Comparative Analysis of Load Distribution and Dynamic Stiffness Characteristics of Back-to-Back Combined Ball Bearings

-

摘要:

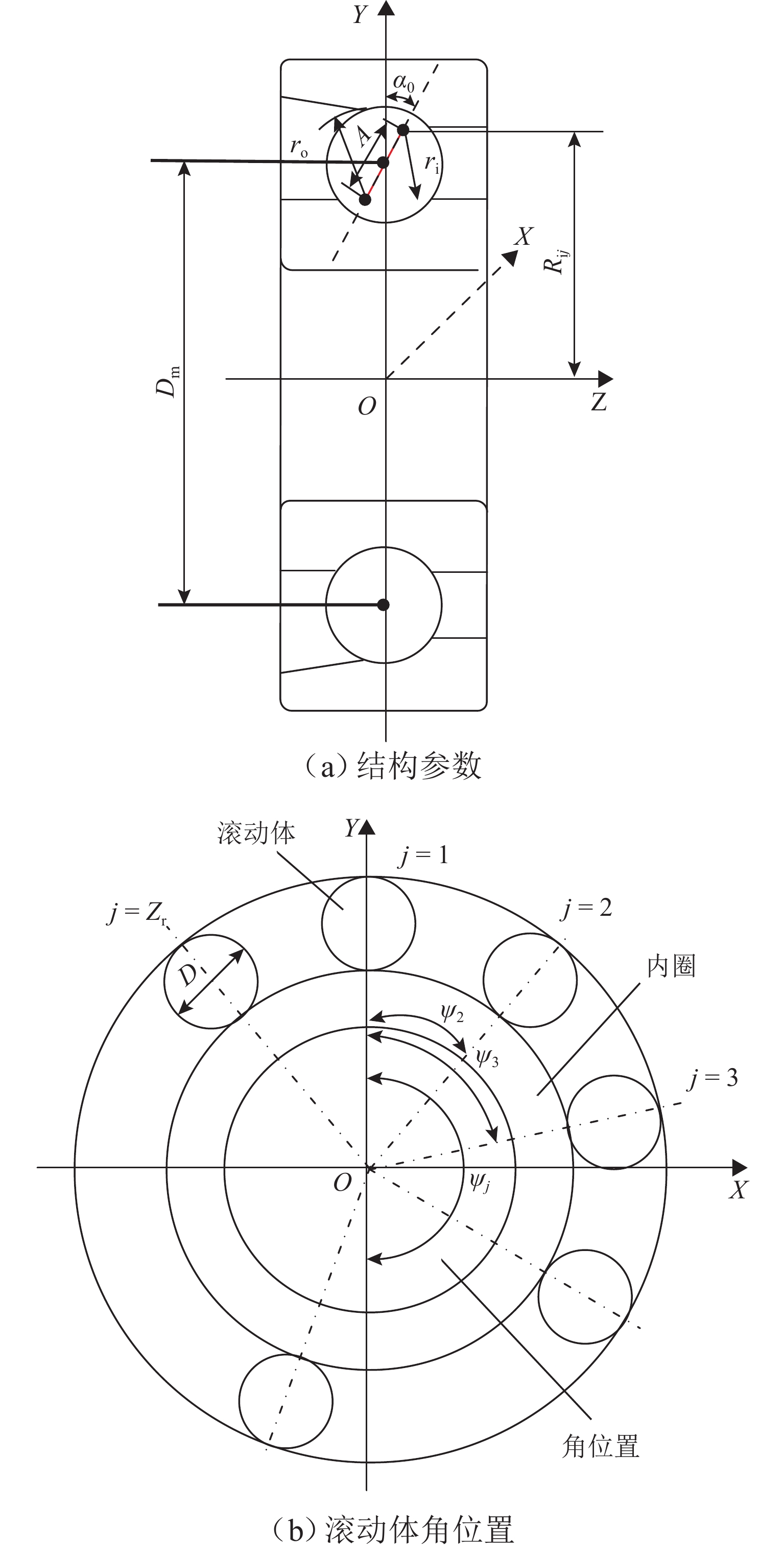

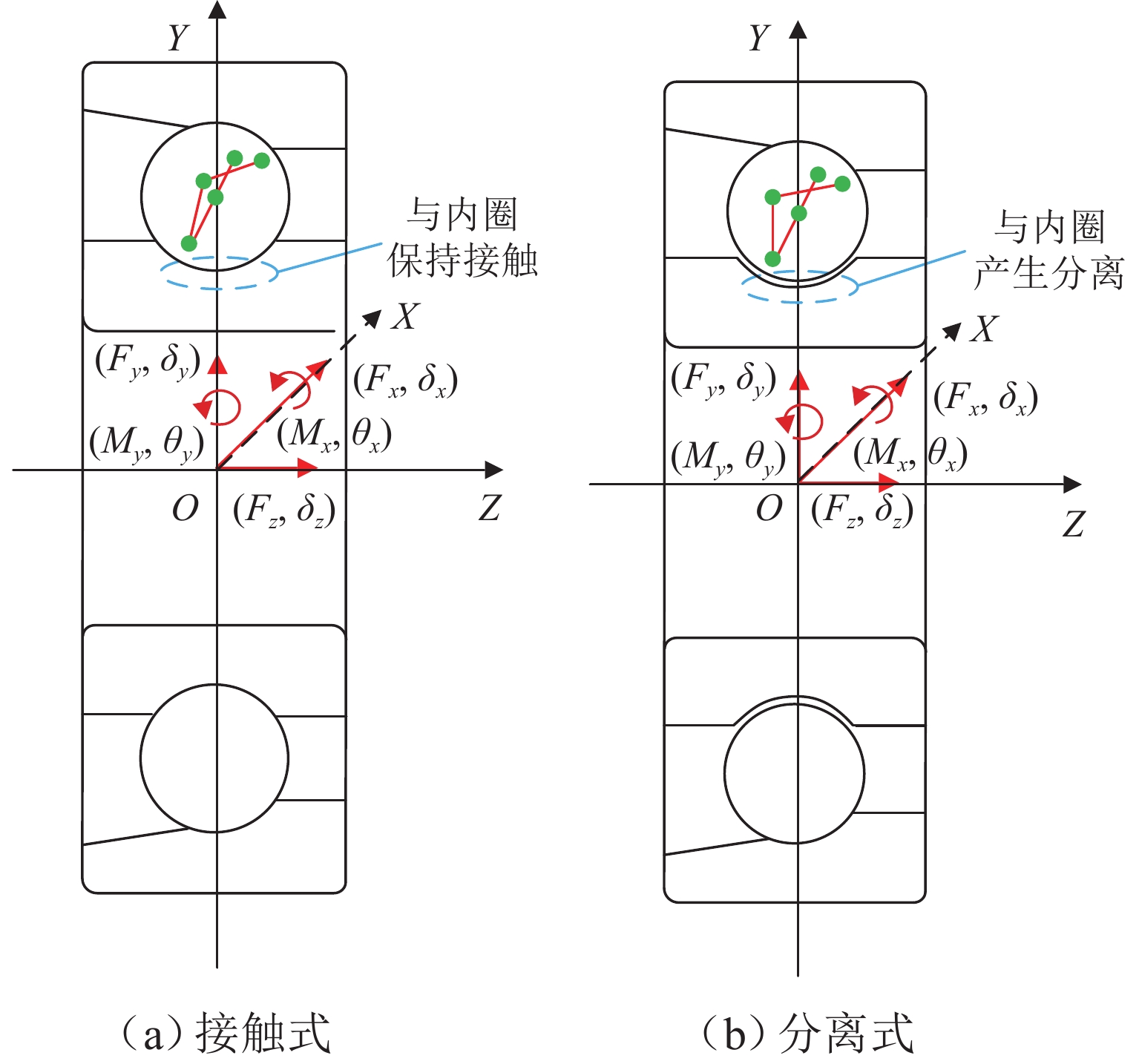

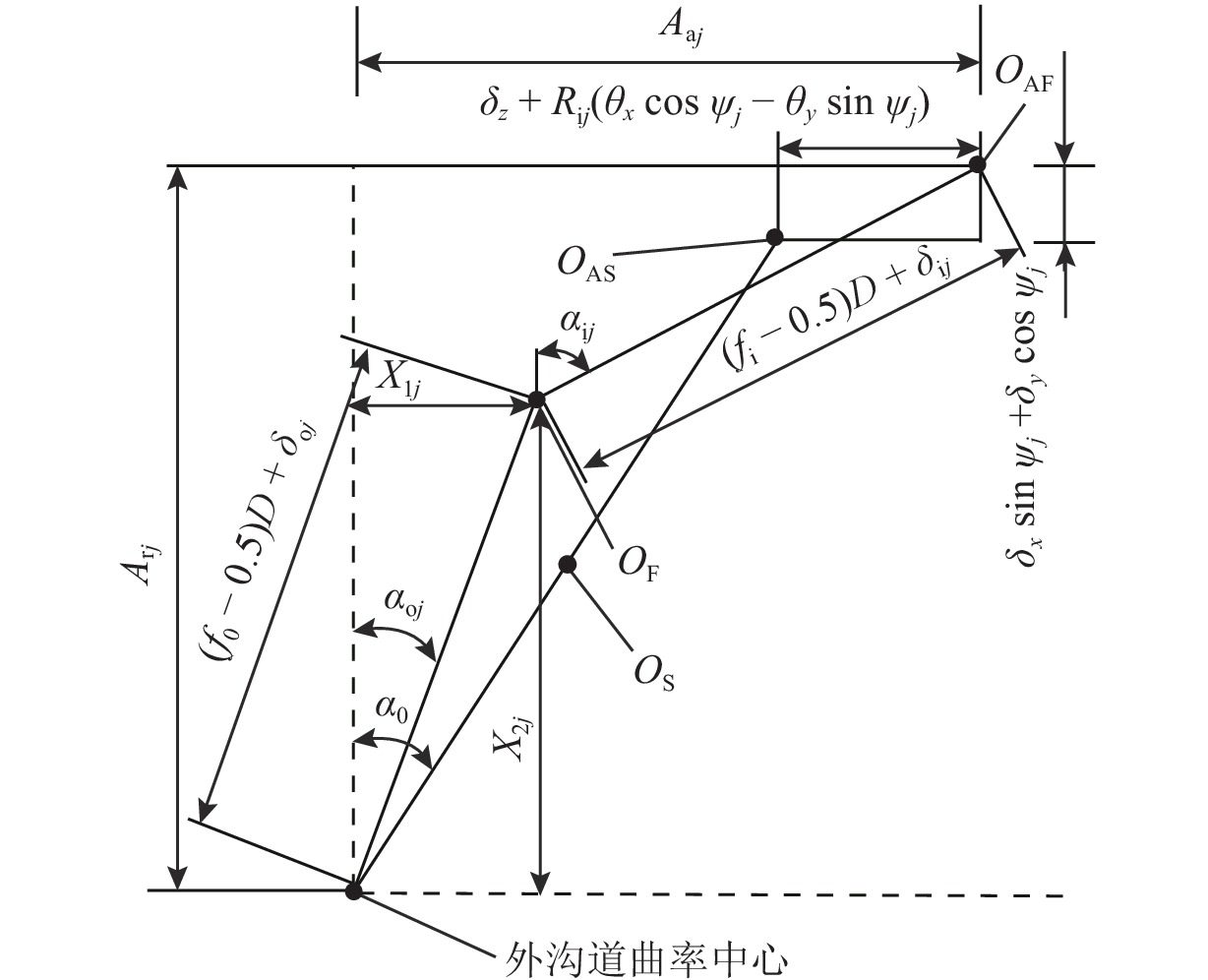

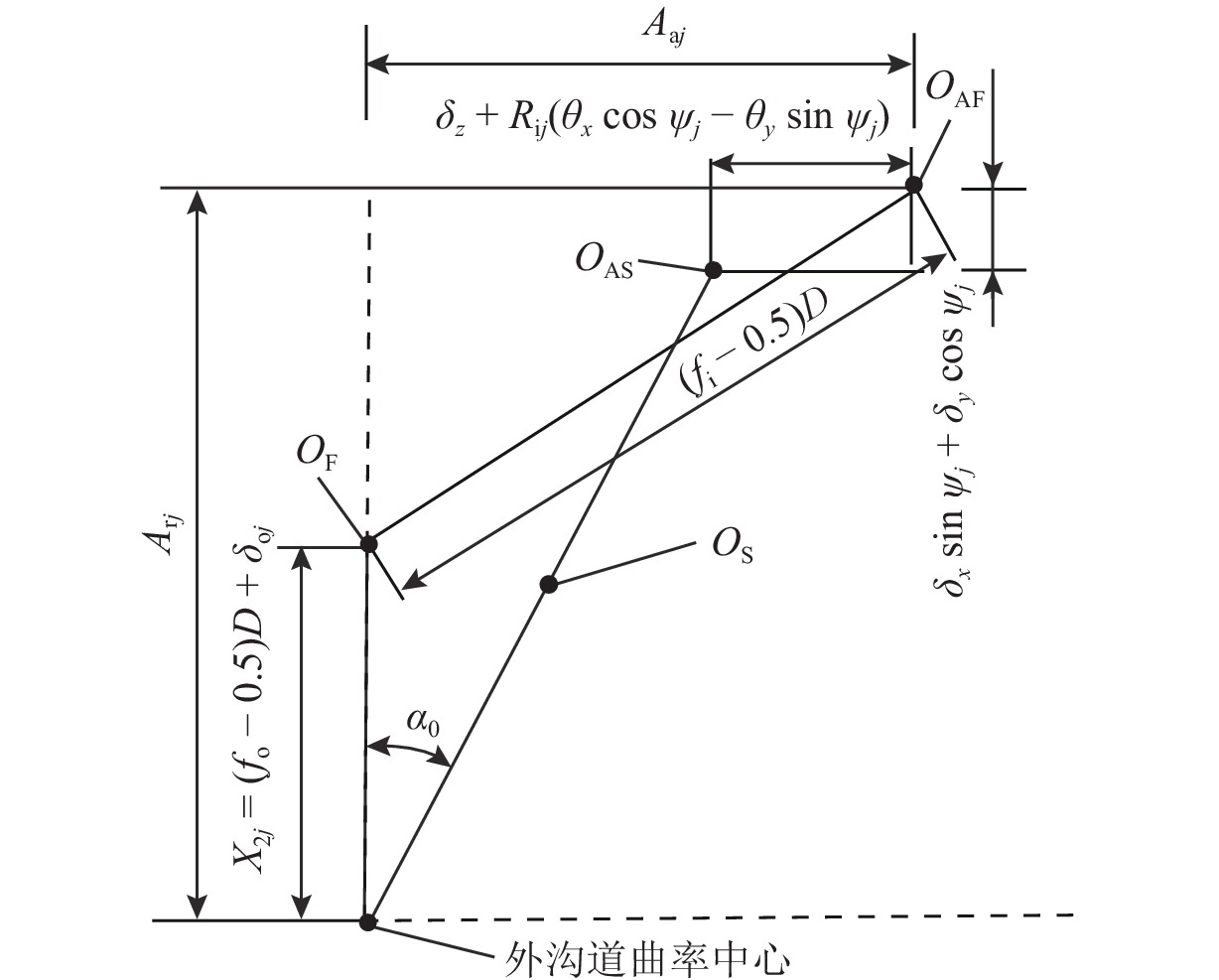

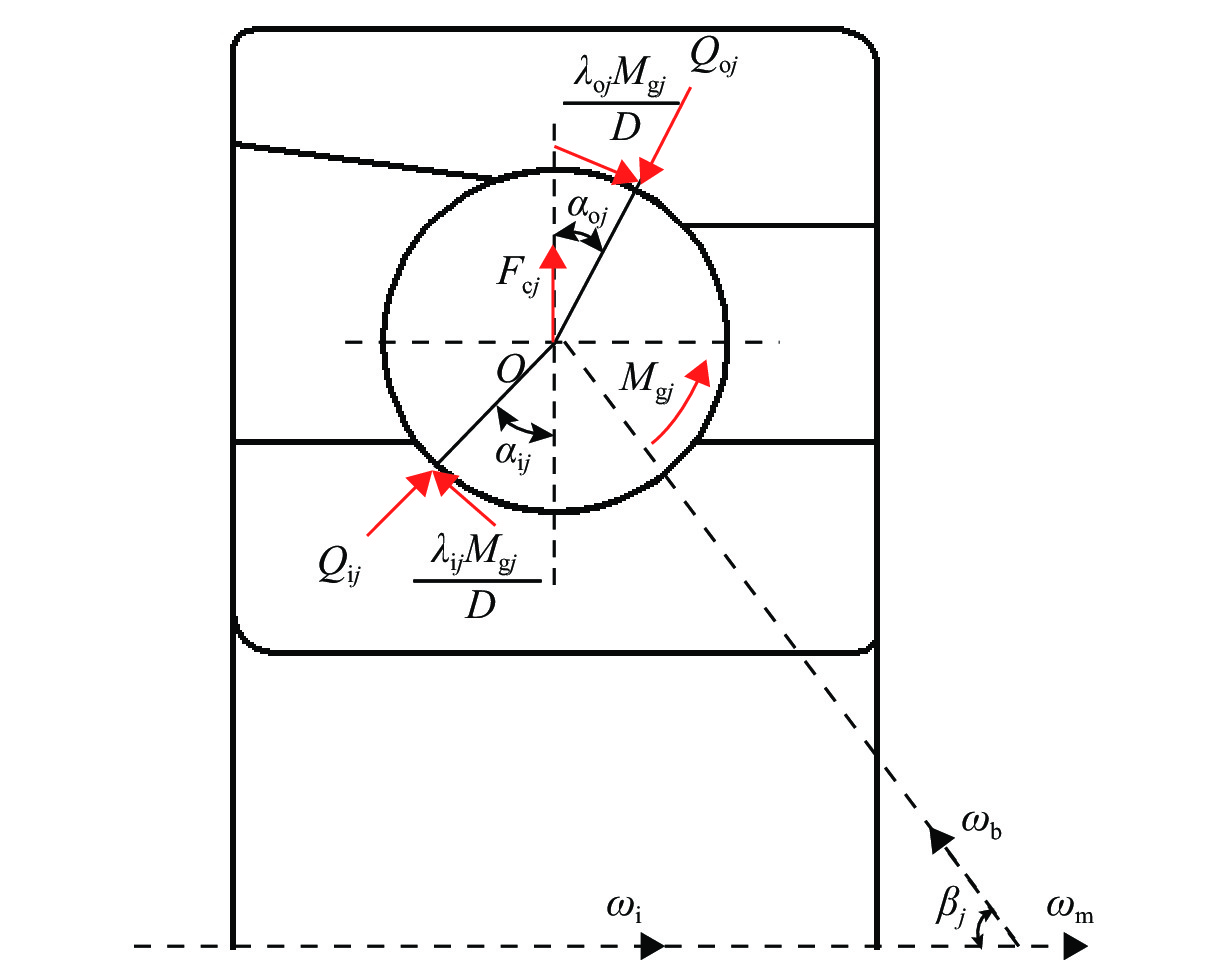

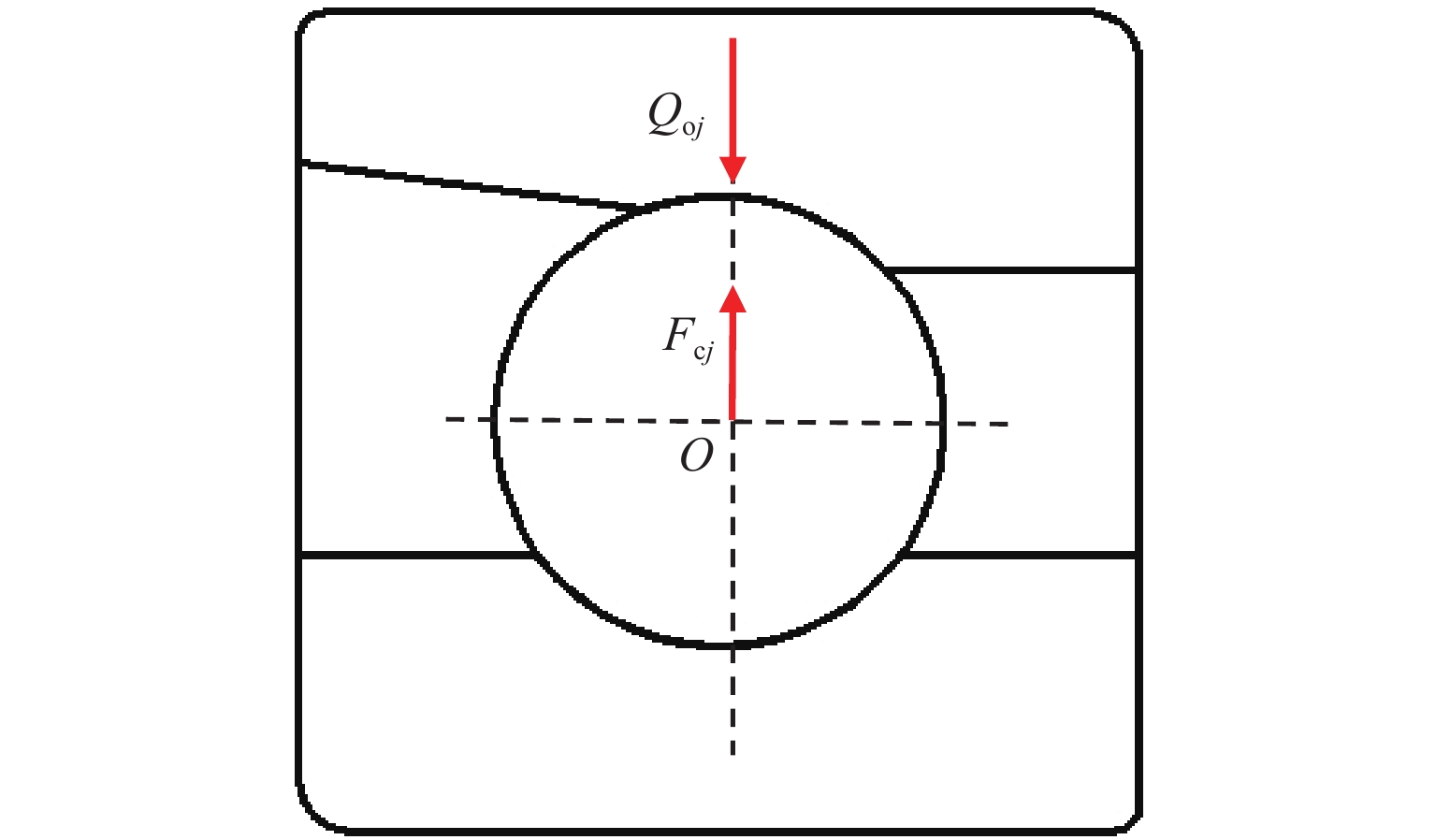

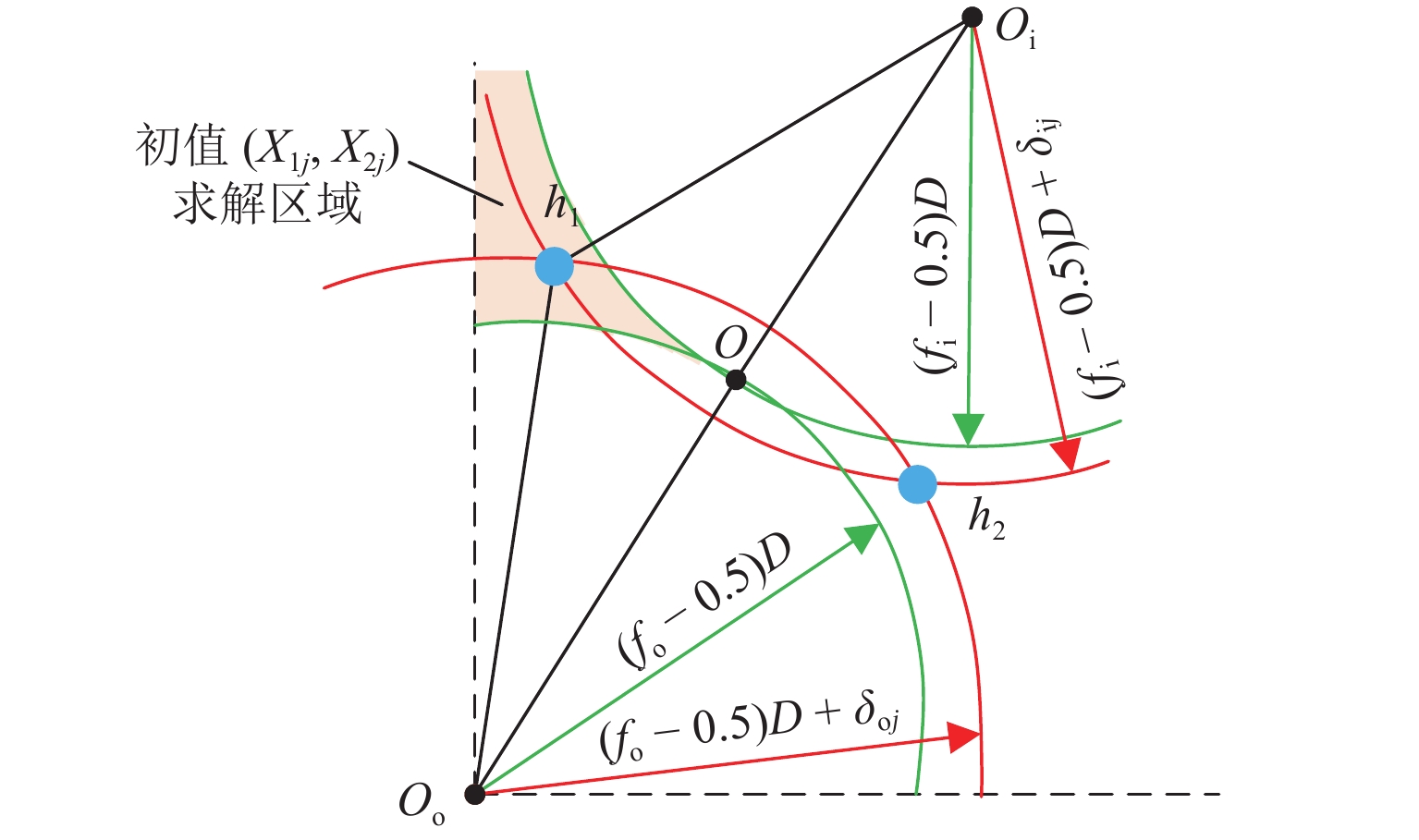

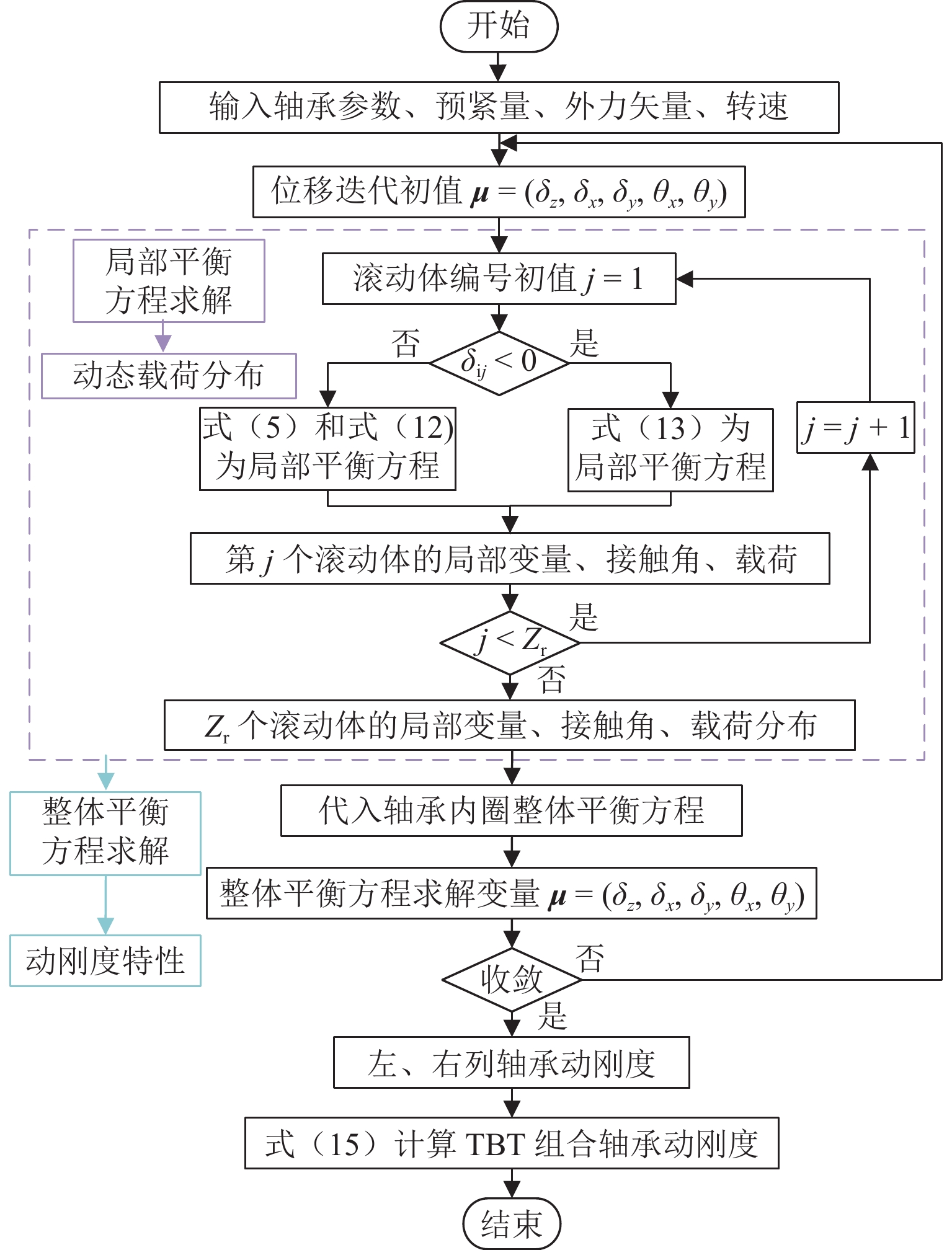

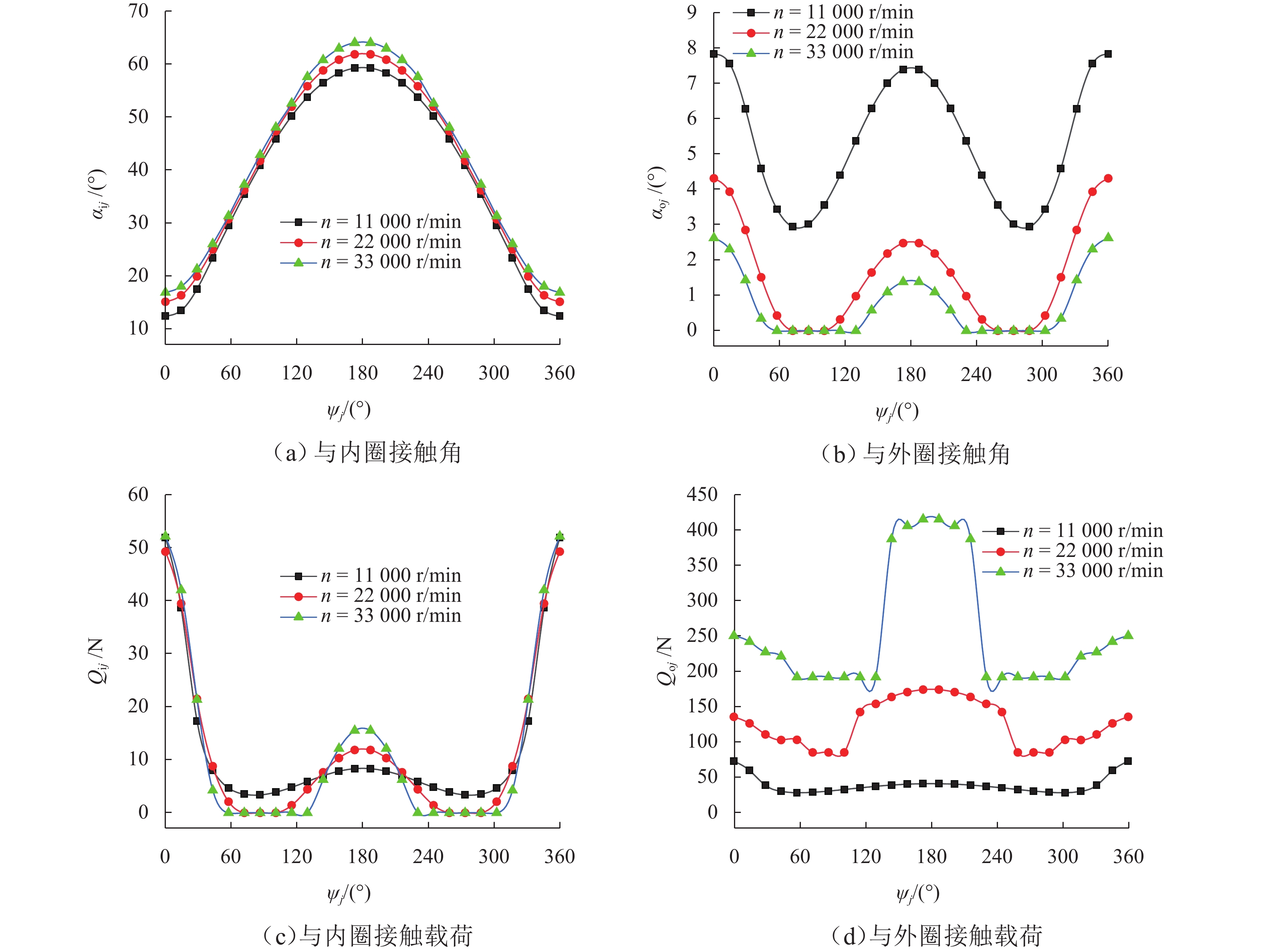

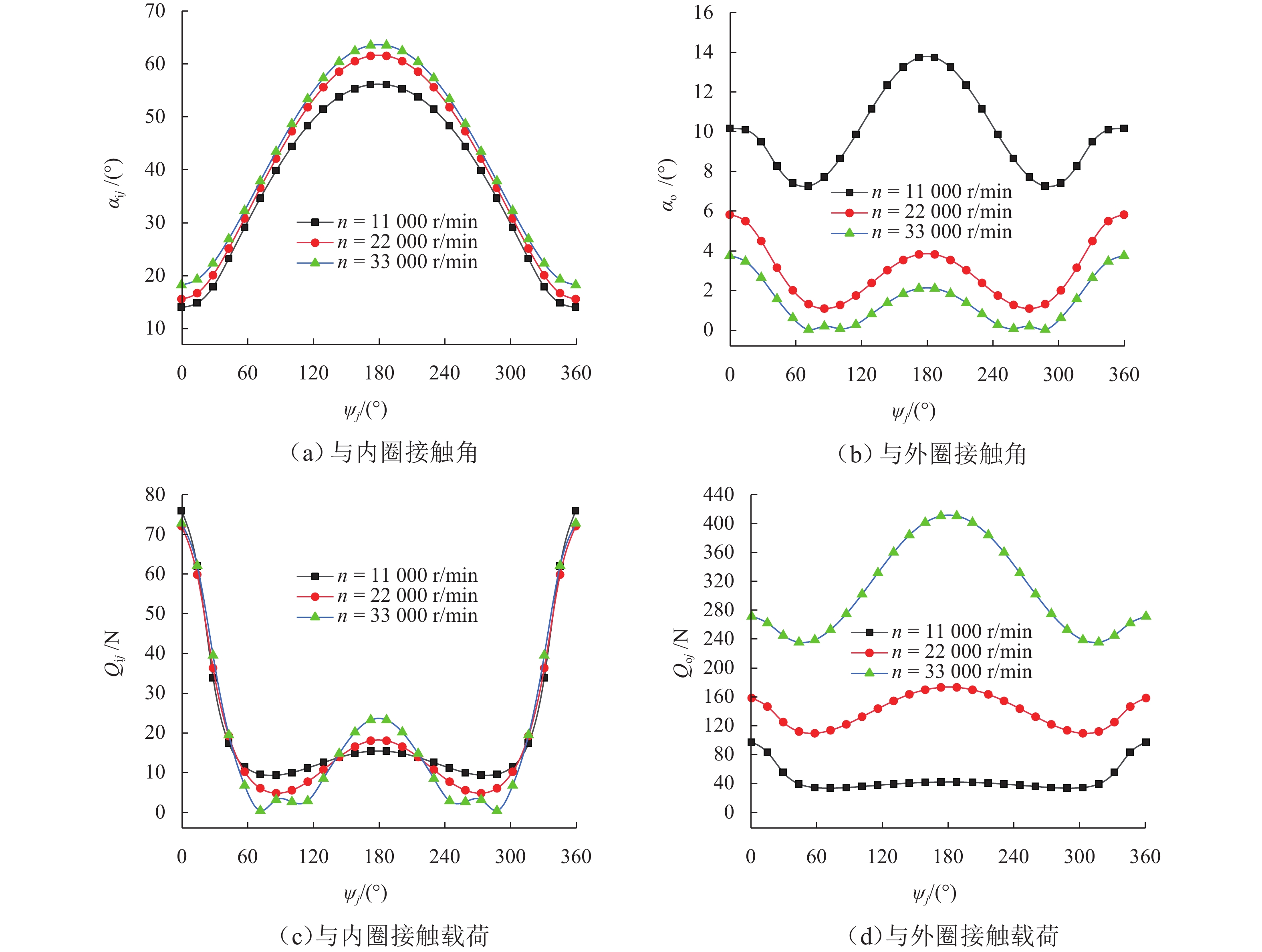

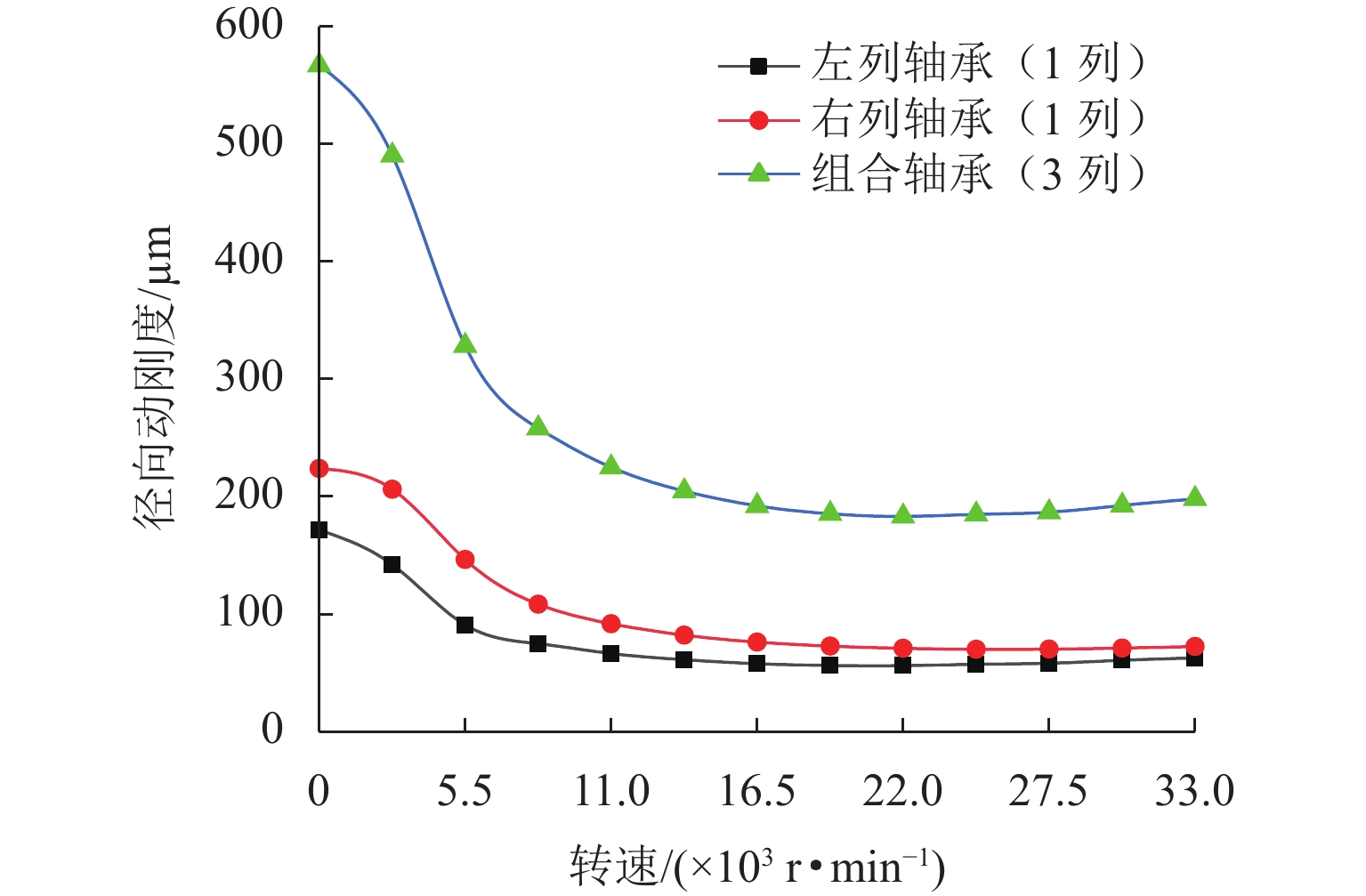

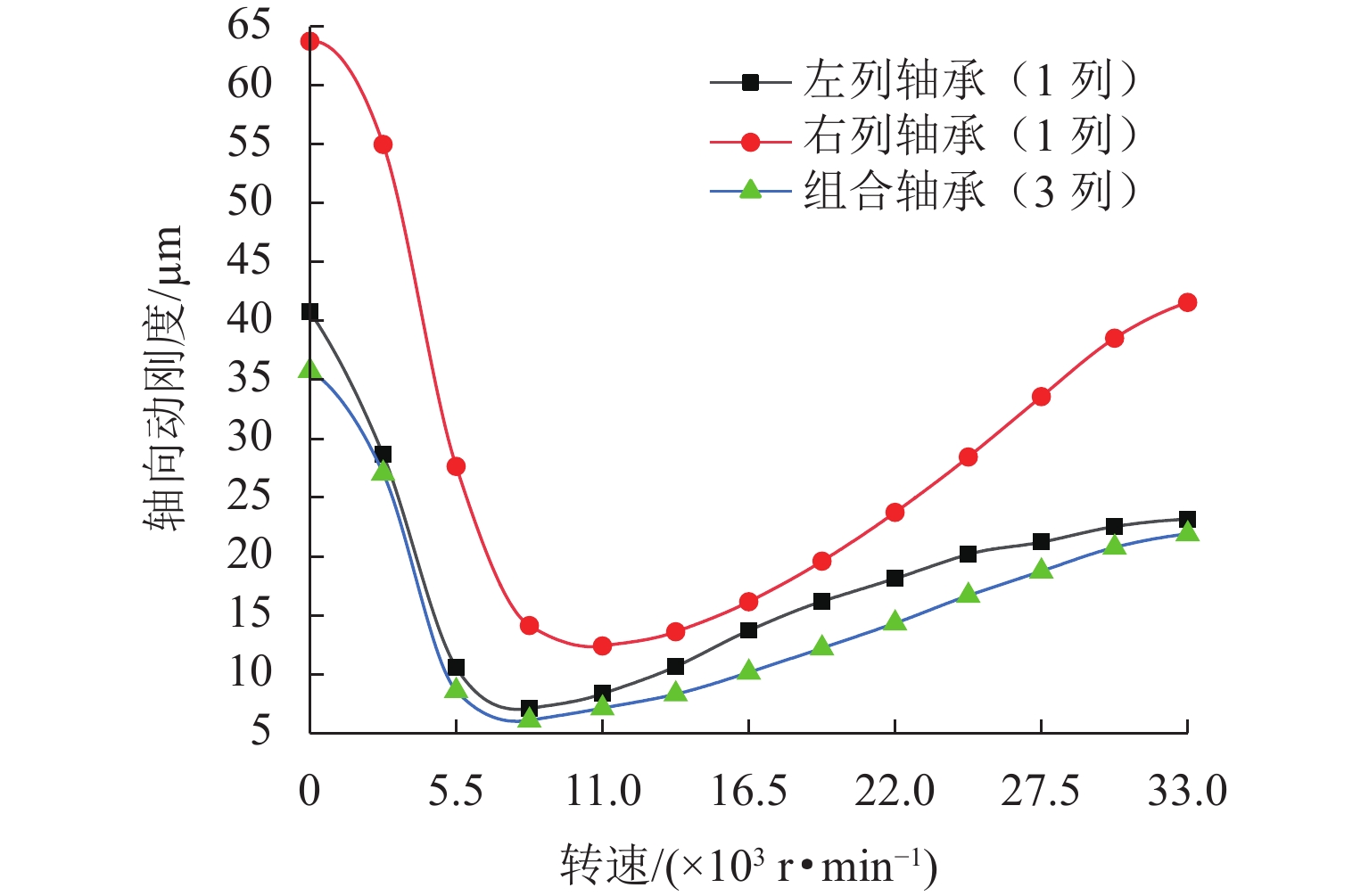

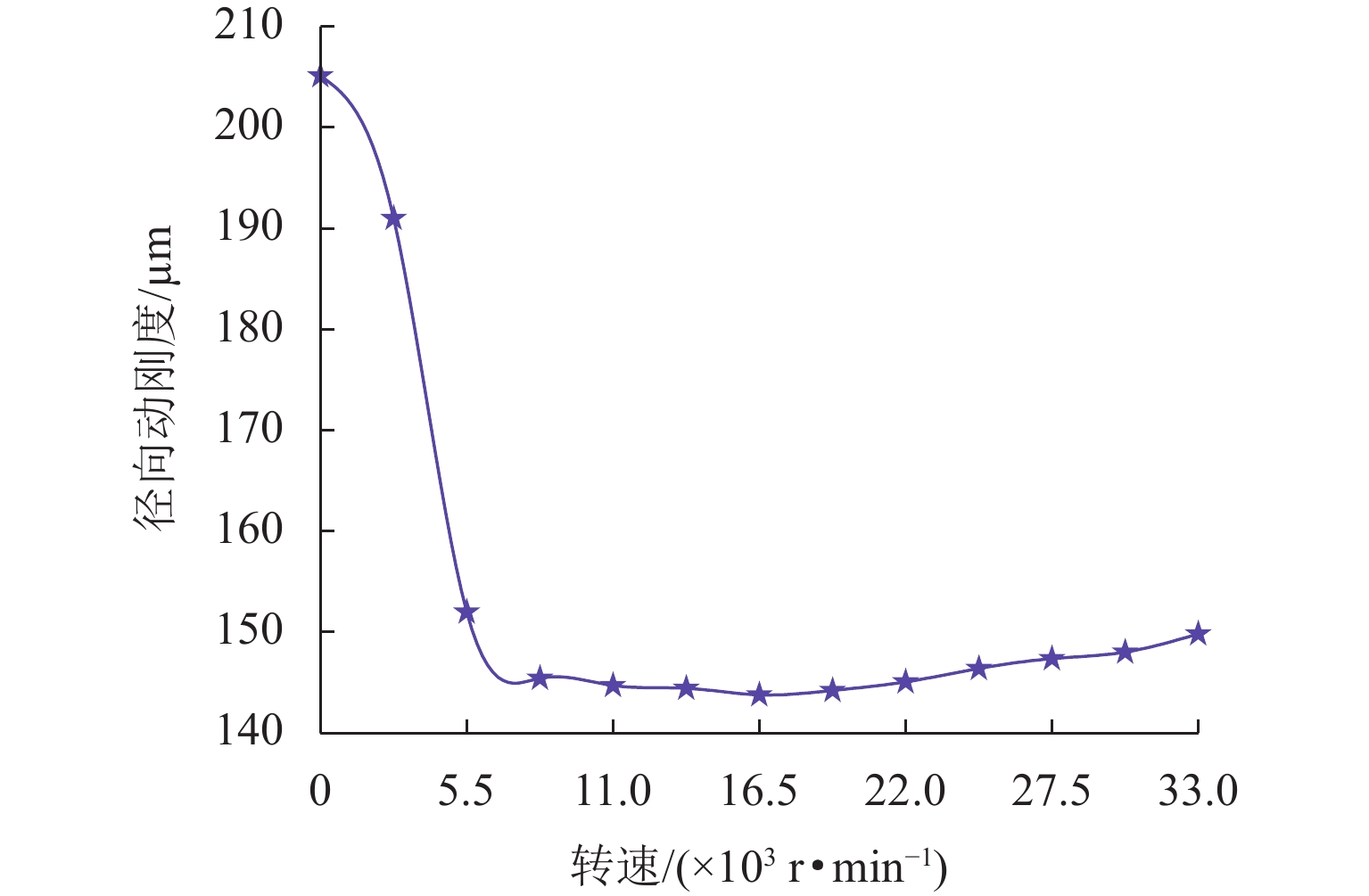

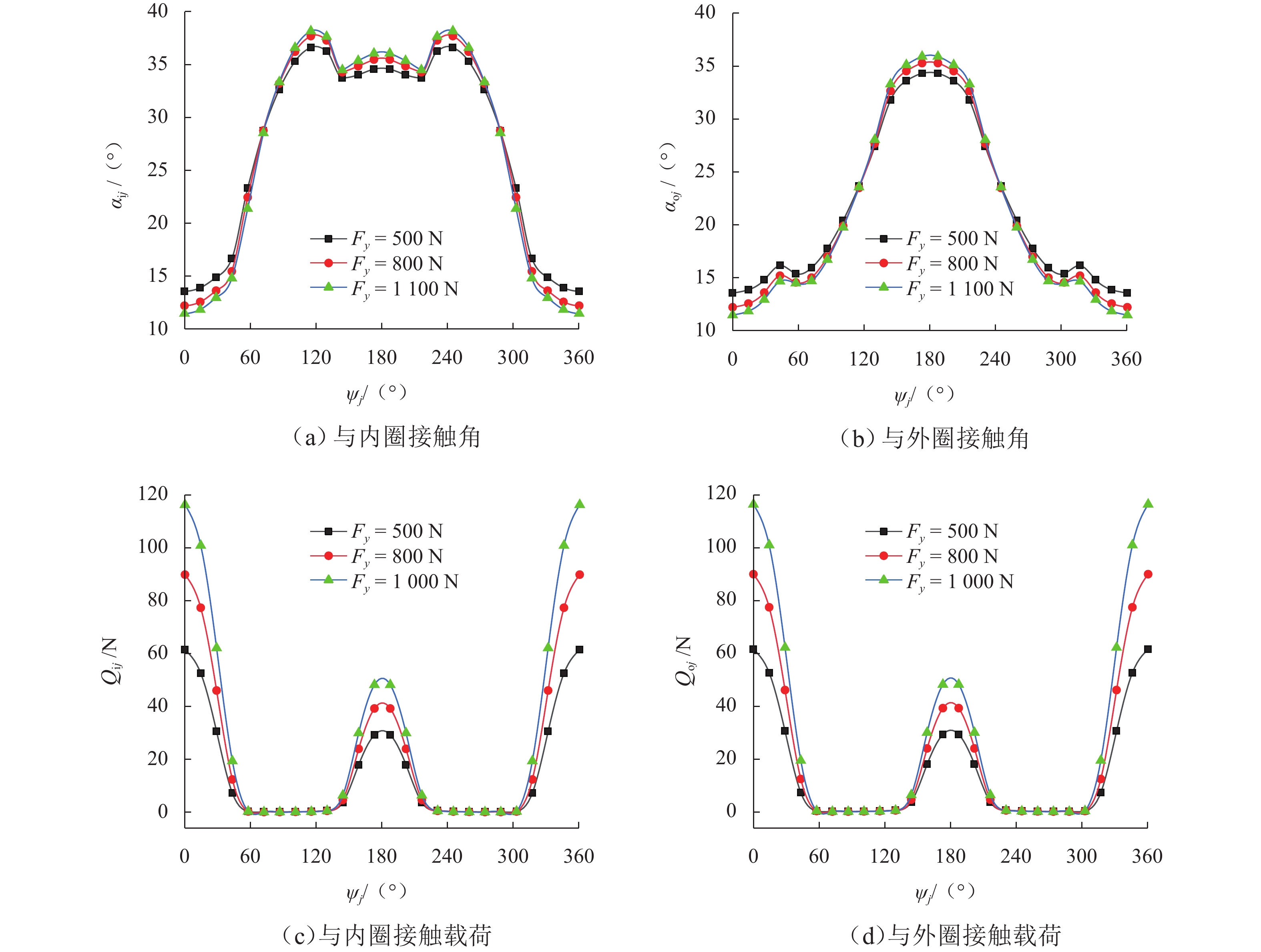

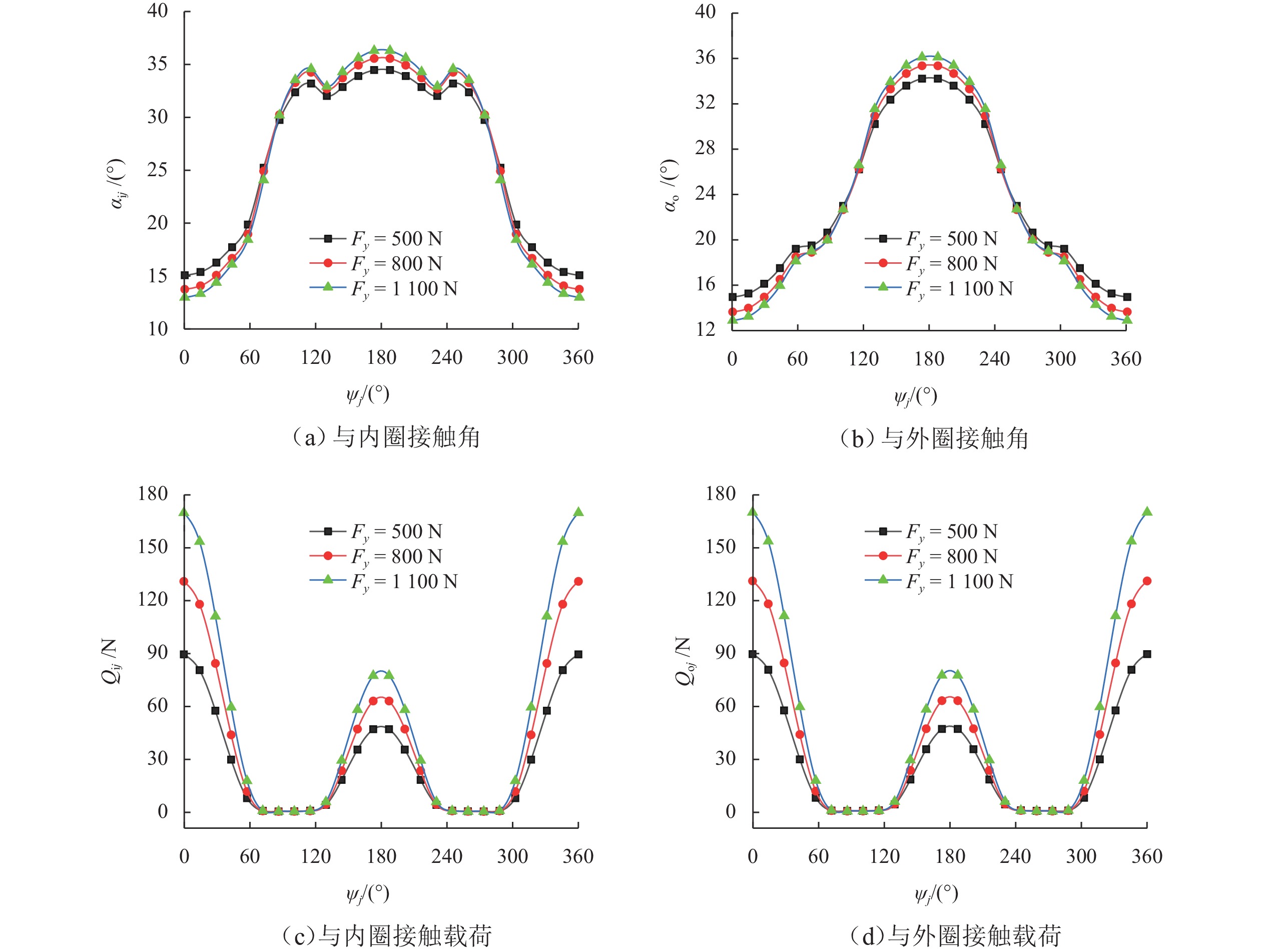

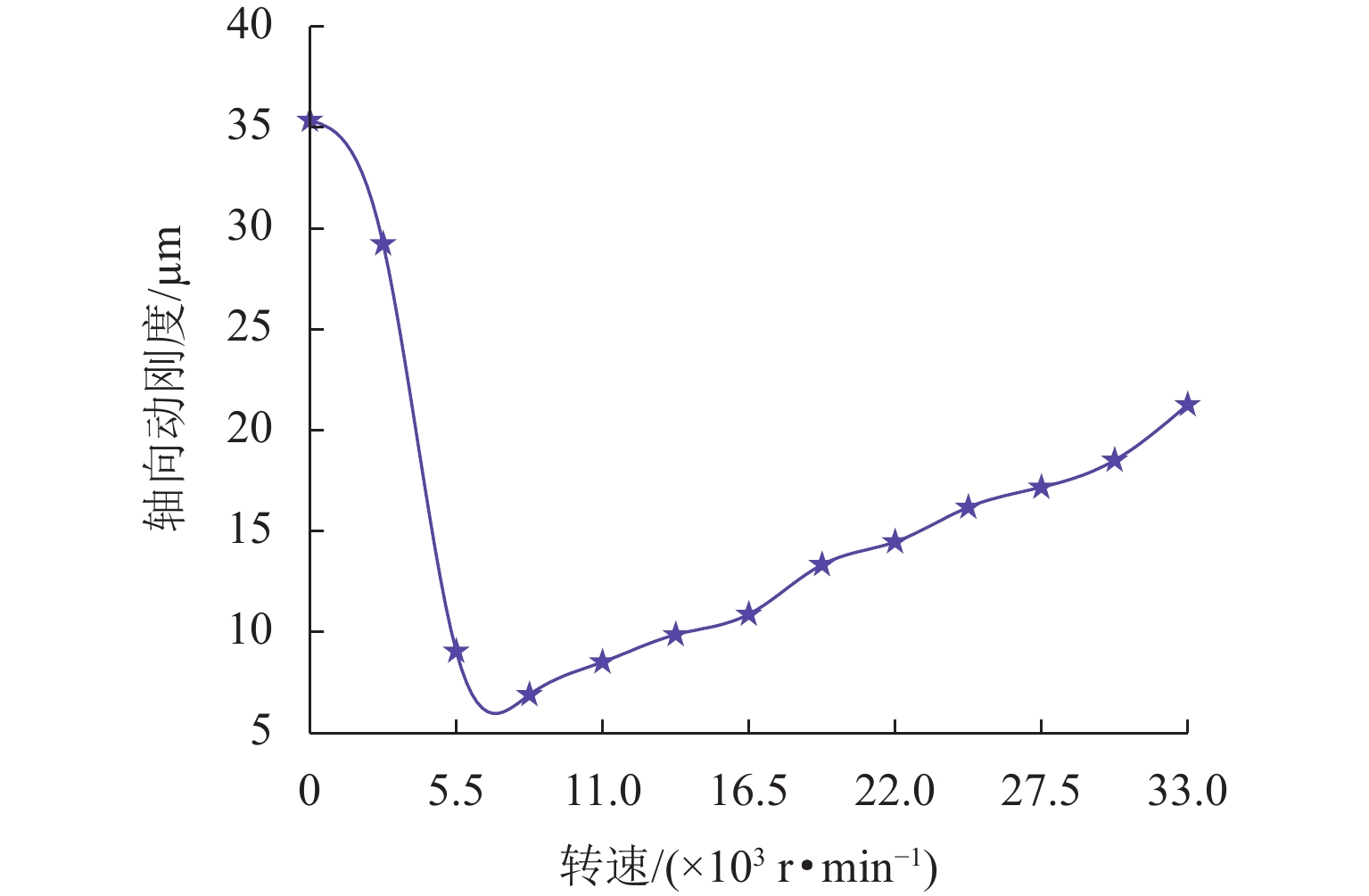

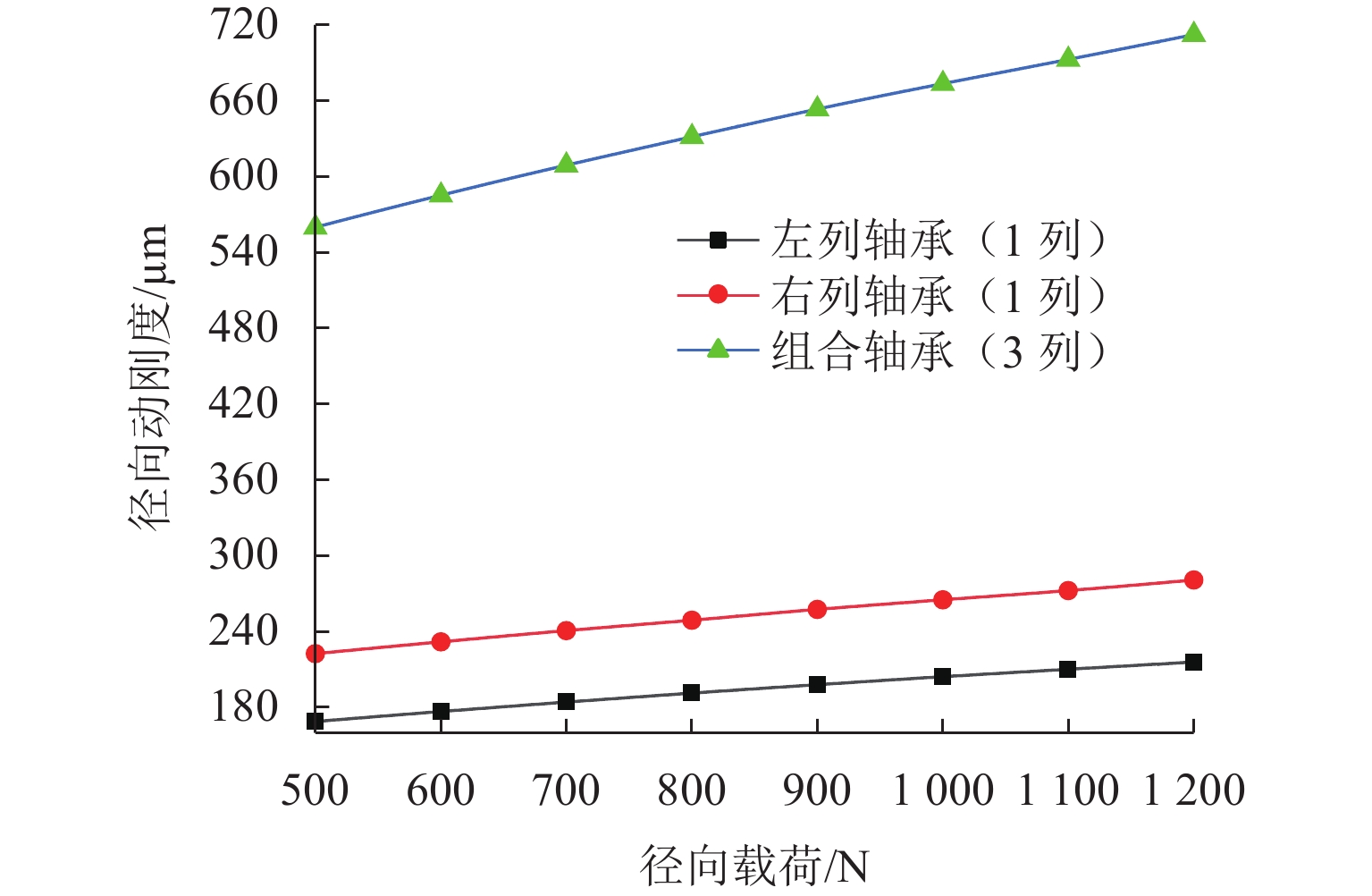

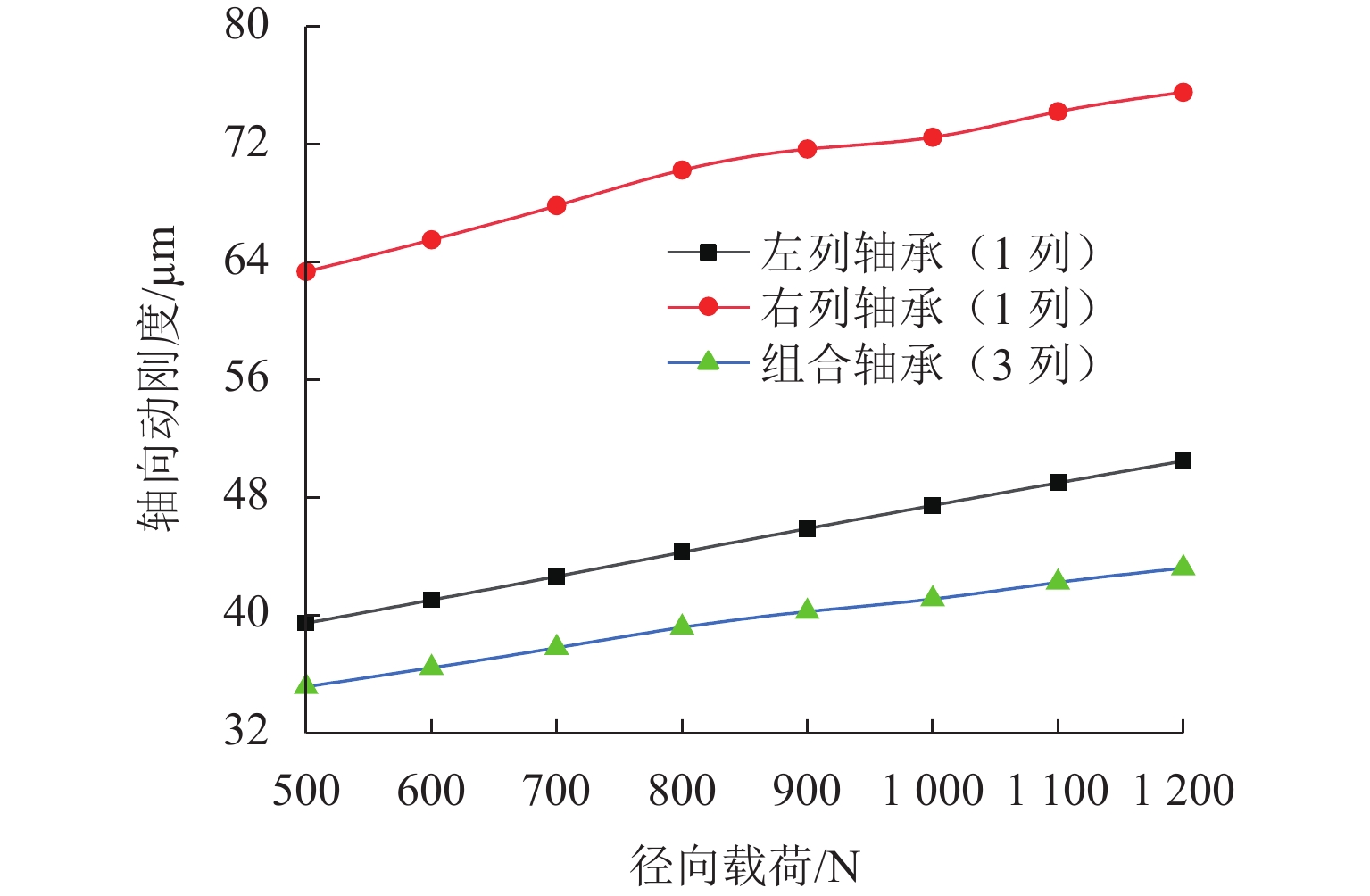

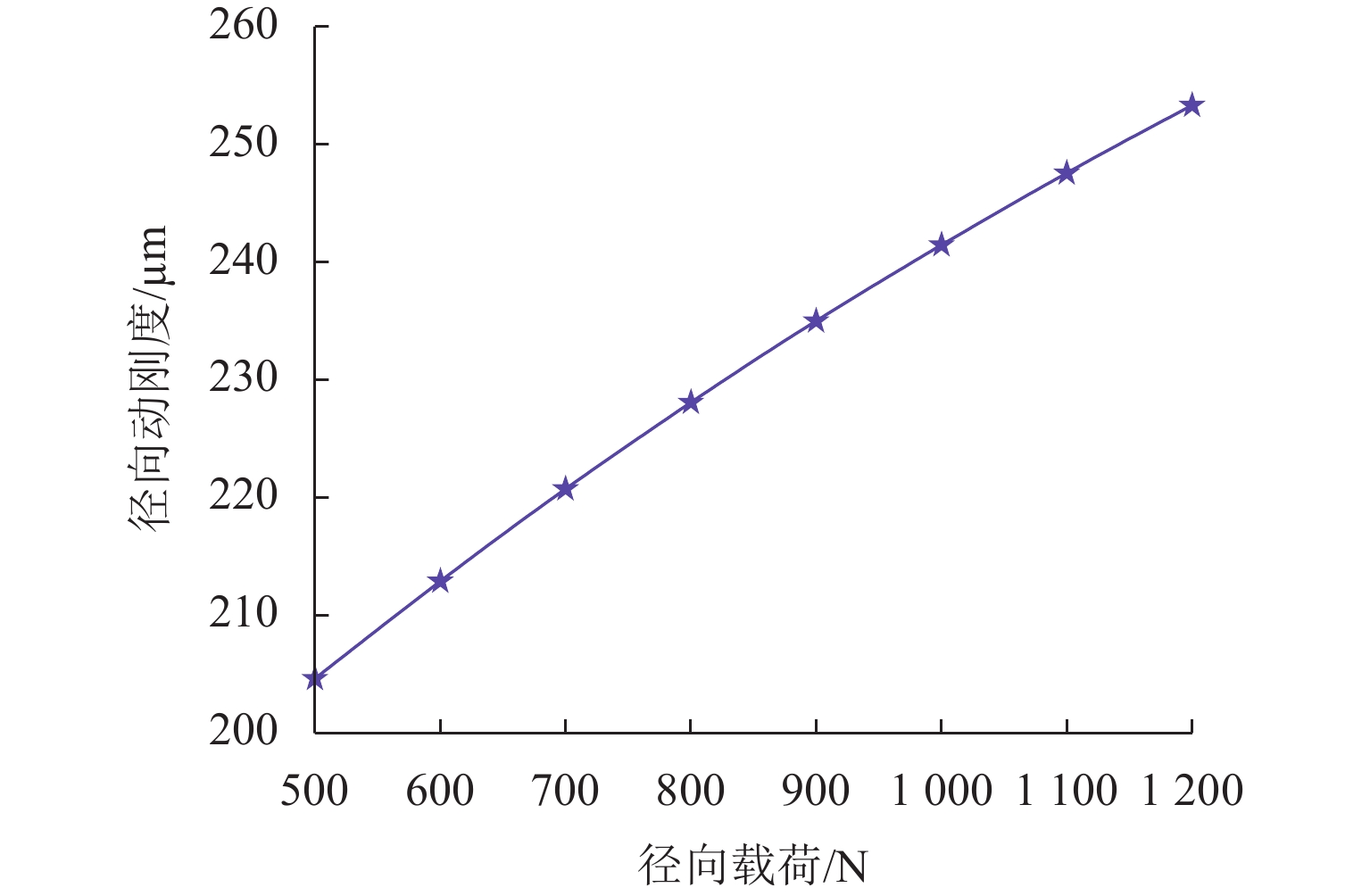

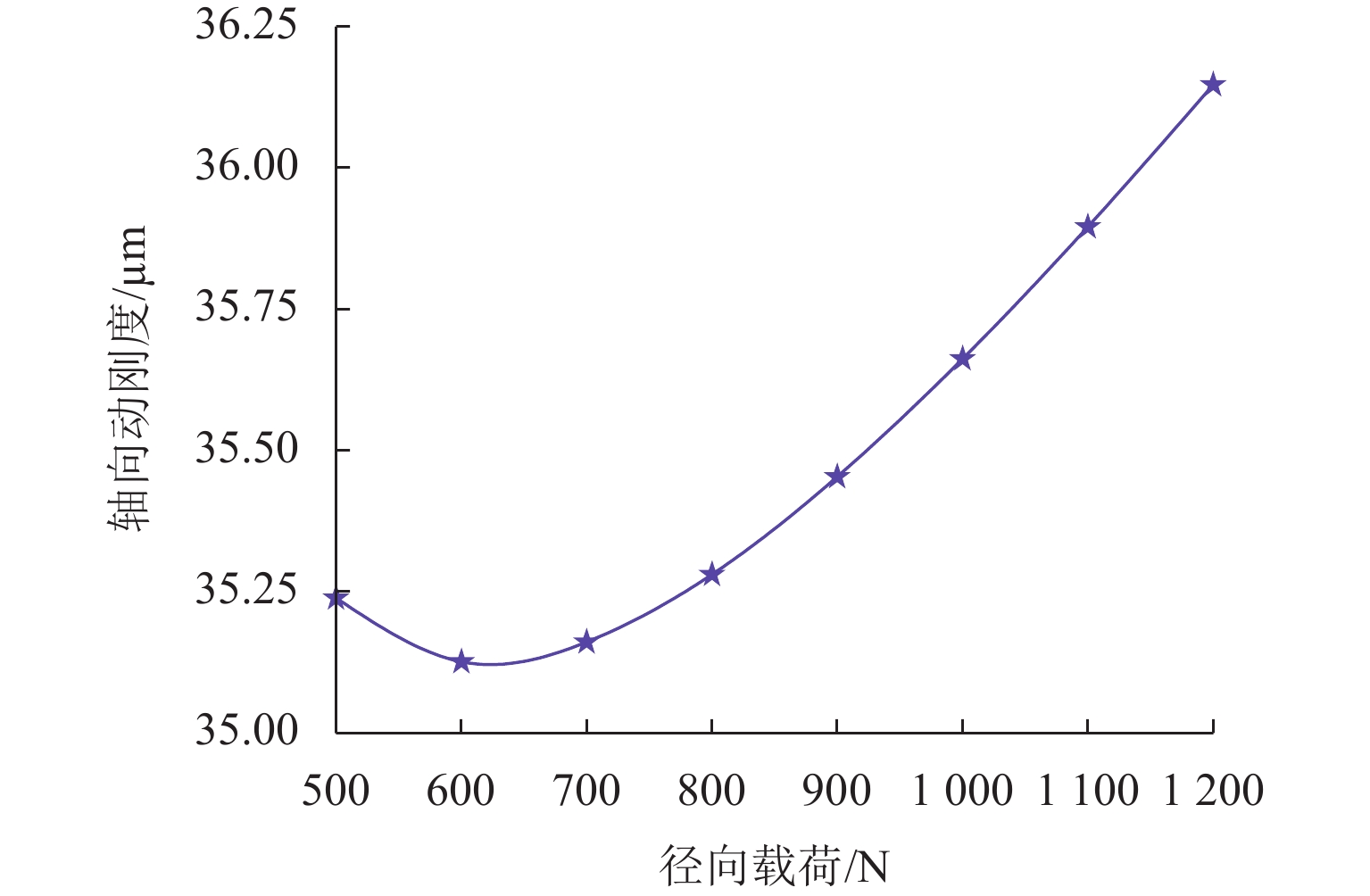

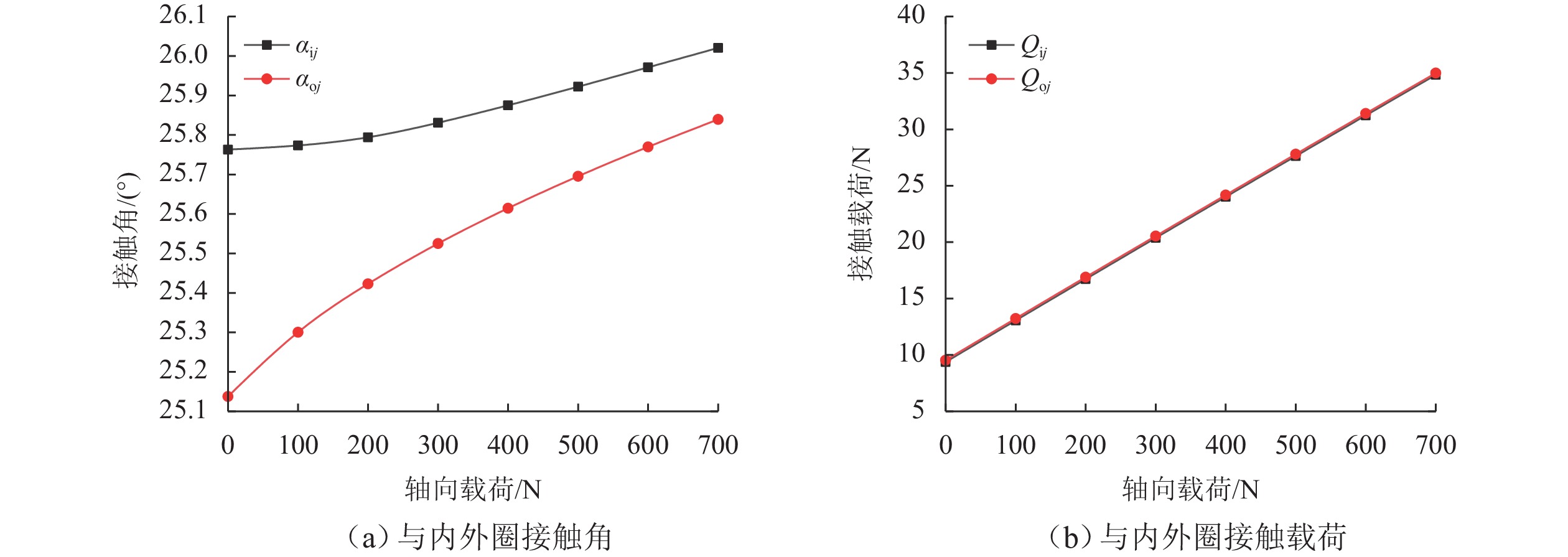

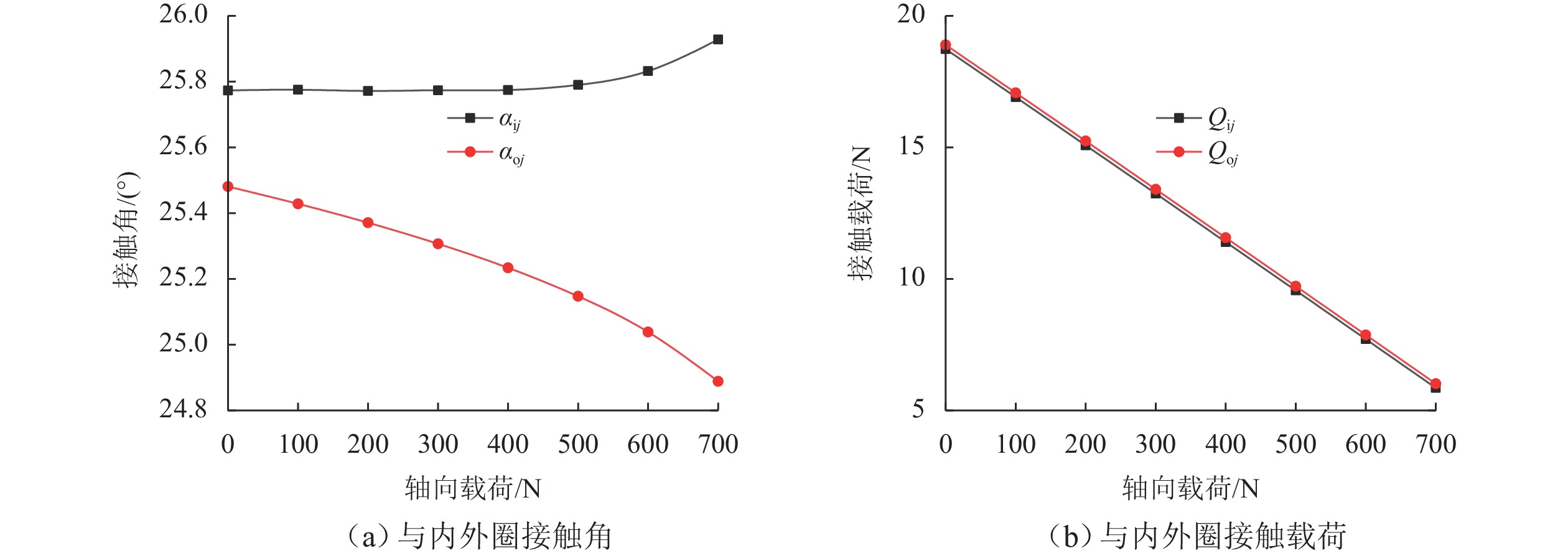

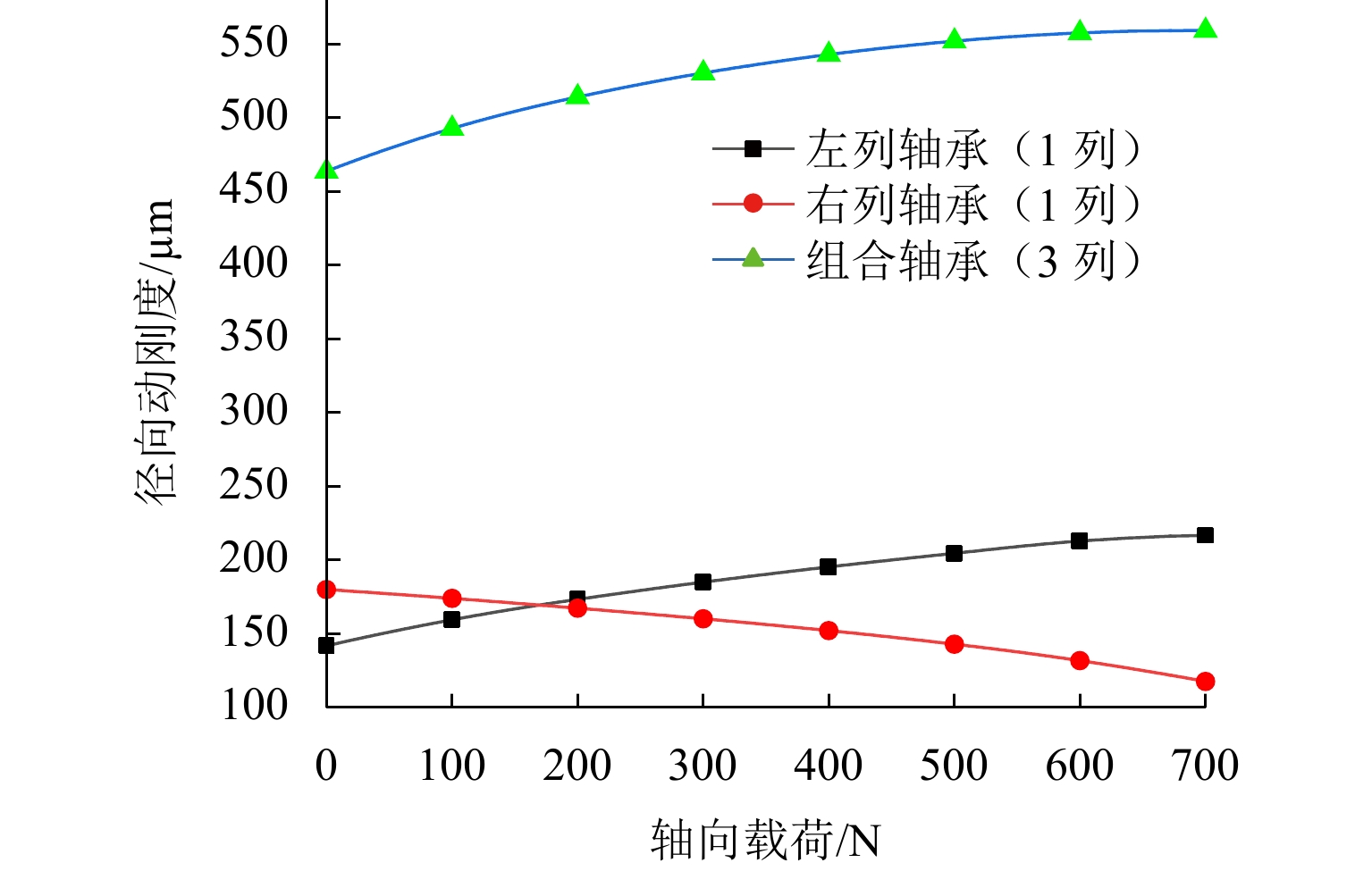

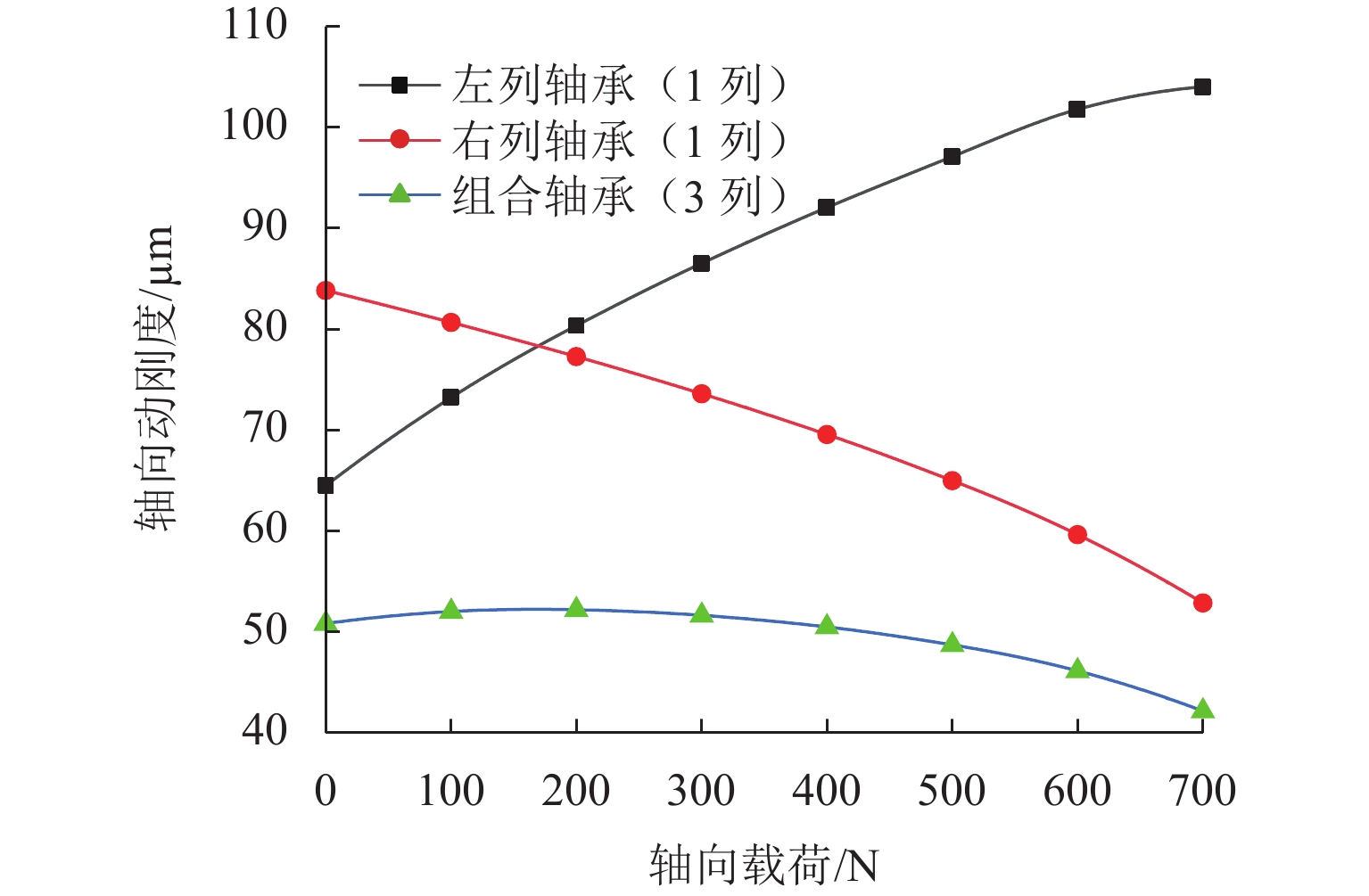

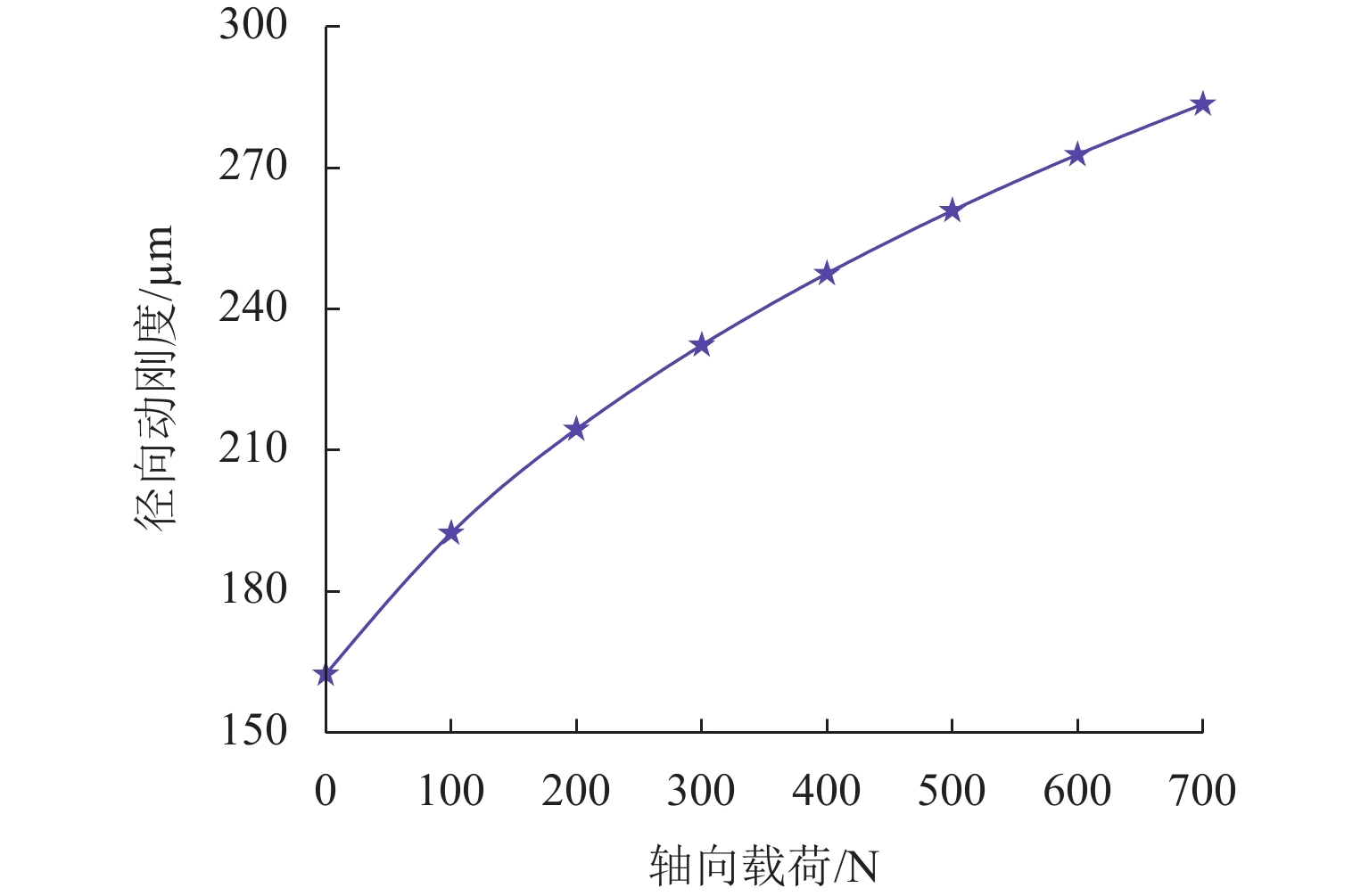

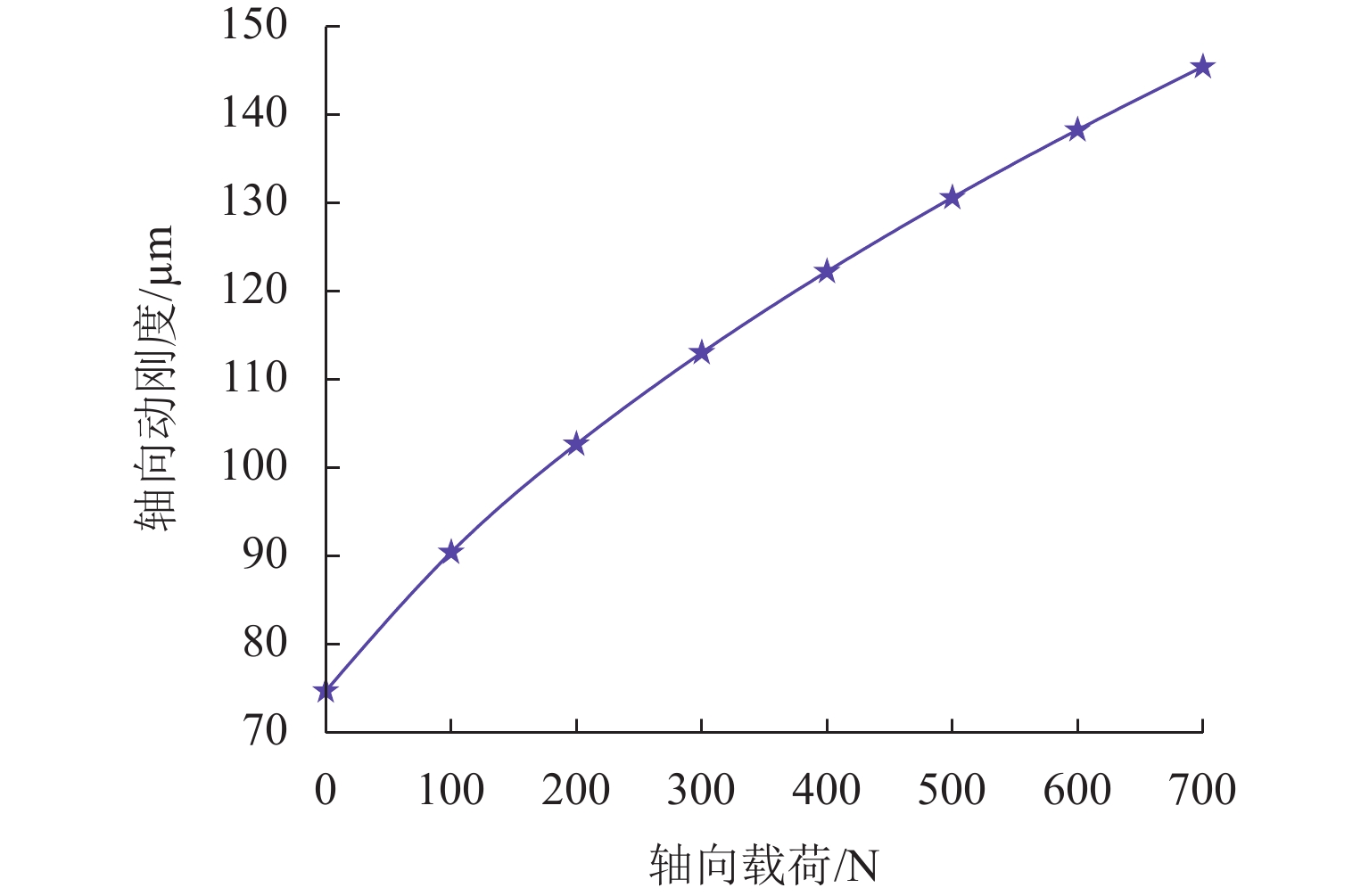

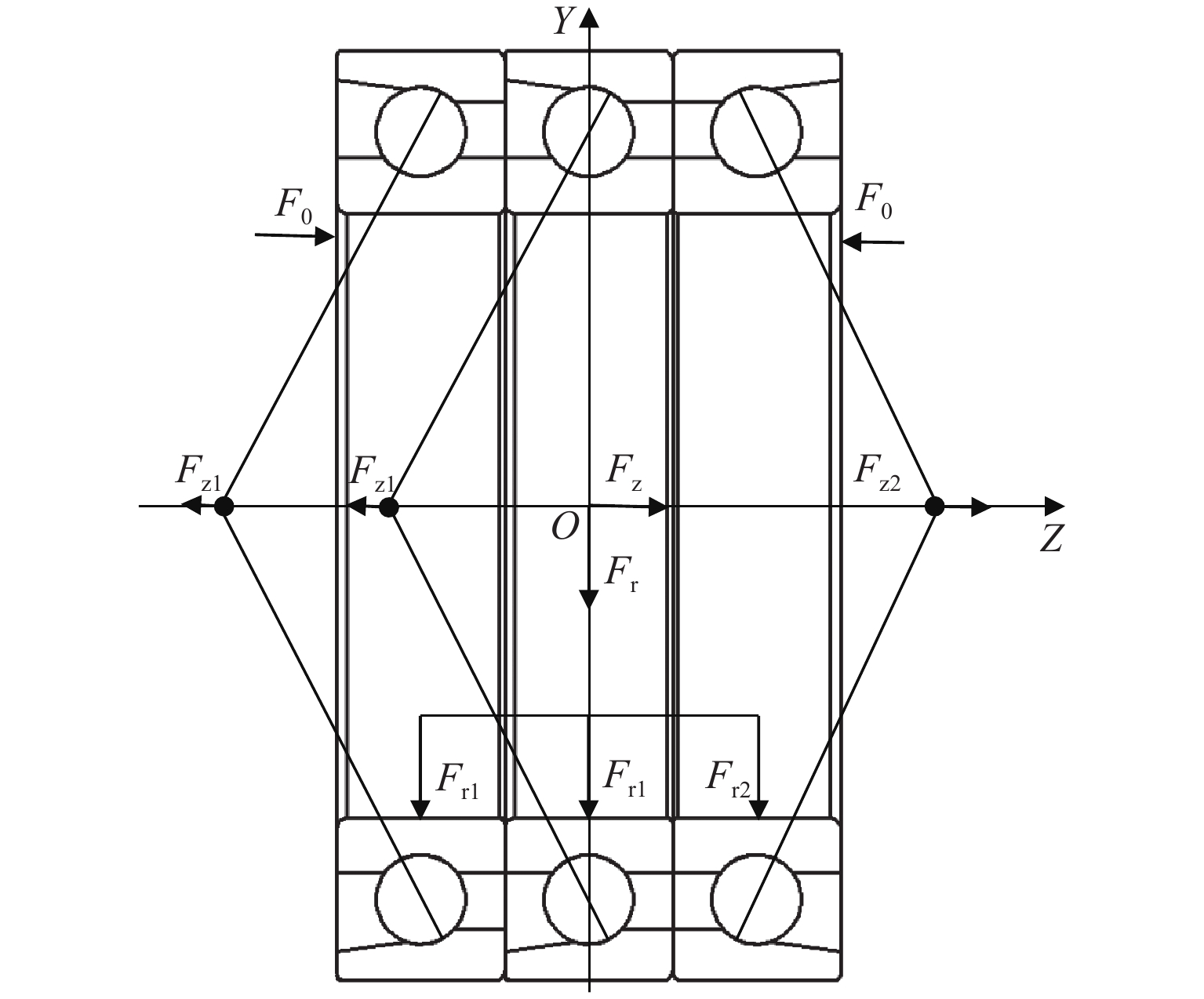

支承轴承的动态载荷分布及刚度特性是引起机床振动和切削稳定性的重要因素,为对比分析TBT (back-to-back)组合式球轴承左列和右列在不同工况下的动态载荷分布与动刚度特性,本文基于非线性弹性Hertz接触理论及Jones-Harris模型,结合滚动体-滚道接触状态判定准则,提出多列组合球轴承五自由度分析模型;采用改进的迭代算法求解,大大提高迭代计算在不同外界条件波动下的求解收敛性,得到恒定预紧力作用下TBT组合式轴承组内轴承动态载荷分布和动刚度特性. 研究结果表明:转速、径向载荷、轴向载荷均会改变组合轴承的载荷分布及动刚度特性,且对左列和右列轴承影响效果不同;转速增加会导致组内轴承内部产生非完全接触区域,使轴承载荷分布发生振荡;相较于单个轴承在等效外界载荷条件下,组合轴承的径向动刚度较轴向动刚度提升效果更明显.

Abstract:The dynamic load distribution and stiffness characteristics of bearings are important factors that cause vibration and cutting stability of machine tools. On the basis of nonlinear elastic Hertz contact theory and Jones-Harris model, combined with the judgment criterion of roller–raceway contact state, a five-degree-of-freedom analysis model of multi-row combined ball bearings was proposed to compare dynamic load distribution and dynamic stiffness characteristics of left and right rows in tandem back-to-back (TBT) combined ball bearings under different operating conditions. The improved iterative algorithm was adopted for solution, which greatly improved the convergence of the iterative calculation under the fluctuation of different external conditions and yielded the dynamic load distribution and dynamic stiffness characteristics within the TBT combined bearings under constant preload. The results show that the rotational speed, radial load, and axial load can change the load distribution and dynamic stiffness characteristics of combined bearings, and have different effects on the left-row and right-row bearings. The increase in rotational speed can lead to the incomplete contact area within the bearings, which makes the load distribution of the bearing oscillate. Compared with that of a single bearing under equivalent external load conditions, the radial dynamic stiffness of the combined bearing is more significantly improved than the axial dynamic stiffness.

-

Key words:

- ball bearing /

- contact state analysis /

- dynamic load distribution /

- dynamic stiffness /

- contact angle

-

表 1 动态接触参数对比结果

Table 1. Comparison results of dynamic contact parameters

表 2 轴承刚度对比结果

Table 2. Comparison results of bearing stiffness

实验组别 ${K_{{\textit{zz}}}}$/(N·mm−1) ${K_{xx}}$/(N·mm−1) Kyy/(N·mm−1) ${K_{{\mathrm{M}}x}}$/(N·mm−1) KMy/(N·mm−1) 本文结果 226453.90 165949.90 165934.90 147401889.30 147401889.30 文献[16] 225376.50 166573.80 166573.80 144386234.10 144386234.10 文献[17] 226011.10 172131.60 155520.70 139304365.40 157160958.50 文献[16]误差/% −0.28 −3.23 7.11 3.65 −8.13 文献[17]误差/% −0.24 −3.59 6.70 5.81 −6.21 表 3 SKF 7012ACE/HCP4A轴承参数

Table 3. 7012ACE/HCP4A bearing parameters

轴承参数 符号 数值 轴承内滚道曲率半径/mm ri 4.08807 轴承外滚道曲率半径/mm ro 4.16745 初始接触角/(°) ${\alpha _0}$ 25 滚动体数量/个 Zr 25 滚动体直径/mm D 7.938 轴承节圆直径/mm Dm 77.591 -

[1] BERCEA I, NÉLIAS D, CAVALLARO G. A unified and simplified treatment of the non-linear equilibrium problem of double-row rolling bearings. Part 1: Rolling bearing model[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2003, 217(3): 205-212. doi: 10.1243/135065003765714854 [2] GUNDUZ A. Multi-dimensional stiffness characteristics of double row angular contact ball bearings and their role in influencing vibration modes [D]. Columbus: The Ohio State University, 2012. [3] XU T F, YANG L H, WU W, et al. Effect of angular misalignment of inner ring on the contact characteristics and stiffness coefficients of duplex angular contact ball bearings[J]. Mechanism and Machine Theory, 2021, 157: 104178. doi: 10.1016/j.mechmachtheory.2020.104178 [4] 李鸿亮, 贺红霞, 刘良勇, 等. 定位预紧配对角接触球轴承工作预紧力分析[J]. 轴承, 2012(9): 37-39. [5] 李鸿亮, 夏旎, 邓四二, 等. 配对角接触球轴承初始预紧力分析[J]. 轴承, 2013(8): 1-3, 7.LI Hongliang, XIA Ni, DENG Sier, et al. Analysis on initial preload of paired angular contact ball bearings[J]. Bearing, 2013(8): 1-3, 7. [6] 蒋蔚, 周彦伟, 梁波. 配对角接触轴承刚度和摩擦力矩分析计算[J]. 轴承, 2006(8): 1-3, 35.JIANG Wei, ZHOU Yanwei, LIANG Bo. Analysis and calculation on rigidity and friction moment of paired angular contact bearings[J]. Bearing, 2006(8): 1-3, 35. [7] 杨兵华, 张振强, 权超健, 等. 不同接触角轴承组配的预紧技术[J]. 轴承, 2017(7): 18-20.YANG Binghua, ZHANG Zhenqiang, QUAN Chaojian, et al. Preloading technology for matched bearings with different contact angles[J]. Bearing, 2017(7): 18-20. [8] 张振强, 王东峰, 李凌鑫, 等. 非等接触角球轴承组配刚度及预紧力分析[J]. 轴承, 2018(2): 10-13.ZHANG Zhenqiang, WANG Dongfeng, LI Lingxin, et al. Analysis on stiffness and preload of matched ball bearings with unequal contact angles[J]. Bearing, 2018(2): 10-13. [9] 冯吉路, 孙志礼, 李皓川, 等. 多列组合角接触球轴承刚度和位移量[J]. 振动. 测试与诊断, 2016, 36(4): 784-789, 816.FENG Jilu, SUN Zhili, LI Haochuan, et al. Investigation of the stiffness and displacement of multiple combinations of angular contact ball bearings[J]. Journal of Vibration, Measurement & Diagnosis, 2016, 36(4): 784-789, 816. [10] LIN S Y, JIANG S Y. Study of the stiffness matrix of preloaded duplex angular contact ball bearings[J]. Journal of Tribology, 2019, 141(3): 032204. doi: 10.1115/1.4041895 [11] HARRIS T A. Rolling bearing analysis[M]. New York: John Wiley and Sons, 2001. [12] DING C G. Raceway control assumption and the determination of rolling element attitude angle[J]. Chinese Journal of Mechanical Engineering, 2001, 37(2): 58. doi: 10.3901/JME.2001.02.058 [13] CAO Y Z, ALTINTAS Y. A general method for the modeling of spindle-bearing systems[J]. Journal of Mechanical Design, 2004, 126(6): 1089-1104. doi: 10.1115/1.1802311 [14] 万长森. 滚动轴承的分析方法[M]. 北京: 机械工业出版社, 1987. [15] 李震, 关先磊, 钟锐, 等. 联合载荷下角接触球轴承的动态特性分析[J]. 机械工程学报, 2020, 56(17): 116-125. doi: 10.3901/JME.2020.17.116LI Zhen, GUAN Xianlei, ZHONG Rui, et al. Analysis of dynamic characteristics of angle contact bearings with combined loads[J]. Journal of Mechanical Engineering, 2020, 56(17): 116-125. doi: 10.3901/JME.2020.17.116 [16] ZHANG X N, HAN Q K, PENG Z K, et al. A comprehensive dynamic model to investigate the stability problems of the rotor–bearing system due to multiple excitations[J]. Mechanical Systems and Signal Processing, 2016, 70: 1171-1192. [17] DIETL P. Damping and stiffness characteristics of rolling element bearings-theory and experiment[D]. Vienna: Technical University of Vienna, 1997. -

下载:

下载: