Review on Key Technologies of Stable Operation for Magnetic Suspension Support-Flywheel System

-

摘要:

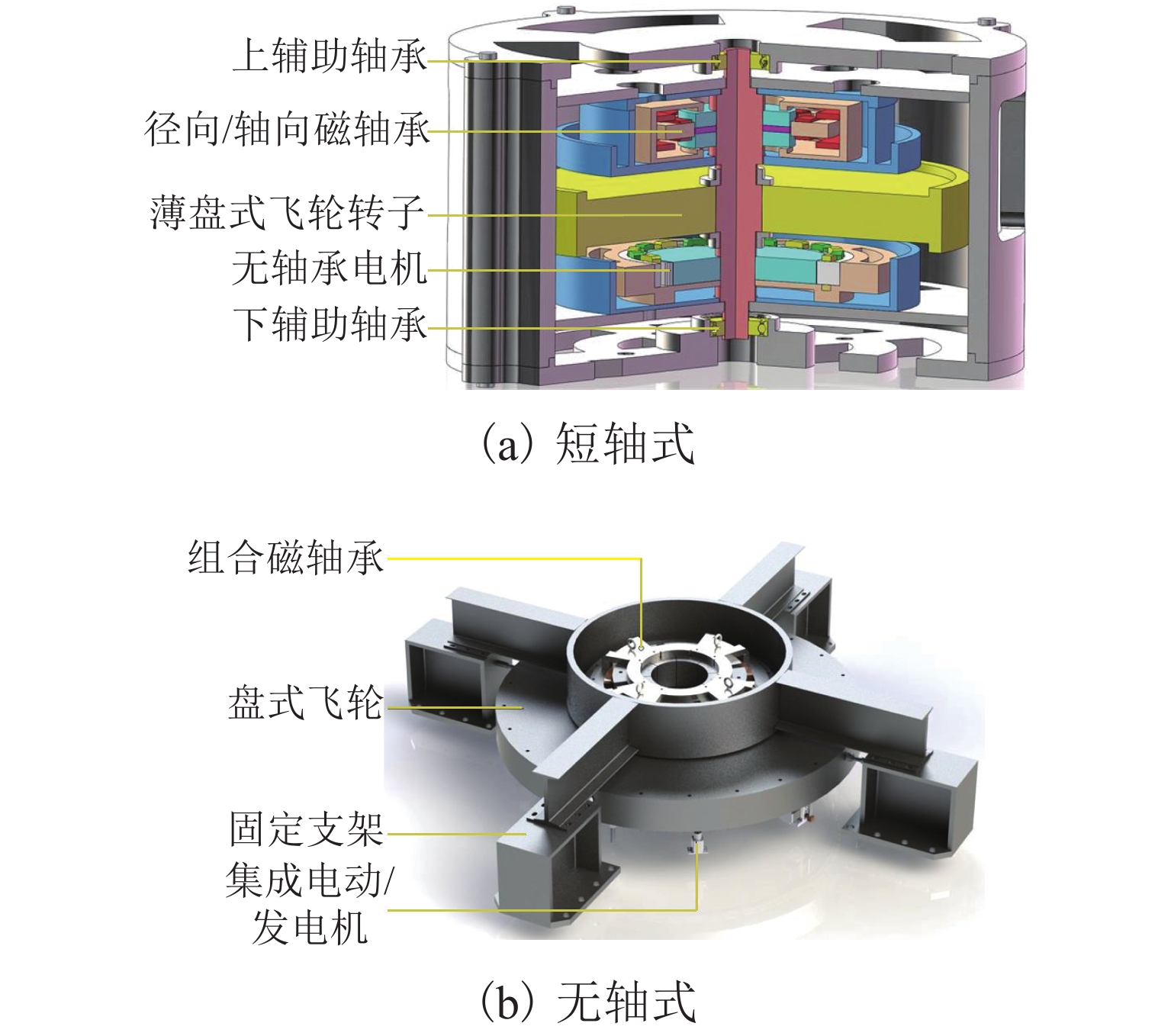

作为飞轮电池(飞轮储能系统)中的核心部件,磁悬浮支承-飞轮系统能否稳定运行直接影响整个飞轮电池系统的运行品质. 为促进我国新能源技术发展,加快“双碳”目标实现,在大量前沿研究成果的基础上,系统分析并总结了影响系统运行品质的复杂振动行为,归纳出模态自激振动与强迫响应振动是导致飞轮转子系统失稳的主要因素;基于两类不稳定因素,介绍了拓扑结构、动力学建模、控制策略、辅助保护等与系统稳定运行相关的关键技术的研究现状;提出了拓扑轴系高集成化、系统材料合理配比、辅助控制容错能力及备用轴承高可靠性这几个方面是今后研究的重点领域,旨在为实现磁悬浮支承-飞轮系统的高稳定运行提供解决思路.

Abstract:Magnetic suspension support-flywheel system is the core component of a flywheel battery system (flywheel energy storage system), its stable operation directly affects the operation quality of the whole flywheel battery device. In order to promote the development of new energy technology in China and accelerate the realization of “dual carbon” goal, based on a large number of cutting-edge research, the complex vibration behavior which affects the operation quality of system is systematically analyzed and summarized. And it is concluded that modal self-excited vibration and forced response vibration are the two main factors leading to the instability of flywheel rotor system. Then based on the two types of unstable factors, the research status of topological structure, dynamic modeling, control strategy, auxiliary protection and other key technologies related to the stable operation of the system are introduced. Moreover, research prospects were proposed for high integration of topological shafting, reasonable ratio of system materials, fault tolerance of auxiliary control, and high reliability of spare bearings. The study provides solutions for the high stability of magnetic suspension support-flywheel system.

-

Key words:

- magnetic suspension /

- flywheel rotor system /

- stability /

- key technologies

-

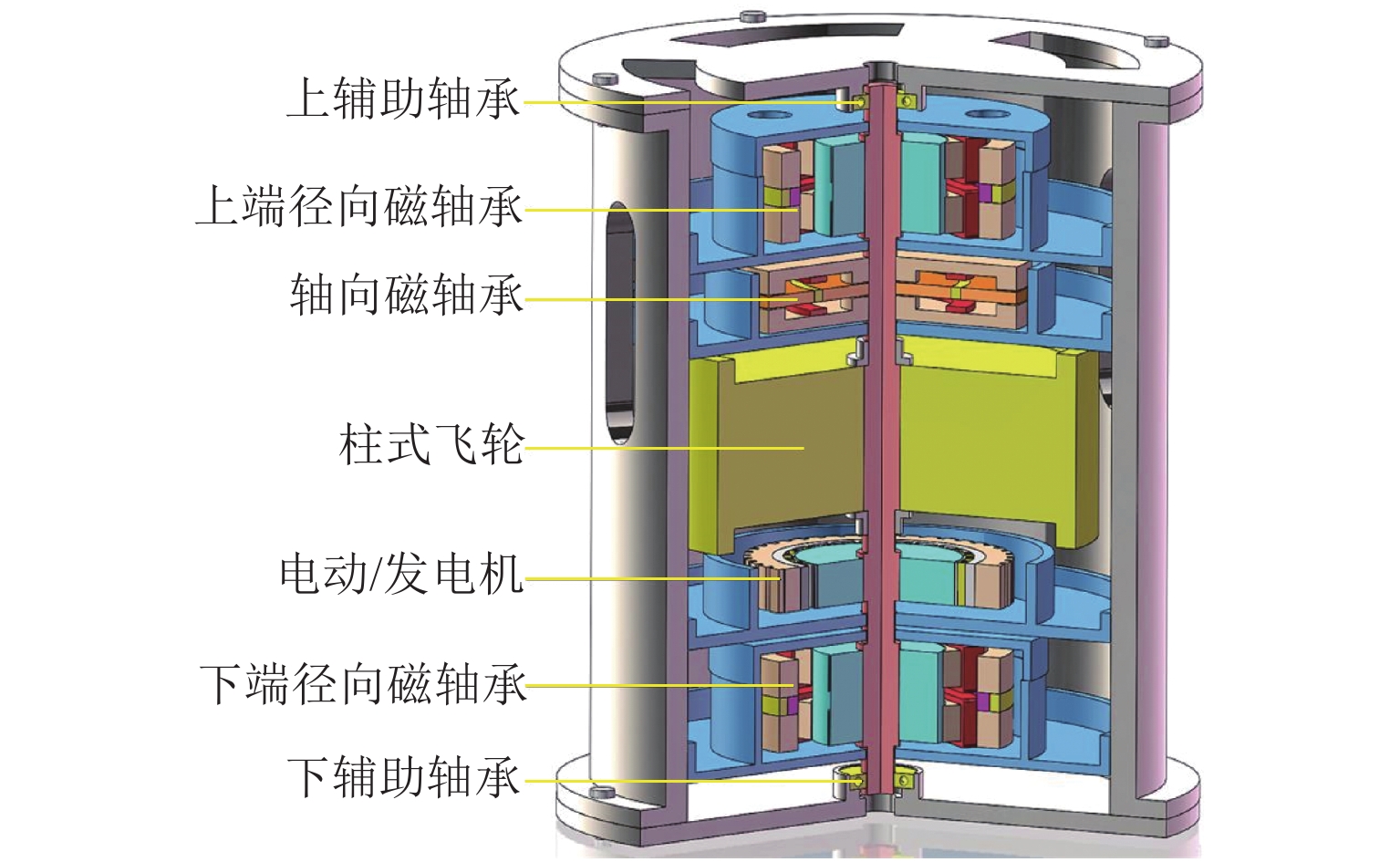

表 1 抑制飞轮转子振动的控制策略

Table 1. Control strategy to suppress flywheel vibration

控制目标 控制策略 主要方法 抑制模态自激振动(强陀螺效应等) 解耦控制 反馈、特征结构配置、奇异摄动、

智能自适应、逆系统解耦抑制强迫响应振动(不平衡振动等) 不平衡控制 陷波、开环不平衡控制、前馈控制、

最小均方根(least mean square,

LMS)控制、自适应补偿等抗干扰控制 自适应控制、前馈控制、

卡尔曼滤波、重复控制等 -

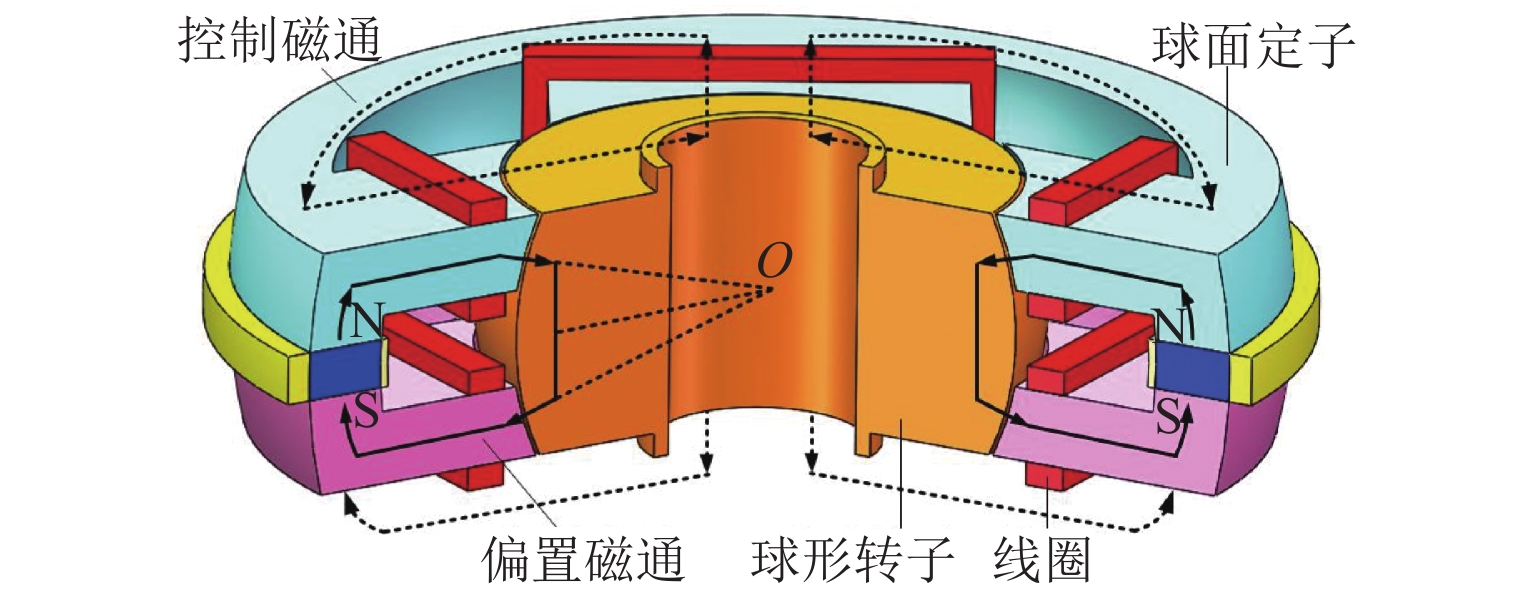

[1] 张维煜,杨恒坤,朱熀秋. 电动汽车用飞轮电池关键技术和技术瓶颈分析[J]. 中国电机工程学报,2018,38(18): 5568-5581.ZHANG Weiyu, YANG Hengkun, ZHU Huangqiu. Key technologies and technical bottleneck analysis of flywheel battery systems for electric vehicle[J]. Proceedings of the CSEE, 2018, 38(18): 5568-5581. [2] PICHOT M A, KAJS J P, MURPHY B R, et al. Active magnetic bearings for energy storage systems for combat vehicles[J]. IEEE Transactions on Magnetics, 2001, 37(1): 318-323. doi: 10.1109/20.911846 [3] PARK C H, CHOI S K, SON Y S, et al. Development of 5 kWh flywheel energy storage system using MATLAB/xPC target[C]//Proceedings of 2009 WRI World Congress on Computer Science and Information Engineering. Los Angeles: IEEE, 2009: 701-705. [4] 董瑞. 飞轮电池在分布式电源微网中对电能质量的改善作用[D]. 兰州: 兰州理工大学, 2013. [5] KOMORI M, UCHIMURA Y. Improving the dynamics of two types of flywheel energy storage systems with SMBs[J]. IEEE Transactions on Applied Superconductivity, 2005, 15(2): 2261-2264. doi: 10.1109/TASC.2005.849626 [6] MASLEN E H, SCHWEITZER G, BLEULER H, et al. Magnetic bearings—theory, design and application to rotating machinery[M]. Heidelberg: Springer-Verlag, 2009. [7] TAKAHASHI N. Reviews of magnetic bearing development in Japan[J]. Journal of System Design and Dynamics, 2013, 7(2): 111-126. doi: 10.1299/jsdd.7.111 [8] NAYEK B, DAS A S, DUTT J K. Model based estimation of inertial parameters of a rigid rotor having dynamic unbalance on Active Magnetic Bearings in presence of noise[J]. Applied Mathematical Modelling, 2021, 97: 701-720. doi: 10.1016/j.apm.2021.04.015 [9] 姜豪. 舰船电磁轴承-转子系统动力学建模和高频噪声抑制方法研究[D]. 武汉: 海军工程大学, 2019. [10] YUBISUI Y, KOBAYASHI S, AMANO R, et al. Effects of nonlinearity of magnetic force on passing through a critical speed of a rotor with a superconducting bearing[J]. IEEE Transactions on Applied Superconductivity, 2013, 23(3): 5202205.1-5202205.5. [11] 张剀,张小章. 磁轴承不平衡控制技术的研究进展[J]. 中国机械工程,2010,21(8): 897-903.ZHANG Kai, ZHANG Xiaozhang. A review of unbalance control technology of active magnetic bearings[J]. China Mechanical Engineering, 2010, 21(8): 897-903. [12] 任正义,周元伟,马燕芹,等. 盘式和柱式飞轮转子系统临界转速分析[J]. 储能科学与技术,2018,7(5): 821-827. doi: 10.12028/j.issn.2095-4239.2018.0076REN Zhengyi, ZHOU Yuanwei, MA Yanqin, et al. Critical speed analysis of disc and column flywheel rotor system[J]. Energy Storage Science and Technology, 2018, 7(5): 821-827. doi: 10.12028/j.issn.2095-4239.2018.0076 [13] 任正义,周元伟,张绍武,等. 转动惯量比对飞轮转子系统稳定性影响[J]. 机械设计与制造,2020(3): 203-206. doi: 10.3969/j.issn.1001-3997.2020.03.049REN Zhengyi, ZHOU Yuanwei, ZHANG Shaowu, et al. Influence of moment of inertia ratio on stability of flywheel rotor system[J]. Machinery Design & Manufacture, 2020(3): 203-206. doi: 10.3969/j.issn.1001-3997.2020.03.049 [14] LI X J, ANVARI B, PALAZZOLO A, et al. A utility-scale flywheel energy storage system with a shaftless, hubless, high-strength steel rotor[J]. IEEE Transactions on Industrial Electronics, 2018, 65(8): 6667-6675. doi: 10.1109/TIE.2017.2772205 [15] 张瑞煜,祝长生. 飞轮轴向永磁轴承的径向干扰力分析与控制研究[J]. 机电工程,2019,36(9): 879-885. doi: 10.3969/j.issn.1001-4551.2019.09.001ZHANG Ruiyu, ZHU Changsheng. Analysis and control of radial disturbing force of the axial permanent magnetic bearing in flywheel[J]. Journal of Mechanical & Electrical Engineering, 2019, 36(9): 879-885. doi: 10.3969/j.issn.1001-4551.2019.09.001 [16] WERFEL F N, FLOEGEL-DELOR U, RIEDEL T, et al. Towards high-capacity HTS flywheel systems[J]. IEEE Transactions on Applied Superconductivity, 2010, 20(4): 2272-2275. doi: 10.1109/TASC.2010.2048708 [17] TOH C S, CHEN S L. Design and control of a ring-type flywheel battery system with hybrid Halbach magnetic bearings[C]//Proceedings of 2014 IEEE/ASME International Conference on Advanced Intelligent Mechatronics. Besacon: IEEE, 2014: 1558-1562. [18] WANG K, WANG D, SHEN Y, et al. Subdomain method for permanent magnet biased homo-polar radial magnetic bearing[J]. IEEE Transactions on Magnetics, 2016, 52(7): 1-5. [19] 李丽君,樊亚洪,袁军. 磁悬浮万向飞轮在卫星姿态机动中的应用[J]. 机械工程学报,2015,51(16): 206-212. doi: 10.3901/JME.2015.16.206LI Lijun, FAN Yahong, YUAN Jun. Application of magnetically suspended gimbaling flywheel in satellite attitude maneuver[J]. Journal of Mechanical Engineering, 2015, 51(16): 206-212. doi: 10.3901/JME.2015.16.206 [20] 王卫杰,任元,刘强,等. 球面磁悬浮万向飞轮转子轮盘优化设计[J]. 航空学报,2016,37(9): 2874-2883.WANG Weijie, REN Yuan, LIU Qiang, et al. Optimal design of rotary table for spherical rotor of magnetically suspending gambling flywheel[J]. Acta Aeronautica et Astronautica Sinica, 2016, 37(9): 2874-2883. [21] 赵航,缪存孝,张立元,等. 磁悬浮径向球面纯电磁磁轴承的设计[J]. 北京航空航天大学学报,2017,43(1): 159-166.ZHAO Hang, MIAO Cunxiao, ZHANG Liyuan, et al. Maglev electromagnetic radial spherical magnetic bearing design[J]. Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(1): 159-166. [22] 缪存孝,赵航,韩天,等. 一种低干扰力矩的三自由度球面磁轴承[J]. 宇航学报,2016,37(12): 1491-1499. doi: 10.3873/j.issn.1000-1328.2016.12.012MIAO Cunxiao, ZHAO Hang, HAN Tian, et al. Three-degree-of-freedom spherical magnetic bearing with low interference torque[J]. Journal of Astronautics, 2016, 37(12): 1491-1499. doi: 10.3873/j.issn.1000-1328.2016.12.012 [23] 康龙云, 李海滨, 曹秉刚. 一种悬浮飞轮电池: 中国, CN200310118907. X [P]. 2006-04-26. [24] ZHANG W Y, YANG H K, CHENG L, et al. Modeling based on exact segmentation of magnetic field for a centripetal force type-magnetic bearing[J]. IEEE Transactions on Industrial Electronics, 2020, 67(9): 7691-7701. [25] ZHANG W Y, CHENG L, ZHU H Q. Suspension force error source analysis and multidimensional dynamic model for a centripetal force type-magnetic bearing[J]. IEEE Transactions on Industrial Electronics, 2020, 67(9): 7617-7628. doi: 10.1109/TIE.2019.2946568 [26] ZHANG W Y, ZHANG L D, LI K, et al. Dynamic correction model considering influence of foundation motions for a centripetal force type-magnetic bearing[J]. IEEE Transactions on Industrial Electronics, 2021, 68(10): 9811-9821. doi: 10.1109/TIE.2020.3028817 [27] 徐旸,时振刚,赵雷,等. 电磁轴承阻尼上限的动态特性分析[J]. 武汉理工大学学报(信息与管理工程版),2010,32(2): 238-240.XU Yang, SHI Zhengang, ZHAO Lei, et al. Maximum damping limit of active magnetic bearing[J]. Journal of Wuhan University of Technology (Information & Management Engineering), 2010, 32(2): 238-240. [28] BEHRENS S, FLEMING A J, MOHEIMANI S O R. Passive vibration control via electromagnetic shunt damping[J]. IEEE/ASME Transactions on Mechatronics, 2005, 10(1): 118-122. doi: 10.1109/TMECH.2004.835341 [29] SASAKI M, SUGIURA T. Vibration reduction of rotor supported by superconducting magnetic bearing utilizing electromagnetic shunt damper[J]. IEEE Transactions on Applied Superconductivity, 2016, 26(3): 1-4. [30] 谢振宇,张景亭,高华,等. 带阻尼器磁悬浮轴承转子系统的不平衡响应[J]. 中国机械工程,2009,20(3): 327-330. doi: 10.3321/j.issn:1004-132X.2009.03.017XIE Zhenyu, ZHANG Jingting, GAO Hua, et al. Unbalance response of active magnetic bearing system with magnetic damper[J]. China Mechanical Engineering, 2009, 20(3): 327-330. doi: 10.3321/j.issn:1004-132X.2009.03.017 [31] 谢振宇,李克雷,赵钦泉,等. 磁悬浮阻尼器对磁悬浮转子系统动态特性影响[J]. 航空动力学报,2008,23(6): 1087-1092.XIE Zhenyu, LI Kelei, ZHAO Qinquan, et al. Influence of magnetic damper on dynamic characteristics of magnetic bearing system[J]. Journal of Aerospace Power, 2008, 23(6): 1087-1092. [32] 闻声,胡雄心,于振杰,等. 新型同位阻尼磁轴承模型及其特性研究[J]. 机电工程,2016,33(7): 831-835.WEN Sheng, HU Xiongxin, YU Zhenjie, et al. Model and characteristics of magnetic bearing with co-located damper[J]. Journal of Mechanical & Electrical Engineering, 2016, 33(7): 831-835. [33] PASSENBRUNNER J, JUNGMAYR G, AMRHEIN W. Simulation and optimization of the starting behavior of an active axial bearing with viscoelastic damping support[C]//Proceedings of 2017 IEEE International Electric Machines and Drives Conference. Miami: IEEE, 2017: 1-6. [34] ZHANG C, WU P, TSENG K J. FEM analyses for the design and modeling of a novel flywheel energy storage system assisted by integrated magnetic bearing[C]// Proceedings of IEEE International Conference on Electric Machines and Drives. San Antonio: IEEE, 2005: 1157-1164. [35] ZINGERLI C M, KOLAR J W. Novel observer based force control for active magnetic bearings[C]// Proceedings of 2010 International Power Electronics Conference. Sapporo: IEEE, 2010: 2189-2196. [36] KHAYYAM U, HE B X, HASSAN S U. Active magnetic bearing design and backstepping-adaptive control for high-speed rotors[J]. IOP Conference Series: Materials Science and Engineering, 2020, 853(1): 012025.1-012025.10. [37] TANG J Q, WANG K, XIANG B. Stable control of high-speed rotor suspended by superconducting magnetic bearings and active magnetic bearings[J]. IEEE Transactions on Industrial Electronics, 2017, 64(4): 3319-3328. doi: 10.1109/TIE.2016.2542786 [38] 张钢, 李松生, 张建生, 等. 磁悬浮轴承-转子系统的机电耦合动力学模型[J]. 机械科学与技术, 2003, 22(增1): 40-43.ZHANG Gang, LI Songsheng, ZHANG Jiansheng, et al. Coupled electromechanical dynamic model of rotor-magnetic bearings system[J]. Mechanical Science and Technology, 2003, 22(S1): 40-43. [39] HAN B C, CHEN Y L, ZHENG S Q, et al. Robust control for a magnetically suspended control moment gyro with strong gyroscopic effects[C]//Proceedings of 44th Annual Conference of the IEEE Industrial Electronics Society. Washington D. C.: IEEE, 2018: 2440-2446. [40] LIN F J, HUANG M S, CHEN S Y. Intelligent double integral sliding-mode control for five-degree-of-freedom active magnetic bearing system[J]. IET Control Theory & Applications, 2011, 5(11): 1287-1303. [41] SONI T, DUTT J K, DAS A S. Dynamic behavior and stability of energy efficient electro-magnetic suspension of rotors involving time delay[J]. Energy, 2021, 231: 120906.1-120906.11. [42] KUMAR P, TIWARI R. Development of a novel approach for quantitative estimation of rotor unbalance and misalignment in a rotor system levitated by active magnetic bearings[J]. Iranian Journal of Science and Technology, Transactions of Mechanical Engineering, 2021, 45(3): 769-786. doi: 10.1007/s40997-020-00364-7 [43] PENG C, FANG J C, CUI P L. Dynamics modeling and measurement of the microvibrations for a magnetically suspended flywheel[J]. IEEE Transactions on Instrumentation and Measurement, 2015, 64(12): 3239-3252. doi: 10.1109/TIM.2015.2459491 [44] YANG W J, QUÉVAL L, MA G T, et al. A 3-D strong-coupled electromagnetic-thermal model for HTS bulk and its uses to study the dynamic characteristics of a linear HTS maglev bearing[J]. IEEE Transactions on Applied Superconductivity, 2020, 30(6): 1-14. [45] 杨红进. 车载飞轮电池减振机理研究[D]. 南京: 南京航空航天大学, 2015. [46] 卢聪慧,胡业发,王晓光. 路面随机激励下车载盘状磁悬浮转子振动的研究[J]. 机械制造,2009,47(9): 21-24. doi: 10.3969/j.issn.1000-4998.2009.09.008 [47] JARROUX C, MAHFOUD J, DEFOY B, et al. Stability of rotating machinery supported on active magnetic bearings subjected to base excitation[J]. Journal of Vibration and Acoustics, 2020, 142(3): 031004.1-031004.7. [48] 张薇薇,胡业发. 磁悬浮轴承-转子-基础系统的耦合动力学模型[J]. 机械设计与制造,2008(11): 137-139. doi: 10.3969/j.issn.1001-3997.2008.11.054ZHANG Weiwei, HU Yefa. Coupled dynamic model of magnetic bearings-rotor-base system[J]. Machinery Design & Manufacture, 2008(11): 137-139. doi: 10.3969/j.issn.1001-3997.2008.11.054 [49] 姜豪,苏振中,王东. 运动平台上磁轴承-转子系统的动力学建模[J]. 电工技术学报,2019,34(23): 4880-4889.JIANG Hao, SU Zhenzhong, WANG Dong. Dynamic modeling of magnetic bearing-rotor system on moving platform[J]. Transactions of China Electrotechnical Society, 2019, 34(23): 4880-4889. [50] 金光宇,陈劭,徐向波. 车载磁悬浮飞轮电池动力学分析及悬浮研究[J]. 林业机械与木工设备,2018,46(4): 23-28.JIN Guangyu, CHEN Shao, XU Xiangbo. Dynamic analysis and static suspension research on vehicle-mounted magnetic suspension flywheel batteries[J]. Forestry Machinery & Woodworking Equipment, 2018, 46(4): 23-28. [51] 高琳,徐宗海,朱凯,等. 锥形磁悬浮轴承的建模与解耦控制[J]. 中国电机工程学报,2013,33(6): 153-160,21.GAO Lin, XU Zonghai, ZHU Kai, et al. Modeling and decoupling control of conical magnetic bearings[J]. Proceedings of the CSEE, 2013, 33(6): 153-160,21. [52] ZHENG S Q, YANG J Y, SONG X D, et al. Tracking compensation control for nutation mode of high-speed rotors with strong gyroscopic effects[J]. IEEE Transactions on Industrial Electronics, 2018, 65(5): 4156-4165. doi: 10.1109/TIE.2017.2767559 [53] SAHA S, AMRR S M, SAIDI A S, et al. Finite-time adaptive higher-order SMC for the nonlinear five DOF active magnetic bearing system[J]. Electronics, 2021, 10(11): 1333.1-1333.20. [54] CHEN L L, ZHU C S, ZHONG Z X, et al. Radial position control for magnetically suspended high-speed flywheel energy storage system with inverse system method and extended 2-DOF PID controller[J]. IET Electric Power Applications, 2020, 14(1): 71-81. doi: 10.1049/iet-epa.2019.0512 [55] 刘彬,房建成,刘刚,等. 磁悬浮飞轮不平衡振动控制方法与试验研究[J]. 机械工程学报,2010,46(12): 188-194. doi: 10.3901/JME.2010.12.188LIU Bin, FANG Jiancheng, LIU Gang, et al. Unbalance vibration control and experiment research of magnetically suspended flywheels[J]. Journal of Mechanical Engineering, 2010, 46(12): 188-194. doi: 10.3901/JME.2010.12.188 [56] 刘超,刘刚,赵光再. 主被动磁悬浮高速转子系统的自动平衡控制[J]. 光学 精密工程,2015,23(3): 714-722. doi: 10.3788/OPE.20152303.0714LIU Chao, LIU Gang, ZHAO Guangzai. Autobalancing control of high-speed rotor suspended by active-passive hybrid magnetic bearings[J]. Optics and Precision Engineering, 2015, 23(3): 714-722. doi: 10.3788/OPE.20152303.0714 [57] 张德魁,江伟,赵鸿宾. 磁悬浮轴承系统不平衡振动控制的方法[J]. 清华大学学报(自然科学版),2000,40(10): 28-31. doi: 10.3321/j.issn:1000-0054.2000.10.008ZHANG Dekui, JIANG Wei, ZHAO Hongbin. Unbalance vibration control methods for active magnetic bearings system[J]. Journal of Tsinghua University (Science and Technology), 2000, 40(10): 28-31. doi: 10.3321/j.issn:1000-0054.2000.10.008 [58] CHEN S L, LIN S Y, TOH C S. Adaptive unbalance compensation for a three-pole active magnetic bearing system[J]. IEEE Transactions on Industrial Electronics, 2020, 67(3): 2097-2106. doi: 10.1109/TIE.2019.2903747 [59] LIU G, LI J L, ZHENG S Q, et al. Suppression of synchronous current using double input improved adaptive Notch filter algorithm[J]. IEEE Transactions on Industrial Electronics, 2020, 67(10): 8599-8607. doi: 10.1109/TIE.2019.2947852 [60] GERAMI A, FITTRO R, KNOSPE C. Improving disturbance rejection in nonlinear active magnetic bearing systems: using lur’e formulation[J]. Journal of Dynamic Systems, Measurement, and Control, 2020, 142(4): 041007.1-041007.8. [61] 蒋科坚,祝长生,乔晓利,等. 移动载体上电磁轴承-转子系统的基础激励振动主动抑制[J]. 机械工程学报,2014,50(11): 108-118. doi: 10.3901/JME.2014.11.108JIANG Kejian, ZHU Changsheng, QIAO Xiaoli, et al. Suppressing vibration due to base motion for active magnetic bearings-rotor system equipped on moving carrier[J]. Journal of Mechanical Engineering, 2014, 50(11): 108-118. doi: 10.3901/JME.2014.11.108 [62] MARX S, NATARAJ C. Suppression of base excitation of rotors on magnetic bearings[J]. International Journal of Rotating Machinery, 2007, 2007: 1-10. [63] 姜豪,苏振中,王东. 磁轴承基于扩展卡尔曼滤波的改进PID控制算法研究[J]. 电机与控制应用,2018,45(3): 72-77. doi: 10.3969/j.issn.1673-6540.2018.03.013JIANG Hao, SU Zhenzhong, WANG Dong. Improvement of magnetic bearing based on extended Kalman filter research on PID control algorithm[J]. Electric Machines & Control Application, 2018, 45(3): 72-77. doi: 10.3969/j.issn.1673-6540.2018.03.013 [64] CUI P L, WANG Q R, LI S, et al. Combined FIR and fractional-order repetitive control for harmonic current suppression of magnetically suspended rotor system[J]. IEEE Transactions on Industrial Electronics, 2017, 64(6): 4828-4835. doi: 10.1109/TIE.2017.2668985 [65] CUI P L, WANG Q R, ZHANG G X, et al. Hybrid fractional repetitive control for magnetically suspended rotor systems[J]. IEEE Transactions on Industrial Electronics, 2018, 65(4): 3491-3498. doi: 10.1109/TIE.2017.2752119 [66] 江绪鑫,徐龙祥. 基于特征模型的主动磁轴承交叉反馈控制研究[J]. 机械制造与自动化,2020,49(2): 212-215.JIANG Xuxin, XU Longxiang. Study of characteristic model based cross-feedback control of active magnetic bearing[J]. Machine Building & Automation, 2020, 49(2): 212-215. [67] MOLINA L M C, BONFITTO A, GALLUZZI R. Offset-Free Model Predictive Control for a cone-shaped active magnetic bearing system[J]. Mechatronics, 2021, 78: 102612.1-102612.14. [68] 万金贵,汪希平,夏翠艳,等. 电磁轴承系统中的辅助轴承与振动影响[J]. 哈尔滨轴承,2006,27(3): 6-9. doi: 10.3969/j.issn.1672-4852.2006.03.002WAN Jingui, WANG Xiping, XIA Cuiyan, et al. Assistant bearing with its vibration effect in active magnetic bearing system[J]. Journal of Harbin Bearing, 2006, 27(3): 6-9. doi: 10.3969/j.issn.1672-4852.2006.03.002 [69] KONG Y N, XUE Y J, YE J, et al. Analysis on the impact factors of auxiliary bearing in vertical magnetic bearing[C]//Proceedings of 2nd World Conference on Mechanical Engineering and Intelligent Manufacturing (WCMEIM). Shanghai: IEEE, 2019: 64-68. [70] TANGREDI A, MELI E, RINDI A, et al. Development and experimental validation of auxiliary rolling bearing models for active magnetic bearings (AMBs) applications[J]. International Journal of Rotating Machinery, 2019, 2019: 4675286.1-4675286.19. [71] KEOGH P S, YONG W Y. Thermal assessment of dynamic rotor/auxiliary bearing contact events[J]. Journal of Tribology, 2007, 129(1): 143-152. doi: 10.1115/1.2401209 [72] YU C T, SUN Y M, WANG H C, et al. Dynamic analysis of magnetic bearing rotor dropping on radial and axial integrated auxiliary bearing[J]. Mechanism and Machine Theory, 2019, 140: 622-640. doi: 10.1016/j.mechmachtheory.2019.06.015 [73] SUN G. Rotor drop and following thermal growth simulations using detailed auxiliary bearing and damper models[J]. Journal of Sound and Vibration, 2006, 289(1/2): 334-359. [74] 何梁,杨国军,刘兴男,等. 带缓冲垫圈的辅助轴承结构特性研究及仿真分析[J]. 润滑与密封,2016,41(11): 15-19. doi: 10.3969/j.issn.0254-0150.2016.11.004HE Liang, YANG Guojun, LIU Xingnan, et al. Structure characteristics research of auxiliary bearing with buffer shim and simulation[J]. Lubrication Engineering, 2016, 41(11): 15-19. doi: 10.3969/j.issn.0254-0150.2016.11.004 [75] COLE M O T, KEOGH P S, BURROWS C R. The dynamic behavior of a rolling element auxiliary bearing following rotor impact[J]. Journal of Tribology, 2002, 124(2): 406-413. doi: 10.1115/1.1430673 [76] KANG X, PALAZZOLO A, ZHONG W. Auxiliary bearing squeeze film dampers for magnetic bearing supported rotors[J]. Tribology International, 2020, 146: 106181.1-106181.17. -

下载:

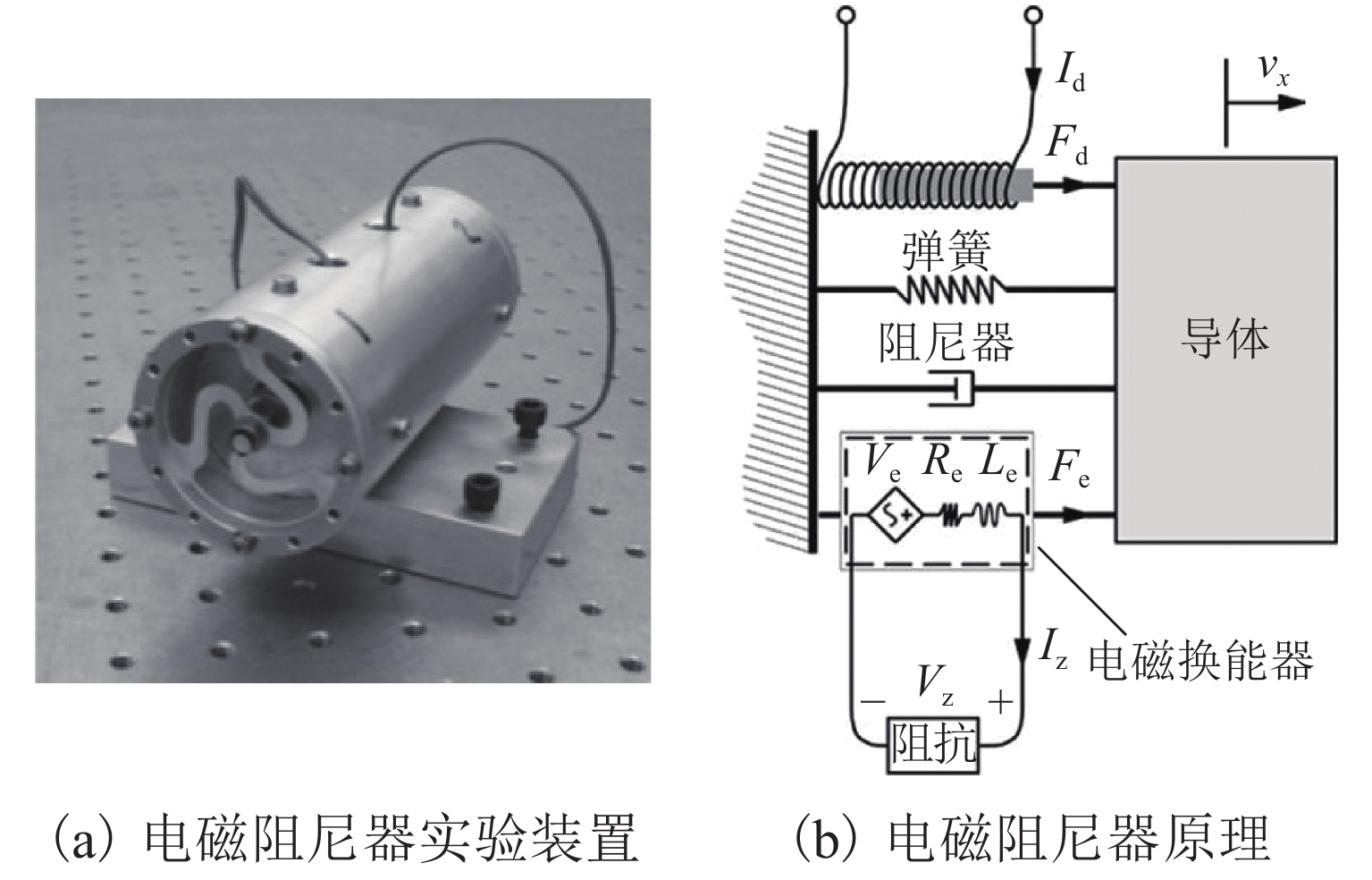

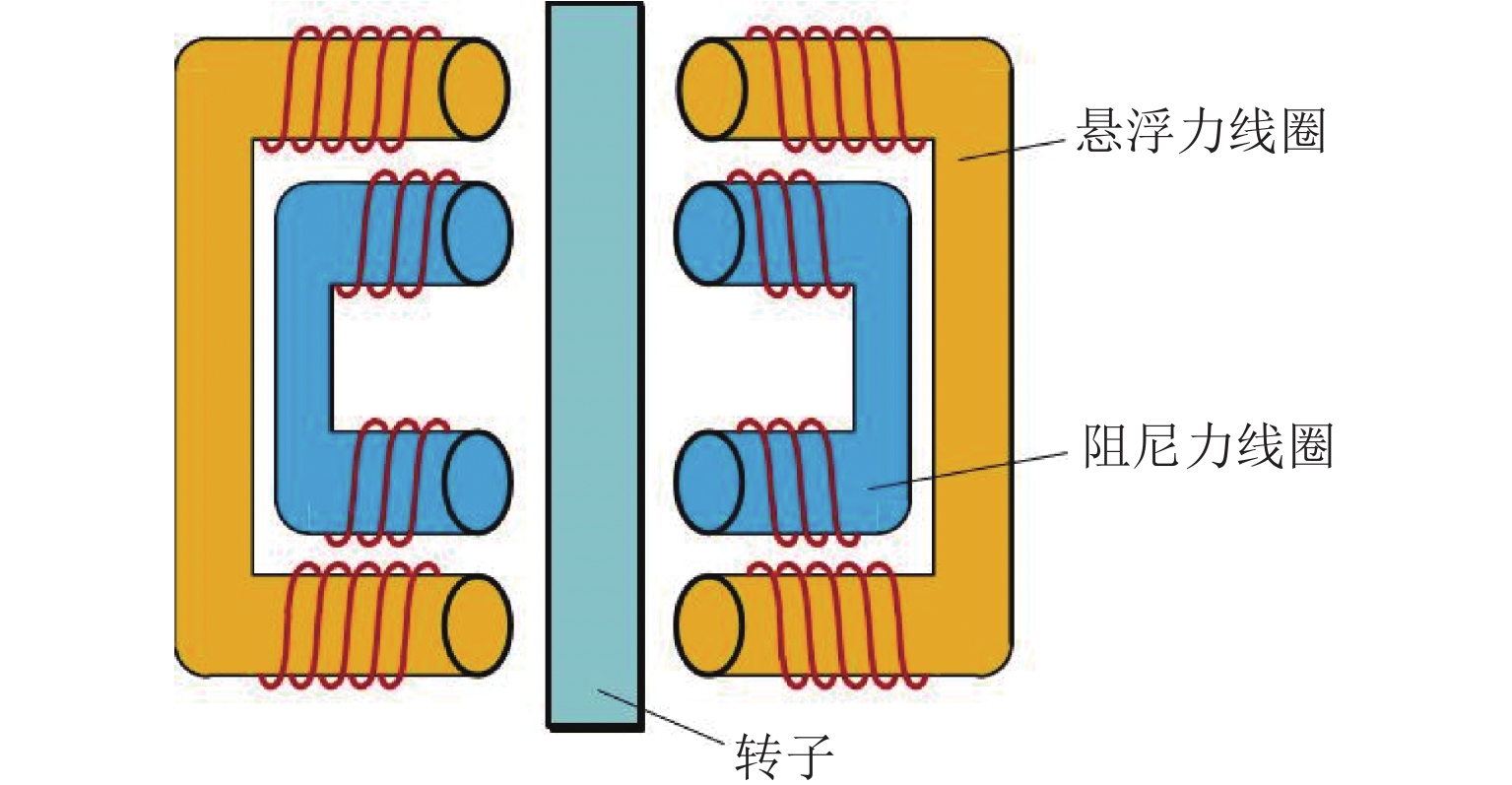

下载: