Seismic Performance of Cross-Shaped Columns Partially Encased with Cold-Formed Thin-Walled Steel and Filled with Lightweight Concrete

-

摘要:

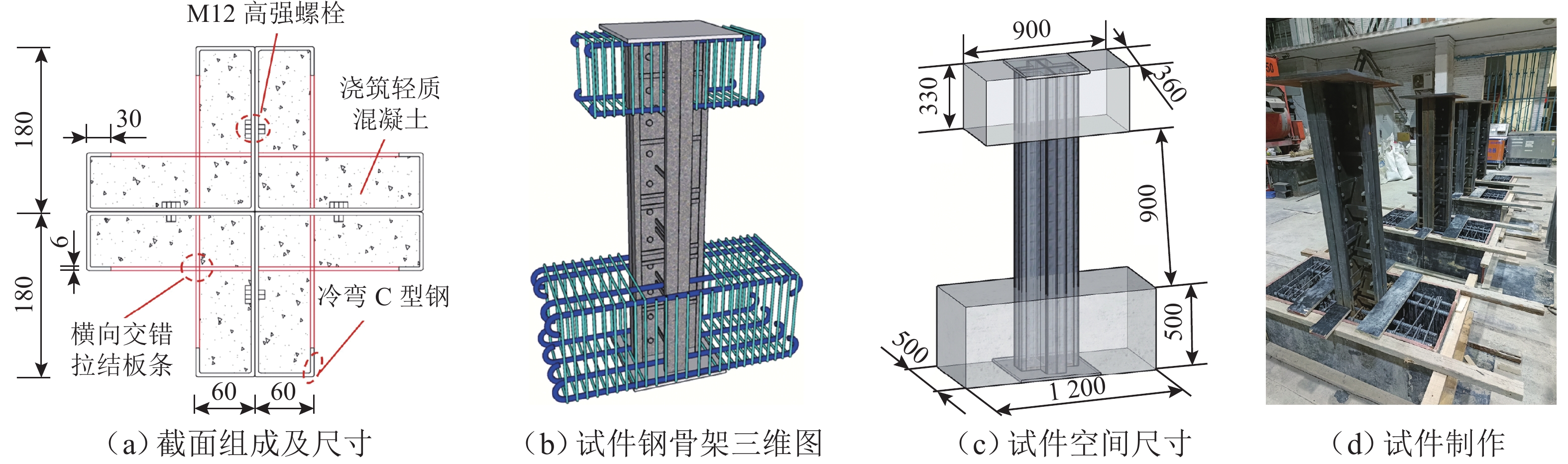

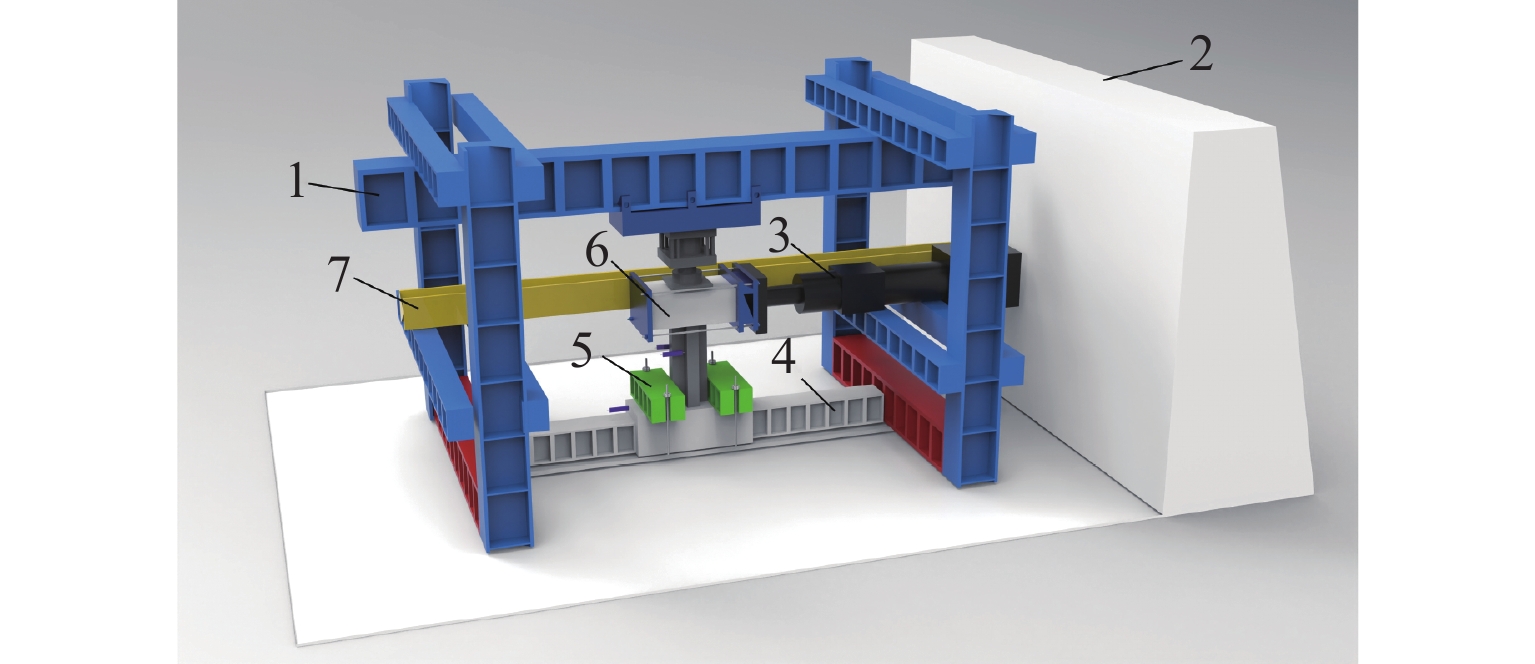

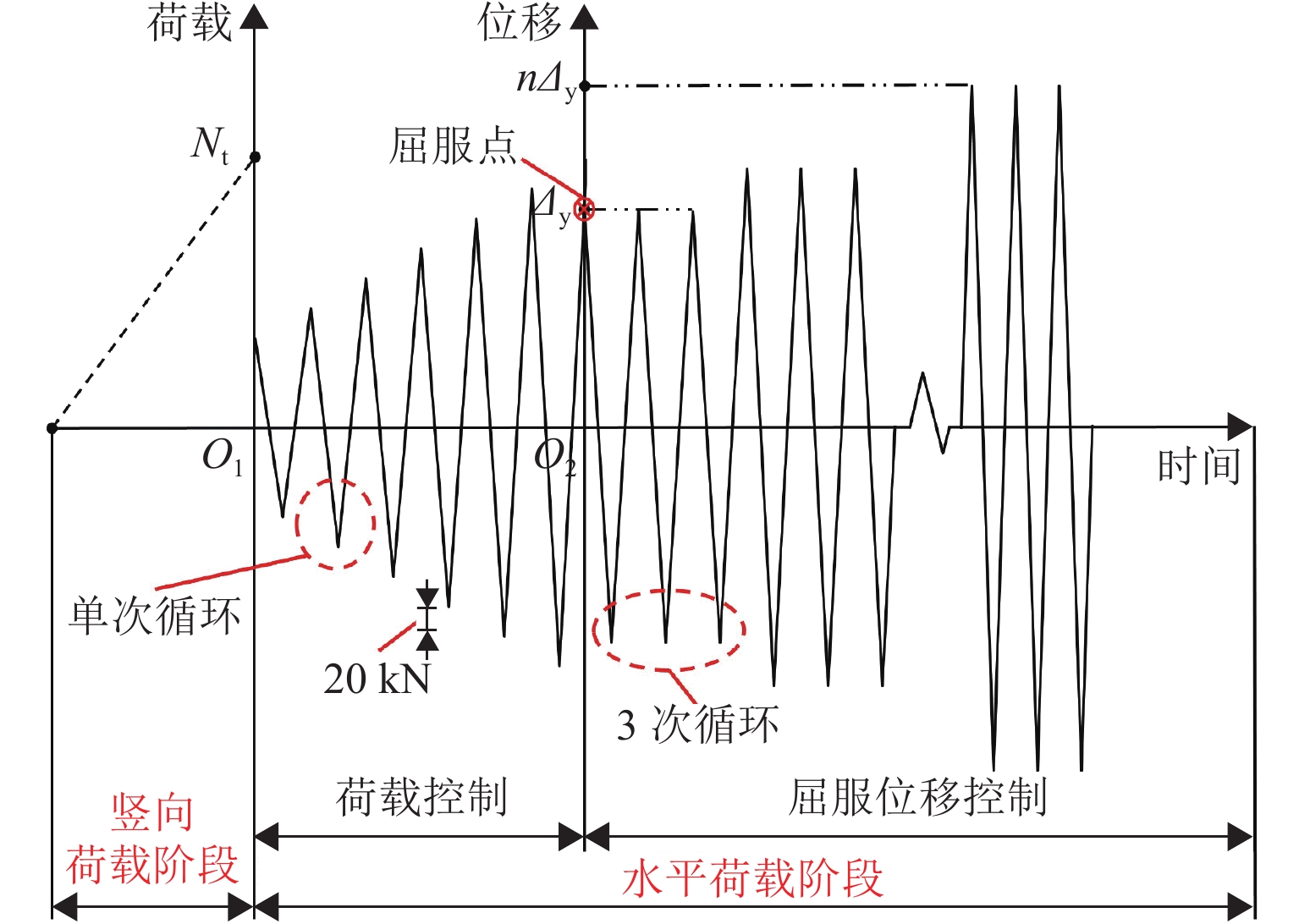

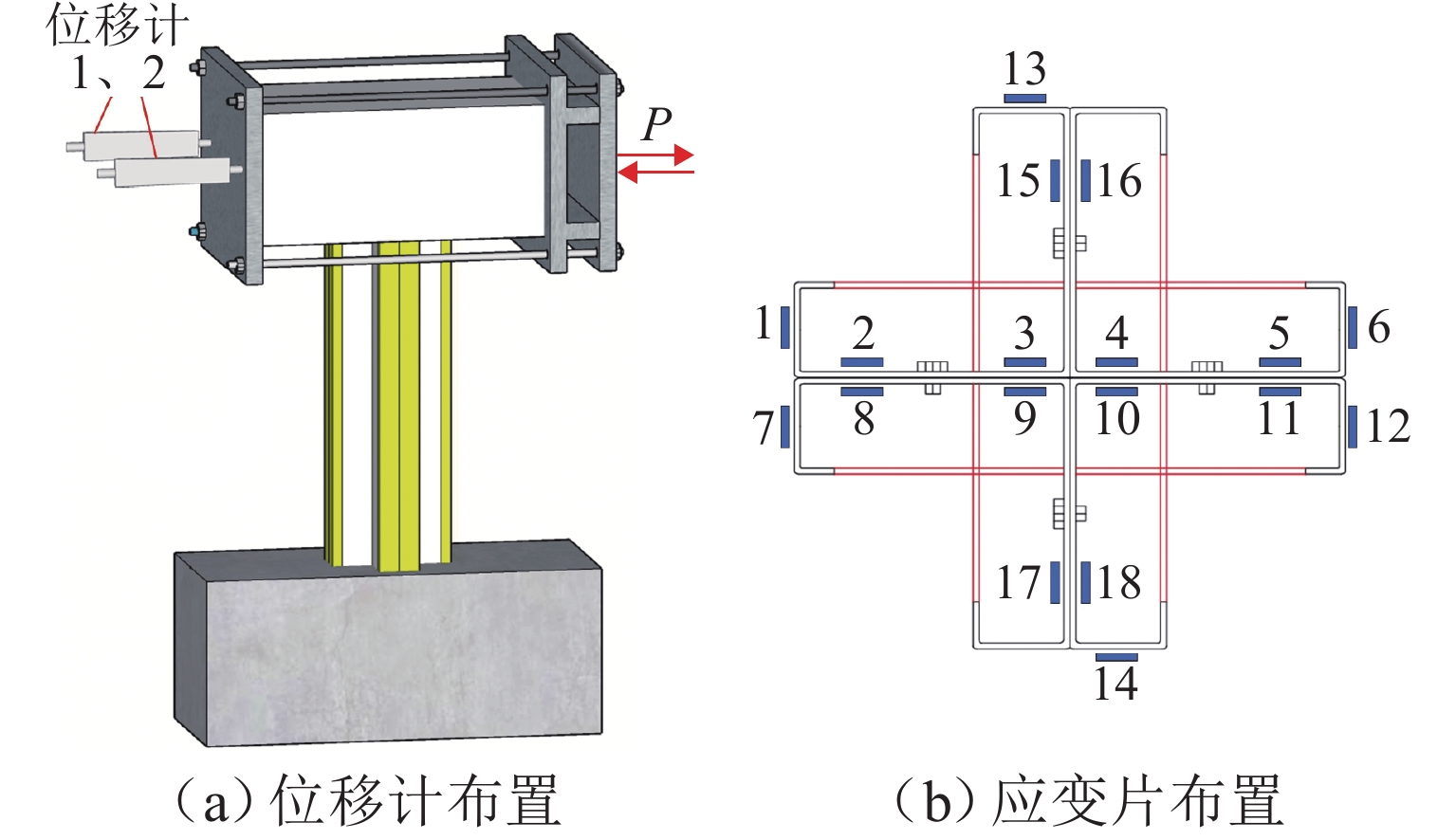

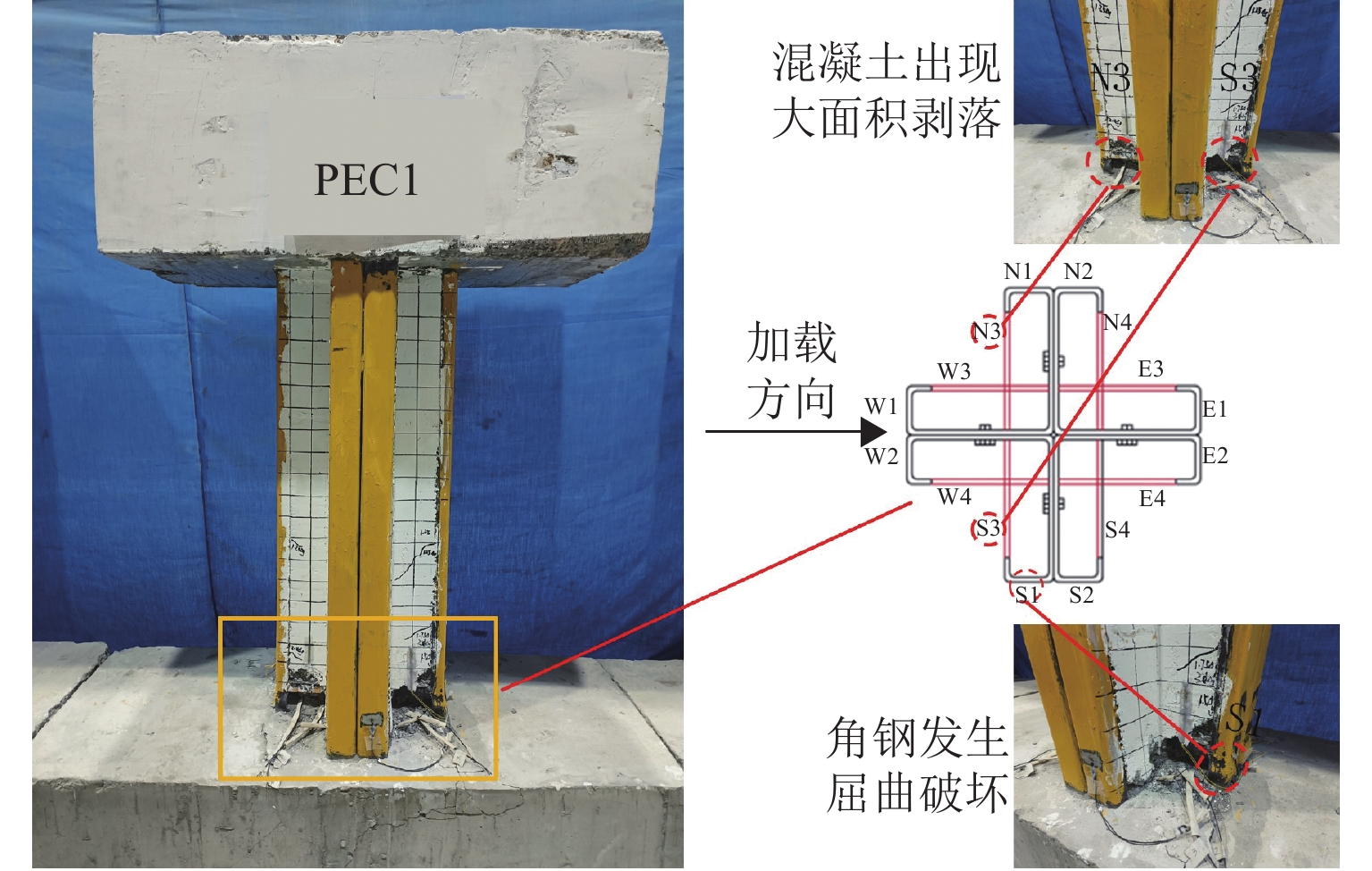

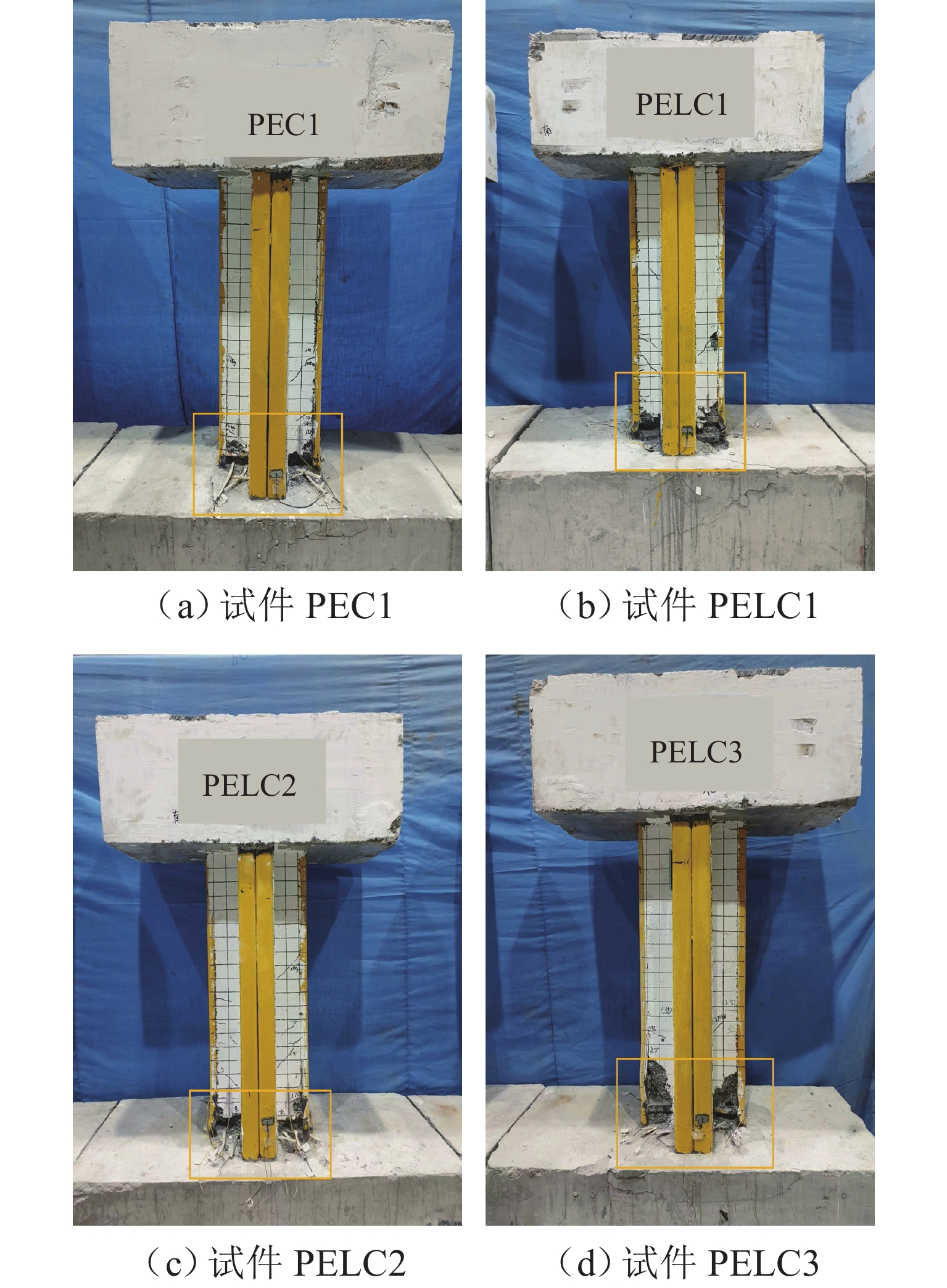

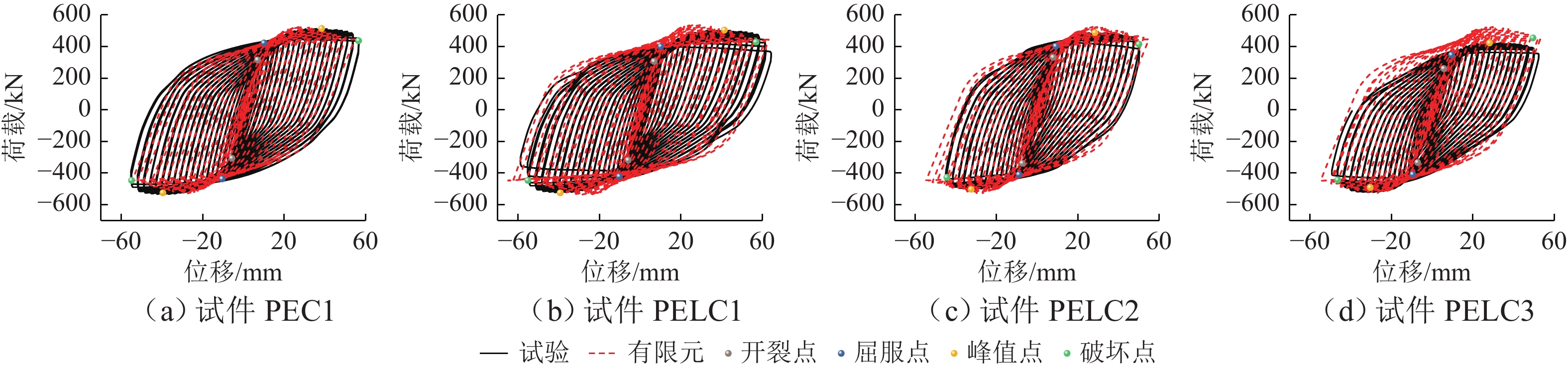

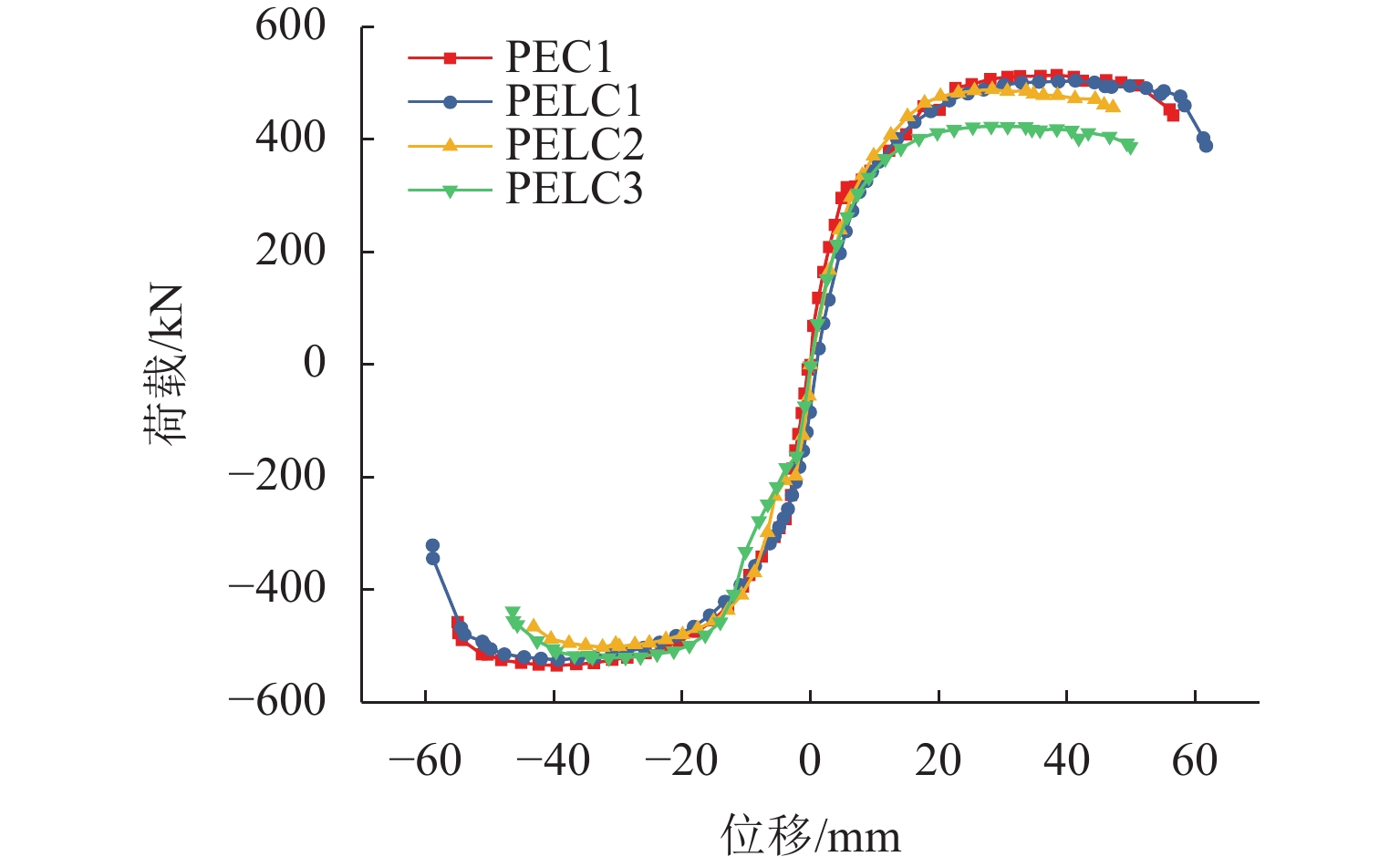

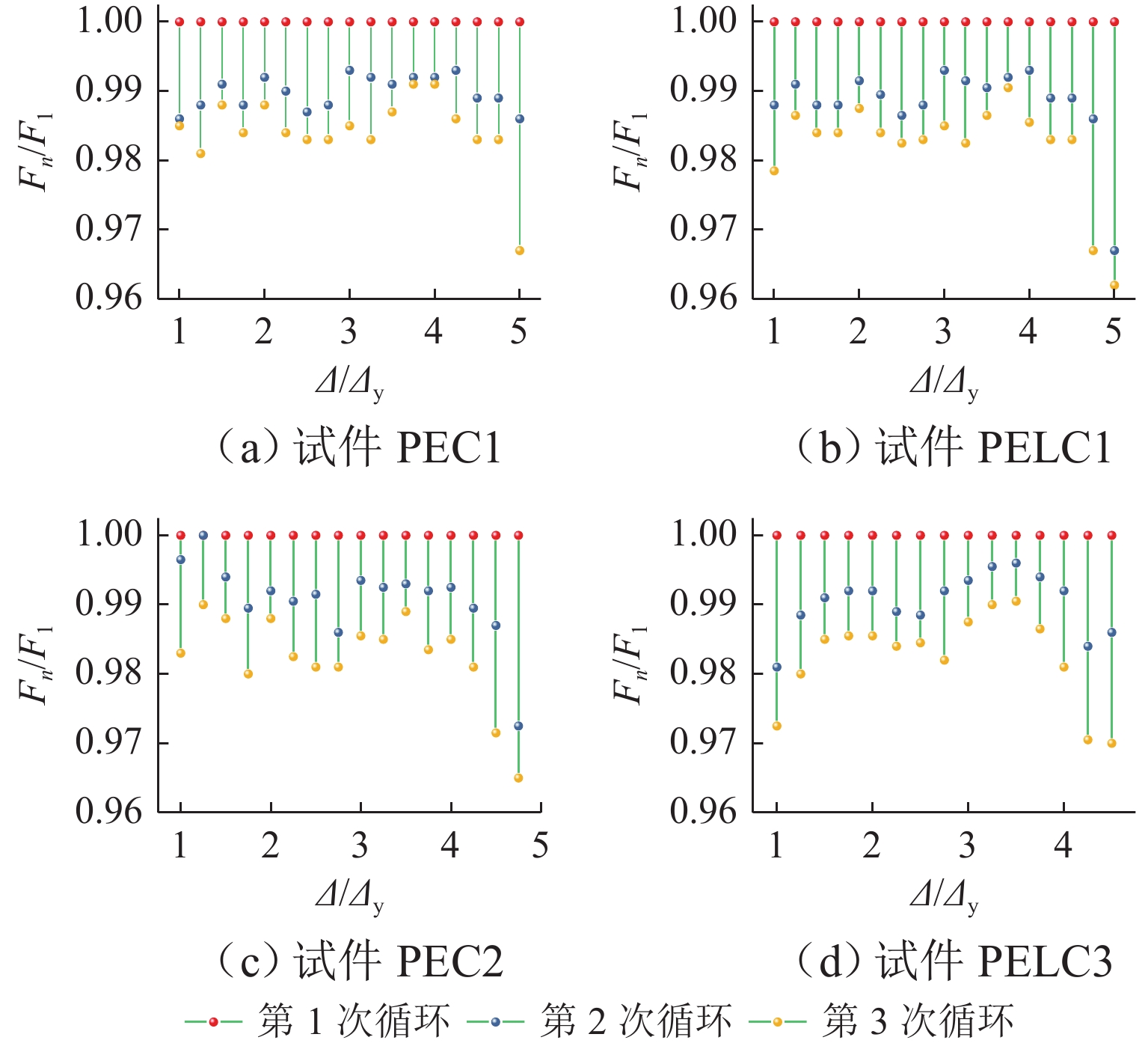

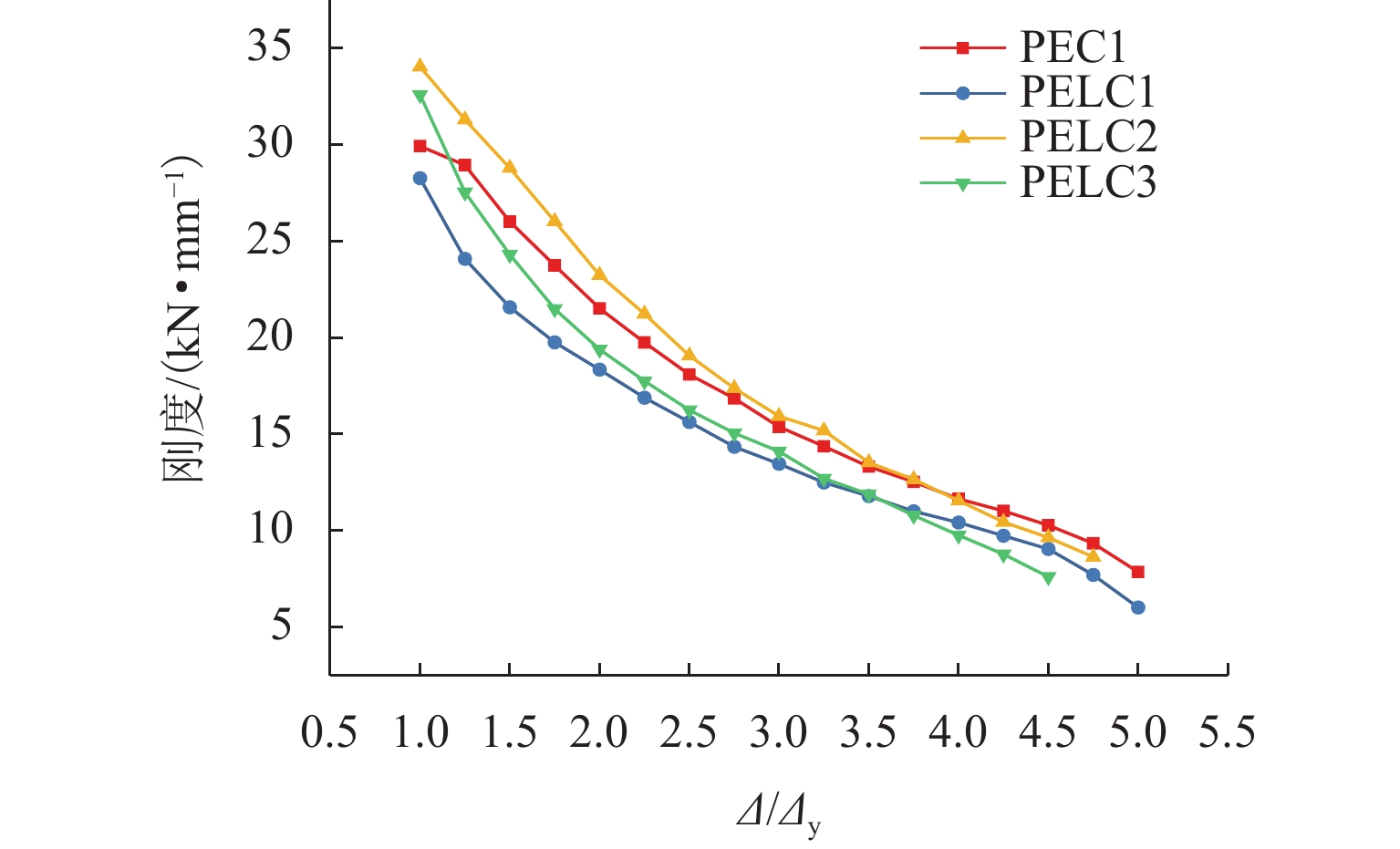

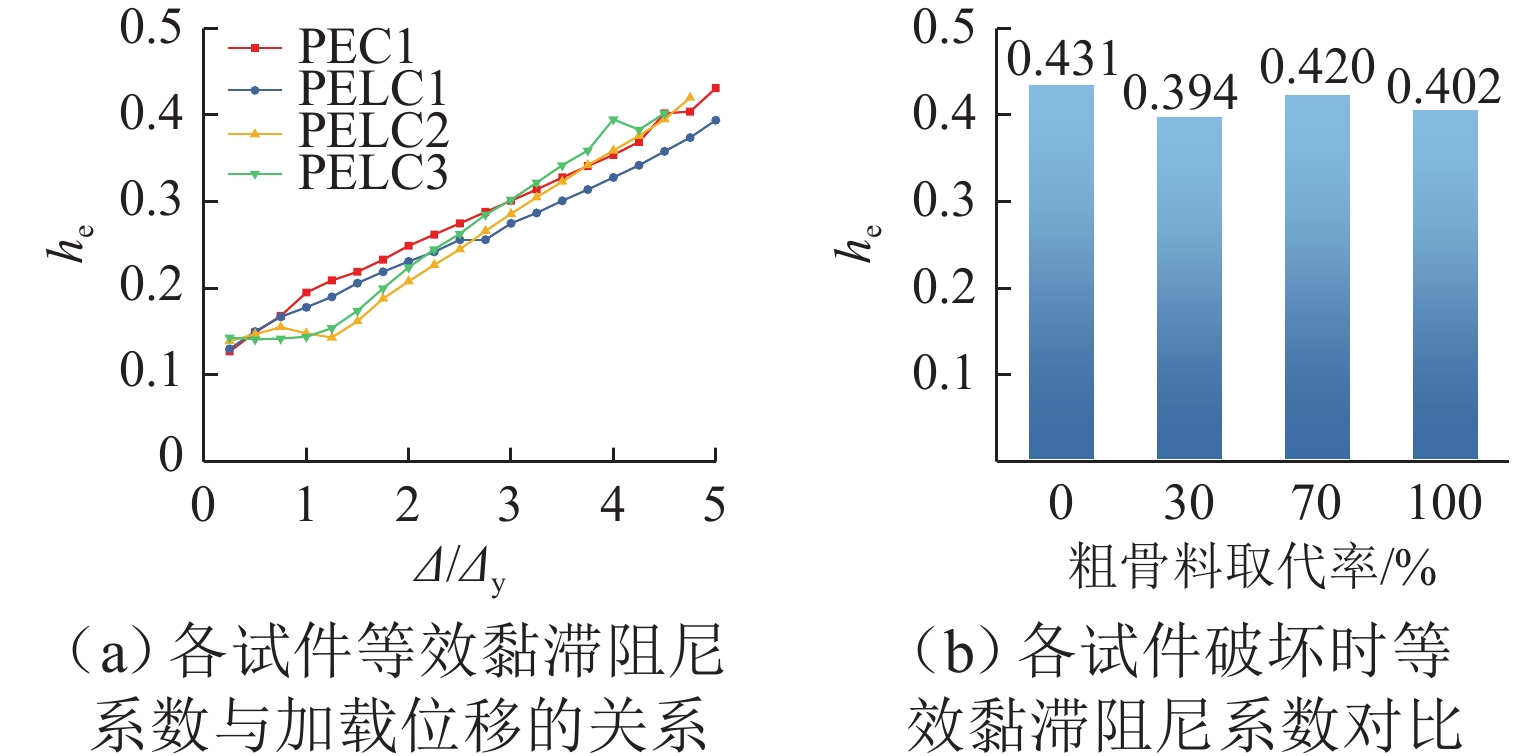

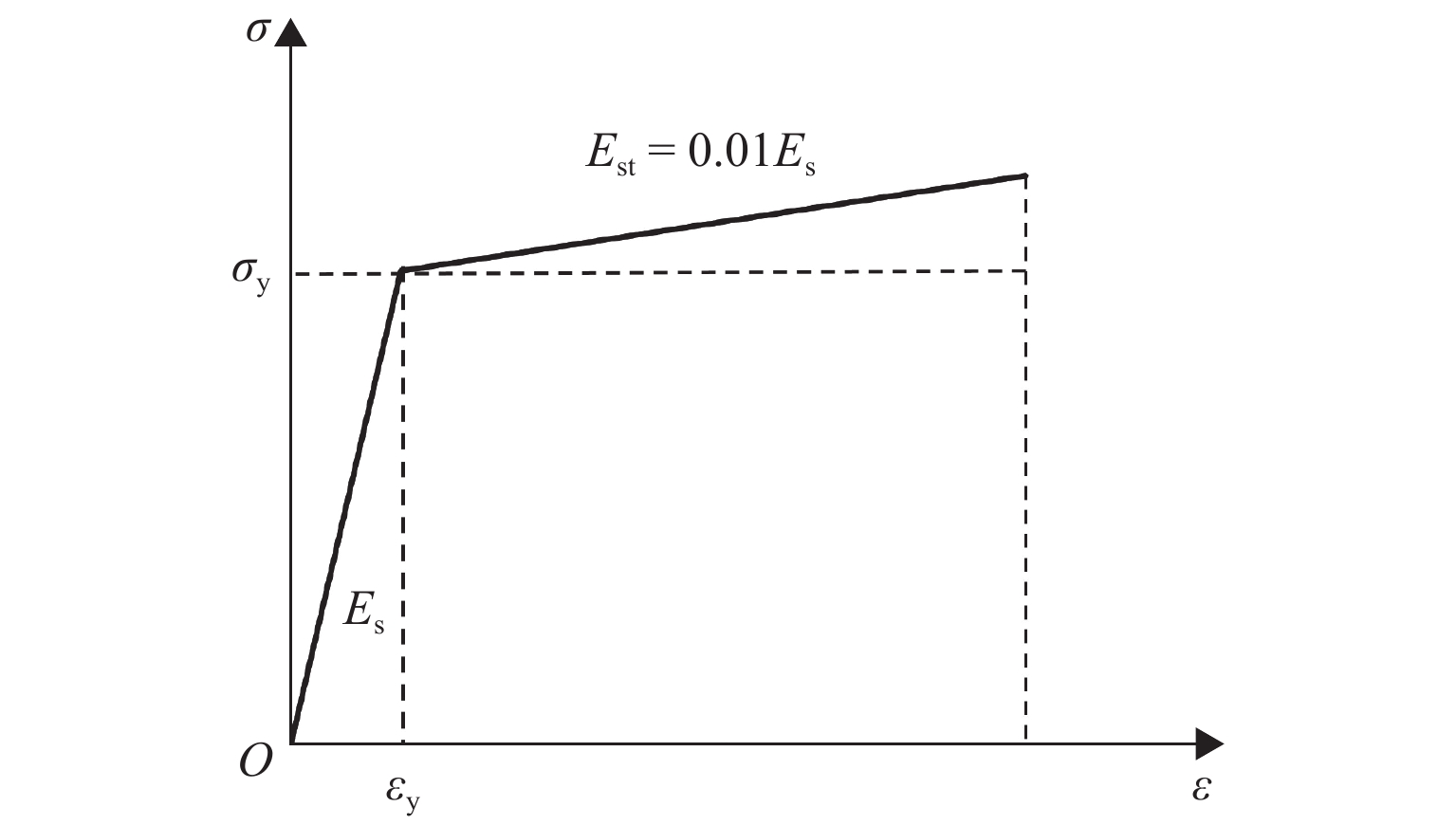

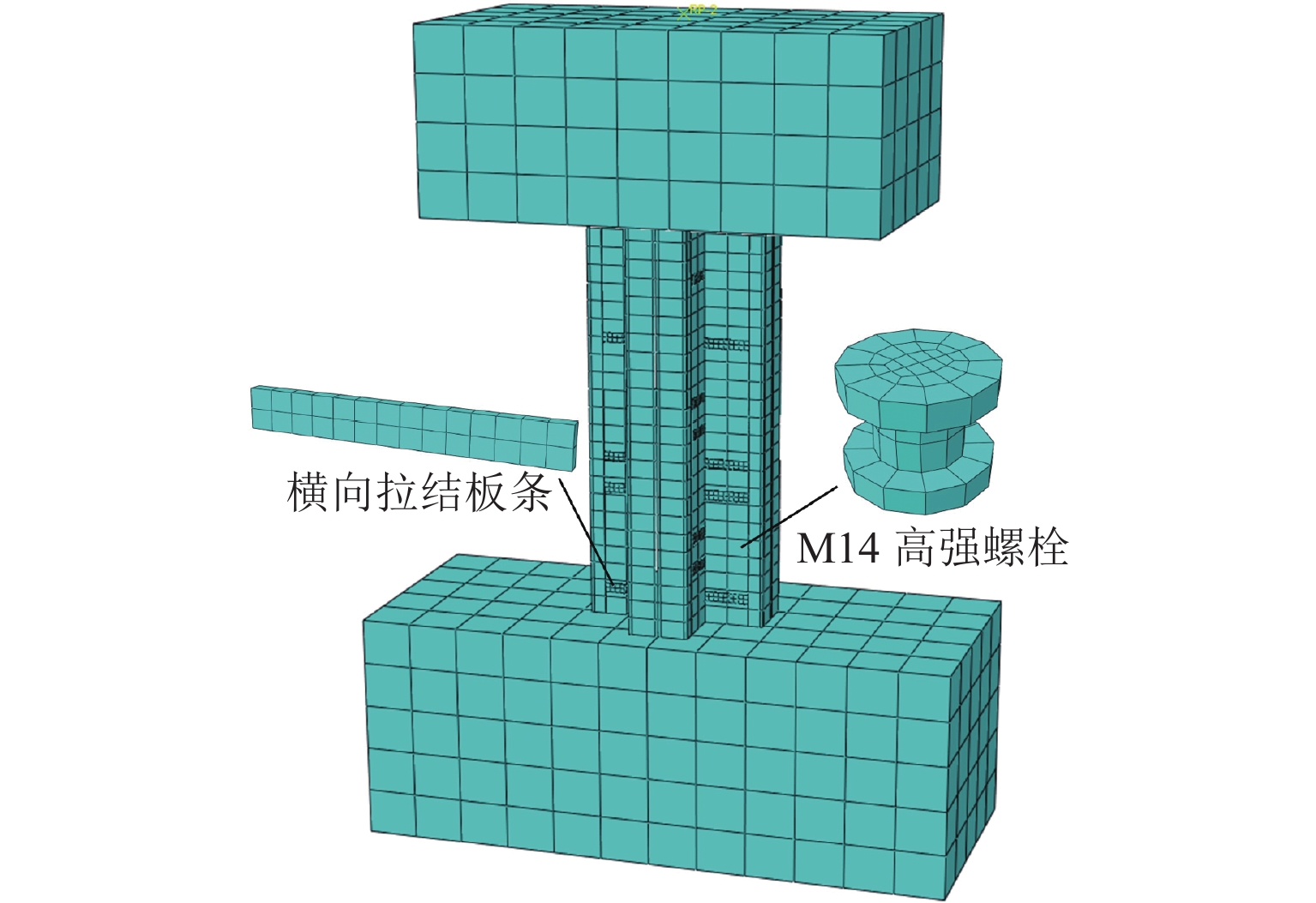

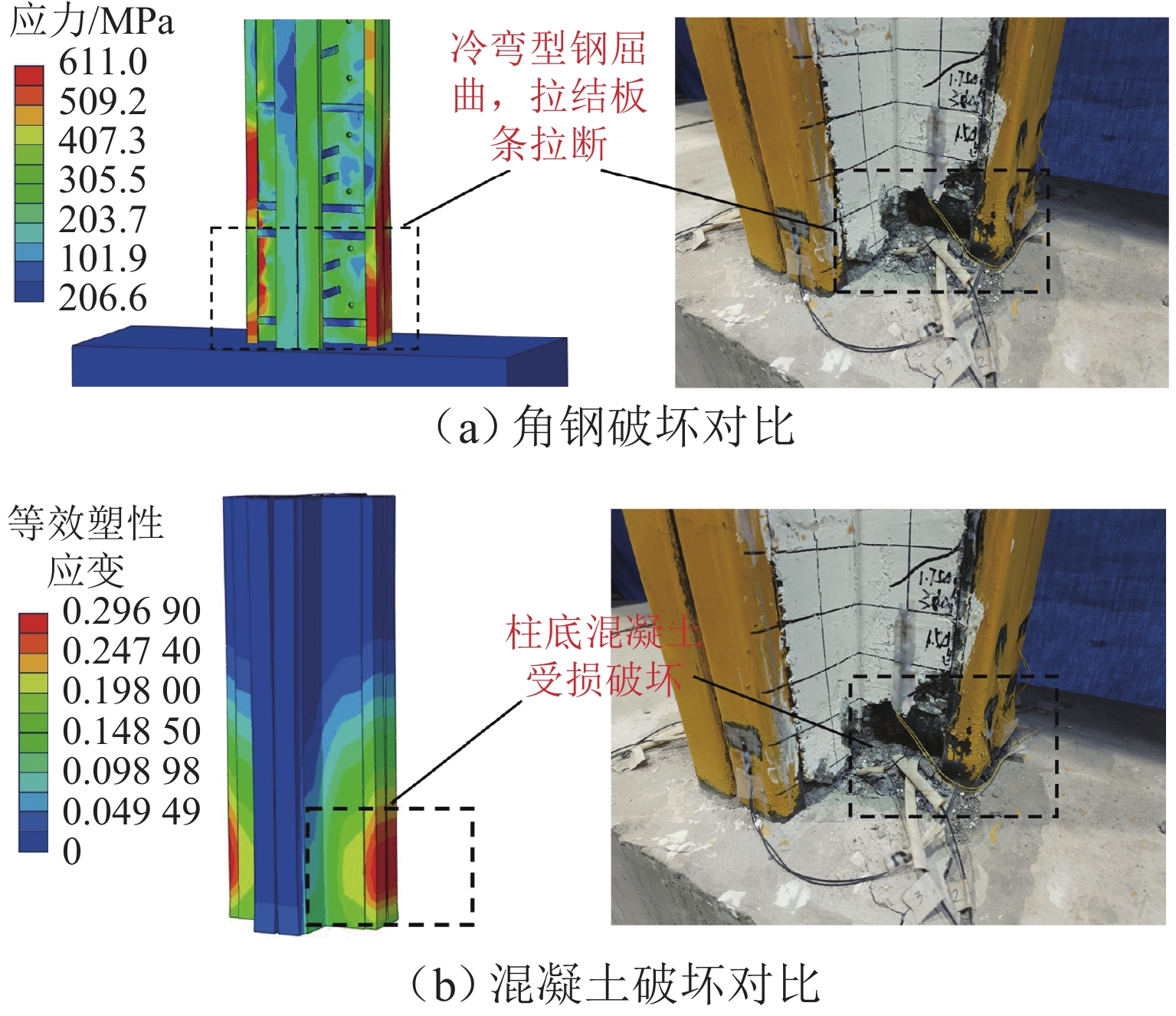

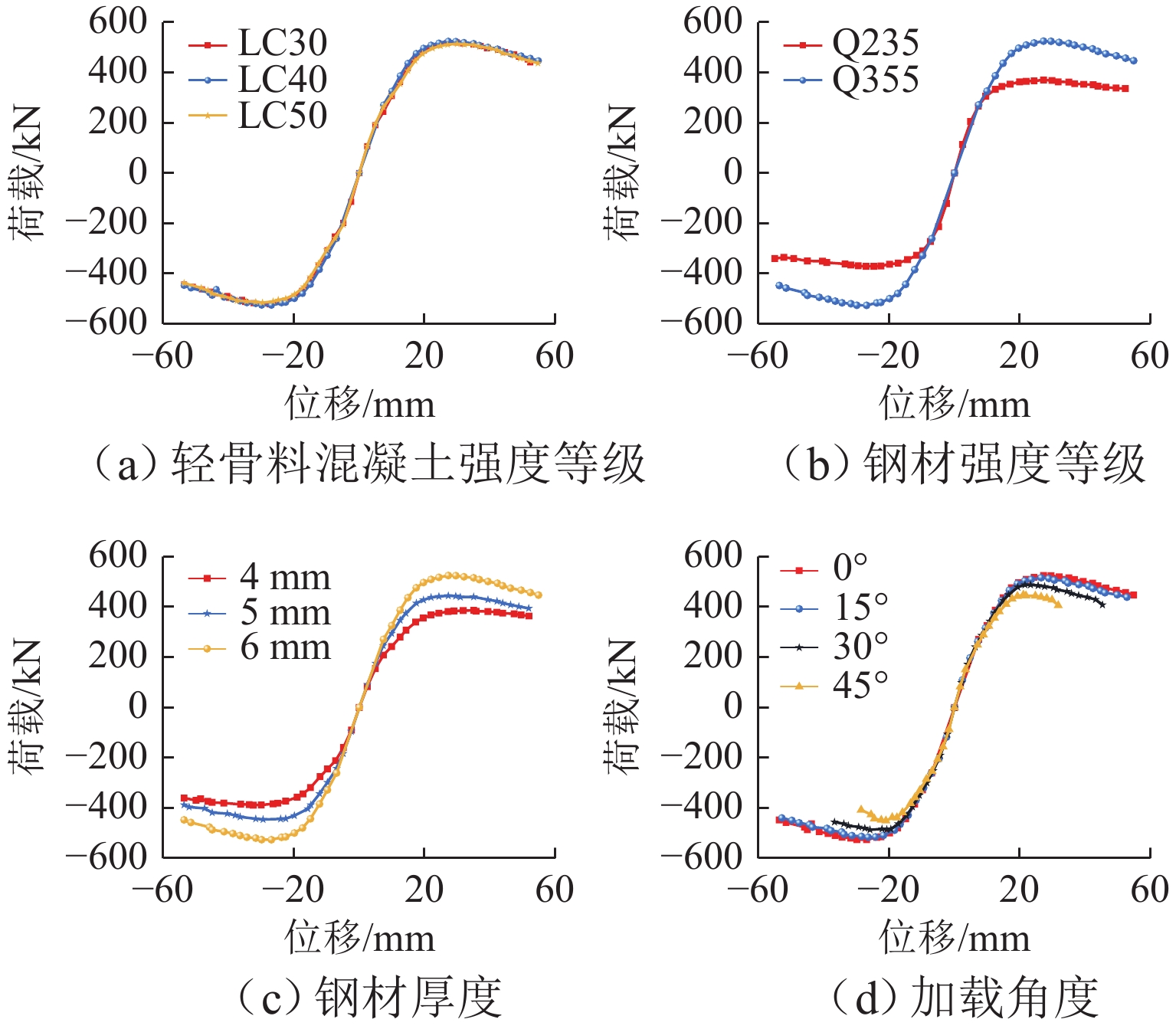

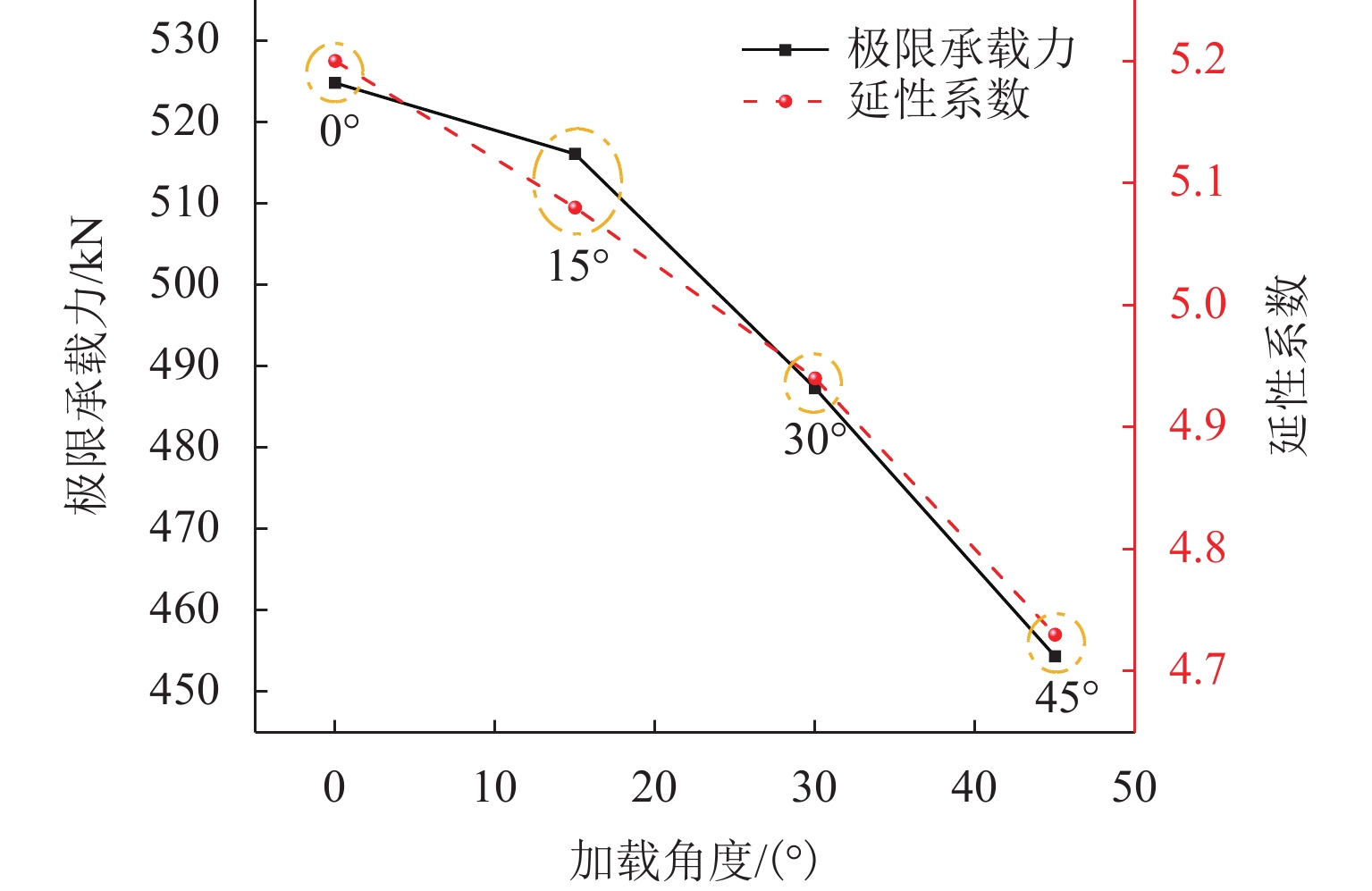

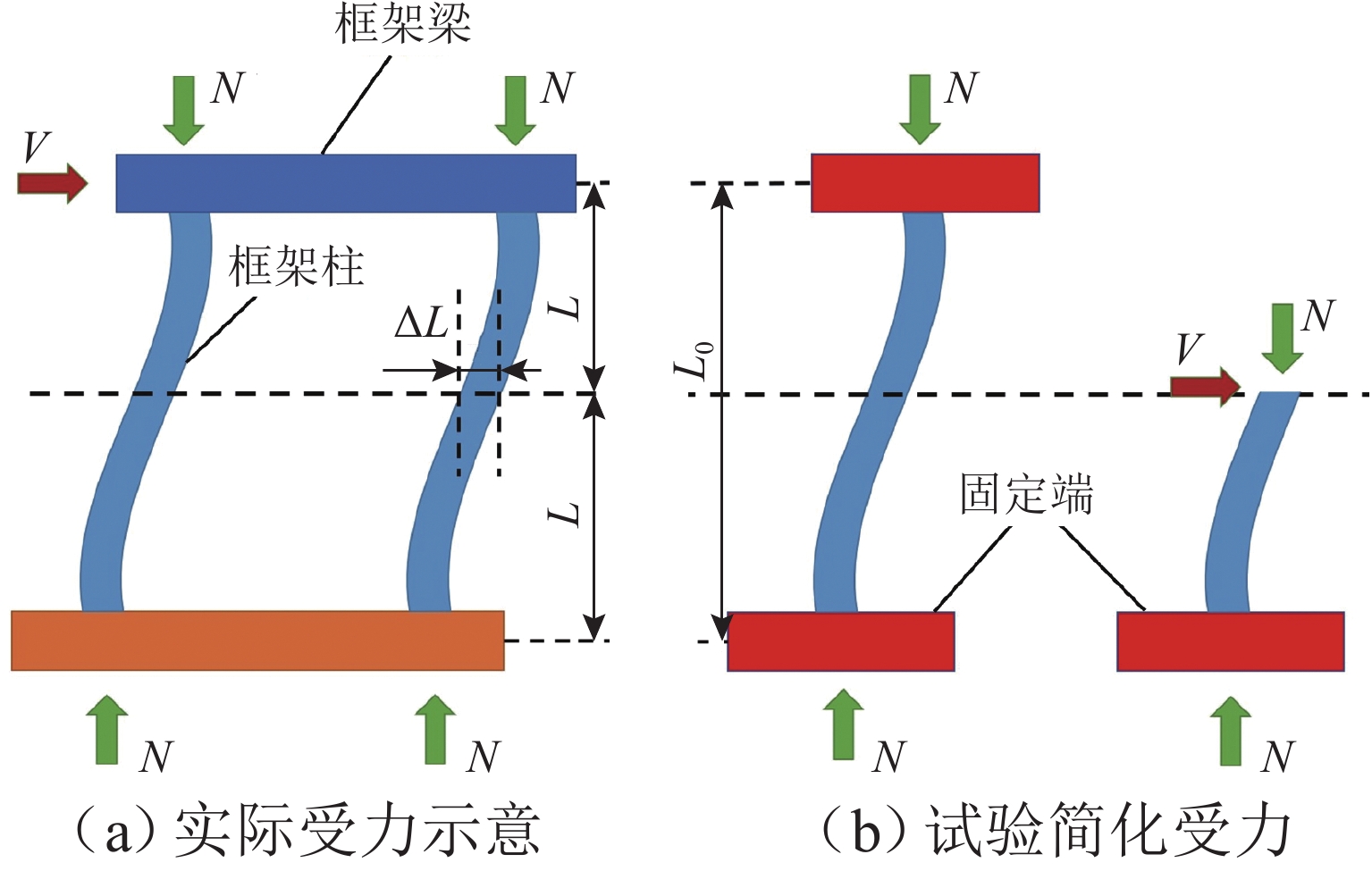

针对冷弯薄壁型钢构件局部易屈曲和陶粒轻质混凝土易开裂问题,考虑建筑室内布置美学方面要求,提出一种可预制装配的冷弯薄壁型钢部分包覆轻质混凝土十形柱. 以粗骨料取代率为参数设计并制作4根十形柱,完成低周往复加载试验;基于此,采用有限元软件ABAQUS对轻骨料混凝土强度、钢板强度、钢板厚度和加载角度进行拓展分析. 试验结果表明:4个试件滞回曲线均呈对称饱满的梭形,试件破坏形态呈现压弯破坏;随着粗骨料取代率由0%增大到30%、70%和100%,试件重量分别减轻77、176、252 kg/m3,碳减排量分别降低19.18%、38.11%和49.93%,极限承载力分别降低1.0%、4.7%和9.2%,延性系数先增大1.4%,后降低3.8%和4.2%,耗能分别降低8.6%、2.5%和6.7%;采用粉煤灰陶粒替代普通石子作为混凝土粗骨料对冷弯薄壁型钢部分包裹混凝土十形柱抗震性能影响不显著,但相比于普通混凝土具有巨大的碳排减潜力;提高轻骨料混凝土强度对试件的承载力、延性及耗能性能提升不明显;当钢板强度由Q235提高至Q355时,试件极限承载力提高45.1%;当钢板厚度由4 mm分别增加至5 mm和6 mm时,试件极限承载力分别提高14.8%和35.5%;试件的最不利加载角度为45°.

Abstract:To address the problems of local buckling of cold-formed thin-walled steel members and cracking of ceramsite lightweight concrete, while considering the aesthetic requirements for interior building layouts, a prefabricated cross-shaped column partially encased with cold-formed thin-walled steel and filled with lightweight concrete was proposed. To investigate the seismic performance of these special-shaped columns, four cross-shaped columns were designed and fabricated using different coarse aggregate replacement rates as a parameter, and the low cyclic reversed loading tests were carried out. Based on the experimental study, the finite element software ABAQUS was used to analyze the lightweight aggregate concrete strength, steel plate strength, steel plate thickness, and loading angle. The test results indicate that the hysteretic curves of the four specimens are symmetrical and full, exhibiting a shuttle shape. A compression-bending failure mode of the specimens was observed. As the coarse aggregate replacement rate increases from 0% to 30%, 70%, and 100%, the specimen weight decreases by 77 kg/m3, 176 kg/m3, and 252 kg/m3, respectively; the carbon emission reductions decrease by 19.18%, 38.11%, and 49.93%; the ultimate load-bearing capacity decreases by 1.0%, 4.7%, and 9.2%; the ductility coefficient increases by 1.4% at first, and then decreases by 3.8% and 4.2%; the energy dissipation reduces by 8.6%, 2.5%, and 6.7%. The use of fly ash ceramsite to replace ordinary stone as a concrete coarse aggregate has no significant effect on the seismic performance of the columns but shows great potential for carbon emission reduction compared to ordinary concrete. Increasing the strength of lightweight aggregate concrete does not significantly improve the load-bearing capacity, ductility, or energy dissipation performance of the specimens. When the steel plate strength increases from Q235 to Q355, the ultimate load-bearing capacity of the specimens increases by 45.1%. When the steel plate thickness increases from 4 mm to 5 mm and 6 mm, the ultimate load-bearing capacity of the specimens increases by 14.8% and 35.5%, respectively. The least favorable loading angle for the specimens is 45°.

-

表 1 试件编号及设计参数

Table 1. Specimen numbers and design parameters

试件编号 λ 粗骨料取代率/% ρa/% Nd/kN nd PEC1 2.5 0 15.0 1440 0.3 PELC1 2.5 30 15.0 1400 0.3 PELC2 2.5 70 15.0 1440 0.3 PELC3 2.5 100 15.0 1400 0.3 表 2 不同粗骨料取代率混凝土的配合比

Table 2. Mix ratios of concrete with different coarse aggregate replacement rates

混凝土强度 粗骨料

取代率/%水/

(kg·m−3)粉煤灰/

(kg·m−3)砂/

(kg·m−3)石/

(kg·m−3)水/

(kg·m−3)粉煤灰陶粒/

(kg·m−3)减水剂/

(kg·m−3)容重/

(kg·m−3)碳排减量[14]/

(kg CO2 eq)C40 0 369 41 782 1081 160 0 8.2 2441 4771.25 LC40 30 369 41 782 756 160 248 8.2 2364 5686.34 LC40 70 369 41 782 325 160 580 8.2 2265 6589.52 LC40 100 369 41 782 0 160 829 8.2 2189 7153.68 表 3 钢板材料性能

Table 3. Steel plate material properties

板厚/mm fy/MPa fat/MPa Es/GPa δ/% ν 5.9 390.9 611.6 207 22.0 0.29 5.8 391.8 607.2 206 23.0 0.30 5.8 391.6 618.9 207 23.0 0.31 均值 391.4 612.6 207 22.7 0.30 表 4 试件承载力和延性特征

Table 4. Load-bearing capacity and ductility characteristics of specimens

试件编号 加载方向 Pcr/kN Δcr/mm Py/kN Δy/mm Pm/kN Δm/mm Pu/kN Δu/mm θu μ PEC1 正向 316.30 6.97 423.10 10.12 514.70 38.39 437.50 56.58 1/19 5.59 负向 306.00 5.62 436.10 10.46 524.70 39.59 445.90 54.98 1/19 5.26 PELC1 正向 306.60 6.76 401.20 10.03 504.60 41.29 428.90 56.87 1/18 5.67 负向 317.80 5.97 421.00 10.35 524.20 39.34 445.60 55.28 1/19 5.34 PELC2 正向 332.20 7.86 402.80 9.11 488.80 28.33 415.50 49.97 1/21 5.49 负向 337.60 7.34 409.20 8.95 502.00 32.45 426.70 44.40 1/24 4.96 PELC3 正向 261.20 5.70 347.70 9.48 423.40 28.18 359.90 52.52 1/20 5.54 负向 332.20 7.18 407.80 9.56 520.80 31.47 442.70 46.42 1/23 4.86 表 5 混凝土塑性损伤参数取值

Table 5. Values for concrete plastic damage parameters

膨胀角/(°) 偏心率 fb/fco k 黏滞系数 40 0.1 1.225 2/3 0.0005 表 6 各试验阶段承载力

Table 6. Load-bearing capacity at each test stage

强度等级 加载方向 Py/kN Pm/kN Pu/kN $ \overline{\mu } $ LC30 正向 468.30 519.70 441.80 5.28 负向 468.80 522.40 444.00 LC40 正向 469.20 524.50 445.80 5.20 负向 468.20 525.10 442.70 LC50 正向 469.50 514.20 437.10 5.17 负向 460.20 515.60 438.30 表 7 各试验阶段承载力

Table 7. Load-bearing capacity at each test stage

试件变量 加载方向 Py/kN Pm/kN Pu/kN $ \overline{\mu } $ Q235 正向 314.00 370.10 335.60 5.26 负向 313.90 371.70 340.10 Q355 正向 469.20 524.50 445.80 5.20 负向 468.20 525.10 442.70 表 8 各试验阶段承载力

Table 8. Load-bearing capacity at each test stage

钢材厚度/mm 加载方向 Py/kN Pm/kN Pu/kN $ \overline{\mu } $ 4 正向 336.10 386.10 363.60 5.05 负向 336.30 388.50 360.30 5 正向 395.70 444.20 394.40 5.32 负向 395.50 445.60 387.30 6 正向 469.20 524.50 445.80 5.20 负向 468.20 525.10 442.70 表 9 各试验阶段承载力

Table 9. Load-bearing capacity at each test stage

加载角度/(°) 加载方向 Py/kN Pm/kN Pu/kN $ \overline{\mu } $ 0 正向 469.20 524.50 445.83 5.20 负向 468.16 525.12 442.68 15 正向 463.71 515.94 438.55 5.08 负向 464.37 516.21 438.78 30 正向 440.05 487.94 414.75 4.94 负向 437.52 486.63 413.64 45 正向 406.06 457.99 405.75 4.73 负向 402.95 450.70 407.60 -

[1] 管宇, 周绪红, 石宇, 等. 多层冷弯薄壁型钢结构房屋刚性楼盖判定及适用性研究[J]. 建筑结构学报, 2023, 44(4): 286-296.GUAN Yu, ZHOU Xuhong, SHI Yu, et al. Research on determination and applicability of rigid floor of multi-storey cold-formed thin-walled steel structural building[J]. Journal of Building Structures, 2023, 44(4): 286-296. [2] 姚行友, 胡成立, 刘亚菲, 等. 冷弯不等肢卷边角钢轴压试验及承载力设计方法[J]. 西南交通大学学报, 2025, 60(1): 93-102.YAO Xingyou, HU Chengli, LIU Yafei, et al. Axial compression test and bearing capacity design method of cold-formed steel with unequal-Leg lipped angles[J]. Journal of Southwest Jiaotong University, 2025, 60(1): 93-102. [3] 陈明, 鲁卫波, 武志远, 等. 双肢冷弯C型钢蒙古包刚架的平面内稳定性[J]. 西南交通大学学报, 2022, 57(1): 215-222.CHEN Ming, LU Weibo, WU Zhiyuan, et al. Investigation on in-plane stability of double-limb cold-formed C-shaped steel rigidframe of yurt[J]. Journal of Southwest Jiaotong University, 2022, 57(1): 215-222. [4] 陈顺, 吴涛, 刘喜, 等. “X”形钢-轻骨料混凝土组合柱抗震性能试验研究[J/OL]. 工程力学, 1-14 [2025-09-29]. https://doi.org/10.6052/j.issn.1000-4750.2024.05.0377. [5] 张登祥, 韦莹, 周佳. 自密实轻骨料混凝土约束收缩试验及抗裂性能研究[J]. 硅酸盐通报, 2019, 38(5): 1462-1467, 1476.ZHANG Dengxiang, WEI Ying, ZHOU Jia. Experimental study on restrained shrinkage and crack resistance of self-compacting lightweight aggregate concrete[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(5): 1462-1467, 1476. [6] GÜNEYISI E, GESOGLU M, TURAN Ö, et al. Fracture behavior and mechanical properties of concrete with artificial lightweight aggregate and steel fiber[J]. Construction and Building Materials, 2015, 84: 156-168. doi: 10.1016/j.conbuildmat.2015.03.054 [7] 李补拴, 周伟, 赵冲, 等. PEC 柱-型钢梁框架异型内节点的抗剪性能试验研究[J]. 西南交通大学学报, 2023, 58(3): 563-574.LI Bushuan, ZHOU Wei, ZHAO Chong, et al. Experimental study on shear resistance of abnormal internal joints in partially-encased concrete column-steel beam frame[J]. Journal of Southwest Jiaotong University, 2023, 58(3): 563-574. [8] 赵根田, 张宇鸣, 曹芙波, 等. 焊接H形钢部分包裹高强混凝土柱抗震性能试验研究[J]. 建筑结构学报, 2019, 40(4): 116-122.ZHAO Gentian, ZHANG Yuming, CAO Fubo, et al. Experimental study on seismic performance of welded H-section steel partially encased columns with high strength concrete[J]. Journal of Building Structures, 2019, 40(4): 116-122. [9] 林德慧, 陈以一. 部分填充钢-混凝土组合柱整体稳定分析[J]. 工程力学, 2019, 36(增1): 71-77, 85.LIN Dehui, CHEN Yiyi. Overall stability analysis of partially filled steel-concrete composite columns[J]. Engineering Mechanics, 2019, 36(S1): 71-77, 85. [10] 方有珍, 陆佳, 马吉, 等. 薄壁钢板组合PEC柱(强轴)滞回性能试验研究[J]. 土木工程学报, 2012, 45(4): 48-55.FANG Youzhen, LU Jia, MA Ji, et al. Hysteretic behavior of PEC columns (strong axis) with thin steel plate composite section[J]. China Civil Engineering Journal, 2012, 45(4): 48-55. [11] 王海生. 高含钢率钢骨混凝土柱滞回性能研究[D]. 上海: 同济大学, 2008. [12] 刘祖强, 周昕, 薛建阳, 等. 配钢率对型钢混凝土异形柱抗震性能的影响分析[J]. 工程力学, 2020, 37(6): 165-173.LIU Zuqiang, ZHOU Xin, XUE Jianyang, et al. Influence of steel ratio on seismic performance of steel reinforced concrete special-shaped column[J]. Engineering Mechanics, 2020, 37(6): 165-173. [13] 中华人民共和国住房和城乡建设部. 轻骨料混凝土应用技术标准: JGJ/T 12—2019[S]. 北京: 中国建筑工业出版社, 2019. [14] 中华人民共和国住房和城乡建设部. 建筑碳排放计算标准: GB/T 51366—2019[S]. 北京: 中国建筑工业出版社. [15] PARK R. State of the art report ductility evaluation from laboratory and analytical testing[C]//Proceedings of Ninth World Conference on Earthquake Engineering. Tokyo: International Association for Earthquake Engineering, 1988: 605-616. [16] 中华人民共和国建设部, 国家质量监督检验检疫总局. 建筑抗震设计规范: GB 50011—2001[S]. 北京: 中国建筑工业出版社, 2004. [17] 刘祖强, 杜振宇, 薛建阳, 等. 实腹式型钢混凝土十形与L形截面柱抗震性能试验及有限元分析[J]. 建筑结构学报, 2019, 40(4): 104-115.LIU Zuqiang, DU Zhenyu, XUE Jianyang, et al. Experimental study and finite element analysis on seismic behavior of solid-web steel reinforced concrete cross-shaped and L-shaped columns[J]. Journal of Building Structures, 2019, 40(4): 104-115. [18] DING F X, YING X Y, ZHOU L C, et al. Unified calculation method and its application in determining the uniaxial mechanical properties of concrete[J]. Frontiers of Architecture and Civil Engineering in China, 2011, 5(3): 381-393. doi: 10.1007/s11709-011-0118-6 [19] 王振宇, 丁建彤, 郭玉顺. 结构轻骨料混凝土的应力-应变全曲线[J]. 混凝土, 2005(3): 39-41, 66.WANG Zhenyu, DING Jiantong, GUO Yushun. Stress-Strain curves of structural lightweight aggregate concretes[J]. Concrete, 2005(3): 39-41, 66. [20] 叶列平, 孙海林, 陆新征, 等. 高强轻骨料混凝土结构: 性能、分析与计算[M]. 北京: 科学出版社, 2009. [21] DING F X, YIN G A, WANG L P, et al. Seismic performance of a non-through-core concrete between concrete-filled steel tubular columns and reinforced concrete beams[J]. Thin-Walled Structures, 2017, 110: 14-26. doi: 10.1016/j.tws.2016.10.014 [22] 孙立鹏, 刘永健. 矩形钢管混凝土壁板的屈曲后强度[J]. 建筑结构学报, 2022, 43(10): 259-273.SUN Lipeng, LIU Yongjian. Post-buckling strength of rectangular concrete-filled steel tube panels[J]. Journal of Building Structures, 2022, 43(10): 259-273. [23] 程睿, 余元林, 章珈瑜, 等. 基于截面分类的U形钢-混凝土组合梁外包钢板件宽厚比限值[J]. 土木与环境工程学报(中英文), 2025, 47(4): 66-77.CHENG Rui, YU Yuanlin, ZHANG Jiayu, et al. Width-thickness ratio limit of outer steel plate of steel-concrete composite beam with U-section based on section classification[J]. Journal of Civil and Environmental Engineering, 2025, 47(4): 66-77. [24] SCHAFER B W, PEKÖZ T. Computational modeling of cold-formed steel: characterizing geometric imperfections and residual stresses[J]. Journal of Constructional Steel Research, 1998, 47(3): 193-210. doi: 10.1016/S0143-974X(98)00007-8 [25] DUBINA D, UNGUREANU V. Effect of imperfections on numerical simulation of instability behaviour of cold-formed steel members[J]. Thin-Walled Structures, 2002, 40(3): 239-262. doi: 10.1016/S0263-8231(01)00046-5 -

下载:

下载: