Digital Management of Crack Defects Information in Steel Truss Bridges Based on Building Information Modeling

-

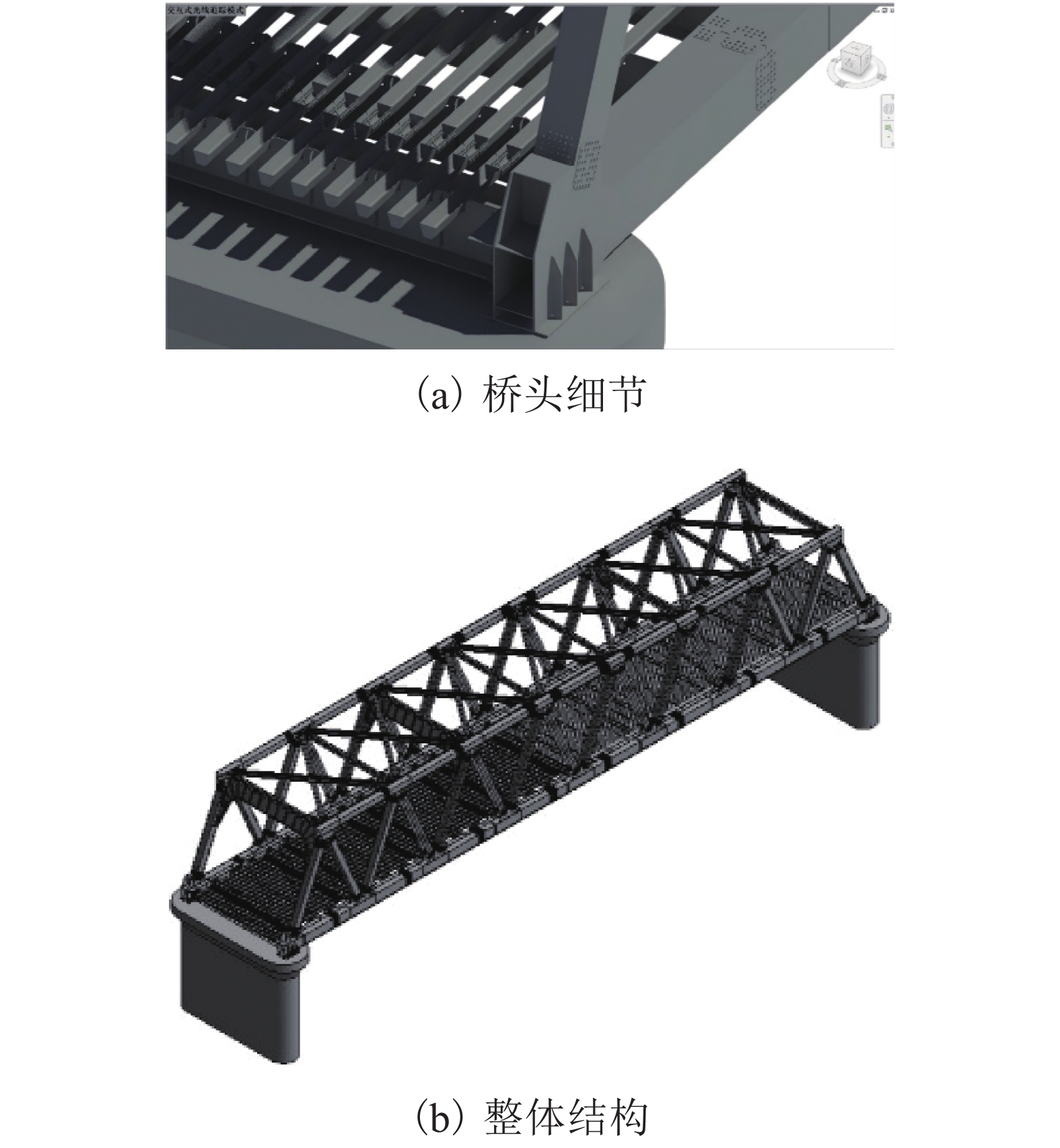

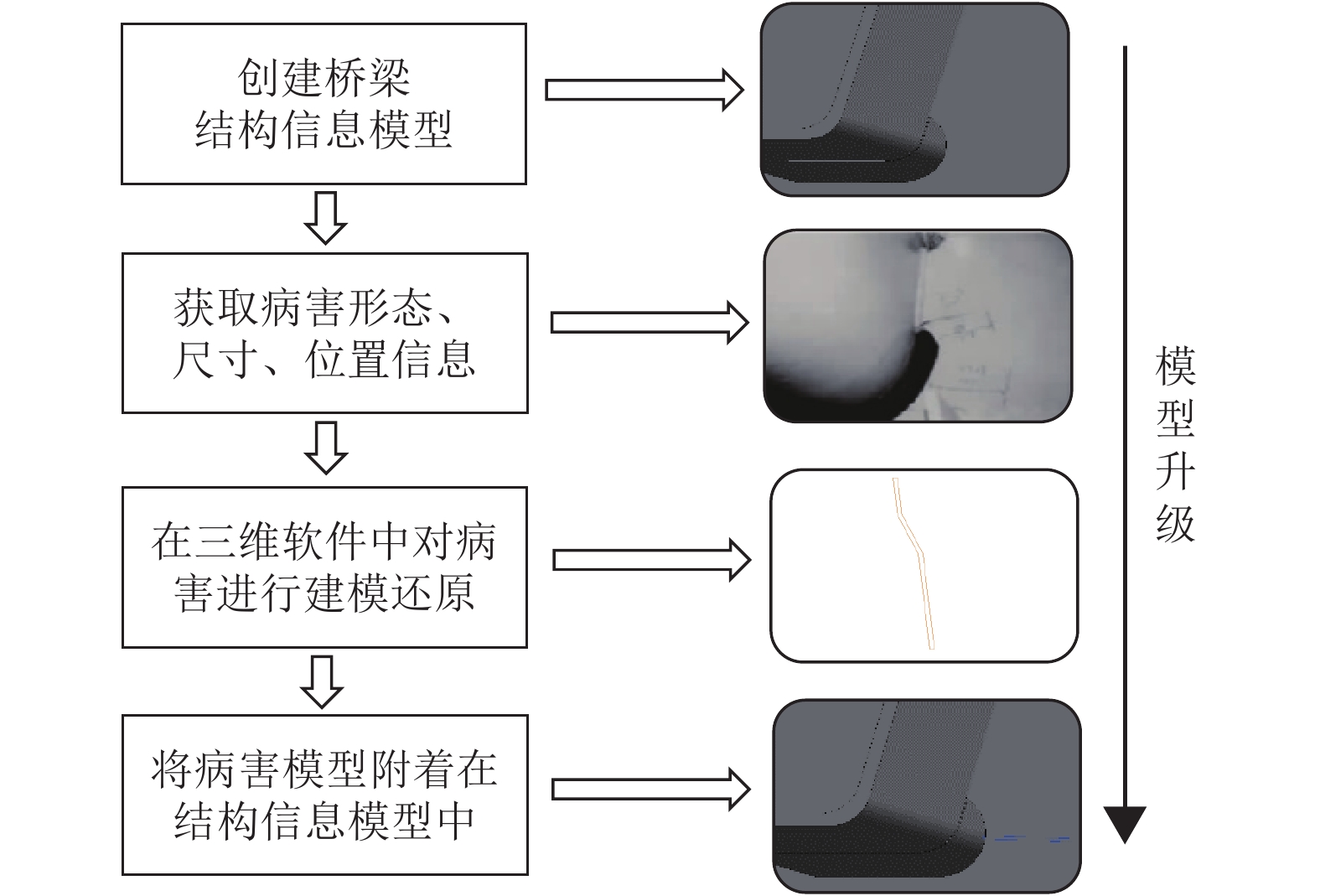

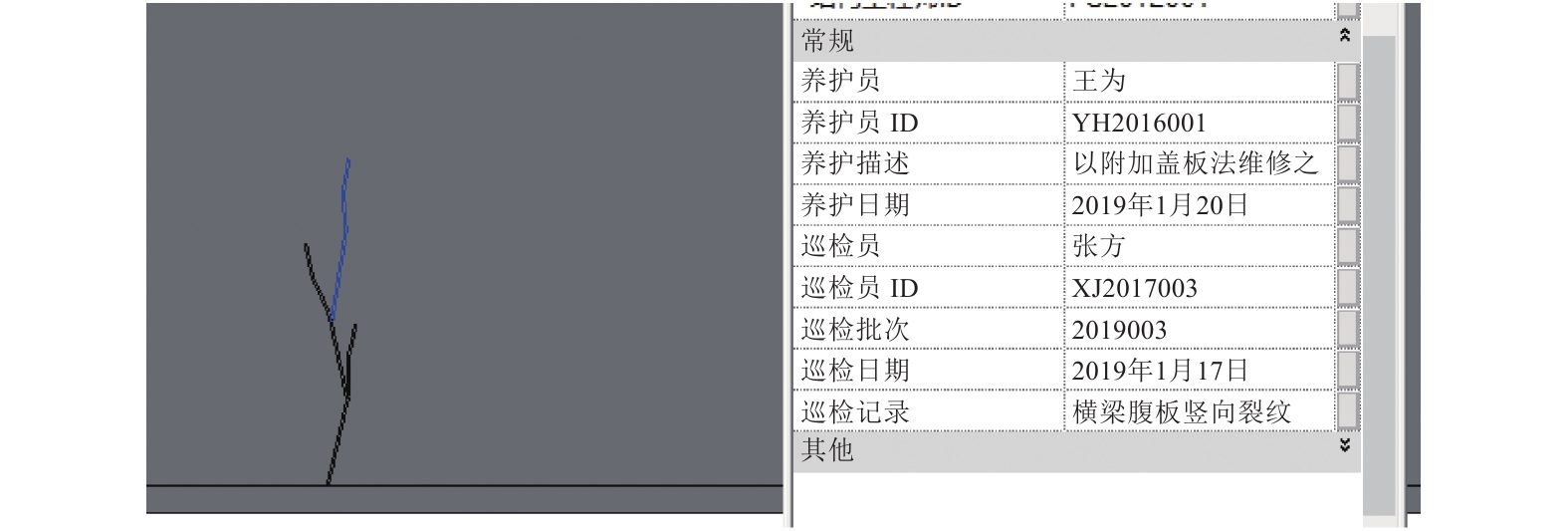

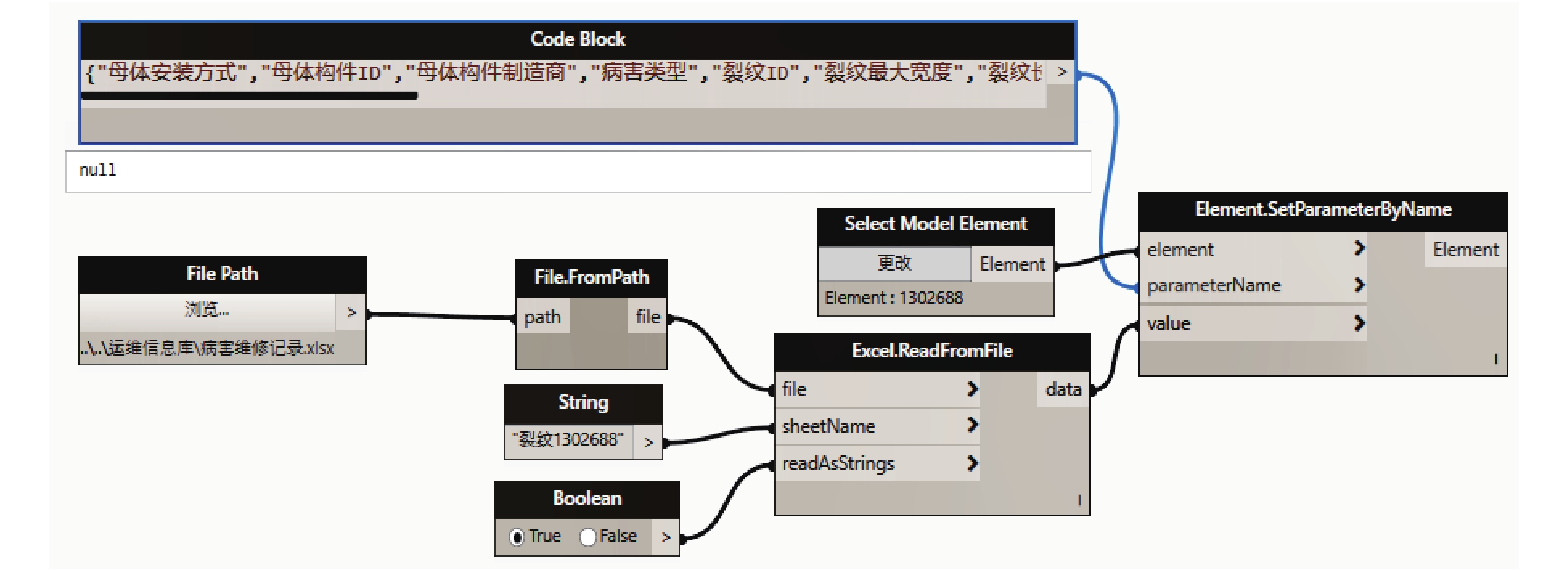

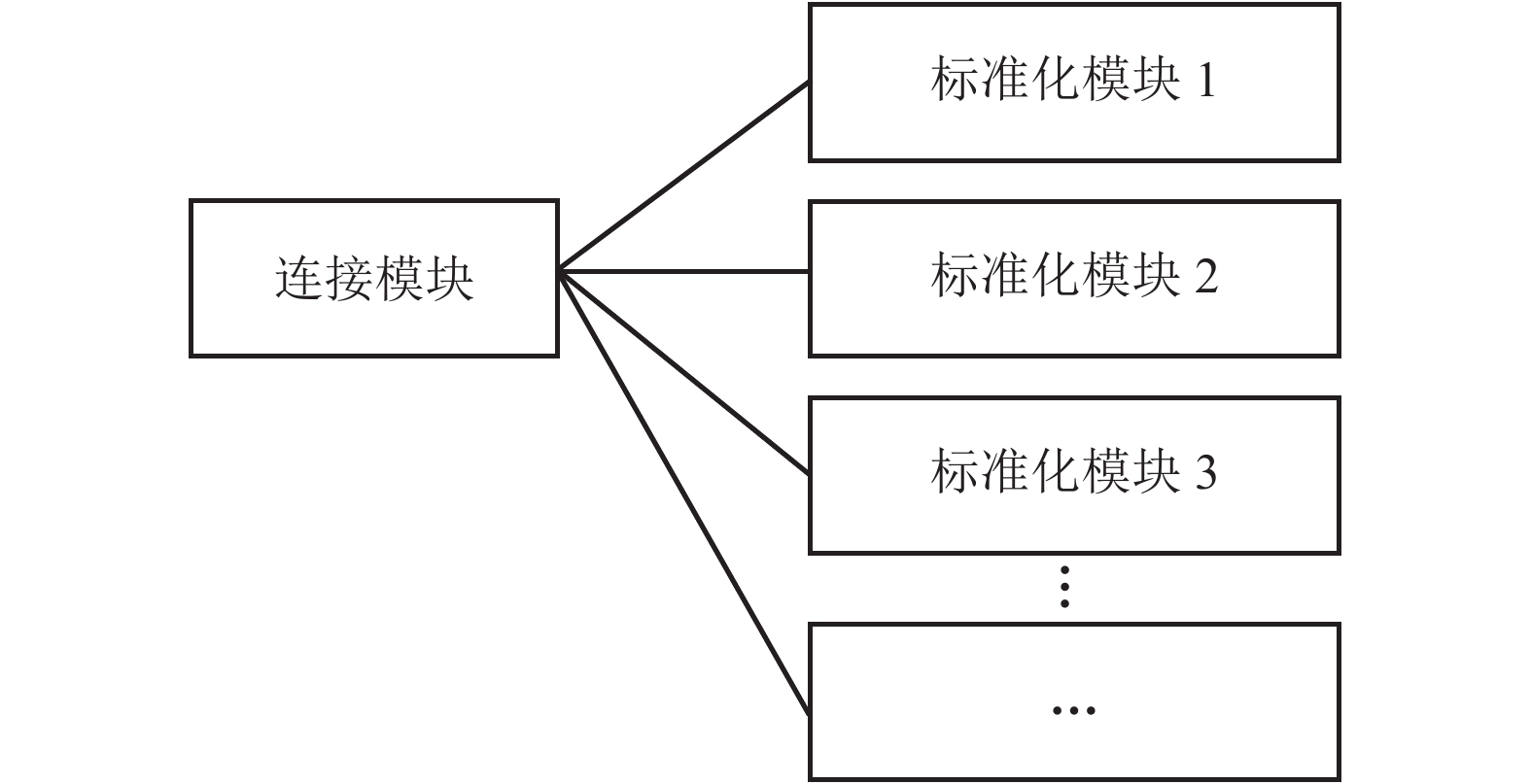

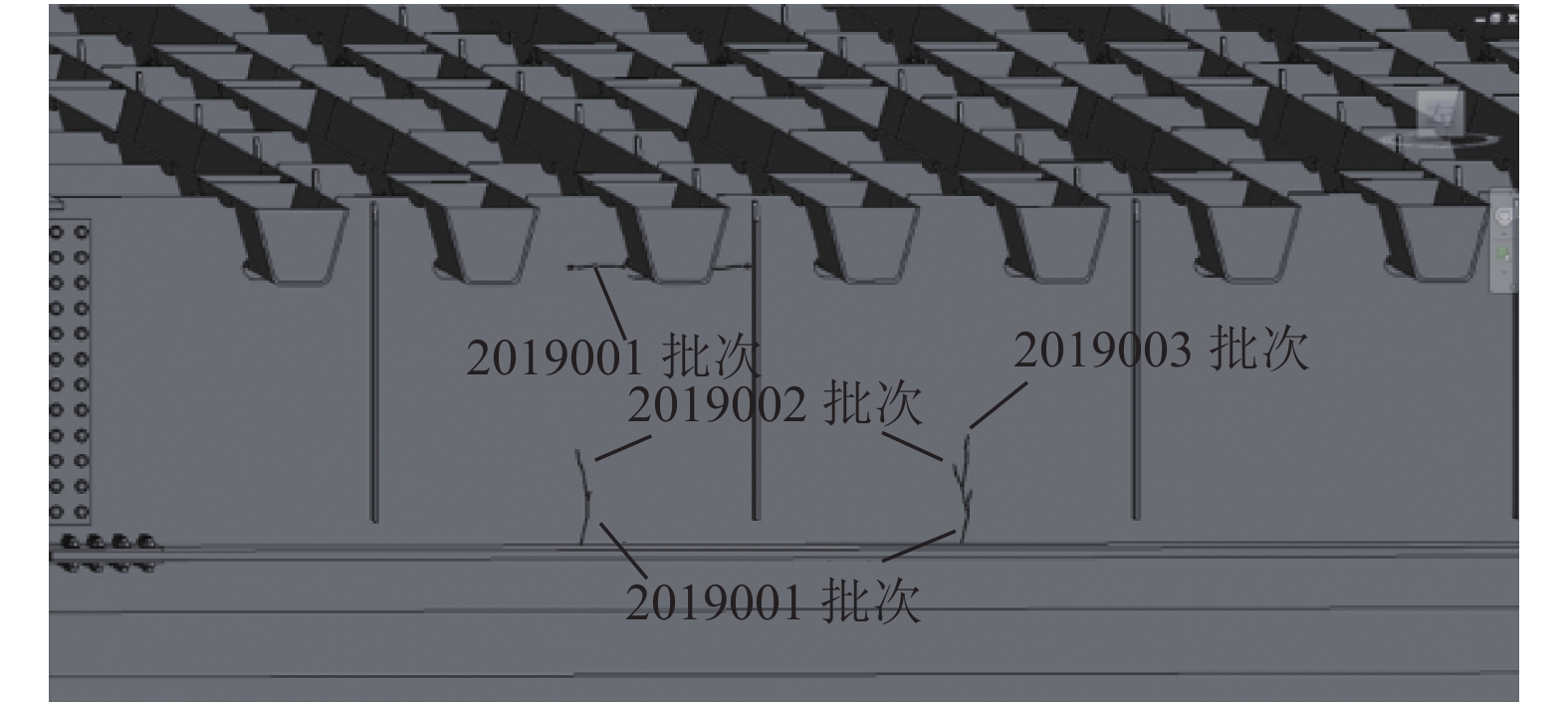

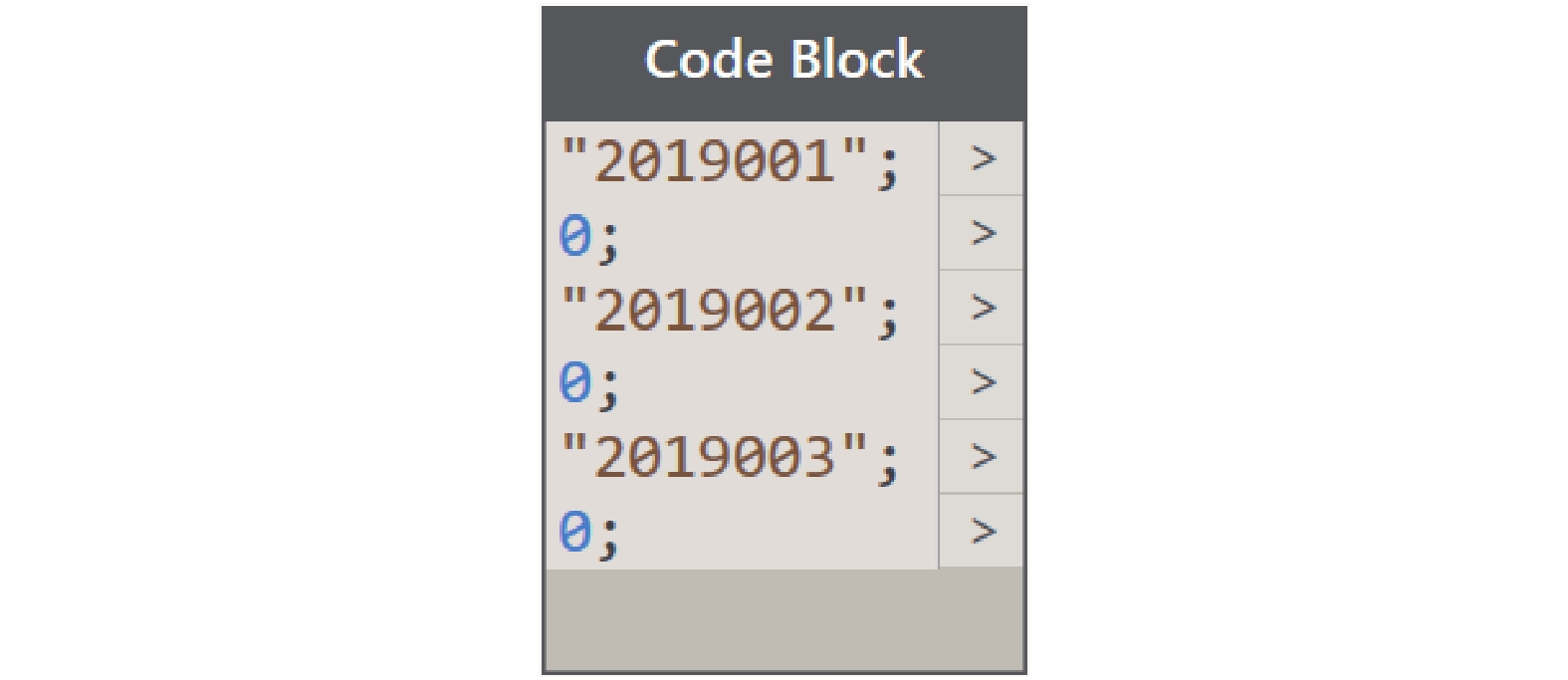

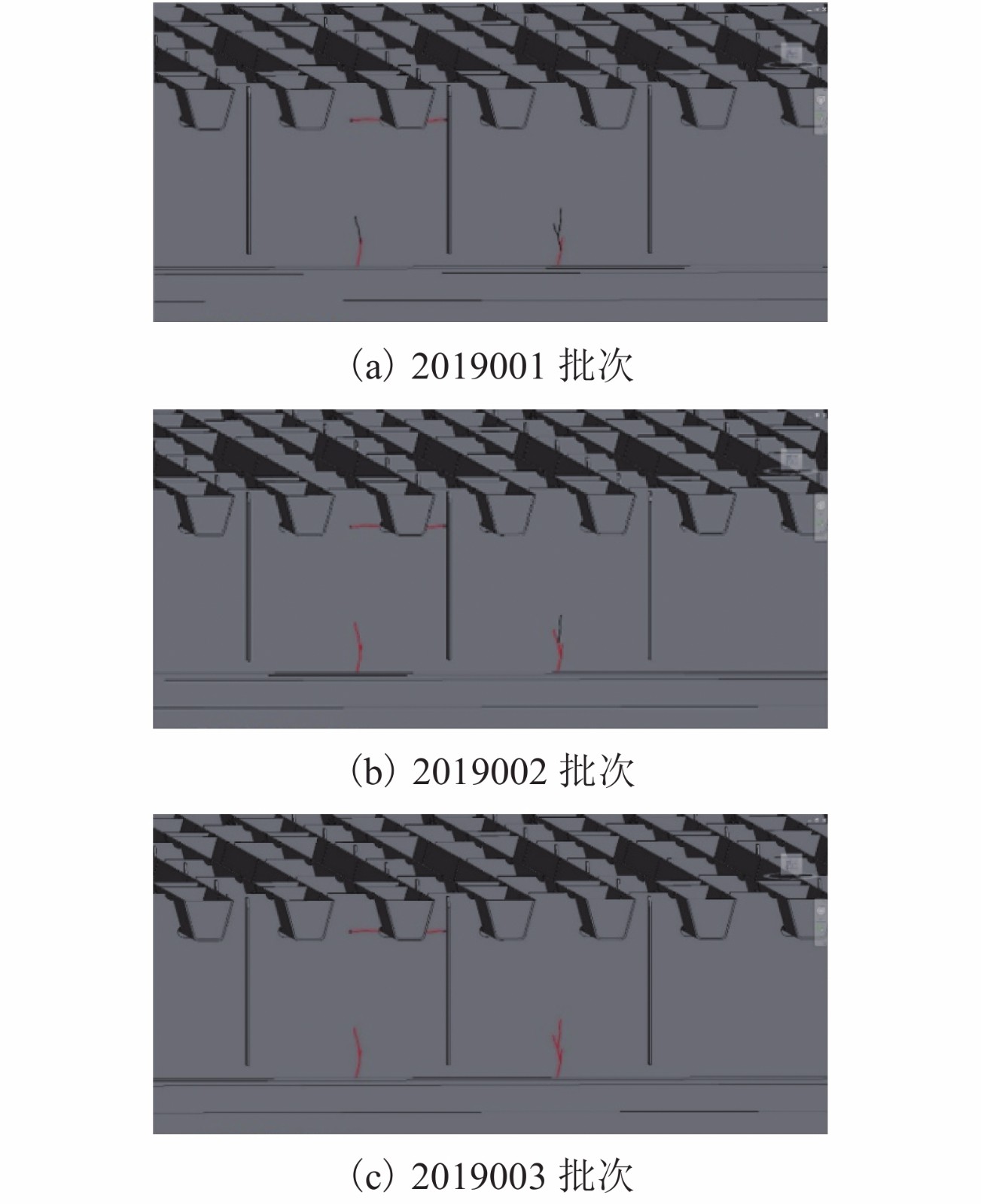

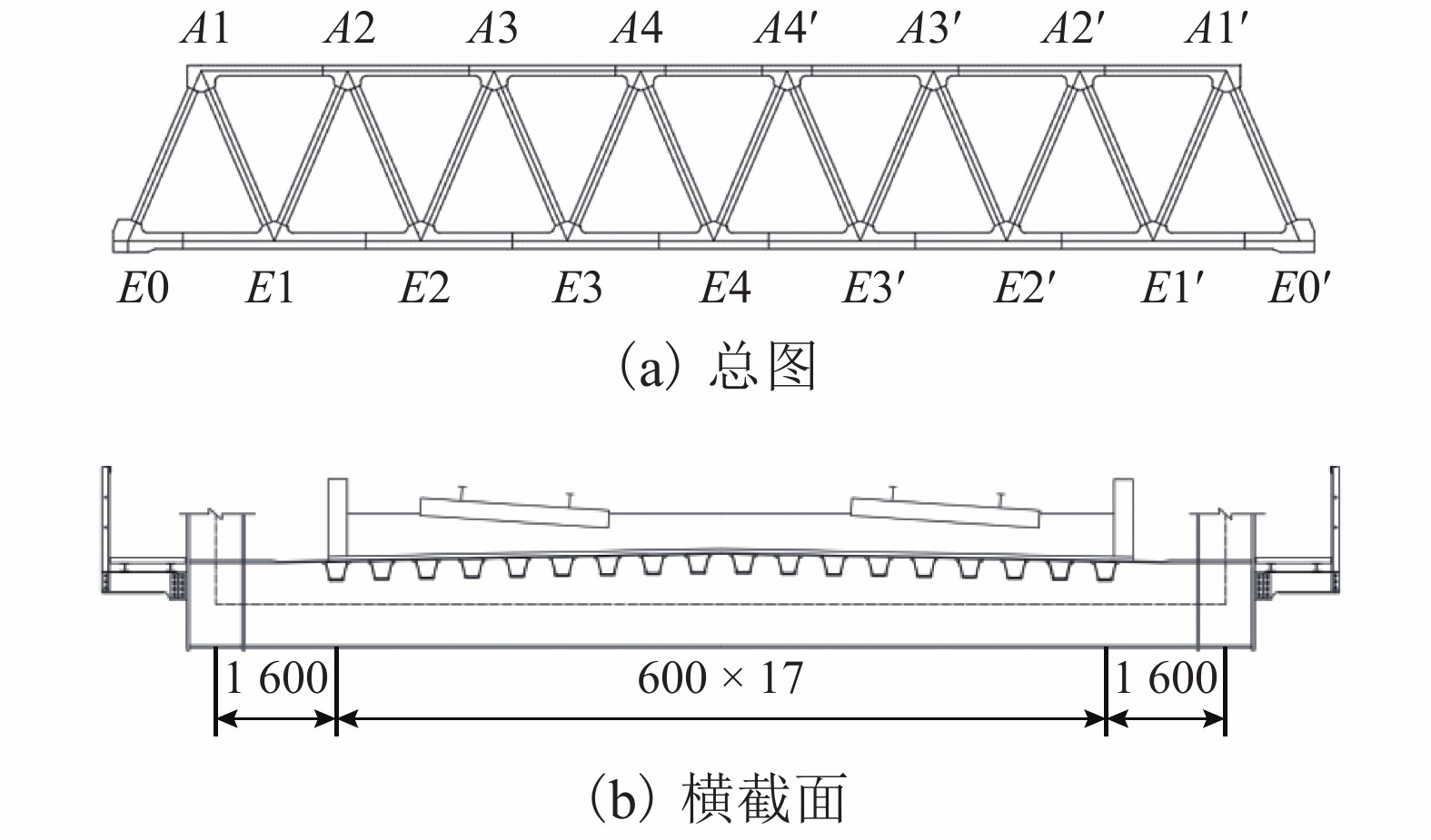

摘要: 为解决传统桥梁病害信息管理过程中数据采集过程复杂、可视化效果不佳及缺乏时间关联要素的问题,结合BIM (building information modeling)技术实现了某钢桁梁桥裂纹病害的可视化,基于可视化编程软件Dynamo研发了一种裂纹病害信息快速批量更新的方法,且将更新代码模块化;通过引入病害时间参数,创建了4D裂纹病害信息模型,实现了裂纹病害信息与三维图形在时间序列上的动态关联,呈现了裂纹的扩展规律. 研究结果表明:在桥梁病害管理系统中引入BIM技术可以提升病害信息管理的效率,实现裂纹病害信息的可视化,通过4D裂纹病害信息模型的创建可以直观地对裂纹病害的发展历程加以呈现,帮助桥梁运维管理人员科学地预测裂纹发展趋势.Abstract: In order to solve the problem of complex data collection process, poor visualization effect and lack of time-related factors in the traditional bridge defects information management process, the building information modeling (BIM) technology was used to realize the visualization of a steel truss bridge crack defect, and a method for rapid batch update of crack defects information was developed with the visual programming software Dynamo, in which the update code is modularized. By introducing time parameters of defects, a 4D crack defects information model was created, whereby the dynamic correlation between crack defect information and 3D graphics in time series was realized, and the crack propagation law was presented. Results show that the introduction of BIM technology into the bridge defects management system can improve the efficiency of defects information management and realize the visualization of crack defects information. The created 4D crack defects information model can intuitively present the development process of crack defects, facilitate bridge operation and maintenance, and help managers scientifically predict the trend of crack development.

-

Key words:

- steel truss bridge /

- crack /

- building information modeling (BIM) /

- disease management /

- time parameter /

- 4D model

-

表 1 主裂纹信息模型关键数据

Table 1. Key data of main crack information model

裂纹

编号出现

部位长度/

mm宽度/

mm深度/

mm角度/(°) 1# 横梁开孔处(左) 170 1 16 90 2# 横梁开孔处(右) 170 1 16 90 3# 横梁底部(左) 310 2 16 80 4# 横梁底部(右) 350 2 16 80 注:主裂纹角度以裂纹根部轴线与板件边缘所夹锐(直)角计. -

JI Y, BORRMANN A, OBERGRIEΒER M. Toward the exchange of parametric bridge models using a neutral data format[C]//ASCE International Workshop on Computing in Civil Engineering: ASCE, 2011: 528-535. JI Y, BEETZ J, BONSMA P, et al. Integration of parametric geometry into IFC-Bridge[C]//Proc. of the 23th Forum Bauinformatik. Cork: University of Cork, 2011: 593-606. FANNING B, CLEVENGER C M, OZBEK M E, et al. Implementing BIM on infrastructure: comparison of two bridge construction projects[J]. Practice Periodical on Structural Design & Construction, 2015, 20(4): 4014044.1-4014044.8. CHEN S S, SHIROLE A M. Integration of informa-tion and automation technologies in bridge engineering and management:extending the state of the art[J]. Transportation Research Record Journal of the Transportation Research Board, 2006, 1976(1): 3-12. LEE S, PARK S, PARK J, et al. Open BIM-based information modeling of railway bridges and its application concept[C]//Computing in Civil and Building Engineering. Orlando: ASCE press, 2014: 504-511. LAISERIN J, WANG X. Comparing pommes and naranjas[J]. Archicreation, 2011, 4: 136-139. RIO J, FERREIRA B, MARTINS J P P. Expansion of IFC model with structural sensors[J]. Informes de la Construccion, 2013, 65(530): 219-228. JI Y, BORRMANN A, BEETZ J, et al. Exchange of parametric bridge models using a neutral data format[J]. Journal of Computing in Civil Engineering, 2012, 27(6): 593-606. KIM D W, LEE K M, NAM S H. Development of BIM based information model interface module for a modular pier[J]. Journal of KIBIM, 2015, 5(1): 1-7. doi: 10.13161/kibim.2015.5.1.001 YOO B Y, YOON H J, KIM Y J, et al. Stepwise application of BIM-based parametric modeling to tapered slip-form system[J]. Procedia Engineering, 2016, 145: 112-119. doi: 10.1016/j.proeng.2016.04.028 SHIN H M, LEE H M, OH S J, et al. Analysis and design of reinforced concrete bridge column based on BIM[J]. Procedia Engineering, 2011, 14: 2160-2163. doi: 10.1016/j.proeng.2011.07.271 GUIRE B M, ATADERO R, CLEVENGER C, et al. Bridge information modeling for inspection and evaluation[J]. Journal of Bridge Engineering, 2016, 21(4): 51-63. 李红学,郭红领,高岩,等. 基于BIM的桥梁工程设计与施工优化研究[J]. 工程管理学报,2012,26(6): 48-52. doi: 10.3969/j.issn.1674-8859.2012.06.013LI Hongxue, GUO Hongling, GAO Yan, et al. BIM-based optimization of design and construction for bridge projects[J]. Journal of Engineering Management, 2012, 26(6): 48-52. doi: 10.3969/j.issn.1674-8859.2012.06.013 唐可佳. 基于BIM的扩大基础重力式锚碇参数化设计研究[D]. 成都: 西南交通大学, 2018. 何欣. 基于BIM技术的钢桁拱施工监控可视化研究[D]. 成都: 西南交通大学, 2018. 龙腾. 基于BIM的变截面桥体可视化施工技术应用研究[D]. 武汉: 武汉科技大学, 2015. 王伟涛. 基于BIM技术的斜拉桥施工控制及信息管理研究[D]. 成都: 西南交通大学, 2018. 宁新稳,朱庆,任晓春,等. 高速铁路施工进度数据图形化处理方法[J]. 西南交通大学学报,2018,53(2): 414-419. doi: 10.3969/j.issn.0258-2724.2018.02.027NING Xinwen, ZHU Qing, REN Xiaochun, et al. Graphical processing method of high-speed railway construction progress data[J]. Journal of Southwest Jiaotong University, 2018, 53(2): 414-419. doi: 10.3969/j.issn.0258-2724.2018.02.027 李浩,赵国堂,范丁元,等. 面向GIS应用的铁路工程三维信息模型数据交换方法[J]. 西南交通大学学报,2018,53(1): 197-205. doi: 10.3969/j.issn.0258-2724.2018.01.024LI Hao, ZHAO Guotang, FAN Dingyuan, et al. Data exchange method of railway engineering information model for GIS applications[J]. Journal of Southwest Jiaotong University, 2018, 53(1): 197-205. doi: 10.3969/j.issn.0258-2724.2018.01.024 卫星,巨云华. 基于BIM+VR技术的钢结构桥梁教学实践改革研究[J]. 图学学报,2018,39(6): 1231-1238.WEI Xing, JU Yunhua. Teaching and practice reform of steel structure bridge based on BIM+VR technology[J]. Journal of Graphics, 2018, 39(6): 1231-1238. -

下载:

下载: