Research Status and Development Trend of Machining Quality Prediction

-

摘要:

机械加工质量预测是智能制造的重要组成内容,也是实现质量闭环控制的前提条件,对推动智能制造系统真正落地应用具有极其重要的作用. 在对机械加工质量预测的历史进行简要回顾时发现,学者多将研究重点放在机床某一关键部件对加工质量影响的机理研究,却鲜见部件耦合影响的关联性研究. 基于上述难题,本文首先剖析影响机械加工质量的7类要素,包括刀具几何参数、切削参数、切削液类型、热误差与热变形、数控机床零部件性能退化、切削颤振以及系统特性;随后,根据各要素数据种类和测量方式的不同,将机械加工质量监测与预测方法划分为4大类,包括机器视觉测量、功率测量、振动测量以及其他测量方法,并对各方法的技术特点、局限性和发展动态进行了阐述;最后,考虑各机械加工质量监测与预测方法的不足,指出材料切削机制研究、数据质量评估方法、面向工业现场数据库构建的标准以及质量预测信息的智能表征与可视化等方面可能是未来的发展趋势.

Abstract:The prediction of machining quality is a vital component of intelligent manufacturing and a prerequisite for achieving quality closed-loop control, playing an extremely important role in promoting the practical application of intelligent manufacturing systems. A brief review of the history of machining quality prediction reveals that scholars have mostly focused on the mechanism of the influence of a key component of the machine tool on machining quality, while research on the correlation between the coupling effects of machine components is rare. Based on the aforementioned challenges, firstly, seven types of factors that affect machining quality are analyzed, including tool geometry parameters, cutting parameters, cutting fluid type, thermal errors and deformations, degradation of CNC machine tool components, cutting chatter, and system characteristics. Subsequently, according to the different types of data and measurement methods for each factor, the monitoring and prediction methods of machining quality are divided into four categories, including machine vision measurement, power measurement, vibration measurement, and other measurement methods. The technical characteristics, limitations, and development trends of each method are then expounded. Finally, considering the deficiencies of various machining quality monitoring and prediction methods, this paper points out that research on material cutting mechanisms, data quality assessment methods, standards for constructing industry site databases, and intelligent representation and visualization of quality prediction information may be future development trends.

-

随着《中国制造2025》战略的落地实施与推进,以智能化、柔性化为主要特点的精益制造理念正在制造业中逐步推广应用. 高端数控机床作为切削加工制造业的核心设备,针对切削加工质量评价指标(表面粗糙度、波纹度以及形状误差)的监测与预测手段对于提升工厂的经济效益具有重要意义. 而机械设备的状态监测与预测方法能够辨识机械设备状态[1],对于加工过程的质量预测至关重要.

在机械加工领域,数控磨床、铣床、车床、车铣复合等大型机械加工装备正在朝着高精、高效、高可靠的方向发展. 保证装备的安全可靠、提升加工质量的一致性程度对现代制造业具有举足轻重的作用[2]. 依靠状态监测与预测理论对加工过程进行保驾护航是大势所趋[3],也是进一步提升加工质量的必经之路.

由于需要监测的制造装备群规模逐步扩大,且每台装备安装的测点多、数据采样的频率差异化、装备从开始服役到寿命终止的数据收集历时长,加工现场往往积累了海量的监测数据. 随着数据规模的扩大,加工制造业正面临着前所未有的数据治理难题.

为充分利用这些监测数据,在数据存储、传输的标准化管理,多源异步监测数据的清洗、配准与填充等多方面都有大量工作亟待进一步研究. 此外,如何充分利用这些数据,通过合理的数据融合方法,提升算法的准确性也有待进一步研究.

本文根据数据种类和测量方式的不同,从多源数据的角度出发,综述基于不同种类数据的加工质量预测方法. 以加工质量的影响因素分析为切入点,进一步分析基于机器视觉的离线监测方法(图像数据)、基于多通道传感器的在线监测方法(功率数据、振动数据等)以及其他监测方法在机械加工质量预测的应用. 分析不同种类不同测量方式数据在机械加工质量预测应用中的适用性,并对近年来一些多种类数据融合的方法进行总结. 最后,依据前述总结和发掘,从材料切削机制研究、数据质量评估方法、面向工业现场的数据库构建的标准、质量预测信息的智能表征与可视化4个方面说明机械加工质量预测方法的未来发展趋势.

1. 加工质量影响因素分析

加工质量影响因素涵盖了与加工表面质量紧密联系的基本因素,包括刀具几何参数、切削参数、切削液类型、数控机床部件性能退化、切削颤振、刀具-工件-夹具机床系统的动静态特性、热变形与热误差等.

1.1 刀具几何参数

刀具参数,如刀具插入形状、切削刃参数、插入前刀类型、前刀半径等也会影响表面粗糙度[4]. 在粗加工中通常选用切削刃位于刀具端面与侧面边缘交界线的平底铣刀,平底铣刀侧面各点的切削速度大小相同,因此在数控加工中具有较明显的优势. 在五轴加工中,可以通过对平底铣刀轴倾角的控制使刀具去除更多的工件材料,提高加工效率[5]. 但平底铣刀加工后的切削余量相对较多,增加了半精加工和精加工中刀具的负担. 平底铣刀的切削刃容易发生磨损,导致工件表面粗糙度增大,增加了数控加工的难度.

在粗加工和半精加工中,通常选用的铣削刀具为环形铣刀,可以采用较小切削深度、较大进给量的加工方法进行加工. 在五轴加工中,可以通过对环形铣刀刀轴倾角的控制使刀具更贴近加工型面[6]. 当选用环形铣刀在较大的切削深度下进行加工时,加工后的工件表面残留高度较大,而且表面残留分布不均[7]. 在精加工中,为了保证工件型面的加工精度,通常选用的铣削刀具为球头铣刀. 球头铣刀刀尖部分的切削速度为0,刀尖区域的切削条件较差,易发生磨损和破损现象,并不适合应用于平坦类曲面的加工[8-9]. Masahiko等[1]开发了2种用于精加工淬硬钢的球头铣刀,与传统的球头铣刀相比,所设计的刀具不仅提高了刀具轮廓精度和抗崩刃能力,而且降低了刀具制造费用,所开发的刀具优化了刀具切削刃和刀具前角. Chen等[10]通过优化进给率和改进刀具轮廓有效地提高了球头铣刀的加工效率. 在球头铣刀加工淬硬钢等高硬度材料时,易出现严重的颤振现象,导致加工表面质量恶化,甚至出现麻点、凹坑和表面振纹[11].

切削刀具的改良除优化刀具几何结构之外,还通过在前刀面制造微沟槽和微织构来储存固体润滑剂,减小前刀面与切屑的摩擦,从而起到润滑降力,进而最终降热的效果[12-13]. Sun等[14]利用激光在刀具表面加工凹坑并进行切削试验,结果表明,织构刀具相比无织构刀具能获得更低的表面粗糙度,且织构刀具凹坑的直径对被加工工件表面粗糙度的影响有一个临界值. 与之类似,Jiang[15]开发了一种仿生切削刀具(类似于鲨鱼齿),与高度抛光的无织构传统刀具相比发现,微织构刀具能提高加工工件的表面光洁度,表面光洁度的提高可以归因于织构刀具具有良好的抗磨损能力. 潘晨等[16]发现,与无织构刀具切削工件表面获得拉应力相比,微沟槽织构刀具切削后的工件表面呈现压应力,提高了工件表层的耐磨损和耐疲劳性能.

1.2 切削参数

铣削加工过程中,不合理的切削参数选择将加剧刀具振动、诱发颤振,严重影响零件加工精度并限制加工效率[17].

目前,国内外学者围绕工艺参数优化模型的建立与求解展开了深入研究[18-19]:李聪波等[20]通过分析加工工艺参数对能耗的影响机理,以能量效率与生产时间为目标建立了铣削工艺参数多目标优化模型;王进峰等[21]以工件最小表面粗糙度和加工过程最大功率系数为目标,结合多响应权重因子的灰色关联法建立并求解了切削参数的优化模型;Maier等[22]提出了基于高斯过程约束的贝叶斯优化方法,用于求解以表面粗糙度和加工时间等参数为目标的优化模型;Kumar等[23]采用回归模型建立加工参数与表面粗糙度和材料去除率的函数关系,并以此为目标结合遗传算法求解最优工艺参数;邓聪颖等[24]采用麻雀搜索算法求解建立的铣削工艺参数优化模型,获取刀具悬伸量及各加工阶段铣削用量的优化配置;Vogler等[25]进行了微细车削试验发现,切削厚度很小时,随着进给量的减小,粗糙度值会上升,因为在加工过程中存在最小切削厚度现象,当刃口半径与最小切削厚度处于同一量级时,会产生不稳定的切削和犁耕,从而增加表面粗糙度值. 国内学者利用PCD (polycrystalline diamond)刀具进行微细车削硬铝合金表面质量试验[26],采用正交试验方法发现,对表面粗糙度影响最大的是进给量,其次是切削速度,影响最小的是切削深度;王慧等[27]采用Box-Behnken设计和二次回归正交试验法建立高速铣削参数与表面粗糙度的显著不失拟回归模型,获得铣削参数影响表面粗糙度的显著性差异,挖掘高速铣削参数交互作用与表面粗糙度关系;李俊烨等[28]采用磨粒流精密加工技术对异形截面深孔进行数值模拟及实验研究揭示了磨粒流动态压力、速度、磨粒对壁面压力和壁面剪切力对壁面作用规律,获得了异形截面孔内流向截面的漩涡位置分布与漩涡产生原因以及漩涡与磨粒相互作用关系;刘枭等[29]针对干切削铝合金工件表面易产生鳞刺、表面完整性较差的问题,采用液氮冷却方式在不同切削参数下对铝合金7075进行了正交切削实验,分析了不同切削速度、进给量、刀具前角和冷却方式(干切削、液氮冷却、切削液)下已加工表面鳞刺分布和尺寸变化规律,并基于鳞刺形成理论讨论了切削参数和液氮冷却对鳞刺形成过程的影响.

1.3 切削液类型

随着材料工业的不断发展,许多高熔点、低导热性的新材料已广泛应用于各个领域. 然而,加工此类材料却伴随着巨大的挑战,此类材料的低导热性会导致切削区域温度迅速升高,进而加剧刀具磨损. 减少刀具磨损的常用手段是使用切削液,切削液在切削过程中可以起到润滑和冷却的作用. 一方面,切削液可以减少切削刀具-切屑之间的摩擦;另一方面,可以带走切削过程中产生的切削热,从而降低切削温度并抑制刀具磨损. 此外,切削液还可以冲掉加工过程中产生的碎屑[30],同样有助于延长刀具寿命. 然而,随着切削液的不断使用,对环境和人类健康也会产生不利影响[31].

直接选用外加的高效冷却、润滑方式,可极大改善工件表面完整性[32],其具体方式有采用绿色加工理念的微量润滑技术[33]、润滑油渗透[34]和纳米流体润滑与强冷的结合方式[35]. 通过将冷却介质雾化,利用流体自身的渗透作用对切削区域进行冷却润滑,其既能保证冷却润滑效果,又能节省冷却液,实现一定程度的绿色环保加工. 纳米石墨颗粒[36]能够提高切削液的润湿性,降低摩擦系数,从而使颗粒流润滑下的刀片顶刃和侧刃磨损明显减弱,崩刃现象较少. 此外,自润滑刀具依靠刀具的自润滑功能,同样能减少切削液的使用.

1.4 热误差与热变形

热误差是机床加工精度的重要影响来源之一. 为提升加工精度,许多研究者对热误差的建模进行了研究,Zhang 等[37]提出了基于灰色模型和人工神经网络的热误差建模方法分析五轴加工中心的主轴轴向误差. 考虑到热误差建模效果的一个关键影响因素是温度敏感点的选取,为提高建模精度和鲁棒性,许多研究者对温度敏感点选取进行了研究:Fu等[38]提出了一种基于K-means聚类的温度敏感点分析方法,并在VMC850机床上对Y方向的热误差漂移进行了建模仿真与验证;Fu等[39]通过考虑不同热源对机床主轴热误差的影响,采用K均值聚类与相关分析方法,获得了机床主轴热误差建模的全局温度敏感点,并对同一速度下的不同误差项进行了分析. 为提升神经网络对不同工况下模型构建的鲁棒性,Li 等[40]提出了一种基于蝙蝠算法的BP (back propagation)神经网络优化算法,优化三轴实验台的热误差定位建模效果;Liu[41]以降低温度敏感点的共线性为切入点,提出了基于分离式的无偏灰色关联分析的鲁棒建模方法,选取影响权重最大的几个温度敏感点,从而减少因温度敏感点波动导致的模型精度下降现象.

1.5 数控机床零部件性能退化

数控机床的关键零部件性能退化对机械加工质量具有较强的影响. 本节对刀具、丝杠2种典型部件的性能退化研究现状进行了分析与总结.

丝杠和轴承是主流数控机床传动系统的核心部件,其退化过程直接影响到切削加工质量和加工精度. 考虑到丝杠的退化过程的负载力和转速差异,高宏力等[42]研究了基于多时频域特征融合与多模型融合的丝杠剩余寿命预测模型. 针对丝杠、轴承的退化周期较长,有标签监测数据量少的问题,Zhang [43]提出了基于深度迁移集成学习的丝杠寿命预测方法. 针对轴承数据耦合程度高,特征提取与识别模型构建困难的问题,郭亮等[44]提出了基于深度学习的轴承状态识别方法. 考虑到实验室环境下人工设置故障与真实故障的差异性,Tan 等[45]提出了一种深度耦合联合分布适应网络. 该网络可以适配边际和条件分布的差异,并提供更准确的分布匹配,从而得到了比较好的效果. 刀具作为切削加工过程的直接执行部件,其磨损和破损现象直接导致了产品质量变差和产品一致性问题. 研究表明,采用如随机森林、动态树等人工智能方法分析基于振动、切削力和声发射信号的间接刀具磨损在线监测方法能够达到较好的精度和识别效果[46-47]. 近年来,考虑到部分传感器成本较高,且监测信号的处理与分析依赖于大量专家经验与理论,一些学者研究了基于机器视觉的刀具磨损监测方法:You [48]研究了基于双远心镜头成像的宽视野下刀具磨损在线监测方法;Liu 等[49]采用变倍镜头,研究了基于切削加工纹理分析的刀具磨损识别方法.

1.6 切削颤振

切削颤振作为一种典型的异常加工状态,是影响加工质量的又一重要因素. 其发生的原因在于不合理的切削参数设置导致了自激振动增强. 其主要表现包括加工工件表面的明显振痕和异常增加的切削力等. 为保障切削加工质量,近年来,许多学者对切削加工稳定性分析、建模和颤振识别进行了研究:李忠群[50]通过仿真系统分析了机床固有频率、阻尼比和刚度等模态参数对颤振稳定域的影响;王跃辉等[51]综述了以往的颤振被动、主动控制技术,并对时滞控制器、神经网络以及模糊控制器等智能方法在颤振检测、控制中的应用进展进行了分析;杨毅青等[52]研究了多种切削力模型在颤振稳定域预测的准确性,其研究表明,指数瞬时切削力和线性切削力模型在稳定域预测上具有较好准确性;张钊[53]研究了薄壁零件加工的颤振分析与抑制方法;张奇[54]从铣削力建模、铣削颤振监测与铣削力系数标定等方面进行了研究.

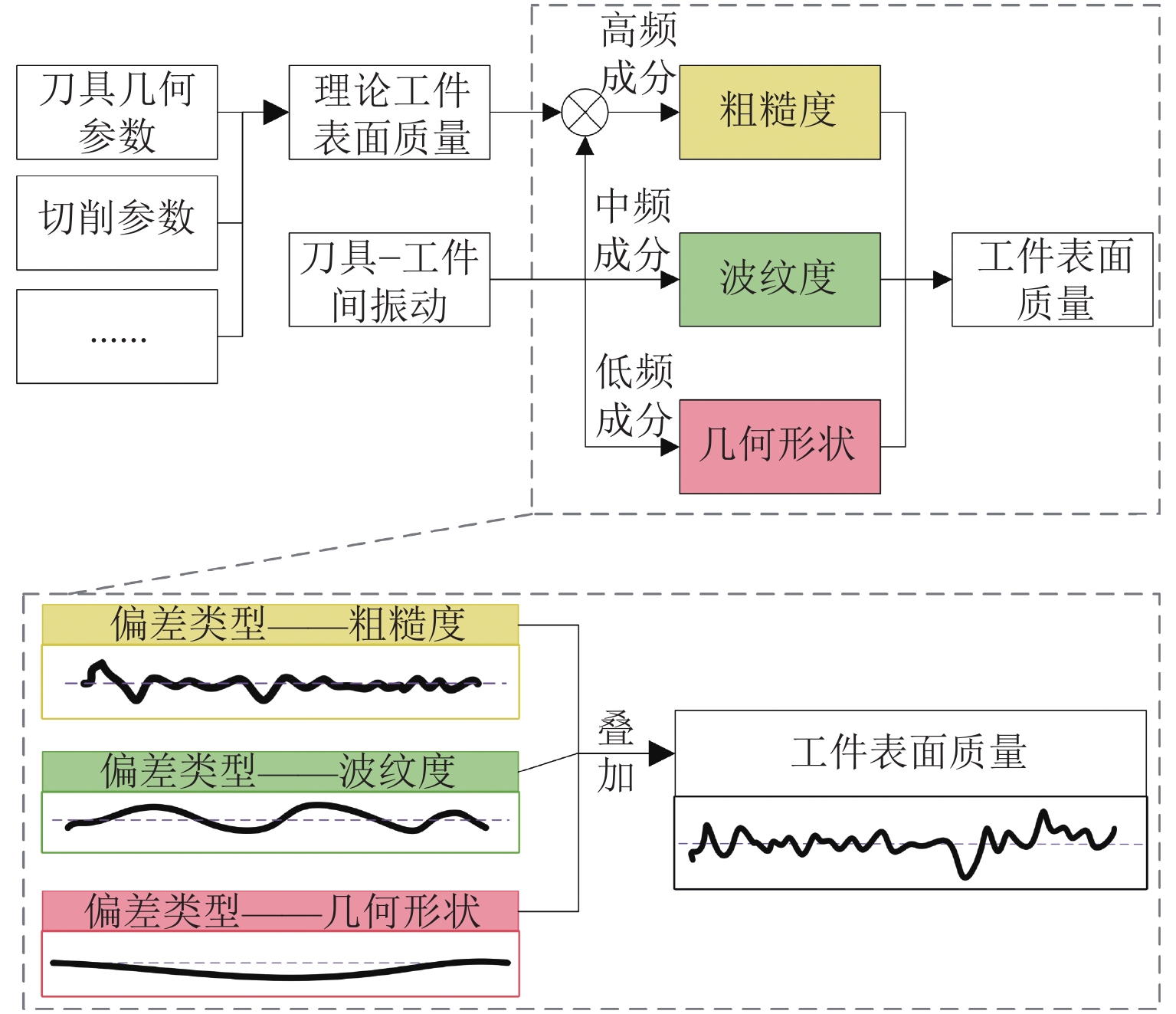

1.7 刀具-工件-夹具-机床系统特性

机床系统特性对机床的切削加工稳定性具有决定性影响,是保障切削加工质量的基础. 机床系统的精度大致分为:1) 准静态精度,主要由热误差和几何误差引起,与机床的运行状况无关. 此类误差多给表面质量引入异常的中低频成分,对表面质量的波纹度和几何形状有显著影响. 2) 动态精度,主要由伺服系统和机械结构的形变导致的异常振动引起,与机床的运行状况相关,此类误差多给表面质量引入异常的高频成分,对表面质量的粗糙度有显著影响.

刀具、工件与夹具组成了切削加工过程的简化模型,得到了许多专家、学者的研究:高翔等[55]研究了用于机床系统静刚度试验的千分表测力环的力学特性;万小金[56]以“工件-夹具-刀具”系统为研究对象,研究了机床误差建模方法,建立了误差源与产品性能约束之间的映射关系;彭诚[57]基于吉村允孝法,研究了计算机床结合面动态特性参数方法,构建了其弹簧阻尼等效模型,并对整机进行了模态和谐响应分析.

1.8 小 结

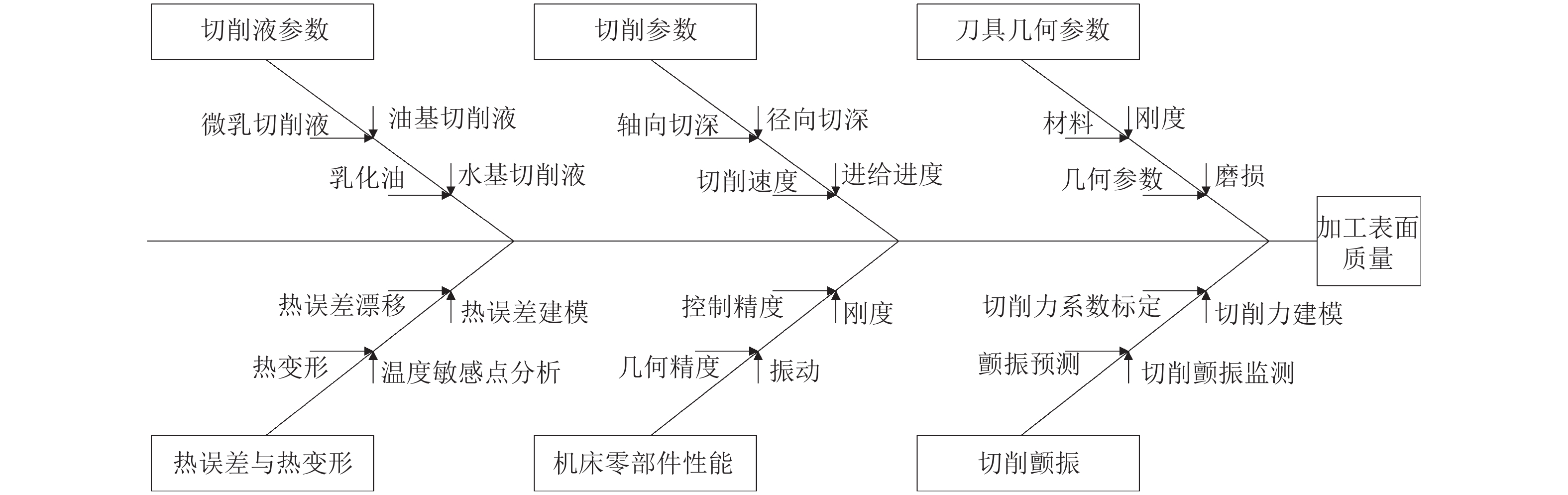

将加工质量影响因素按照类型、影响是否显著、主要监测手段进行划分和总结,如表1. 并根据上述文献调研,将机械加工表面质量的影响因素进行分析,如图1.

综上所述,在机械加工过程中,刀具、工件、夹具和机床构成复杂制造工艺系统,属于典型的多因素耦合非线性时变系统. 在刀具与工件相互作用产生的多维切削力作用下,完成工件多余材料的去除. 其中,动态切削力是各个数控轴产生轨迹波动的主要激励源,制造工艺系统的动态响应特性直接影响加工精度,多个轴误差的非线性耦合共同决定产品加工质量. 因此,刀具几何参数、机床零部件退化下运动轴几何精度和运动精度、机床热误差与热变形、工件和夹具刚度、工艺参数不合理等因素都直接影响加工质量. 而上述因素对机械加工质量的影响,都能从基于离线监测的机器视觉图像数据以及基于在线监测的功率数据和振动数据等直接或间接反映. 因此,本文从机器视觉测量、功率测量、振动测量以及其他测量方法的角度出发,总结和分析机械加工质量监测和预测的研究成果和发展趋势,能系统地反映机械加工质量监测和预测的研究现状,并能更清晰地发掘其仍面临的难题.

2. 机器视觉测量加工质量预测方法

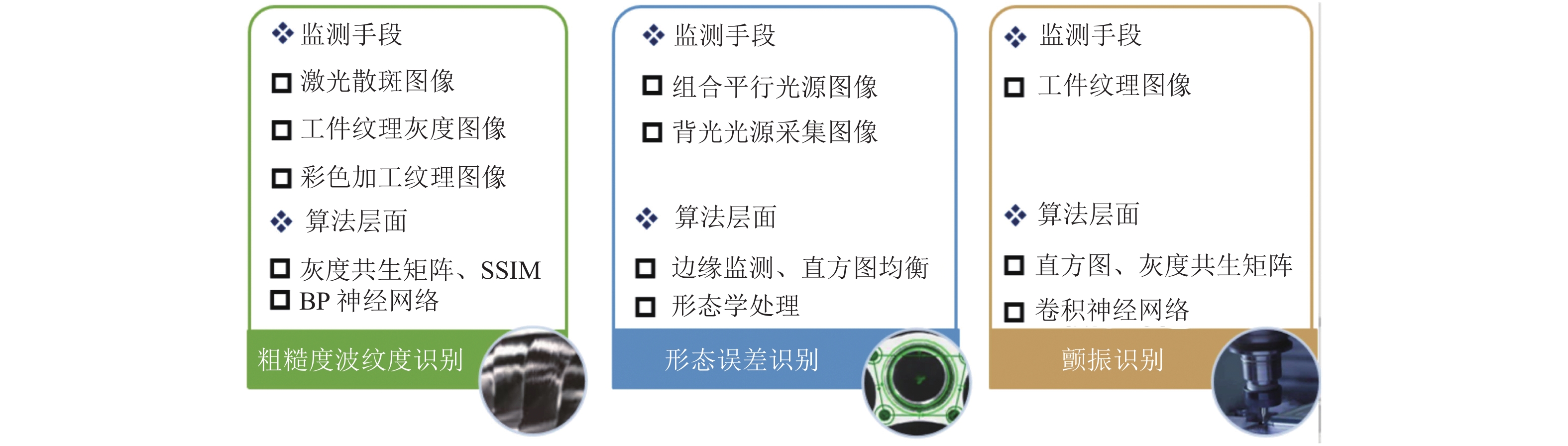

基于机器视觉的质量预测是一种相对较为直观、有效的监测手段. 图2概述了当前基于视觉测量的加工质量预测方法,包括粗糙度波纹度识别、形状误差识别以及颤振识别等3个方面,成分来源及特点如图3所示. 在监测手段上,灰度图像是主流方法,对于粗糙度识别任务部分研究采用彩色纹理图像作为主要分析手段;在算法层面,手工特征提取方法(灰度共生矩阵、直方图等)与深度学习方法均具有较全面的应用研究.

基于机器视觉的加工质量监测方法主要使用工业相机在现场环境下采集图像,通过算法设计与实验验证,提取被测工件的纹理特征、形状特征等图像信息;然后根据指标实现对加工工件进行在线或在机的粗糙度评估或预测. 对于加工质量评估任务,常用的指标包括加工灰度共生矩阵等纹理特征[58]、边缘检测算子(Sobel、Canny)等. 对于加工质量预测任务的研究相对较少,李瑛等[59]探究了视觉测量的孔径数据与温度、刀具工作时间等数据综合判断销孔位置度的模型.

2.1 基于机器视觉的粗糙度、波纹度识别

粗糙度和波纹度是2种重要的表面质量评估指标,反映了金属加工表面的微观形貌与轮廓误差. 近年来,许多学者对机器视觉的粗糙度和波纹度识别可行性和准确性进行了研究:万志坚[60]研究了基于纹理周期度量的非接触式表面粗糙度测量方法,通过图像处理方法提取纹理特征与数据库中标准样块的纹理进行比较,按照最近似原则判定所求表面的粗糙度;路恩会[61]研究了一种基于图像质量评估算法的粗糙度估计方法,在梯度相似性与图像质量评估算法的基础上,引入了区域对比度的概念,提出了基于区域对比度与梯度结构相似度的图像质量评价方法并进行了相应的计算推导,设计和制作了一套基于图像质量评估的磨削表面粗糙度快速测量系统. 对于波纹度测量应用:Chen 等[62]研究了基于机器视觉的大尺寸表面粗糙度检测方法,通过图像纹理构建的多维特征矩阵与BP神经网络实现对表面粗糙度的预测;考虑到图像灰度信息对环境光强变化的敏感等因素影响,易怀安[63]研究了彩色加工纹理图样的粗糙度识别方法. 考虑到激光的优良准直性,一些研究者对采用激光散斑的粗糙度纹理分析方法进行了研究:蔡雯等[64]研究了基于激光散射光斑图样分析的粗糙度测量方法,该测量方法使用机器视觉对磨削加工波纹度进行测量,在对机理进行分析的基础上,开发了机器视觉的测量系统原型,并对系统性能进行了评价,验证提出方法以及设计测量系统的准确性;Li等[65]研究了基于切削加工纹理的粗糙度在位监测系统,并设计了相对应的伺服控制以及碎屑检测功能.

对于粗糙度监测任务,现有的光学测量方法能够实现工件小范围区域的准确离线测量,而机器视觉测量方法则是另一种潜在的可面向实际加工环境的测量手段,能够对切削加工过程进行在线或在机监测. 如表2所示,为2种主要的视觉粗糙度测量方法比较. 由表2可见,机器视觉监测手段可以在现代制造业的自动化和大规模生产场景下高效、快速地识别物体,并通过纹理分析来检测加工过程中出现的颤振现象,从而保障生产过程的稳定性和效率. 但如何提升间接监测方法的鲁棒性与准确性是亟待解决的问题.

表 2 2种主要的视觉测量粗糙度等表面质量识别方法Table 2. Comparison of two main visual measurement methods for surface quality recognition such as roughness测量方式 优点 缺点 光学测量

(白光干涉仪、超景深三维显微系统)非接触式测量,对被测工件无损伤;对区域的微观三维形貌的准确测量 单次检测区域较小;设备测试、维护较为昂贵;对检测环境要求高,容易受到现场加工环境影响 视觉间接测量(基于机器视觉的加工纹理图样分析方法) 容易满足批量化测试需求,进而实现在线或在机测量;测试与监测过程自动化程度高,能够实现快速、高效地反馈工件加工质量情况 准确性和对于实际加工过程的多变工况、光源设置差异等情形的鲁棒性有待优化;对于颤振纹理识别效果

较好2.2 基于机器视觉的形状误差识别

形状误差识别是机器视觉的另一应用方向:陈向伟等[66]研究了基于计算机视觉的机械零件检测技术;朱萃[67]研究了基于机器视觉的微小型组件精密测量与装配方法;雷红胜[68]研究了基于机器视觉的零件尺寸测量与精度分析方法;王营营[69]研究了基于机器视觉的曲轴轴颈轴线直线度误差检测方法. 近年来,许多研究者针对曲面或者复杂曲面的测量与高精度尺寸测量技术进行了研究:付泰等[70]研究了基于机器视觉的复杂平面零件尺寸检测方法;陆兴华等[71]设计了远心镜头组合平行光源的采集系统获取弹簧的二维图像,利用直方图均衡化等预处理算法实现图像增强,并通过形态学的开运算使弹簧的轮廓等参数更为清晰,以获取准确的表面信息,并给出了弹簧参数测量的公式;张海心[72]根据轴类零件的特性,设计了立式机器视觉结构,以及工件回转台,并以大面阵CMOS (complementary metal oxide semiconductor)和背光光源作为数据采集的采集硬件,对采集数据的误差进行了分析;包昊菁[73]研究了链轮的径向跳动视觉测量方法,并探讨了方法在其他轴齿类零件相关参数的视觉测量的应用可行性.

对于形状误差识别任务,由于被测任务的多样性,需要根据被测工件尺寸调整机器视觉系统的视野大小和分辨率,选用远心镜头、背光源等专用硬件设备并设计边缘检测、图像增强、亚像素边缘检测等算法以适配测量、检测任务. 基于机器视觉的形状误差识别方法比较如表3所示.

表 3 基于机器视觉的形状误差识别Table 3. Shape error recognition based on machine vision2.3 基于机器视觉的颤振识别

颤振是影响切削加工质量的一种典型异常加工状态,不仅会缩短刀具的剩余使用寿命,还会影响工件表面的切削加工质量. 颤振可发生在多种切削加工过程,图4展示了多种车削、铣削与钻削过程出现的颤振现象.

颤振的发生往往是由于不合理的切削加工参数设置导致了自激振动频带范围的能量聚集. 在切削纹理上反映为明显的振痕. 因而,许多学者研究了颤振的视觉识别方法:Khalifa 等[74]研究了用于车削加工颤振识别的图像处理算法,使用直方图方法和灰度共生矩阵算法实现纹理特征的提取,并分析了粗糙度与颤振幅度之间相关性;Feng 等[75]研究了砂轮表面磨损情况的图像特征识别算法,通过腐蚀、膨胀等图像处理手段能够有效辨识砂轮的工作状况;Bamberger 等[76]提出了几种基于圆形拟合和灰度共生矩阵的计算颤振严重性的方法;Szydłowski 等[77]研究了基于纹理图像局部梯度的工件颤振区域识别方法. 近五年来,随着深度学习的不断发展,端到端的有监督训练模型可以自适应的对机器视觉采集系统获取的纹理图像进行特征知识提取,进而实现对颤振现象的自动识别功能.

许多学者对基于深度学习的颤振识别进行了研究:Lei 等[78]研究了高速铣削加工的颤振识别方法;Rifai 等[79]构建了一种深度卷积神经网络,能够较准确地识别不同铣削和车削加工纹理的颤振情况;Zhu 等[80]研究了一种优化的卷积神经网络,用于薄壁零件铣削的颤振检测;王志学等[81]从传感器选择、特征提取、颤振识别、颤振抑制等方面综述了切削加工过程的智能监测方法.

2.4 小 结

根据文献调研结果,目前在机加工过程的机器视觉系统主要应用于加工质量的评估[82],加工质量预测的相关研究较少[59],一些研究者也探究了机器视觉方法与其他传感器信号进行多源特征融合的加工质量预测方法[83]. 此外,机器视觉方法与多源监测数据融合,不仅能丰富监测信息维度,还能够对动力学分析、有限元仿真分析模型的构建进行验证[78],是提升预测模型准确性的一种可行手段[84-85].

利用彩色、灰度图像等机器视觉方法采集的图像信息可以完成加工表面质量的准确识别任务,并将代表文献和相关信息展示在图5中. 然而,现今大部分的研究主要具有以下2个特点:一是大多采用单一视觉传感器进行测量,缺乏对多个或多种视觉类传感器的组合测量研究;二是当前的研究缺乏对实际加工环境在机监测任务特点的考虑,包括监测效率、算法鲁棒性以及在加工设备上的部署、安装问题. 因而设计的算法仍然难以应用或部署在实际加工现场环境. 开发多种视觉传感器组合测量方法并提升研究算法在实际加工现场环境下的适用性,是当前研究所需要解决的2个主要问题.

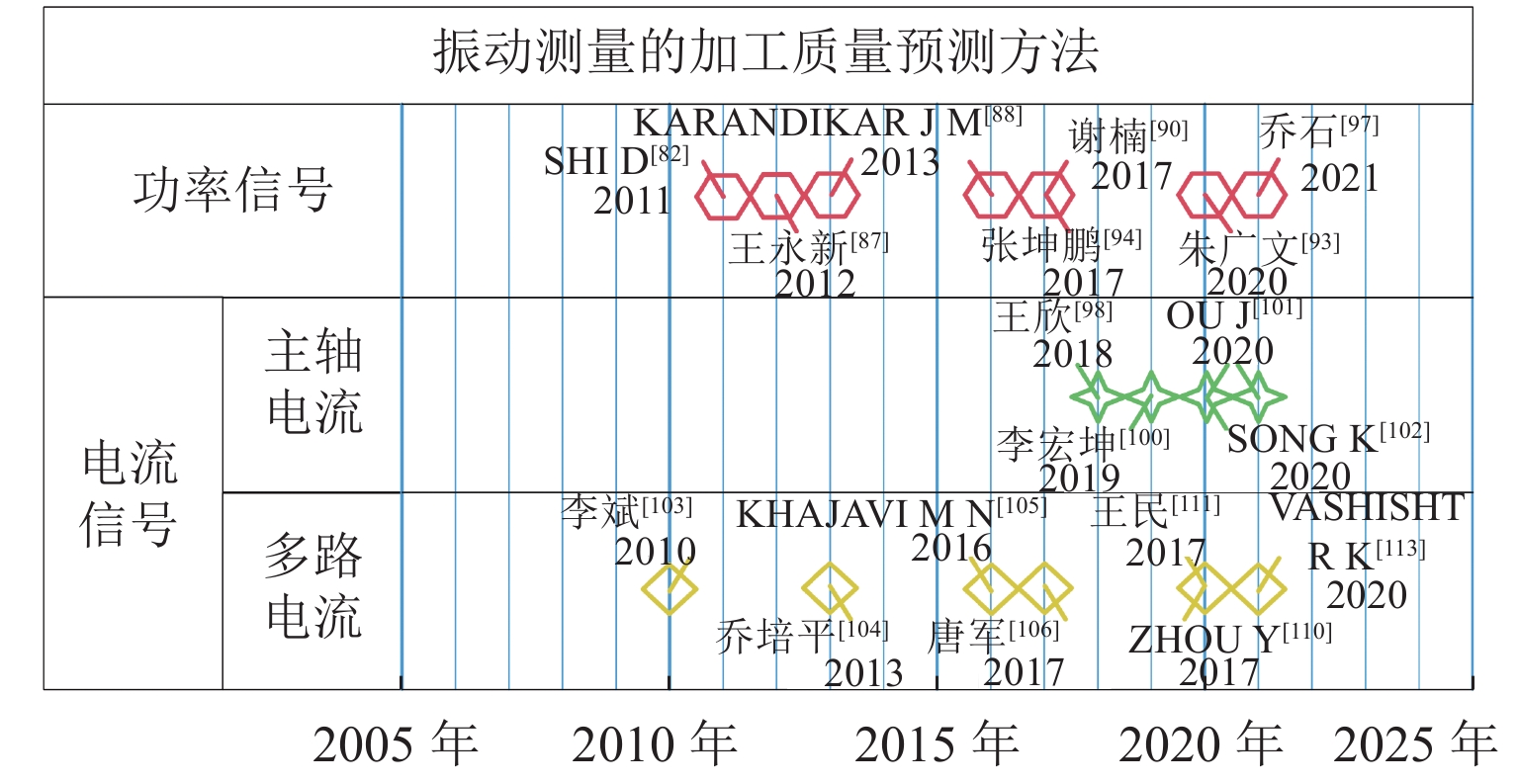

3. 功率测量加工质量预测方法

加工质量通常与切削刀具的磨损程度密不可分,因此,加工质量的监测与预测一般也能通过监测和预测切削刀具的磨损来进行. 在用功率信号监测和预测加工质量的方法中,通常可以分为两大类,即直接测量主轴功率信号的方法和间接测量主轴电流进而反映主轴功率的方法:直接测量主轴功率的方法直接利用功率传感器或者同时利用电流和电压传感器获取主轴的功率信号;间接测量主轴电流的方法用一个或者几个电流传感器测量主轴的某一相或多相电流信号来反映主轴的功率信息.

3.1 基于功率信号的方法

主轴功率信号相比其他各种信号更能直接反应工件的加工质量,由于其具有干扰小、准确性高、获取成本低等特点,相对于干扰大的振动和声发射信号以及成本高的切削力信号来说,许多学者越来越青睐用其进行刀具的监测和工件的加工质量监测与预测.

刀具的磨损情况与表面质量密切相关,因此,准确预测刀具的磨损情况是预测表面质量的必要前提. 众多学者已在此方面展开丰富研究. 贺晓辉等[86]将数控车床主轴电机的功率信号通过Mallat多分辨分析小波算法提取特征序列,作为特征参考模板,在工件批量加工时采用改进的实时小波算法提取特征向量序列,并与特征参考模板序列进行局部实时广义互相关系数计算,同时监测刀具的状态;王永新[87]利用机床主轴的功率信号为数据样本,用功率波动系数监控刀具破损和折断情况,在重构的相空间中利用径向基神经网络实现刀具磨损情况监控和预测;Karandikar 等[88]监测车削实验中主轴功率信号及刀具侧面磨损,用功率信号的均方根生成样本均方根幂增长曲线,并使用贝叶斯规则更新每条曲线的真实增长曲线的概率,将更新的概率用于确定剩余寿命;Drouillet 等[89]对不锈钢工件进行了不同主轴转速下的端面铣削试验,并记录了主轴功率,采用不同MATLAB训练函数的神经网络曲线拟合方法对均方根功率值进行拟合,用来预测刀具的剩余寿命;谢楠等[90]使用功率传感器监测机床加工功率,对功率信号进行后处理并运用非支配排序遗传算法优化的稀疏贝叶斯学习方法建立预测模型来预测刀具磨损;李聪波等[91]对功率信号进行滤波处理,结合数控系统判断机床的运行状态,实时计算切削功率阈值与实际加工过程切削功率进行比较并监测刀具的磨损状况;付细群等[92]采用希尔伯特-黄变换对主轴功率信号进行处理,构建了2个反映刀具磨损状态的刀具磨损系数,建立了钻削工况下精确度高达95%的刀具磨损量预测模型;朱广文等[93]通过信号处理技术,对功率信号进行分析,实时监控电机功率,设置合理的功率以及功率变化范围等参数,根据功率识别结果实现刀具磨损的监测预警.

在上述研究的基础上,众多学者提出了更准确、更全面的表面质量预测方法,将基于主轴功率的表面质量预测提升到一个新的高度. Shi 等[82]将功率传感器安装在车床主轴上以测量功率信号,应用小波变换将获取的信号分解到不同尺度并提取特征,再用支持向量机构建预测模型,预测了刀具的磨损量及工件的加工质量;张坤鹏[94]针对汽轮机转子切削过程复杂、加工质量不稳定等问题,建立了基于功率信号的铣削过程在线监控系统,得出了相应的换刀策略;万文波等[95]提出在功率监测法的基础上,利用自适应神经模糊系统与支持向量回归建立功率与加工参数之间的模型,计算标准切削功率,并与实际切削功率进行实时对比分析,从而判断刀具加工状态并执行换刀策略;桂宇飞等[96]为了提高加工效率、改善产品质量,提出了一种基于希尔伯特-黄变换和机床主轴功率信号的刀具磨损状态在线监测方法,对刀具磨损状态进行在线监测;乔石等[97]用三相功率传感器实时采集加工过程中机床主轴的功率信号,并对信号数据进行数据筛选、数据分析、离线学习,计算出功率阈值区间,以功率阈值区间为监测标准,实现了对航空发动机压气机叶片的铣削刀具加工过程的监测以及对刀具寿命的预测,保证了航空发动机压气机叶片的加工质量. 通过对多种工况下的分析情况确定主轴功率具有与刀具磨损最高的相关性,采用粒子群优化算法优化建立的主轴功率与刀具磨损的映射模型,并以主轴功率监测刀具的状态,实现铣削加工质量的监测.

3.2 基于电流信号的方法

由于主轴电流也能反应加工功率信息,且主轴电流的测量较为方便,只需一个或者几个电流传感器便可以获取主轴电流信号,另外主轴电流的变化几乎只受切削刀具的磨损情况或者工况改变的影响,不受噪声以及冗余信息的干扰,因此许多学者也用主轴电流信号来监测和预测加工质量.

通过上述分析,不难发现主轴电流与加工质量存在强相关性,因此学者们以此为基础展开了大量的研究. 王欣等[98]将正常刀具以及发生破损刀具旋转的主轴电机电流作为原始采集信号,并进行消噪处理后用MATLAB分析时域均方根和信号功率谱密度随频率的分布情况,从而提取刀具破损特征,再应用最小二乘支持向量分类机模型进行刀具破损模式识别;李宏坤等[99]融合切削力系数和主轴电流的优点,建立铣削电流模型,根据切削电流模型进行切削电流系数辨识,记录新刀状态下切削系数,使用切削系数实时估计相同加工工况下新刀切削电流,监测实际切削电流偏离估计值的程度,判断铣刀磨损状态及预测加工质量;李宏坤等[100]利用压缩感知对添加了高斯白噪声的电流信号的频域数据进行数据压缩,将压缩后的数据输入堆栈稀疏自编码网络,利用有监督学习与无监督学习相结合的方法,提取刀具磨损所引起的特征信息,用于表征刀具磨损程度和监测工件表面质量;Ou 等[101]以三相主轴电流信号代替传统的力信号和振动信号,通过阶次分析将变速信号转化为角度域平稳信号,利用堆叠稀疏自编码器神经网络对刀具磨损状态进行监测,进而提高工件的加工质量;Song 等[102]将铣刀的磨损状态分为正常磨损、严重磨损、刀具磨损引起的异常振动和刀具锋利时刀具参数选择不当引起的异常振动4类,再采用深度卷积神经网络模型从主轴电流杂波信号中提取特征作为铣刀磨损状态分类指标,监测铣刀的状态和工件的加工质量.

随着研究的深入,学者们发现仅依靠主轴电流建立的表面质量预测模型鲁棒性差,因此多路电流被引入来增强模型的稳定性. 李斌等[103]利用db8小波基对电流信号进行4层小波包分解,将分解后各频带上的均值与方差作为特征量,建立从新刀到刀具磨损状态下特征量随刀具切削时间的变化关系,根据特征量的变化判别刀具磨损状态,从而监测加工质量;乔培平[104]针对目前刀具切削状态检测中出现的问题,提出了一种利用回归技术和模糊分类建立钻削过程的电流信号状态切削模型的原理和方法,并利用该方法改善加工质量;Khajavi 等[105]分析了刀具磨损、进给量、切削深度等参数对电机电流消耗的影响,以电机电流、进给量、切削深度和刀具转速的均方根为输入,采用多层感知器神经网络对面铣削过程中的刀具磨损进行预测;唐军等[106]首先基于电流监测法搭建了数控铣刀的磨损电流监测系统,然后确定BP神经网络中用于刀具磨损诊断的输入特征量和目标特征量,并应用MATLAB软件对样本数据进行归一化处理和神经网络训练,最后利用遗传算法对BP 神经网络模型进行优化来预测刀具磨损及工件加工质量;Tang等[107]采用电流监测方法建立圆盘铣刀的检测与控制系统,测量用于刀具磨损诊断的BP神经网络的输入特征量和目标特征量,基于GA-BP算法建立圆盘铣刀磨损状态预测神经网络,最后实现铣刀磨损状态的在线预测,进而对加工质量进行预测;孙巍伟等[108]为了监测和预测工件的加工质量以及降低因刀具失效而出现工件报废的概率,使用电流传感器采集变频器输入侧的电流,并利用三相畸变线电流计算其平均有效电流值,将平均有效电流值信号和传统RMS (root mean square)有效电流值信号分别进行时域、频域和时频域分析,设计了一套系统监测刀具磨损状态;张小翠等[109]利用三相平均有效电流计算法和传统RMS计算法来获取计算后的有效电流信号,结合小波降噪和EEMD(ensemble empirical mode decomposition)对信号进行降噪、分解及重构处理,分析重构后其时频域下2种方法计算的有效电流值信号各频带能量和均方差并将其组成特征向量,将特征向量输入CPSO-ELM(chaotic particle swarm optimization-extreme learning machines)和PNN (probabilistic neural network)神经网络等分类器进行状态监测与识别; Zhou 等[110]选择与刀具磨损状况有很强相关性的时域、频域和时频域的电流传感器信号特征,采用2层网络结构和不包含超参数角度核函数的核极限学习机来精确监测刀具状态和工件加工质量;王民等[111]利用傅里叶级数拟合将电流波形分解为反映电流有效值准静态变化的谐波成分和反映立铣刀刃口和后刀面磨损状态以及振动异常的电流杂波信号,然后将电流杂波信号输入到卷积神经网络中进行立铣刀状态特征提取和分类,进而保证工件的加工质量;Ou 等[112]采集数控机床主轴在切削过程中的3种电流信号,并综合其有效值来训练一种新的堆叠去噪自动编码器神经网络,基于原始电流信号获取低维特征,利用在线顺序极限学习机实现了对铣刀的识别与分类,从而监测加工质量;Vashisht等[113]模拟刀具在颤振条件下的振动行为,并在模拟控制电流序列的基础上,训练长短时记忆神经网络检测颤振,并应用其对数控机床滚珠丝杠的颤振进行了检测,以提高工件的表面光洁度.

3.3 小 结

本节讨论了基于测量功率信号预测加工质量的方法,基于功率信号直接测量和基于电流信号间接反映的方法回顾了加工质量预测相关的文献,旨在为工业应用中的工作者提供指导,同时也为学术研究中的研究人员提供启发,并将代表文献和相关信息展示在图6中. 通过回顾上述文献可以看出:近几年,基于功率信号预测加工质量的方法中,主要集中于使用数学回归模型和信号处理手段进行,而使用人工神经网络技术的研究工作有少量开展;基于电流信号预测加工质量的方法中,逐渐从更多使用信号处理手段转变为更多使用人工神经网络技术. 随着技术的发展与新技术的提出与应用,基于功率信息预测加工质量的精度与效率都有明显提升,但是,目前在该方面的研究工作仍存在一些问题,比如功率或者电流对加工质量的影响机理、功率或者电流信号对加工质量的表征机理、真实工业条件下利用功率或电流信号对加工质量预测等问题,需要在未来的研究中重点关注.

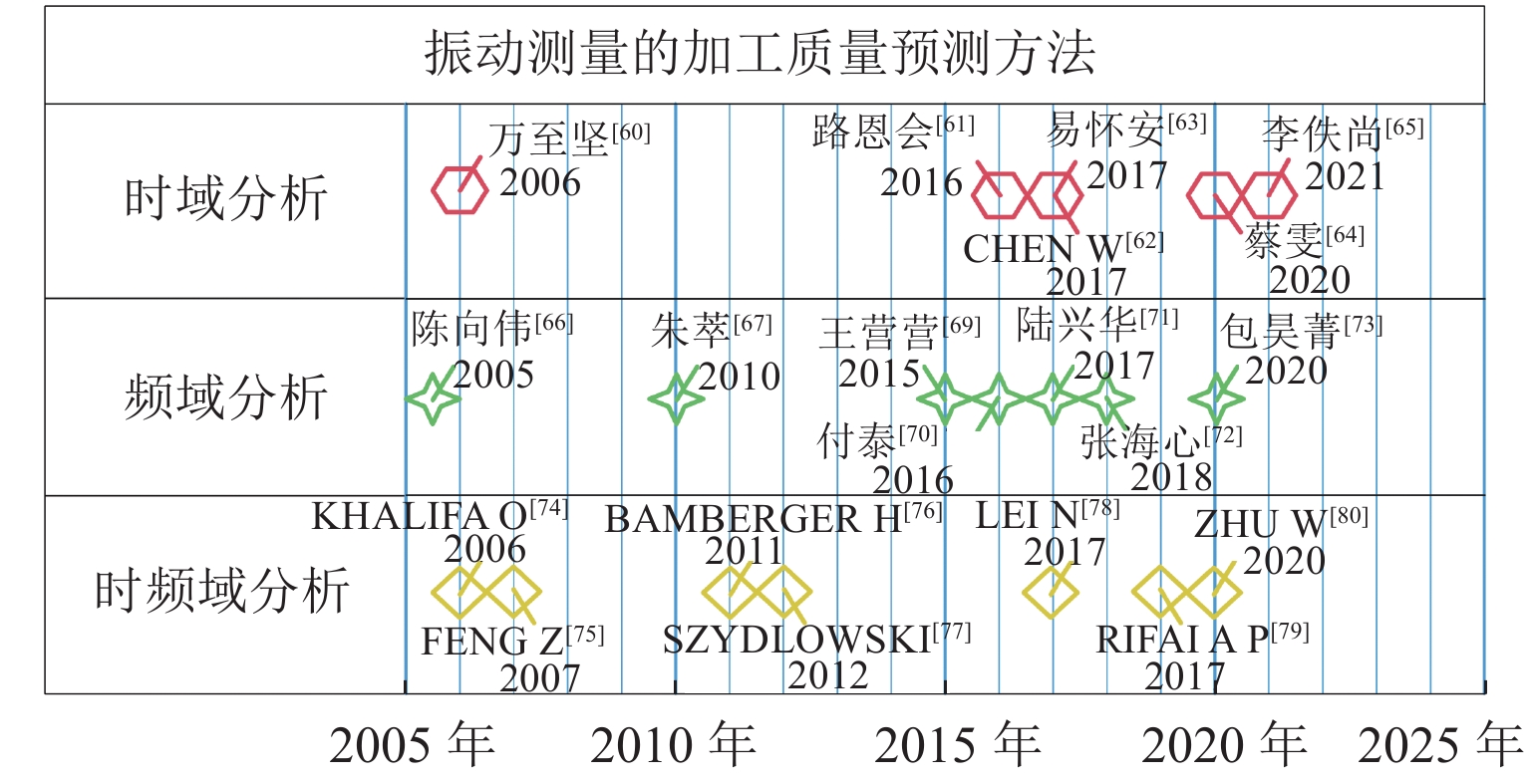

4. 振动测量加工质量预测方法

截至目前,已有大量的研究者在探索振动信号与加工质量的相关性. 不过相关工作集中在振动信号对粗糙度的预测上,振动信号对加工质量其他指标(例如波纹度和形貌误差)的影响,却鲜有报道.

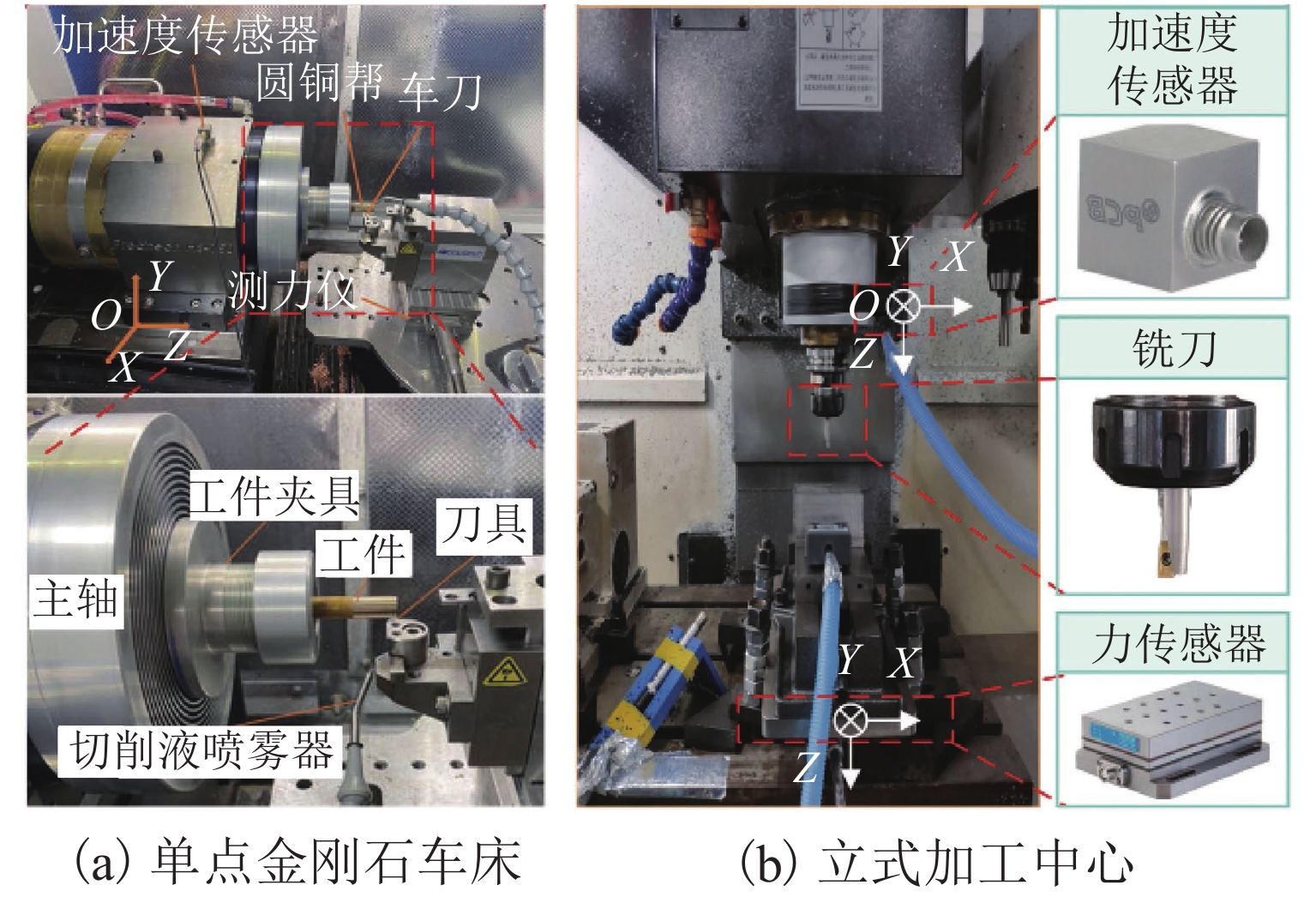

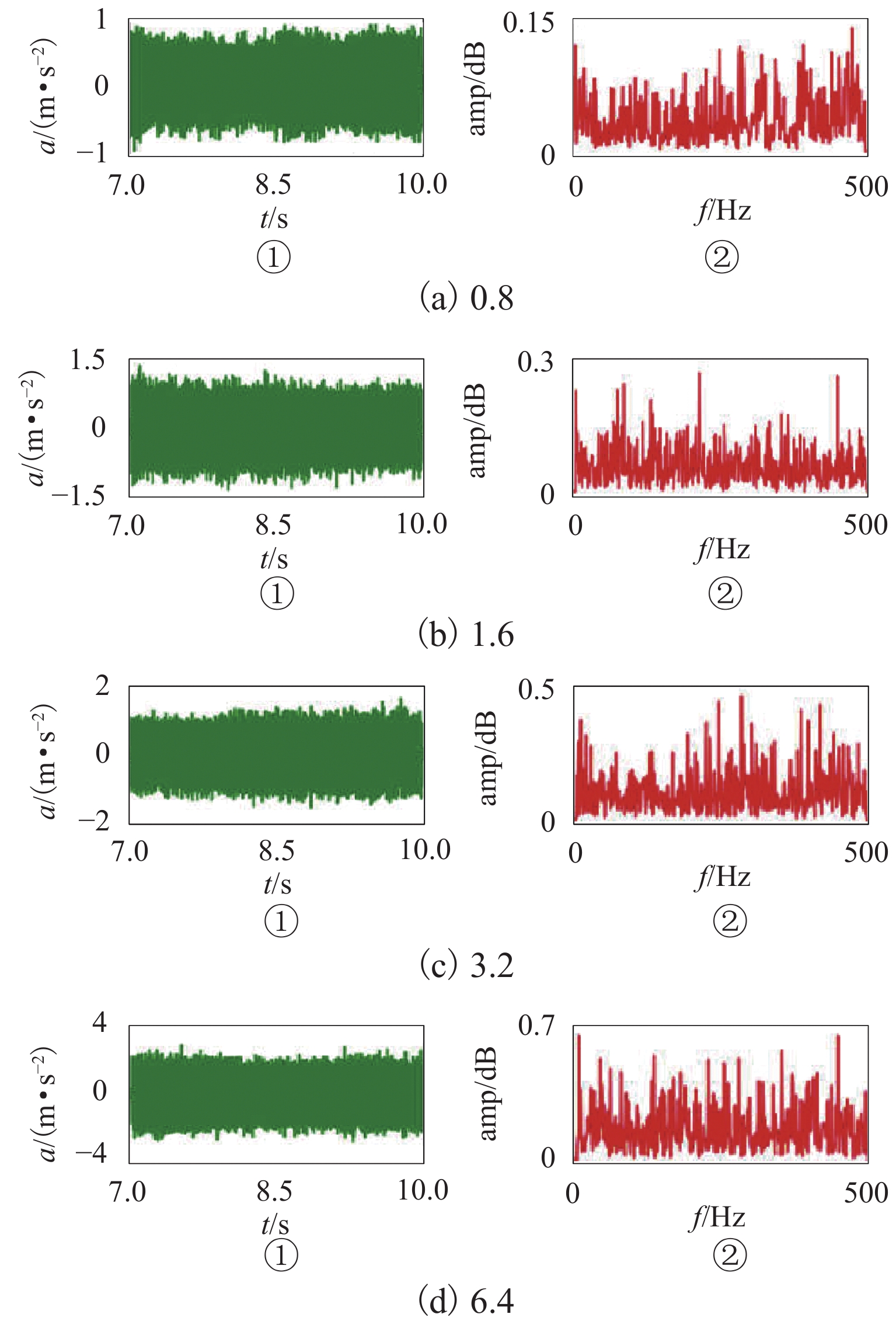

振动信号加工质量预测方法的研究往往集中在3个主线(时域分析、频域分析和时频分析),其典型实验平台如图7. 以不同粗糙度为例,立式加工中心的时域信号和频域信号如图8所示. 相关文献调研如表4所示.

表 4 振动信号预测表面粗糙度方法Table 4. Surface roughness prediction method based on vibration signal作者 采用信号 方法 结果 数据集(工件数量) Hessainia Z等 [114] 轴向和径向振动信号、切削条件 TDA R=99.9% 训练集:27,测试集=训练集 Upadhay V等[115] 三向振动信号、切削条件 TDA R2adj=93.2%,ˉer=3.5% 训练集:15,测试集=训练集 Salgado D R等[116]

三向振动信号、切削条件、刀具参数SSA ˉer=5.74% 训练集:35,测试集:20 García P E等[117] 三向振动信号 SSA R2adj=87.8%,ˉer=14.60%

R=92%训练集:270,测试集:90 Kirby E D等[118] 轴向加速度信号、切削条件 TDA ˉer=5.00% 训练集:83,测试集:7 Risbod K A等[119] 径向振动信号、切削条件 TDA er,max=5.00% 训练集:—,测试集:20 Plaza E G等[120] 三向加速度信号、三向振动信号 FFT R2adj=86.7%,ˉer=9.80% 训练集:52,测试集:12 时域中使用最广泛的方法是时间信号直接分析法(TDA)[114-115],简单且分析计算成本低. 但是在某些情况下,对于获取信号数据不够有效. 因此很多研究人员通过奇异谱分析(SSA)[116-120]或主成分分析(PCA)[121]等预处理手段,削弱无用信号和增强有效信号.

在频域中,广泛使用快速傅立叶变换 (FFT)[122]和功率谱密度(PSD)[123]方法. 其中变换常用到的方法是FFT. 该方法一般将复杂的时间波形分解为一系列组合的谐波分量来获得信号频率结构、相位和功率等信息. 然而,频域分析不允许对瞬态事件进行临时定位,对处理过程中的参数监控构成了相当大的限制.

为了克服此类缺点,时频域分析应运而生. 时频域分析可以在时域和频域中同时分析信号. 时频分析中最常用的方法是短时傅里叶变换(STFT)[124-125]和小波变换(WT)[126].

4.1 时域分析

作为一种分析传感器信号动态、瞬态和稳态的方法,时域特征分析可直接基于时域中的波形数据建立相关统计特征集.

时域分析处理振动信号的方法大多数依靠传感器捕获的离线数据,并且将其作为在线信号的额外数据源. 虽然,离线数据可能会显著改善预测结果,但离线数据仅在特定的理想处理条件下(如实验室)才能被采集,因此获取难度极高. 并且,离线数据可能会引起预测模型的过拟合. 因此在经常遇到随机事件的实际工作条件下,预测结果会急剧衰减.

与SSA时间序列分析等其他方法相比,TDA方法的时域信号处理得到了广泛的应用. 基于TDA方法处理振动信号的监测系统,需要离线数据的补充数据才能获得满意的结果. Risbood 等[119]在使用径向振动信号(ax)和切削条件(v,f,d)来预测模型的粗糙度,使用20个验证工件计算得出,在随机切削条件下,预测模型的最大预测相对误差为20%;Kirby 等[118]研究发现,振动分量(az)很重要,并且将该信号与切削条件(v,f)融合,融合生成模型的平均相对预测误差为5%,在本研究中,仅使用在非随机切削条件下,并且只选择7个工件进行模型验证,验证集过小导致该模型并没有通用性;Hessainia 等[114]利用振动信号(ax,az)和切削条件(v,f,d)作为监测参数,证明切削条件是影响表面加工质量的关键因素,而振动信号对其影响较小,在预测和实验的表面粗糙度之间观察到了良好的一致性(R=99.9%),一致性来源于建立模型和预测模型使用同样的数据集,并且该数据集只包含27条数据;Upadhyay 等[115]通过振动信号(ax,ay,az)和切削条件(v,f,d)监测表面粗糙度,仅使用振动信号进行预测,该模型可以取得92%的预测精度,如果结合切削条件同时作为输入数据,模型的性能可以提升4.5%,此项研究虽然在连续切削的研究中取得显著进步,但是仅使用了15个工件构建和验证模型,方法的通用性依旧无法保证.

相比之下,SSA方法仅应用于少数场合. Salgado等[116]使用振动信号(ax,ay,az)、切削条件(v,f,d)、刀具角度和半径来预测模型的粗糙度,平均误差为5.74%,并使用35个工件的数据建立模型,20个工件的数据进行验证. 该研究虽然取得了很好的结果,但过多使用互补性离线数据源导致系统过度固化,没有可迁移性. 类似地,García 等[117]利用SSA技术,通过振动信号来预测加工件表面粗糙度,平均误差为14.6%,预测准确率为90%,SSA方法因其复杂的矩阵计算带来高昂计算成本,限制了在实时监测中的应用.

时域特征是对信号进行简单的数理统计,对于稳定周期信号的处理问题,时域分析法一般可以取得较好的结果. 但是对于非线性、非平稳信号而言,提取其时域特征往往无法得到好的结果,因此需要进一步提取信号的频域特征.

4.2 频域分析

加工过程中采集到的信号以时间序列的形式呈现,要想分析信号的频域特征就需要将时域上的信号变换到频域上加以分析,常用到的方法就是傅里叶变换. 该方法一般将复杂的时间波形分解为一系列组合的谐波分量来获得信号频率结构、相位和功率等信息.

Lin [127]根据切削理论建立了车削过程中表面粗糙度的预测模型,指出刀具与工件间的振动频率和幅值对工件表面粗糙度影响很大,而且刀具振动频率与主轴转速的比值是影响粗糙度的更加重要的参数,径向振动对工件表面粗糙度的影响远远大于其他2个方向;Cheung [128]研究了刀具和工件之间的相对切削振动发现,被加工工件粗糙度在低频范围内呈现特定的频率分量,在高频范围内与主轴工件系统的固有频率密切相关;Abouelatta[129]使用FFT分析刀具径向和进给方向的振动,找出了车削过程中表面粗糙度与切削振动之间的关系,基于切削参数(v,f,d)和机床振动建立预测粗糙度参数的数学模型;Zhang [130]建立了一种分析超精密金刚石车削中零件表面粗糙度成形的模型,在其仿真系统中考虑了刀具几何形状、加工参数、刀具与工件间的相对振动3个因素,也有助于分析机床振动对工件表面质量的影响及机床故障的诊断;Shore 等[131]在超精密钻石车削中研究了刀具的多模态高频振动对表面粗糙度的影响,通过理论与实验验证了金刚石刀具具有多个高频成分(刀柄段的次高频、刀尖的高频、金刚石刀尖的超高频),阻尼器会引起刀具多模态高频成分的变化,会在加工表面上产生非均匀的斑马状条纹.

虽然频域分析可以得到信号的结构、功率等信息,仅凭这些信息,无法在加工的过程中实时评估表面的粗糙度. 因此,在信号分析时,除了时域和频域的信息,需要进一步提取信号的时频域特征.

4.3 时频域分析

为了从原始信号中提取有用的信息,利用小波包变换多分辨率特性、时域局部特性、去相关特性来实现信号特征提取是时频域分析较为常用的手段.

Fu 等[132]根据相关滤波器组的传输特性,建立了选择合适小波进行表面分析的准则. 由于当前的表面纹理标准是根据滤波器的传输特性来指定滤波器的,因此,在相似的标准下评估不同的小波是表面纹理分析的必要前提. 在传输特性方面推荐使用Bior6.8,与ISO高斯滤波器的参数比较表明,其与现有标准有较好的相关性. Abu-Mahfouz 等[133]以铝材为研究对象,使用统计参数、FFT谱和小波包构建特征集,并以此为基础建立支持向量机分类器来分析特征集,表面粗糙度预测的准确率为81%. García 等[116]提出了一种使用小波包变换方法监测数控车削过程中的表面粗糙度方法. 该方法使用传感器来采集车削过程中的振动信号,然后将信号分解为多个独立的时频信号,称为分组. 本研究从分组中提取了一些特征值,如能量、方差、标准差等,并用它们来预测表面粗糙度. 结果表明,3个正交振动分量的融合信息(ax+ay+az)可以得到较好的预测结果. 但未考虑提取最优统计特征量选取对人工经验依赖性强的问题,增加了实际在线预测成本.

在加工过程中,传感器振动信号的频率成分发生变化,在不同频率范围内的能量也会有差别,因而在不同频率范围中包含着工件表面粗糙度的信息. 利用小波包分解可以提取不同频率范围内对应的能量值,并建立相应的特征向量,以此评估加工过程中的表面粗糙度.

4.4 小 结

利用振动信号的时域、频域和时频域分析方法可以完成对加工表面粗糙度的准确预测. 大部分的研究集中在刀具以及机床主轴的振动对表面成形的影响上. 但是,机床的其他结构(工作台,床身等)的振动也会对表面成形产生影响,而且不同结构的影响程度不同. 因此,还需要对材料振动和机床其他结构的运行振动特性进行研究,并探究其对表面成形的影响机制.

5. 其他测量加工质量预测方法

根据铣削工艺参数和测量数据,将使用模糊推理系统(FIS)估计表面质量. 在不同的切削速度、进给速度、切削深度下进行了不同的切削实验. 针对切削过程中切削条件的变化,采用神经网络模型对切削过程中的表面粗糙度进行预测. 该模型可以预测该表面在不同切削速度、进给量和切削深度参数组合下加工后的粗糙度. 在稳定的铣削条件下,提出的数学模型将表面粗糙度由进给率和刀片几何形状(如刀尖半径和刀尖角度)的函数公式化.

6. 发展趋势

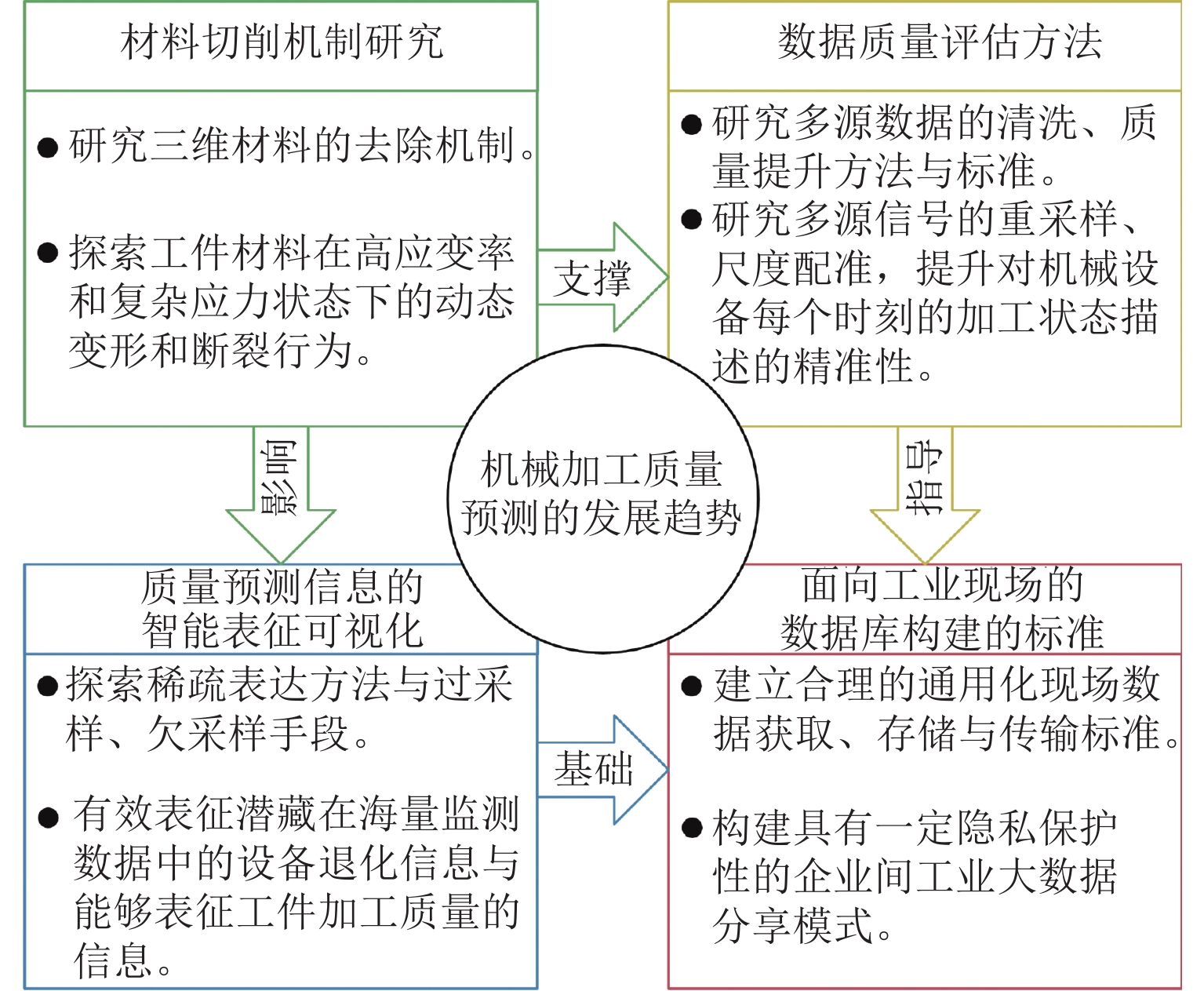

针对机械加工质量预测的特点,作者从以下方面简述了加工质量监测与预测发展趋势,为实际制造场景下加工质量在线监测与预测提供理论方法与可靠的技术手段,进而充分利用质量预测的先验信息与加工过程监测信息,实现准确、鲁棒的机械加工质量监测与预测,其关系如图9所示.

1) 材料切削机制研究,机械加工过程中切削速度正飞速增长. 类似于摩尔定律,随着高速机床和超硬切削工具的发展,切削速度和相关材料去除率每2年增加约100%. 与此同时,金属基、陶瓷基复合材料等新型工程材料也不断涌现,并逐步应用于工业. 切削速度的不断提高和新的工程材料的应用,必然会产生不同的材料去除机制(如韧脆转变),这值得在未来进行更多的研究. 而目前对机械加工过程中材料去除机理的研究主要局限于二维切削模式. 在实际切削中,广泛使用的三维材料去除机制缺乏足够的研究. 相应地,工件材料在高应变率和更复杂应力状态下的动态变形和断裂行为需要进一步探索. 因此,适用于三维机械加工的材料切削模型亟须开发.

2) 数据质量评估方法,由于智能化监测应用的大量落地应用测试,制造现场产生了规模庞大的监测数据. 由于信号来源多样、采样形式多变、各类传感器干扰来源差异化,因而监测数据呈现出明显的碎片化、分布差异化等特点. 因而,研究实际工业现场环境下多传感器数据融合的诊断与预测应用,建议开展下列研究:研究多源数据的清洗、质量提升方法与标准,充分考量数据的时效性、精确性和完整性;研究多源信号的重采样、尺度配准,提升对机械设备每个时刻的加工状态描述的精准性.

3) 面向工业现场的数据库构建的标准,建立合理的通用化现场数据获取、存储与传输标准,构建具有一定隐私保护性的企业间工业大数据分享模式,提升数据的商品属性与流通性. 数据类型上着重收集较为完备的全寿命周期范围的完整退化过程质量监测信息,并提供尽可能多的零级级别监测信息,且监测信息应包含多种且互不相同的类型(机器视觉方法、多通道传感器监测信号等),从而充分提升设备部件的剩余寿命利用率.

4) 质量预测信息的智能表征与可视化,机械设备质量监测信息具有稀疏性与类间不平衡性等特点,探索稀疏表达方法与过采样、欠采样手段,有效表征潜藏在海量监测数据中的设备退化信息与能够表征工件加工质量的信息,从而实现准确、鲁棒的机械设备加工质量预测. 在可视化方面,可视化的水平决定了工业软件与现场工程师的交互有效性,是保障质量监测算法充分发挥效能的关键环节. 以提取特征、预测指标的充分可视化以及识别、预测结果的可视化为主要框架,利用多通道、异步采样的多源传感器信号,从多个维度、多层次、多角度地完整描述整个生产周期内机械设备加工质量预测的实时情况.

7. 结束语

本文从机械加工质量的影响因素出发,以多种类不同测量方式的监测数据(如:机器视觉图像数据、功率数据、振动数据等)处理方法为主线,综述了其在机械加工质量监测与预测中的应用. 通过文献调研,阐明了影响机械加工质量的影响因素,总结了多通道异步、多源传感器数据在加工质量预测上的理论依据和技术手段. 且详细查阅了70项表面加工质量相关研究(其中大部分发表于2012年—2019年). 分析表明,目前机械加工质量预测方法多集中于机器视觉测量和功率测量. 值得注意的是,振动测量的机械加工质量预测方法较少,特别是时频域分析方法.

此外,给出了基于监测数据的机械设备加工质量预测的潜在方向. 在发展趋势上,应该从材料切削机制研究、数据质量评估方法、面向工业现场的数据库构建的标准、质量预测信息的智能表征与可视化等方面展开深入研究,将以监测数据为驱动的机械质量预测应用于实际制造过程的智能监测,提升工厂效率,为现代生产过程创造更高的经济效益.

-

表 1 加工质量影响因素统计

Table 1. Statistics of influencing factors of processing quality

表 2 2种主要的视觉测量粗糙度等表面质量识别方法

Table 2. Comparison of two main visual measurement methods for surface quality recognition such as roughness

测量方式 优点 缺点 光学测量

(白光干涉仪、超景深三维显微系统)非接触式测量,对被测工件无损伤;对区域的微观三维形貌的准确测量 单次检测区域较小;设备测试、维护较为昂贵;对检测环境要求高,容易受到现场加工环境影响 视觉间接测量(基于机器视觉的加工纹理图样分析方法) 容易满足批量化测试需求,进而实现在线或在机测量;测试与监测过程自动化程度高,能够实现快速、高效地反馈工件加工质量情况 准确性和对于实际加工过程的多变工况、光源设置差异等情形的鲁棒性有待优化;对于颤振纹理识别效果

较好表 3 基于机器视觉的形状误差识别

Table 3. Shape error recognition based on machine vision

表 4 振动信号预测表面粗糙度方法

Table 4. Surface roughness prediction method based on vibration signal

作者 采用信号 方法 结果 数据集(工件数量) Hessainia Z等 [114] 轴向和径向振动信号、切削条件 TDA R=99.9% 训练集:27,测试集=训练集 Upadhay V等[115] 三向振动信号、切削条件 TDA R2adj=93.2%,ˉer=3.5% 训练集:15,测试集=训练集 Salgado D R等[116]

三向振动信号、切削条件、刀具参数SSA ˉer=5.74% 训练集:35,测试集:20 García P E等[117] 三向振动信号 SSA R2adj=87.8%,ˉer=14.60%

R=92%训练集:270,测试集:90 Kirby E D等[118] 轴向加速度信号、切削条件 TDA ˉer=5.00% 训练集:83,测试集:7 Risbod K A等[119] 径向振动信号、切削条件 TDA er,max=5.00% 训练集:—,测试集:20 Plaza E G等[120] 三向加速度信号、三向振动信号 FFT R2adj=86.7%,ˉer=9.80% 训练集:52,测试集:12 -

[1] MASAHIKO J, ISAMU G, TAKESHI W. Development of cBN ball-nosed end mill with newly designed cutting edge[J]. Journal of Materials Processing Technology, 2007, 192/193: 48-54. doi: 10.1016/j.jmatprotec.2007.04.054 [2] JARDINE A K S, LIN D, BANJEVIC D. A review on machinery diagnostics and prognostics implementing condition-based maintenance[J]. Mechanical Systems and Signal Processing, 2006, 20(7): 1483-1510. doi: 10.1016/j.ymssp.2005.09.012 [3] TETI R, JEMIELNIAK K, O’DONNELL G. Advanced monitoring of machining operations[J]. CIRP Annals, 2010, 59(2): 717-739. doi: 10.1016/j.cirp.2010.05.010 [4] 雷亚国,许学方,蔡潇,等. 面向机械装备健康监测的数据质量保障方法研究[J]. 机械工程学报,2021,57(4): 1-9. doi: 10.3901/JME.2021.04.001LEI Yaguo, XU Xuefang, CAI Xiao, et al. Research on data quality assurance for health condition monitoring of machinery[J]. Journal of Mechanical Engineering, 2021, 57(4): 1-9. doi: 10.3901/JME.2021.04.001 [5] ARUNACHALAM R M, MANNAN M A, SPOWAGE A C. Residual stress and surface roughness when facing age hardened Inconel 718 with CBN and ceramic cutting tools[J]. International Journal of Machine Tools and Manufacture, 2004, 44(9): 879-887. doi: 10.1016/j.ijmachtools.2004.02.016 [6] RAO A, SARMA R. On local gouging in five-axis sculptured surface machining using flat-end tools[J]. Computer-Aided Design, 2000, 32(7): 409-420. doi: 10.1016/S0010-4485(99)00105-0 [7] TOURNIER C, DUC E. Iso-scallop tool path generation in 5-axis milling[J]. The International Journal of Advanced Manufacturing Technology, 2005, 25(9/10): 867-875. [8] 刘献礼,姜志鹏,李茂月,等. 基于残留高度设计的模具加工用新型圆角端铣刀[J]. 机械工程学报,2015,51(5): 192-204. doi: 10.3901/JME.2015.05.192LIU Xianli, JIANG Zhipeng, LI Maoyue, et al. New rounded end mill for mold processing based on scallop-height[J]. Journal of Mechanical Engineering, 2015, 51(5): 192-204. doi: 10.3901/JME.2015.05.192 [9] 姜彦翠,刘献礼,丁云鹏,等. 汽车大型覆盖件淬硬钢模具切削加工技术[J]. 哈尔滨理工大学学报,2013,18(1): 7-13. doi: 10.3969/j.issn.1007-2683.2013.01.002JIANG Yancui, LIU Xianli, DING Yunpeng, et al. Machining technology of hardened steel molds of automobile large covering[J]. Journal of Harbin University of Science and Technology, 2013, 18(1): 7-13. doi: 10.3969/j.issn.1007-2683.2013.01.002 [10] CHEN J S B, HUANG Y K, CHEN M S. Feedrate optimization and tool profile modification for the high-efficiency ball-end milling process[J]. International Journal of Machine Tools and Manufacture, 2005, 45(9): 1070-1076. doi: 10.1016/j.ijmachtools.2004.11.020 [11] 张安山. 汽车模具小曲率面宽行加工技术研究及其刀具开发[D]. 哈尔滨: 哈尔滨理工大学, 2015. [12] CHEN L X, LIU Z Q, SHEN Q. Enhancing tribological performance by anodizing micro-textured surfaces with nano-MoS2 coatings prepared on aluminum-silicon alloys[J]. Tribology International, 2018, 122: 84-95. doi: 10.1016/j.triboint.2018.02.039 [13] DENG J X, LIAN Y S, WU Z. Performance of femtosecond laser-textured cutting tools deposited with WS2 solid lubricant coatings[J]. Surface and Coatings Technology, 2013, 222: 135-143. doi: 10.1016/j.surfcoat.2013.02.015 [14] SUN J L, ZHOU Y H, DENG J X, et al. Effect of hybrid texture combining micro-pits and micro-grooves on cutting performance of WC/Co-based tools[J]. The International Journal of Advanced Manufacturing Technology, 2016, 86(9/10/11/12): 3383-3394. [15] JIANG W P. Bio-inspired self-sharpening cutting tool surface for finish hard turning of steel[J]. CIRP Annals, 2014, 63(1): 517-520. doi: 10.1016/j.cirp.2014.03.047 [16] 潘晨,李庆华,胡恺星,等. 微织构刀具对工件表面残余应力影响有限元分析[J]. 组合机床与自动化加工技术,2020(1): 14-16,21.PAN Chen, LI Qinghua, HU Kaixing, et al. The effect of micro-textured tool on surface residual stress of workpiece based on finite element analysis[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2020(1): 14-16,21. [17] 马峰,张华,曹华军. 面向低能耗少切削液的多目标加工参数优化[J]. 机械工程学报,2017,53(11): 157-163. doi: 10.3901/JME.2017.11.157MA Feng, ZHANG Hua, CAO Huajun. Multi-objective machining parameters optimization for low energy and minimum cutting fluid consumption[J]. Journal of Mechanical Engineering, 2017, 53(11): 157-163. doi: 10.3901/JME.2017.11.157 [18] 陈行政,李聪波,李丽,等. 面向能效的多工步数控铣削工艺参数多目标优化模型[J]. 计算机集成制造系统,2016,22(2): 538-546. doi: 10.13196/j.cims.2016.02.026CHEN Xingzheng, LI Congbo, LI Li, et al. Multi-objective parameter optimization model of multi-pass CNC milling for energy efficiency[J]. Computer Integrated Manufacturing Systems, 2016, 22(2): 538-546. doi: 10.13196/j.cims.2016.02.026 [19] MOURA R R. The effect of application of cutting fluid with solid lubricant in suspension during cutting of Ti-6Al-4V alloy[J]. Wear, 2015, 332/333: 762-771. doi: 10.1016/j.wear.2015.02.051 [20] 李聪波,朱岩涛,李丽,等. 面向能量效率的数控铣削加工参数多目标优化模型[J]. 机械工程学报,2016,52(21): 120-129. doi: 10.3901/JME.2016.21.120LI Congbo, ZHU Yantao, LI Li, et al. Multi-objective CNC milling parameters optimization model for energy efficiency[J]. Journal of Mechanical Engineering, 2016, 52(21): 120-129. doi: 10.3901/JME.2016.21.120 [21] 王进峰,潘丽娟,邢迪雄,等. 基于能耗效率的SiCp/Al复合材料切削参数多目标优化[J]. 中南大学学报(自然科学版),2020,51(6): 1565-1574.WANG Jinfeng, PAN Lijuan, XING Dixiong, et al. Multi-objective optimization of cutting parameters on turning SiCp/Al composites based on energy efficiency[J]. Journal of Central South University (Science and Technology), 2020, 51(6): 1565-1574. [22] MAIER M, ZWICKER R, AKBARI M. Bayesian optimization for autonomous process set-up in turning[J]. CIRP Journal of Manufacturing Science and Technology, 2019, 26: 81-87. doi: 10.1016/j.cirpj.2019.04.005 [23] KUMAR S P L. Measurement and uncertainty analysis of surface roughness and material removal rate in micro turning operation and process parameters optimization[J]. Measurement, 2019, 140: 538-547. doi: 10.1016/j.measurement.2019.04.029 [24] 邓聪颖,叶波,禄盛,等. 基于切削稳定性与表面质量约束的铣削工艺参数优化研究[J]. 仪器仪表学报,2021,42(11): 190-199.DENG Congying, YE Bo, LU Sheng, et al. Optimization of milling process parameters considering the constraints of cutting stability and surface quality[J]. Chinese Journal of Scientific Instrument, 2021, 42(11): 190-199. [25] VOGLER M P, DEVOR R E, KAPOOR S G. On the modeling and analysis of machining performance in micro-endmilling, part I: surface generation[J]. Journal of Manufacturing Science and Engineering, 2004, 126(4): 685-694. doi: 10.1115/1.1813470 [26] 石文天,刘玉德,丁悦,等. PCD刀具微细车削硬铝合金的表面质量研究[J]. 机床与液压,2011,39(17): 15-17. doi: 10.3969/j.issn.1001-3881.2011.17.005SHI Wentian, LIU Yude, DING Yue, et al. Research of surface quality in micro-turning aluminum alloy using PCD tools[J]. Machine Tool & Hydraulics, 2011, 39(17): 15-17. doi: 10.3969/j.issn.1001-3881.2011.17.005 [27] 王慧,李南奇,赵国超,等. 基于航空铸造钛合金Ti-6Al-4V高速铣削参数的表面质量及切削效率优化[J]. 表面技术,2022,51(2): 331-337,346. doi: 10.16490/j.cnki.issn.1001-3660.2022.02.033WANG Hui, LI Nanqi, ZHAO Guochao, et al. Optimization of surface quality and cutting efficiency for high-speed milling parameters of titanium alloy Ti-6Al-4V for aviation casting[J]. Surface Technology, 2022, 51(2): 331-337,346. doi: 10.16490/j.cnki.issn.1001-3660.2022.02.033 [28] 李俊烨,朱志宝,张心明,等. 异形截面孔磨粒流精密加工质量分析[J]. 中国机械工程,2021,32(17): 2063-2073. doi: 10.3969/j.issn.1004-132X.2021.17.007LI Junye, ZHU Zhibao, ZHANG Xinming, et al. Quality analysis for abrasive flow precision machining of special-shaped holes[J]. China Mechanical Engineering, 2021, 32(17): 2063-2073. doi: 10.3969/j.issn.1004-132X.2021.17.007 [29] 刘枭,邓文君,陈海涛,等. 低温切削7075铝合金鳞刺形成规律及抑制措施[J]. 中国机械工程,2022,33(3): 261-269. doi: 10.3969/j.issn.1004-132X.2022.03.002LIU Xiao, DENG Wenjun, CHEN Haitao, et al. Scale thorn formation regularity and inhibitory measures in cryogenic cutting processes of aluminum alloy 7075[J]. China Mechanical Engineering, 2022, 33(3): 261-269. doi: 10.3969/j.issn.1004-132X.2022.03.002 [30] KRISHNA P V, SRIKANT R R, RAO D N. Experimental investigation on the performance of nanoboric acid suspensions in SAE-40 and coconut oil during turning of AISI 1040 steel[J]. International Journal of Machine Tools and Manufacture, 2010, 50(10): 911-916. doi: 10.1016/j.ijmachtools.2010.06.001 [31] MARKSBERRY P W. Micro-flood (MF) technology for sustainable manufacturing operations that are coolant less and occupationally friendly[J]. Journal of Cleaner Production, 2007, 15(10): 958-971. doi: 10.1016/j.jclepro.2006.01.006 [32] KAYNAK Y, GHARIBI A, YILMAZ U. A comparison of flood cooling, minimum quantity lubrication and high pressure coolant on machining and surface integrity of titanium Ti-5553 alloy[J]. Journal of Manufacturing Processes, 2018, 34: 503-512. doi: 10.1016/j.jmapro.2018.06.003 [33] 袁松梅,韩文亮,朱光远,等. 绿色切削微量润滑增效技术研究进展[J]. 机械工程学报,2019,55(5): 175-185. doi: 10.3901/JME.2019.05.175YUAN Songmei, HAN Wenliang, ZHU Guangyuan, et al. Recent progress on the efficiency increasing methods of minimum quantity lubrication technology in green cutting[J]. Journal of Mechanical Engineering, 2019, 55(5): 175-185. doi: 10.3901/JME.2019.05.175 [34] YAN L T, ZHANG Q J, YU J Z. Analytical models for oil penetration and experimental study on vibration assisted machining with minimum quantity lubrication[J]. International Journal of Mechanical Sciences, 2018, 148: 374-382. doi: 10.1016/j.ijmecsci.2018.09.016 [35] JAMIL M, KHAN A M, HEGAB H, et al. Effects of hybrid Al2O3-CNT nanofluids and cryogenic cooling on machining of Ti–6Al–4V[J]. The International Journal of Advanced Manufacturing Technology, 2019, 102(9/10/11/12): 3895-3909. [36] PARK K H, EWALD B, KWON P Y. Effect of nano-enhanced lubricant in minimum quantity lubrication balling milling[J]. Journal of Tribology, 2011, 133(3): 031803.1-031803.8. [37] ZHANG Y, YANG J G, JIANG H. Machine tool thermal error modeling and prediction by grey neural network[J]. The International Journal of Advanced Manufacturing Technology, 2012, 59(9/10/11/12): 1065-1072. [38] FU G Q, GONG H W, GAO H L, et al. Integrated thermal error modeling of machine tool spindle using a chicken swarm optimization algorithm-based radial basic function neural network[J]. The International Journal of Advanced Manufacturing Technology, 2019, 105(5/6): 2039-2055. [39] FU G Q, TAO C, XIE Y P, et al. Temperature-sensitive point selection for thermal error modeling of machine tool spindle by considering heat source regions[J]. The International Journal of Advanced Manufacturing Technology, 2021, 112(9/10): 2447-2460. [40] LI Y, ZHAO J, JI S J. Thermal positioning error modeling of machine tools using a bat algorithm-based back propagation neural network[J]. The International Journal of Advanced Manufacturing Technology, 2018, 97(5/6/7/8): 2575-2586. [41] LIU H. Thermal error robust modeling method for CNC machine tools based on a split unbiased estimation algorithm[J]. Precision Engineering, 2018, 51: 169-175. doi: 10.1016/j.precisioneng.2017.08.007 [42] 高宏力,李登万,许明恒. 基于人工智能的丝杠寿命预测技术[J]. 西南交通大学学报,2010,45(5): 685-691. doi: 10.3969/j.issn.0258-2724.2010.05.006GAO Hongli, LI Dengwan, XU Mingheng. Intelligent monitoring system for screw life evaluation[J]. Journal of Southwest Jiaotong University, 2010, 45(5): 685-691. doi: 10.3969/j.issn.0258-2724.2010.05.006 [43] ZHANG L. Instance-based ensemble deep transfer learning network: a new intelligent degradation recognition method and its application on ball screw[J]. Mechanical Systems and Signal Processing, 2020, 140: 106681.1-106681.14. [44] 郭亮,高宏力,张一文,等. 基于深度学习理论的轴承状态识别研究[J]. 振动与冲击,2016,35(12): 166-170,195. doi: 10.13465/j.cnki.jvs.2016.12.026GUO Liang, GAO Hongli, ZHANG Yiwen, et al. Research on bearing condition monitoring based on deep learning[J]. Journal of Vibration and Shock, 2016, 35(12): 166-170,195. doi: 10.13465/j.cnki.jvs.2016.12.026 [45] TAN Y W, GUO L, GAO H L, et al. Deep coupled joint distribution adaptation network: a method for intelligent fault diagnosis between artificial and real damages[J]. IEEE Transactions on Instrumentation and Measurement, 2021, 70: 1-12. [46] 高宏力. 切削加工过程中刀具磨损的智能监测技术研究[D]. 成都: 西南交通大学, 2005. [47] 高宏力,许明恒,傅攀,等. 基于动态树理论的刀具磨损监测技术[J]. 机械工程学报,2006,42(7): 227-230. doi: 10.3321/j.issn:0577-6686.2006.07.041GAO Hongli, XU Mingheng, FU Pan, et al. Tool wear monitoring based on dynamic tree[J]. Chinese Journal of Mechanical Engineering, 2006, 42(7): 227-230. doi: 10.3321/j.issn:0577-6686.2006.07.041 [48] YOU Z C. On-line milling cutter wear monitoring in a wide field-of-view camera[J]. Wear, 2020, 460/461: 203479.1-203479.15. doi: 10.1016/j.wear.2020.203479 [49] LIU Y K, YU Y X, GUO L, et al. Automatically designing network-based deep transfer learning architectures based on genetic algorithm for in situ tool condition monitoring[J]. IEEE Transactions on Industrial Electronics, 2022, 69(9): 9483-9493. doi: 10.1109/TIE.2021.3113004 [50] 李忠群. 复杂切削条件高速铣削加工动力学建模、仿真与切削参数优化研究[D]. 北京: 北京航空航天大学, 2008. [51] 王跃辉,王民. 金属切削过程颤振控制技术的研究进展[J]. 机械工程学报,2010,46(7): 166-174. doi: 10.3901/JME.2010.07.166WANG Yuehui, WANG Min. Advances on machining chatter suppression research[J]. Journal of Mechanical Engineering, 2010, 46(7): 166-174. doi: 10.3901/JME.2010.07.166 [52] 杨毅青,张斌,刘强. 铣削建模中多种切削力模型的分析比较[J]. 振动工程学报,2015,28(1): 82-90.YANG Yiqing, ZHANG Bin, LIU Qiang. Analysis and comparison of various cutting force models in the milling process simulation[J]. Journal of Vibration Engineering, 2015, 28(1): 82-90. [53] 张钊. 薄壁结构铣削过程颤振分析及抑制研究[D]. 上海: 上海交通大学, 2018. [54] 张奇. 铣削加工颤振稳定性分析和颤振辨识研究[D]. 上海: 上海交通大学, 2020. [55] 高翔,游红武,翁晓红,等. 机床系统静刚度试验用千分表测力环力学特性[J]. 轻工机械,2013,31(3): 28-31. doi: 10.3969/j.issn.1005-2895.2013.03.008GAO Xiang, YOU Hongwu, WENG Xiaohong, et al. Study on mechanical properties of dynamometer ring used in static stiffness experiment of machine tools system[J]. Light Industry Machinery, 2013, 31(3): 28-31. doi: 10.3969/j.issn.1005-2895.2013.03.008 [56] 万小金. 工件−夹具−刀具系统的几何误差分析与预测研究[D]. 武汉: 华中科技大学, 2010. [57] 彭诚. 车铣复合机床静动态特性分析及关键部件的优化[D]. 合肥: 合肥工业大学, 2019. [58] 李轶尚. 基于机器视觉的清洁切削加工表面粗糙度在位测量方法及其系统构建[D]. 济南: 山东大学, 2021. [59] 李瑛. 拖拉机传动箱端面销孔加工质量机器视觉测量与预警分析[D]. 杭州: 浙江大学, 2019. [60] 万志坚. 非接触式表面粗糙度识别方法的研究[J]. 制造技术与机床,2006(10): 73-75. doi: 10.3969/j.issn.1005-2402.2006.10.028WAN Zhijian. Study on the method for non-contact roughness detection[J]. Manufacturing Technology and Machine Tool, 2006(10): 73-75. doi: 10.3969/j.issn.1005-2402.2006.10.028 [61] 路恩会. 基于机器视觉的磨削表面粗糙度检测方法研究[D]. 长沙: 湖南大学, 2016. [62] CHEN W, ZOU B, LI Y S, et al. A study of a rapid method for detecting the machined surface roughness[J]. The International Journal of Advanced Manufacturing Technology, 2021, 117(9/10): 3115-3127. [63] 易怀安. 基于色彩信息的机器视觉粗糙度检测方法研究[D]. 长沙: 湖南大学, 2017. [64] 蔡雯,陈培锋,王英,等. 基于激光散射的表面粗糙度测量系统研究[J]. 激光技术,2020,44(5): 611-615. doi: 10.7510/jgjs.issn.1001-3806.2020.05.014CAI Wen, CHEN Peifeng, WANG Ying, et al. Research of surface roughness measurement system based on laser scattering[J]. Laser Technology, 2020, 44(5): 611-615. doi: 10.7510/jgjs.issn.1001-3806.2020.05.014 [65] LI Y S, ZOU B, SHI Z Y, et al. Wear patterns and mechanisms of sialon ceramic end-milling tool during high speed machining of nickel-based superalloy[J]. Ceramics International, 2021, 47(4): 5690-5698. doi: 10.1016/j.ceramint.2020.10.155 [66] 陈向伟,王龙山,刘庆民. 图像技术在微小零件几何尺寸测量中的应用[J]. 工具技术,2005,39(8): 86-89. doi: 10.3969/j.issn.1000-7008.2005.08.027CHEN Xiangwei, WANG Longshan, LIU Qingmin. Application of CCD image technology on measuring size of micro part[J]. Tool Engineering, 2005, 39(8): 86-89. doi: 10.3969/j.issn.1000-7008.2005.08.027 [67] 朱萃. 基于机器视觉的微小型组件精密测量与装配[D]. 大连: 大连理工大学, 2010. [68] 雷红胜. 基于机器视觉的零件尺寸测量及加工精度分析[D]. 南昌: 南昌航空大学, 2014. [69] 王营营. 基于机器视觉的曲轴轴颈轴线直线度误差检测[D]. 太原: 太原科技大学, 2015. [70] 付泰,王桂棠,程书豪,等. 基于机器视觉的复杂平面零件尺寸精密检测[J]. 机电工程技术,2016,45(8): 7-9,84. doi: 10.3969/j.issn.1009-9492.2016.08.003FU Tai, WANG Guitang, CHENG Shuhao, et al. Size sophisticated detection based on machine vision complex plane parts[J]. Mechanical and Electrical Engineering Technology, 2016, 45(8): 7-9,84. doi: 10.3969/j.issn.1009-9492.2016.08.003 [71] 陆兴华,魏盼. 基于机器视觉的柱状弹簧质量综合检测系统[J]. 工具技术,2017,51(12): 110-114. doi: 10.3969/j.issn.1000-7008.2017.12.029LU Xinghua, WEI Pan. Quality measuring system of cylindrical spring based on machine vision[J]. Tool Engineering, 2017, 51(12): 110-114. doi: 10.3969/j.issn.1000-7008.2017.12.029 [72] 张海心. 基于机器视觉的轴类零件测量仪设计[D]. 哈尔滨: 哈尔滨工业大学, 2018. [73] 包昊菁. 基于机器视觉的链轮径向跳动测量技术研究[D]. 长春: 吉林大学, 2020. [74] KHALIFA O O, DENSIBALI A, FARIS W. Image processing for chatter identification in machining processes[J]. The International Journal of Advanced Manufacturing Technology, 2006, 31(5/6): 443-449. [75] FENG Z, CHEN X. Image processing of the grinding wheel surface[J]. The International Journal of Advanced Manufacturing Technology, 2007, 32(5/6): 452-458. [76] BAMBERGER H, RAMACHANDRAN S, HONG E, et al. Identification of machining chatter marks on surfaces of automotive valve seats[J]. Journal of Manufacturing Science and Engineering, 2011, 133(4): 041003.1-041003.4. [77] SZYDŁOWSKI M, POWAŁKA B. Chatter detection algorithm based on machine vision[J]. The International Journal of Advanced Manufacturing Technology, 2012, 62(5/6/7/8): 517-528. [78] LEI N, SOSHI M. Vision-based system for chatter identification and process optimization in high-speed milling[J]. The International Journal of Advanced Manufacturing Technology, 2017, 89(9/10/11/12): 2757-2769. [79] RIFAI A P, FUKUDA R, AOYAMA H. Surface roughness estimation and chatter vibration identification using vision-based deep learning[J]. Journal of the Japan Society for Precision Engineering, 2019, 85(7): 658-666. doi: 10.2493/jjspe.85.658 [80] ZHU W G, ZHUANG J C, GUO B S, et al. An optimized convolutional neural network for chatter detection in the milling of thin-walled parts[J]. The International Journal of Advanced Manufacturing Technology, 2020, 106(9/10): 3881-3895. [81] 王志学,刘献礼,李茂月,等. 切削加工颤振智能监控技术[J]. 机械工程学报,2020,56(24): 1-23. doi: 10.3901/JME.2020.24.001WANG Zhixue, LIU Xianli, LI Maoyue, et al. Intelligent monitoring and control technology of cutting chatter[J]. Journal of Mechanical Engineering, 2020, 56(24): 1-23. doi: 10.3901/JME.2020.24.001 [82] SHI D F, GINDY N. Tool wear prediction based on wavelet transform and support vector machines[J]. ICINCO, 2011: 479-485. [83] 张航. 基于迁移学习的磨削表面粗糙度测量方法研究[D]. 长沙: 湖南大学, 2017. [84] 史雪春. 基于机器学习的切削状态监测技术研究[D]. 北京: 北京理工大学, 2018. [85] 唐梓珏. 激光熔化沉积熔池动态特征演化行为及关键形性质量预测研究[D]. 大连: 大连理工大学, 2020. [86] 贺晓辉,鄢萍,张佳毅,等. 功率信息互相关法的刀具破损在线监测[J]. 重庆大学学报,2011,34(9): 9-16. doi: 10.11835/j.issn.1000-582X.2011.09.002HE Xiaohui, YAN Ping, ZHANG Jiayi, et al. On-line tool breakage monitoring method based on power information and cross-correlation algorithm[J]. Journal of Chongqing University, 2011, 34(9): 9-16. doi: 10.11835/j.issn.1000-582X.2011.09.002 [87] 王永新. 基于功率和神经网络的刀具状态在线监测研究[J]. 科技创新与应用,2012(7): 9-10. [88] KARANDIKAR J M, ABBAS A, SCHMITZ T L. Remaining useful tool life predictions in turning using Bayesian inference[J]. International Journal of Prognostics and Health Management, 2020, 4(2): 1-11. [89] DROUILLET C. Tool life predictions in milling using spindle power with the neural network technique[J]. Journal of Manufacturing Processes, 2016, 22: 161-168. doi: 10.1016/j.jmapro.2016.03.010 [90] 谢楠,段明雷,高英强,等. 基于功率传感器的刀具磨损量预测方法[J]. 同济大学学报(自然科学版),2017,45(3): 420-426. doi: 10.11908/j.issn.0253-374x.2017.03.017XIE Nan, DUAN Minglei, GAO Yingqiang, et al. Tool wear prediction approach based on power sensor[J]. Journal of Tongji University (Natural Science), 2017, 45(3): 420-426. doi: 10.11908/j.issn.0253-374x.2017.03.017 [91] 李聪波,万腾,陈行政,等. 基于切削功率的数控车削批量加工刀具磨损在线监测[J]. 计算机集成制造系统,2018,24(8): 1910-1919. doi: 10.13196/j.cims.2018.08.003LI Congbo, WAN Teng, CHEN Xingzheng, et al. On-line monitoring method of tool wear for NC turning in batch processing based on cutting power[J]. Computer Integrated Manufacturing Systems, 2018, 24(8): 1910-1919. doi: 10.13196/j.cims.2018.08.003 [92] 付细群,刘俊,熊文亮. 基于HHT算法和功率信号的刀具磨损预测[J]. 机械工程与自动化,2019(5): 159-161. doi: 10.3969/j.issn.1672-6413.2019.05.063FU Xiqun, LIU Jun, XIONG Wenliang. Tool wear prediction based on HHT algorithm and power signal[J]. Mechanical Engineering and Automation, 2019(5): 159-161. doi: 10.3969/j.issn.1672-6413.2019.05.063 [93] 朱广文,魏代善,孙佳隆,等. 基于功率监测的刀具磨损状态识别[J]. 电子制作,2020(22): 28-29. doi: 10.3969/j.issn.1006-5059.2020.22.010ZHU Guangwen, WEI Daishan, SUN Jialong, et al. Tool Wear State Recognition Based on Power Monitoring[J]. Electronic Production, 2020(22): 28-29. doi: 10.3969/j.issn.1006-5059.2020.22.010 [94] 张坤鹏. 基于功率信号的转子轮槽铣削在线监控研究[J]. 热力透平,2017,46(1): 52-55. doi: 10.13707/j.cnki.31-1922/th.2017.01.012ZHANG Kunpeng. Online monitoring system for the rotor groove milling based on power signal[J]. Thermal Turbine, 2017, 46(1): 52-55. doi: 10.13707/j.cnki.31-1922/th.2017.01.012 [95] 万文波,李江雄,毕运波. 基于功率信号的钻锪刀具监测及其系统开发[J]. 计算机集成制造系统,2019,25(9): 2140-2148. doi: 10.13196/j.cims.2019.09.002WAN Wenbo, LI Jiangxiong, BI Yunbo. Drilling and dimpling tool monitoring based on power signal and its system development[J]. Computer Integrated Manufacturing Systems, 2019, 25(9): 2140-2148. doi: 10.13196/j.cims.2019.09.002 [96] 桂宇飞,官威,陈标,等. 基于HHT算法与主轴功率信号的刀具磨损状态在线监测[J]. 机械设计与研究,2019,35(5): 63-69. doi: 10.13952/j.cnki.jofmdr.2019.0277GUI Yufei, GUAN Wei, CHEN Biao, et al. Online tool condition monitoring based on Hilbert-Huang transform and spidle power signal[J]. Machine Design and Research, 2019, 35(5): 63-69. doi: 10.13952/j.cnki.jofmdr.2019.0277 [97] 乔石,刘阔,都书博,等. 基于功率信息的航空发动机叶片铣削刀具监测试验研究[J]. 航空制造技术,2021,64(16): 87-92,110. doi: 10.16080/j.issn1671-833x.2021.16.087QIAO Shi, LIU Kuo, DU Shubo, et al. Research on monitoring test of milling tool for aero-engine blade based on power information[J]. Aeronautical Manufacturing Technology, 2021, 64(16): 87-92,110. doi: 10.16080/j.issn1671-833x.2021.16.087 [98] 王欣,强云玥. 铣刀在铣削加工中破损特征的识别方法研究[J]. 农业装备与车辆工程,2018,56(10): 65-70. doi: 10.3969/j.issn.1673-3142.2018.10.017WANG Xin, QIANG Yunyue. Identification method for milling cutter breakage features in milling process[J]. Agricultural Equipment and Vehicle Engineering, 2018, 56(10): 65-70. doi: 10.3969/j.issn.1673-3142.2018.10.017 [99] 李宏坤,张孟哲,郝佰田,等. 基于切削电流系数的铣刀磨损状态监测[J]. 振动测试与诊断,2019,39(4): 713-719,900.LI Hongkun, ZHANG Mengzhe, HAO Baitian, et al. Monitoring milling cutter wear condition based on cutting current coefficients[J]. Journal of Vibration, Measurement and Diagnosis, 2019, 39(4): 713-719,900. [100] 李宏坤,郝佰田,代月帮,等. 基于压缩感知和加噪堆栈稀疏自编码器的铣刀磨损程度识别方法研究[J]. 机械工程学报,2019,55(14): 1-10. doi: 10.3901/JME.2019.14.001LI Hongkun, HAO Baitian, DAI Yuebang, et al. Wear status recognition for milling cutter based on compressed sensing and noise stacking sparse auto-encoder[J]. Journal of Mechanical Engineering, 2019, 55(14): 1-10. doi: 10.3901/JME.2019.14.001 [101] OU J Y, LI H K, HUANG G J, et al. A novel order analysis and stacked sparse auto-encoder feature learning method for milling tool wear condition monitoring[J]. Sensors (Basel, Switzerland), 2020, 20(10): 2878-2891. doi: 10.3390/s20102878 [102] SONG K Y, WANG M, LIU L M, et al. Intelligent recognition of milling cutter wear state with cutting parameter independence based on deep learning of spindle current clutter signal[J]. The International Journal of Advanced Manufacturing Technology, 2020, 109(3/4): 929-942. [103] 李斌,丁玉发,刘红奇. 小波包分析技术在电流刀具磨损监测系统中的应用[J]. 心智与计算,2010,4(4): 258-264. doi: 10.13706/j.cnki.xizh.2010.04.001LI Bin, DING Yufa, LIU Hongqi. Application of wavelet package analysis in tool wear monitoring system using current[J]. Mind and Computation, 2010, 4(4): 258-264. doi: 10.13706/j.cnki.xizh.2010.04.001 [104] 乔培平. 基于电流信号刀具磨损状态的模糊模式识别[J]. 工具技术,2013,47(11): 73-74. doi: 10.3969/j.issn.1000-7008.2013.11.022QIAO Peiping. Tool wear state based on current signal of fuzzy pattern recongnition[J]. Tool Engineering, 2013, 47(11): 73-74. doi: 10.3969/j.issn.1000-7008.2013.11.022 [105] KHAJAVI M N, NASERNIA E, ROSTAGHI M. Milling tool wear diagnosis by feed motor current signal using an artificial neural network[J]. Journal of Mechanical Science and Technology, 2016, 30(11): 4869-4875. doi: 10.1007/s12206-016-1005-9 [106] 唐军,赵波,李文星. 基于遗传算法和BP神经网络的盘形成形铣刀磨损状态预测[J]. 河南理工大学学报(自然科学版),2017,36(5): 66-71. doi: 10.16186/j.cnki.1673-9787.2017.05.011TANG Jun, ZHAO Bo, LI Wenxing. Research on prediction tool of wear conditions of disk milling cutter based on genetic algorithm and BP neural network[J]. Journal of Henan Polytechnic University (Natural Science), 2017, 36(5): 66-71. doi: 10.16186/j.cnki.1673-9787.2017.05.011 [107] TANG J, LI W X, ZHAO B. The application of GA-BP algorithm in prediction of tool wear state[J]. IOP Conference Series: Materials Science and Engineering, 2018, 398: 012025.1-012025.8. [108] 孙巍伟,黄民,李康. 基于电流信号的刀具磨损状态监测方法研究[J]. 河南理工大学学报(自然科学版),2019,38(6): 77-84,107. doi: 10.16186/j.cnki.1673-9787.2019.6.11SUN Weiwei, HUANG Min, LI Kang. Research on tool condition monitoring method based on current signal[J]. Journal of Henan Polytechnic University (Natural Science), 2019, 38(6): 77-84,107. doi: 10.16186/j.cnki.1673-9787.2019.6.11 [109] 张小翠,徐小明. 一种基于变频器电流检测机床刀具磨损新方法的研究[J]. 机床与液压,2019,47(13): 213-218. doi: 10.3969/j.issn.1001-3881.2019.13.043ZHANG Xiaocui, XU Xiaoming. Research on new method of tool wear for machine tool based on frequency converter current detection[J]. Machine Tool and Hydraulics, 2019, 47(13): 213-218. doi: 10.3969/j.issn.1001-3881.2019.13.043 [110] ZHOU Y Q, SUN W F. Tool wear condition monitoring in milling process based on current sensors[J]. IEEE Access, 2020, 8: 95491-95502. [111] 王民,刘利明,宋铠钰,等. 基于主轴驱动电流杂波的立铣刀复杂工况下磨损状态辨识[J]. 计算机集成制造系统,2021,27(12): 3429-3438. doi: 10.13196/j.cims.2021.12.005WANG Min, LIU Liming, SONG Kaiyu, et al. Wear status identification of end milling cutter under complex cutting conditions based on clutter signal of spindle current[J]. Computer Integrated Manufacturing Systems, 2021, 27(12): 3429-3438. doi: 10.13196/j.cims.2021.12.005 [112] OU J Y, LI H K, HUANG G J. Intelligent analysis of tool wear state using stacked denoising autoencoder with online sequential-extreme learning machine[J]. Measurement, 2021, 167: 108153.1-108153.14. [113] VASHISHT R K, PENG Q J. Online chatter detection for milling operations using LSTM neural networks assisted by motor current signals of ball screw drives[J]. Journal of Manufacturing Science and Engineering, 2021, 143(1): 011008.1-011008.13. [114] HESSAINIA Z, BELBAH A, YALLESE M A. On the prediction of surface roughness in the hard turning based on cutting parameters and tool vibrations[J]. Measurement: Journal of the International Measurement Confederation, 2013, 46(5): 1671-1681. doi: 10.1016/j.measurement.2012.12.016 [115] UPADHYAY V, JAIN P K, MEHTA N K. In-process prediction of surface roughness in turning of Ti-6Al-4V alloy using cutting parameters and vibration signals[J]. Measurement, 2013, 46(1): 154-160. doi: 10.1016/j.measurement.2012.06.002 [116] SALGADO D R, ALONSO F J, CAMBERO I, et al. In-process surface roughness prediction system using cutting vibrations in turning[J]. The International Journal of Advanced Manufacturing Technology, 2009, 43(1/2): 40-51. [117] GARCÍA PLAZA E, NÚÑEZ P J, RODRÍGUEZ SALGADO D, et al. Contribution of surface finish monitoring signals in CNC taper turning[J]. Materials Science Forum, 2014, 797: 41-46. doi: 10.4028/www.scientific.net/MSF.797.41 [118] KIRBY E D, CHEN J C. Development of a fuzzy-nets-based surface roughness prediction system in turning operations[J]. Computers and Industrial Engineering, 2007, 53(1): 30-42. doi: 10.1016/j.cie.2006.06.018 [119] RISBOOD K A. Prediction of surface roughness and dimensional deviation by measuring cutting forces and vibrations in turning process[J]. Journal of Materials Processing Technology, 2003, 132(1/2/3): 203-214. [120] PLAZA E G, NÚÑEZ L P J. Surface roughness monitoring by singular spectrum analysis of vibration signals[J]. Mechanical Systems and Signal Processing, 2017, 84: 516-530. doi: 10.1016/j.ymssp.2016.06.039 [121] SHI D F, GINDY N N. Tool wear predictive model based on least squares support vector machines[J]. Mechanical Systems and Signal Processing, 2007, 21(4): 1799-1814. doi: 10.1016/j.ymssp.2006.07.016 [122] BHUIYAN M S H, CHOUDHURY I A, DAHARI M. Monitoring the tool wear, surface roughness and chip formation occurrences using multiple sensors in turning[J]. Journal of Manufacturing Systems, 2014, 33(4): 476-487. doi: 10.1016/j.jmsy.2014.04.005 [123] WANG H, TO S, CHAN C Y. Investigation on the influence of tool-tip vibration on surface roughness and its representative measurement in ultra-precision diamond turning[J]. International Journal of Machine Tools and Manufacture, 2013, 69: 20-29. doi: 10.1016/j.ijmachtools.2013.02.006 [124] MARINESCU I, AXINTE D. A time-frequency acoustic emission-based monitoring technique to identify workpiece surface malfunctions in milling with multiple teeth cutting simultaneously[J]. International Journal of Machine Tools and Manufacture, 2009, 49(1): 53-65. doi: 10.1016/j.ijmachtools.2008.08.002 [125] REHORN A G, SEJDIĆ E, JIANG J. Fault diagnosis in machine tools using selective regional correlation[J]. Mechanical Systems and Signal Processing, 2006, 20(5): 1221-1238. doi: 10.1016/j.ymssp.2005.01.010 [126] ZHU K P, WONG Y S, HONG G S. Wavelet analysis of sensor signals for tool condition monitoring: a review and some new results[J]. International Journal of Machine Tools and Manufacture, 2009, 49(7/8): 537-553. [127] LIN S C. A study on the effects of vibrations on the surface finish using a surface topography simulation model for turning[J]. International Journal of Machine Tools and Manufacture, 1998, 38(7): 763-782. doi: 10.1016/S0890-6955(97)00073-4 [128] CHEUNG C F. A multi-spectrum analysis of surface roughness formation in ultra-precision machining[J]. Precision Engineering, 2000, 24(1): 77-87. doi: 10.1016/S0141-6359(99)00033-1 [129] ABOUELATTA O B. Surface roughness prediction based on cutting parameters and tool vibrations in turning operations[J]. Journal of Materials Processing Technology, 2001, 118(1/2/3): 269-277. [130] ZHANG S J. A theoretical and experimental investigation into multimode tool vibration with surface generation in ultra-precision diamond turning[J]. International Journal of Machine Tools and Manufacture, 2013, 72: 32-36. doi: 10.1016/j.ijmachtools.2013.05.005 [131] SHORE P, MORANTZ P, LUO X, et al. Big OptiX ultra precision grinding/measuring system[C]//Optical Systems Design 2005. Proc SPIE 5965, Optical Fabrication, Testing, and Metrology Ⅱ, Jena: [s.n.], 2005, 5965: 241-248. [132] FU S Y, MURALIKRISHNAN B, RAJA J. Engineering surface analysis with different wavelet bases[J]. Journal of Manufacturing Science and Engineering, 2003, 125(4): 844-852. doi: 10.1115/1.1616947 [133] ABU-MAHFOUZ I, EL ARISS O, ESFAKUR RAHMAN A H M, et al. Surface roughness prediction as a classification problem using support vector machine[J]. The International Journal of Advanced Manufacturing Technology, 2017, 92(1/2/3/4): 803-815. 期刊类型引用(6)

1. 袁奎,付恒勋,谌立贵,秦东,吴怀超,王则皓. 轴类工件圆度误差亚像素视觉检测和评定方法研究. 现代制造工程. 2025(02): 94-100 .  百度学术

百度学术2. 贾俊良. 机械加工质量影响因素及控制措施. 造纸装备及材料. 2025(03): 73-75 .  百度学术

百度学术3. 刘铁民,彭硕,田志宾,褚晓冬,李昆,刘飞墨,贾奇勇,杨海涛. 电缆测井仪器复杂液压主基体加工工艺探讨. 机械工程师. 2025(05): 165-167+172 .  百度学术

百度学术4. 胡书平,王霈显,高原. 无尘环境下精密光机部件的微小振动切割方法研究. 集成电路应用. 2024(11): 46-48 .  百度学术

百度学术5. 汤其富,李咪,赵静,郭羊庭,彭松. PCB型电磁感应式直线位移传感器短周期误差抑制方法. 西南交通大学学报. 2024(06): 1314-1321 .  本站查看

本站查看6. 王炳堂,史玉皓. 浅谈人工智能技术背景下我国自动络筒机的机遇和挑战. 山东纺织科技. 2024(06): 53-56 .  百度学术

百度学术其他类型引用(7)

-

下载:

下载:

下载:

下载:

百度学术

百度学术