Effect of Rail Hardness on Fatigue Cracks Initiation and Rail Wear

-

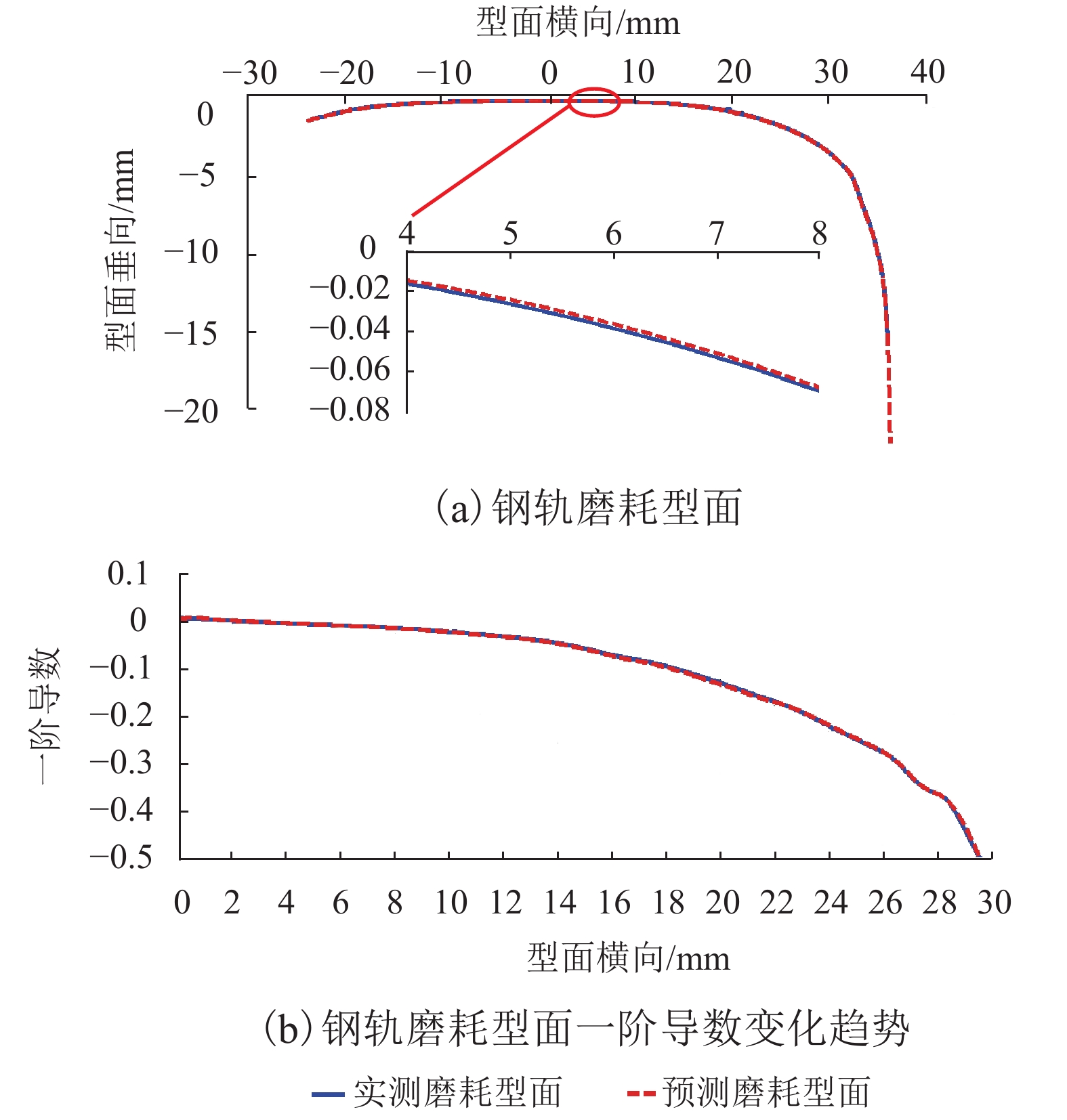

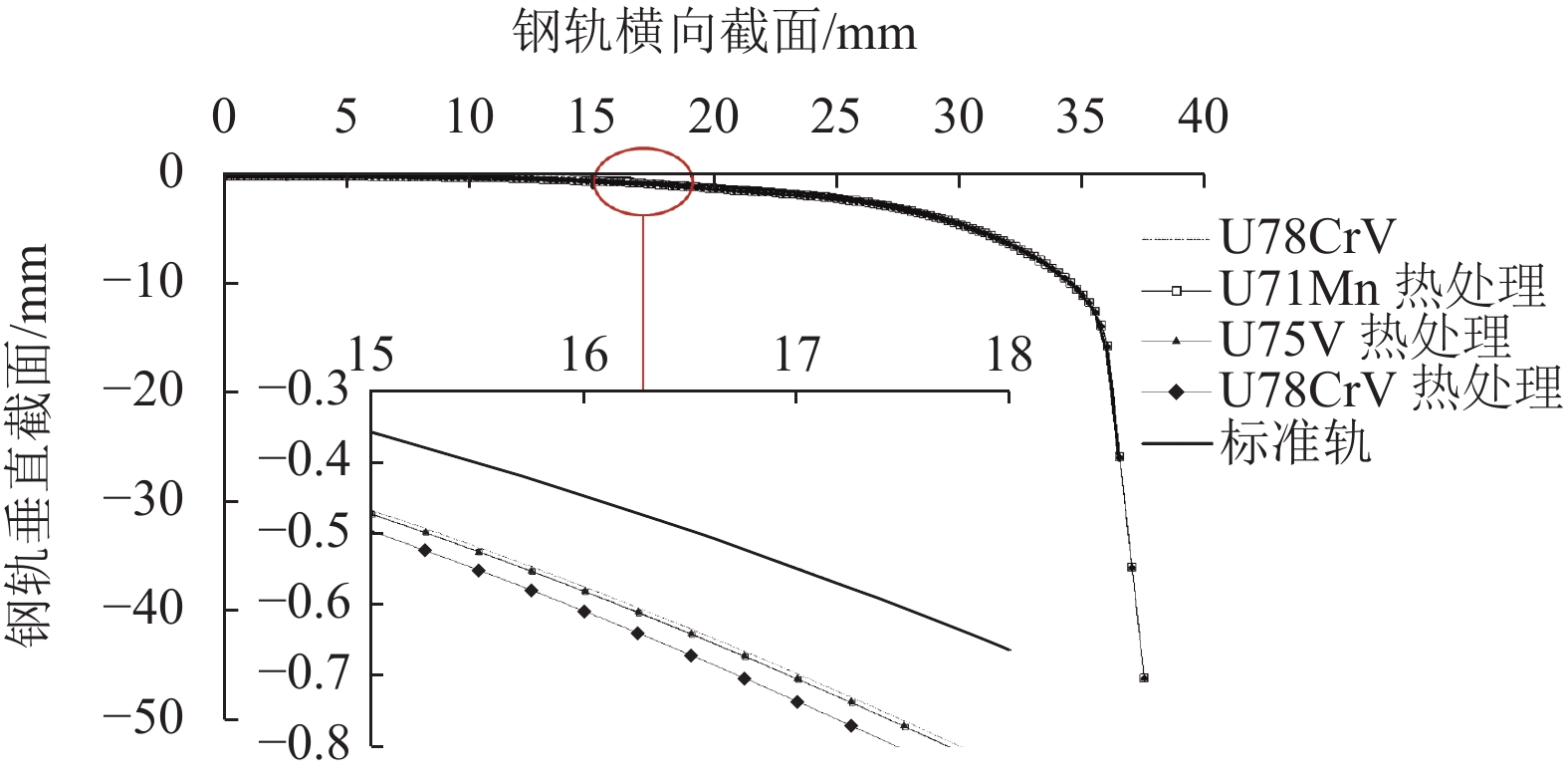

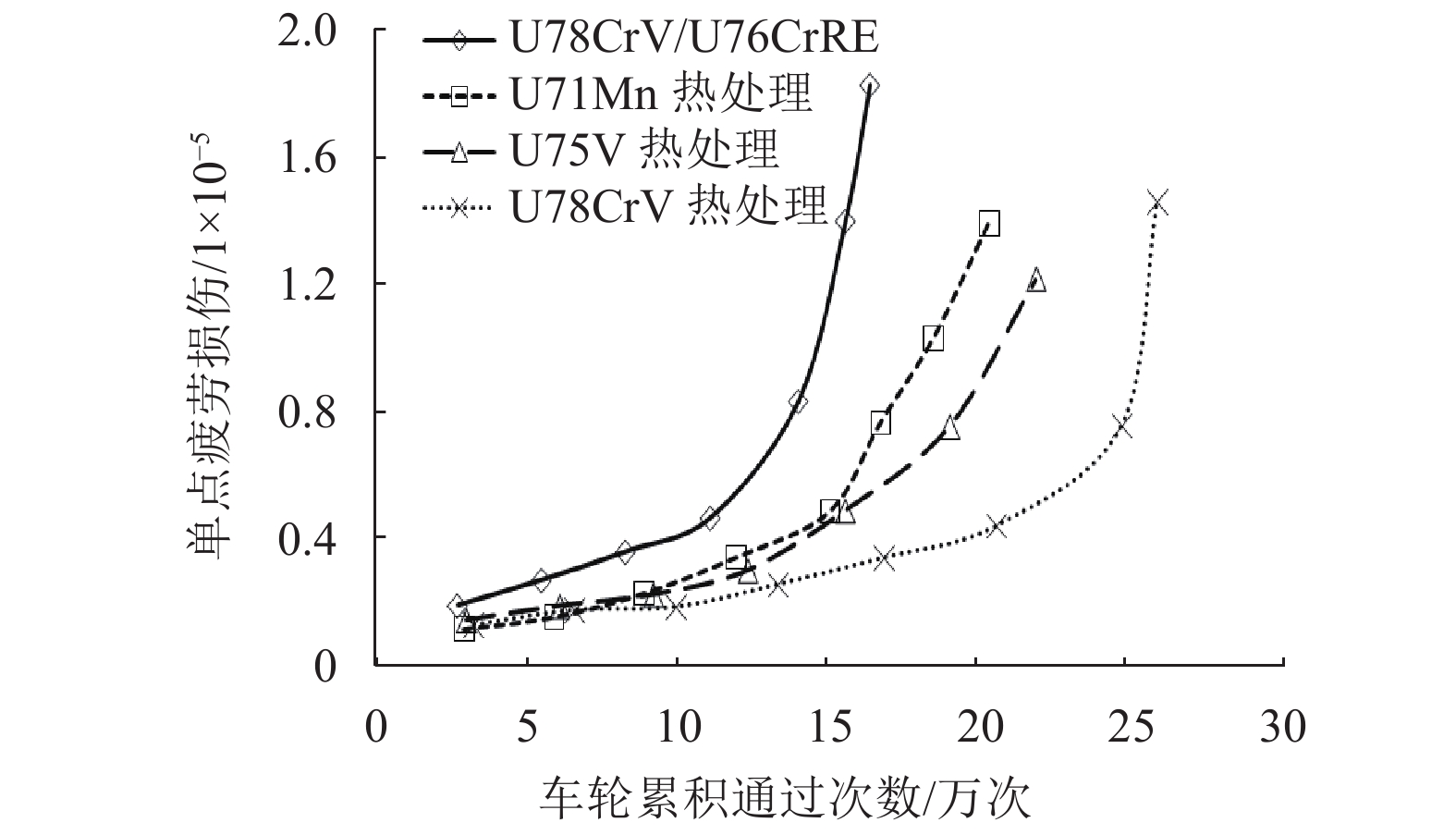

摘要: 为了研究钢轨磨耗和疲劳裂纹萌生寿命与钢轨硬度的关系,基于Archard磨耗模型和临界平面法疲劳裂纹萌生预测模型,结合磨耗和型面变化分段迭代和疲劳损伤累积,提出了钢轨疲劳裂纹萌生和磨耗共存预测方法;对4种不同硬度钢轨的磨耗发展、疲劳损伤累积以及疲劳裂纹萌生寿命进行研究. 结果表明:该方法预测的裂纹萌生寿命与现场观测结果有较好的吻合性;高硬度钢轨可以降低磨耗、延长疲劳裂纹萌生寿命,适合在小半径曲线上应用;4种硬度的钢轨中,钢轨硬度每提高10 HBW,平均磨耗发展率将降低约3%~6%,疲劳裂纹萌生寿命延长约9%~12%;对比U78CrV/U76CrRE热轧钢轨,U78CrV热处理钢轨的平均硬度值增加了17.9%,磨耗发展率降低了约19.8%,疲劳裂纹萌生寿命延长了约57.7%;在轮轨摩擦系数为0.3时,4种钢轨的疲劳裂纹均萌生于轨面1.0~2.5 mm以下的亚表面范围内,距离轨顶中心15~18 mm.Abstract: In order to study the relationship between rail hardness and rail wear and fatigue cracks initiation life, based on the Archard wear model and the critical plane fatigue cracks initiation prediction model, the prediction method for the coexistence of rail fatigue cracks initiation and wear was presented by combining wear and sectional iteration of profile changes and fatigue damage accumulation. The wear growth, fatigue damage accumulation and fatigue cracks initiation life of 4 kinds of rails with different hardness were researched. The results show that the fatigue cracks initiation life predicted by above-mentioned method has a good agreement with that of the field observation. The rail with high hardness can reduce wear and prolong the fatigue cracks initiation life, which is suitable for sharp curves. Among the rails with four hardness, the average wear growth rate can be reduced by about 3% − 6% and the fatigue cracks initiation life can be prolonged by about 9% − 12% when the hardness of the rail increases by every 10 HBW. Comparing to the U78CrV/U76CrRE hot rolled rail, the average hardness of the U78CrV heat-treated rail increases by about 17.9% while the wear growth rate reduces by about 19.8% and its fatigue cracks initiation life prolongs by about 57.7%. With the wheel/rail friction coefficient of 0.3, the fatigue cracks are initiated at rail sub-surface which is below rail surface of about 1.0 − 2.5 mm and close to rail top center of about 15 − 18 mm in all 4 kinds of rails.

-

Key words:

- rail /

- hardness /

- wear /

- rolling contact fatigue /

- rail type selection

-

表 1 钢轨磨耗及裂纹状态

Table 1. Rail wear and crack state

通过总

重/MGT显微观测

(残留)裂纹深度/mm垂直磨耗/mm 实际裂纹深度/mm 平均值 中位数 最大值 11.0 1.58 0.35 0.26 0.85 1.94 表 2 裂纹萌生预测结果对比

Table 2. Comparison of prediction results of crack initiation

表 3 钢轨硬度及其抗拉强度

Table 3. Rail hardness and strength

钢牌号 布氏硬度/HBW 抗拉强度/MPa U78CrV/U76CrRE

热轧310~360 (335) 1130 U71Mn 热处理 320~380 (350) 1170 U75V 热处理 340~400 (370) 1256 U78CrV 热处理 370~420 (395) 1357 注:括号中的硬度中间值为本文仿真计算中所用到的硬度值. 表 4 不同钢轨的疲劳裂纹萌生寿命

Table 4. Fatigue cracks initiation life of the different kinds of rails

钢牌号 裂纹萌生寿命(车轮通过次数)/(× 105 次) 裂纹萌生寿命

(通过总重)/MGTU78CrV/U76CrRE

热轧1.63 3.00 U71Mn 热处理 2.02 3.71 U75V 热处理 2.17 4.00 U78CrV 热处理 2.57 4.72 表 5 钢轨硬度、磨耗和疲劳裂纹萌生寿命的关系

Table 5. Relationship between rail hardness, wear growth and head check initiation life

钢牌号 裂纹萌生寿命(车轮通过次数)/(×105次) 平均磨耗发展率/

(μm•万次−1)U78CrV/U76CrRE 热轧 1.63 4.763 U71Mn 热处理 2.02 4.349 U75V 热处理 2.17 4.265 U78CrV 热处理 2.57 3.818 -

张银花, 周清跃, 陈朝阳, 等. 重载铁路钢轨现状及发展方向探讨[C]//铁路重载运输技术交流会论文集. 北京: 中国铁道出版社, 2014: 381-386. 王金虎. 大秦重车线延长钢轨寿命试验段跟踪研究[C]//铁路重载运输技术交流会论文集. 北京: 中国铁道出版社, 2014: 387-391. 张银花,周清跃,陈朝阳,等. 重载铁路高强钢轨的试验研究[J]. 中国铁道科学,2010,31(4): 20-26.ZHANG Yinhua, ZHOU Qingyue, CHEN Zhaoyang, et al. Test study on the high strength rails of heavy haul railway[J]. China Railway Science, 2010, 31(4): 20-26. 陈朝阳,周清跃,张银花,等. 低合金高强度贝氏体钢轨的试验研究[J]. 铁道学报,2013,35(8): 75-79. doi: 10.3969/j.issn.1001-8360.2013.08.012CHEN Zhaoyang, ZHOU Qingyue, ZHANG Yinhua, et al. Study on high strength low alloy bainitic steel rail[J]. Journal of the China Railway Society, 2013, 35(8): 75-79. doi: 10.3969/j.issn.1001-8360.2013.08.012 张银花,李闯,周清跃,等. 我国重载铁路用过共析钢轨的试验研究[J]. 中国铁道科学,2013,34(6): 1-7. doi: 10.3969/j.issn.1001-4632.2013.06.01ZHANG Yinhua, LI Chuang, ZHOU Qingyue, et al. Test study on hypereutectoid rail for heavy haul railway in China[J]. China Railway Science, 2013, 34(6): 1-7. doi: 10.3969/j.issn.1001-4632.2013.06.01 ZHOU Y, WANG S F, WANG T Y, et al. Field and laboratory investigation of the relationship between rail head check and wear in a heavy-haul railway[J]. Wear, 2014, 315(1): 68-77. OLOFSSON U, TELLISKIVI T. Plastic deformation and fricition of two rail steels — a full-scale test and a laboratory study[J]. Wear, 2003, 254(1/2): 80-93. ENBLOM R, BERG M. Proposed procedure and trial simulation of rail profiles evolution due to uniform wear[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2008,222(1): 15-25. WANG W J, HU J, GUO J, et al. Effect of laser cladding on wear and damage behaviors of heavy-haul wheel/rail materials[J]. Wear, 2014, 311(1/2): 130-136. MUSTER H, SCHMEDDERS H, WICK K, et al. Rail rolling contact fatigue,the performance of naturally hard and head-hardened rails in track[J]. Wear, 1996, 191(1): 54-64. LI Z L, KALKER J J. Simulation of severe wheel-rail wear[C]//Proceedings of the 6th International Conference on Computer Aided Design, Manufacture and Operation in the Railway and Other Advanced Mass Transit Systems. [S.l.]: WIT Press, 1998: 393-402. JENDEL T, BERG M. Contact mechanics: prediction of wheel wear for rail vehicles— methodology and verification[M]. Berlin: Springer Netherlands, 2002: 229-236. 王少锋,周宇,许玉德,等. 基于蠕滑理论的钢轨临界平面疲劳参量仿真[J]. 铁道学报,2014,36(4): 65-70. doi: 10.3969/j.issn.1001-8360.2014.04.012WANG Shaofeng, ZHOU Yu, XU Yude, et al. Simulation of fatigue parameters of rail critical plane based on wheel-rail creep theory[J]. Journal of the China Railway Society, 2014, 36(4): 65-70. doi: 10.3969/j.issn.1001-8360.2014.04.012 LEWIS R, BRAGHIN F, WARD A, et al. Integrating dynamics and wear modelling to predict railway wheel profile evolution[C]//6th International Conference on Contact Mechanics and Wear of Rail/Wheel Systems (CM2003). Gothenburg: [s.n.], 2003: 7-16. ZHOU Yu, YU Miao, JIANG Junnan. Effects of rail hardness on rail wear and head check initiation[J]. Journal of the Transportation Research Board, 2016,2545: 55-65. 周宇,张杰,王少峰,等. 考虑磨耗的钢轨疲劳裂纹萌生寿命预测仿真[J]. 铁道学报,2016,38(7): 91-97. doi: 10.3969/j.issn.1001-8360.2016.07.013ZHOU Yu, ZHANG Jie, WANG Shaofeng, et al. Simulation on rail head check initiation lifetime prediction considering rail wear[J]. Journal of the China Railway Society, 2016, 38(7): 91-97. doi: 10.3969/j.issn.1001-8360.2016.07.013 ZHOU Y, HAN Y B, MU D S, et al. Prediction of the coexistence of rail head check initiation and wear growth[J]. International Journal of Fatigue, 2018, 112: 289-300. RINGSBERG J W, LOO-MORREY M, JOSEFSON B L, et al. Prediction of fatigue crack initiation for rolling contact fatigue[J]. International Journal of Fatigue, 2000, 22(3): 205-215. WANG J X, XU Y D, LIAN S L, et al. Probabilistic prediction model for initiation of RCF cracks in heavy-haul railway[J]. International Journal of Fatigue, 2011, 33(2): 212-216. 邓铁松,李伟,温泽峰,等. 钢轨滚动接触疲劳裂纹萌生寿命预测[J]. 润滑与密封,2013,38(8): 46-51. doi: 10.3969/j.issn.0254-0150.2013.08.010DENG Tiesong, LI Wei, WEN Zefeng, et al. Prediction on rolling contact fatigue crack initiation life of rails[J]. Lubrication Engineering, 2013, 38(8): 46-51. doi: 10.3969/j.issn.0254-0150.2013.08.010 周宇,王少锋,张杰,等. 轨底坡对曲线线路钢轨疲劳裂纹萌生寿命的影响[J]. 中国铁道科学,2015,36(1): 25-32. doi: 10.3969/j.issn.1001-4632.2015.01.04ZHOU Yu, WANG Shaofeng, ZHANG Jie, et al. Effect of rail cant on fatigue crack initiation life of curve rail[J]. China Railway Science, 2015, 36(1): 25-32. doi: 10.3969/j.issn.1001-4632.2015.01.04 -

下载:

下载: