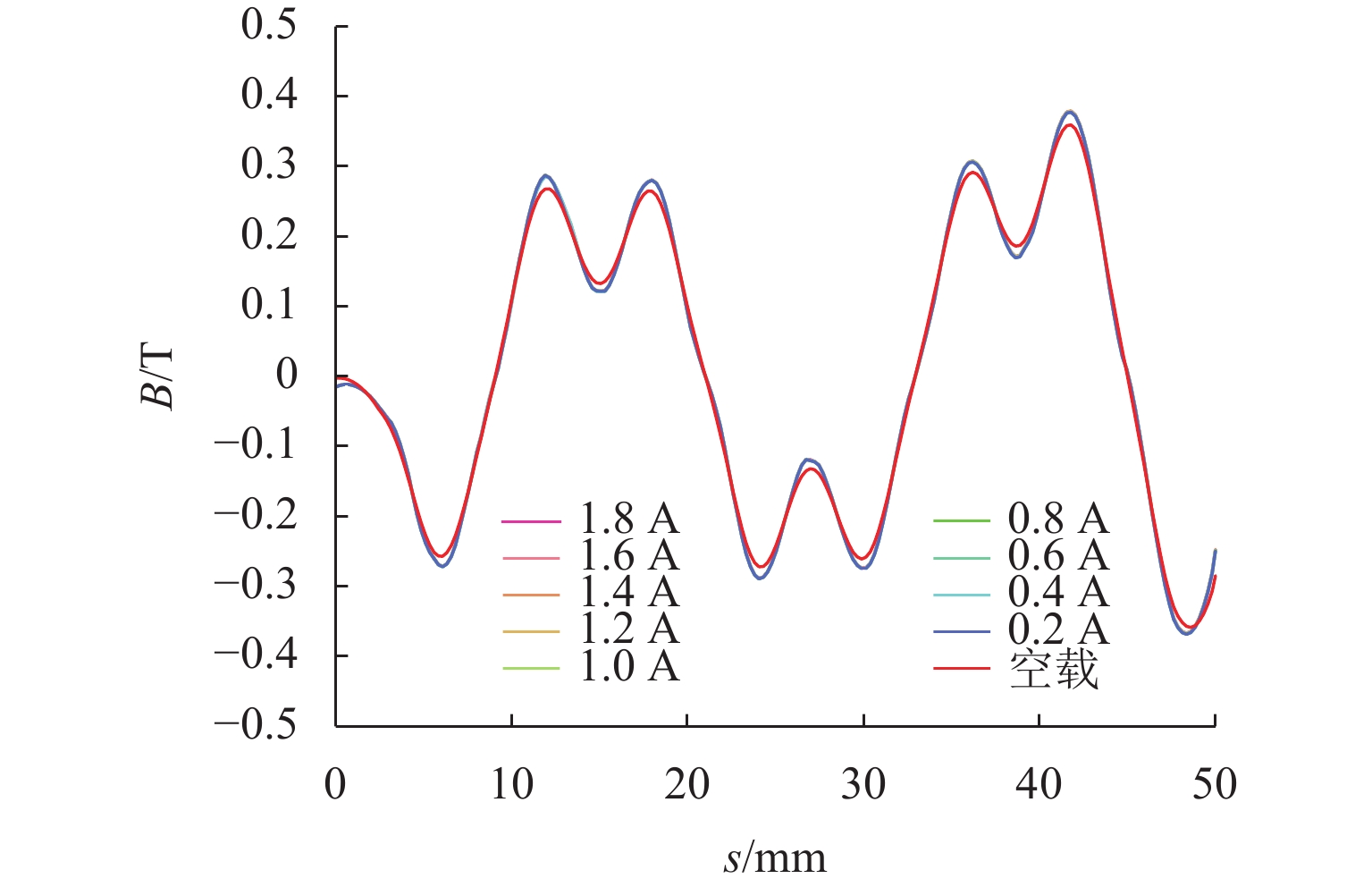

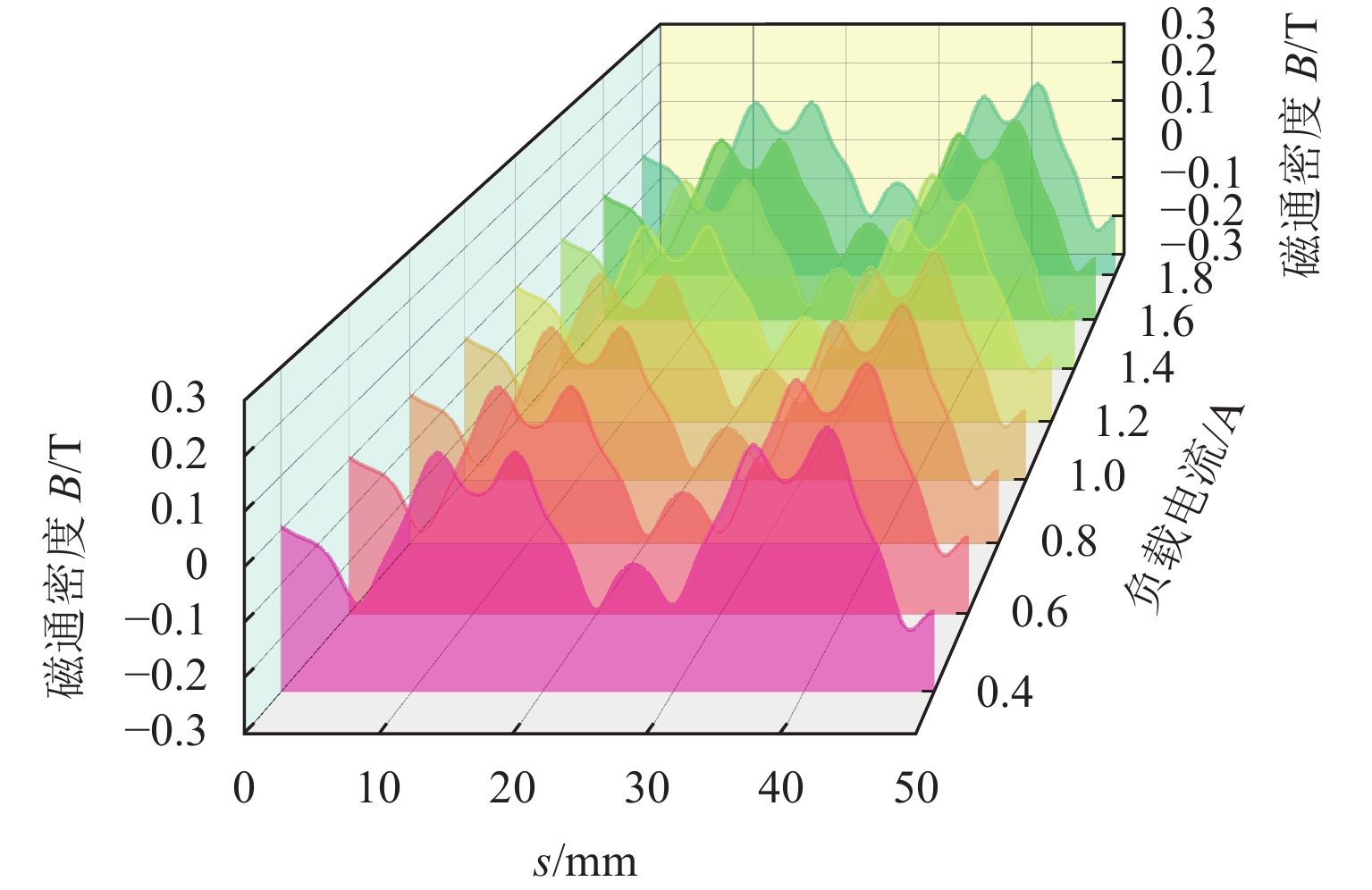

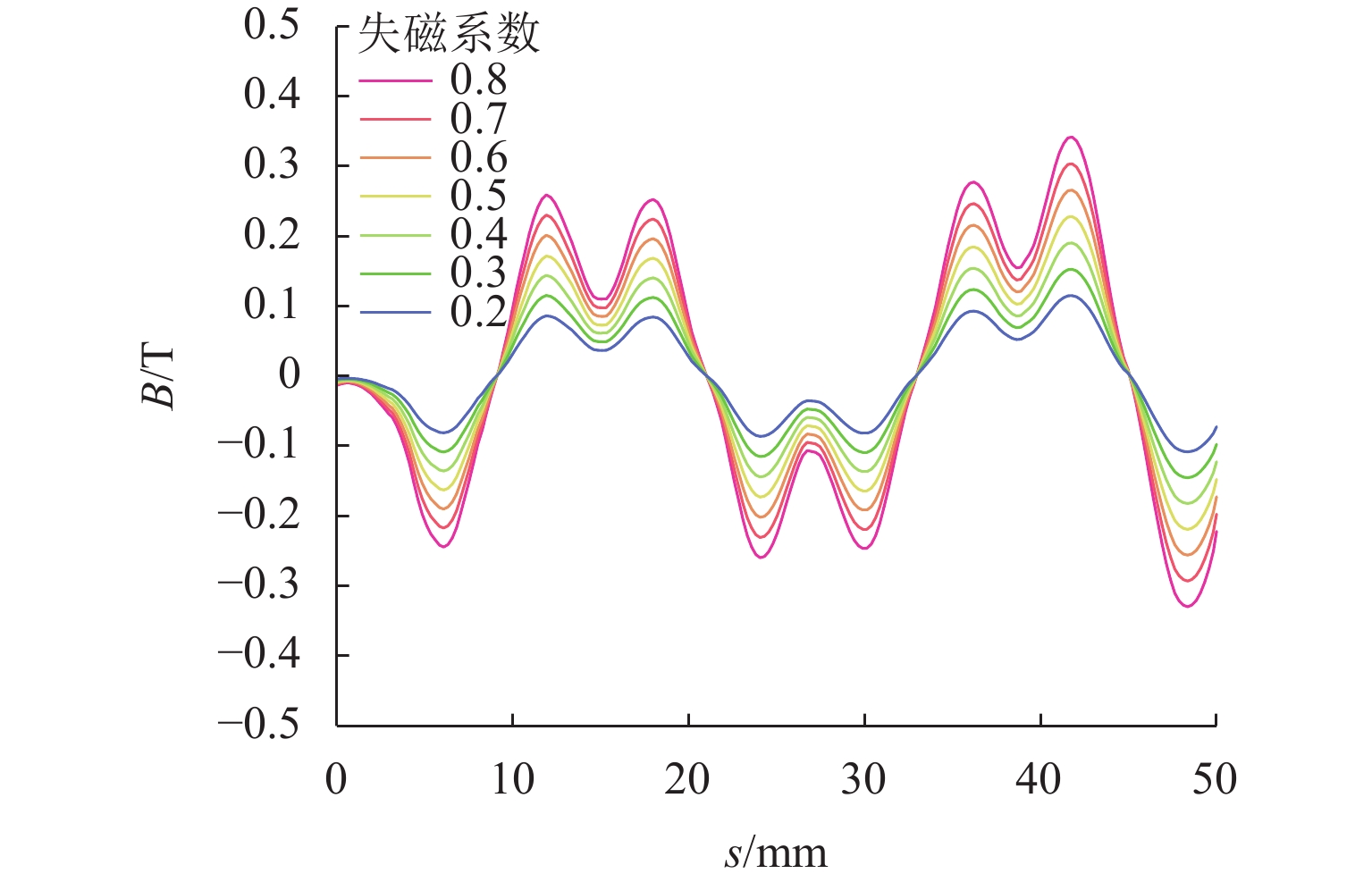

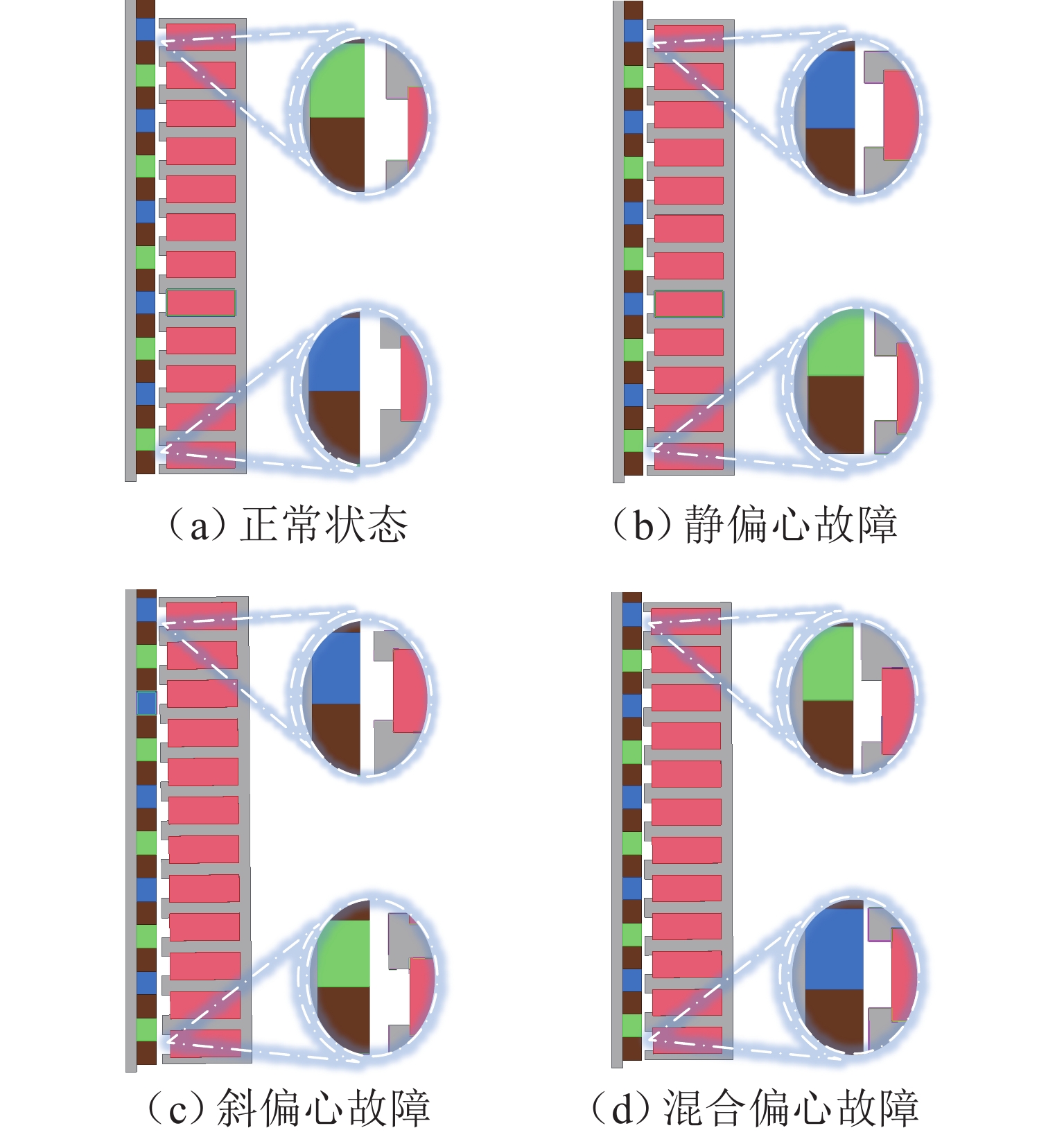

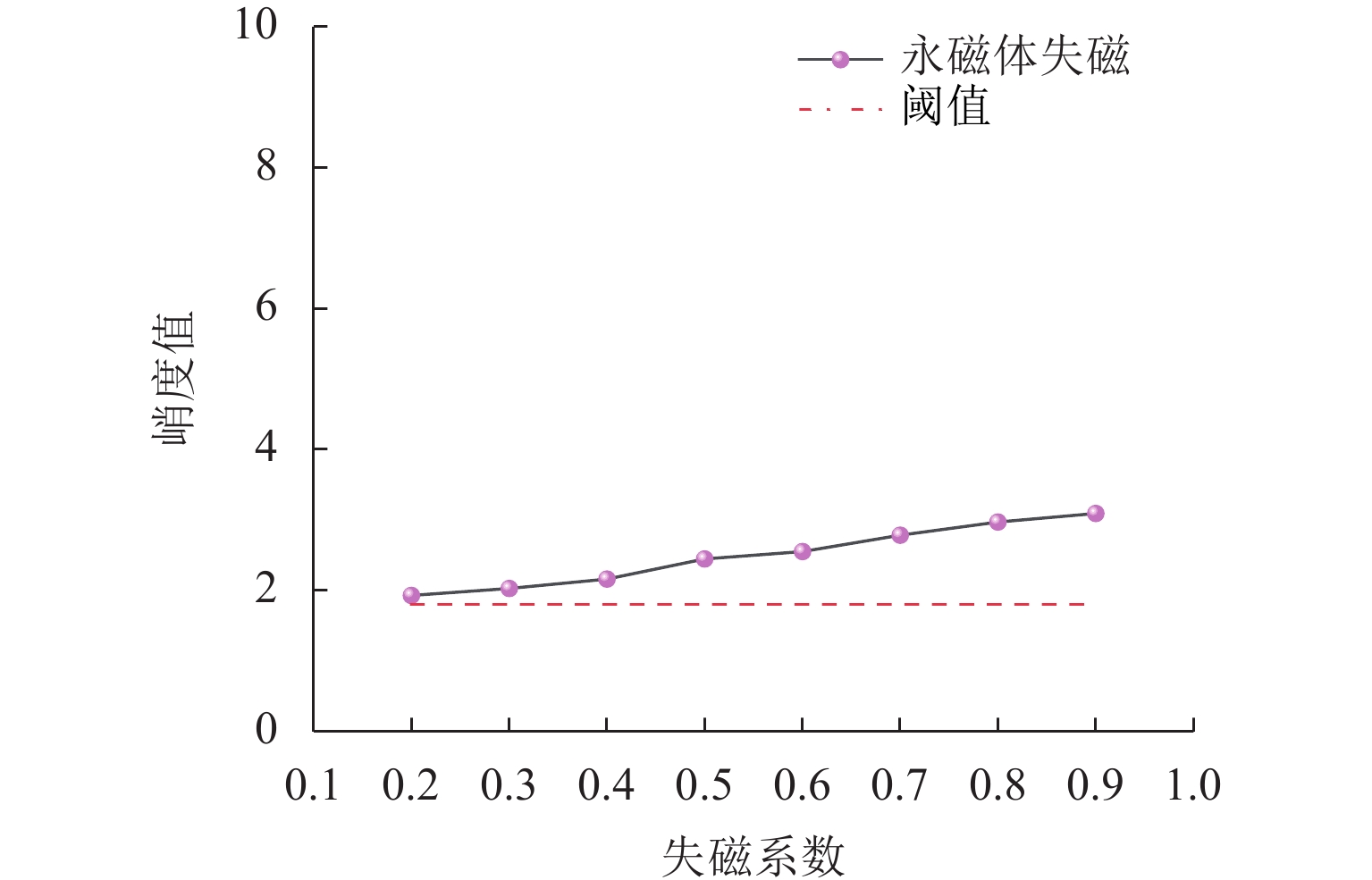

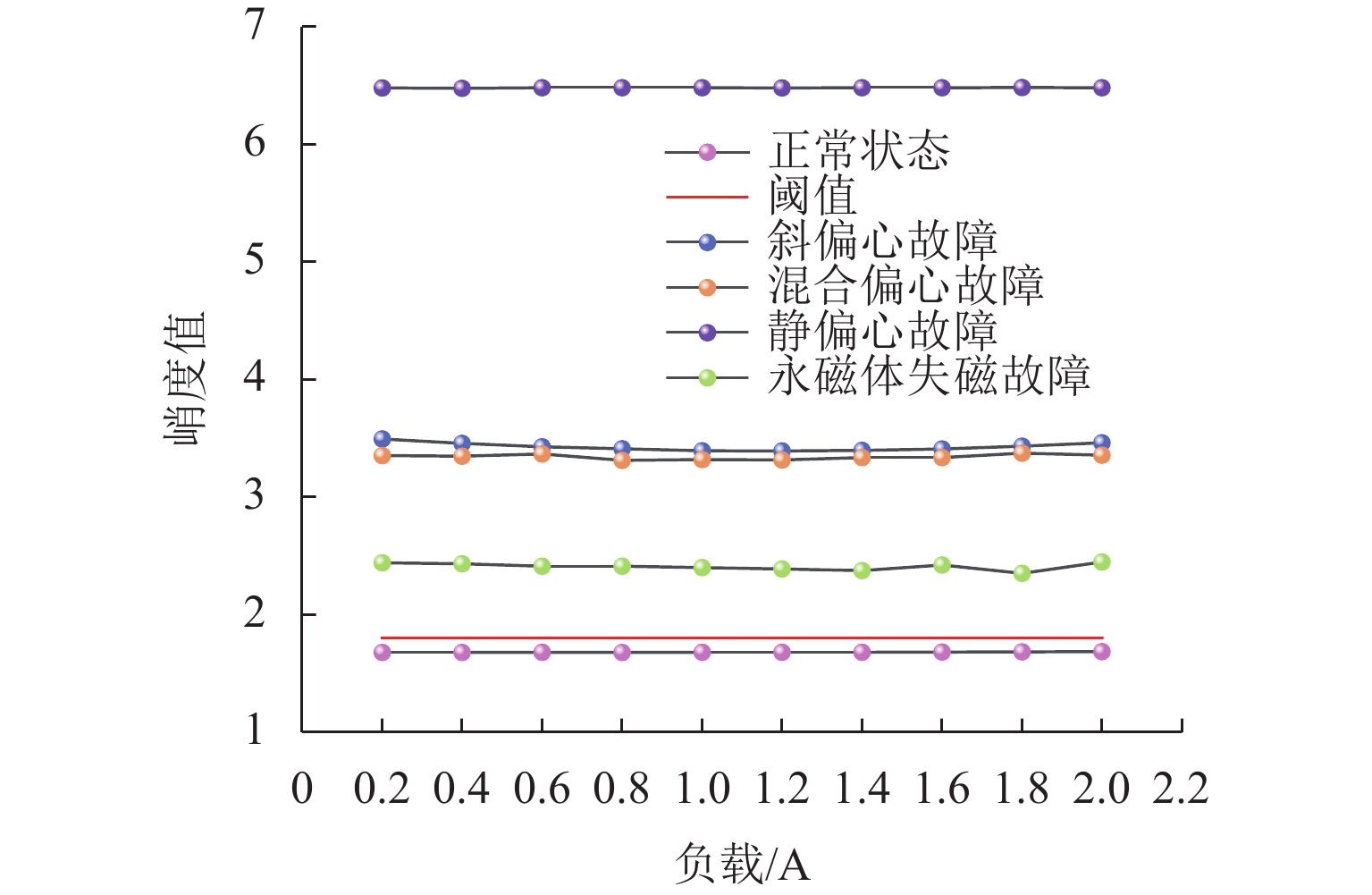

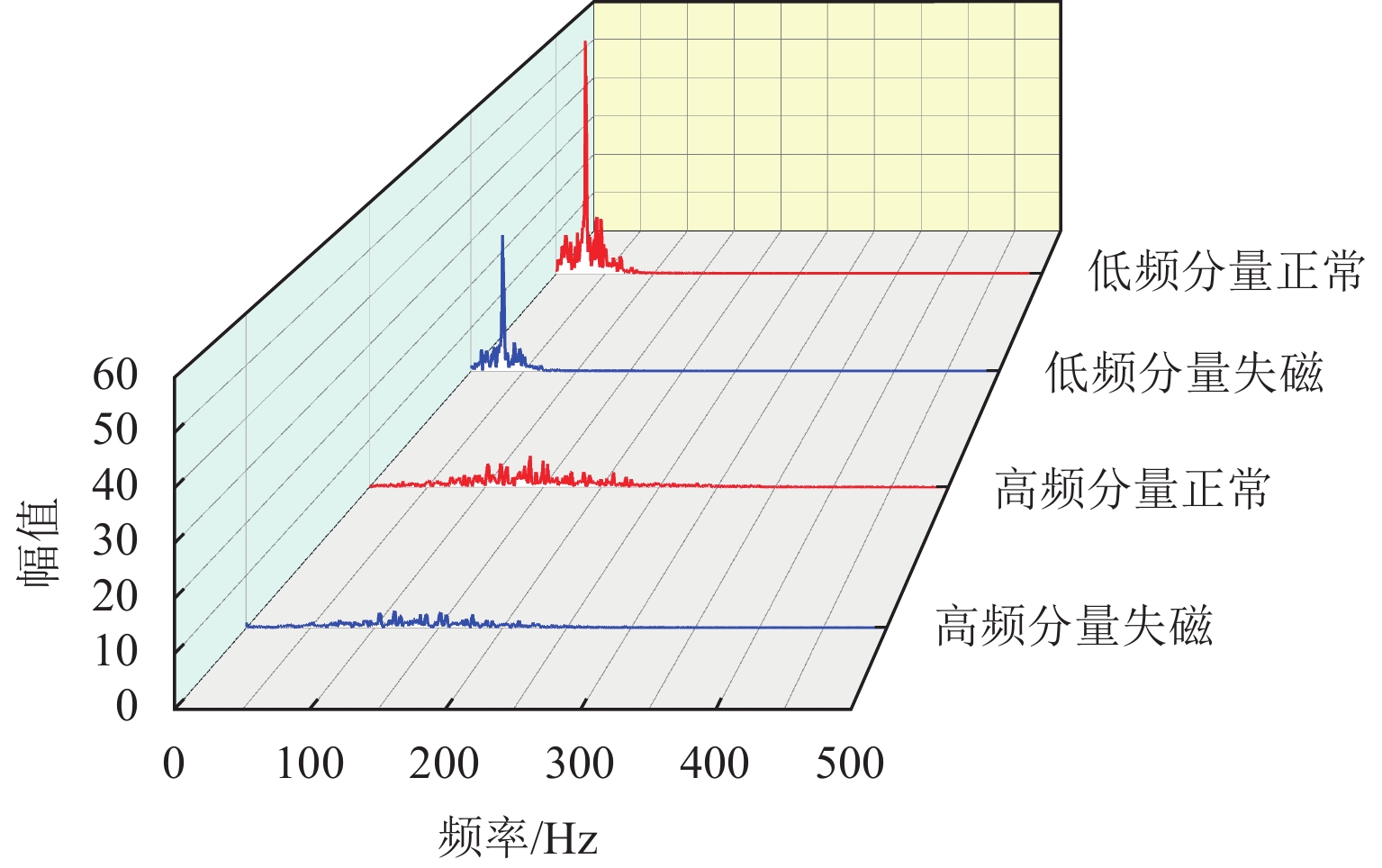

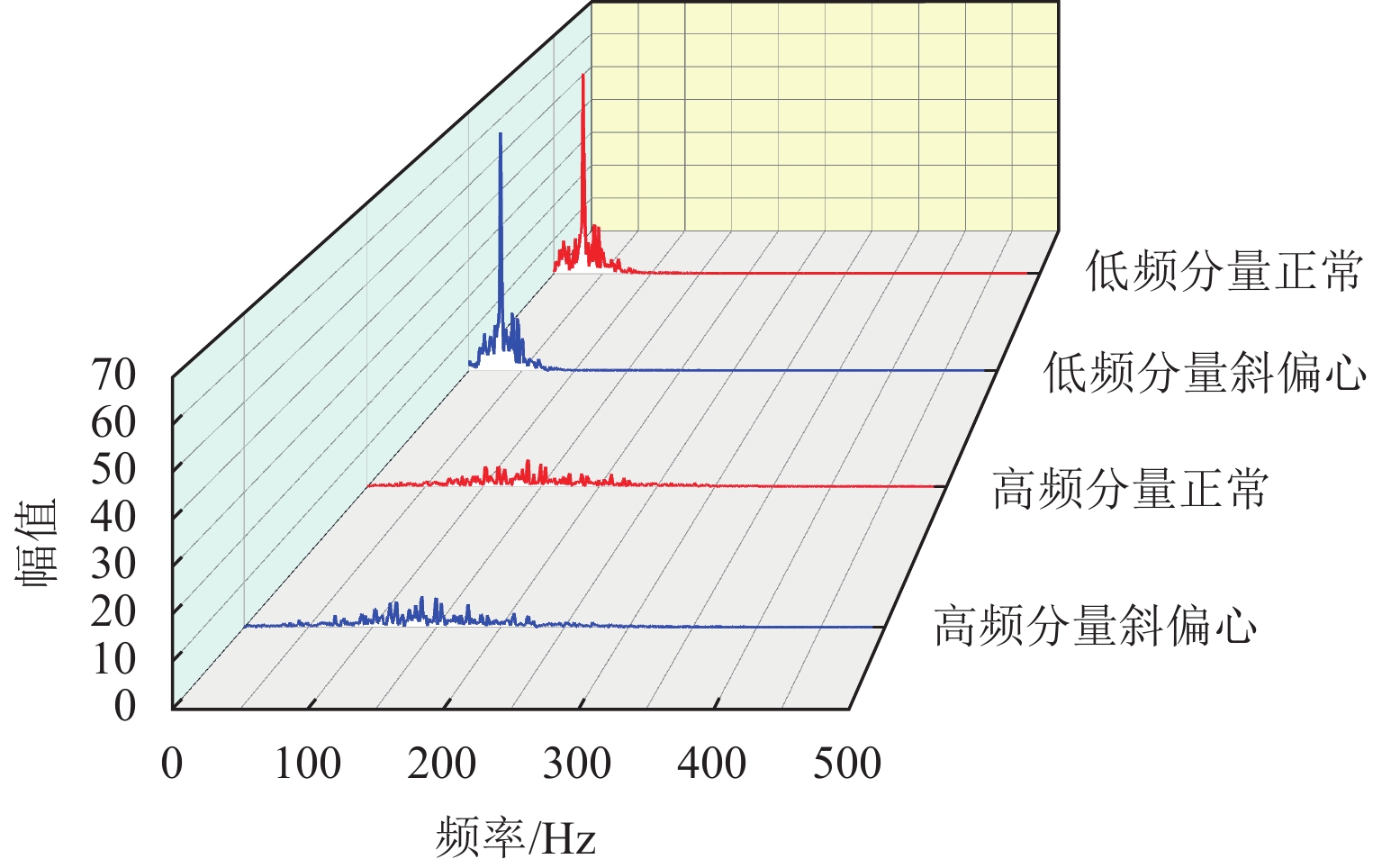

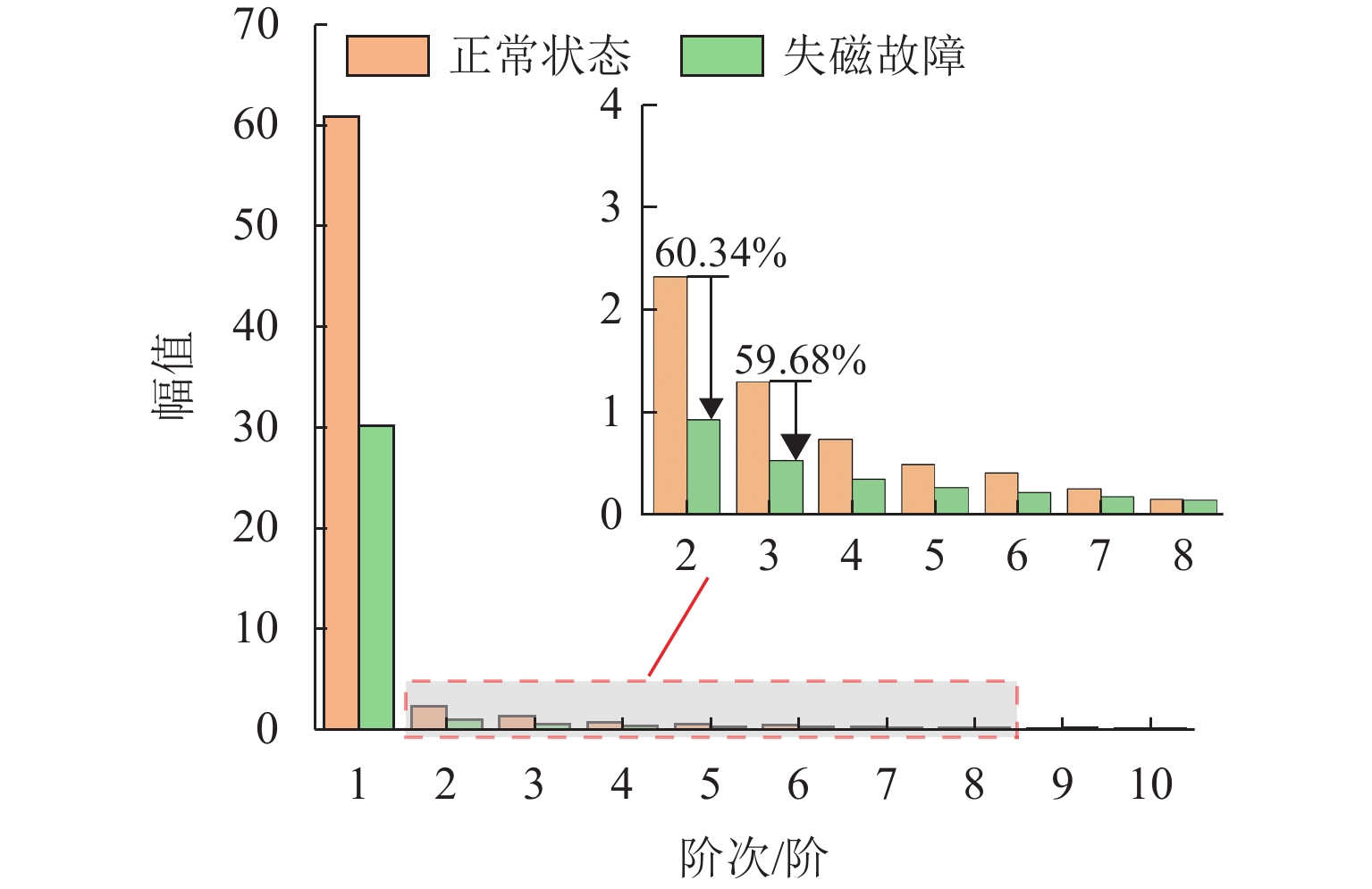

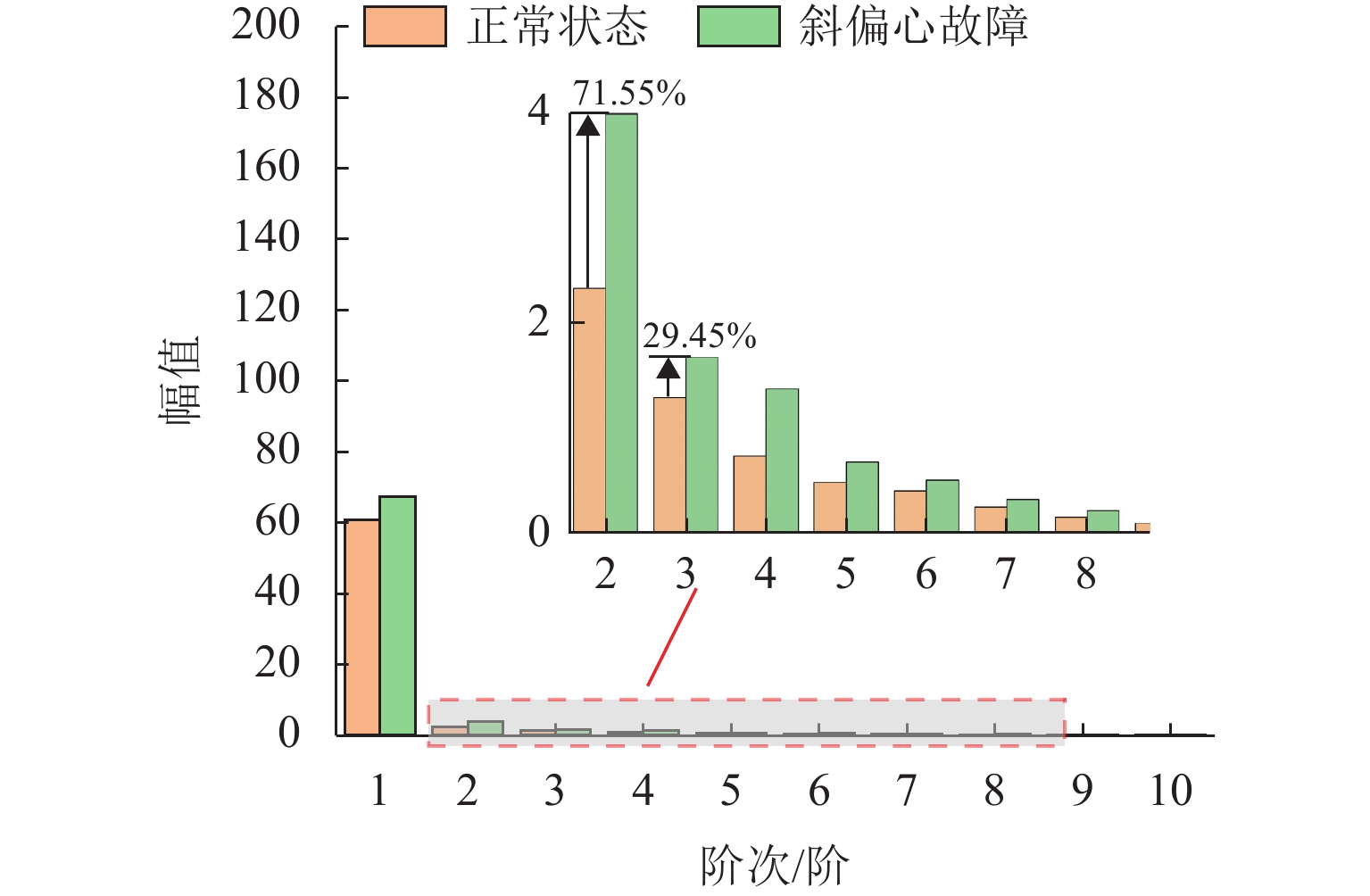

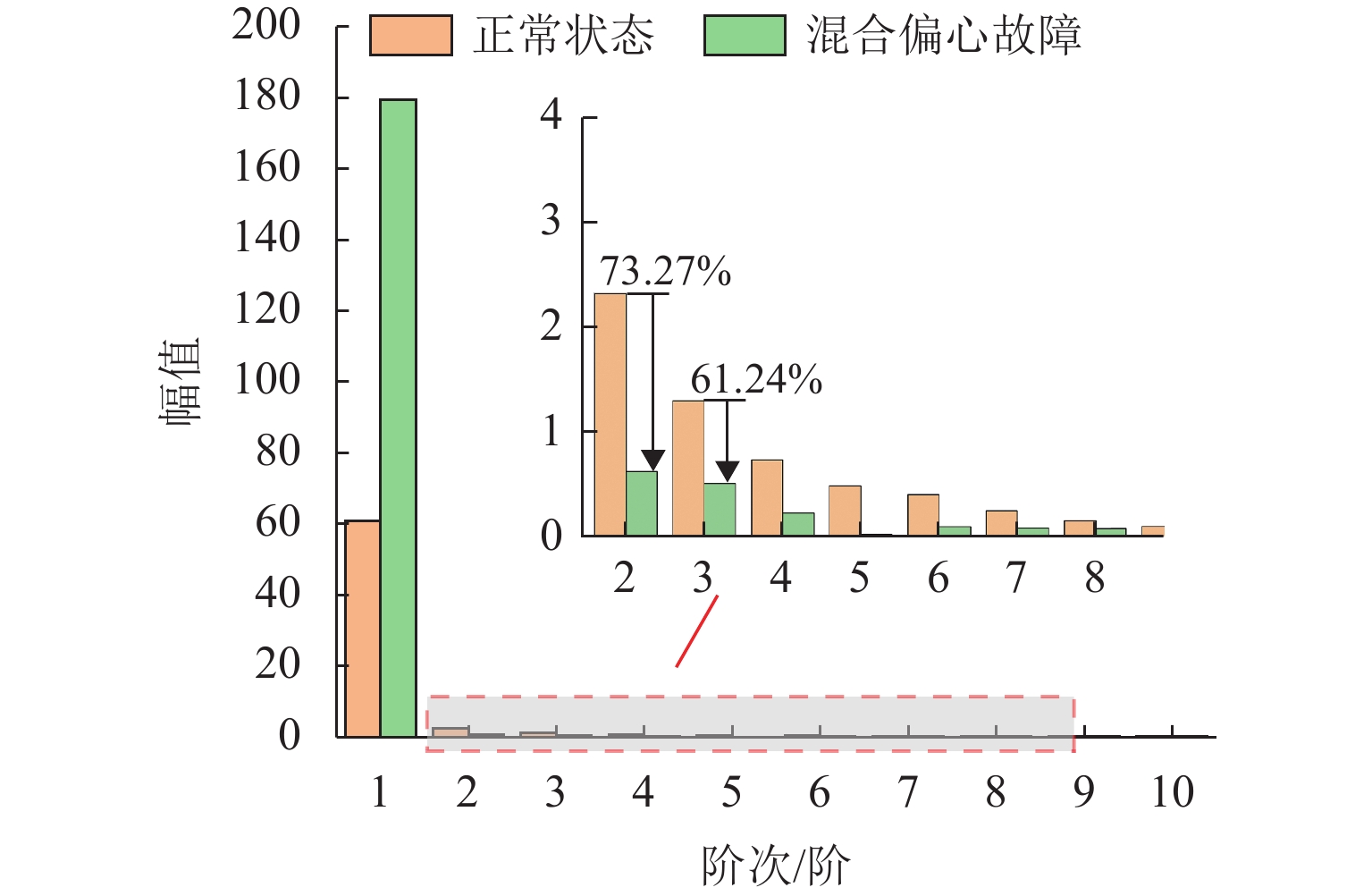

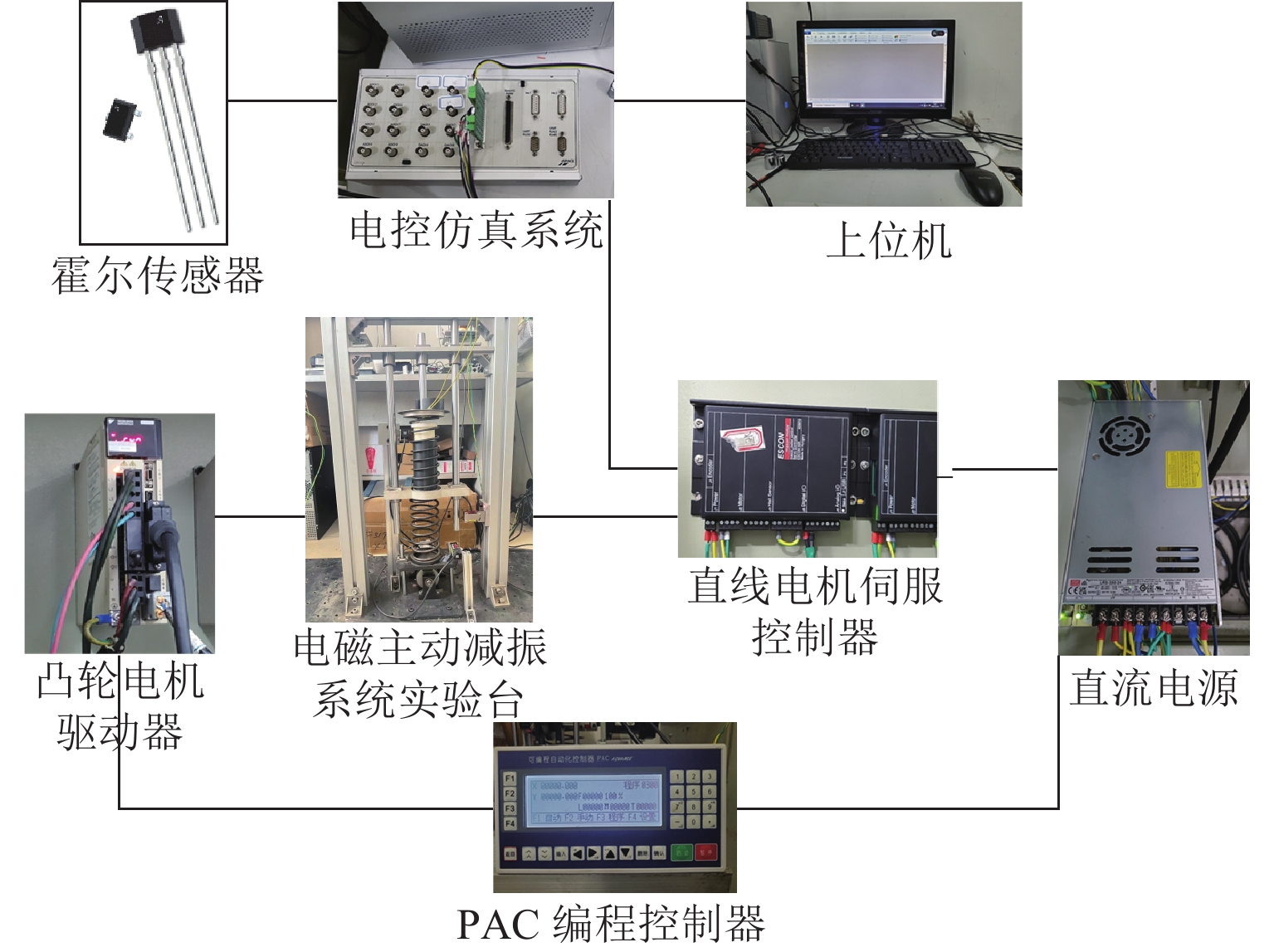

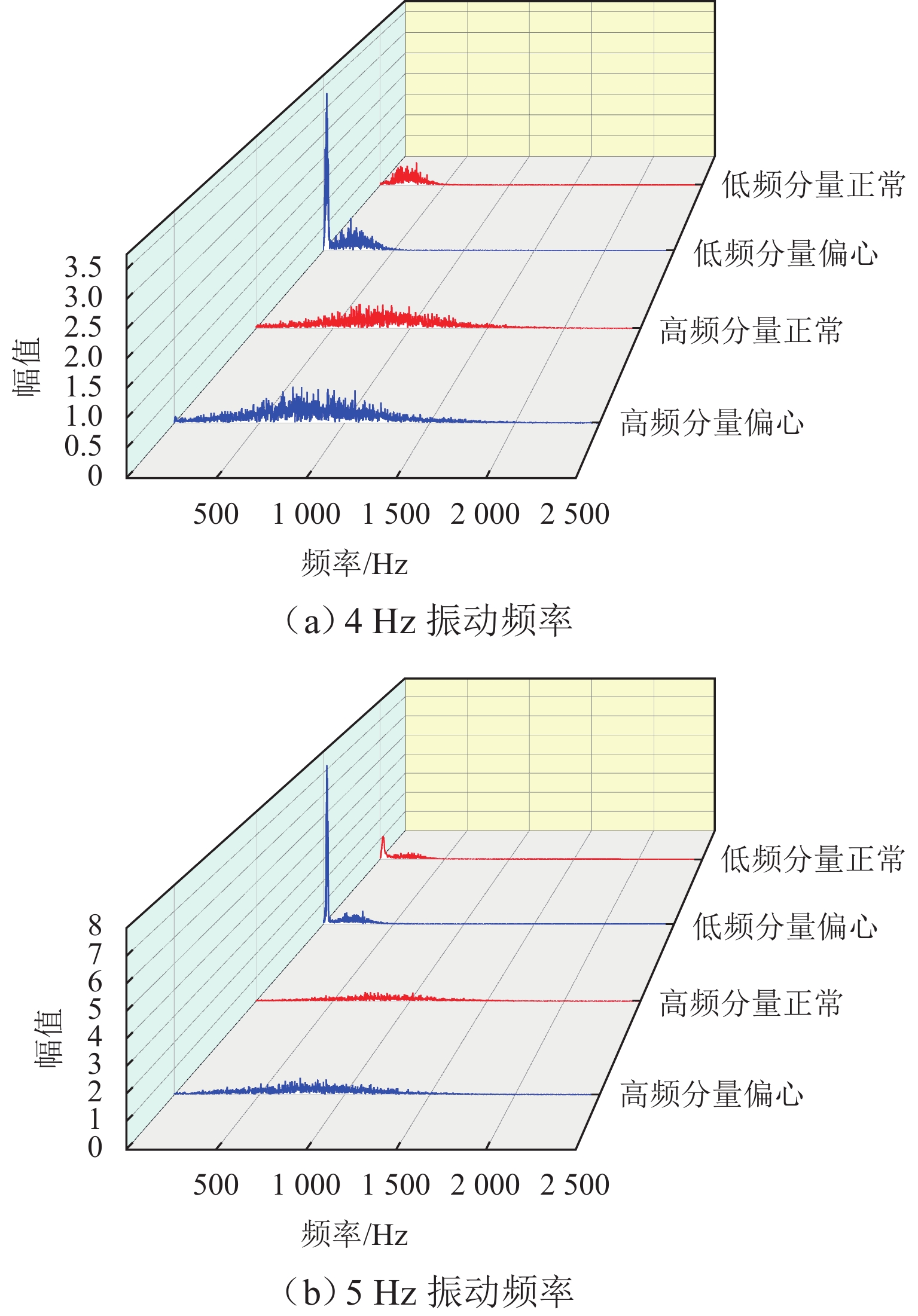

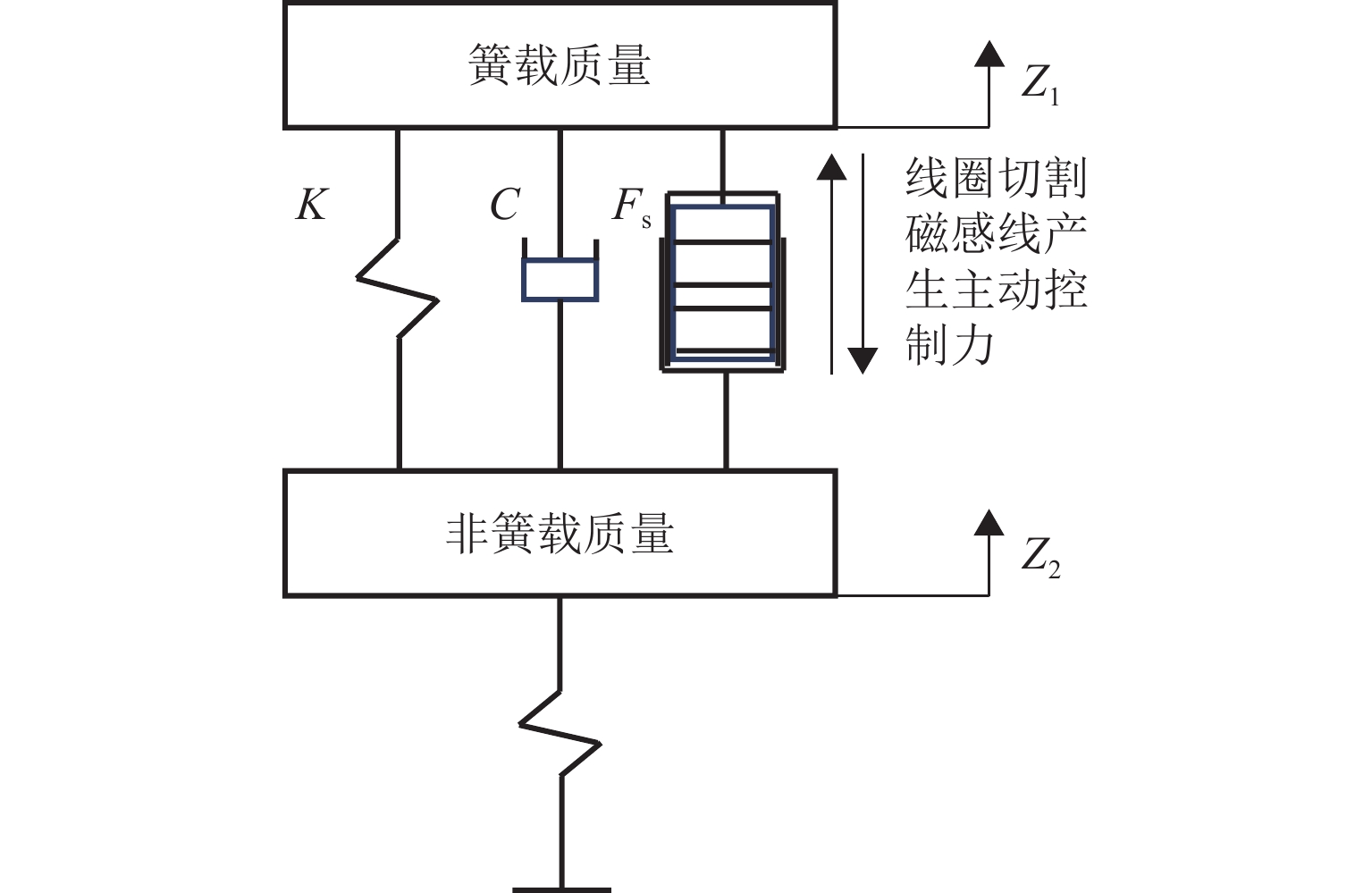

当前电磁减振系统故障诊断方面的研究大多基于力学特征(位移信号或加速度信号)展开,而对系统内部磁场信号变化的研究相对较少. 本文以霍尔传感器检测的磁场信号为条件,基于考虑直线电机式电磁减振系统服役状态过程中各故障对气隙磁密信号的影响,对电磁减振系统有限元建模,并分析、探讨故障监测. 首先,对直线电机式电磁减振系统进行磁路分析,建立等效磁路模型,分析各故障对气隙磁密信号影响条件;然后,采用Maxwell电磁仿真平台建立电磁减振系统仿真模型,研究电磁减振系统不同故障下气隙磁场的磁通密度信号参数变化规律;最后,通过获取各故障条件下检测得到的电磁减振系统时频域故障特征信息,使用集合经验模态分解(EEMD)对信号频域特征信息进行经验模态分解,对比分析时频域特征信息,实现对各故障的监测. 研究结果表明:系统正常状态下时域峭度值为1.6,失磁及偏心故障状态下的时域峭度值分别为2.5、6.5,其频域评价指标较正常状态有不同幅度的变化,并通过实验验证了故障监测方法的有效性.

Abstract:Most existing fault diagnosis studies for electromagnetic vibration damping systems rely on mechanical signals such as displacement or acceleration signals, while relatively few studies focus on the changes in internal magnetic field signals. Magnetic field signals detected by the Hall sensor were used as the basis. By considering the effects of various faults during the service process of a linear motor-type electromagnetic vibration damping system on the air gap magnetic flux density signals, a finite element model of the electromagnetic vibration damping system was established, and fault monitoring was analyzed. First, a magnetic circuit analysis of the linear motor-type electromagnetic vibration damping system was carried out; an equivalent magnetic circuit model was established, and the conditions under which various faults affected the air gap magnetic flux density signals were analyzed. Then, a simulation model of the electromagnetic vibration damping system was established using the Maxwell electromagnetic simulation platform to study the variation patterns of magnetic flux density signal parameters in the air gap under different fault conditions. Finally, fault characteristic information in the time and frequency domains was obtained under various fault conditions. Ensemble empirical mode decomposition (EEMD) was applied to the frequency-domain feature information, and the time-frequency domain characteristics were compared to achieve fault monitoring. The results show that the time-domain kurtosis value is 1.6 under normal conditions, while the values are 2.5 and 6.5 under demagnetization and eccentricity fault conditions, respectively. The frequency-domain evaluation indicators exhibit different degrees of variation compared with those under normal conditions, and the effectiveness of the fault monitoring method is verified through experiments.

-

表 1 电磁减振器设计参数

Table 1. Design parameters of electromagnetic vibration absorber

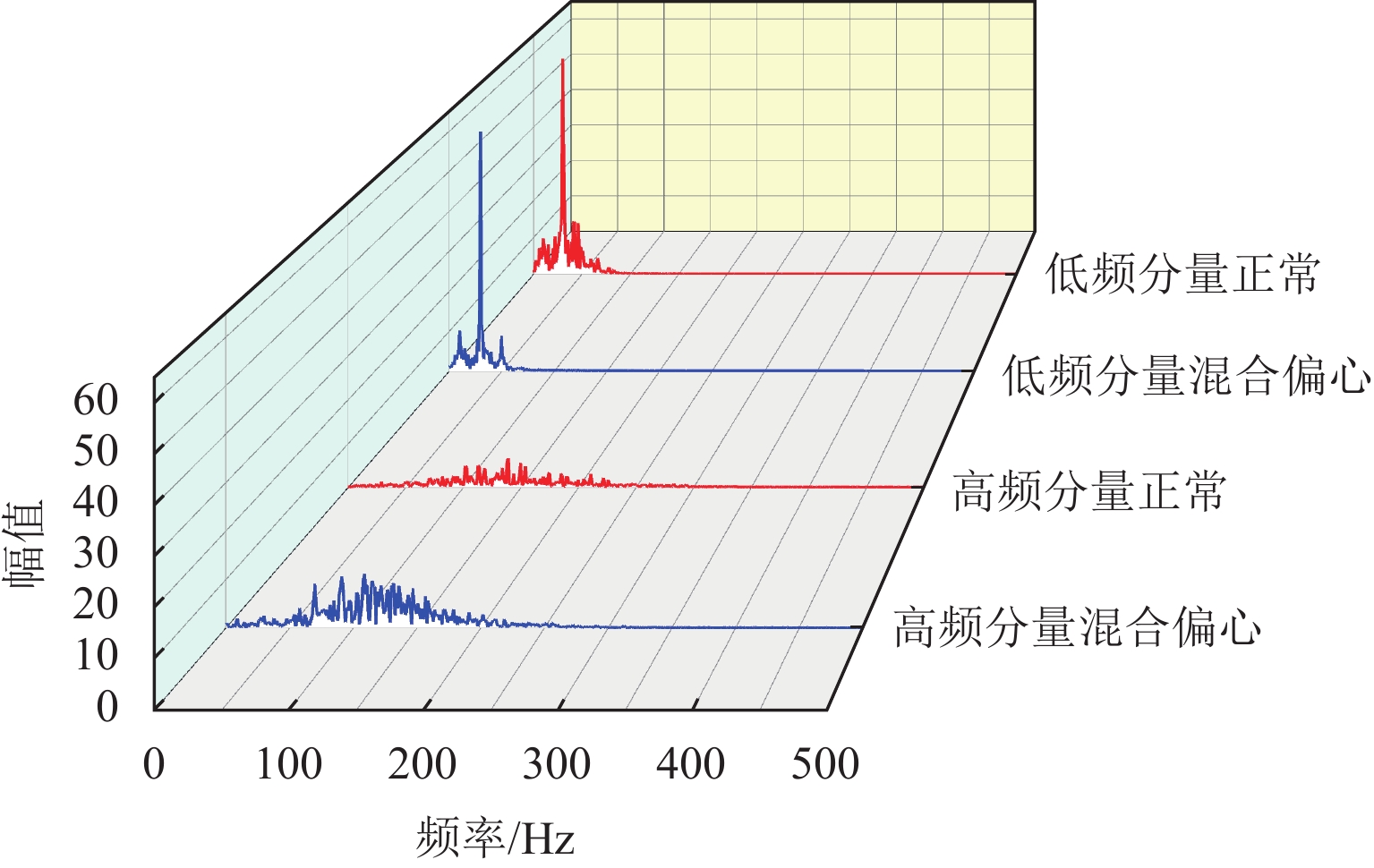

参数名称 数值 初级长度/mm 126 初级外径/mm 100 次级长度/mm 360 槽数/个 12 极对数/对 5 极距/mm 12 气隙/mm 1.5 表 2 各故障与正常状态高频分量与低频分量最大值对比

Table 2. Comparison of maximum values of high-frequency and low-frequency components under various faults and normal condition

故障分类 高频分量最

大值变化/%低频分量最

大值变化/%永磁体失磁 −52 −46 静偏心故障 −1 20 斜偏心故障 5 10 混合偏心故障 68 104 表 3 霍尔传感器参数

Table 3. Hall sensor parameters

项目 WSH138 灵敏度/(mv·Gs−1) 8.3 工作电流/mA $ \leqslant 5 $ 检测范围/Gs $ \pm $ 200 表 4 偏心故障霍尔信号时域峭度值变化对比

Table 4. Comparison of time-domain kurtosis values of Hall signal with eccentricity fault

项目 4 Hz 下峭度值变化 5 Hz 下峭度值变化 阈值 正常状态 2.29 2.59 3.2 偏心故障 3.76 3.37 3.2 -

[1] 《中国公路学报》编辑部. 中国汽车工程学术研究综述•2023[J]. 中国公路学报,2023,36(11): 1-192.Editorial Department of China Journal of Highway and Transport. Review on China’s automotive engineering research progress: 2023[J]. China Journal of Highway and Transport, 2023, 36(11): 1-192. [2] 刘秀梅,李永涛. 车辆油气悬架技术研究综述[J]. 西南交通大学学报,2025,60(2): 374-394. doi: 10.3969/j.issn.0258-2724.20230168LIU Xiumei, LI Yongtao. Review of research on vehicle hydro-pneumatic suspension technology[J]. Journal of Southwest Jiaotong University, 2025, 60(2): 374-394. doi: 10.3969/j.issn.0258-2724.20230168 [3] 贺益雄,张晓寒,胡惟璇,等. 基于航向控制系统的船舶动态避碰机理[J]. 西南交通大学学报,2020,55(5): 988-993,1027.HE Yixiong, ZHANG Xiaohan, HU Weixuan, et al. Ship dynamic collision avoidance mechanism based on course control system [J]Journal of Southwest Jiaotong University, 2020, 55(5): 988-993, 1027. [4] 杨云帆,周青,巩磊,等. 轮对柔性对直线电机车辆动态响应的影响分析[J]. 西南交通大学学报,2020,55(6): 1313-1319. doi: 10.3969/j.issn.0258-2724.20180866YANG Yunfan, ZHOU Qing, GONG Lei, et al. Analysis of the influence of wheelset flexibility on the dynamic response of linear motor vehicles[J]. Journal of Southwest Jiaotong University, 2020, 55(6): 1313-1319. doi: 10.3969/j.issn.0258-2724.20180866 [5] 杨绍普,顾晓辉,刘永强,等. 转向架关键运动部件动力学机理与故障诊断研究综述[J]. 机械工程学报,2023,59(20): 225-243. doi: 10.3901/JME.2023.20.225YANG Shaopu, GU Xiaohui, LIU Yongqiang, et all. Review of research on dynamic mechanism and fault diagnosis of key moving parts of bogie[J]. Mechanical Engineering, 2023, 59(20): 225-243. doi: 10.3901/JME.2023.20.225 [6] 陈雪峰,李继猛,程航,等. 风力发电机状态监测和故障诊断技术的研究与进展[J]. 机械工程学报,2011,47(9): 45-52. doi: 10.3901/JME.2011.09.045CHEN Xuefeng, LI Jimeng, CHENG Hang, et al. Research and application of condition monitoring and fault diagnosis technology in wind turbines[J]. Journal of Mechanical Engineering, 2011, 47(9): 45-52. doi: 10.3901/JME.2011.09.045 [7] 严亮,向芃桔,孙启昕. 永磁直线电机磁极拓扑构型研究综述[J]. 导航与控制,2021,20(5): 1-12. doi: 10.3969/j.issn.1674-5558.2021.05.001YAN Liang, XIANG Pengjie, SUN Qixin. Overview of magnetic pole topological configuration of permanent magnet linear machines[J]. Navigation and Control, 2021, 20(5): 1-12. doi: 10.3969/j.issn.1674-5558.2021.05.001 [8] 寇发荣,贺嘉杰,李孟欣,等. 基于路面识别的电磁混合式悬架自适应模糊控制[J]. 振动与冲击,2023,42(2): 303-311.KOU Farong, HE Jiajie, LI Mengxin, et al. Adaptive fuzzy control of electromagnetic hybrid suspension based on road identification [J]Journal of Vibration and Shock, 2023, 42 (2): 303-311. [9] MORATO M M, SENAME O, DUGARD L, et al. Fault estimation for automotive electro-rheological dampers: LPV-based observer approach[J]. Control Engineering Practice, 2019, 85: 11-22. doi: 10.1016/j.conengprac.2019.01.005 [10] 汪佳佳,陈龙,汪若尘. 混合电磁悬架阻尼系数优化设计[J]. 汽车工程学报,2017,7(2): 93-99. doi: 10.3969/j.issn.2095-1469.2017.02.03WANG Jiajia, CHEN Long, WANG Ruochen. Optimization design of damping coefficient used in hybrid electromagnetic suspension systems[J]. Chinese Journal of Automotive Engineering, 2017, 7(2): 93-99. doi: 10.3969/j.issn.2095-1469.2017.02.03 [11] 寇发荣,陈若晨,胡凯仑,等. 电磁混合主动悬架滑模容错控制研究[J]. 现代制造工程,2023(8): 66-74.KOU Farong, CHEN Ruochen, HU Kailun, et al. Research on sliding mode fault tolerant control of electromagnetic hybrid active suspension[J]. Modern Manufacturing Engineering, 2023(8): 66-74. [12] 孟建军,彭伟尧,胥如迅,等. 基于故障补偿的高速列车主动悬架主动容错控制[J]. 现代制造工程,2022(10): 34-42,33.MENG Jianjun, PENG Weiyao, XU Ruxun, et al. Active fault tolerant control of high-speed train active suspension based on fault compensation[J]. Modern Manufacturing Engineering, 2022(10): 34-42,33. [13] 汪若尘,郭一鸣,王炜,等. 基于变时域模型预测的混合电磁悬架控制方法[J]. 江苏大学学报(自然科学版),2023,44(4): 408-414. doi: 10.3969/j.issn.1671-7775.2023.04.006WANG Ruochen, GUO Yiming, WANG Wei, et al. Hybrid electromagnetic suspension control method based on variable time domain model prediction[J]. Journal of Jiangsu University (Natural Science Edition), 2023, 44(4): 408-414. doi: 10.3969/j.issn.1671-7775.2023.04.006 [14] HERNÁNDEZ-ALCÁNTARA D, TUDÓN-MARTÍNEZ J C, AMÉZQUITA-BROOKS L, et al. Modeling, diagnosis and estimation of actuator faults in vehicle suspensions[J]. Control Engineering Practice, 2016, 49: 173-186. doi: 10.1016/j.conengprac.2015.12.002 [15] MRAZGUA J, TISSSIR E H, OUAHI M. Fuzzy fault-tolerant H∞ control approach for nonlinear active suspension systems with actuator failure[J]. Procedia Computer Science, 2019, 148: 465-474. doi: 10.1016/j.procs.2019.01.059 [16] 姚行艳. 基于自适应模糊的汽车半主动悬架容错控制[J]. 机械设计与制造,2021(2): 144-147.YAO Xingyan. Fault tolerant control of automotive semi-active suspension based on adaptive fuzzy control[J]. Machinery Design & Manufacture, 2021(2): 144-147. [17] 寇发荣,武江浩,许家楠,等. 整车电磁混合主动悬架故障诊断与容错控制研究[J]. 振动与冲击,2022,41(4):101-109.KOU Farong, WU Jianghao, XU Jiannan, et al. Research on fault diagnosis and fault-tolerant control of vehicle electromagnetic hybrid active suspension[J]. Journal of Vibration and Shock, 2022, 41(4):101-109. [18] 徐敦煌,王东,林楠,等. 失磁故障下交错磁极混合励磁发电机的等效二维解析磁场模型[J]. 电工技术学报,2017,32(21): 87-93.XU Dunhuang, WANG Dong, LIN Nan, et al. An equivalent two-dimensional analytical model for the consequent-pole hybrid-excitation generator with demagnetization fault[J]. Transactions of China Electrotechnical Society, 2017, 32(21): 87-93. [19] PARK Y, FERNANDEZ D, LEE S B, et al. Online detection of rotor eccentricity and demagnetization faults in PMSMs based on hall-effect field sensor measurements[J]. IEEE Transactions on Industry Applications, 2019, 55(3): 2499-2509. [20] MIRZAEVA G, SAAD K I. Advanced diagnosis of rotor faults and eccentricity in induction motors based on internal flux measurement[J]. IEEE Transactions on Industry Applications, 2018, 54(3): 2981-2991. [21] 丁石川,吴振兴,李亚,等. 基于气隙磁密差信号峭度因子的永磁同步电机局部退磁故障诊断[J]. 中国电机工程学报,2024,44(14): 5747-5756.DING Shichuan, WU Zhenxing, LI Ya, et al. Research on local demagnetization fault diagnosis of permanent magnet synchronous motor based on kurtosis factor of air gap magnetic density difference signal[J]. China Industrial Economics, 2024, 44(14): 5747-5756. [22] 张丹,赵吉文,董菲,等. 基于概率神经网络算法的永磁同步直线电机局部退磁故障诊断研究[J]. 中国电机工程学报,2019,39(1): 296-306,344.ZHANG Dan, ZHAO Jiwen, DONG Fei, et al. Partial demagnetization fault diagnosis research of permanent magnet synchronous motors based on the PNN algorithm[J]. Proceedings of the CSEE, 2019, 39(1): 296-306,344. [23] 唐子辉,蒋学君,孙晓丽. 小波包分解结合LSSVM的永磁同步电机偏心故障诊断[J]. 机械设计与制造工程,2024,53(1): 65-70. doi: 10.3969/j.issn.2095-509X.2024.01.014TANG Zihui, JIANG Xuejun, SUN Xiaoli. Eccentric fault diagnosis of permanent magnet synchronous motor based on wavelet packet decomposition and LSSVM[J]. Mechanical Design and Manufacturing Engineering, 2024, 53(1): 65-70. doi: 10.3969/j.issn.2095-509X.2024.01.014 [24] 任强,官晟,王凤军,等. 基于EEMD和PSO-SVM的电机气隙偏心故障诊断[J]. 组合机床与自动化加工技术,2021(2): 73-76,85.REN Qiang, GUAN Sheng, WANG Fengjun, et al. Air gap eccentricity fault diagnosis based on EEMD and PSO-SVM[J]. Modular Machine Tools and Automated Machining Techniques, 2021(2): 73-76,85. [25] 郑近德,潘海洋,程军圣,等. 基于自适应经验傅里叶分解的机械故障诊断方法[J]. 机械工程学报,2020,56(9): 125-136. doi: 10.3901/JME.2020.09.125ZHENG Jinde, PAN Haiyang, CHENG Junsheng, et al. Adaptive empirical Fourier decomposition based mechanical fault diagnosis method[J]. Journal of Mechanical Engineering, 2020, 56(9): 125-136. doi: 10.3901/JME.2020.09.125 [26] 刘军辉. 双定子圆筒型直线电机多物理场分析与偏心故障检测[D]. 杭州:浙江理工大学,2022. -

下载:

下载: