Adaptive Sliding Mode Control of Shift Clutch In Hydraulic Mechanical Transmission Based on Linear Quadratic Optimization

-

摘要:

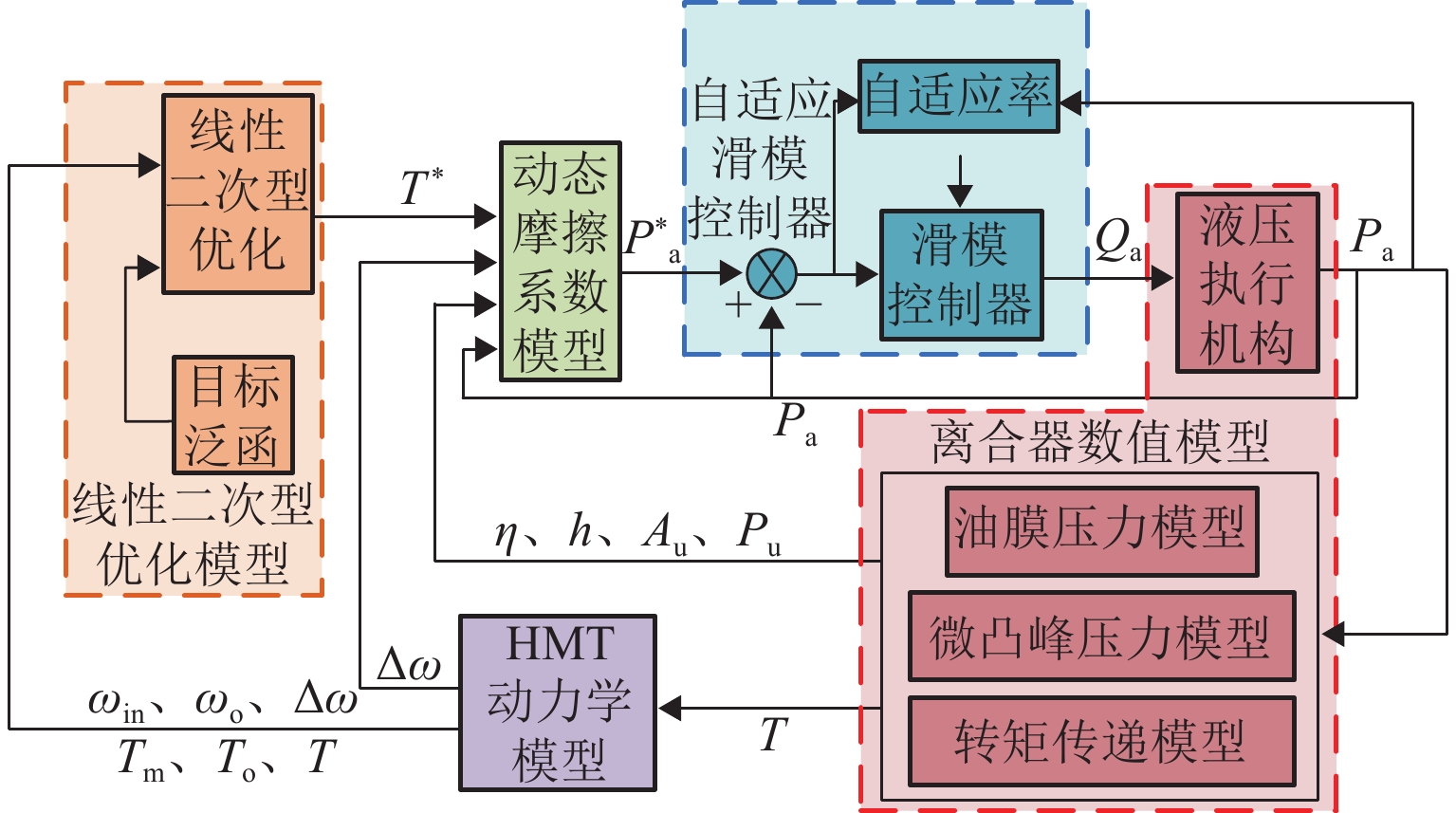

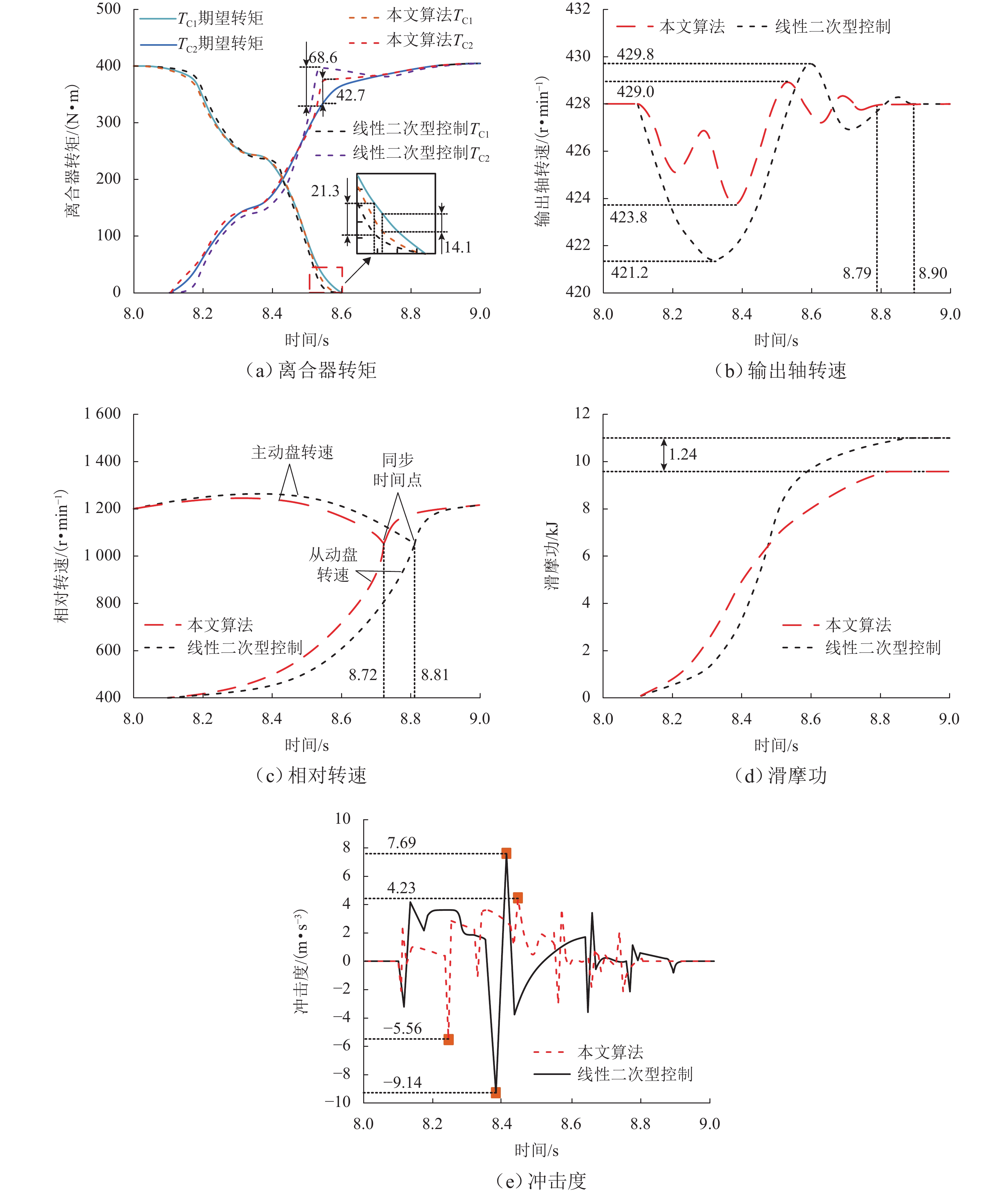

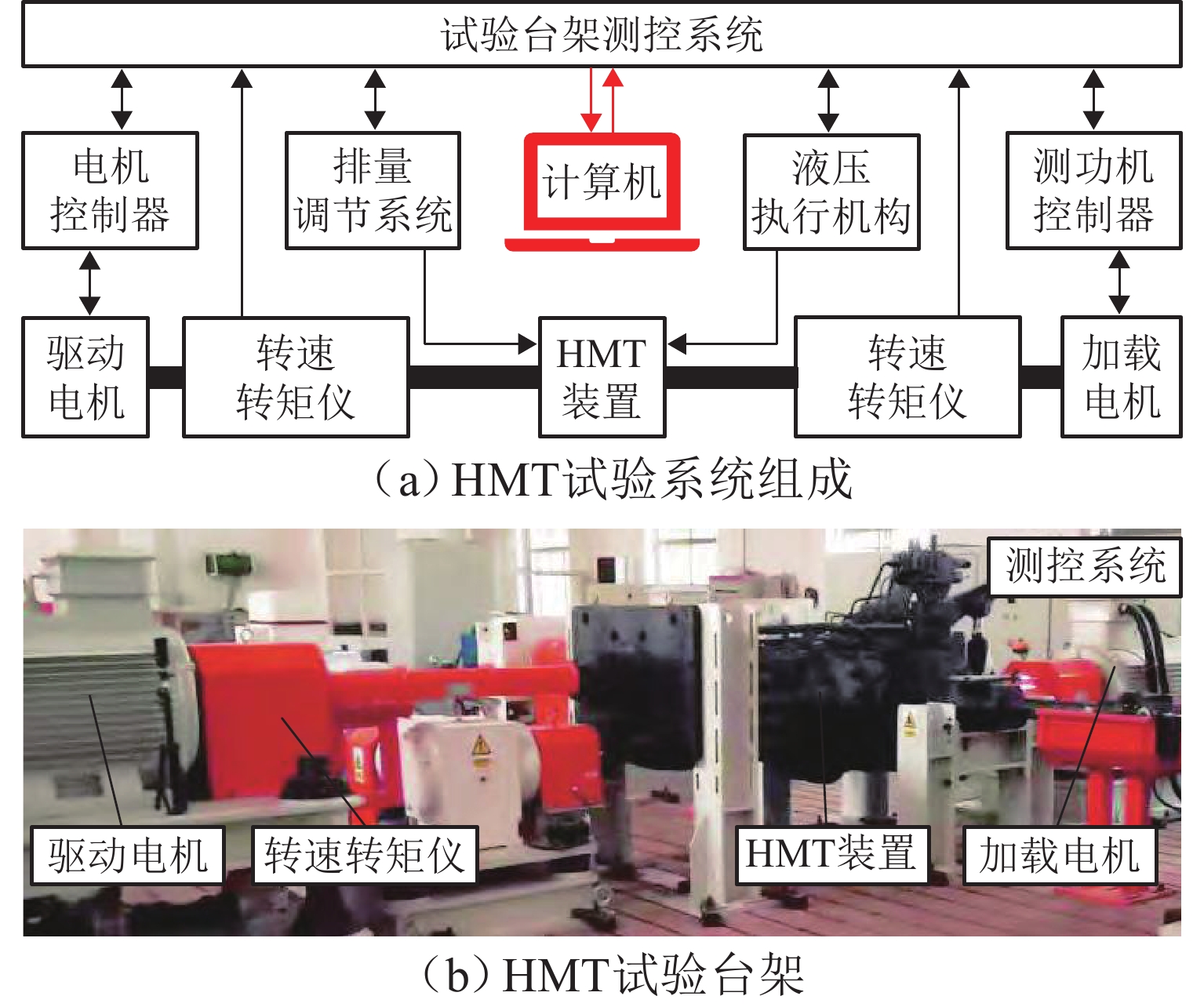

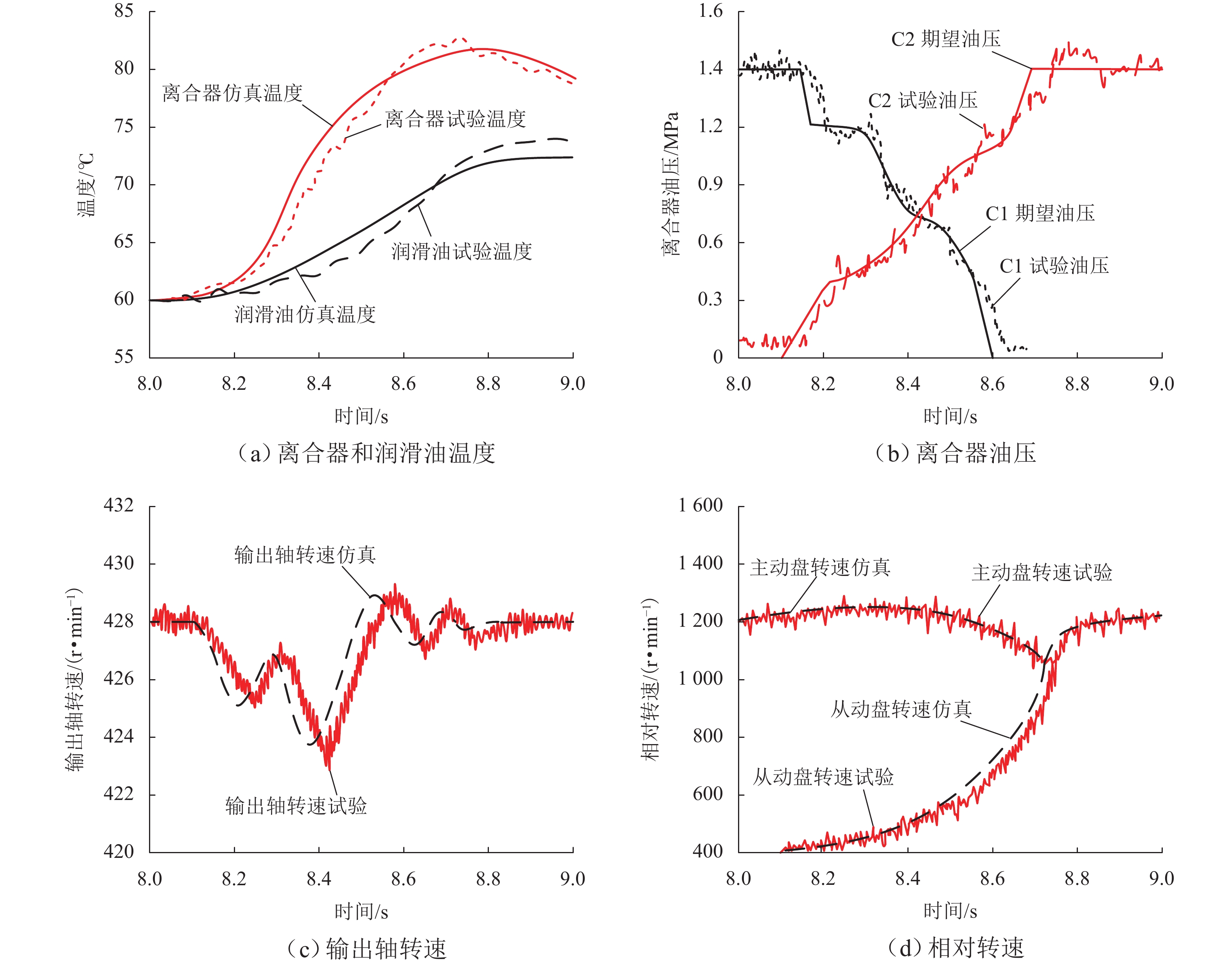

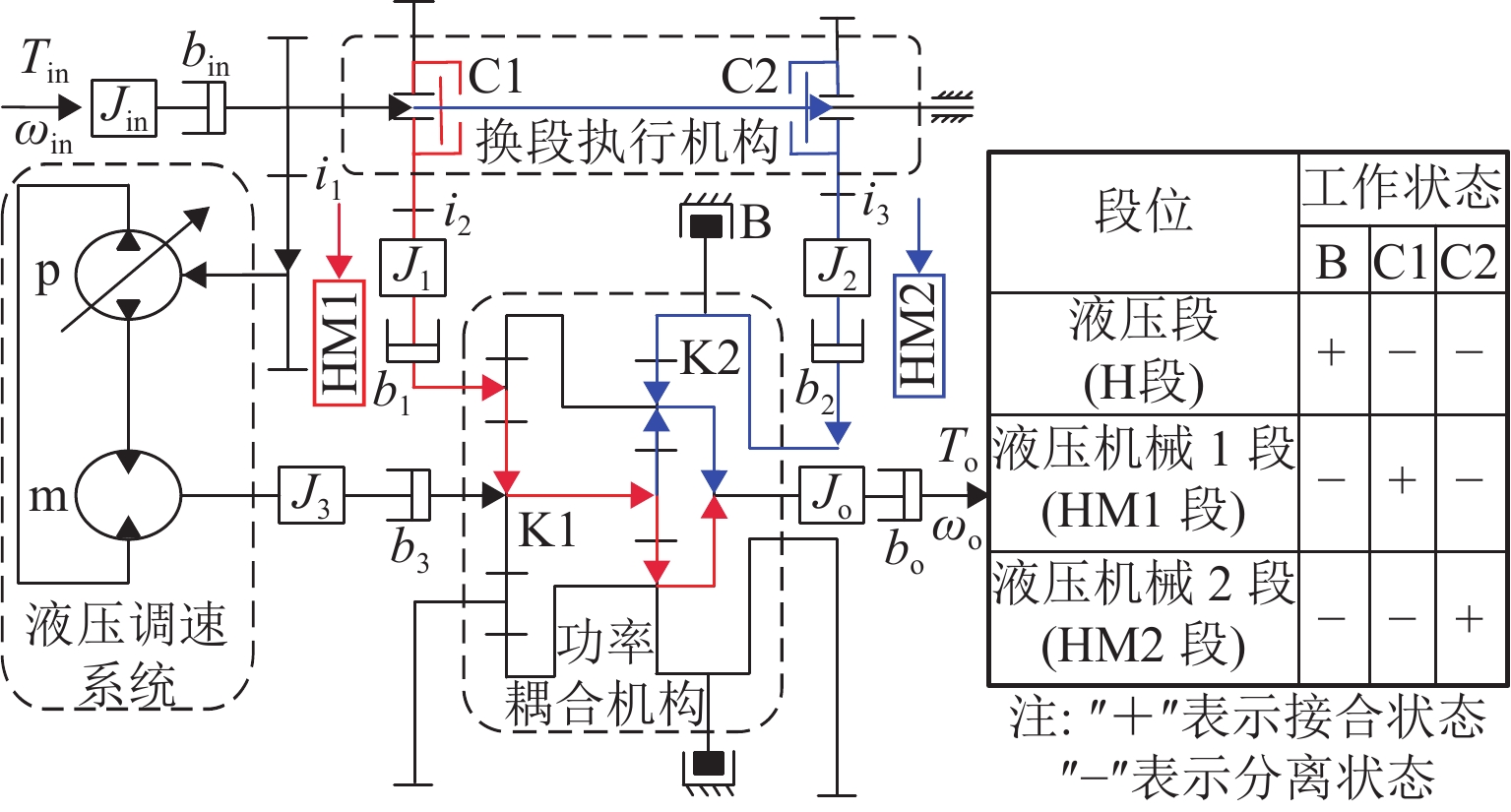

为提高液压机械传动(HMT)换段离合器的转矩传递控制精度,改善其换段质量,提出一种基于线性二次型优化的自适应滑模控制方法. 首先,构建HMT换段动力学模型和离合器数值模型;其次,基于线性二次型优化模型求解目标泛函下换段离合器最优转矩传递轨迹,并结合动态摩擦因数模型,将该轨迹变量转换为考虑润滑油膜时变效应与摩擦界面动态接触特性的期望油压轨迹;最后,利用自适应滑模控制算法对期望油压轨迹进行跟踪控制. 仿真结果表明:与直接采用线性二次型控制方案相比,所提算法有效提高了换段离合器的转矩传递控制精度,换段时间缩短13.8%,滑摩功降低11.2%,最大冲击度减小39.1%;试验进一步证实,该算法在有效提高换段离合器转矩传递控制精度的同时,改善了HMT换段质量. 研究结果可为HMT装置工程应用中的换段控制策略制定提供参考.

Abstract:To improve the torque transmission control accuracy of the shift clutch in hydraulic mechanical transmission (HMT) and enhance its shift quality, an adaptive sliding mode control method based on linear quadratic optimization was proposed. Firstly, the shift dynamics model of HMT and the numerical model of the clutch were constructed. Secondly, the optimal torque transmission trajectory of the shift clutch was solved under the target functional based on the linear quadratic optimization model. Combined with the dynamic friction coefficient model, the trajectory variable was converted into the expected oil pressure trajectory considering the time-varying effect of the lubricating oil film and the dynamic contact characteristics of the friction interface. Finally, the adaptive sliding mode control algorithm was used to track and control the expected oil pressure trajectory. Simulation results show that compared with the direct application of the linear quadratic control scheme, the proposed algorithm effectively improves the torque transmission control accuracy of the shift clutch, shortens the shift time by 13.8%, reduces the sliding friction work by 11.2%, and decreases the maximum shock by 39.1%. Experiments further confirm that the algorithm not only effectively improves the torque transmission control accuracy of the shift clutch but also improves the shift quality of HMT. The research results can provide a reference for the formulation of shift control strategies in the engineering application of HMT devices.

-

表 1 主要仿真参数

Table 1. Key simulation parameters

参数名称 参数值 整车整备质量/kg 12 500 驱动轮半径/m 0.485 主减速器传动比 9.0 定量马达排量/(mL•r−1) 100 变量泵最大排量/(mL•r−1) 125 离合器润滑油初始温度/℃ 60 离合器初始油膜厚度/m 1 × 10−4 离合器微凸峰曲率半径/m 8.5 × 10−4 离合器摩擦副联合粗糙度/m 8.4 × 10−6 离合器摩擦副当量弹性模量/Pa 2.5 × 107 -

[1] BAEK S M, KIM W S, SOO K Y, et al. Design of the hydro-mechanical transmission for a 55kW-class agricultural tractor[J]. Journal of Drive and Control, 2020, 17(2): 19-27. [2] 朱镇, 王登峰, 孙晓东, 等. 机液复合传动装置构型分析[J]. 吉林大学学报(工学版), 2022, 52(10): 2265-2277.ZHU Zhen, WANG Dengfeng, SUN Xiaodong, et al. Configuration analysis of hydro-mechanical composite transmission devices[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(10): 2265-2277. [3] ZHANG M Z, WANG N N, ZHOU S K. Research on fuel economy of hydro-mechanical continuously variable transmission rotary-tilling tractor[J]. Energies, 2025, 18(6): 1490. doi: 10.3390/en18061490 [4] 夏光, 魏志祥, 唐希雯, 等. 新型液压机械双流传动模式切换分析与控制研究[J]. 中国机械工程, 2023, 34(13): 1611-1627. doi: 10.3969/j.issn.1004-132X.2023.13.011XIA Guang, WEI Zhixiang, TANG Xiwen, et al. Research on mode switching analysis and control of new hydraulic mechanical dual-flow transmissions[J]. China Mechanical Engineering, 2023, 34(13): 1611-1627. doi: 10.3969/j.issn.1004-132X.2023.13.011 [5] 朱镇, 蔡英凤, 陈龙, 等. 多模式机液复合传动装置设计方案分析[J]. 中国公路学报, 2020, 33(8): 51-62.ZHU Zhen, CAI Yingfeng, CHEN Long, et al. Design schemes analysis of multi-mode hydro-mechanical composite transmission devices[J]. China Journal of Highway and Transport, 2020, 33(8): 51-62. [6] LI J, DONG H, HAN B, et al. Designing comprehensive shifting control strategy of hydro-mechanical continuously variable transmission[J]. Applied Sciences, 2022, 12(11): 5716. doi: 10.3390/app12115716 [7] DUTTA A, IONESCU C M, ZHONG Y, et al. Switched predictive control design for optimal wet-clutch engagement[J]. IFAC Proceedings Volumes, 2012, 45(30): 241-246. doi: 10.3182/20121023-3-FR-4025.00065 [8] JUNG S, CHOI S B, KIM J, et al. Adaptive feed-forward control of the clutch filling phase for wet dual clutch transmission[J]. IEEE Transactions on Vehicular Technology, 2020, 69(9): 9577-9588. doi: 10.1109/TVT.2020.3003061 [9] 曹付义, 王越航, 冯琦, 等. 液压机械传动装置模式切换滚动协调控制[J]. 西安交通大学学报, 2021, 55(3): 136-144. doi: 10.7652/xjtuxb202103016CAO Fuyi, WANG Yuehang, FENG Qi, et al. Rolling coordinated control of mode switching for hydro-mechanical transmission device[J]. Journal of Xi’an Jiaotong University, 2021, 55(3): 136-144. doi: 10.7652/xjtuxb202103016 [10] 刘永刚, 张静晨, 万有刚, 等. 基于数据驱动的双离合器自动变速器换挡过程自适应控制[J]. 汽车工程, 2021, 43(6): 891-898, 923.LIU Yonggang, ZHANG Jingchen, WAN Yougang, et al. Adaptive shifting control for data driven dual clutch transmission[J]. Automotive Engineering, 2021, 43(6): 891-898,923 [11] 张延安, 杜岳峰, 毛恩荣, 等. 基于数字孪生的大马力拖拉机湿式离合器压力控制方法研究[J]. 机械工程学报, 2023, 59(13): 268-279. doi: 10.3901/JME.2023.13.268ZHANG Yan’an, DU Yuefeng, MAO Enrong, et al. Pressure control method of wet clutch in high-powered tractor based on digital twin[J]. Journal of Mechanical Engineering, 2023, 59(13): 268-279. doi: 10.3901/JME.2023.13.268 [12] 郑良杰, 马彪, 陈漫, 等. 控制油压对湿式多片离合器分离动态特性的影响[J]. 兵工学报, 2022, 43(10): 2451-2459. doi: 10.12382/bgxb.2021.0506ZHENG Liangjie, MA Biao, CHEN Man, et al. Influence of the control oil pressure on the dynamic characteristics of a wet multi-disc clutch in the disengaging process[J]. Acta Armamentarii, 2022, 43(10): 2451-2459. doi: 10.12382/bgxb.2021.0506 [13] 崔家豪, 吴健鹏, 刘继凯, 等. 考虑界面接触状态的湿式离合器扭矩特性[J]. 哈尔滨工业大学学报, 2024, 56(4): 101-107, 119.CUI Jiahao, WU Jianpeng, LIU Jikai, et al. Torque characteristics of wet clutches considering interface contact state[J]. Journal of Harbin Institute of Technology, 2024, 56(4): 101-107,119. [14] 刘永刚, 张静晨, 王鑫, 等. 摩擦因数自适应的双离合器自动变速器起步智能控制[J]. 机械工程学报, 2023, 59(10): 197-209.LIU Yonggang, ZHANG Jingchen, WANG Xin, et al. Intelligent control of starting process for dual clutch transmissions for friction coefficient self-adaptation[J]. Journal of Mechanical Engineering, 2023, 59(10): 197-209. [15] 吴海康, 钟再敏, 余卓平. 基于Lipschitz观测器的新型离合器执行机构控制算法[J]. 西南交通大学学报, 2015, 50(2): 270-278. doi: 10.3969/j.issn.0258-2724.2015.02.010WU Haikang, ZHONG Zaimin, YU Zhuoping. A novel clutch actuator control algorithm based on lipschitz observer[J]. Journal of Southwest Jiaotong University, 2015, 50(2): 270-278. doi: 10.3969/j.issn.0258-2724.2015.02.010 [16] CHENG Z, LU Z X. Research on dynamic load characteristics of advanced variable speed drive system for agricultural machinery during engagement[J]. Agriculture, 2022, 12(2): 161. doi: 10.3390/agriculture12020161 [17] MISHRA K D, SRINIVASAN K. Robust control and estimation of clutch-to-clutch shifts[J]. Control Engineering Practice, 2017, 65: 100-114. doi: 10.1016/j.conengprac.2017.05.007 [18] 孙凤, 邢大壮, 周冉, 等. 考虑能耗的电磁主动悬架LQR控制策略[J]. 西南交通大学学报, 2023, 58(4): 754-760, 798. doi: 10.3969/j.issn.0258-2724.20220815SUN Feng, XING Dazhuang, ZHOU Ran, et al. LQR control strategy for electromagnetic active suspension considering energy consumption[J]. Journal of Southwest Jiaotong University, 2023, 58(4): 754-760,798. doi: 10.3969/j.issn.0258-2724.20220815 [19] 靖永志, 贾兴科, 倪胜, 等. 基于扰动补偿的电磁悬浮系统自适应终端滑模控制策略研究[J/OL]. 西南交通大学学报, 2025: 1-9. (2025-08-26). https://kns.cnki.net/kcms/detail/51.1277.U.20250826.1358.002.html.JING Y Z, JIA X K, NI S, et al. Research on adaptive terminal sliding mode control strategy of electromagnetic levitation system based on disturbance compensation[J/OL]. Journal of Southwest Jiaotong University, 2025: 1-9. (2025-08-26). https://kns.cnki.net/kcms/detail/51.1277.U.20250826.1358.002.html. [20] 商晓波. 湿式离合器接合过程理论分析及试验研究[D]. 杭州: 浙江大学, 2019. [21] GAO H, BARBER G C. Engagement of a rough, lubricated and grooved disk clutch ith a porous deformable paper-based friction material[J]. Tribology Transactions, 2002, 45(4): 464-470. doi: 10.1080/10402000208982575 [22] 王成. 考虑湿式离合器动态接合特性的DCT车辆起步控制研究[D]. 重庆: 重庆大学, 2020. [23] 李中奇, 余剑烽, 周靓. 重载列车运行过程的滑模自抗扰控制方法[J/OL]. 西南交通大学学报, 2024: 1-10. (2024-10-31). https://kns.cnki.net/kcms/detail/51.1277.u.20241030.1442.004.html.LI Z Q, YU J F, ZHOU (J /L). Sliding mode active disturbance rejection control method for heavy-haul train running process[J/OL]. Journal of Southwest Jiaotong University, 2024: 1-10. (2024-10-31). https://kns.cnki.net/kcms/detail/51.1277.u.20241030.1442.004.html. [24] 李晓祥, 王安麟, 樊旭灿, 等. 面向离合器接合过程的比例电磁阀动态特性模型与设计[J]. 西安交通大学学报, 2020, 54(5): 46-52.LI Xiaoxiang, WANG Anlin, FAN Xucan, et al. Dynamic characteristics model and design of proportional solenoid valve for clutch engagement process[J]. Journal of Xi’an Jiaotong University, 2020, 54(5): 46-52. [25] 于亮, 马彪, 陈漫, 等. 润滑油温度对铜基湿式离合器摩擦转矩的影响[J]. 机械工程学报, 2020, 56(20): 155-163. doi: 10.3901/JME.2020.20.155YU Liang, MA Biao, CHEN Man, et al. Influence of the temperature of lubricating oil on the friction torque of Cu-based wet clutch[J]. Journal of Mechanical Engineering, 2020, 56(20): 155-163. doi: 10.3901/JME.2020.20.155 [26] KAKAC S, YENER Y, NAVEIRA-COTTA C P. Heat conduction[M]// 5th Edition. Florida: CRC Press, 2018. [27] 马克. 基于湿式双离合变速器的分布式执行机构设计与控制方法研究[D]. 重庆: 重庆大学, 2022. -

下载:

下载: