Study on Safety Threshold for Rail Corrugation in High-Speed Railway Lines Under Coupled Action of Wheel’s Concave Wear

-

摘要:

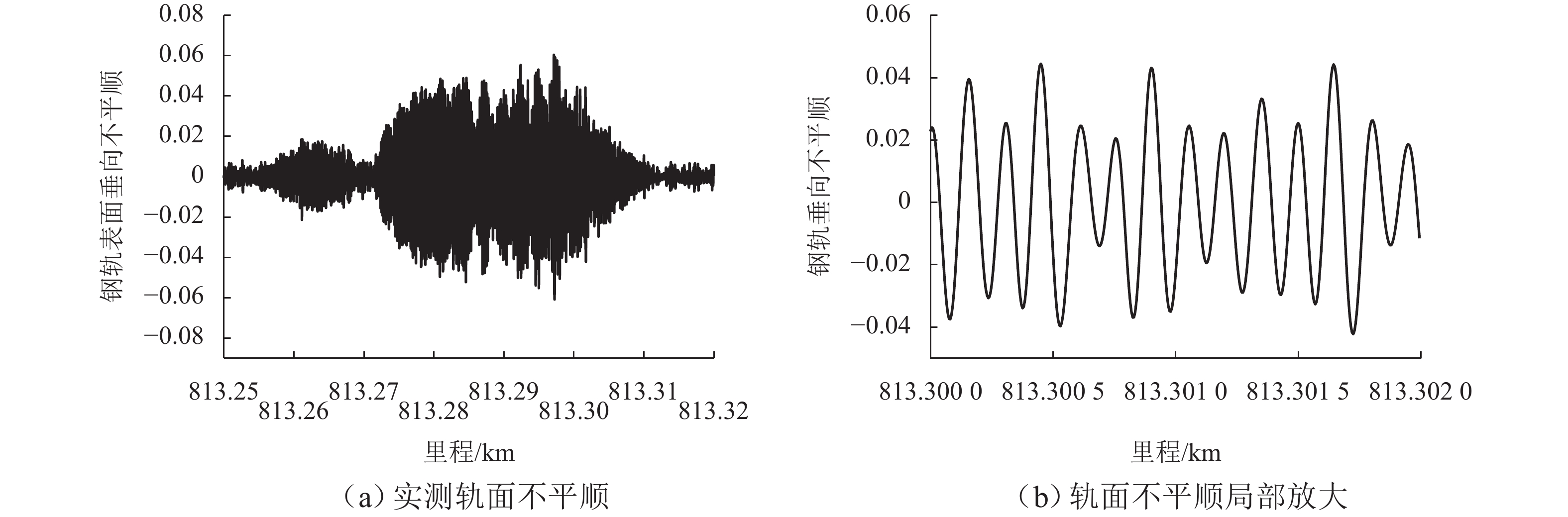

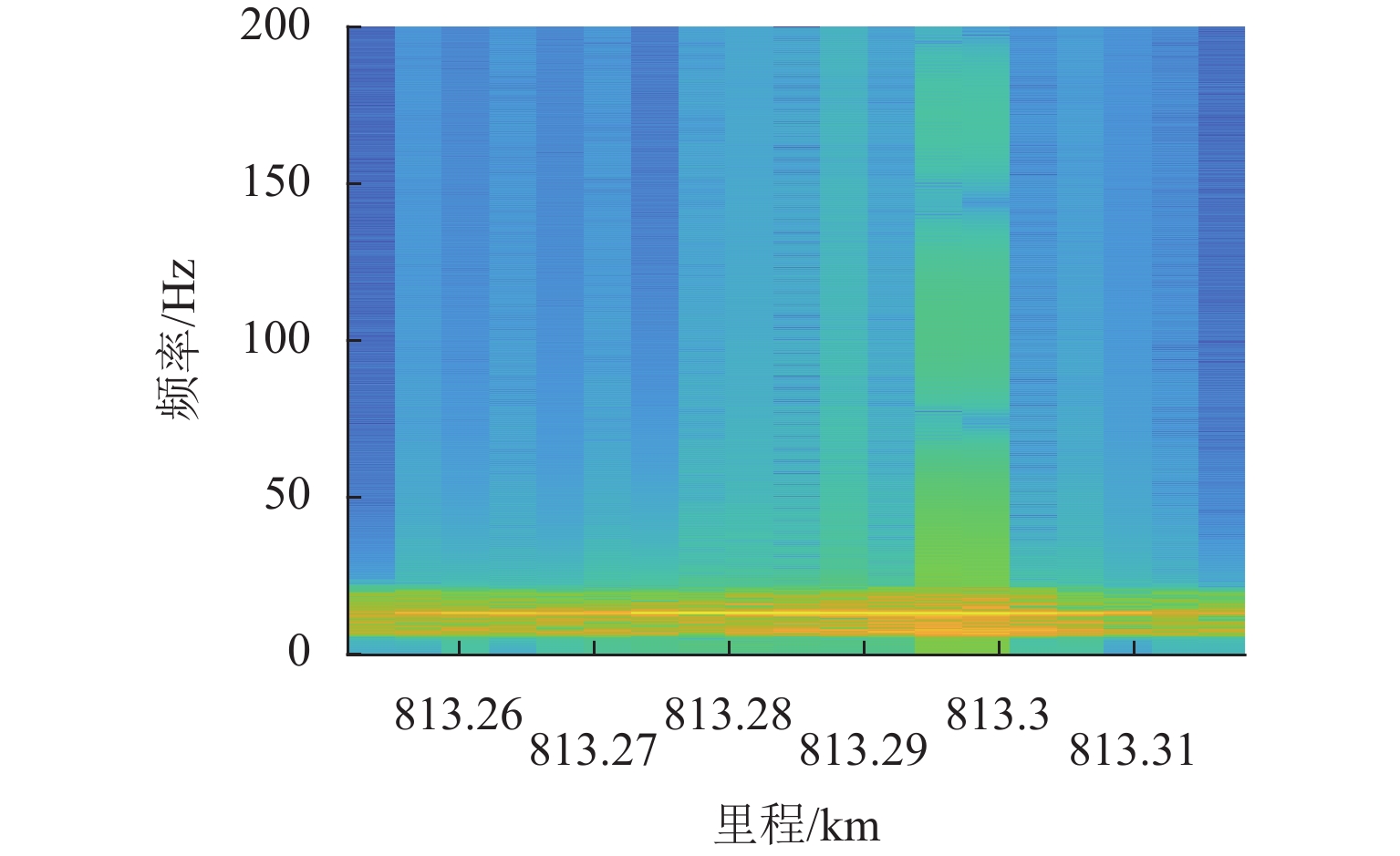

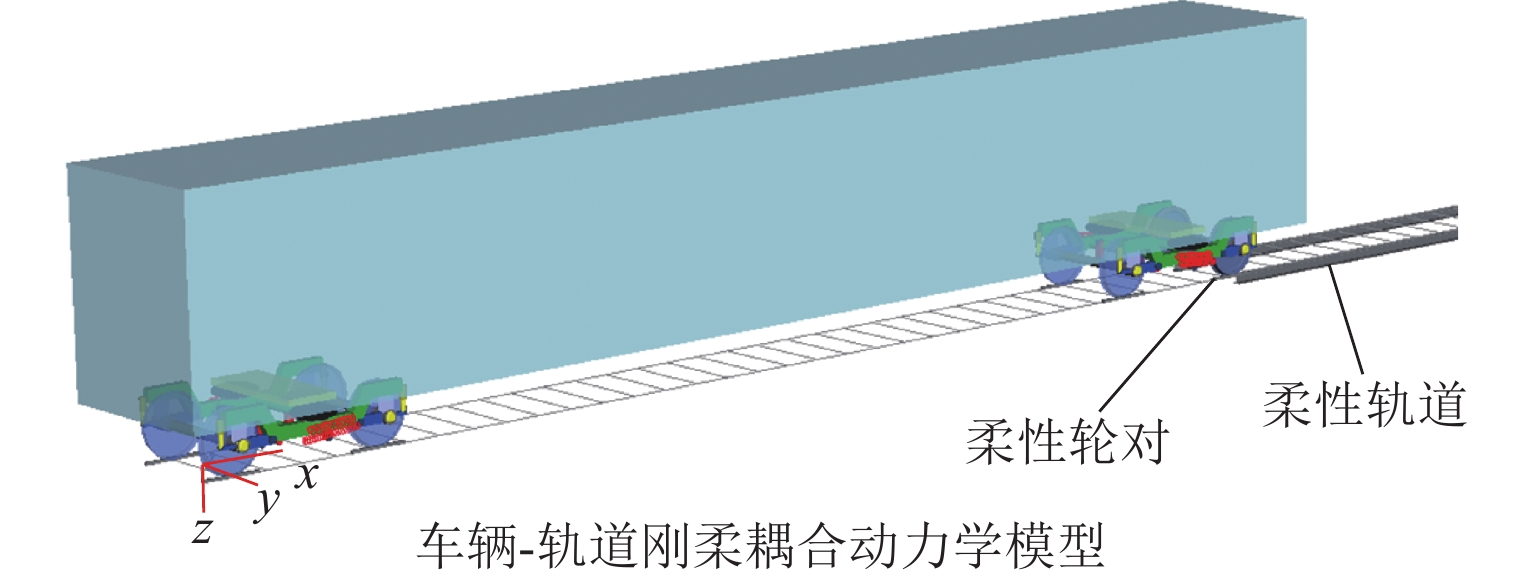

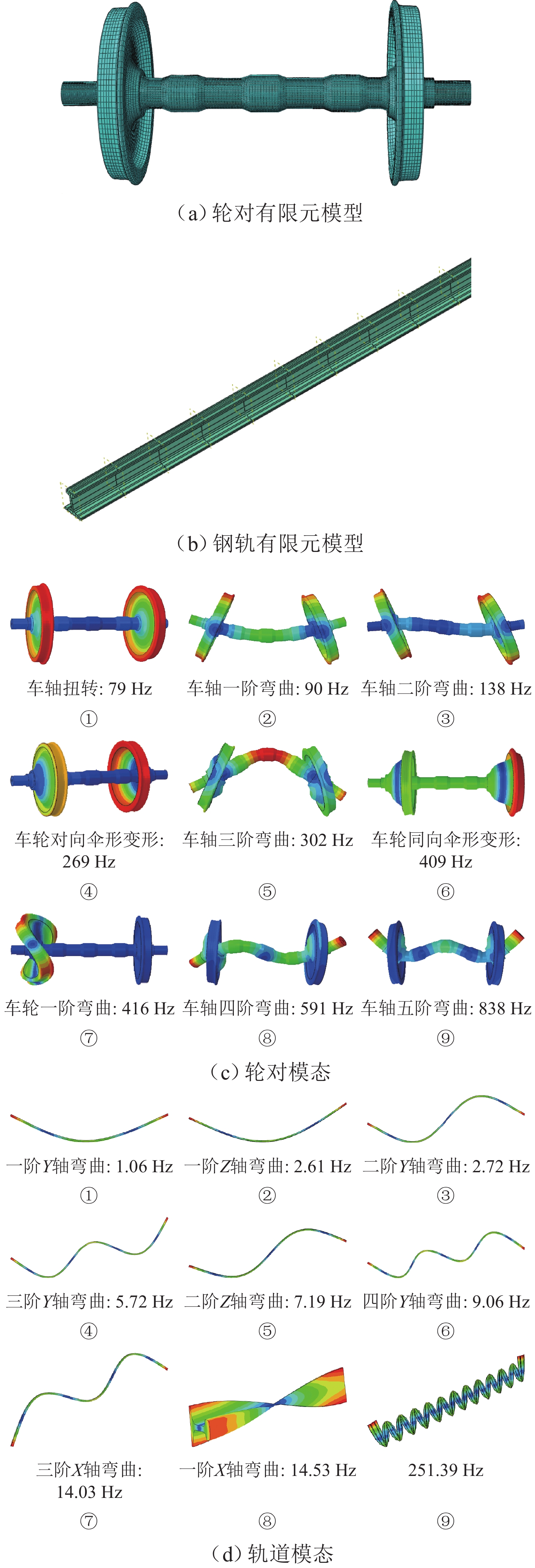

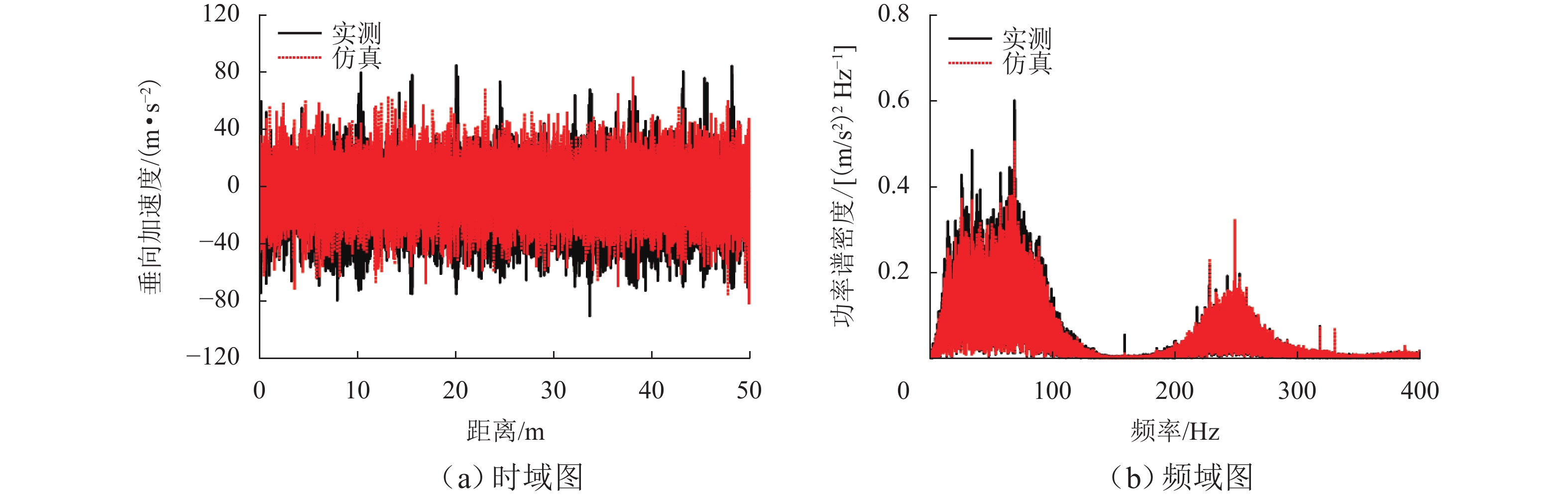

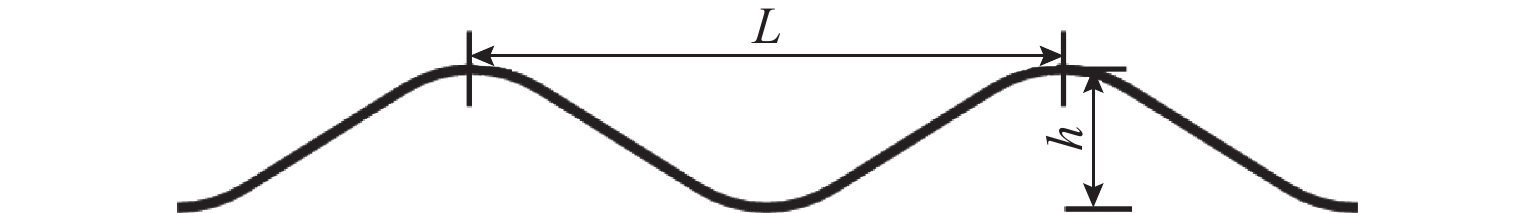

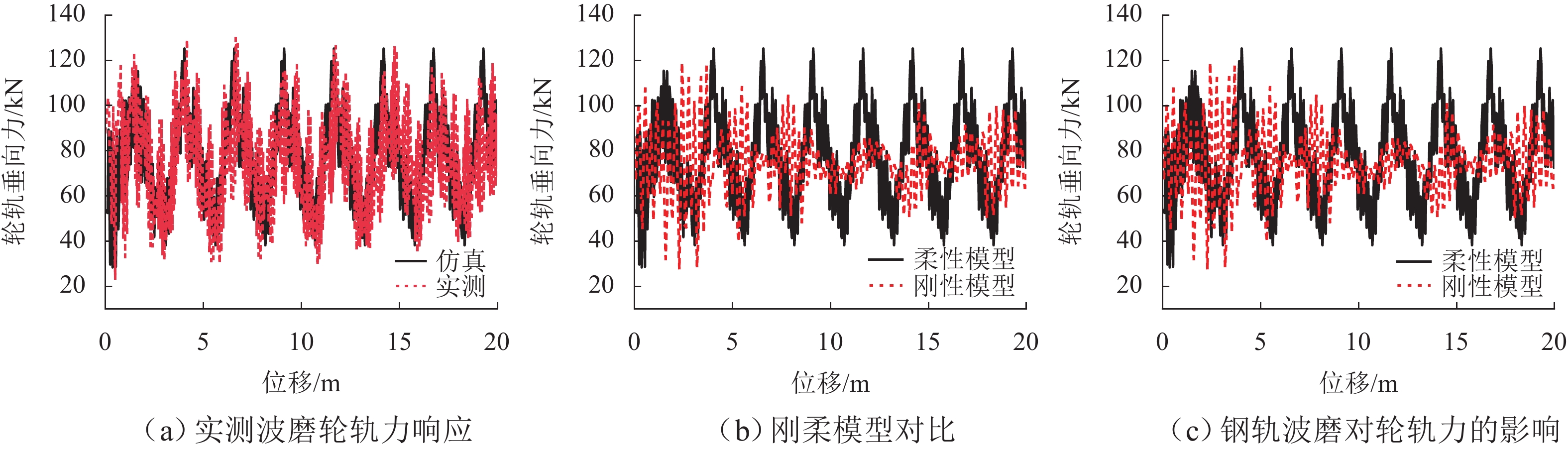

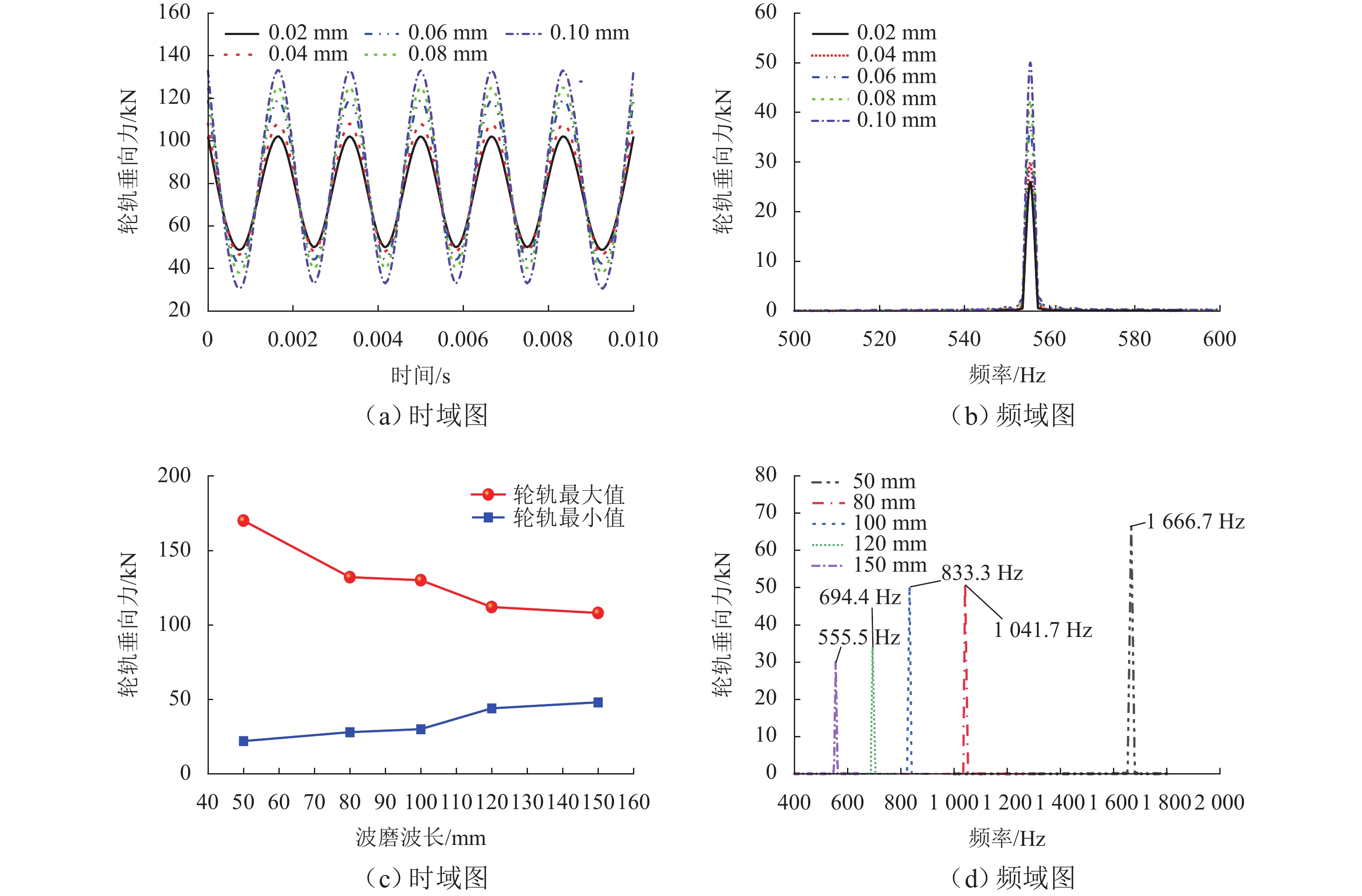

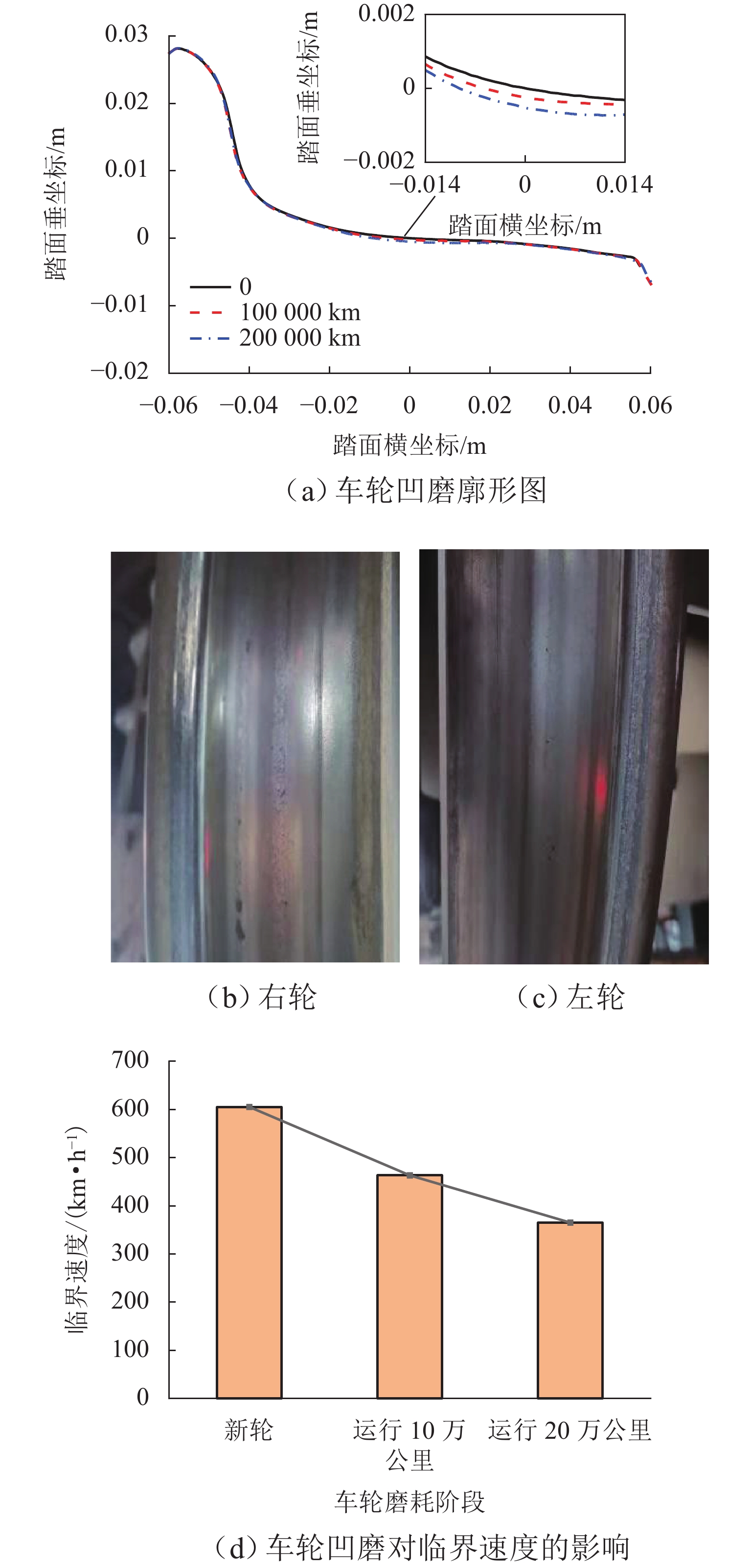

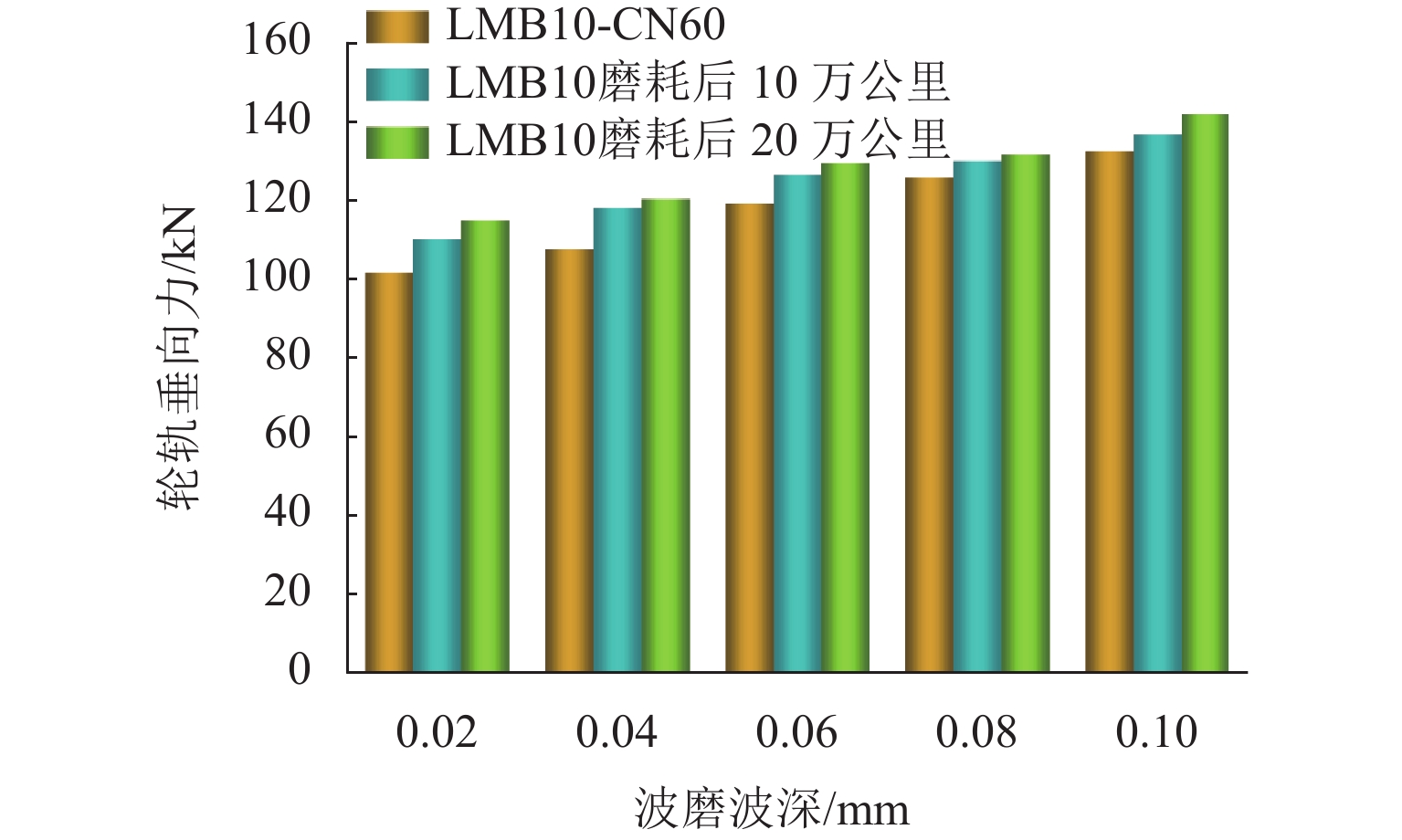

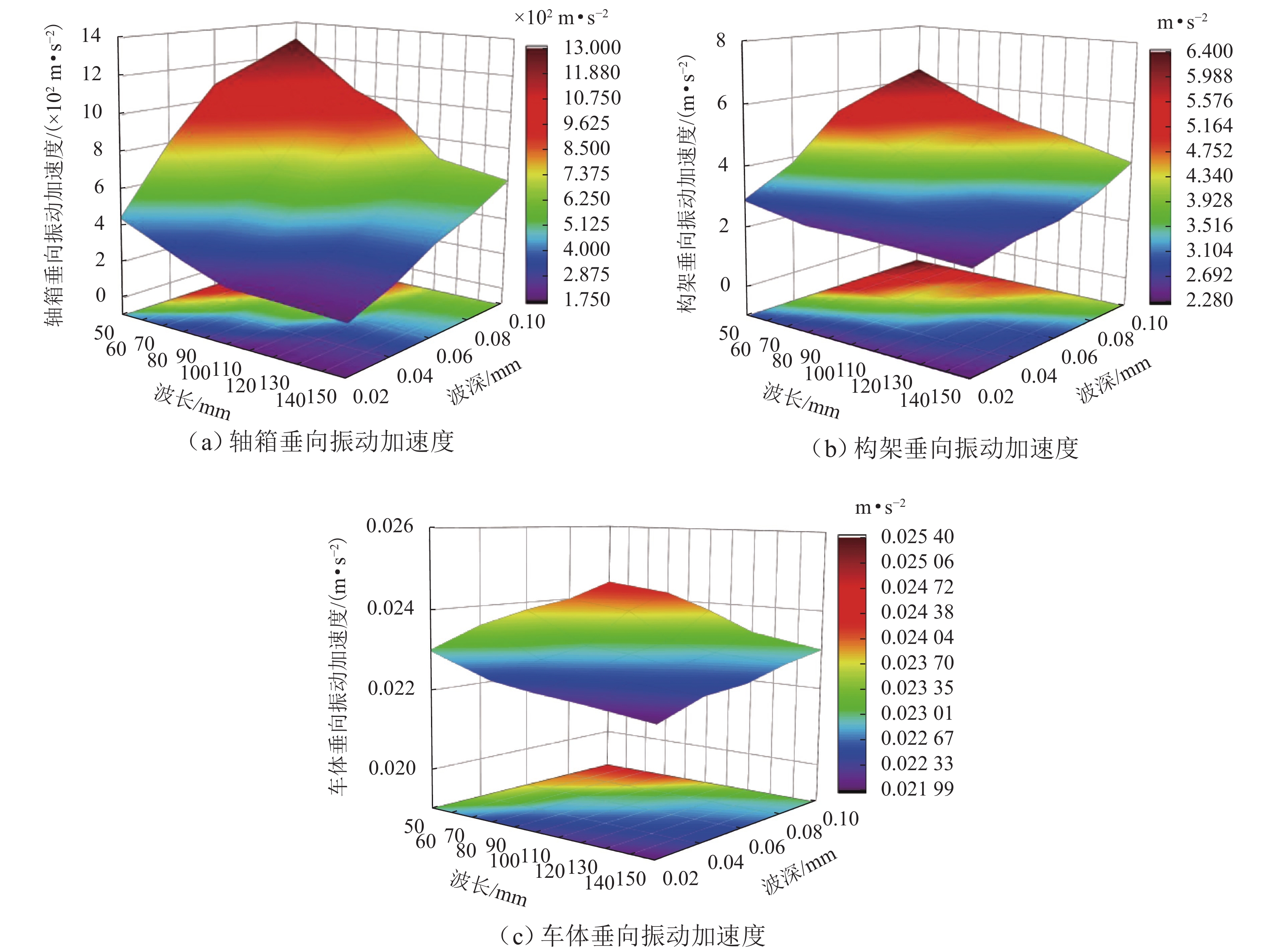

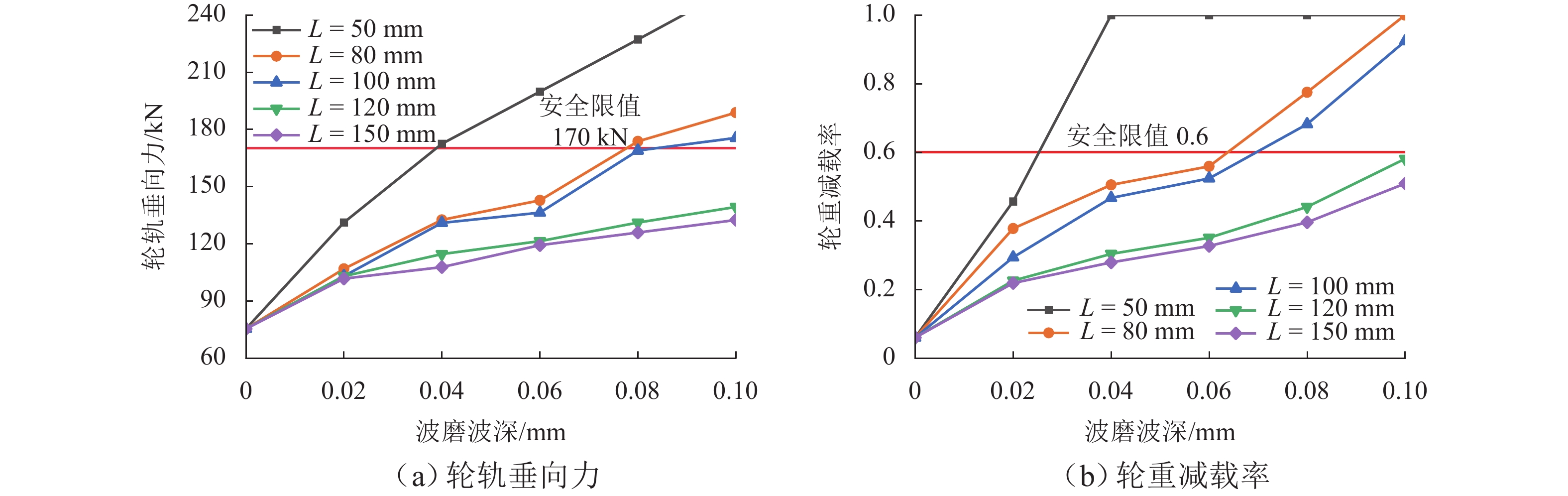

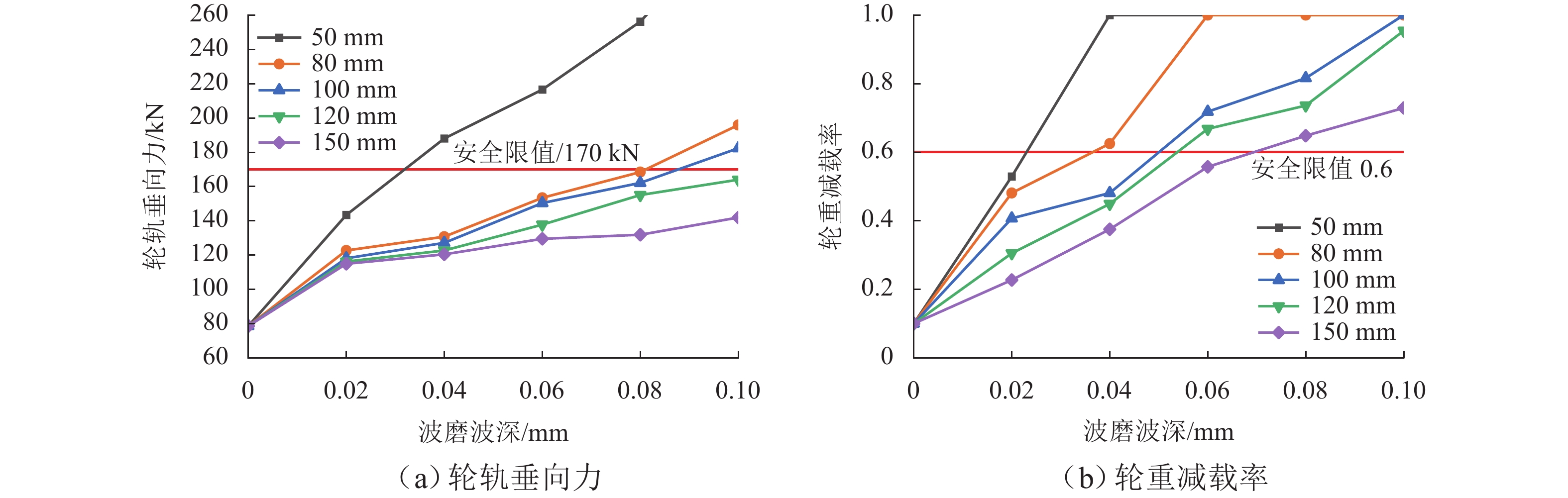

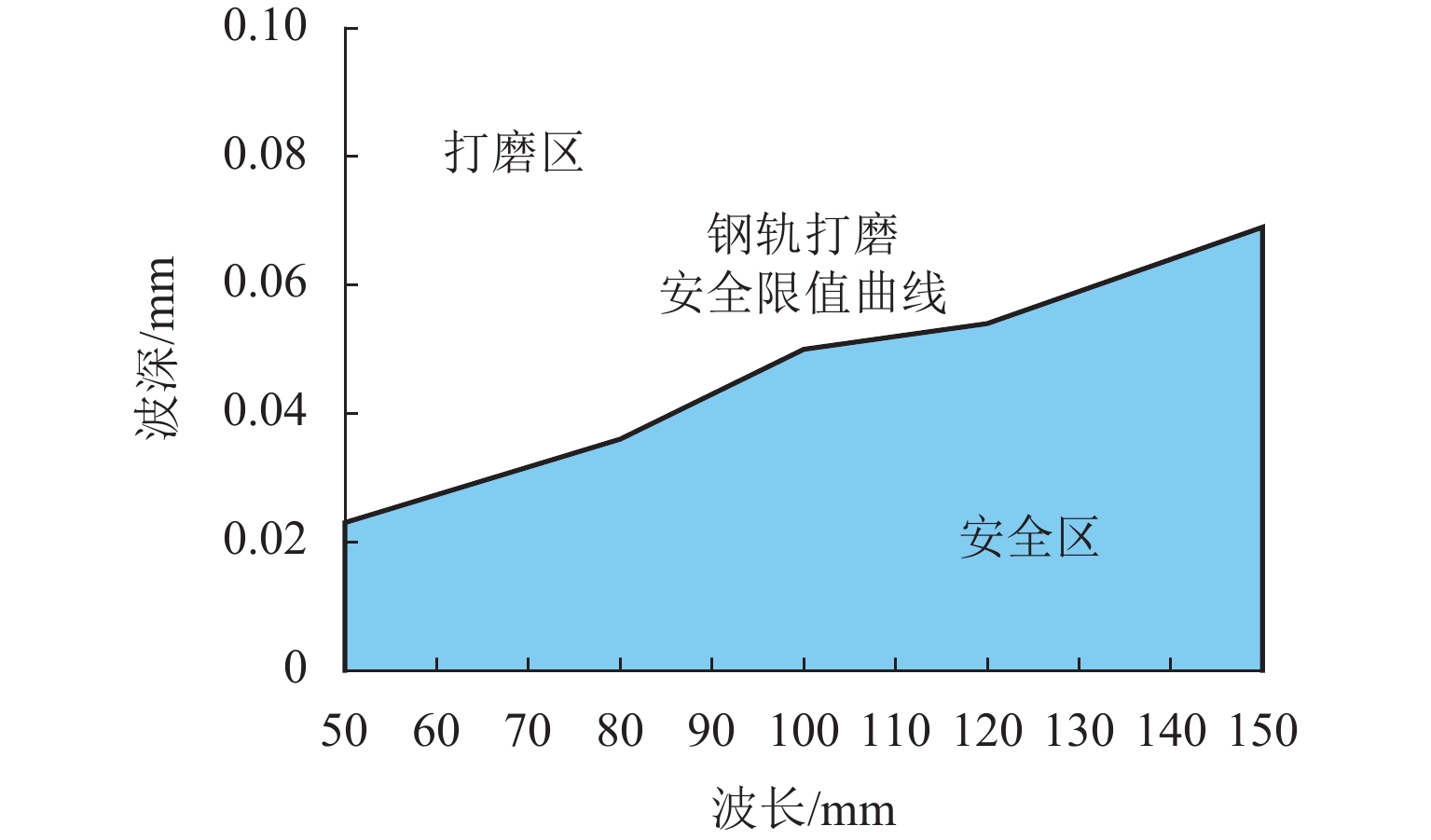

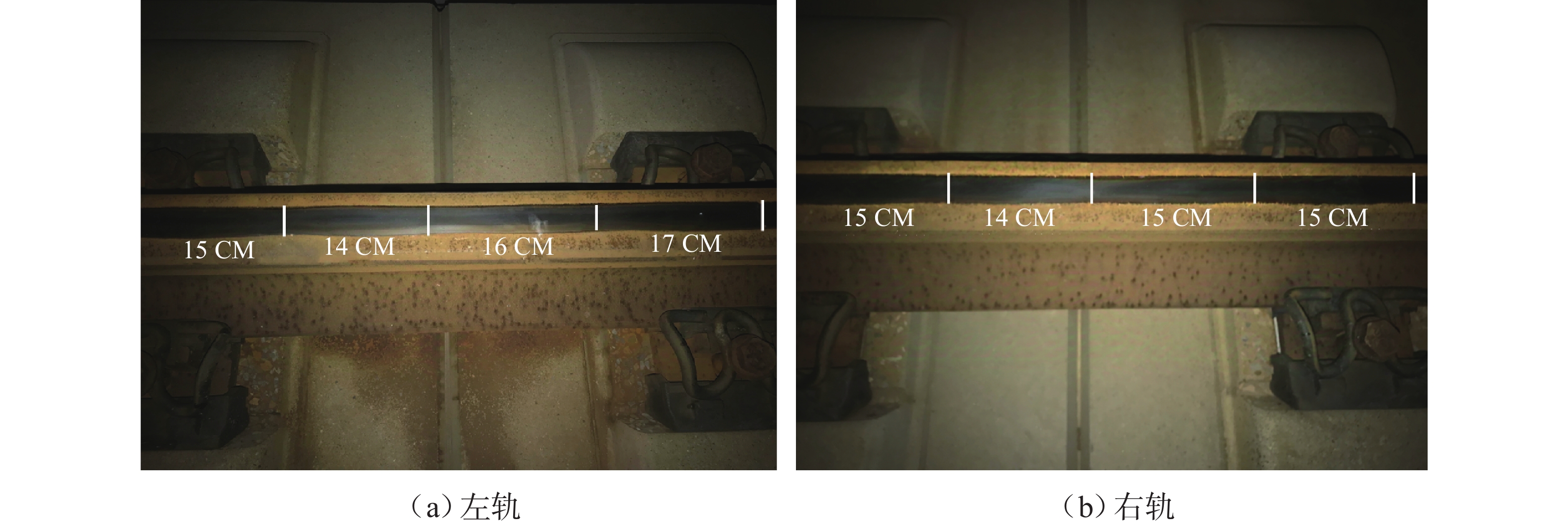

为探究钢轨波磨耦合车轮凹磨对高速列车轮轨系统动力学特性的影响,并确定高速铁路钢轨波磨的安全限值,基于车辆-轨道耦合动力学理论,结合现场调研获取的某线路钢轨波磨实测数据,构建CRH3型高速列车的车辆-轨道刚柔耦合动力学模型;将钢轨波磨和武广轨道谱叠加作为不平顺激励输入,探讨不同波长和波深的钢轨波磨对轮轨动力学特性的影响;探究不同运营里程的车轮凹磨与钢轨波磨的耦合作用,分析其对车辆各子系统振动加速度的影响,并在此基础上提出钢轨波磨安全限值. 研究结果表明:钢轨波磨显著增加轮轨垂向力,车轮凹磨和波磨耦合作用下进一步加大了轮轨力的响应,且凹磨越严重,轮轨力越大,运行20万公里的磨耗轮的轮轨垂向力相较于新轮增加了10.8%;考虑车轮凹磨,平均运行速度为300 km/h的高速列车建议50、80、100、120、150 mm钢轨波磨的波深安全限值为0.023、0.036、0.05、0.054、0.069 mm. 实际应用中,应结合具体运营条件和轨道结构调整维护策略,波深超出安全限值后应及时打磨.

Abstract:To investigate the influence of rail corrugation coupled with wheel concave wear on the dynamics characteristics of the high-speed train’s wheel-rail system and determine the safety threshold for rail corrugation in high-speed railways, based on vehicle-track coupling dynamics theory and field-measured rail corrugation data of a certain line, a vehicle-track rigid flexible coupling dynamics model of the CRH3 high-speed train was established. Rail corrugation superimposed on the Wuhan–Guangzhou track irregularity spectrum was used as the excitation input.. The influence of rail corrugation with different wavelengths and depths on wheel-rail dynamics characteristics was explored, and the coupling effect of wheel concave wear at different operation mileages with rail corrugation on vehicle subsystem’s vibration acceleration was analyzed. Then, the safety threshold for rail corrugation was proposed. Results show that rail corrugation significantly increases the wheel-rail vertical force. The coupled action of wheel concave wear and rail corrugation further amplifies the wheel-rail force response, with more severe concave wear leading to greater wheel-rail forces. Worn wheels that have traveled 200 000 km show an 10.8% increase in wheel-rail vertical force compared to new wheels. By considering wheel concave wear, for high-speed trains operating at an average speed of 300 km•h−1, the recommended safety thresholds for rail corrugation of 50 mm, 80 mm, 100 mm, 120 mm, and 150 mm are wave depths of 0.023 mm, 0.036 mm, 0.05 mm, 0.054 mm, and 0.069 mm, respectively. In practical applications, maintenance strategies should be adjusted according to specific operating conditions and track structures, and grinding should be carried out promptly when wave depths exceed the safety thresholds.

-

Key words:

- high-speed railway /

- rail corrugation /

- wheel’s concave wear /

- safety threshold /

- vibration response

-

表 1 钢轨波磨通过频率

Table 1. Passing frequency of rail corrugation

波长/mm 50 80 100 120 150 频率/Hz 1666.7 1041.7 833.3 694.4 555.6 -

[1] WEN Z F, JIN X S. Elastic-plastic finite-element analysis of repeated, two-dimensional wheel-rail rolling contact under time-dependent load[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2006, 220(5): 603-613. doi: 10.1243/09544062JMES201 [2] 金学松, 李霞, 李伟, 等. 铁路钢轨波浪形磨损研究进展[J]. 西南交通大学学报, 2016, 51(2): 264-273.JIN Xuesong, LI Xia, LI Wei, et al. Review of rail corrugation progress[J]. Journal of Southwest Jiaotong University, 2016, 51(2): 264-273. [3] 崔晓璐, 彭双千, 徐佳, 等. 钢轨波磨区段科隆蛋扣件弹条断裂机理[J]. 西南交通大学学报, 2025, 60(1): 205-213. doi: 10.3969/j.issn.0258-2724.20230025CUI Xiaolu, PENG Shuangqian, XU Jia, et al. Fracture mechanism of cologne-egg fastener clips in rail corrugation sections[J]. Journal of Southwest Jiaotong University, 2025, 60(1): 205-213. doi: 10.3969/j.issn.0258-2724.20230025 [4] 祁亚运, 李龙, 石怀龙, 等. 高寒动车组温变特性对运行性能的影响分析[J]. 西南交通大学学报, 2025, 60(2): 336-345.QI Yayun, LI Long, SHI Huailong, et al. Influence of temperature-varying characteristics on operating performance of alpine electric multiple units[J]. Journal of Southwest Jiaotong University, 2025, 60(2): 336-345. [5] 蒋忠辉, 赵国堂, 张合吉, 等. 车辆轨道关键参数对高速铁路钢轨波磨发展的影响[J]. 机械工程学报, 2018, 54(4): 57-63.JIANG Zhonghui, ZHAO Guotang, ZHANG Heji, et al. Effects of vehicle and track key parameters on the rail corrugation of high-speed railways[J]. Journal of Mechanical Engineering, 2018, 54(4): 57-63. [6] GRASSIE S L. Rail corrugation: characteristics, causes, and treatments[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2009, 223(6): 581-596. doi: 10.1243/09544097JRRT264 [7] GRASSIE S L, KALOUSEK J. Rail corrugation: characteristics, causes and treatments[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 1993, 207(1): 57-68. doi: 10.1243/PIME_PROC_1993_207_227_02 [8] GRASSIE S L. Rail corrugation: advances in measurement, understanding and treatment[J]. Wear, 2005, 258(7/8): 1224-1234. doi: 10.1016/j.wear.2004.03.066 [9] JIN X S, WANG K Y, WEN Z F, et al. Effect of rail corrugation on vertical dynamics of railway vehicle coupled with a track[J]. Acta Mechanica Sinica, 2005, 21(1): 95-102. doi: 10.1007/s10409-004-0010-x [10] JIN X S, WEN Z F, WANG K Y, et al. Three-dimensional train–track model for study of rail corrugation[J]. Journal of Sound and Vibration, 2006, 293(3/4/5): 830-855. doi: 10.1016/j.jsv.2005.12.013 [11] 郭涛, 侯银庆, 胡晓依, 等. 钢轨波磨对高速车辆动力学性能的影响[J]. 铁道建筑, 2019, 59(3): 111-115. doi: 10.3969/j.issn.1003-1995.2019.03.28GUO Tao, HOU Yinqing, HU Xiaoyi, et al. Influences of rail corrugations on dynamic performances of high speed vehicles[J]. Railway Engineering, 2019, 59(3): 111-115. doi: 10.3969/j.issn.1003-1995.2019.03.28 [12] 刘国云, 曾京, 张波. 钢轨波磨对高速车辆振动特性的影响[J]. 振动与冲击, 2019, 38(6): 137-143.LIU Guoyun, ZENG Jing, ZHANG Bo. Influence of rail corrugation on high-speed vehicle vibration performances[J]. Journal of Vibration and Shock, 2019, 38(6): 137-143. [13] MA C Z, GAO L, XIN T, et al. The dynamic resonance under multiple flexible wheelset-rail interactions and its influence on rail corrugation for high-speed railway[J]. Journal of Sound and Vibration, 2021, 498: 115968. doi: 10.1016/j.jsv.2021.115968 [14] CUI X L, CHENG Z, YANG Z C, et al. Study on the phenomenon of rail corrugation on high-speed rail based on the friction-induced vibration and feedback vibration[J]. Vehicle System Dynamics, 2022, 60(2): 413-432. doi: 10.1080/00423114.2020.1817507 [15] 祁亚运, 戴焕云, 干锋, 等. 基于车轮磨耗和舒适度的CRH3型动车组型面优化研究[J]. 振动与冲击, 2021, 40(18): 148-155.QI Yayun, DAI Huanyun, GAN Feng, et al. Wheel profile optimization of CRH3 type of EMU based on wheel wear and passenger comfort[J]. Journal of Vibration and Shock, 2021, 40(18): 148-155. [16] 祁亚运, 戴焕云, 干锋. 高速列车车轮型面多目标优化研究[J]. 机械工程学报, 2022, 58(24): 188-197.QI Yayun, DAI Huanyun, GAN Feng. Optimization of wheel profiles for high-speed trains[J]. Journal of Mechanical Engineering, 2022, 58(24): 188-197. [17] 施以旋, 戴焕云, 毛庆洲, 等. 基于车轨耦合的地铁车轮多边形形成机理[J]. 西南交通大学学报, 2024, 59(6): 1357-1367, 1388.SHI Yixuan, DAI Huanyun, MAO Qingzhou, et al. Formation mechanism of metro wheel polygonal based on vehicle-track coupling[J]. Journal of Southwest Jiaotong University, 2024, 59(6): 1357-1367,1388. [18] 祁亚运, 戴焕云, 干锋, 等. 高速动车组车轮偏磨影响因素与限值研究[J]. 表面技术, 2023, 52(5): 51-60.QI Yayun, DAI Huanyun, GAN Feng, et al. Influencing factors and limits of asymmetrical wheel wear of high-speed EMUs[J]. Surface Technology, 2023, 52(5): 51-60. [19] 林凤涛, 贾喆, 翁涛涛, 等. 车轮凹磨特征指数对车辆运行性能影响分析[J]. 铁道科学与工程学报, 2023, 20(6): 1994-2003.LIN Fengtao, JIA Zhe, WENG Taotao, et al. Analysis of the impact of wheel recess characteristic index on vehicle running performance[J]. Journal of Railway Science and Engineering, 2023, 20(6): 1994-2003. [20] 王晨, 罗世辉, 许自强, 等. 高速动车组构架横向失稳问题仿真分析与试验验证[J]. 铁道学报, 2021, 43(1): 39-48. doi: 10.3969/j.issn.1001-8360.2021.01.005WANG Chen, LUO Shihui, XU Ziqiang, et al. Simulation analysis and field test verification of lateral instability of high-speed EMU framework[J]. Journal of the China Railway Society, 2021, 43(1): 39-48. doi: 10.3969/j.issn.1001-8360.2021.01.005 [21] 祁亚运, 戴焕云, 桑虎堂, 等. 高速动车组抗蛇行减振器参数优化研究[J]. 振动工程学报, 2023, 36(5): 1326-1334. doi: 10.16385/j.cnki.issn.1004-4523.2023.05.017QI Yayun, DAI Huanyun, SANG Hutang, et al. Optimization study of anti-yaw damper parameters for high-speed EMUs[J]. Journal of Vibration Engineering, 2023, 36(5): 1326-1334. doi: 10.16385/j.cnki.issn.1004-4523.2023.05.017 [22] 祁亚运, 戴焕云, 吴昊, 等. 高速动车组转向架蛇行状态下的车轮磨耗分析[J]. 振动与冲击, 2023, 42(7): 38-45, 76. doi: 10.13465/j.cnki.jvs.2023.07.006QI Yayun, DAI Huanyun, WU Hao, et al. Wheel wear analysis of high-speed EMUs under bogie hunting[J]. Journal of Vibration and Shock, 2023, 42(7): 38-45,76. doi: 10.13465/j.cnki.jvs.2023.07.006 [23] 张鹏飞, 姚典, 冯青松, 等. 地铁波磨对轮轨动力特性影响及其安全阈值分析[J]. 振动与冲击, 2022, 41(5): 123-130, 150. doi: 10.13465/j.cnki.jvs.2022.05.017ZHANG Pengfei, YAO Dian, FENG Qingsong, et al. Effects of metro rail corrugation on wheel-track system dynamic characteristics and its wave depth safety threshold[J]. Journal of Vibration and Shock, 2022, 41(5): 123-130,150. doi: 10.13465/j.cnki.jvs.2022.05.017 [24] 谷永磊, 赵国堂, 金学松, 等. 高速铁路钢轨波磨对车辆—轨道动态响应的影响[J]. 中国铁道科学, 2015, 36(4): 27-31.GU Yonglei, ZHAO Guotang, JIN Xuesong, et al. Effects of rail corrugation of high speed railway on vehicle-track coupling dynamic response[J]. China Railway Science, 2015, 36(4): 27-31. [25] 姜子清, 司道林, 李伟, 等. 高速铁路钢轨波磨研究[J]. 中国铁道科学, 2014, 35(4): 9-14.JIANG Ziqing, SI Daolin, LI Wei, et al. On rail corrugation of high speed railway[J]. China Railway Science, 2014, 35(4): 9-14 [26] 朱海燕, 袁遥, 肖乾, 等. 钢轨波磨研究进展[J]. 交通运输工程学报, 2021, 21(3): 110-133.ZHU Haiyan, YUAN Yao, XIAO Qian, et al. Research progress on rail corrugation[J]. Journal of Traffic and Transportation Engineering, 2021, 21(3): 110-133. [27] 国家铁路局. 机车车辆动力学性能评定及试验鉴定规范: GB/T 5599—2019 [S]. 北京: 中国国家标准化管理委员会, 2019. [28] 中华人民共和国铁道部. 高速铁路工程动态验收技术规范: TB 10761—2013[S]. 北京: 中国铁道出版社, 2018 -

下载:

下载: