Checking and Analysis of Reinforcement Arrangement Scheme for Slab Track Based on Comprehensive Index Method

-

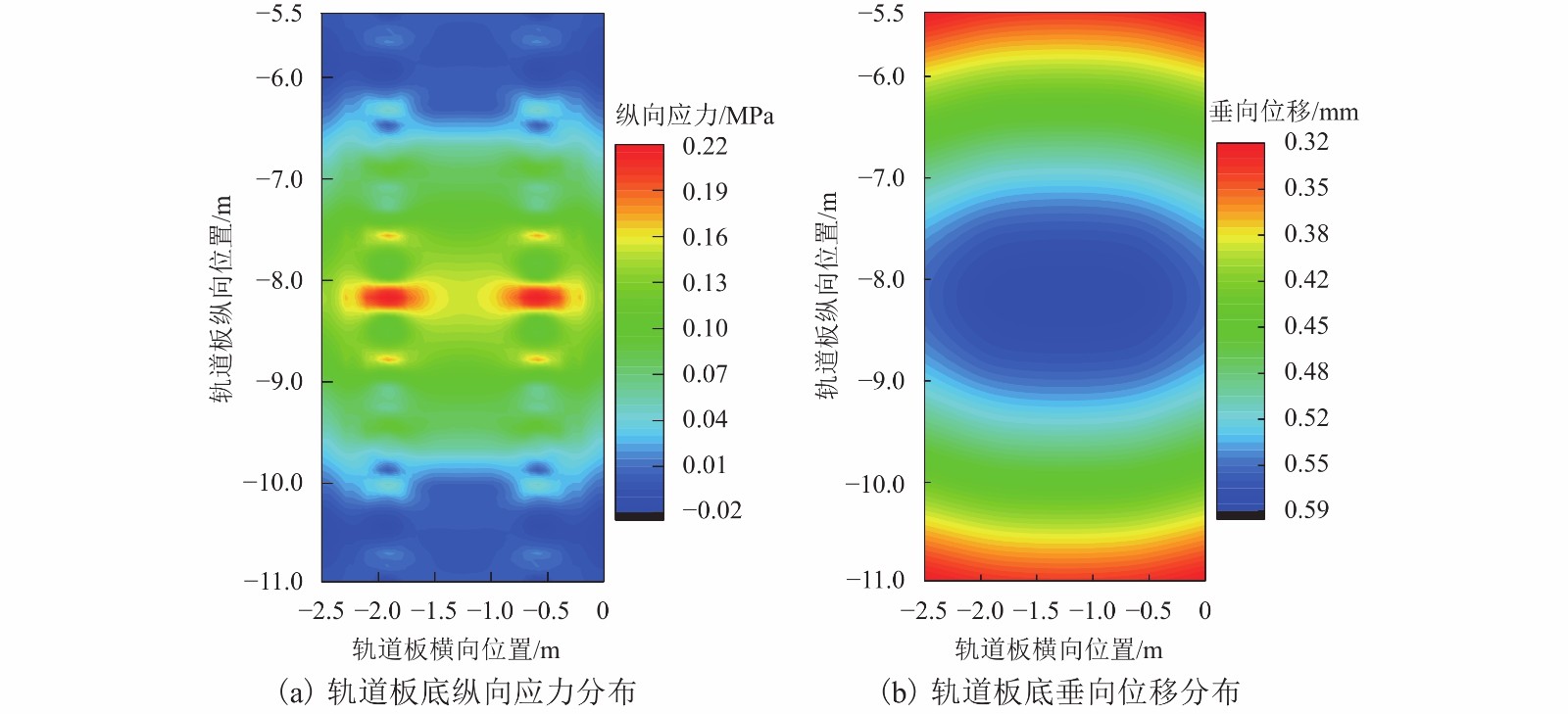

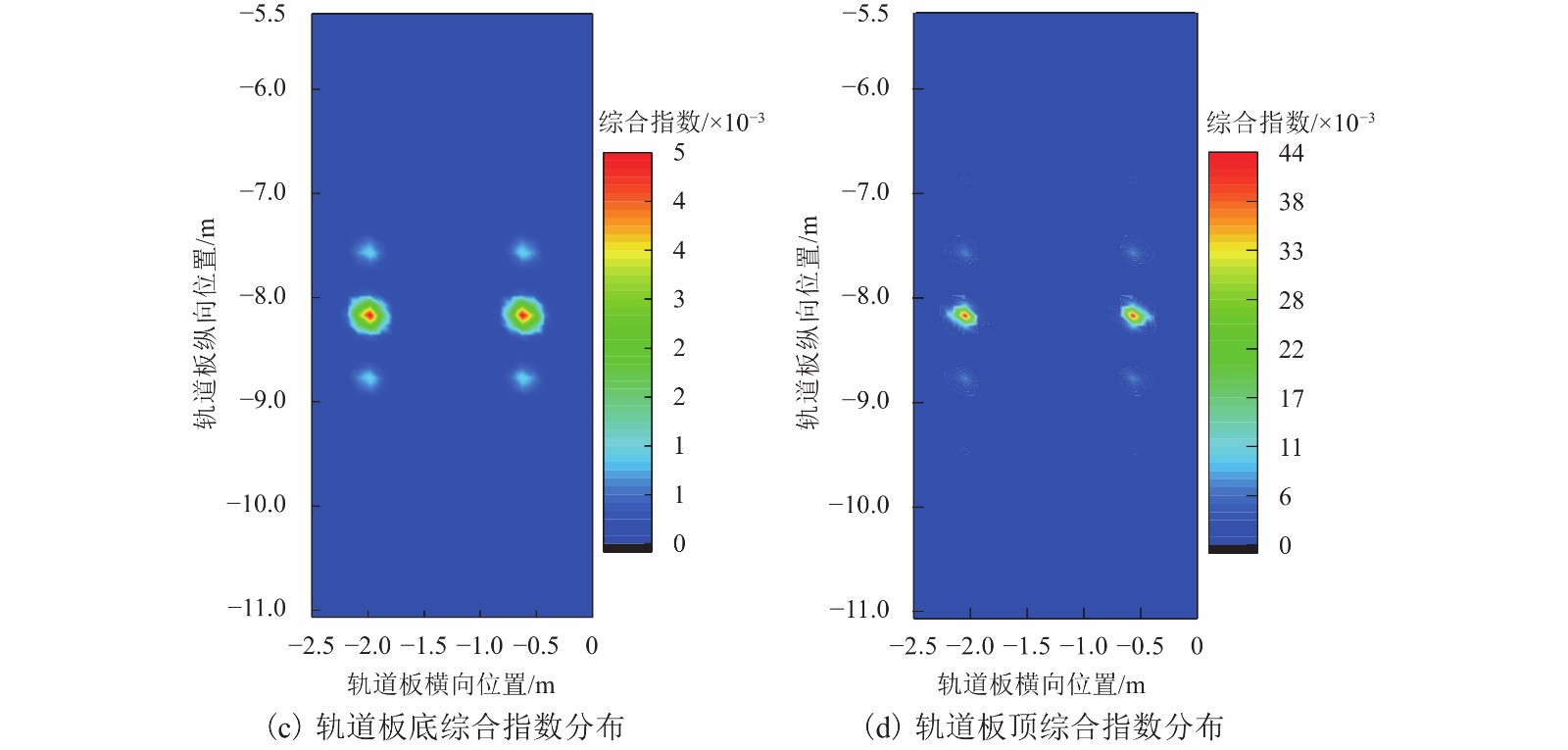

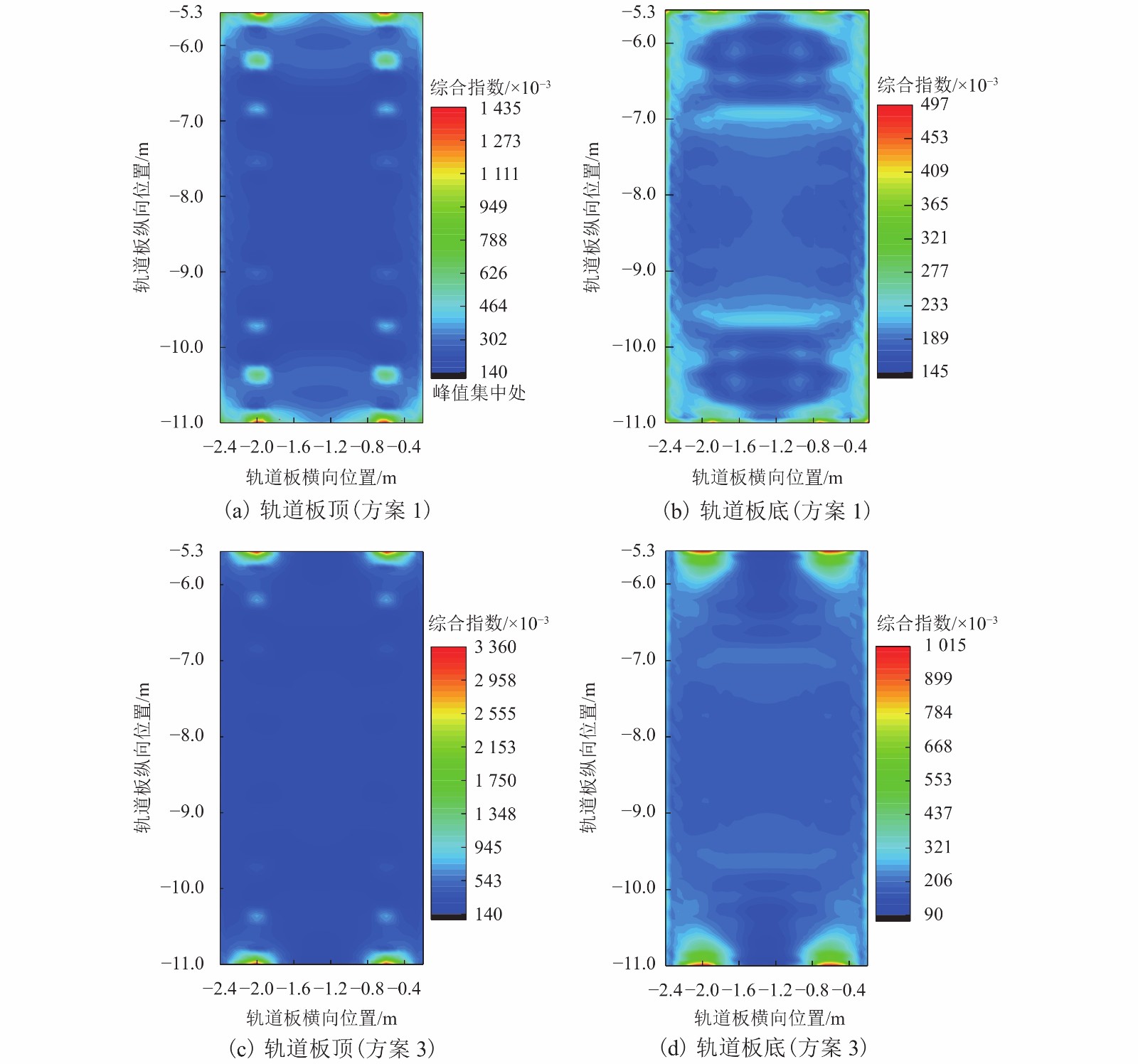

摘要: 为优化无砟轨道配筋后结构受力的均衡性,基于综合指数法提出了轨道配筋检算评估方法,选取形状改变能密度与高斯曲率作为评价分量构造了量化的配筋检算指标;建立了无砟轨道配筋检算有限元模型,以CRTSⅢ型普通板式无砟轨道板配筋为例,研究了不同钢筋排布方式对无砟轨道板整体受力性能的影响. 研究结果表明:相较传统应力变形指标,构建的综合指数指标能够凸显轨道板的不均匀受力区域;配筋时在轨下位置额外密布钢筋能够提升轨道板抵抗垂向车辆荷载的能力;局部配筋过于集中的方案会降低轨道板适应温度荷载的能力;在升温荷载作用下其轨道板端部的综合指数较最优工况时至少增大了1倍;综合来看,钢筋直径较大、排列稀疏的方案受力均衡性较差,无砟轨道板应选择钢筋直径较小、排列密布且轨下位置适当加密的配筋方案.Abstract: To optimize the mechanical performance of the slab track after reinforcement, an evaluation method for track reinforcement was proposed based on comprehensive index method. The shape change energy density and Gaussian curvature were selected as the evaluation components to construct the quantitative checking index of the reinforcement. Taking CTRS Ⅲ ordinary type slab track as an example, a finite element model for slab reinforcement checking was established, and the influence of different reinforcement schemes on the overall mechanical performance of slab was analyzed. The results indicate that the proposed comprehensive index could highlight the uneven stress area of the track slab. The centralized reinforcement under the rail position can improve the resistance of the track slab to the vertical vehicle load. However, the excessively concentrated reinforcement will lead to a worse adaptability to the temperature load. Compared to the optimum scheme, the comprehensive index of the end of the track plate of the excessively concentrated reinforcement scheme under the heating load is more than doubled. The scheme with larger steel bar diameter and sparse arrangement has poor force balance. The track slab should choose a reinforcement scheme with smaller steel bar diameter, densely arranged, and appropriate centralized under the rail.

-

Key words:

- slab track /

- reinforcement /

- temperature effect /

- structural optimization /

- comprehensive index method

-

表 1 数值仿真模型材料参数

Table 1. Material parameters of numerical model

结构部件 弹性模量/MPa 泊松比 密度/(kg•m−3) 线胀系数/℃ 垫层刚度/(kN•mm−1) 垂向刚度/(MPa•m−1) 轨道板 36500 0.200 2500 1× 10−5 自密实混凝土 34000 0.167 2500 1× 10−5 底座 28000 0.167 2500 凹槽弹性垫层 30 路基 76 表 2 保证相同配筋率条件下不同普通钢筋配置方案

Table 2. Different reinforcement arrangement scheme under same reinforcement ratio

方案名称 上层纵向钢筋 下层纵向钢筋 上层横向钢筋 下层横向钢筋 方案 1 9ϕ16 9ϕ16 11ϕ16 11ϕ16 方案 2、3 17ϕ12 17ϕ12 21ϕ12 21ϕ12 表 3 横纵向钢筋在轨道板内部的具体位置

Table 3. Specific position of transverse and longitudinal reinforcement inside the rail plate

方案名称 横向钢筋在轨道板内部的具体位置 纵向钢筋在轨道板内部的具体位置 方案 1

方案 2

方案 3

表 4 车辆荷载作用下不同普通钢筋配置方案下板底指标对比

Table 4. Comparison of statistical indexes of bottom of track slab for each scheme under vehicle load

方案名称 纵向应力 垂向位移 综合指数 峰值/Pa 均方差/Pa2 变异系数 峰值/mm 均方差/×10−5mm2 变异系数 峰值/×10−8 均方差/×10−8 变异系数 方案 1 240443 62520.44 1.00302 0.336899 8.4307 0.16550 5.76 0.37 4.89 方案 2 220511 56545.35 0.94748 0.316384 7.8893 0.16631 4.87 0.31 4.82 方案 3 220434 56409.00 0.94488 0.316378 7.8896 0.16551 4.82 0.30 4.81 表 5 车辆荷载作用下不同普通钢筋配置方案下板顶各综合指数指标对比

Table 5. Comparison of statistical indexes oftrack slab top for each scheme under vehicle load

方案 峰值/×10−7 均方差/×10−8 变异系数 方案 1 5.29 2.17 9.90 方案 2 4.39 1.80 9.75 方案 3 4.30 1.76 9.71 表 6 整体升温作用下不同普通钢筋配置方案板顶、底各综合指数指标对比

Table 6. Comparison of comprehensive statistical indexes of different schemes under overall temperature rising load

方案名称 顶面 底面 峰值/×10−5 均方差/×10−6 变异系数 峰值/×10−6 均方差/×10−7 变异系数 方案 1 1.654 95 1.533 0.60 7.601 9 6.800 0.36 方案 2 1.430 19 1.273 0.46 4.966 3 4.005 0.20 方案 3 3.354 46 2.767 0.91 10.108 9 9750 0.91 表 7 正、负温度梯度作用下不同普通钢筋配置方案综合指数指标

Table 7. Comprehensive index of different reinforcement schemes under positive and negative temperature gradients

温度阶梯 方案名称 顶面 底面 峰值/×10−8 均方差/×10−8 变异系数 峰值/×10−7 均方差/×10−8 变异系数 正 方案 1 5.97 1.39 0.40 2.080 1.31 1.46 方案 2 5.97 1.35 0.38 1.831 1.20 1.25 方案 3 5.98 1.35 0.38 1.827 1.20 1.25 负 方案 1 37.87 0.10 0.65 2.633 0.06 0.73 方案 2 37.69 0.10 0.65 2.644 0.06 0.73 方案 3 37.69 0.10 0.65 2.644 0.06 0.73 表 8 不同荷载作用下各方案综合比较(以方案2为参照)

Table 8. Comparison of different schemes under different loads (referring to scheme 2)

方案名称 车辆荷载作用 整体升降温作用 正温度梯度作用 负温度梯度作用 方案 1 ↓ ↓ ↓ — 方案 2 — — — — 方案 3 ↑ ↓↓ — — 注:“↑”为表示此方案更优;“↓”表示此方案表现更劣;“—”表明方案间相差不大. -

高亮. 轨道工程[M]. 2版. 中国铁道出版社, 2015. 赵磊. 高速铁路无砟轨道空间精细化分析方法及其应用研究[D]. 北京: 北京交通大学, 2015. 原中华人民共和国铁道部. 铁路桥涵钢筋混凝土和预应力混凝土结构设计规范: TB 10002.3—2005[S]. 北京: 中国铁道出版社, 2005. 苏乾坤,杨荣山,南雄,等. 基于极限状态法的宽轨距CRTSⅢ型板式无砟轨道配筋研究[J]. 铁道科学与工程学报,2016,13(11): 2107-2114. doi: 10.3969/j.issn.1672-7029.2016.11.002SU Qiankun, YANG Rongshan, NAN Xiong, et al. The reinforce ment design of CRTS Ⅲ slab ballastless track with track gauge widening which was based on limi-state method[J]. Journal of Railway Science and Engineering, 2016, 13(11): 2107-2114. doi: 10.3969/j.issn.1672-7029.2016.11.002 李培刚,王伟华,杨荣山. 客运专线板式轨道轨道板配筋设计的检算方法[J]. 路基工程,2010(4): 197-199. doi: 10.3969/j.issn.1003-8825.2010.04.075LI Peigang, WANG Weihua, YANG Rongshan. Verification method of track slab reinforcement design in passenger dedicated line[J]. Subgrade Engineering, 2010(4): 197-199. doi: 10.3969/j.issn.1003-8825.2010.04.075 王森荣. 双块式无砟轨道与配筋混凝土路面结构设计研究[J]. 铁道工程学报,2010,27(6): 18-22. doi: 10.3969/j.issn.1006-2106.2010.06.005WANG Senrong. Study on structural design of double-block blab ballastles track and continuous reinforced concrete pavement[J]. Journal of Railway Engineering, 2010, 27(6): 18-22. doi: 10.3969/j.issn.1006-2106.2010.06.005 CHO Y K, KIM S M, CHUNG W, et al. Effect of steel ratio on behavior of continuously reinforced concrete railway track under environmental loads[J]. KSCE Journal of Civil Engineering, 2014, 18(6): 1688-1695. doi: 10.1007/s12205-014-1559-y 赵坪锐,闫见华,王克江,等. 连续道床板拉伸开裂模型试验研究[J]. 西南交通大学学报,2014,49(5): 793-798. doi: 10.3969/j.issn.0258-2724.2014.05.008ZHAO Pingrui, YAN Jianhua, WANG Kejiang, et al. Model experiment study of continuous track slab tension cracks[J]. Journal of Southwest Jiaotong University, 2014, 49(5): 793-798. doi: 10.3969/j.issn.0258-2724.2014.05.008 刘学毅,苏成光,向芬,等. 无砟轨道混凝土开裂特性模型试验研究[J]. 铁道学报,2017,39(7): 105-110. doi: 10.3969/j.issn.1001-8360.2017.07.015LIU Xueyi, SU Chengguang, XIANG Fen, et al. Model experiment on concrete cracking characteristics of ballastless track[J]. Journal of the China Railway Society, 2017, 39(7): 105-110. doi: 10.3969/j.issn.1001-8360.2017.07.015 任娟娟,刘学毅,赵坪锐. 连续道床板裂纹计算方法及影响因素[J]. 西南交通大学学报,2010,45(1): 34-38. doi: 10.3969/j.issn.0258-2724.2010.01.006REN Juanjuan, LIU Xueyi, ZHAO Pingrui. Crack calculation method and influence factors for continuously reinforced slab[J]. Journal of Southwest Jiaotong University, 2010, 45(1): 34-38. doi: 10.3969/j.issn.0258-2724.2010.01.006 林红松,李培刚,颜华,等. 列车荷载下考虑道床裂纹的无砟轨道受力特性[J]. 西南交通大学学报,2010,45(6): 904-908. doi: 10.3969/j.issn.0258-2724.2010.06.014LIN Hongson, LI Peigang, YAN Hua, et al. Mechanical analysis of ballastless track with damaged cracks under train load[J]. Journal of Southwest Jiaotong University, 2010, 45(6): 904-908. doi: 10.3969/j.issn.0258-2724.2010.06.014 赵磊,高亮,蔡小培,等. CRTSⅠ型无砟轨道板预应力筋破坏所致附加荷载的影响分析[J]. 铁道学报,2015,37(12): 74-80. doi: 10.3969/j.issn.1001-8360.2015.12.012ZHAO Lei, GAO Liang, CAI Xiaopei, et al. Analysis of influence of additional load caused by prestressed reinforcement destruction of CRTSⅠtrack slab[J]. Journal of the China Railway Society, 2015, 37(12): 74-80. doi: 10.3969/j.issn.1001-8360.2015.12.012 徐家铎. 客货共线CRTS Ⅰ型板式无砟轨道锚穴部位损伤分布及裂纹扩展研究[D]. 成都: 西南交通大学, 2018. 陈仁杰,钱海雷,袁东,等. 改良综合指数法及其在上海市水源水质评价中的应用[J]. 环境科学学报,2010,30(2): 431-437.CHEN Renjie, QIAN Hailei, YUAN Dong, et al. Improved comprehensive index method and its application to evaluation of source water quality in Shanghai[J]. Acta Scientiae Circumstantiae, 2010, 30(2): 431-437. 黄立葵,王瑞金,刘虹江,等. 不同基层类型沥青路面的形变能响应分析[J]. 公路工程,2017,42(3): 45-47,63. doi: 10.3969/j.issn.1674-0610.2017.03.009HUANG Likui, WANG Ruijin, LIU Hongjiang, et al. Analysis on distortion energy of asphalt pavement under different base types[J]. Highway Engineering, 2017, 42(3): 45-47,63. doi: 10.3969/j.issn.1674-0610.2017.03.009 高亮,赵磊,曲村,等. 路基上CRTSⅢ型板式无砟轨道设计方案比较分析[J]. 同济大学学报(自然科学版),2013,41(6): 848-855.GAO Liang, ZHAO Lei, QU Cun, et al. Analysis on design scheme of CRTSⅢ slab track structure on roadbed[J]. Journal of Tongji University (Natural Science), 2013, 41(6): 848-855. 杨国涛,高亮,刘秀波,等. 基于动力分析的CRTSⅢ板式无砟轨道路基冻胀控制标准研究[J]. 铁道学报,2017,39(10): 110-117. doi: 10.3969/j.issn.1001-8360.2017.10.015YANG Guotao, GAO Liang, LIU Xiubo, et al. Research on division standard of subgrade frost heaving for CRTS Ⅲ slab track based on dynamic analysis[J]. Journal of the China Railway Society, 2017, 39(10): 110-117. doi: 10.3969/j.issn.1001-8360.2017.10.015 中国铁路总公司. 高速铁路设计规范: TB 10621—2014[S]. 北京: 中国铁道出版社, 2014. -

下载:

下载: