Fatigue Characteristic of High-Frequency Vibration for CRTS Ⅱ Track Slab

-

摘要:

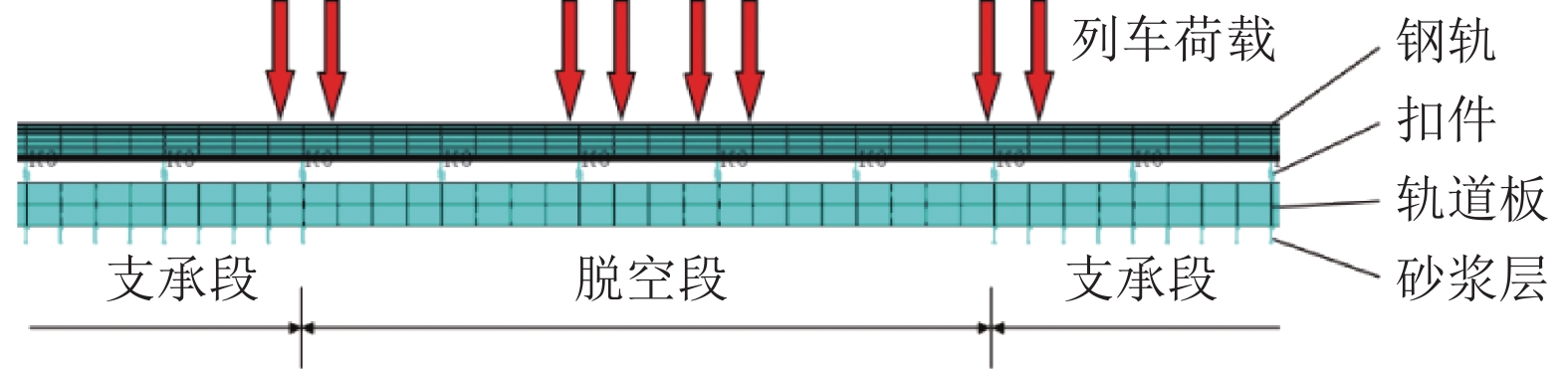

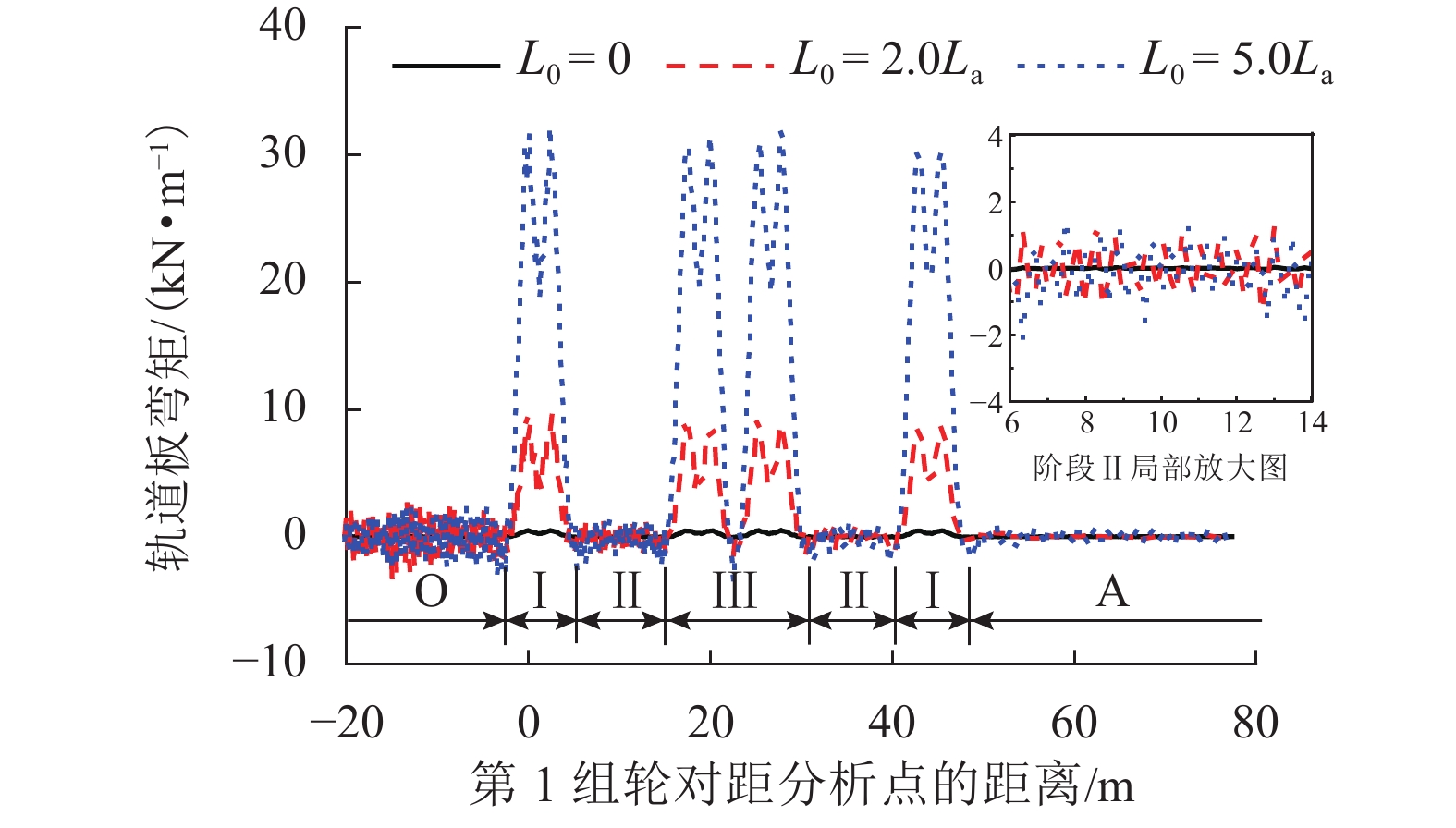

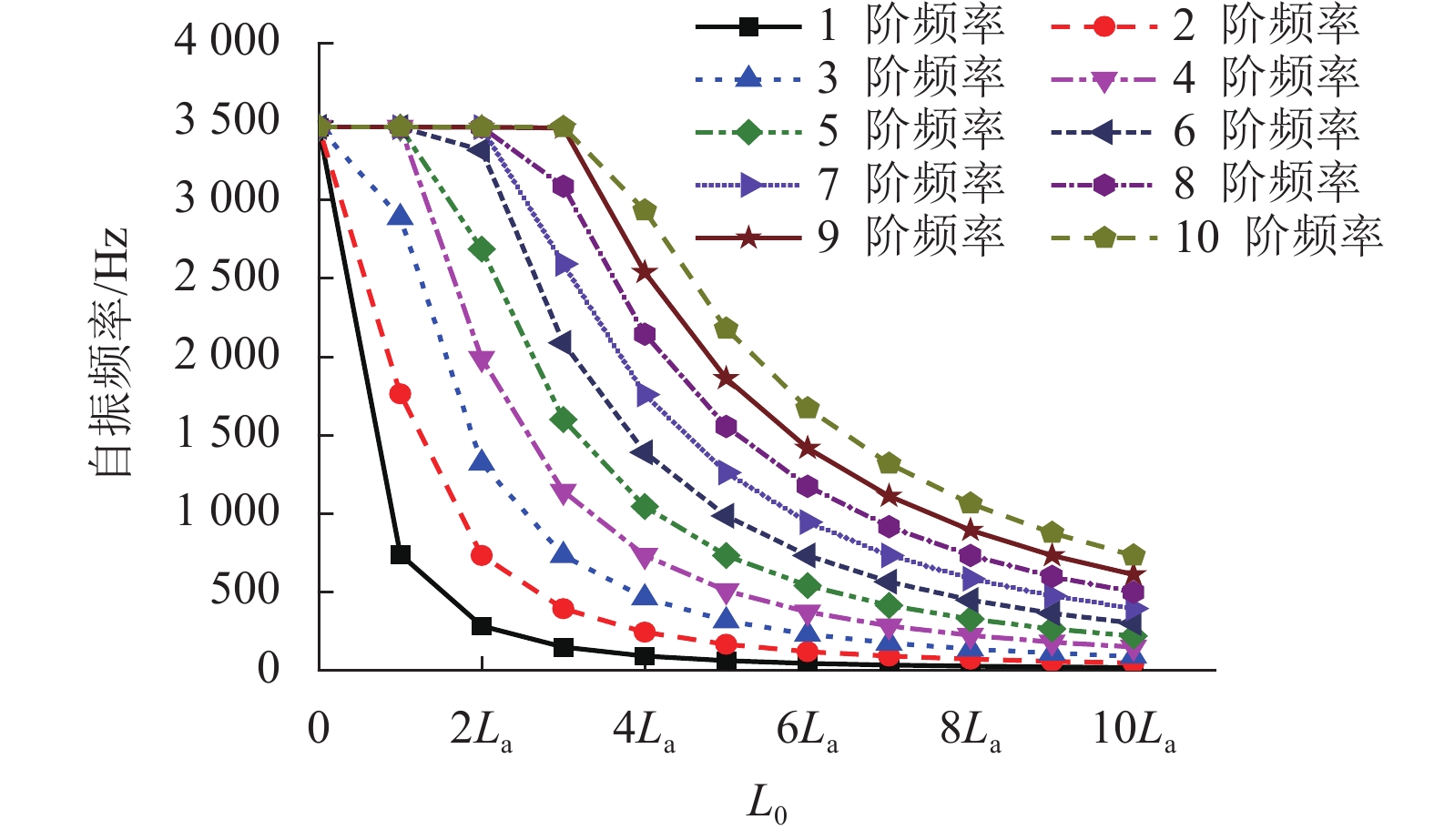

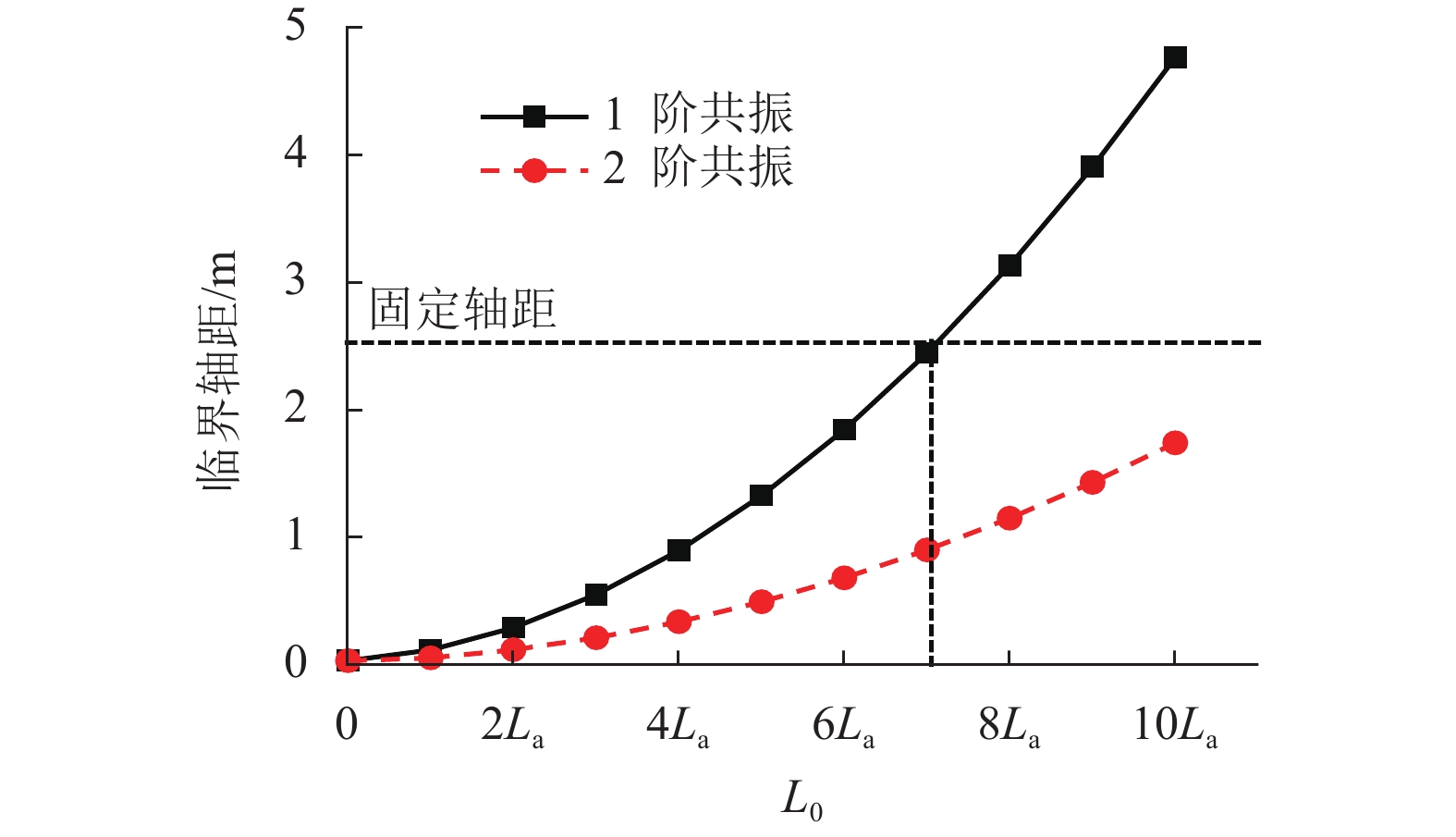

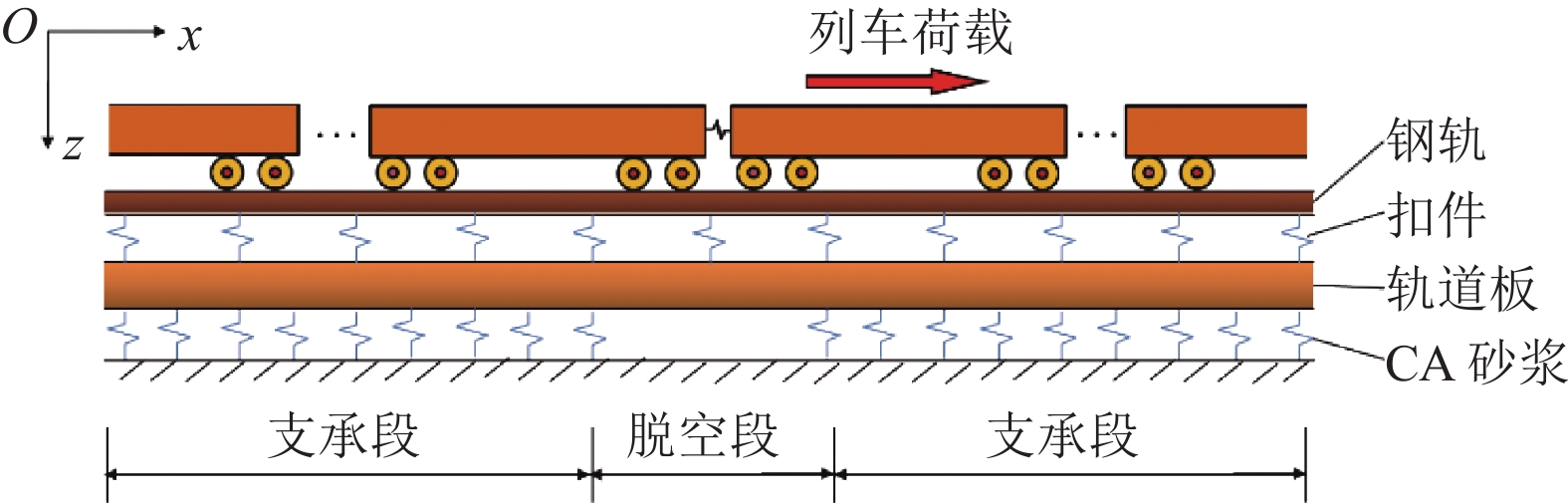

列车轮载作用会引发轨道板的高频自振效应. 为分析高频荷载下CRTS Ⅱ型轨道板的疲劳特性以及板体自振效应对疲劳寿命的影响程度,基于现有的疲劳损伤准则,探究轮对作用间隙阶段轨道板自振影响下的疲劳特性. 对脱空长度影响下轨道板的疲劳寿命进行预测,并与仅考虑荷载作用次数的结果进行对比. 结果表明:轨道结构完好时,列车轮载引发轨道板伤损的可能性较小;若列车行车速度为360 km/h,列车轮载在引发轨道板共振前即发生板底开裂;轨道结构完好时,列车轮载引发的板体自振效应对轨道板疲劳损伤影响程度最大,此时列车轮载对轨道板产生约1.8倍的疲劳荷载当量;当轨道板脱空长度大于2.0倍枕距后,可忽略板体自振对疲劳损伤的影响;轨道板的脱空长度大于3.2倍枕距后,现场无砟轨道难以维持60 a的使用寿命.

-

关键词:

- 无砟轨道 /

- CRTS Ⅱ型轨道板 /

- 疲劳特性 /

- 板体自振 /

- 局部脱空

Abstract:The effect of the wheel load could cause the self-vibration effect of high frequency for the track slab. To analyze the fatigue characteristic of CRTS Ⅱ track slab under high-frequency load and the effect of the self-vibration of the track slab on its fatigue life, the fatigue characteristics of the track slab under the influence of this self-vibration during the interval in the wheelset was explored on the basis of existing fatigue damage criteria. The fatigue life of the track slab was predicted with reference to the effect of the de-bonding length, and the results obtained were compared with the results obtained when only the number of load actions was considered. Results show that, the possibility of damage to the track slab caused by the train wheel load is reduced when the track structure is intact. The bottom of the track slab would crack before resonance triggering occurred if the train speed was 360 km/h. When the track structure is intact, the self-vibration effect in the track slab caused by the wheel load has its greatest impact on the fatigue damage to the track slab, and the wheel load produces approximately 1.8 times the equivalent fatigue load to the track slab. The effect of the self-vibration effect in the track slab on the fatigue damage could be ignored when the slab de-bonding length is more than twice the distance between sleepers. When de-bonding length of the track slab is more than 3.2 times the distance between sleepers, it becomes difficult for the ballastless track on-site to maintain its expected 60-year service life.

-

表 1 主要计算参数

Table 1. Main calculation parameters

部件 项目 取值 钢轨 弹性模量/Pa 2.06 × 1011 惯性矩/m4 7.745 × 10−3 密度/(kg•m−3) 7850 泊松比 0.30 扣件刚度/(N•m−1) 6.0 × 107 轨道板 弹性模量/Pa 3.55 × 1010 密度/(kg•m−3) 2400 泊松比 0.20 宽度(厚度)/m 2.55 (0.20) CA砂浆 弹性模量/Pa 7.0 × 109 厚度/m 0.03 单向受压刚度/(N•m−2) 5.95 × 1011 -

[1] 刘笑凯,刘学毅,肖杰灵,等. 温度作用下纵连式无砟轨道垂向稳定性研究[J]. 西南交通大学学报,2018,53(5): 921-927, 944. doi: 10.3969/j.issn.0258-2724.2018.05.007LIU Xiaokai, LIU Xueyi, XIAO Jieling, et al. Vertical stability of longitudinal continuous ballastless track under temperature variation[J]. Journal of Southwest Jiaotong University, 2018, 53(5): 921-927, 944. doi: 10.3969/j.issn.0258-2724.2018.05.007 [2] 张鹏飞,桂昊,雷晓燕. CRTS Ⅱ型板断裂条件下桥上无缝线路伸缩力特性[J]. 西南交通大学学报,2020,55(5): 1036-1043.ZHANG Pengfei, GUI Hao, LEI Xiaoyan. Expansion-constriction force characteristics of continuously rails on bridge under fracture condition of CRTS Ⅱ track slab welded[J]. Journal of Southwest Jiaotong University, 2020, 55(5): 1036-1043. [3] LICHTBERGER B. Track compendium: formation, permanent way, maintenance, economics[M]. Hamburg: Eurail Press, 2005. [4] 李培刚. CRTS Ⅱ型板式轨道层间损伤及其影响研究[D]. 成都: 西南交通大学, 2015: 18-19. [5] 宋玉普,王怀亮,贾金青. 混凝土的多轴疲劳性能[J]. 建筑结构学报,2008,29(增刊1): 260-265.SONG Yupu, WANG Huailiang, JIA Jinqing. Behavior of concrete under multi-axial fatigue loading[J]. Journal of Building Structures, 2008, 29(S1): 260-265. [6] 王怀亮,宋玉普. 定侧压混凝土双轴疲劳破坏准则研究[J]. 土木工程学报,2010,43(10): 1-7.WANG Huailiang, SONG Yupu. Criterion of concrete fatigue failure under biaxial fatigue stress and constant confining stress[J]. China Civil Engineering Journal, 2010, 43(10): 1-7. [7] 冯秀峰,宋玉普,朱美春. 随机变幅疲劳荷载下预应力混凝土梁疲劳寿命的试验研究[J]. 土木工程学报,2006,39(9): 32-38. doi: 10.3321/j.issn:1000-131X.2006.09.005FENG Xiufeng, SONG Yupu, ZHU Meichun. An experimental study on the fatigue life of prestressed concrete beams under random-amplitude fatigue loading[J]. China Civil Engineering Journal, 2006, 39(9): 32-38. doi: 10.3321/j.issn:1000-131X.2006.09.005 [8] CORNELISSEN H A W, REINHARDT H W. Uniaxial tensile fatigue failure of concrete under constant- amplitude and programme loading[J]. Magazine of Concrete Research, 1984, 129(36): 216-227. [9] DOBROMIL P, JAN C, RADOMIR P. Material model for finite element modelling of fatigue crack growth in concrete[J]. Procedia Engineering, 2010, 2(1): 203-212. doi: 10.1016/j.proeng.2010.03.022 [10] 刘学毅, 赵坪锐, 杨荣山. 客运专线无砟轨道设计理论与方法[M]. 成都: 西南交通大学出版社, 2010. [11] 徐庆元,林青腾,方子匀,等. 桥上纵连板式无砟轨道疲劳应力谱的理论研究[J]. 西南交通大学学报,2018,53(5): 906-912. doi: 10.3969/j.issn.0258-2724.2018.05.005XU Qingyuan, LIN Qingteng, FANG Ziyun, et al. Theoretical study on fatigue stress spectrum of longitudinal connected slab track on bridge[J]. Journal of Southwest Jiaotong University, 2018, 53(5): 906-912. doi: 10.3969/j.issn.0258-2724.2018.05.005 [12] 徐庆元,林青腾,方子匀,等. 组合荷载下桥上纵连板式无砟轨道疲劳特性[J]. 中国铁道科学,2017,38(6): 37-46. doi: 10.3969/j.issn.1001-4632.2017.06.06XU Qingyuan, LIN Qingteng, FANG Ziyun, et al. Fatigue characteristics of longitudinally connected slab ballastless track on bridge under combined load[J]. China Railway Science, 2017, 38(6): 37-46. doi: 10.3969/j.issn.1001-4632.2017.06.06 [13] POVEDA E, YU R C, LANCHA J C, et al. A numerical study on the fatigue life design of concrete slabs for railway tracks[J]. Engineering Structures, 2015, 100: 455-467. doi: 10.1016/j.engstruct.2015.06.037 [14] TARIFA M, ZHANG X X, RUIZ G, et al. Full-scale fatigue tests of precast reinforced concrete slabs for railway tracks[J]. Engineering Structures, 2015, 100: 610-621. doi: 10.1016/j.engstruct.2015.06.016 [15] KONINGS P. A study on the lifetime aspects of the RHEDA 2000 track system [D]. Delft: Delft University of Technology, 2005. [16] 刘学毅,刘丹,赵坪锐,等. CRTS Ⅲ型板式无砟轨道疲劳性能试验研究[J]. 铁道工程学报,2016,33(11): 51-56,112. doi: 10.3969/j.issn.1006-2106.2016.11.010LIU Xueyi, LIU Dan, ZHAO Pingrui, et al. Experimental research on the fatigue behavior test of CRTS Ⅲ slab track[J]. Journal of Railway Engineering Society, 2016, 33(11): 51-56,112. doi: 10.3969/j.issn.1006-2106.2016.11.010 [17] 童明娜,卢朝辉,赵衍刚,等. CRTS Ⅱ型无砟轨道板疲劳时变可靠度研究[J]. 铁道学报,2020,42(10): 92-100. doi: 10.3969/j.issn.1001-8360.2020.10.013TONG Mingna, LU Zhaohui, ZHAO Yangang, et al. Time-dependent fatigue reliability evaluation of CRTS Ⅱ ballastless track slab[J]. Journal of the China Railway Society, 2020, 42(10): 92-100. doi: 10.3969/j.issn.1001-8360.2020.10.013 [18] CHAPELEAU X, SEDRAN T, COTTINEAU L M, et al. Study of ballastless track structure monitoring by distributed optical fiber sensors on a real-scale mockup in laboratory[J]. Engineering Structures, 2013, 56: 1751-1757. doi: 10.1016/j.engstruct.2013.07.005 [19] 王青,卫军,董荣珍,等. CRTS Ⅱ板式无砟轨道结构的疲劳力学性能分析[J]. 铁道工程学报,2014,31(5): 41-47. doi: 10.3969/j.issn.1006-2106.2014.05.008WANG Qing, WEI Jun, DONG Rongzhen, et al. Fatigue behavior analysis of CRTS Ⅱ slab ballastless track structure[J]. Journal of Railway Engineering Society, 2014, 31(5): 41-47. doi: 10.3969/j.issn.1006-2106.2014.05.008 [20] 曹伟,宋玉普,刘海成. 混凝土三轴变幅拉-压疲劳性能试验研究[J]. 工程力学,2006,23(3): 111-117. doi: 10.3969/j.issn.1000-4750.2006.03.020CAO Wei, SONG Yupu, LIU Haicheng. Fatigue properties of plain concrete under triaxial variable-amplitude tension-compression cyclic loading[J]. Engineering Mechanics, 2006, 23(3): 111-117. doi: 10.3969/j.issn.1000-4750.2006.03.020 [21] TEPFERS R, KUTTI T. Fatigue strength of plain,ordinary and lightweight concrete[J]. Journal of the American Concrete Institute, 1979, 76(5): 635-652. [22] 徐庆元,张泽,陈效平,等. 桥上CRTS Ⅱ型板式无砟轨道混凝土疲劳寿命预测模型试验研究[J]. 铁道科学与工程学报,2017,14(8): 1565-1570. doi: 10.3969/j.issn.1672-7029.2017.08.001XU Qingyuan, ZHANG Ze, CHEN Xiaoping, et al. Experimental study on fatigue life prediction model of concrete of CRTS Ⅱ slab track on bridge[J]. Journal of Railway Science and Engineering, 2017, 14(8): 1565-1570. doi: 10.3969/j.issn.1672-7029.2017.08.001 [23] 祝志文,黄炎,文鹏翔,等. 随机车流下钢-UHPC组合正交异性桥面疲劳性能研究[J]. 中国公路学报,2017,30(3): 200-209. doi: 10.3969/j.issn.1001-7372.2017.03.022ZHU Zhiwen, HUANG Yan, WEN Pengxiang, et al. Investigation on fatigue performance of orthotropic bridge deck with steel-UHPC composite system under random traffic flows[J]. China Journal of Highway and Transport, 2017, 30(3): 200-209. doi: 10.3969/j.issn.1001-7372.2017.03.022 -

下载:

下载: