Dynamic Tensile Properties of Ultra-High Ductile Concrete Under Different Strain Rates

-

摘要:

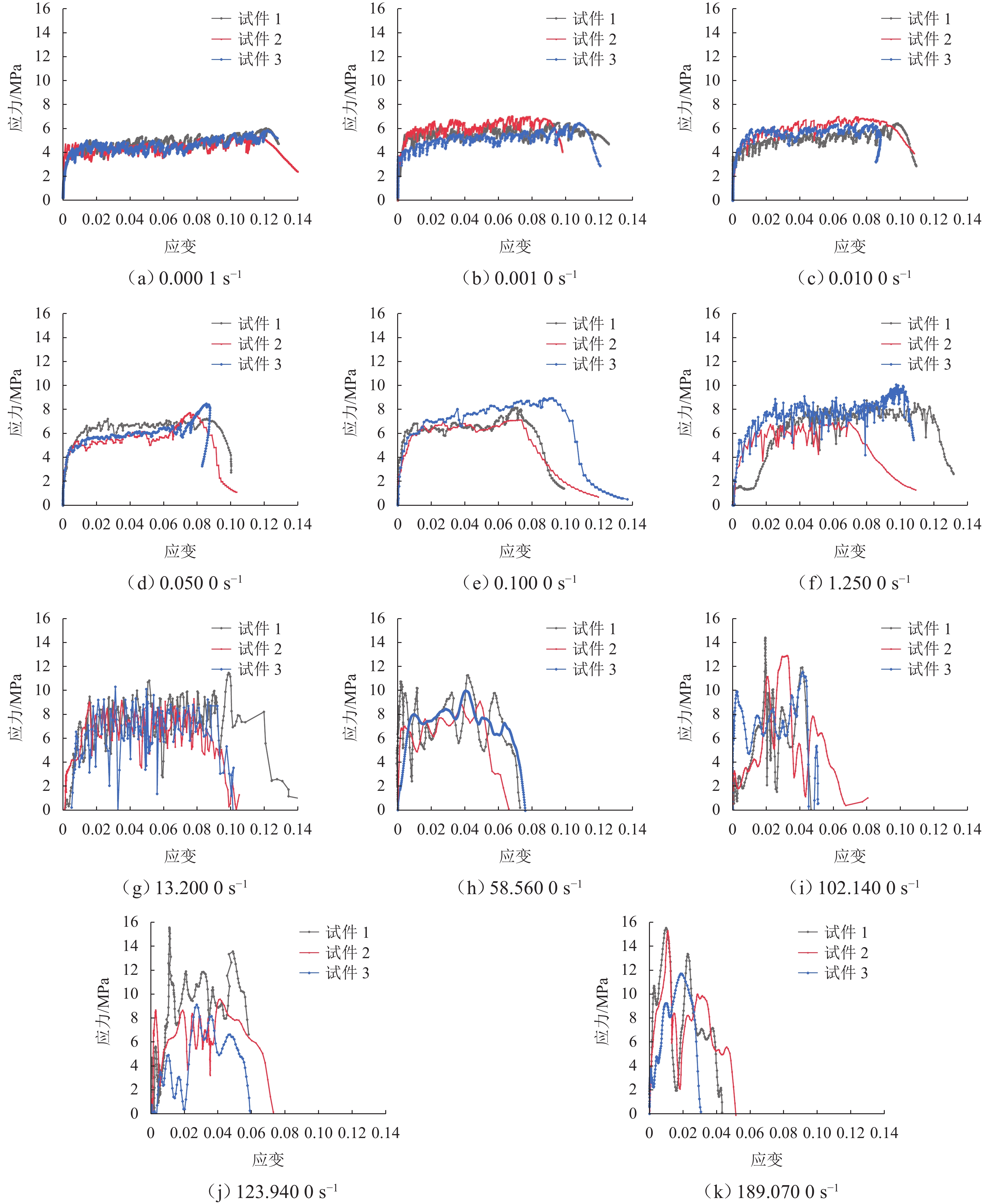

超高延性混凝土(UHDC)具有优异的应变硬化和多裂缝开裂特性,在抵抗冲击荷载等方面具有巨大的应用潜力. 为研究UHDC拉伸性能的应变率效应,在从准静态到冲击状态范围内的11种应变率(

0.0001 ~189.0700 s−1)条件下进行直接拉伸试验,分析应变率对UHDC拉伸应力-应变曲线形态、裂缝开裂模式以及拉伸性能指标的影响,进一步建立拉伸性能指标动态增长因子关于应变率的表达式;此外,分析拉伸速率对纤维-基体界面黏结性能的影响,进一步解释UHDC拉伸性能的应变率效应. 结果表明:UHDC变形能力随应变率的增加呈下降趋势,但在应变率达到102.0000 s−1时,依然具有显著的应变硬化和多缝开裂能力,拉伸应变可达4%;平均裂缝宽度基本不随应变率变化,保持在100 μm左右,显示出UHDC优异的裂缝控制能力;拉伸性能指标动态增长因子与应变率的关系曲线呈现明显的两阶段特性.Abstract:Ultra-high ductile concrete (UHDC) has excellent strain hardening and multi-cracking characteristics, and it has great potential in impact load resistance. Direct tensile tests were conducted under 11 strain rates (0.000 1–

189.0700 s−1) ranging from quasi-static to impact states to investigate the strain rate effect on the tensile properties of UHDC. The influence of strain rate on the shape of the tensile stress–strain curves, cracking pattern, and tensile performance indicators of UHDC was analyzed. The expression of the dynamic increase factor of tensile performance indicators regarding strain rate was established. In addition, the influence of the tensile rate on the fiber–matrix interface bonding performance was analyzed to further explain the strain rate effect on the tensile properties of UHDC. The results show that the deformation capacity of UHDC decreases with the increase in strain rate. When the strain rate is 102.000 0 s−1, UHDC still has significant strain hardening and multi-cracking pattern capacity, with the tensile strain capacity up to 4%. The average crack width, which keeps a constant value of 100 μm, does not vary with the strain rate change, exhibiting the excellent crack control capacity of UHDC. The relationship curves between the dynamic increase factor of the tensile performance indicators and strain rate show a clear two-stage characteristic. -

表 1 UHDC配合比

Table 1. Mix proportion of UHDC

kg/m3 材料 水泥 粉煤灰 石英砂 水 外加剂 纤维 配合比 936.7 401.4 401.4 360.1 4.2 19.4 表 2 PE纤维的性能参数

Table 2. Performance parameters of PE fibers

参数 长度/

mm直径/

μm抗拉强度/

MPa弹性模量/

GPa延伸率/

%密度/

(g•cm−3)取值 24 25 2900 116 2.42 0.97 表 3 不同应变率下拉伸试件的裂缝信息

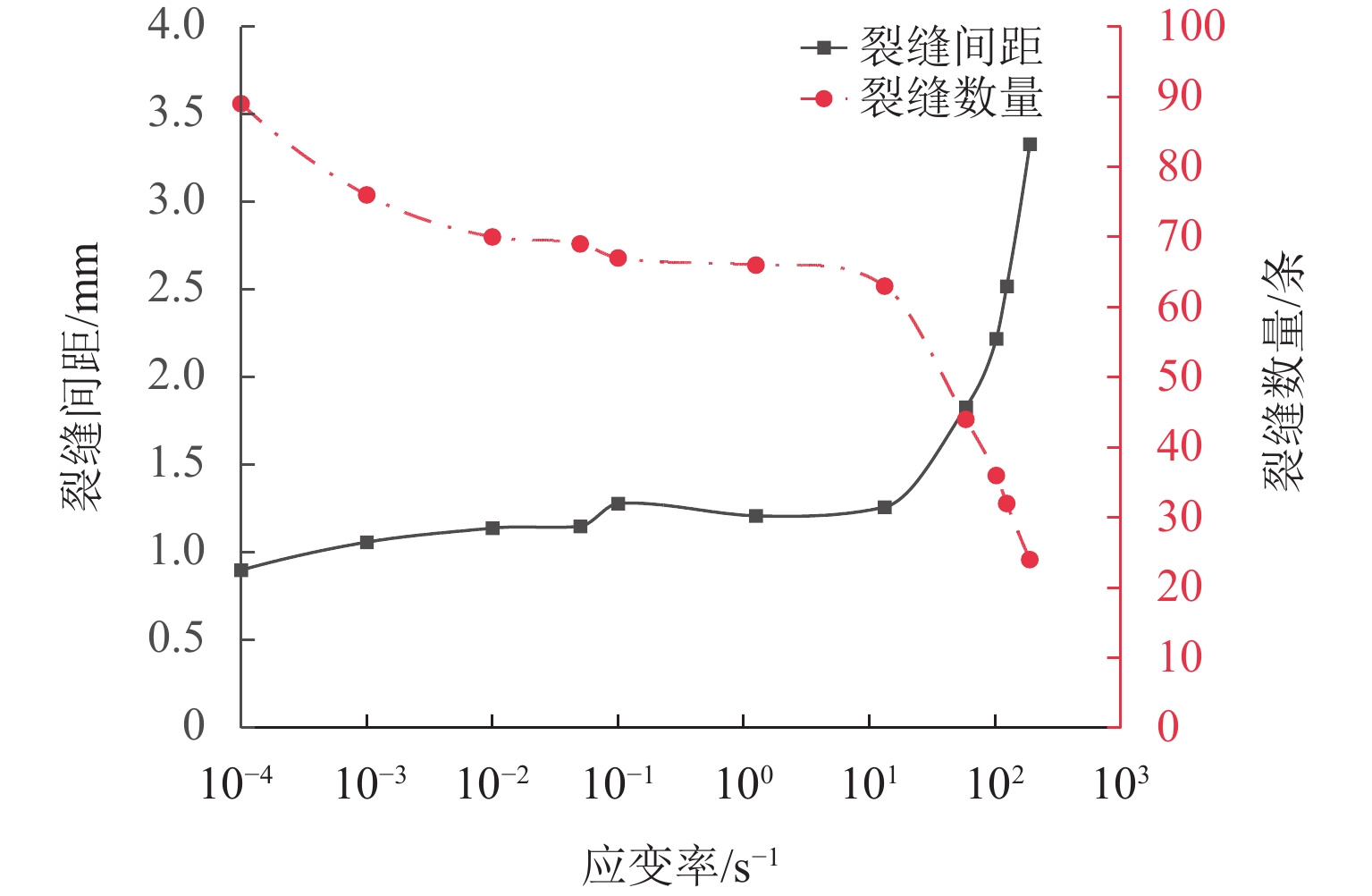

Table 3. Crack information of tensile specimens under different strain rates

应变率/s−1 Nc/条 wc/μm sc/mm 0.0001 89 104.6 0.90 0.0010 76 104.8 1.06 0.0100 70 103.0 1.14 0.0500 69 96.9 1.15 0.1000 67 92.8 1.28 1.2500 66 108.0 1.21 13.2000 63 103.3 1.26 58.5600 44 102.4 1.83 102.1400 36 98.0 2.22 123.9100 32 93.9 2.52 189.0700 24 93.7 3.33 表 4 UHDC各应变率下的拉伸参数

Table 4. Tensile parameters of UHDC at various strain rates

应变率/s−1 σtc/MPa σtu/MPa εtu/% gse/ (kJ•m−3) Et/GPa 0.0001 2.74 (0.66) 5.70 (0.29) 11.68 (0.66) 531.5 (46.28) 15.75 (2.75) 0.0010 3.04 (0.64) 6.50 (0.27) 9.93 (1.81) 451.9 (73.97) 16.06 (3.09) 0.0100 3.43 (0.90) 6.60 (0.28) 9.02 (1.44) 448.5 (55.33) 14.72 (1.87) 0.0500 3.91 (0.78) 7.80 (0.52) 8.28 (0.50) 492.1 (53.77) 19.75 (0.56) 0.1000 4.03 (0.26) 8.06 (0.74) 7.84 (1.00) 534.4 (110.69) 18.70 (5.49) 1.2500 4.20 (1.75) 8.41 (1.14) 7.79 (1.97) 417.6 (195.01) 13.2000 5.09 (1.27) 9.77 (0.71) 6.79 (0.52) 425.3 (211.58) 58.5600 6.65 (0.63) 10.10 (0.96) 4.41 (0.75) 289.4 (58.68) 102.1400 6.21 (0.83) 11.65 (0.24) 3.94 (1.37) 107.8 (85.24) 123.9100 7.43 (1.21) 12.88 (1.04) 2.38 (1.15) 154.6 (93.6) 189.0700 8.01 (1.26) 15.07 (0.48) 1.31 (0.39) 112.9 (98.60) 注:括号内数值为相应的标准差. 表 5 各类ECC拉伸参数的对比

Table 5. Comparison of various ECC tensile parameters

文献 峰值应

力/MPa峰值应

变/%应变能/

(kJ•m−3)应变率/

s−1ECC

类型文献[9] 5.5 0.80 45.2 0.0100 PVA-ECC 文献 [14] 8.6 0.80 68.8 0.1000 PVA-ECC 文献[15] 17.5 3.00 525.0 0.1000 PE-ECC 文献[18] 3.5 4.00 140.0 0.1000 PVA-ECC 文献[17] 5.5 3.90 217.9 0.0100 PVA-ECC 文献[24] 5.9 3.80 224.2 0.1000 PVA-ECC 文献[24] 4.2 3.20 134.4 0.1000 PE-ECC 本文 6.6 9.02 448.5 0.0100 UHDC 8.1 7.80 534.4 0.1000 10.1 4.40 289.4 58.5600 表 6 UHDC各应变率下的动态增长因子

Table 6. Dynamic increase factors of UHDC at various strain rates

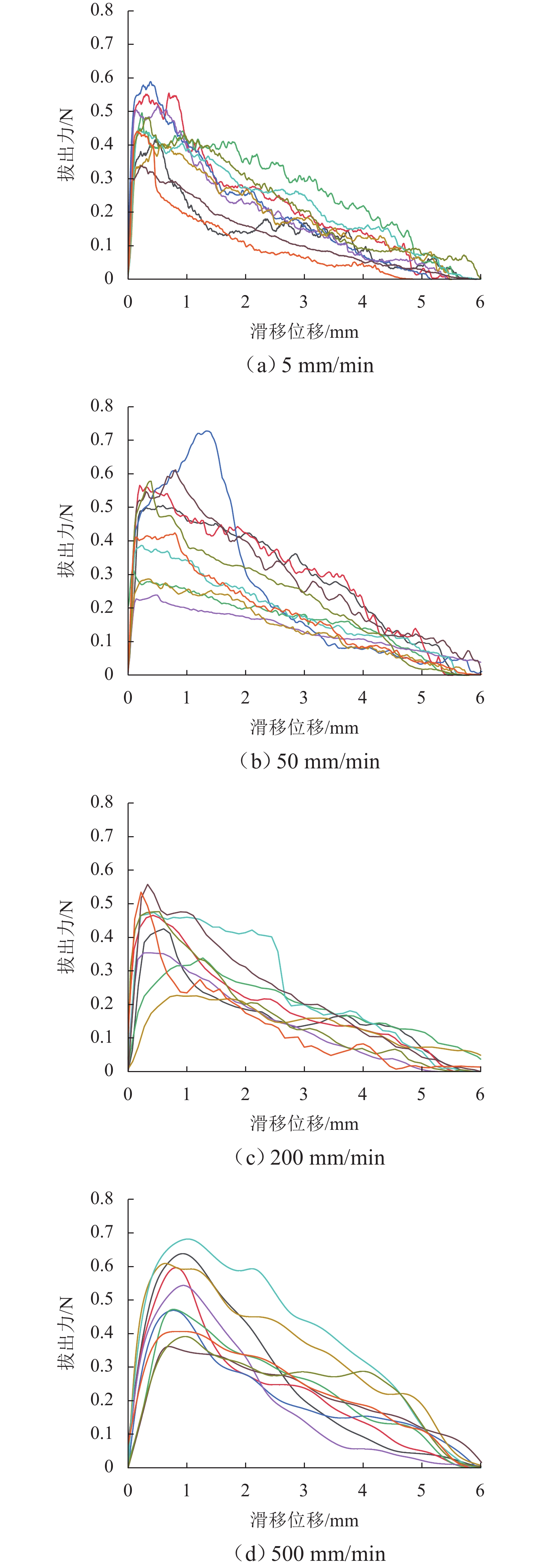

应变率/s−1 ftc ftu fε fE 0.0001 1.00 1.00 1.00 1.00 0.0010 1.11 1.14 0.85 1.02 0.0100 1.25 1.16 0.77 0.93 0.0500 1.43 1.37 0.71 1.25 0.1000 1.47 1.41 0.67 1.19 1.2500 1.53 1.48 0.67 13.2000 1.86 1.71 0.58 58.5600 2.43 1.77 0.38 102.1400 2.27 2.04 0.34 123.9100 2.71 2.26 0.20 189.0700 2.92 2.64 0.11 表 7 单纤维拔出试验结果

Table 7. Single fiber pull-out test results

加载速率/

(mm•min−1)脱黏位移/

mm脱黏力/

N峰值位移/

mm峰值力/

N5 0.095 0.390 0.382 0.469 50 0.116 0.409 0.505 0.488 200 0.524 0.522 500 0.871 0.527 -

[1] 宁建国, 宋卫东, 任会兰, 等. 冲击载荷作用下材料与结构的响应与防护[J]. 固体力学学报, 2010, 31(5): 532-552.NING Jianguo, SONG Weidong, REN Huilan, et al. Response and protection of materials and structures under impact loadings[J]. Chinese Journal of Solid Mechanics, 2010, 31(5): 532-552. [2] 李新忠, 魏雪英, 赵均海. 混凝土力学性能的应变率效应[J]. 长安大学学报(自然科学版), 2012, 32(2): 82-86.LI Xinzhong, WEI Xueying, ZHAO Junhai. Strain rate effect on mechanical properties of concrete[J]. Journal of Chang’an University (Natural Science Edition), 2012, 32(2): 82-86. [3] YOO D Y, BANTHIA N. Impact resistance of fiber-reinforced concrete: a review[J]. Cement and Concrete Composites, 2019, 104: 103389. doi: 10.1016/j.cemconcomp.2019.103389 [4] 赵昕. 超高韧性水泥基复合材料动态力学性能试验与理论研究[D]. 杭州: 浙江大学, 2018. [5] YU K Q, WANG Y C, YU J T, et al. A strain-hardening cementitious composites with the tensile capacity up to 8%[J]. Construction and Building Materials, 2017, 137: 410-419. doi: 10.1016/j.conbuildmat.2017.01.060 [6] DING Y, YU J T, YU K Q, et al. Basic mechanical properties of ultra-high ductility cementitious composites: from 40 MPa to 120 MPa[J]. Composite Structures, 2018, 185: 634-645. doi: 10.1016/j.compstruct.2017.11.034 [7] 王义超, 侯梦君, 余江滔, 等. 聚乙烯纤维制备超高延性水泥基复合材料的试验研究[J]. 材料导报, 2018, 32(20): 3535-3540.WANG Yichao, HOU Mengjun, YU Jiangtao, et al. Experimental study on mechanical properties of ultra-high ductile cementitious composites[J]. Materials Review, 2018, 32(20): 3535-3540. [8] 董伟, 泽里罗布, 银英姿, 等. 玄武岩纤维风积沙混凝土单轴受压应力-应变试验研究[J]. 西南交通大学学报, 2026, 61(1): 65-73.DONG Wei, ZELI Luobu, YIN Yingzi, et al. Experimental study on uniaxial compressive stress–strain of basalt fiber aeolian sand concrete[J]. Journal of Southwest Jiaotong University, 2026, 61(1): 65-73. [9] CUROSU I, MECHTCHERINE V, MILLON O. Effect of fiber properties and matrix composition on the tensile behavior of strain-hardening cement-based composites (SHCCs) subject to impact loading[J]. Cement and Concrete Research, 2016, 82: 23-35. doi: 10.1016/j.cemconres.2015.12.008 [10] WANG Y C, LIU F C, YU J T, et al. Effect of polyethylene fiber content on physical and mechanical properties of engineered cementitious composites[J]. Construction and Building Materials, 2020, 251: 118917. doi: 10.1016/j.conbuildmat.2020.118917 [11] YU K Q, DAI J G, LU Z D, et al. Rate-dependent tensile properties of ultra-high performance engineered cementitious composites (UHP-ECC)[J]. Cement and Concrete Composites, 2018, 93: 218-234. doi: 10.1016/j.cemconcomp.2018.07.016 [12] LI H D, XU S L. Rate dependence of ultra high toughness cementitious composite under direct tension[J]. Journal of Zhejiang University: Science A, 2016, 17(6): 417-426. doi: 10.1631/jzus.A1600031 [13] 王小娟, 崔浩儒, 周宏元, 等. 玄武岩纤维增强泡沫混凝土的单轴拉伸及准静态压缩性能[J]. 复合材料学报, 2023, 40(3): 1569-1585.WANG Xiaojuan, CUI Haoru, ZHOU Hongyuan, et al. Mechanical performance of basalt fiber reinforced foam concrete subjected to quasi-static tensile and compressive tests[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1569-1585. [14] YANG E H, LI V C. Strain-rate effects on the tensile behavior of strain-hardening cementitious composites[J]. Construction and Building Materials, 2014, 52: 96-104. doi: 10.1016/j.conbuildmat.2013.11.013 [15] RANADE R, LI V C, HEARD W F. Tensile rate effects in high strength-high ductility concrete[J]. Cement and Concrete Research, 2015, 68: 94-104. doi: 10.1016/j.cemconres.2014.11.005 [16] KANDA T, LI V C. Multiple cracking sequence and saturation in fiber reinforced cementitious composites[J]. Concrete Research and Technology, 1998, 9(2): 19-33. doi: 10.3151/crt1990.9.2_19 [17] MECHTCHERINE V, DE ANDRADE SILVA F, BUTLER M, et al. Behaviour of strain-hardening cement-based composites under high strain rates[J]. Journal of Advanced Concrete Technology, 2011, 9(1): 51-62. doi: 10.3151/jact.9.51 [18] BOSHOFF W P, VAN ZIJL G P A G. Time-dependent response of ECC: characterisation of creep and rate dependence[J]. Cement and Concrete Research, 2007, 37(5): 725-734. doi: 10.1016/j.cemconres.2007.02.001 [19] PYO S, WILLE K, EL-TAWIL S, et al. Strain rate dependent properties of ultra high performance fiber reinforced concrete (UHP-FRC) under tension[J]. Cement and Concrete Composites, 2015, 56: 15-24. doi: 10.1016/j.cemconcomp.2014.10.002 [20] Japan Society of Civil Engineers. Recommendations for design and construction of high performance fiber reinforced cement composite with multiple fine cracks (HPFRCC)[S]. [S.l.]: Japan Society of Civil Engineers, 2007. [21] GHIASSI B, XAVIER J, OLIVEIRA D V, et al. Application of digital image correlation in investigating the bond between FRP and masonry[J]. Composite Structures, 2013, 106: 340-349. doi: 10.1016/j.compstruct.2013.06.024 [22] KUMAR S L, ARAVIND H B, HOSSINEY N. Digital image correlation (DIC) for measuring strain in brick masonry specimen using Ncorr open source 2D MATLAB program[J]. Results in Engineering, 2019, 4: 100061. doi: 10.1016/j.rineng.2019.100061 [23] WEEKS C A, SUN C T. Modeling non-linear rate-dependent behavior in fiber-reinforced composites[J]. Composites Science and Technology, 1998, 58(3/4): 603-611. [24] YANG E H, LI V C. Tailoring engineered cementitious composites for impact resistance[J]. Cement and Concrete Research, 2012, 42(8): 1066-1071. doi: 10.1016/j.cemconres.2012.04.006 [25] NOH H W, TRUONG V D, CHO J Y, et al. Dynamic increase factors for fiber-reinforced cement composites: a review[J]. Journal of Building Engineering, 2022, 56: 104769. doi: 10.1016/j.jobe.2022.104769 [26] PARK J K, KIM S W, KIM D J. Matrix-strength-dependent strain-rate sensitivity of strain-hardening fiber-reinforced cementitious composites under tensile impact[J]. Composite Structures, 2017, 162: 313-324. doi: 10.1016/j.compstruct.2016.12.022 [27] CEB. Concrete structures under impact and impulsive loading: synthesis report: Bulletin d’information No. 187[S]. Lausanne: Comité Euro-International du Béton, 1988. [28] MALVAR L J, ROSS C A. Review of strain rate effects for concrete in tension[J]. ACI Materials Journal, 1998, 95(6): 735-739. [29] ROSS C A, JEROME D M, TEDESCO J W, et al. Moisture and strain rate effects on concrete strength[J]. ACI Materials Journal, 1996, 93(3): 293-300. -

下载:

下载: