Flexural Behavior of GFRP Reinforced Granite Cladding Panels with Undercut Bolt Anchorage

-

摘要:

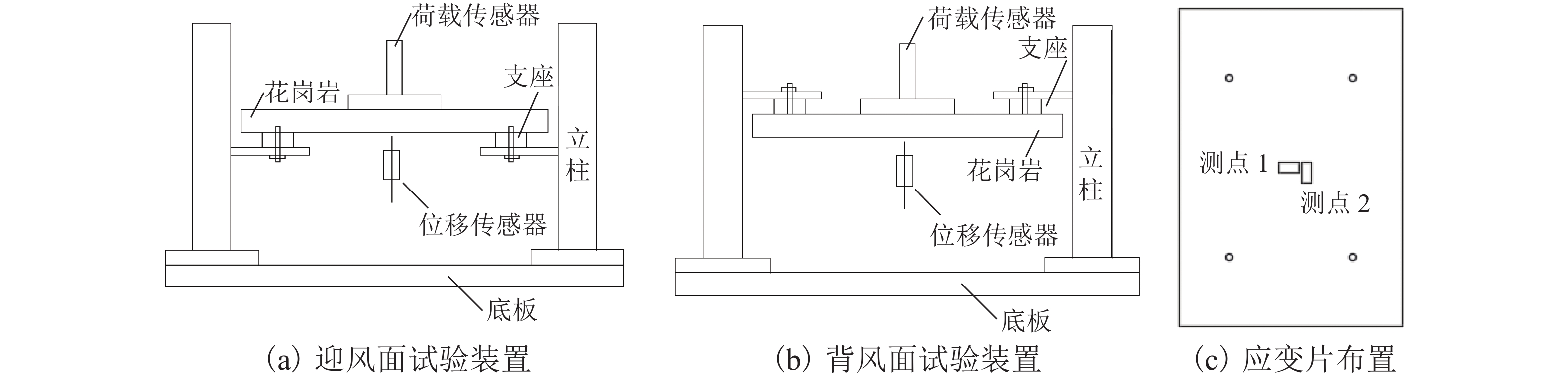

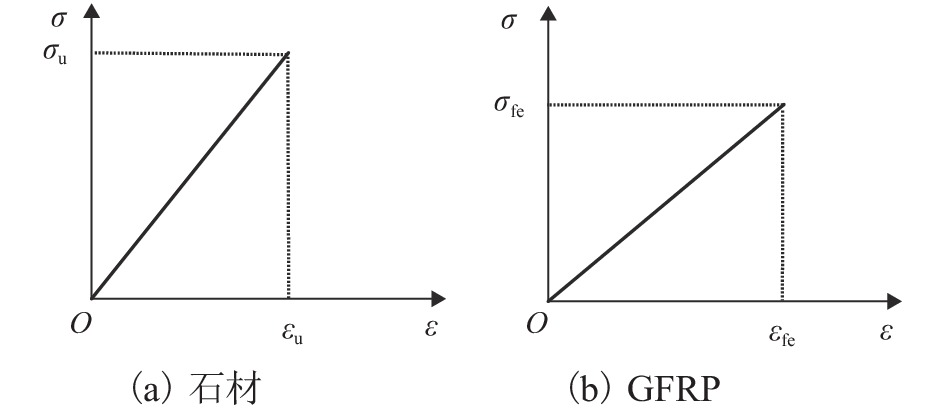

为研究石材面板在不同加固形式下的破坏形态和抗弯承载力,对33块背栓式花岗岩石材面板进行了迎风面和背风面的抗弯试验. 石材幕墙面板的连接节点用金属圆环加固,面板背面用GFRP (glass fiber reinforced plastics)进行十字、对角、横向全贴和纵向全贴的粘贴方式加固,并对其承载力进行了分析. 结果表明:石材幕墙面板采用节点加固后在背风面加载方向的破坏形态有所改善,承载力相对于未进行节点加固石材面板提高了0.50倍;石材面板背面粘贴GFRP的4种加固方式,都能较好地保证石材面板破坏后的整体性,并能提高石材面板迎风面加载方向的抗弯承载力,最大提高2.30倍. 研究验证了背栓式石材幕墙节点加固在工程应用中的可行性.

Abstract:To explore the failure mode and bearing capacity of the granite cladding panel under different reinforcements, flexural tests were conducted on the windward and leeward sides of 33 granite cladding panels with undercut bolt anchorage. The joints of the granite cladding panels were reinforced with metal ring, and the panel back was reinforced with glass fiber reinforced plastics (GFRP) in cross, diagonal, horizontal, and vertical paste; then the bearing capacity of the panels was analyzed.The results show that after the panel is reinforced at the joints, the failure mode of the leeward side is improved in the loading direction. Compared with the panel without joint reinforcement, its bearing capacity is increased by 0.50 times. The four GFRP reinforcement modes at the back of the panel can keep its integrity after failure emerges and also improve the bending capacity of the panel windward side in the loading direction by 2.30 times at most, verifying the feasibility of the reinforcement measure of granite cladding panels with undercut bolt anchorage for engineering applications.

-

表 1 试件设计参数

Table 1. Details of specimens

试件编号 数量/个 厚度/mm 连接节点 GFRP 粘贴方式 试件编号 数量/个 厚度/mm 连接节点 GFRP 粘贴方式 BS-F 3 30 BS-B 3 30 BS-J-F 3 30 加固 BS-J-B 3 30 加固 BS-J-F-1 3 30 加固 十字 BS-J-B-1 3 30 加固 十字 BS-J-F-2 3 30 加固 对角 BS-J-B-2 3 30 加固 对角 BS-J-F-3 3 30 加固 纵向全贴 BS-J-B-3 3 30 加固 纵向全贴 BS-J-F-4 3 30 加固 横向全贴 表 2 GFRP实测性能

Table 2. Measured performance of GFRP

试样 抗拉强度/MPa 厚度/mm 弹性模量/MPa GFRP 1 444.4 0.167 1.33 × 105 表 3 不同荷载下试验结果

Table 3. Test results under different loadings

试件编号 试验 极限荷载/N 极限位移/mm 破坏形态 试件编号 试验 极限荷载/N 极限位移/mm 破坏形态 BS-F (1) 20.530 1.12 节点破坏 BS-B (1) 9.423 1.29 节点破坏 (2) 21.873 0.91 (2) 9.603 1.22 (3) 20.794 1.05 (3) 9.279 1.19 平均荷载 21.065 1.03 平均荷载 9.435 1.23 BS-J-F (1) 23.676 1.18 板断裂 BS-J-B (1) 14.051 1.91 板断裂 (2) 23.245 1.26 (2) 13.946 1.94 (3) 24.152 1.22 (3) 14.513 2.08 平均荷载 23.691 1.22 平均荷载 14.170 1.98 BS-J-F-1 (1) 69.533 5.03 板断裂 BS-J-B-1 (1) 14.867 1.63 板断裂 (2) 70.463 4.97 (2) 14.513 1.45 (3) 68.987 4.85 (3) 14.725 1.53 平均荷载 69.661 4.95 平均荷载 14.702 1.54 BS-J-F-2 (1) 58.765 4.22 板断裂 BS-J-B-2 (1) 16.478 1.32 板断裂 (2) 57.360 4.13 (2) 16.344 1.51 (3) 57.553 4.24 (3) 15.681 1.45 平均荷载 57.893 4.20 平均荷载 16.168 1.43 BS-J-F-3 (1) 31.113 1.43 板断裂 BS-J-B-3 (1) 14.862 1.29 板断裂 (2) 38.031 1.52 (2) 15.577 1.36 (3) 36.145 1.48 (3) 15.245 1.45 平均荷载 35.096 1.48 平均荷载 15.227 1.37 BS-J-F-4 (1) 56.975 2.71 板断裂 (2) 60.895 2.77 平均荷载 58.935 2.74 表 4 荷载模拟值与试验值对比

Table 4. Comparison of simulated and experimental values

试件编号 试验值/N 模拟值/N 误差/% BS-B 9 435.45 9 965.11 5.61 BS-J-B 14 170.55 15 383.55 8.56 BS-J-B-1 14 702.06 15 957.79 8.54 BS-J-B-2 16 168.12 17 680.88 9.36 BS-J-B-3 15 227.31 13 246.92 13.01 BS-F 21 065.81 23 706.66 12.54 BS-J-F-1 69 661.34 78 417.77 12.57 BS-J-F-2 57 893.21 64 527.76 11.46 BS-J-F-3 35 096.88 38 880.32 10.78 表 5 初始安装缺陷分析

Table 5. Initial installation defect analysis

石材

编号缺陷数/个 极限荷载/N 试验荷载/N 降低率/% BS-B 1 6 382.3 9 435.0 32.36 BS-B 2 (对角) 4 229.7 9 435.0 55.17 -

[1] 王明贵,郝锐坤. 背栓式连接石材幕墙抗震试验研究[J]. 建筑结构,2001,31(4): 70.WANG Minggui, HAO Ruikun. Seismic test study on back-connected stone curtain wall[J]. Building Structure, 2001, 31(4): 70. [2] 周桂云,徐跃华,王明贵. 大型石材幕墙抗震试验研究[J]. 建筑结构,2003,33(8): 62-63.ZHOU Guiyun, XU Yuehua, WANG Minggui. Test on anti-seismic ability of big stone curtain wall[J]. Building Structure, 2003, 33(8): 62-63. [3] 王翠坤,肖从真,赵西安. 幕墙抗震性能试验研究[J]. 建筑结构,2002,32(9): 65-67.WANG Cuikun, XIAO Congzhen, ZHAO Xi’an. Experimental research on the earthquake-resistant property of curtain wall[J]. Building Structure, 2002, 32(9): 65-67. [4] 赵君. 大面积幕墙工程中干挂石材背栓安装质量对挂装强度影响的试验研究[J]. 广东土木与建筑,2014(2): 39-41.ZHAO Jun. Experimental study on the influence of the installation quality of dry-hanging stone undercut anchorage on the mounting strength in large-area curtain wall projects[J]. Guangdong Architecture Civil Engineering, 2014(2): 39-41. [5] YEUN K W, HONG K N, KIM J. Development of a retrofit anchor system for remodeling of building exteriors[J]. Structural Engineering and Mechanics, 2012, 44(6): 839-856. doi: 10.12989/sem.2012.44.6.839 [6] CHANG K K, PARK N W. Development and performance evaluation of under cut anchor stone curtain wall construction method[J]. Journal of the Korea Institute for Structural Maintenance and Inspection, 2014, 18(4): 138-146. doi: 10.11112/jksmi.2014.18.4.138 [7] NETO N, DE BRITO J. Validation of an inspection and diagnosis system for anomalies in natural stone cladding (NSC)[J]. Construction and Building Materials, 2012, 30: 224-236. doi: 10.1016/j.conbuildmat.2011.12.032 [8] NETO N, DE BRITO J. Inspection and defect diagnosis system for natural stone cladding[J]. Journal of Materials in Civil Engineering, 2011, 23(10): 1433-1443. doi: 10.1061/(ASCE)MT.1943-5533.0000314 [9] MALAGA K, SCHOUENBORG B, GRELK B. Bowing and expansion of natural stone panels marble and limestone testing and assessment[J]. Materiales De Construction, 2008, 58(290): 97-112. [10] BEASLEY K J. Latent building facade failures[C]//Sixth Congress on Forensic Engineering. San Francisco, Reston: American Society of Civil Engineers, 2012: 918-927. [11] ERDLY J L, VALENTINO E R, HOIGARD K, et al. Investigation of masonry failure of a granite and limestone clad historic church in eastern Pennsylvania[J]. Journal of ASTM International, 2007, 4(5): 100853. doi: 10.1520/JAI100853 [12] 王金昌, 陈页开. ABAQUS在土木工程中的应用[M]. 杭州: 浙江大学出版社, 2006: 68-88. -

下载:

下载: