Analysis of Unilateral Rail Corrugation Mechanism Based on Friction Self-Excited Theory

-

摘要:

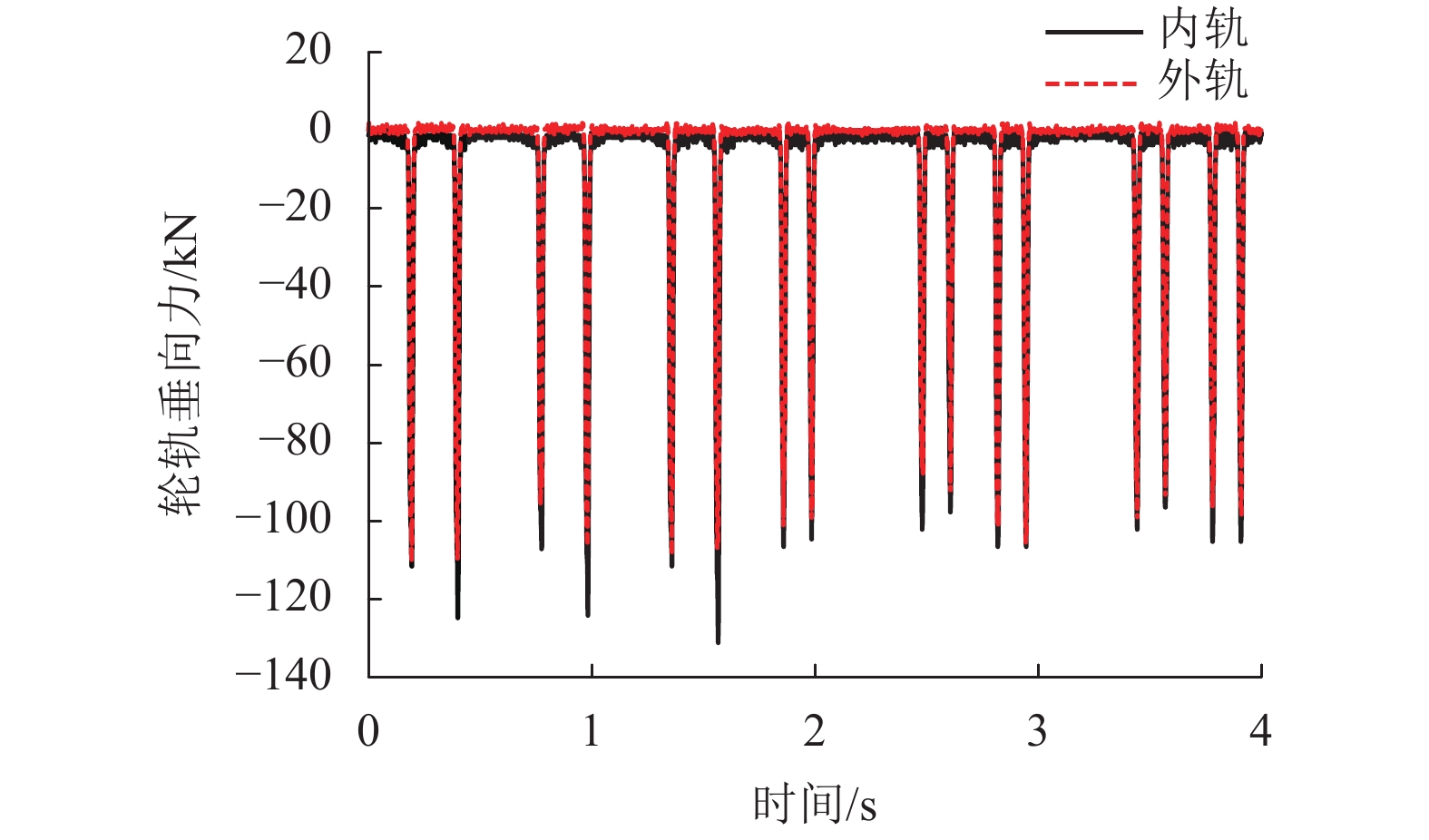

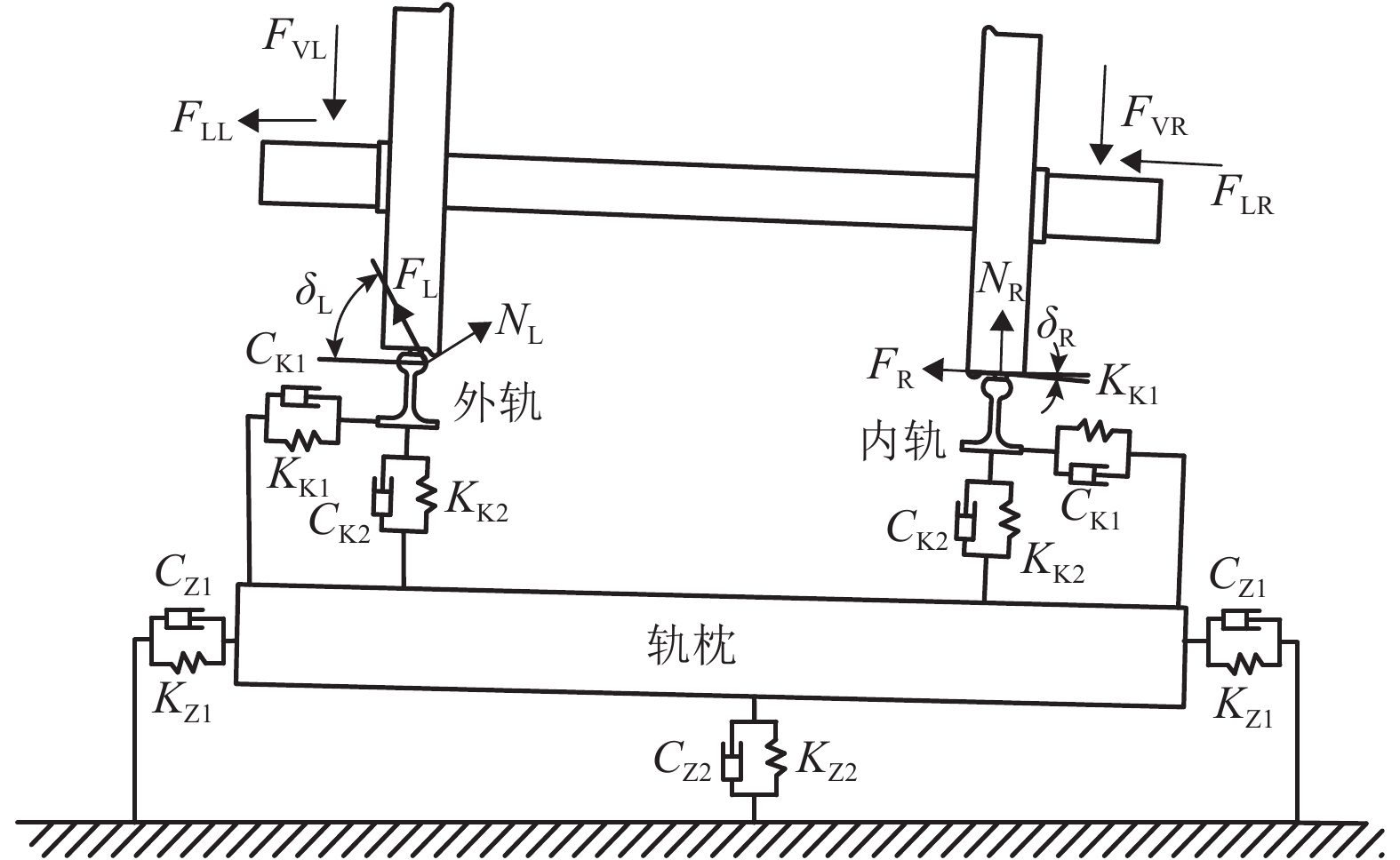

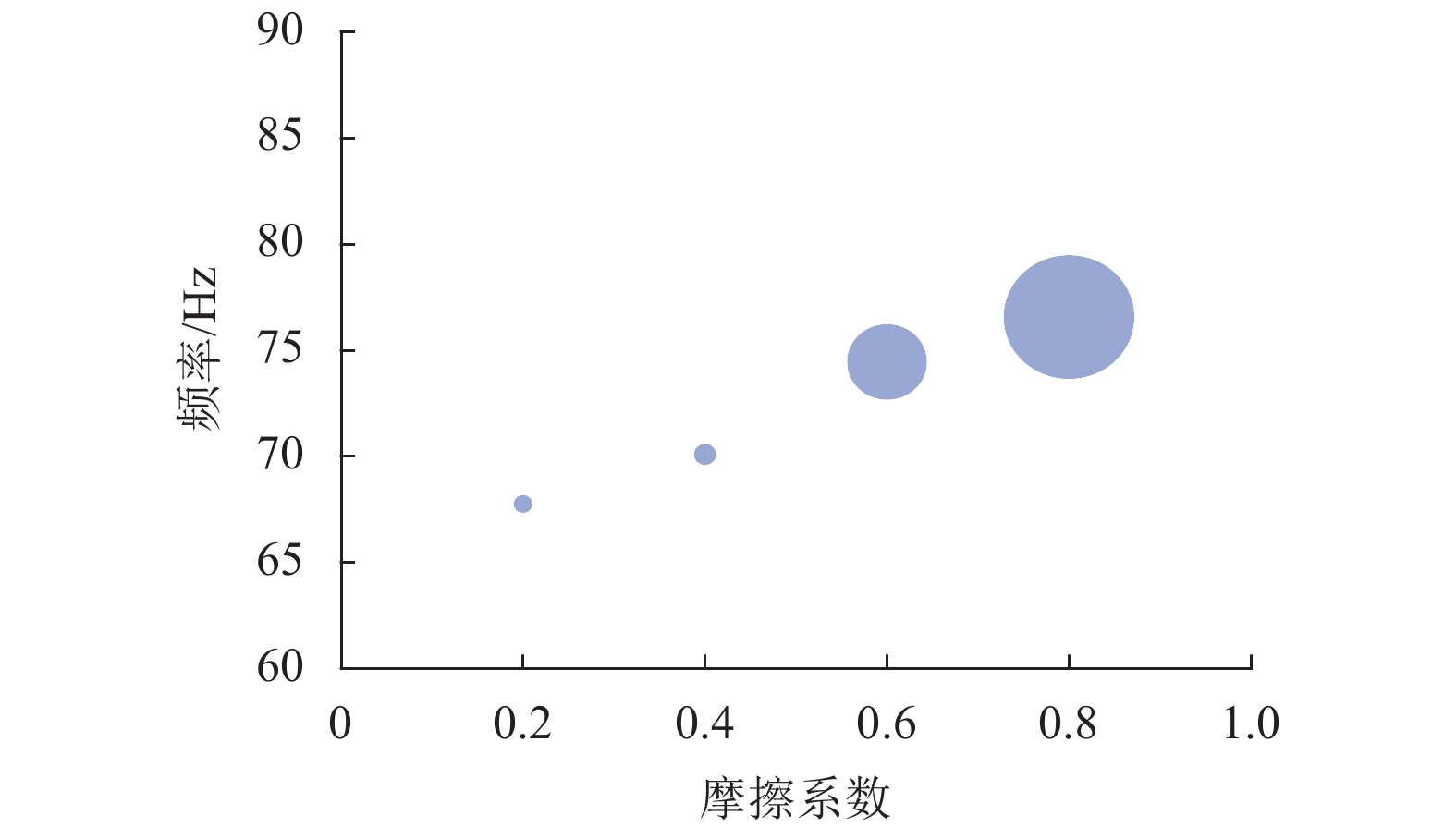

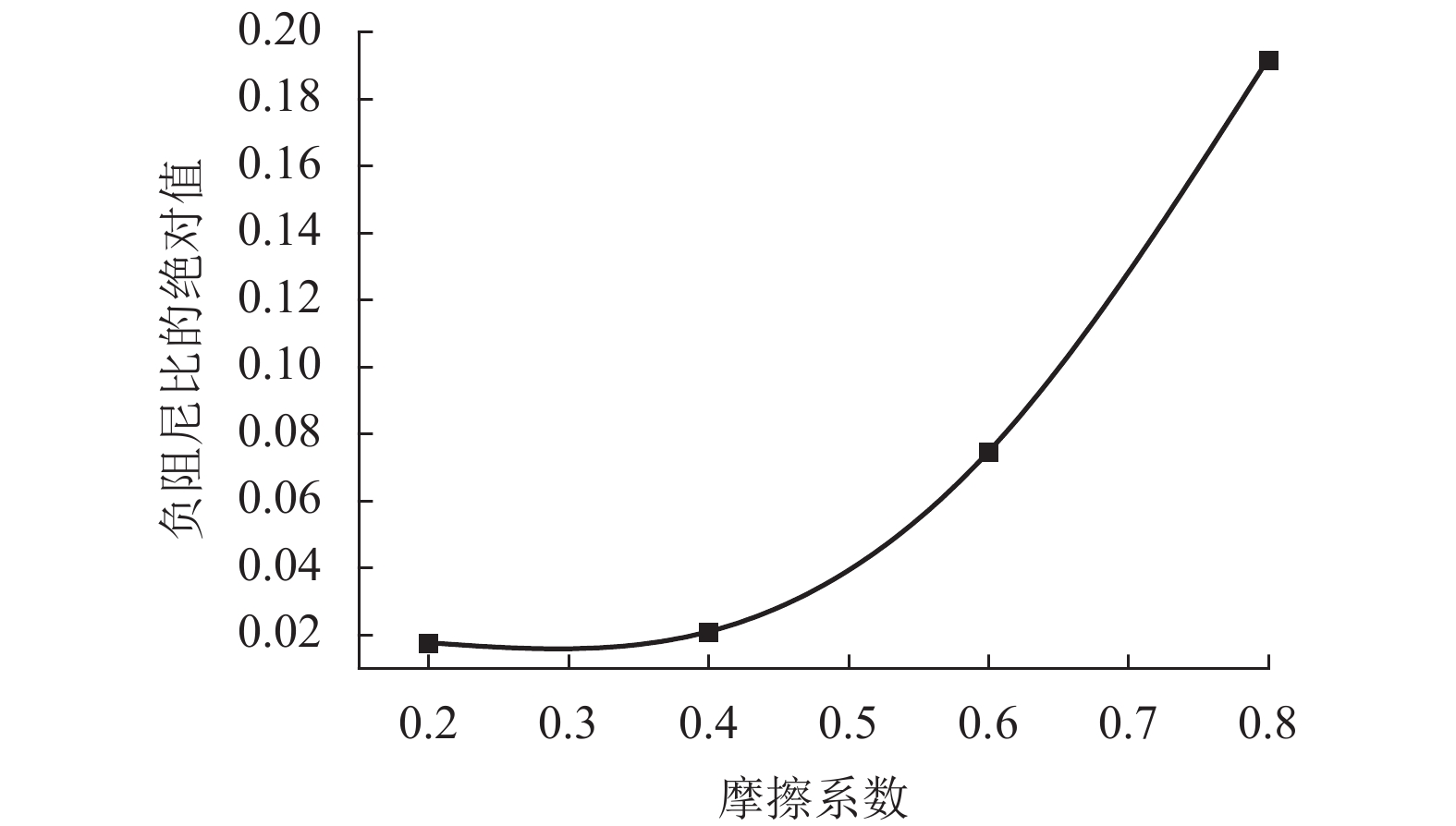

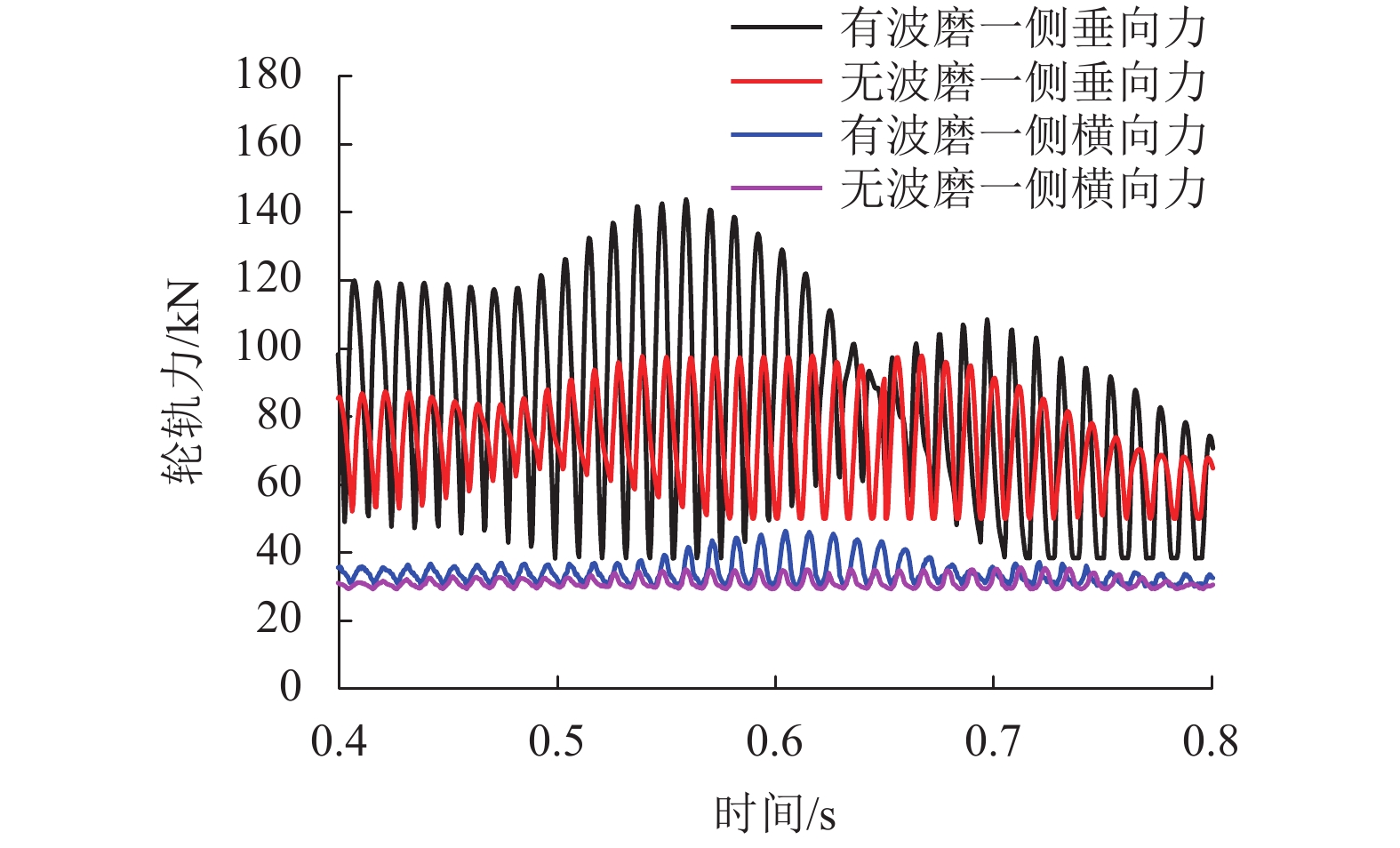

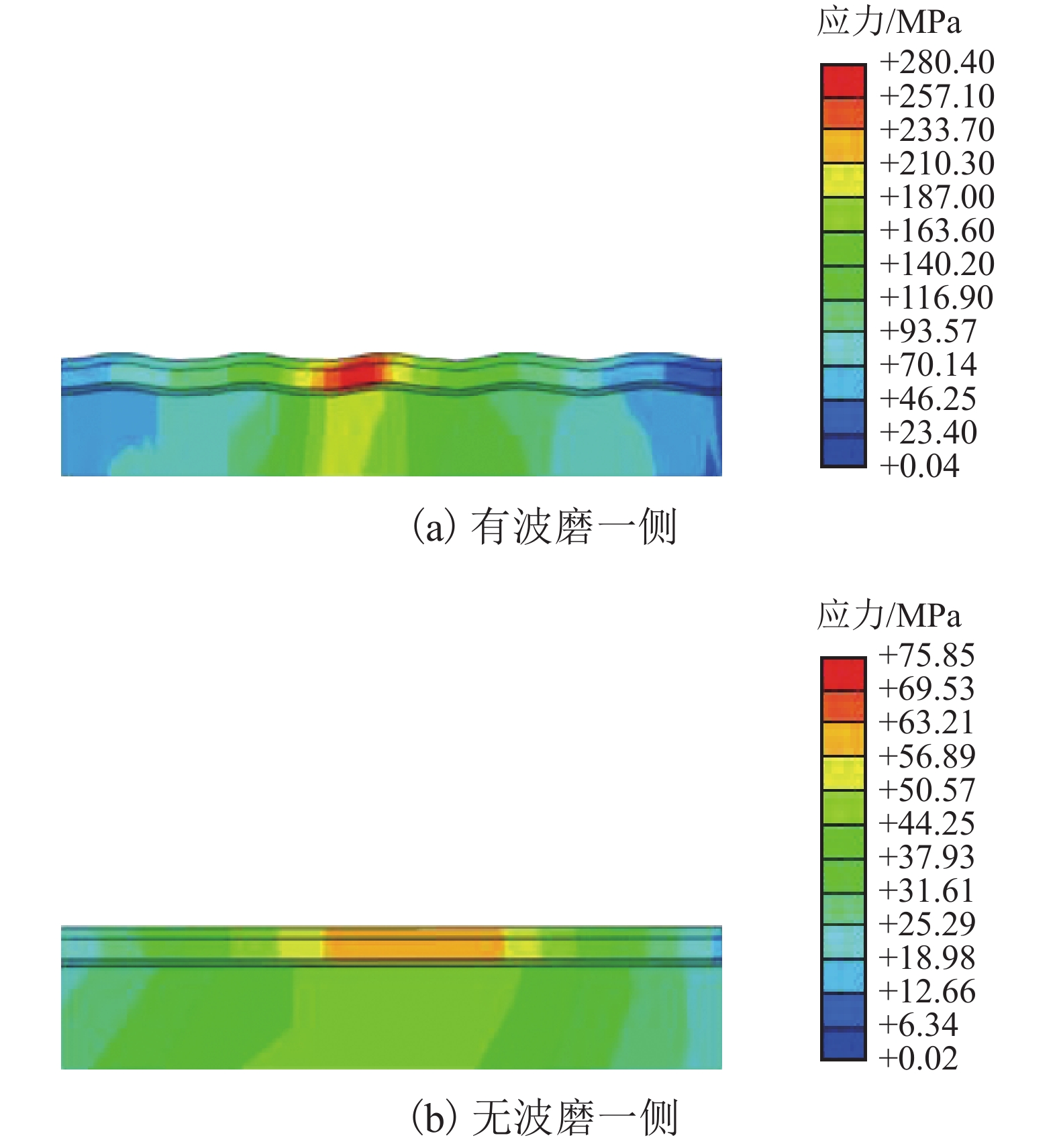

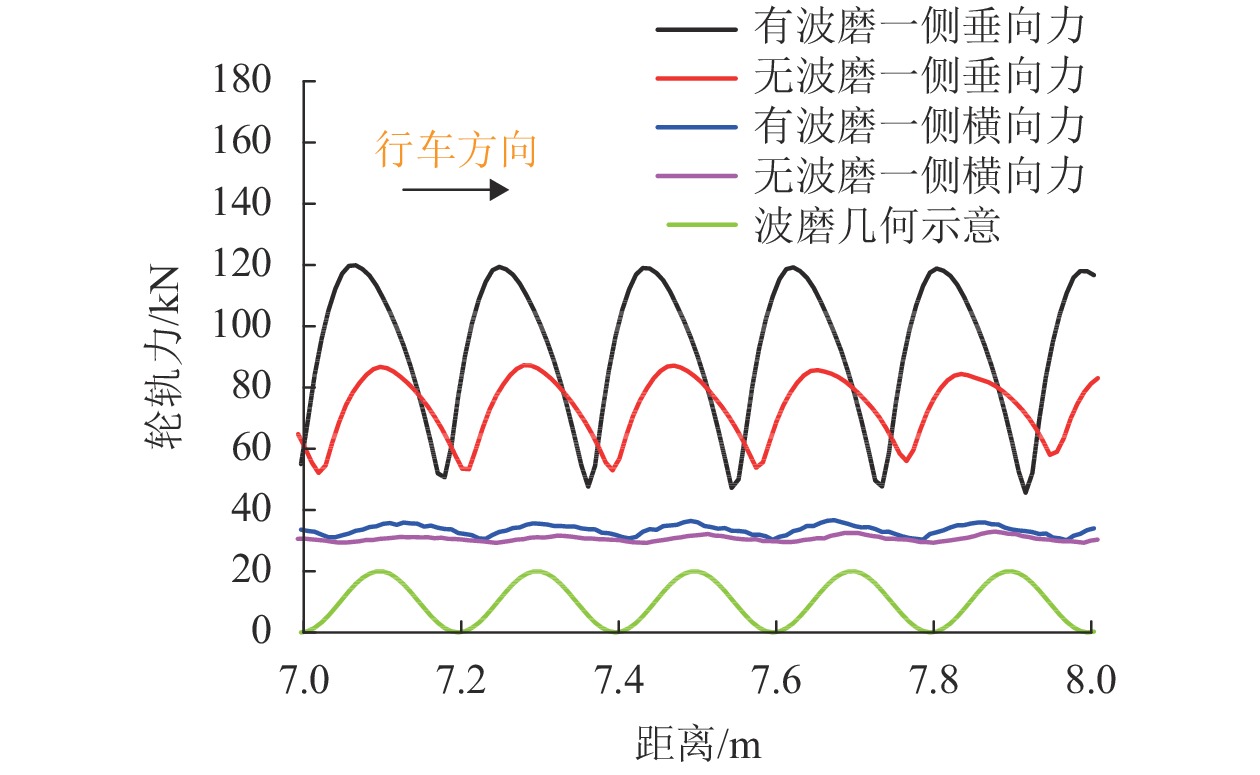

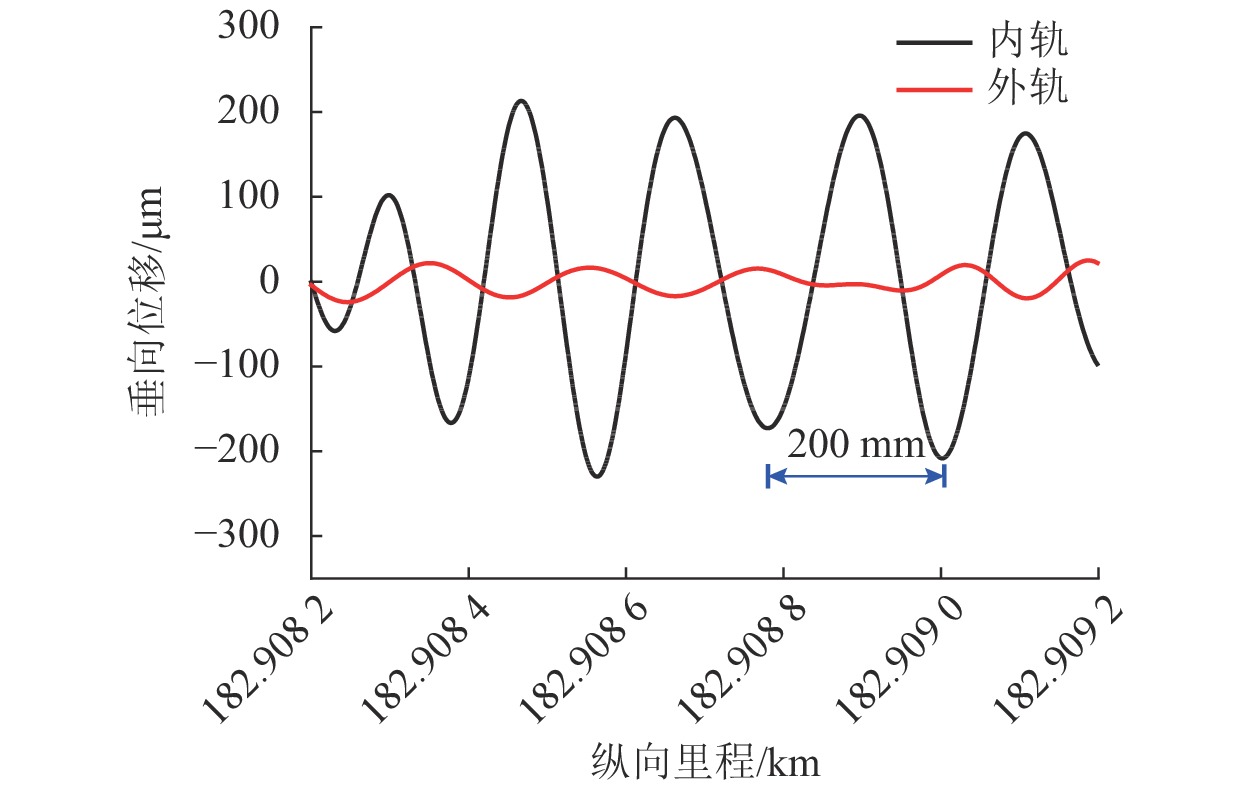

为了分析重载铁路曲线地段钢轨波磨的产生原因,基于摩擦自激振动理论建立小半径曲线轮轨三维接触精细化模型,讨论了不同扣件刚度、摩擦系数、超高对轮轨系统不稳定摩擦自激振动的影响,揭示了单侧钢轨波磨产生的内在原因,并通过轮轨瞬态动力学方法,分析了单侧钢轨波磨的传递及演化过程. 结果表明:超高和实际运行速度的不匹配是曲线内股钢轨首先产生波磨的主要原因;内股钢轨波磨产生后会导致轮轨系统不稳定,并将振动传递至外股钢轨,从而诱发小半径曲线地段两侧钢轨均产生波磨;适当地提高扣件垂横向刚度、控制轮轨摩擦系数在0.4以下,能够有效地降低轮轨系统发生不稳定振动的趋势,从而抑制波磨发展.

Abstract:In order to analyze the causes of rail corrugation in curve section of heavy haul railway, a refined wheel-rail three-dimensional contact model is established based on the friction self-excited vibration theory. The influences of different stiffness, friction coefficient and superelevation on the unstable friction self-excited vibration of wheel-rail system were discussed, and the internal causes of single rail corrugation were revealed, and the transmission and evolution process of single rail corrugation were analyzed by means of the explicit dynamic model. The results show that the mismatch between superelevation and actual running speed is the main cause of unilateral rail corrugation. The corrugation of the inner rail will lead to the instability of the wheel/rail system, and the vibration will be transmitted to the outer rail, which will induce corrugation of the rails on both sides of the small radius curve section. By properly improving the vertical and lateral stiffness of fasteners and controlling the wheel-rail friction coefficient below 0.4, the tendency of unstable vibration of wheel-rail system can be effectively reduced, and the development of ripples can be restrained.

-

表 1 计算结果对比

Table 1. Comparison of calculation results

kN 项目 外轨垂向力 内轨垂向力 现场实测值 126.72 132.11 模型计算值 124.66 128.86 注:现场实测值取多测点平均值,模型计算值取不平顺曲线段平均值. 表 2 扣件刚度计算工况

Table 2. Working conditions of fastener stiffness calculation

MN/m 刚度 工况 1 工况 2 工况 3 工况 4 工况 5 工况 6 工况 7 工况 8 工况 9 横向 40 40 40 60 60 60 80 80 80 垂向 40 80 120 40 80 120 40 80 120 表 3 不同超高下系统最小负等效阻尼比分布及主导振动振型

Table 3. Distribution of minimum negative equivalent damping ratio and dominant vibration mode for different superelevation

超高 最小负等效阻尼比 主导振型图 欠超高 30 mm −0.01901

欠超高15 mm −0.00221

平衡超高 −0.00129

过超高15 mm −0.00331

过超高 30 mm −0.02101

-

[1] 温泽峰, 金学松. 钢轨波浪形磨损研究[D]. 成都: 西南交通大学, 2006. [2] 朱波. 大轴重作用下重载铁路路基结构荷载传递规律及设计方法研究[D]. 成都: 西南交通大学, 2018. [3] XIE G, IWNCKI S D. Calculation of wear on a corrugated rail using a three-dimensional contact model[J]. Wear, 2008, 265(9/10): 1238-1248. [4] JIN X, WEN Z, WANG K, et al. Effect of passenger car curving on rail corrugation at a curved track[J]. Wear, 2006, 260(6): 619-633. doi: 10.1016/j.wear.2005.03.016 [5] JIN X, WEN Z. Rail corrugation formation studied with a full-scale test facility and numerical analysis[J]. Proceedings of the Institution of Mechanical Engineers,Part J:Journal of Engineering Tribology, 2007, 221(6): 675-698. doi: 10.1243/13506501JET269 [6] JIN X, WEN Z, WANG K, et al. Effect of a scratch on curved rail on initiation and evolution of rail corrugation[J]. Tribology International, 2004, 37(5): 385-394. doi: 10.1016/j.triboint.2003.07.002 [7] 张厚贵. 北京地铁钢轨波磨的机理及整治方案研究[D]. 北京: 北京交通大学, 2015. [8] CHEN G X, ZHOU Z R, OUYANG H, et al. A finite element study on rail corrugation based on saturated creep force-induced self-excited vibration of a wheelset –track system[J]. Journal of Sound and Vibration, 2010, 329(22): 4643-4655. doi: 10.1016/j.jsv.2010.05.011 [9] 肖祥龙. 基于轮对-钢轨-轨枕系统摩擦自激振动引起的直线轨道钢轨波磨研究[D]. 成都: 西南交通大学, 2012. [10] 刘超,赵鑫,赵小罡,等. 单侧钢轨波磨对两侧轮轨瞬态响应的影响分析[J]. 机械工程学报,2017,53(22): 117-124. doi: 10.3901/JME.2017.22.117LIU Chao, ZHAO Xin, ZHAO Xiaogang, et al. Analyses of transient wheel-rail interactions excited by unilateral rail corrugation[J]. Journal of Mechanical Engineering, 2017, 53(22): 117-124. doi: 10.3901/JME.2017.22.117 [11] 崔晓璐,陈光雄,杨宏光. 轮对结构和扣件刚度对钢轨波磨的影响[J]. 西南交通大学学报,2017,52(1): 112-117. doi: 10.3969/j.issn.0258-2724.2017.01.016CUI Xiaolu, CHEN Guangxiong, YANG Hongguang. Influence of wheelset structure and fastener stiffness on rail corrugation[J]. Journal of Southwest Jiaotong University, 2017, 52(1): 112-117. doi: 10.3969/j.issn.0258-2724.2017.01.016 [12] 中华人民共和国国家铁路局. 轮轨横向力和垂向力地面测试方法: TB/T 2489—2016[S]. 北京: 中国铁道出版社, 2016. [13] SAULOT A, DESCARTES S, DESMYTER D, et al. A tribological characterization of the "damage mechanism" of low rail corrugation on sharp curved track[J]. Wear, 2006, 260(9): 984-995. [14] KURZECK B. Combined friction induced oscillations of wheelset and track during the curving of metros and their influence on corrugation[J]. Wear, 2011, 271(1): 299-310. [15] 李霞. 地铁钢轨波磨形成机理研究[D]. 成都: 西南交通大学, 2012. [16] 王璞,高亮,蔡小培. 重载铁路钢轨磨耗演变过程的数值模拟[J]. 铁道学报,2014,36(10): 70-75. doi: 10.3969/j.issn.1001-8360.2014.10.012WANG Pu, GAO Liang, CAI Xiaopei. Numerical simulation of rail wear evolution of heavy-hual railways[J]. Journal of the China Railway Society, 2014, 36(10): 70-75. doi: 10.3969/j.issn.1001-8360.2014.10.012 [17] 张晴. 重载铁路钢轨磨耗预测研究[D]. 成都: 西南交通大学, 2017. [18] XIAO H, YANG S, WANG H Y, et al. Initiation and development of rail corrugation based on track vibration in metro systems[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2018, 232(9): 0954409718768956.1-0954409718768956.16. [19] CARLBERGER A, TORSTENSSON P T, NIELSEN J C O, et al. An iterative methodology for the prediction of dynamic vehicle– track interaction and long-term periodic rail wear[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2018, 232(6): 1718-1730. [20] BROCKLEY C A, KO P L. An investigation of rail corrugation using friction-induced vibration theory[J]. Wear, 1988, 128(1): 99-106. doi: 10.1016/0043-1648(88)90256-6 [21] 中华人民共和国国家铁路局. 铁路轨道设计规范: TB 10082—2017[S]. 北京: 中国铁道出版社, 2017. [22] 刘春阳. 一系悬挂和扣件参数对钢轨波磨影响的仿真分析[D]. 成都: 西南交通大学, 2018. [23] 赵江伟. 摩擦自激振动导致地铁小半径曲线钢轨波磨有限元分析及模型研究[D]. 成都: 西南交通大学, 2018. -

下载:

下载: