Design and Test Study of New Dual-Curved Carbon Fiber-Reinforced Polymer Plate Anchorage

-

摘要:

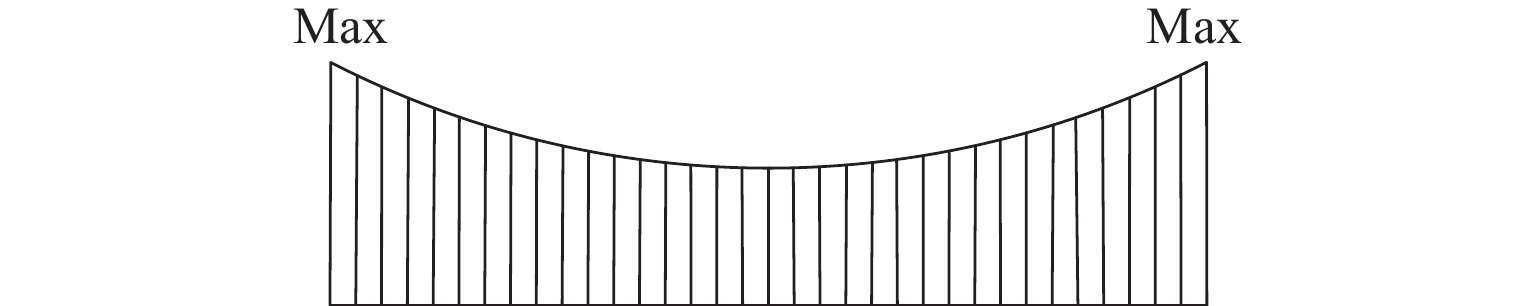

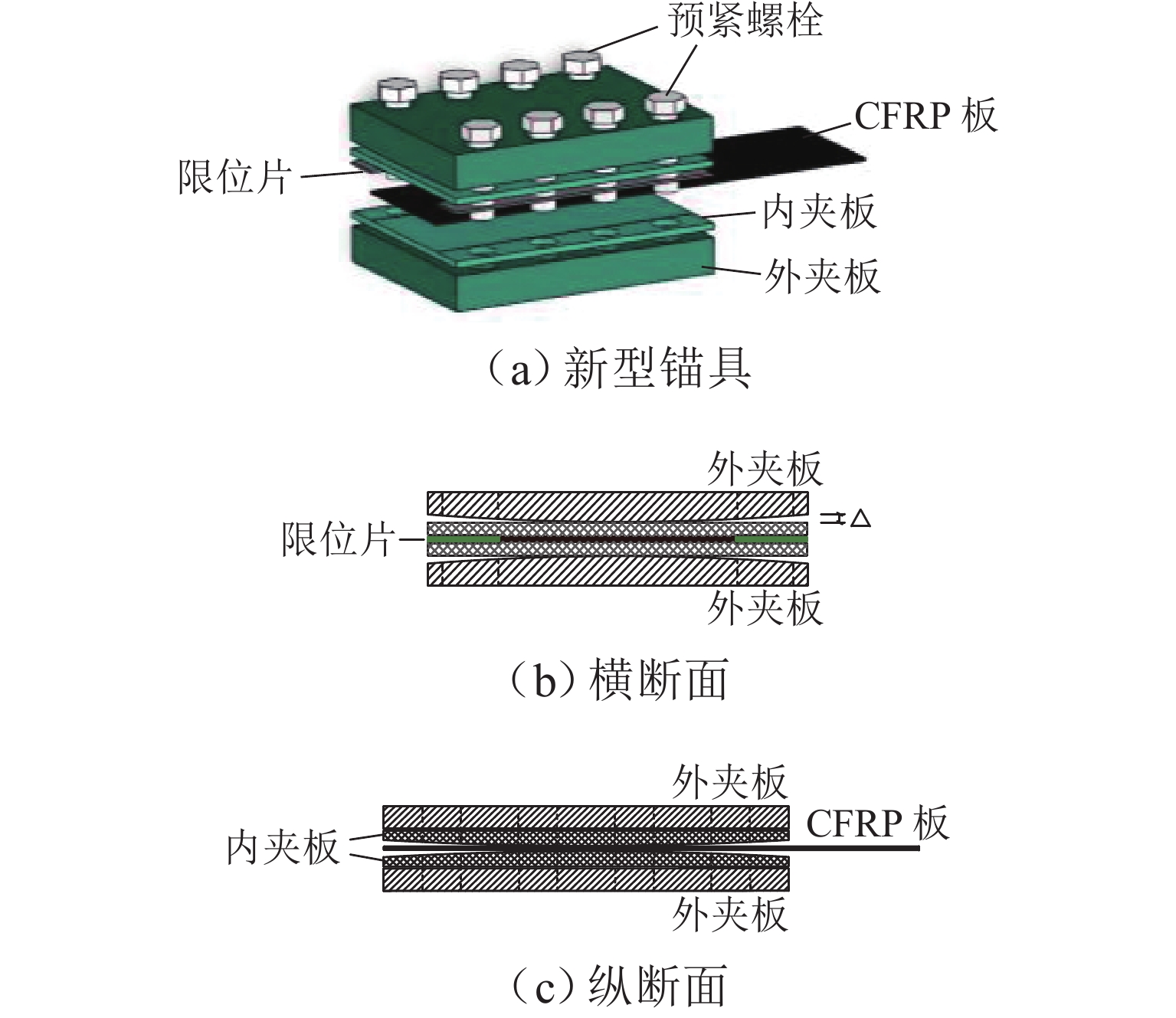

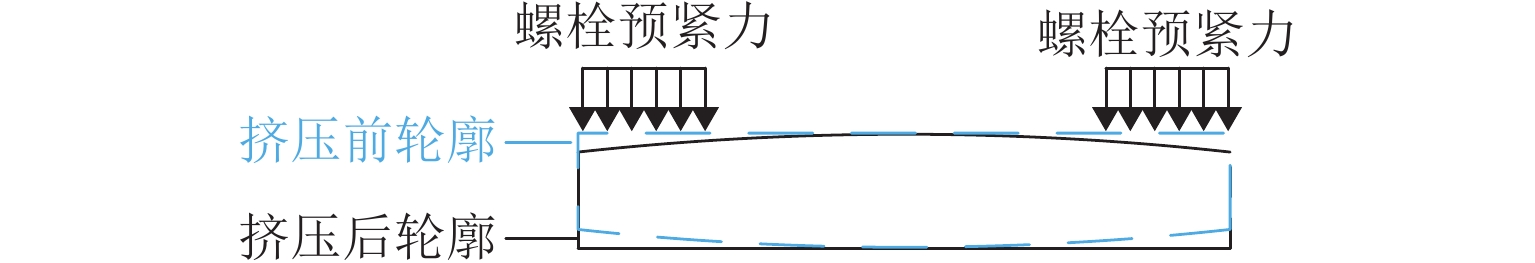

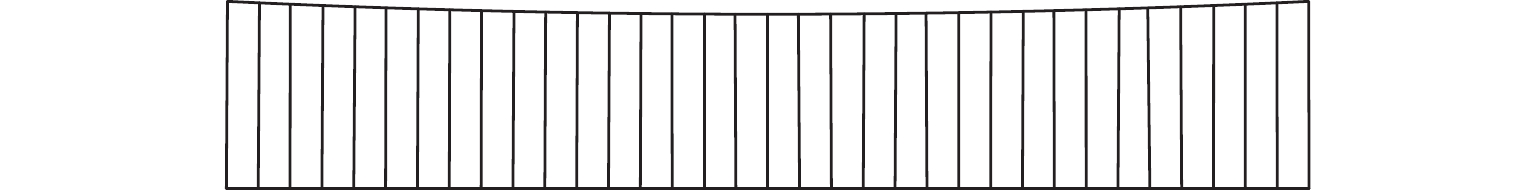

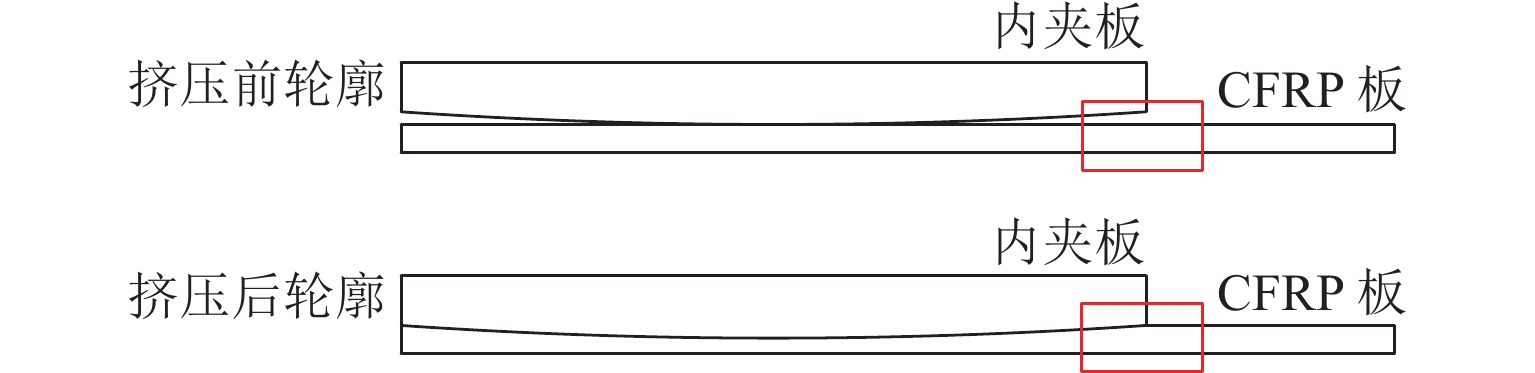

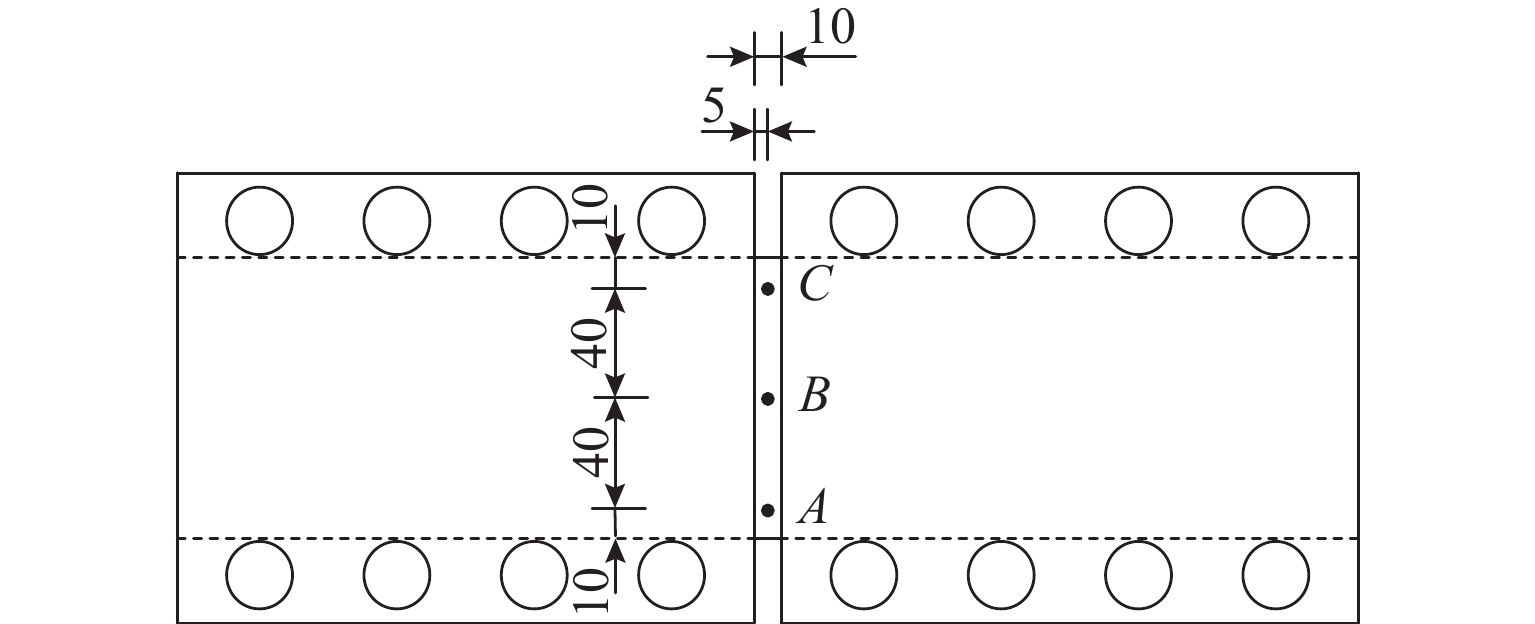

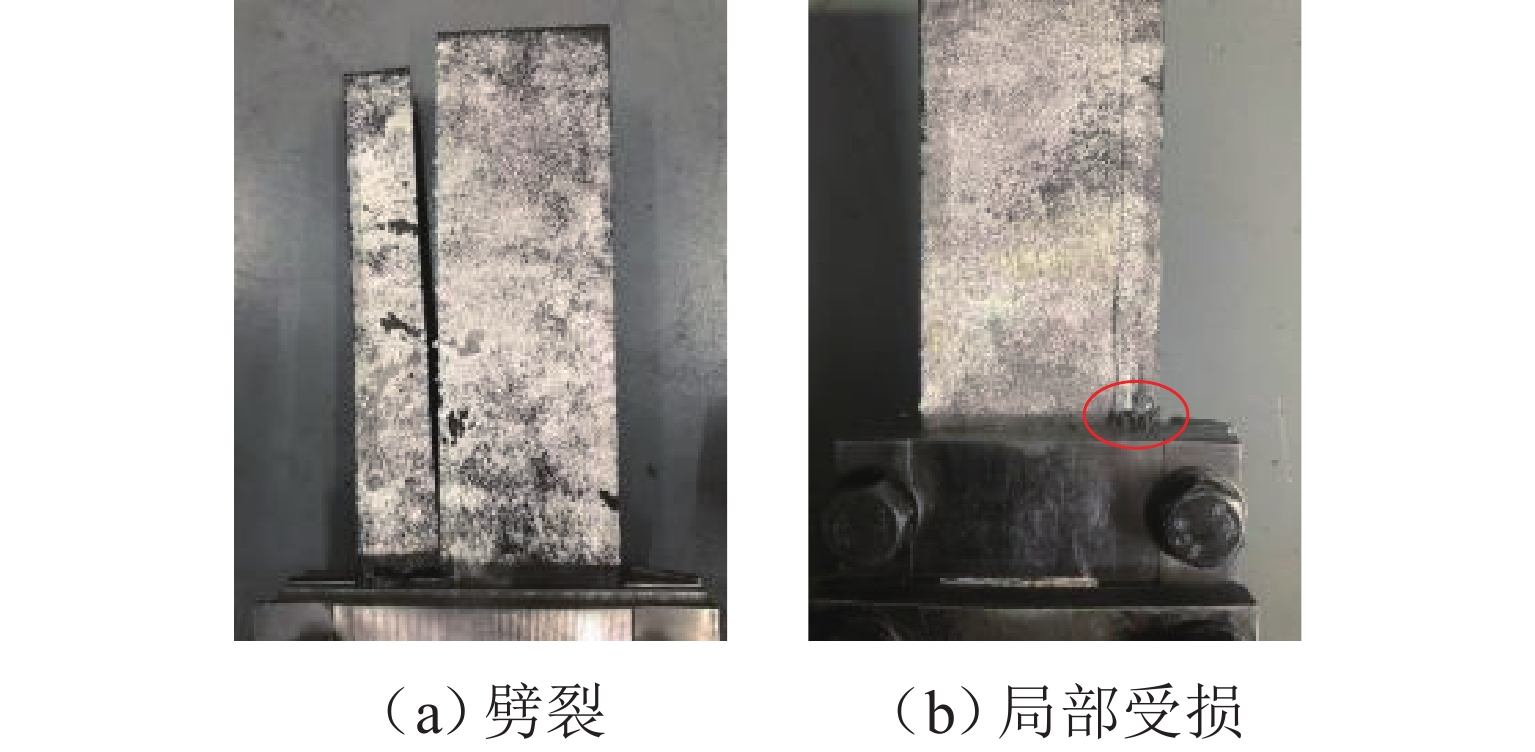

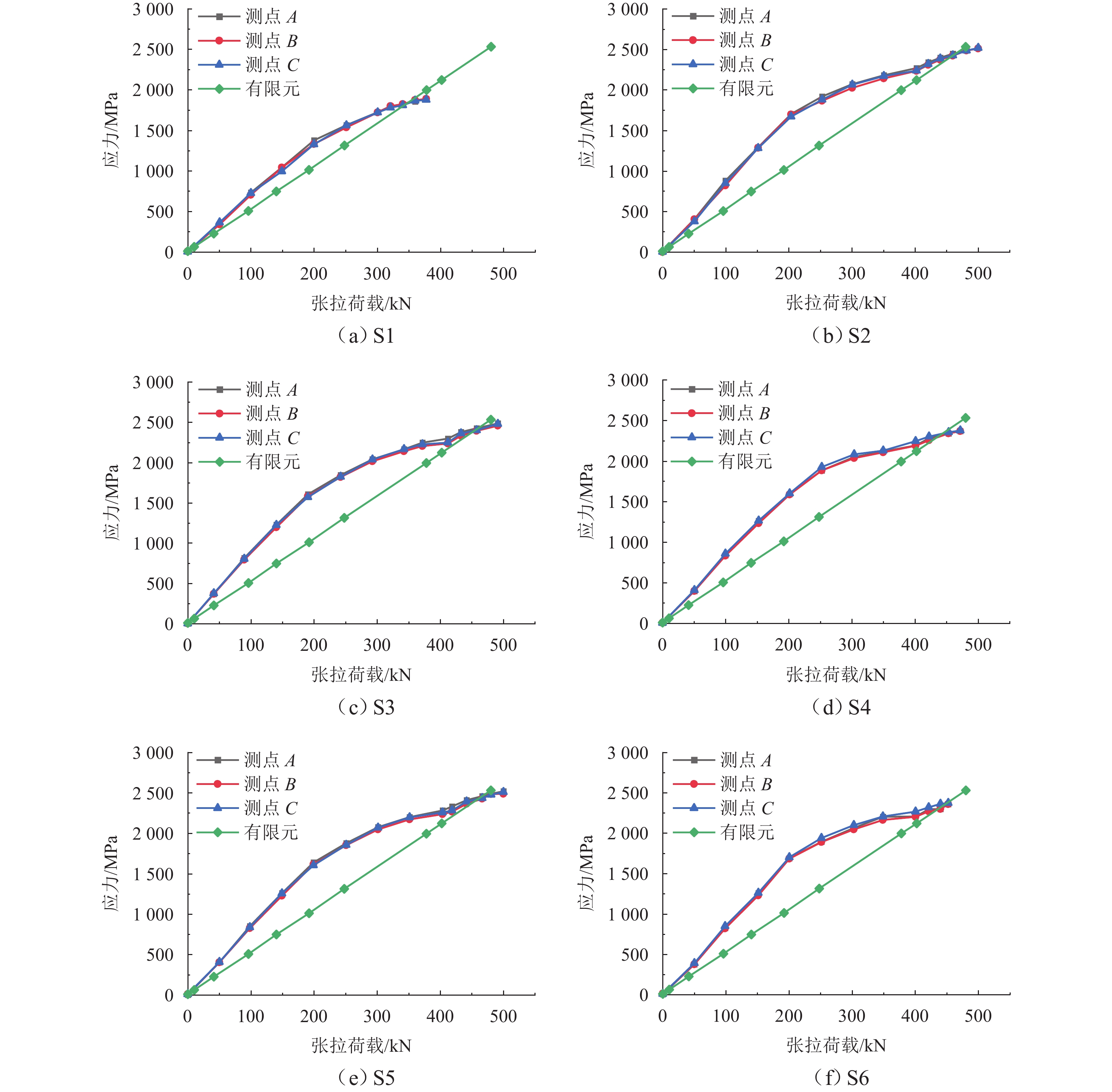

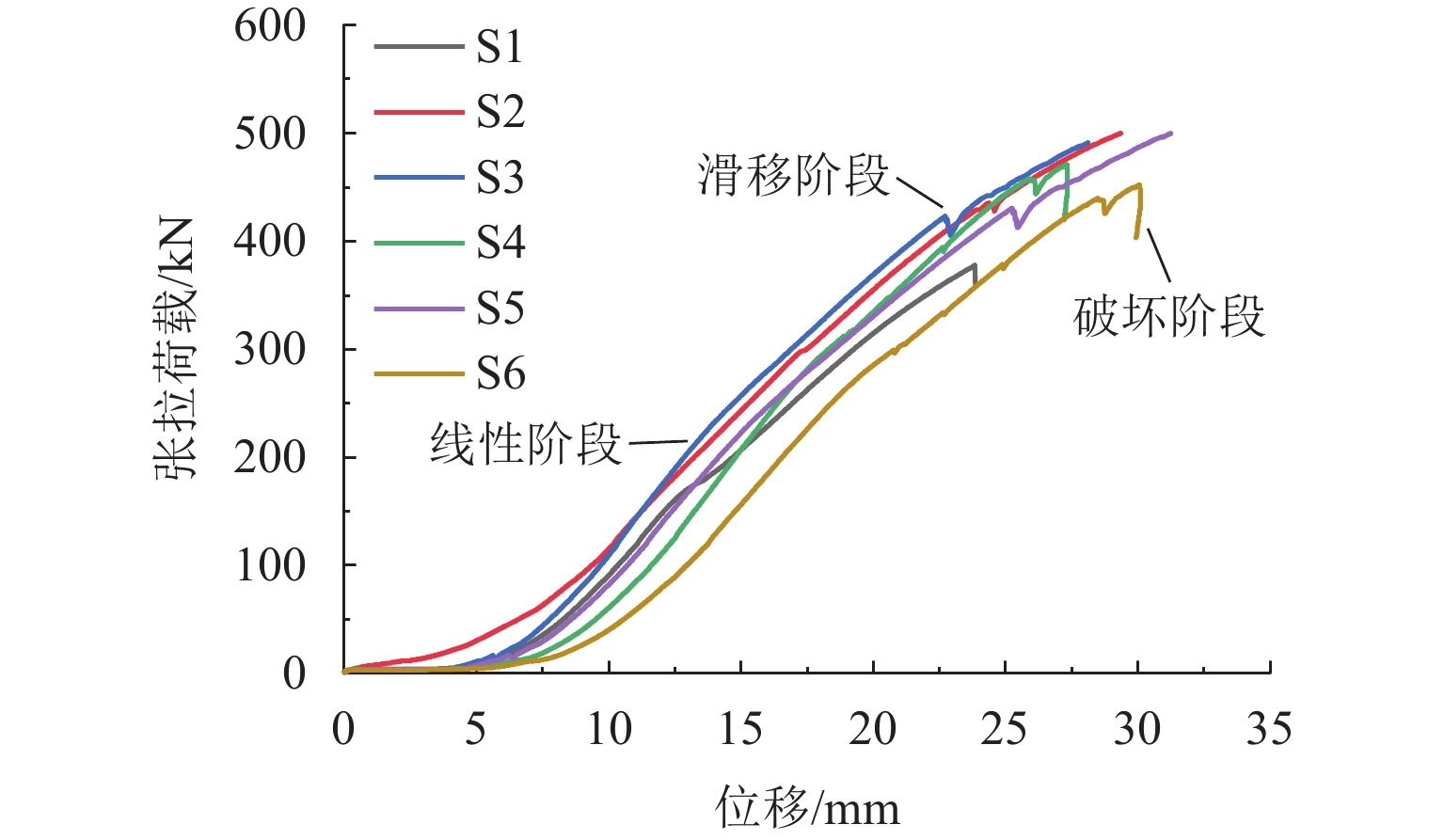

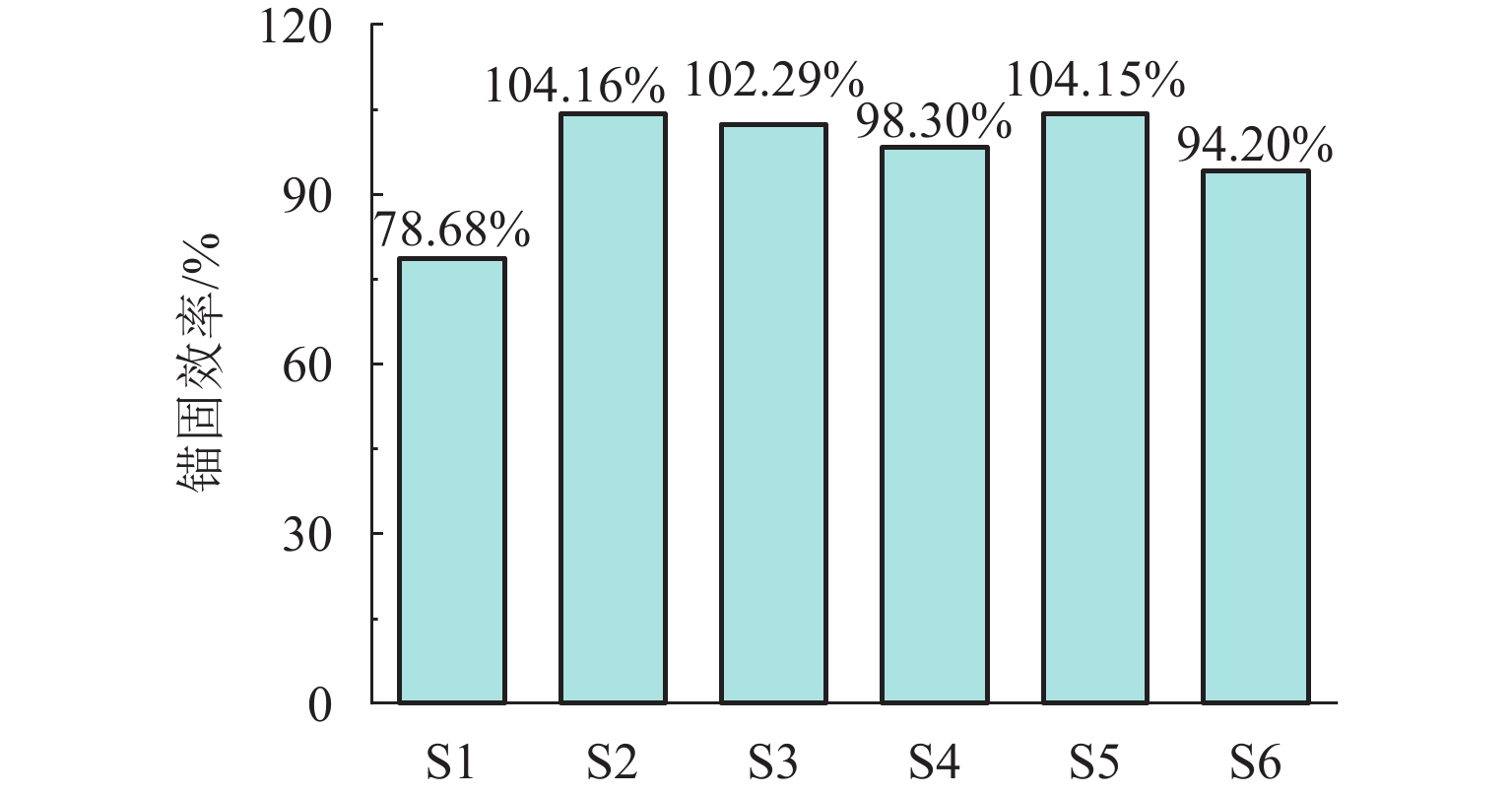

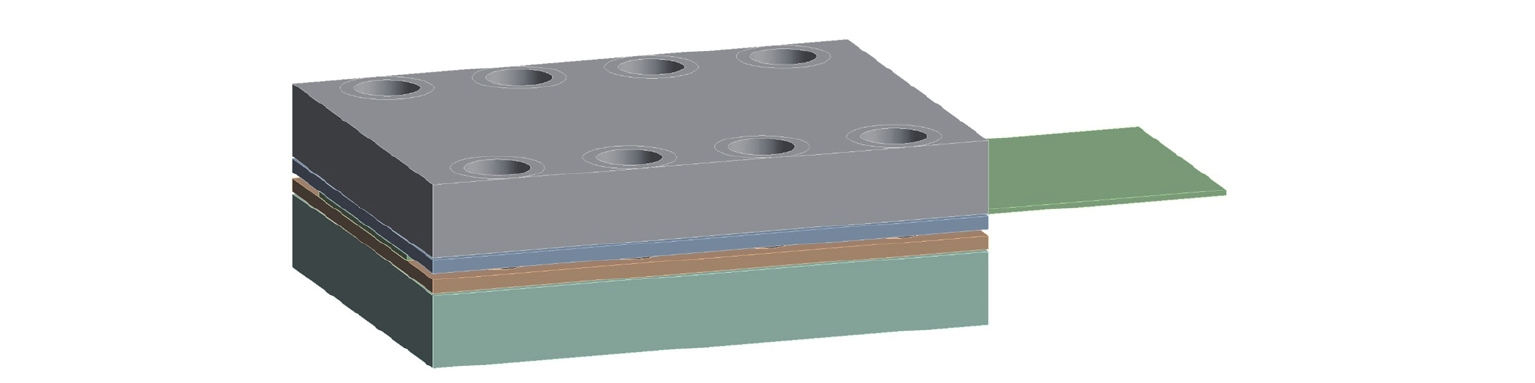

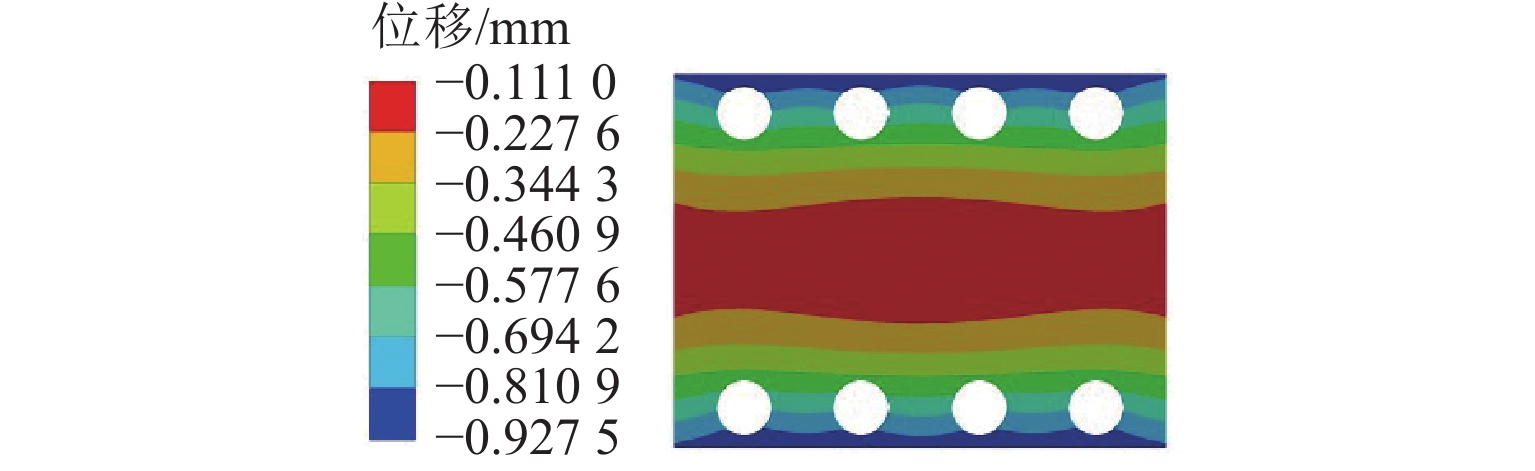

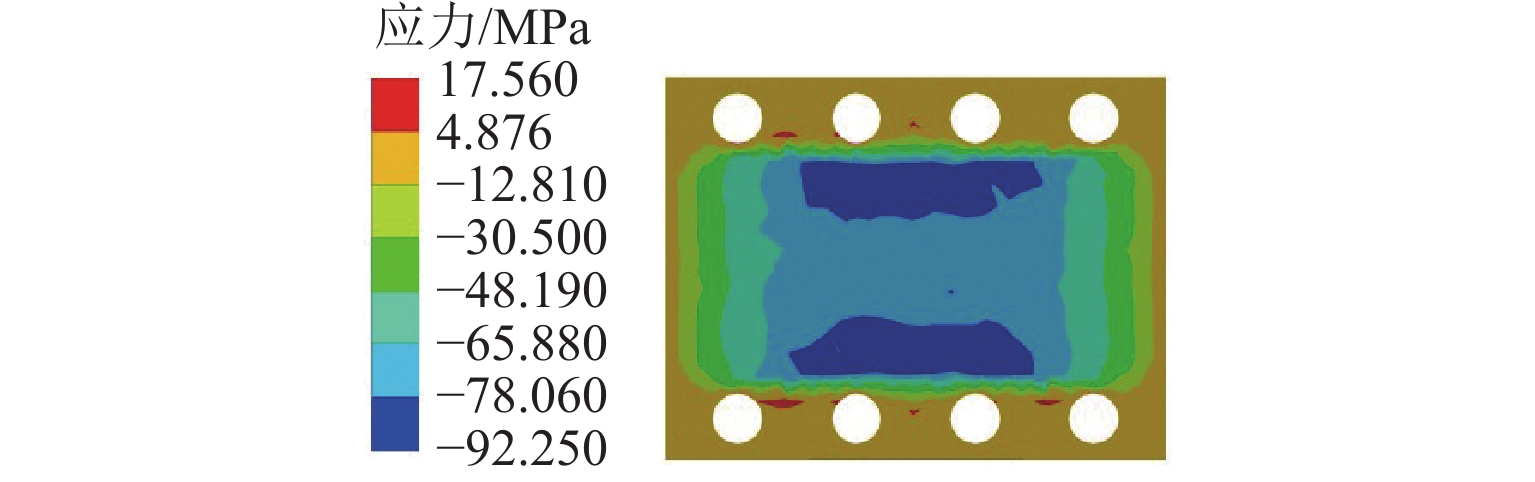

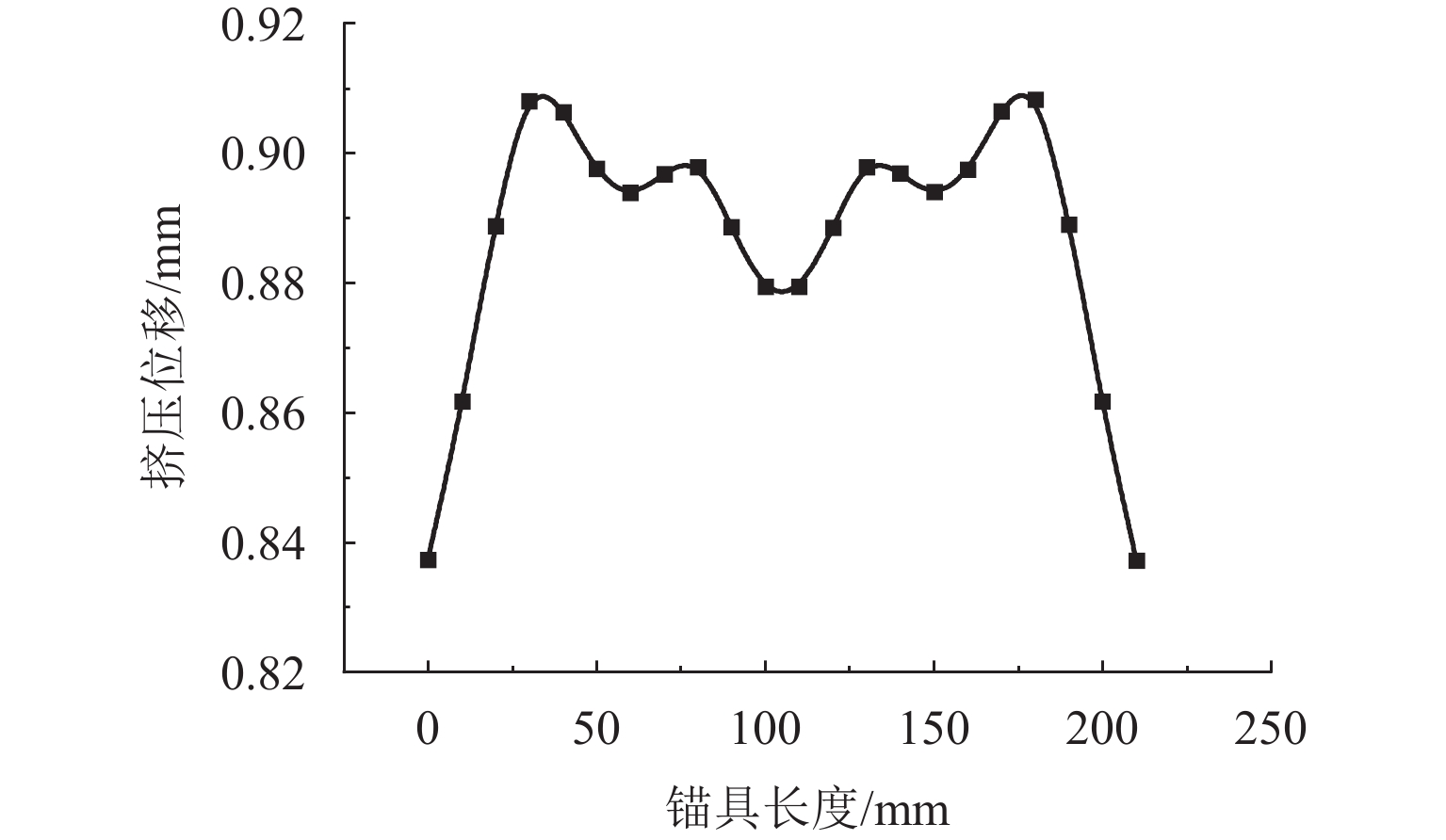

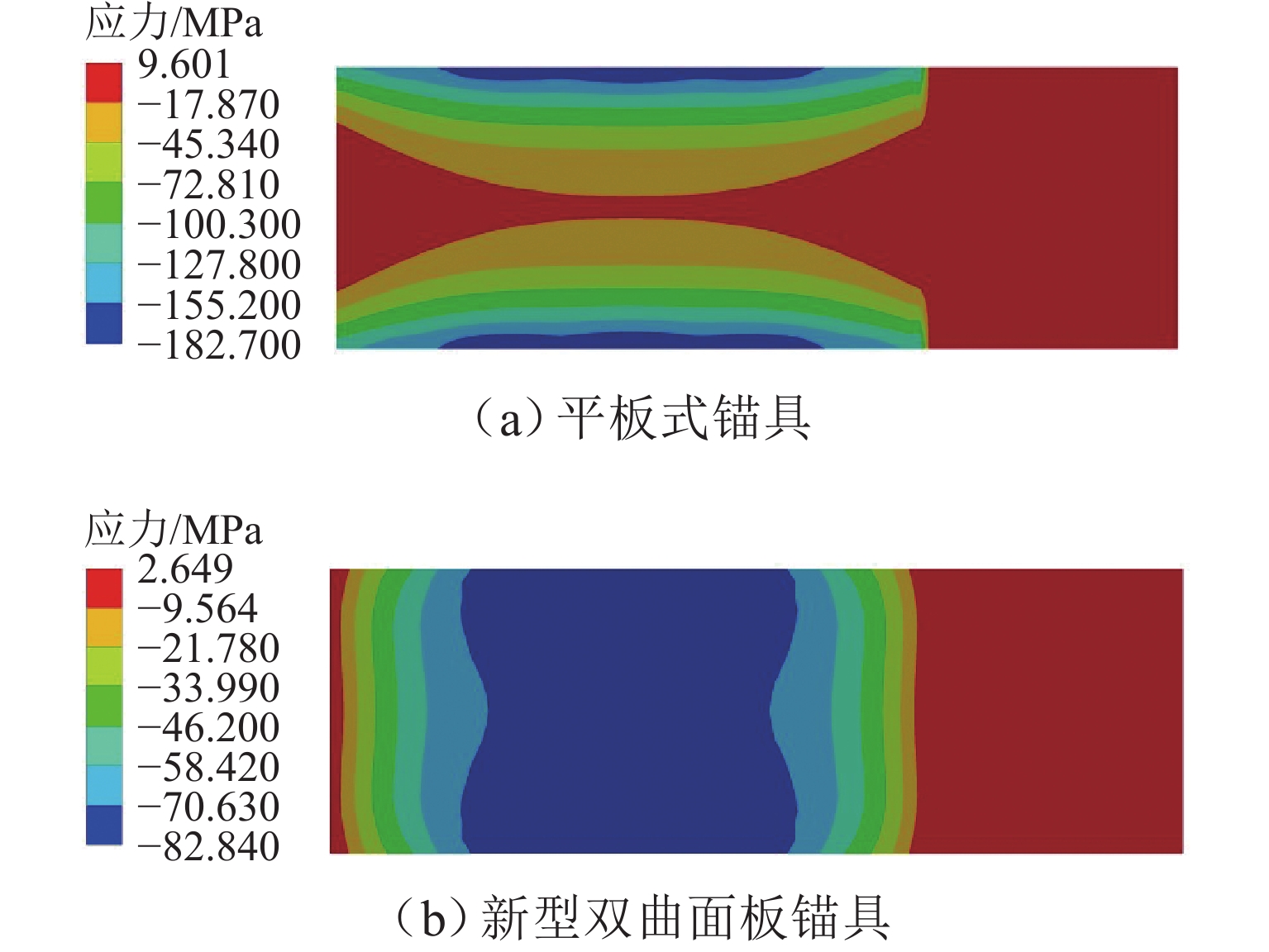

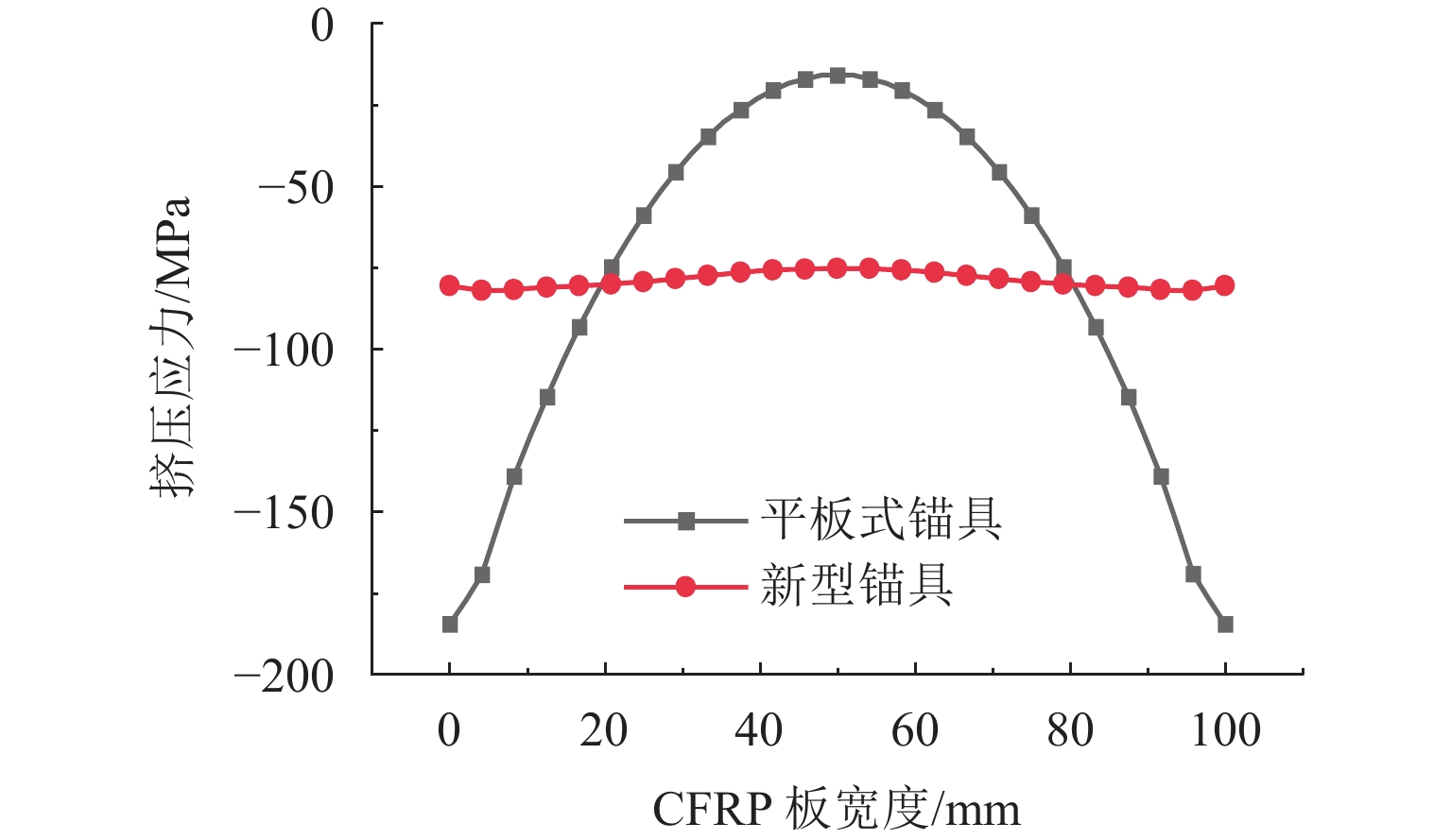

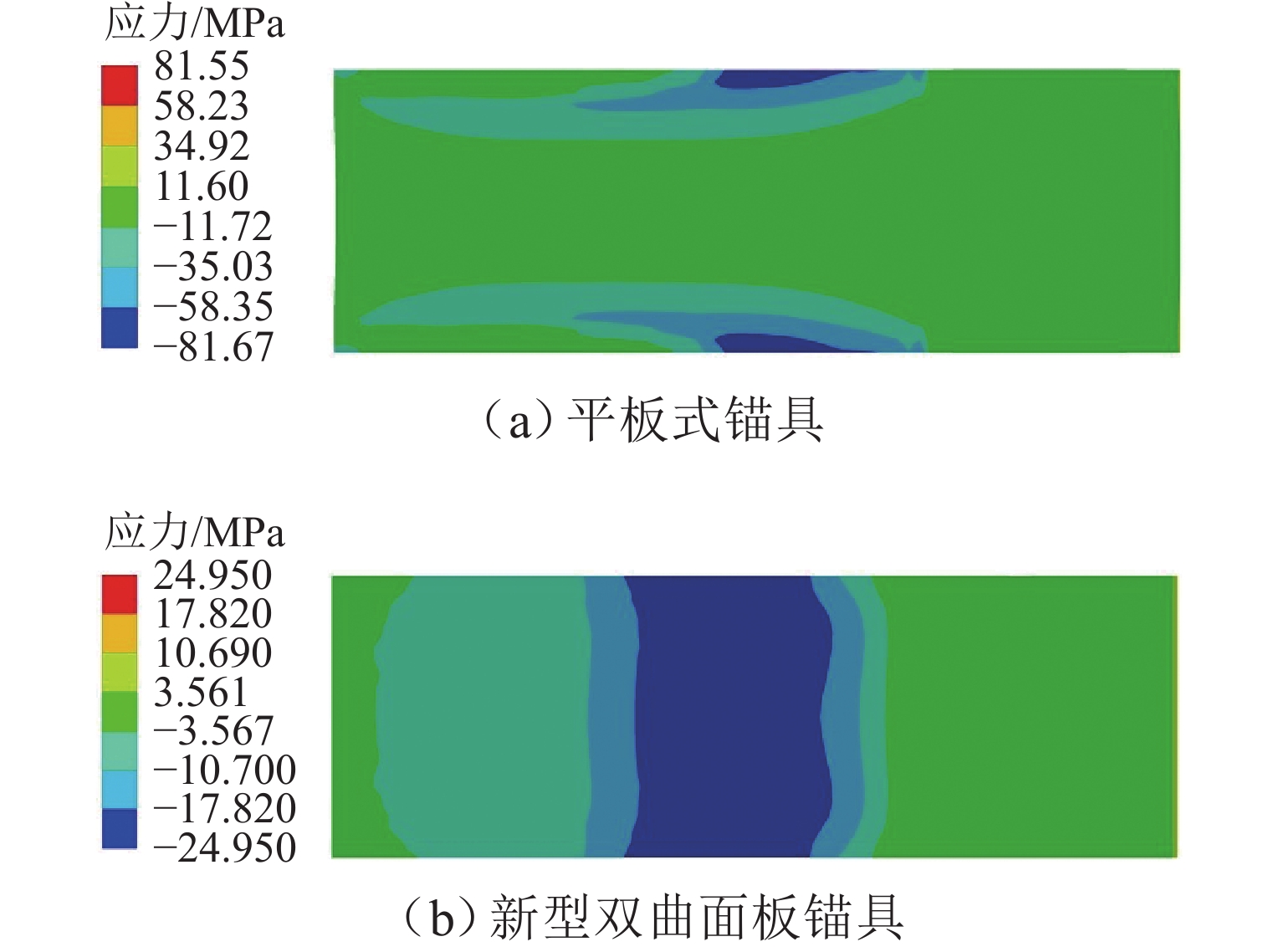

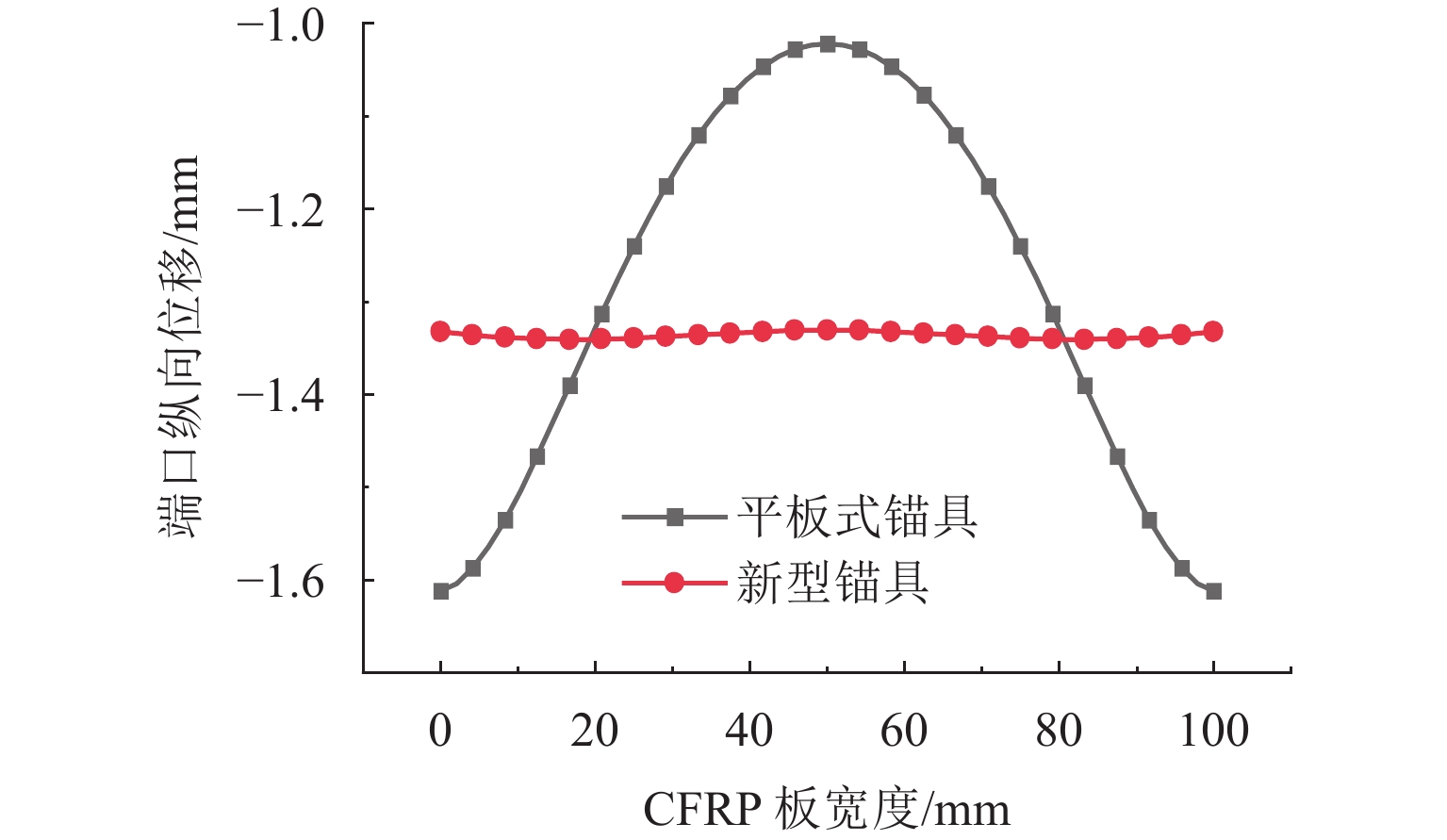

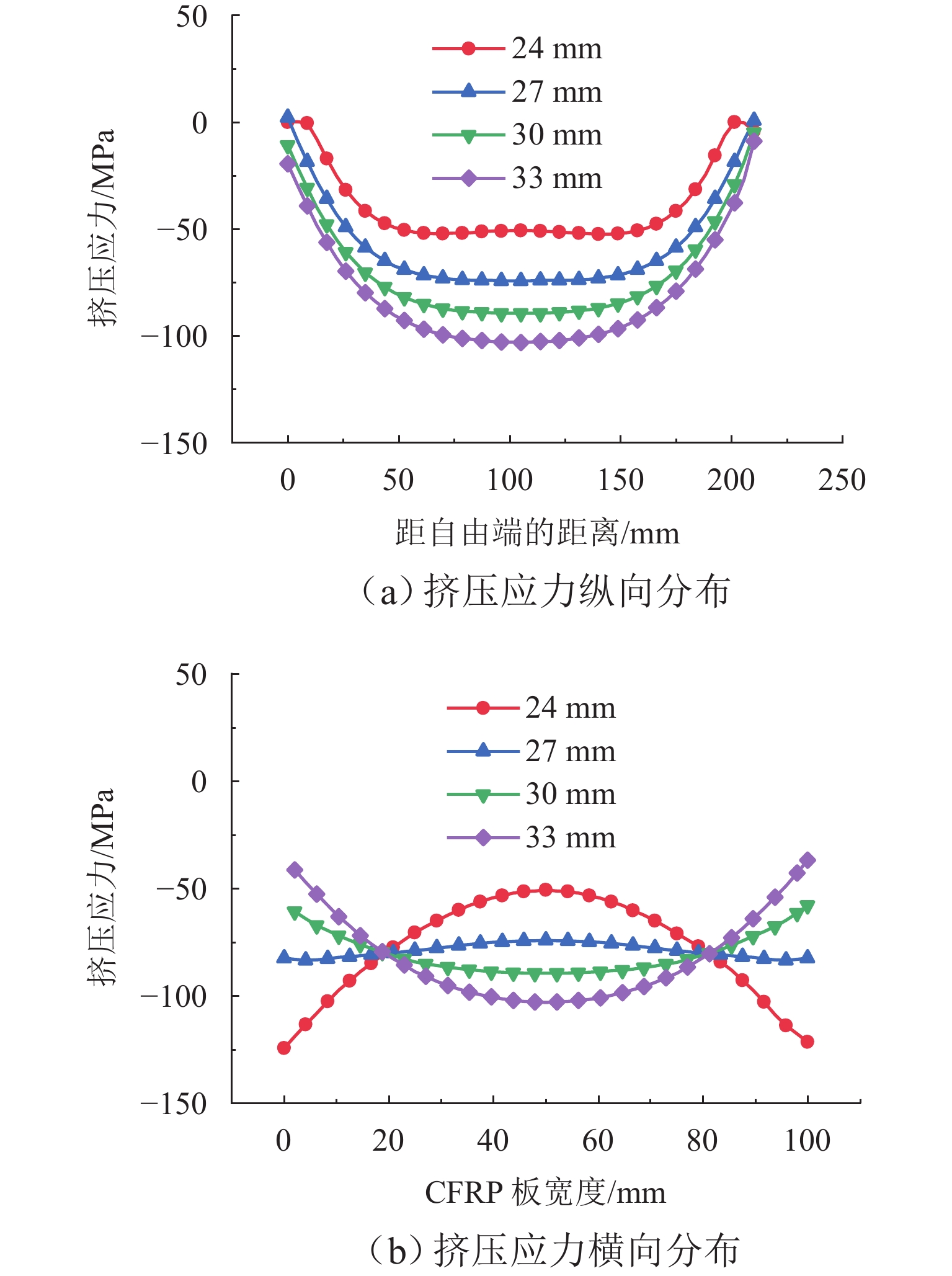

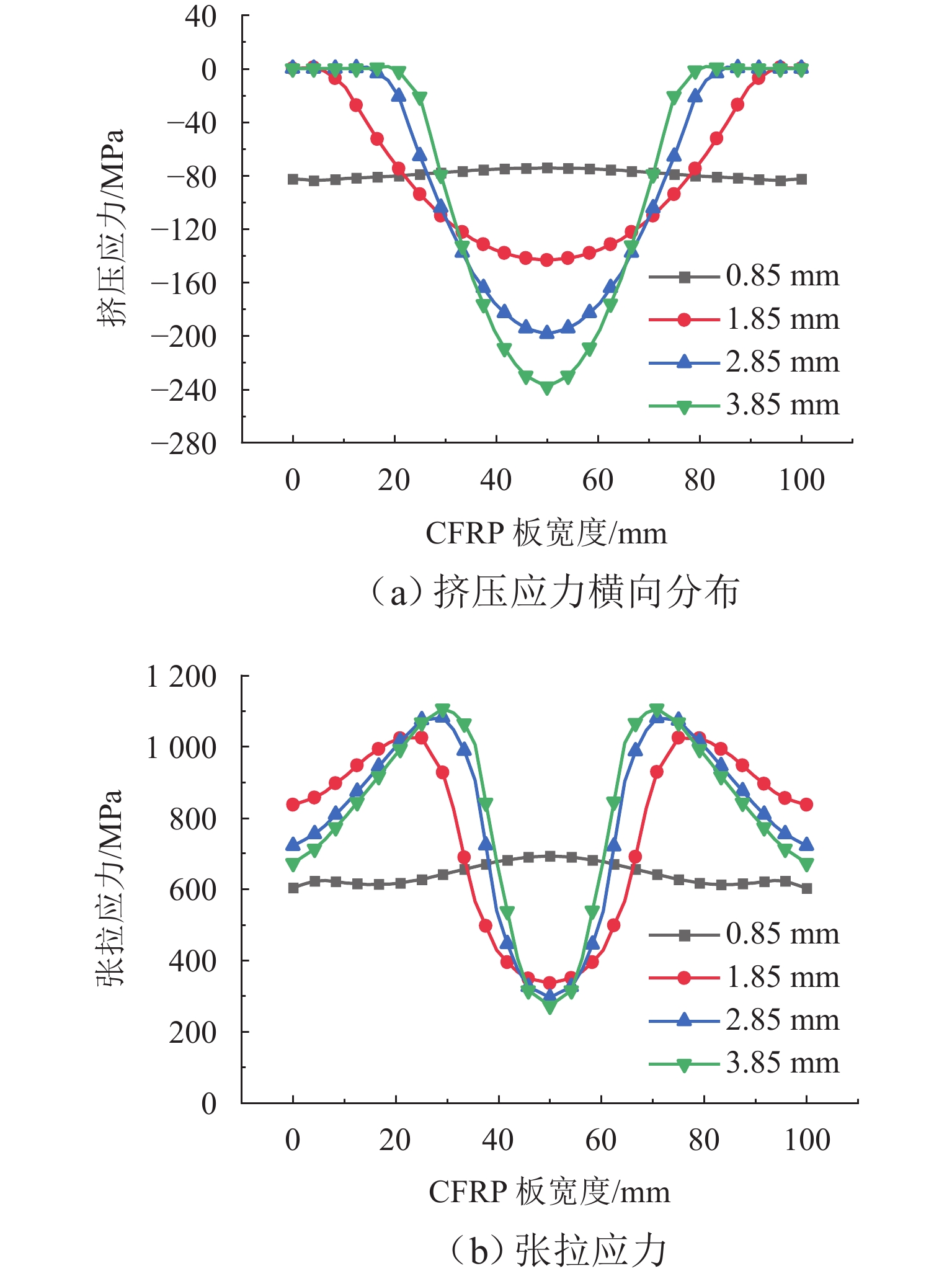

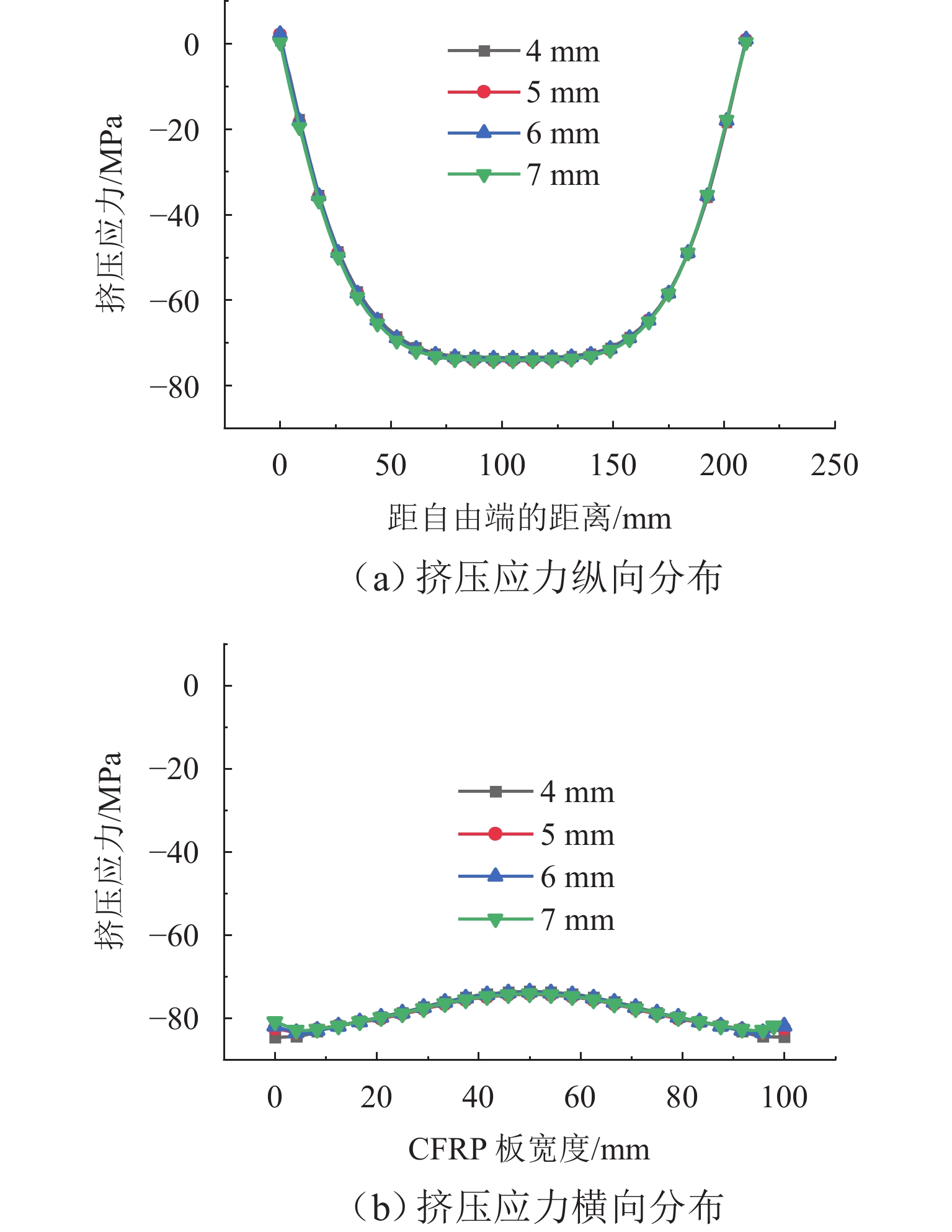

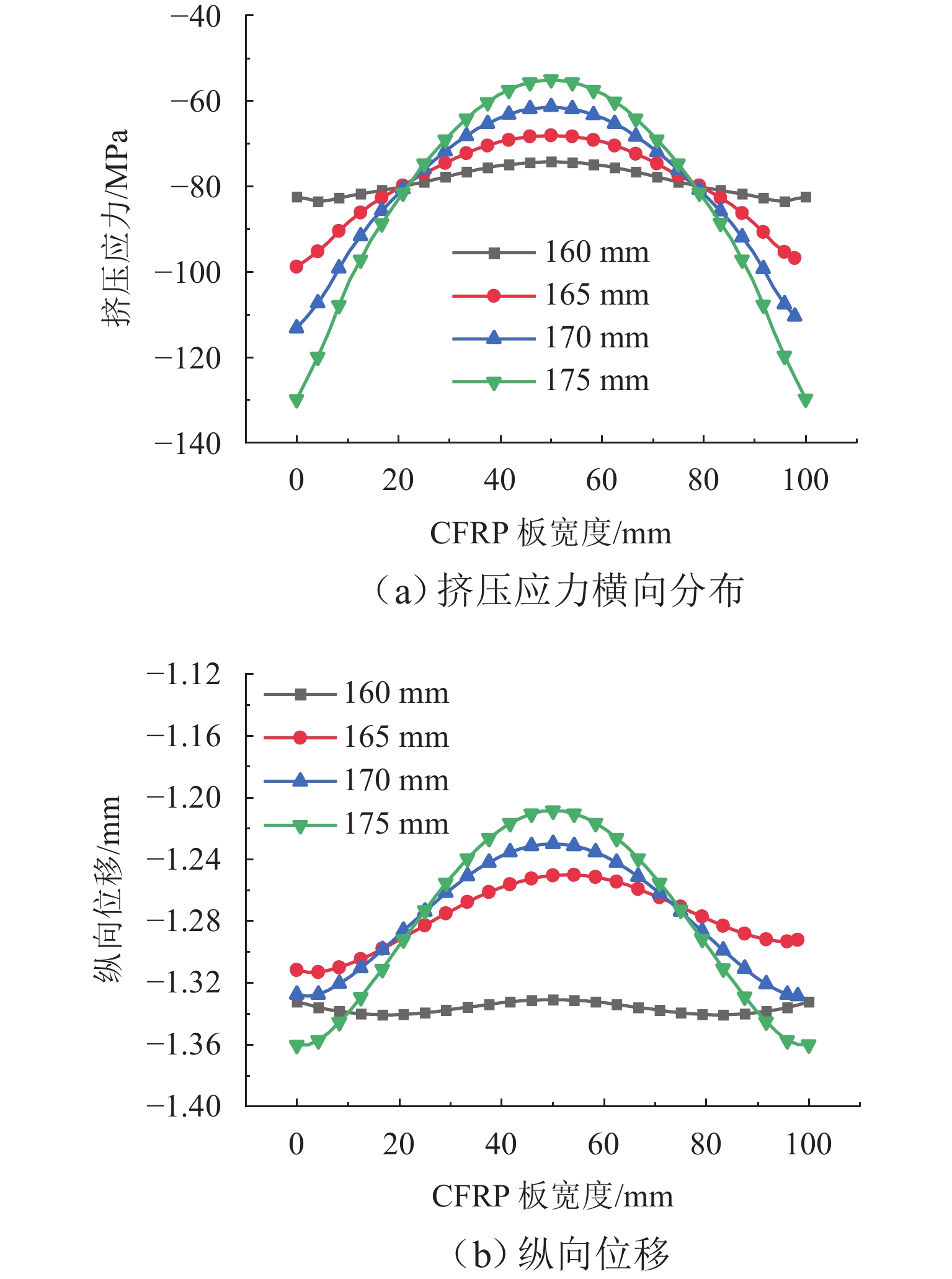

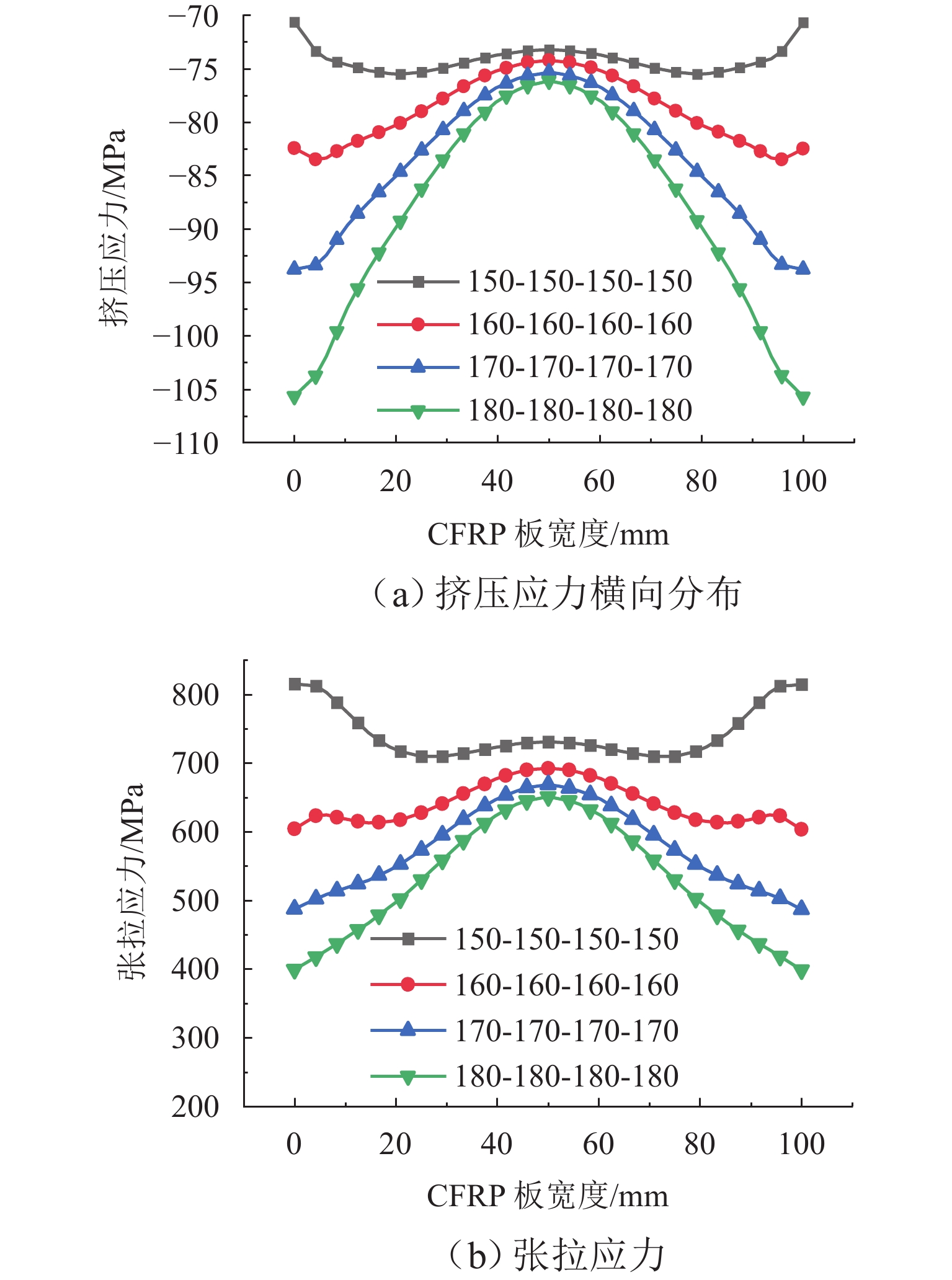

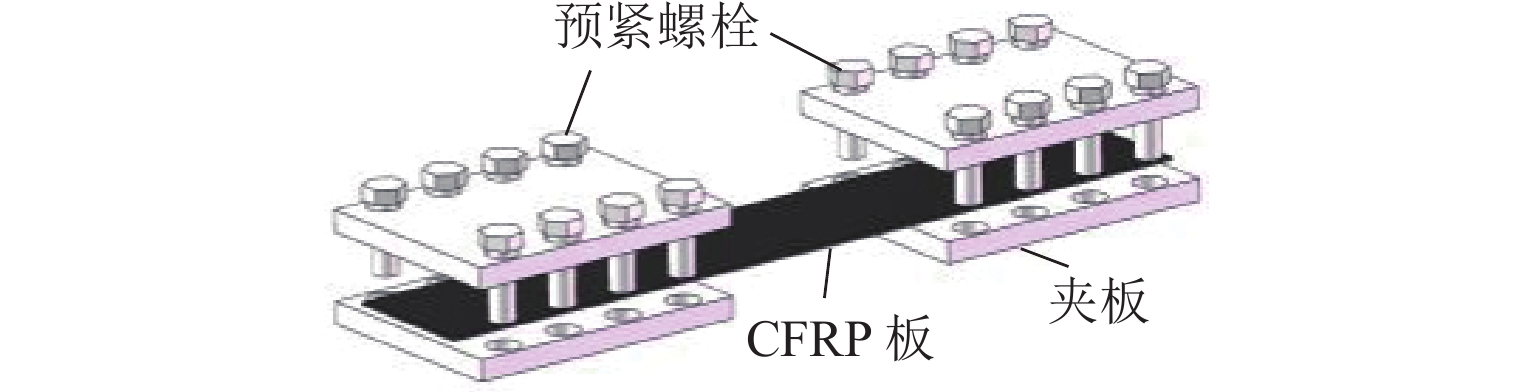

针对现有CFRP板锚固技术中挤压应力横向分布不均匀导致板材承拉后易撕裂破坏,难以控制螺栓预紧力的问题,本文研制了双曲面CFRP板锚具,其主要构造特征为外夹板设有横向圆弧面(可使CFRP板所受挤压应力横向分布较均匀),内夹板设有纵向圆弧面(可充分挤压锚固区中段,避免端口处剪切破坏);通过限位片控制外夹板挤压位移,以实现所需的预紧力锚固CFRP板;对6组新型锚具试件进行锚固性能试验,探究其受力机理;利用ANSYS有限元软件进行受力模拟,深入分析影响锚固性能的关键参数,同时与平板式锚具的受力性能展开对比. 研究表明:外夹板厚度是影响CFRP板挤压应力横向分布不均匀的主要因素,当外夹板厚度为27 mm时,CFRP板挤压应力横向分布较均匀,最大与最小压应力之差仅为9.3 MPa;内、外夹板的弧面设计优化了CFRP板挤压应力分布状态,同时减小了碳纤维间的应力差,使CFRP板的横向变形更同步;试件破坏状态为撕裂破坏,但新型锚具锚固效率系数可达104.16%.

-

关键词:

- 桥梁工程 /

- 双曲面CFRP板锚具 /

- 静载张拉试验 /

- 有限元模拟 /

- 锚固效率

Abstract:To address the issues of uneven transverse distribution of compressive stress in existing carbon fiber-reinforced polymer (CFRP) plate anchorage technology, which leads to tearing failure of plates under tension and the difficulty in controlling bolt preload, a dual-curved CFRP plate anchorage was developed. This device’s main construction features were outer clamping plates with transverse arc surfaces to ensure uniform transverse distribution of compressive stress sustained by the CFRP plate and inner clamping plates with longitudinal arc surfaces to fully compress the middle section of the anchorage zone and avoid shear failure at the ends. The compressive displacement of the outer clamping plates was controlled by the limit plate to anchor the CFRP plate with the required preload. The anchorage performance test for six groups of new anchorage specimens was carried out to explore their stress-bearing principle. Finite element software ANSYS was used to perform stress simulation; the key parameters affecting anchorage performance were deeply analyzed; the stress-bearing performance of CFRP plate anchorage was compared with that of flat-plate anchorage. The results indicate that the thickness of the outer clamping plates is the dominant factor influencing the non-uniform transverse distribution of compressive stress sustained by CFRP plates. When the thickness of outer clamping plates is 27 mm, the CFRP plates exhibit a higher uniform transverse distribution of compressive stress, with a compressive stress difference of only 9.3 MPa between maximum and minimum values. The curved surface design of inner and outer clamping plates effectively optimizes the compressive stress distribution state of the CFRP plate, while minimizing stress difference among carbon fibers and resulting in significantly improved synchronization of transverse deformation of CFRP plates. Although the specimens ultimately fail in a tearing state, the new anchorage achieves an exceptional anchoring efficiency coefficient of 104.16%.

-

表 1 内、外夹板材料性能

Table 1. Material performance of inner and outer clamping plates

抗拉强度/MPa 屈服强度/MPa 弹性模量/GPa 泊松比 980 785 206 0.3 表 2 高强螺栓性能

Table 2. Performance of high-strength bolts

抗拉强度/MPa 屈服比 屈服强度/MPa 最小拧紧力矩/N*m 1200 0.9 1085 635 表 3 CFRP板材料性能

Table 3. Material performance of CFRP plate

弹性模量/GPa 极限抗拉强度/MPa 极限承载力/kN 层间剪切强度/MPa 极限延伸率/% 160 2400 480 50 1.5 -

[1] 周小燚, 钱盛域, 王能威, 等. FRP工程结构多尺度不确定性分析研究进展[J]. 中国公路学报, 2023, 36(1): 97-113.ZHOU Xiaoyi, QIAN Shengyu, WANG Nengwei, et al. Research advances on multiscale uncertainty quantification for fiber reinforced polymer composite structures[J]. China Journal of Highway and Transport, 2023, 36(1): 97-113. [2] 刘文迪, 张芝芳, 王景东. 纤维增强复合材料结构的弯曲疲劳性能研究现状[J]. 南京工业大学学报(自然科学版), 2023, 45(5): 478-489.LIU Wendi, ZHANG Zhifang, WANG Jingdong. Review of bending fatigue behavior of fiber reinforced polymer composites[J]. Journal of Nanjing Tech University (Natural Science Edition), 2023, 45(5): 478-489. [3] MICHELS J, MARTINELLI E, CZADERSKI C, et al. Prestressed CFRP strips with gradient anchorage for structural concrete retrofitting: experiments and numerical modeling[J]. Polymers, 2014, 6(1): 114-131. doi: 10.3390/polym6010114 [4] HOSSEINI A, GHAFOORI E, AL-MAHAIDI R, et al. Strengthening of a 19th-century roadway metallic bridge using nonprestressed bonded and prestressed unbonded CFRP plates[J]. Construction and Building Materials, 2019, 209: 240-259. doi: 10.1016/j.conbuildmat.2019.03.095 [5] 陈伟宏, 乔泽惠, 首维荣. CFRP加固震损非延性RC框架抗震性能试验研究[J]. 西南交通大学学报, 2020, 55(5): 1009-1016.CHEN Weihong, QIAO Zehui, SHOU Weirong. Experimental study on seismic performance of carbon fibre reinforced plastics-retrofitted earthquake-damaged non-ductile reinforced concrete frames[J]. Journal of Southwest Jiaotong University, 2020, 55(5): 1009-1016. [6] WANG L C, ZHANG J Y, XU J, et al. Anchorage systems of CFRP cables in cable structures: a review[J]. Construction and Building Materials, 2018, 160: 82-99. doi: 10.1016/j.conbuildmat.2017.10.134 [7] JIANG X, TAN C, QIANG X H, et al. An innovative circular anchor system for CFRP plates: Experimental investigation and field application[J]. Case Studies in Construction Materials, 2023, 19: e02678. doi: 10.1016/j.cscm.2023.e02678 [8] MOHEE F M, AL-MAYAH A, PLUMTREE A. Anchors for CFRP plates: State-of-the-art review and future potential[J]. Composites Part B: Engineering, 2016, 90: 432-442. doi: 10.1016/j.compositesb.2016.01.011 [9] 邓朗妮, 燕柳斌, 陈华, 等. 预应力CFRP板夹片式锚具的研制与试验研究[J]. 建筑技术, 2009, 40(11): 1043-1045.DENG Langni, YAN Liubin, CHEN Hua, et al. Development and experimental investigation of wedge-type anchorage for prestressed CFRP plates[J]. Architecture Technology, 2009, 40(11): 1043-1045. [10] 吴志平, 俞志杰, 娄亮, 等. 预应力碳纤维板平板锚具锚固性能试验[J]. 沈阳建筑大学学报(自然科学版), 2013, 29(2): 251-256.WU Zhiping, YU Zhijie, LOU Liang, et al. Experimental research on the plate anchorage for prestressed CFRP plates[J]. Journal of Shenyang Jianzhu University (Natural Science), 2013, 29(2): 251-256. [11] 卓静. 高强度复合材料FRP片材波形齿夹具锚锚固系统及应用研究[D]. 重庆: 重庆大学, 2005. [12] 诸葛萍, 强士中, 侯苏伟. 碳纤维筋夹片式锚具参数试验研究[J]. 西南交通大学学报, 2010, 45(4): 514-520.ZHUGE Ping, QIANG Shizhong, HOU Suwei. Experimental investigation of wedge-anchor parameters for CFRP tendons[J]. Journal of Southwest Jiaotong University, 2010, 45(4): 514-520. [13] 储焙宇, 钱登朝, 诸葛萍, 等. 预应力CFRP板平板锚具承载力评估理论与试验研究[J]. 宁波大学学报(理工版), 2020, 33(4): 41-48.CHU Beiyu, QIAN Dengchao, ZHUGE Ping, et al. Theoretical and experimental study on load-carrying capacity evaluation of CFRP plates bond-type anchors[J]. Journal of Ningbo University (Natural Science & Engineering Edition), 2020, 33(4): 41-48. [14] 齐艺佳, 肖丹, 王中强. 夹片外伸式CFRP板锚具设计优化与试验研究[J]. 中外公路, 2025, 45(6): 189-198.QI Yijia, XIAO Dan, WANG Zhongqiang. Design Optimization and Experimental Study of CFRP Plate Anchorage with Clip-Extension Type[J]. Journal of China & Foreign Highway, 2025, 45(6): 189-198. [15] MOHEE F M, AL-MAYAH A, PLUMTREE A. Development of a novel prestressing anchor for CFRP plates: Experimental investigations[J]. Composite Structures, 2017, 176: 20-32. doi: 10.1016/j.compstruct.2017.05.011 [16] BURTSCHER S L. Wedge anchorage for CFRP strips[J]. Journal of Composites for Construction, 2008, 12(4): 446-453. doi: 10.1061/(ASCE)1090-0268(2008)12:4(446) [17] YE H W, LIU C M, HOU S W, et al. Design and experimental analysis of a novel wedge anchor for prestressed CFRP plates using pre-tensioned bolts[J]. Composite Structures, 2018, 206: 313-325. doi: 10.1016/j.compstruct.2018.08.075 [18] ZHANG Z P, BAI J, YUE Q R, et al. A novel wedge anchor system for double-layer CFRP plate cables: concept, theoretical analysis and FEA[J]. Materials, 2024, 17(14): 3608. doi: 10.3390/ma17143608 [19] 黎伟捷. 碳纤维复材平行板拉索及曲面板锚具性能研究[D]. 北京: 清华大学, 2016. [20] PORTNOV G G, KULAKOV V L, ARNAUTOV A K. Grips for the transmission of tensile loads to a FRP strip[J]. Mechanics of Composite Materials, 2013, 49(5): 457-474. doi: 10.1007/s11029-013-9363-1 [21] 龙佩恒, 史文浩, 侯苏伟, 等. 基于位移控制CFRP板新型锚具锚固性能研究[J]. 中国公路学报, 2021, 34(5): 76-85.LONG Peiheng, SHI Wenhao, HOU Suwei, et al. Anchorage performance of a new carbon fiber board anchor based on displacement control[J]. China Journal of Highway and Transport, 2021, 34(5): 76-85. [22] 侯苏伟, 田树恒, 唐志强, 等. CFRP板新型夹持式锚具试验研究[J]. 西南交通大学学报, 2025, 60(5): 1160-1169.HOU Suwei, TIAN Shuheng, TANG Zhiqiang, et al. Experimental study on a new clamping anchor for carbon fiber reinforced polymer plate[J]. Journal of Southwest Jiaotong University, 2025, 60(5): 1160-1169. [23] 中华人民共和国交通运输部. 桥梁用预应力碳纤维板—夹持式锚具: JT/T 1267—2019[S]. 北京: 人民交通出版社, 2019. -

下载:

下载: