Design and Implementation of Magnetic Suspension Vibration Isolation Platform with Quasi-Zero Stiffness Based on Fuzzy PID Control

-

摘要:

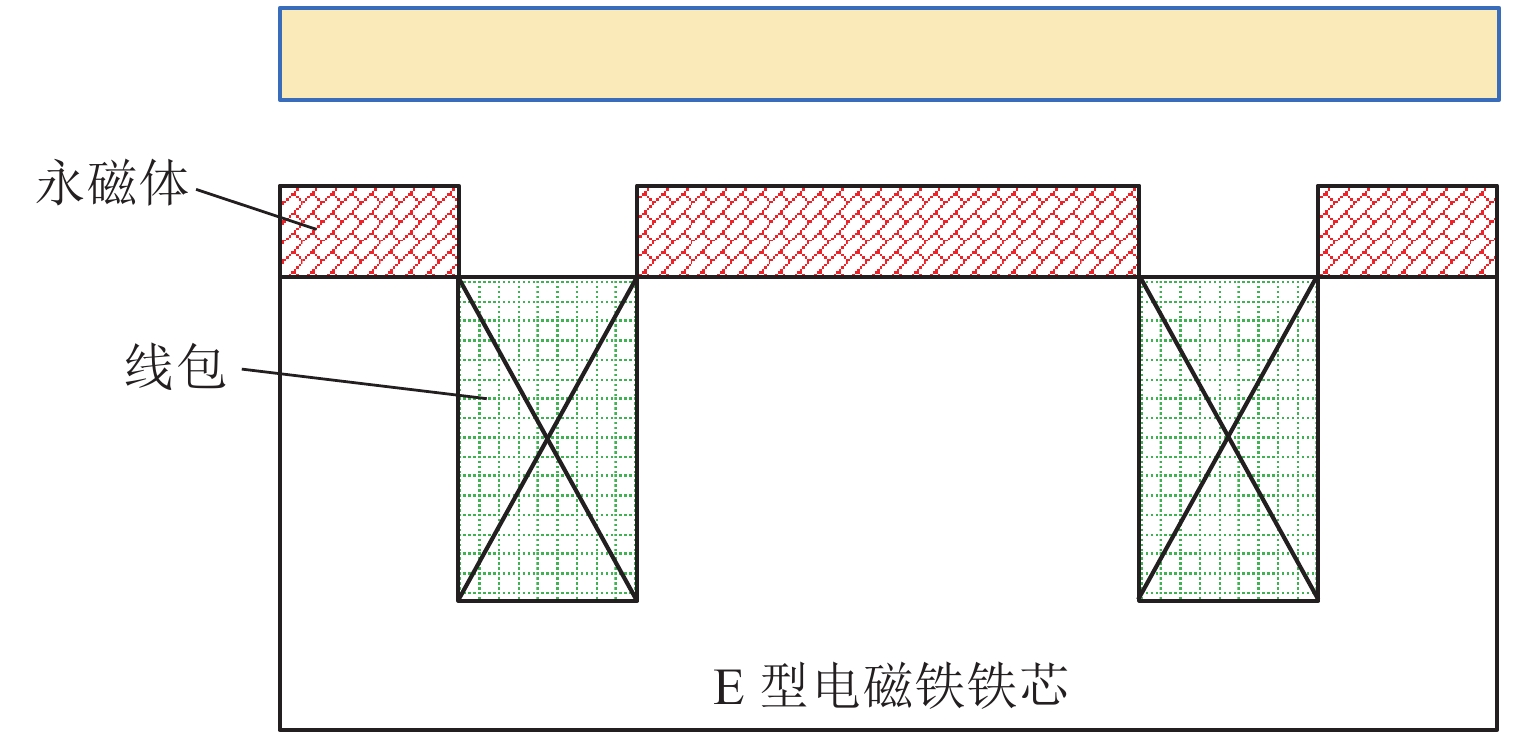

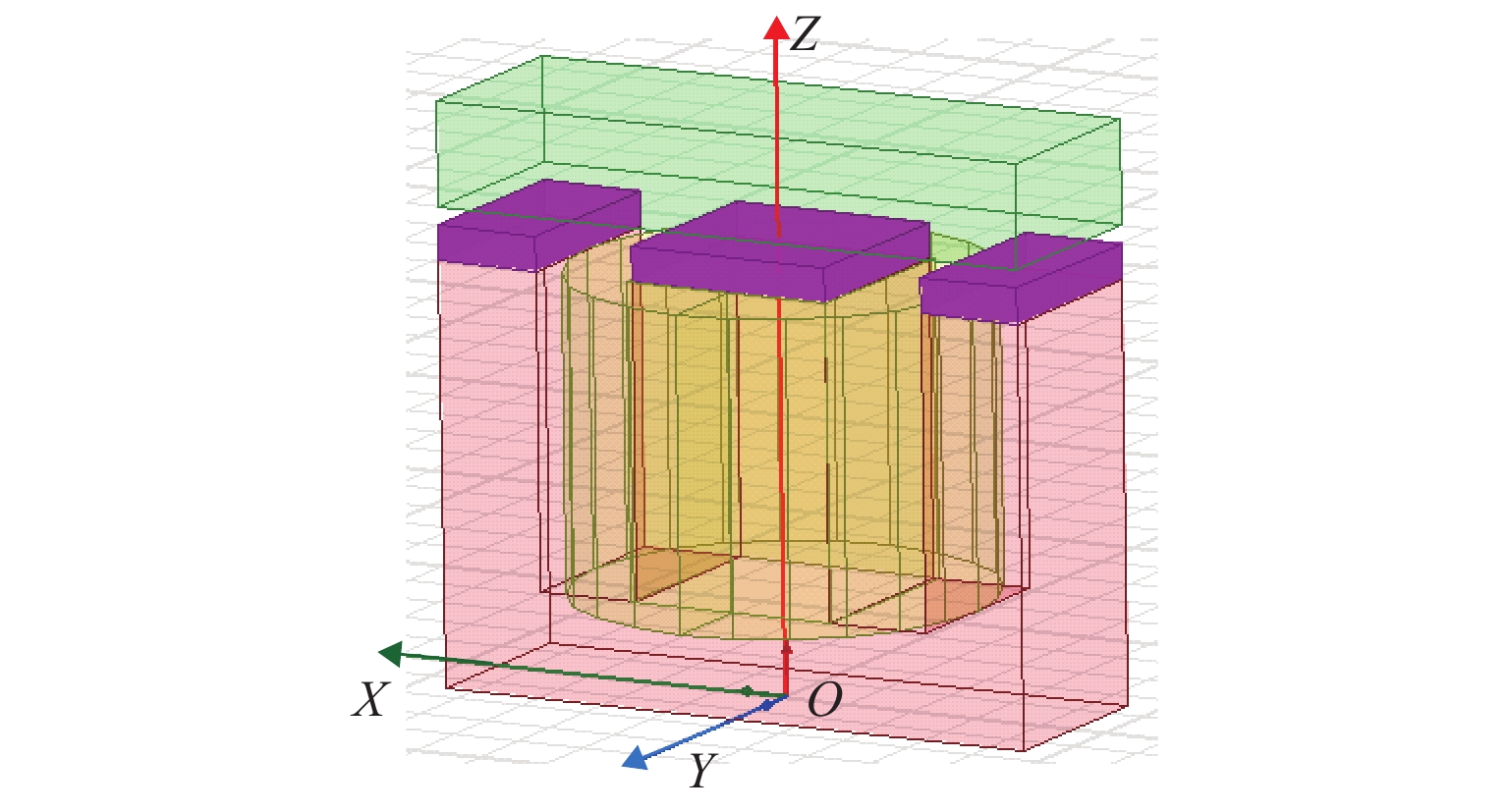

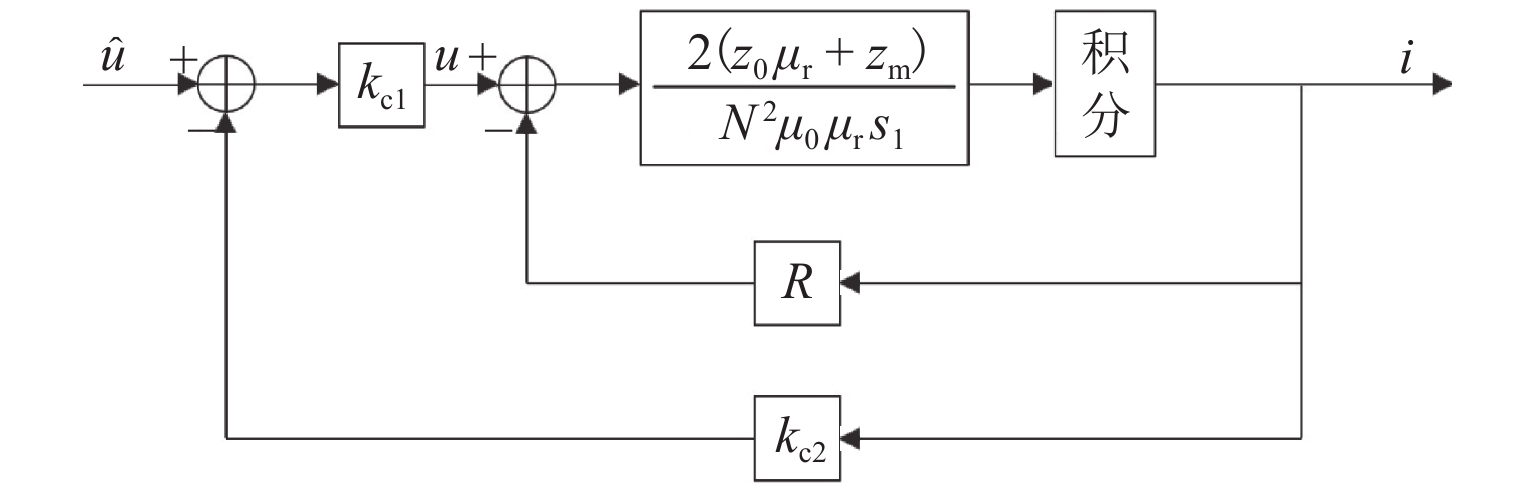

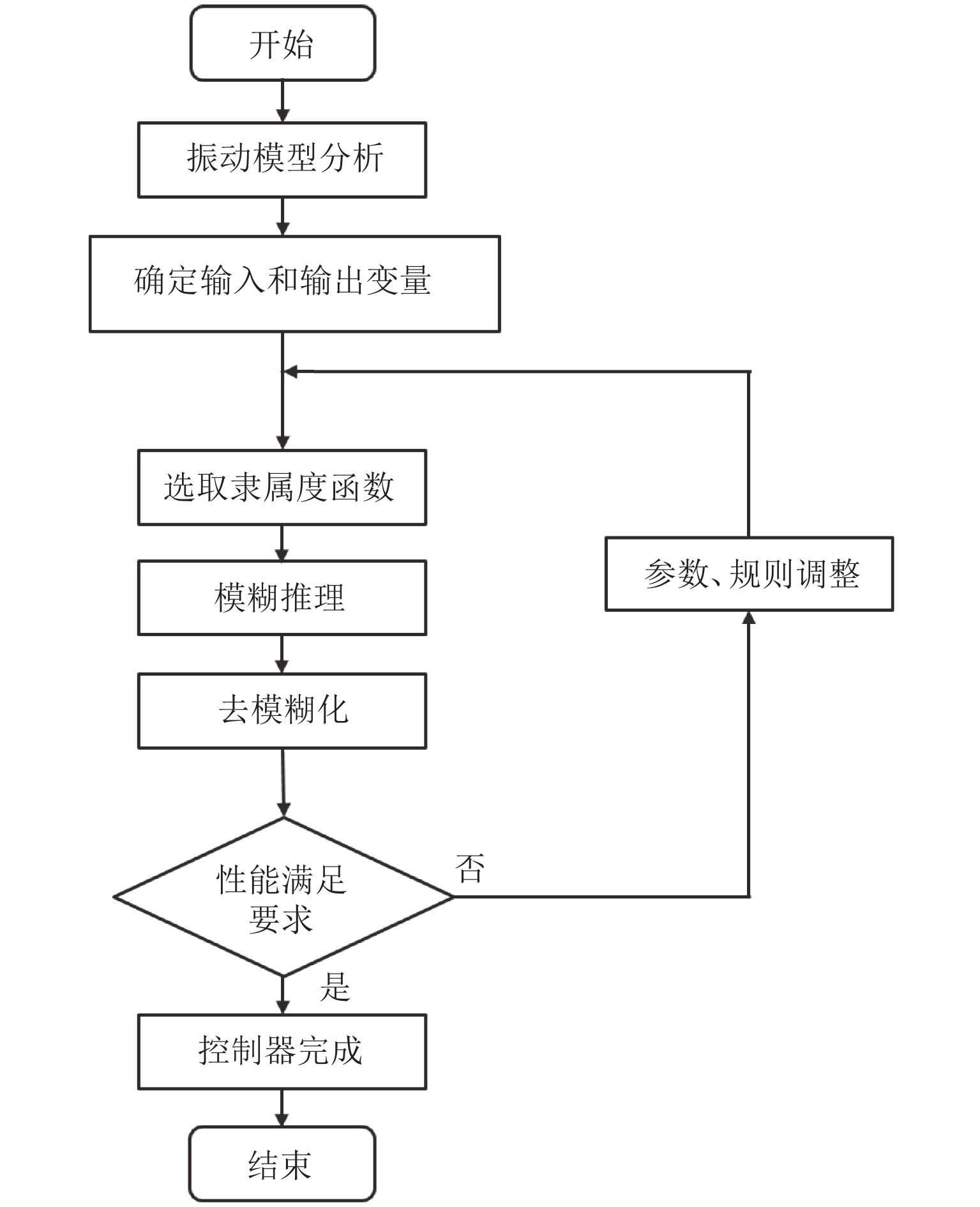

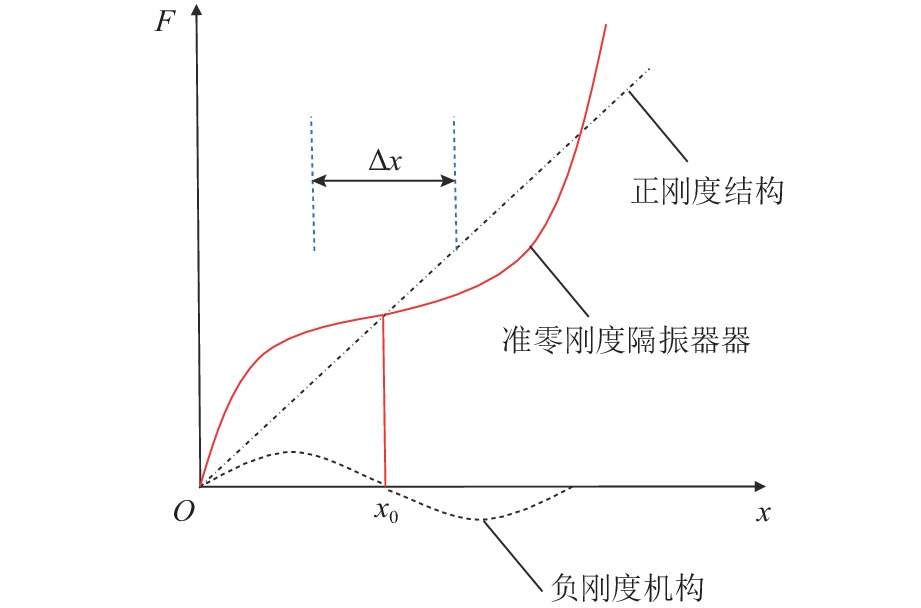

为有效降低系统固有频率,获得外部振动在多频段的强衰减,以永磁电磁混合作动器为负刚度结构提出并设计了一种准零刚度的磁悬浮隔振平台,实现了基于模糊PID (proportional integral differential)算法的振动主动控制系统. 首先,通过特性分析与参数计算,基于准零刚度理论完成了准零刚度磁悬浮隔振平台的方案设计;其次,建立磁悬浮隔振系统模型,提出基于模糊PID算法的振动主动控制策略,可主动调节系统的等效刚度和阻尼;最后,基于Speedgoat实时目标机开发振动主动控制系统,搭建隔振测试平台,并开展了隔振性能测试. 研究结果表明:本文设计的准零刚度磁悬浮隔振平台通过采用模糊PID的控制策略能够主动调节PID参数,动态调整系统的等效刚度和阻尼;外部振动频率在20~100 Hz频率段内,振动衰减率大于80%;外部振动频率在100~500 Hz频率段内,振动衰减率大于90%.

Abstract:In order to effectively reduce the natural frequency of systems and realize the strong attenuation of external vibrations in multiple frequency bands, a magnetic suspension vibration isolation platform with quasi-zero stiffness was designed, in which the permanent-magnet and electromagnetic hybrid actuator was the negative stiffness structure, and an active vibration control system based on fuzzy PID (proportional integral differential) algorithm was implemented. Firstly, based on the theory of quasi-zero stiffness, the scheme of the magnetic suspension vibration isolation platform with quasi-zero stiffness was designed through characteristic analysis and parameter calculation; secondly, the model of the magnetic suspension vibration isolation system was established, and the active vibration control strategy based on fuzzy PID algorithm was designed to actively adjust the equivalent stiffness and damping of the system; finally, an active vibration control system was developed based on the Speedgoat real-time target machine. A vibration isolation test platform was built, and a series of vibration isolation performance tests were carried out. The results show that the magnetic suspension vibration isolation platform with quasi-zero stiffness can actively adjust PID parameters by adopting a fuzzy PID control strategy and dynamically adjust the equivalent stiffness and damping of the system. When the external vibration frequency is 20–100 Hz, the vibration attenuation rate is greater than 80%; when the external vibration frequency is 100–500 Hz, the vibration attenuation rate is greater than 90%.

-

表 1 永磁体具体参数

Table 1. Detailed parameters of permanent magnet

参数名称 参数符号 参数值 剩余磁感应强度/T Br 1.2 矫顽力/(kA•m−1) Hc 896 相对磁导率 $\mu_{{\rm{r}}}$ 1.05 表 2 永磁体在工作点附近产生的电磁吸力

Table 2. Electromagnetic attraction generated by permanent magnet near working point

N 永磁体

厚度/mm悬浮间隙/mm 9.5 10.0 10.5 7 465.1 430.4 399.0 8 532.5 493.9 459.3 9 595.4 553.1 515.6 10 652.2 608.9 567.8 11 705.5 658.7 615.3 12 753.2 704.2 659.3 13 797.1 747.0 699.9 表 3 模糊控制器参数

Table 3. Parameters of fuzzy controller

模糊变量 基本论域 模糊论域 映射系数 $ e $ [−0.0025,0.0025] [−1,1] 400 $ \delta $ [−0.05,0.05] [−1,1] 20 $\Delta K_{{\rm{P}}}$ [−5000,5000] [−1,1] 0.0002 $\Delta K_{{\rm{I}}}$ [−10,10] [−1,1] 0.1 $\Delta K_{{\rm{D}}}$ [−50,50] [−1,1] 0.02 表 4 $\Delta K_{{\rm{P}}}$整定规则

Table 4. Setting rules of $\Delta K_{{\rm{P}}}$

e δ NB NM NS ZE PS PM PB NB NB NB NM NM NM ZE ZE NM NB NM NM NM NS ZE PS NS NM NM NS NS ZE PS PS ZE NM NS NS ZE PS PS PM PS NS NS ZE PS PS PM PM PM NS ZE PS PM PM PM PB PB ZE ZE PM PM PM PB PB 表 5 $\Delta K_{{\rm{I}}}$整定规则

Table 5. Setting rules of $\Delta K_{{\rm{I}}}$

e δ NB NM NS ZE PS PM PB NB ZE ZE ZE ZE ZE ZE ZE NM ZE ZE ZE ZE ZE ZE ZE NS PS PS PS PS PS PS PS ZE PS PS PS PS PS PS PS PS PS PS PS PS PS PS PS PM ZE ZE ZE ZE ZE ZE ZE PB ZE ZE ZE ZE ZE ZE ZE 表 6 $\Delta K_{{\rm{D}}}$整定规则

Table 6. Setting rules of $\Delta K_{{\rm{D}}}$

e δ NB NM NS ZE PS PM PB NB NB NB PM PM PS ZE ZE NM NB NB PM PS PS ZE ZE NS NB NM PS PS ZE NS NS ZE NM NS PS ZE NS NS NM PS NS NS ZE NS NS NM NB PM ZE ZE NS NS NM NB NB PB ZE ZE NS NM NM NB NB 表 7 振动衰减率和振动传递率

Table 7. Vibration attenuation rate and vibration transmission rate

振动频率/Hz 振动衰减率/% 振动传递率/dB 20 83.64 −15.72 50 90.55 −19.83 100 91.91 −21.84 200 92.60 −22.61 300 93.52 −23.77 500 95.35 −26.66 -

[1] ZHOU N, LIU K. A tunable high-static-low-dynamic stiffness vibration isolator[J]. Journal of Sound and Vibration, 2010, 329(9): 1254-1273. doi: 10.1016/j.jsv.2009.11.001 [2] REN C, YANG D, QIN H. Mechanical performance of multidirectional buckling-based negative stiffness metamaterials: an analytical and numerical study[J]. Materials, 2018, 11(7): 1078.1-1078.19. [3] 张磊. 电磁主动隔振系统建模与控制方法研究[D]. 武汉: 武汉大学, 2020. [4] YAN B, YU N, WU C Y. A state-of-the-art review on low-frequency nonlinear vibration isolation with electromagnetic mechanisms[J]. Applied Mathematics and Mechanics, 2022, 43(7): 1045-1062. doi: 10.1007/s10483-022-2868-5 [5] ZHANG F, SHAO S B, TIAN Z, et al. Active-passive hybrid vibration isolation with magnetic negative stiffness isolator based on Maxwell normal stress[J]. Mechanical Systems and Signal Processing, 2019, 123: 244-263. doi: 10.1016/j.ymssp.2019.01.022 [6] 沈铖武. 车载光电瞄准平台主被动隔振关键技术研究[D]. 北京: 中国科学院大学, 2021. [7] 黄翠翠,李晓龙,杨洋,等. 基于自抗扰技术的机械-电磁悬浮复合隔振控制[J]. 西南交通大学学报,2022,57(3): 582-587,617. doi: 10.3969/j.issn.0258-2724.20210850HUANG Cuicui, LI Xiaolong, YANG Yang, et al. Mechanical-electromagnetic suspension compound vibration isolation control based on active disturbance rejection technology[J]. Journal of Southwest Jiaotong University, 2022, 57(3): 582-587,617. doi: 10.3969/j.issn.0258-2724.20210850 [8] CARRELLA A, BRENNAN M, KOVACIC I, et al. On the force transmissibility of a vibration isolator with quasi-zero stiffness[J]. Journal of Sound and Vibration, 2009, 322(4): 707-717. [9] 苏攀,吴杰长,刘树勇,等. 弹簧-电磁力准零刚度隔振器研究[J]. 海军工程大学学报,2018,30(5): 36-41.SU Pan, WU Jiechang, LIU Shuyong, et al. Spring-electromagnetic force vibration isolator with quasi-zero-stiffness[J]. Journal of Naval University of Engineering, 2018, 30(5): 36-41. [10] 江友亮. 磁气混合准零刚度隔振系统设计与控制研究[D]. 武汉: 武汉理工大学, 2019. [11] XU J W, YANG X F, LI W, et al. Research on semi-active vibration isolation system based on electromagnetic spring[J]. Mechanics & Industry, 2020, 21(1): 101.1-101.12. [12] ZHANG L, ZHUAN X T. An experimental study of an electromagnetic isolator system with active control[J]. International Journal of Applied Electromagnetics and Mechanics, 2019, 61(3): 329-340. doi: 10.3233/JAE-180112 [13] 邹圣楠,刘畅,邓舒同,等. 基于混合式磁浮平台的解耦及控制分析[J]. 西南交通大学学报,2022,57(3): 40-548.ZOU Shengnan, LIU Chang, DENG Shutong, et al. Decoupling and control stability analysis based on hybrid repulsion maglev platform[J]. Journal of Southwest Jiaotong University, 2022, 57(3): 40-548. [14] HU Y F, CHEN C H, WU H C, et al. Study on structural optimization design and cascade PID control of maglev actuator for active vibration isolation system[J]. Journal of Vibration and Control, 2018, 24(10): 1829-1847. doi: 10.1177/1077546317714939 [15] SUN Y G, XU J Q, WU H, et al. Deep learning based semi-supervised control for vertical security of maglev vehicle with guaranteed bounded airgap[J]. IEEE Transactions on Intelligent Transportation Systems, 2021, 22(7): 4431-4442. doi: 10.1109/TITS.2020.3045319 [16] MITRA P, DEY C, MUDI R K. Fuzzy rule-based set point weighting for fuzzy PID controller[J]. SN Applied Sciences, 2021, 3(6): 1-34. [17] YANG T, SUN N, FANG Y C. Adaptive fuzzy control for a class of MIMO underactuated systems with plant uncertainties and actuator deadzones: design and experiments[J]. IEEE Transactions on Cybernetics, 2022, 52(8): 8213-8226. doi: 10.1109/TCYB.2021.3050475 [18] WANG H Q, LIU P X, ZHAO X D, et al. Adaptive fuzzy finite-time control of nonlinear systems with actuator faults[J]. IEEE Transactions on Cybernetics, 2019, 50(5): 1786-1797. -

下载:

下载: