Seismic Performance of Hybrid Reinforced Columns with Built-in Spiral Stirrup Core Columns Under Composite Salt Erosion

-

摘要:

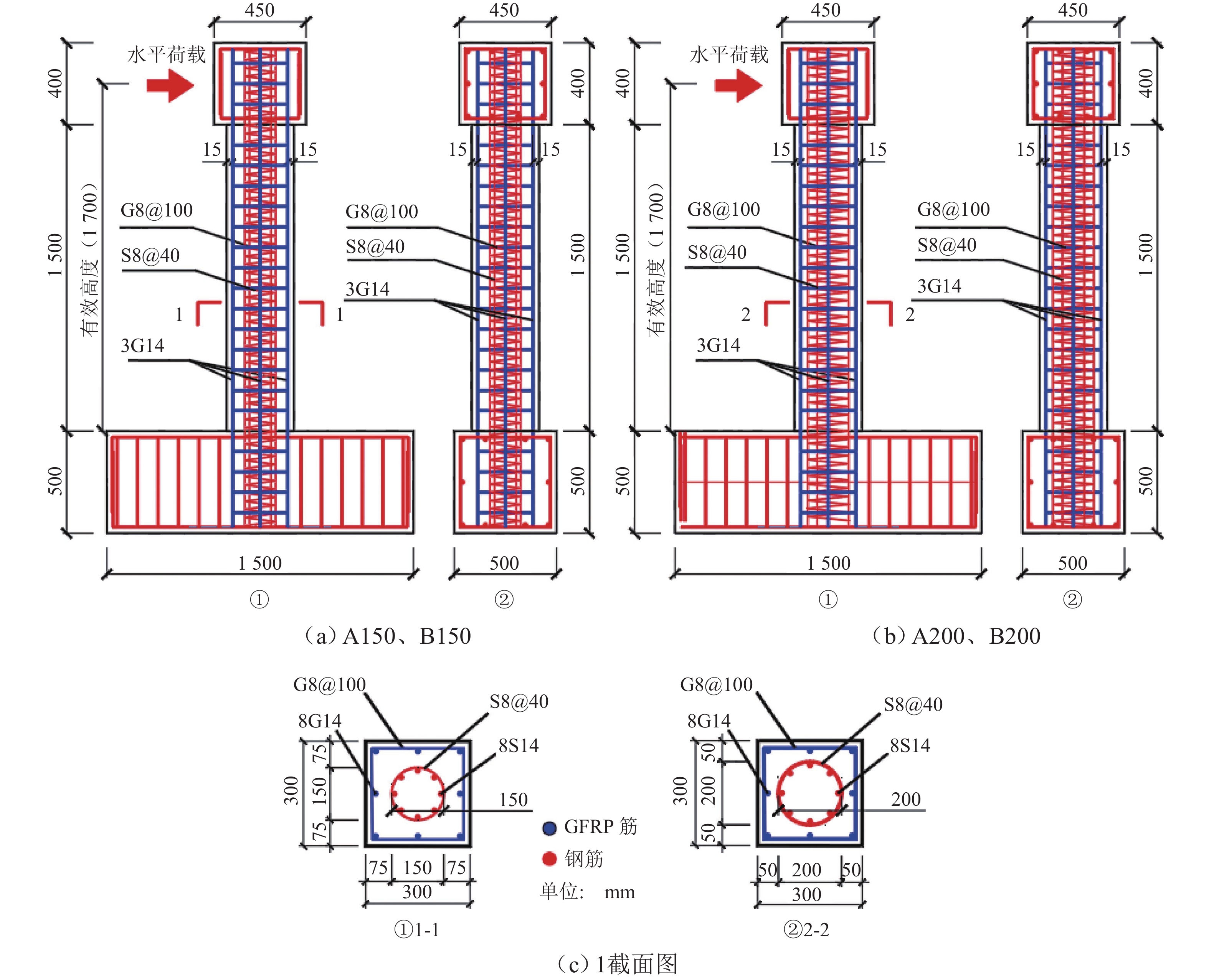

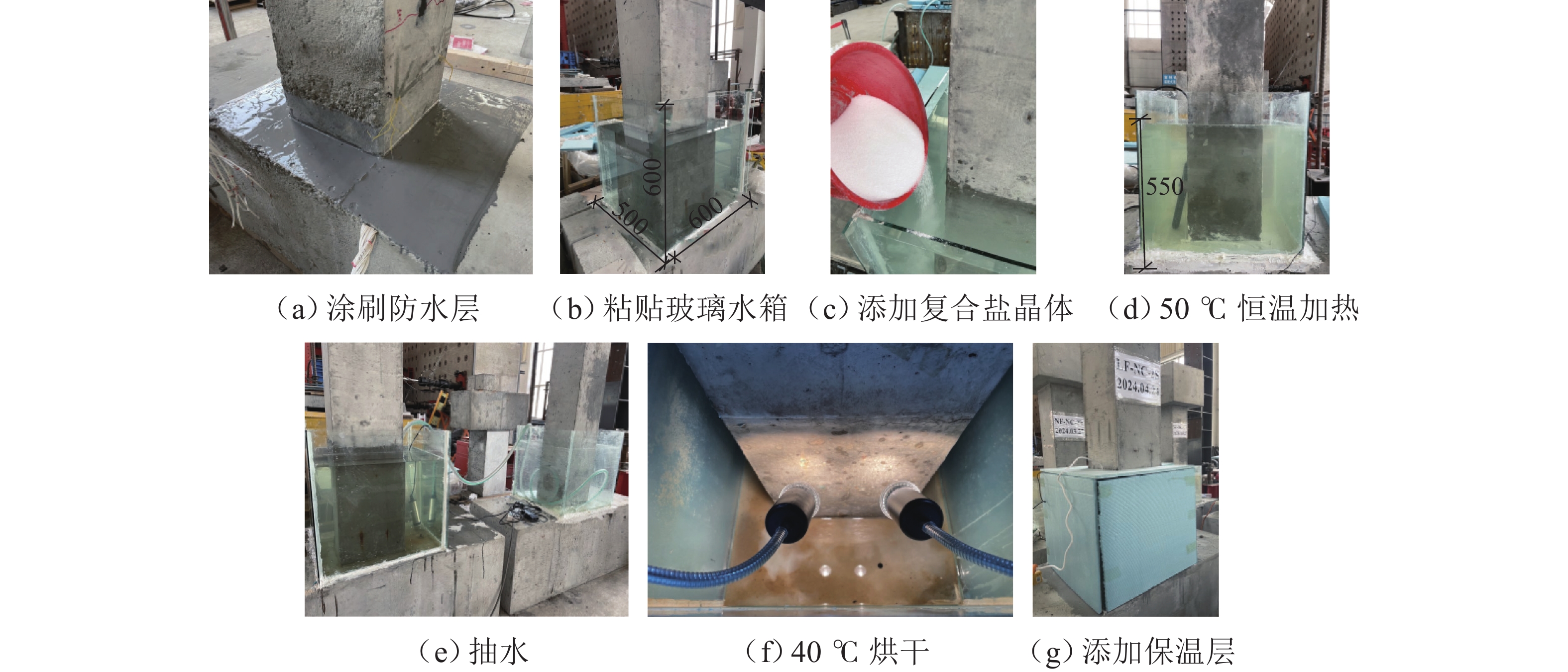

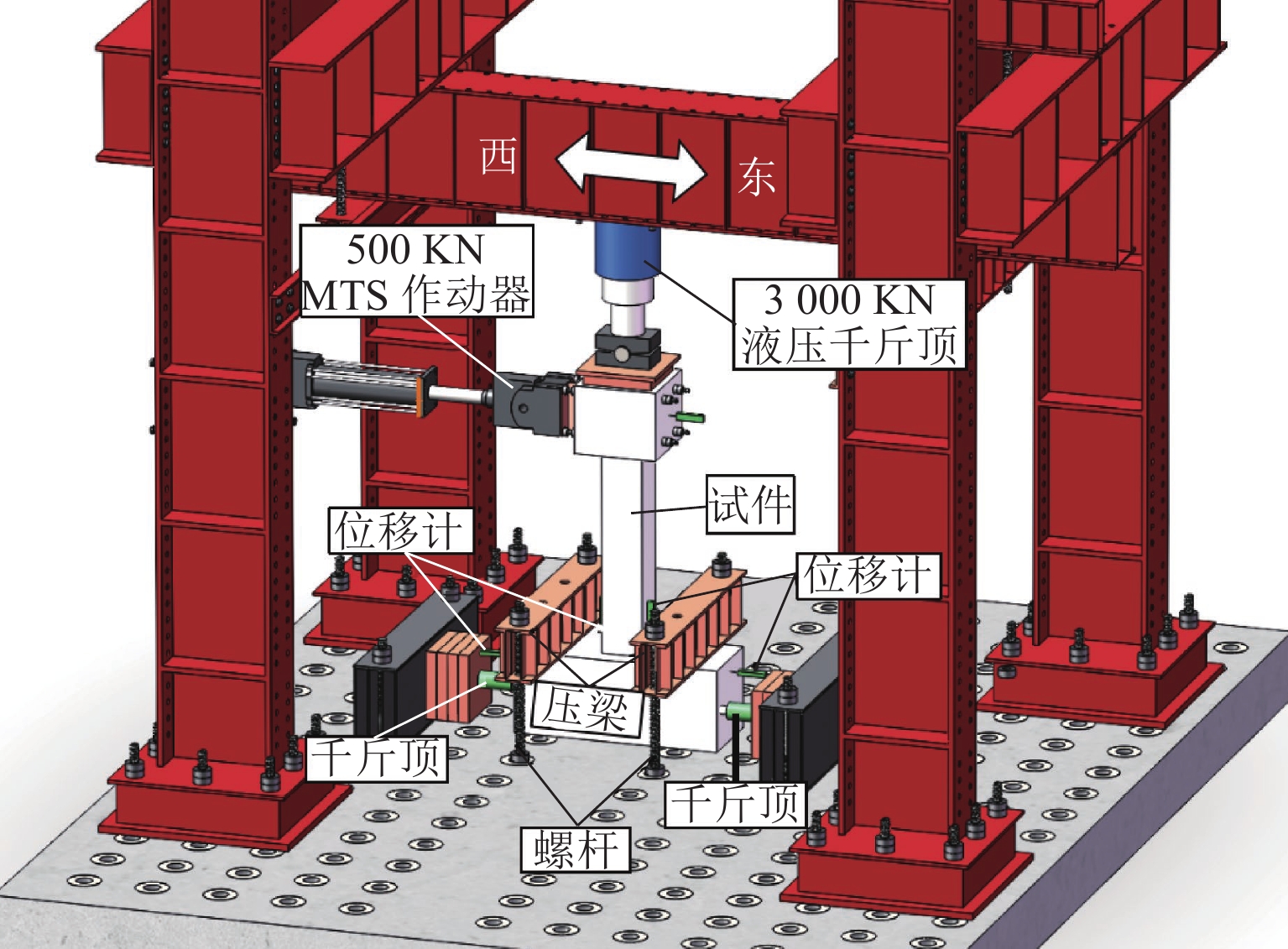

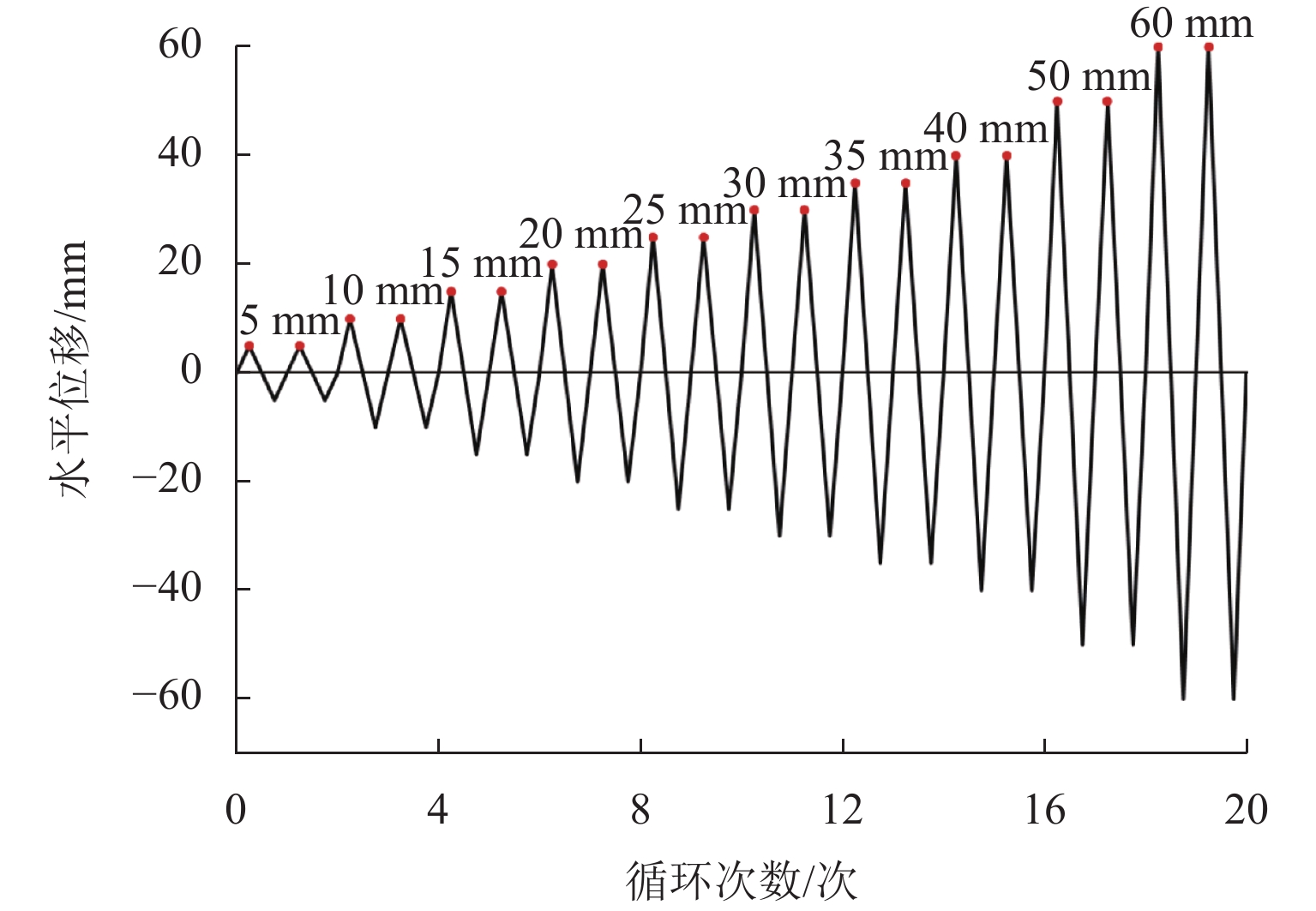

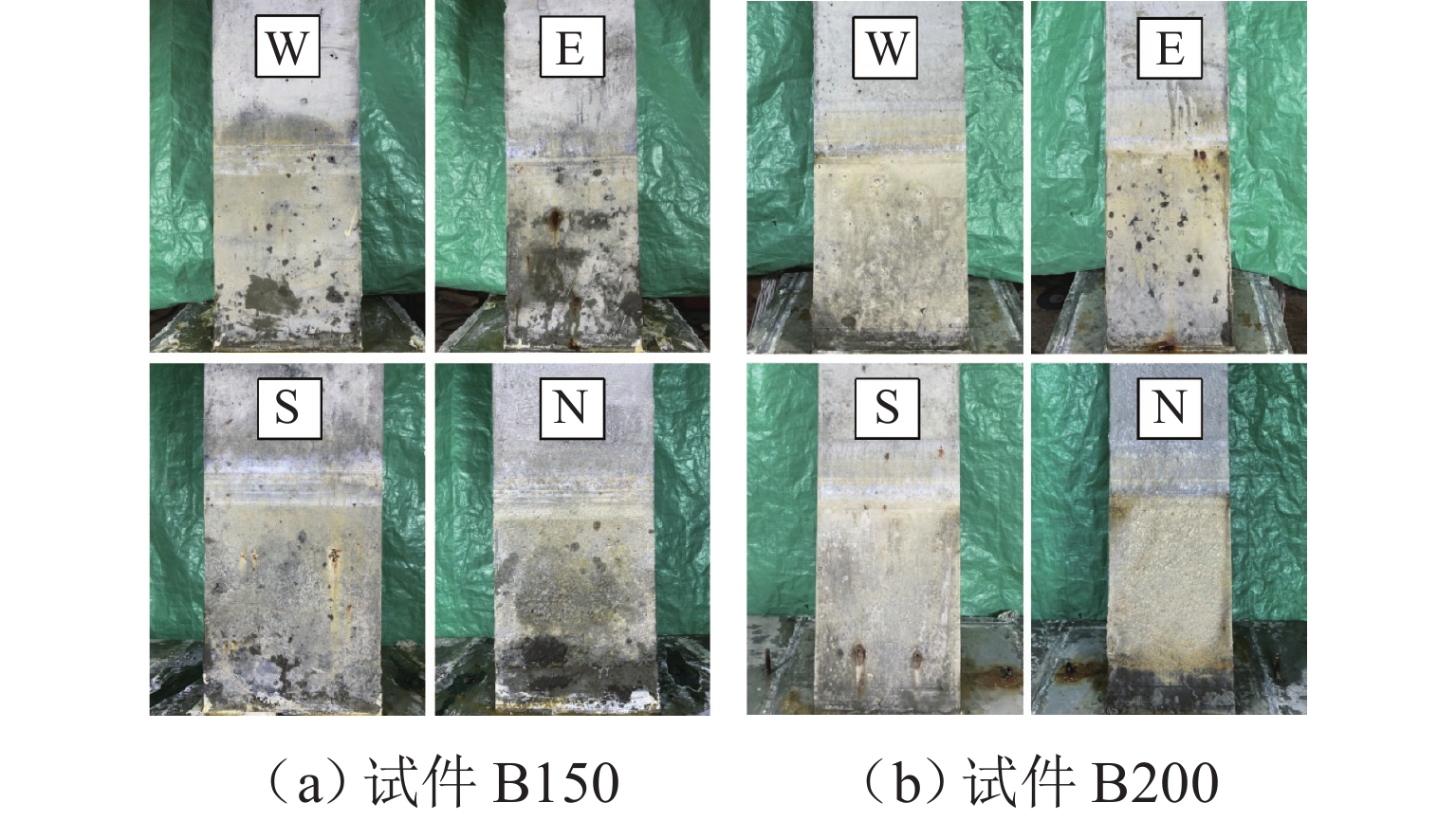

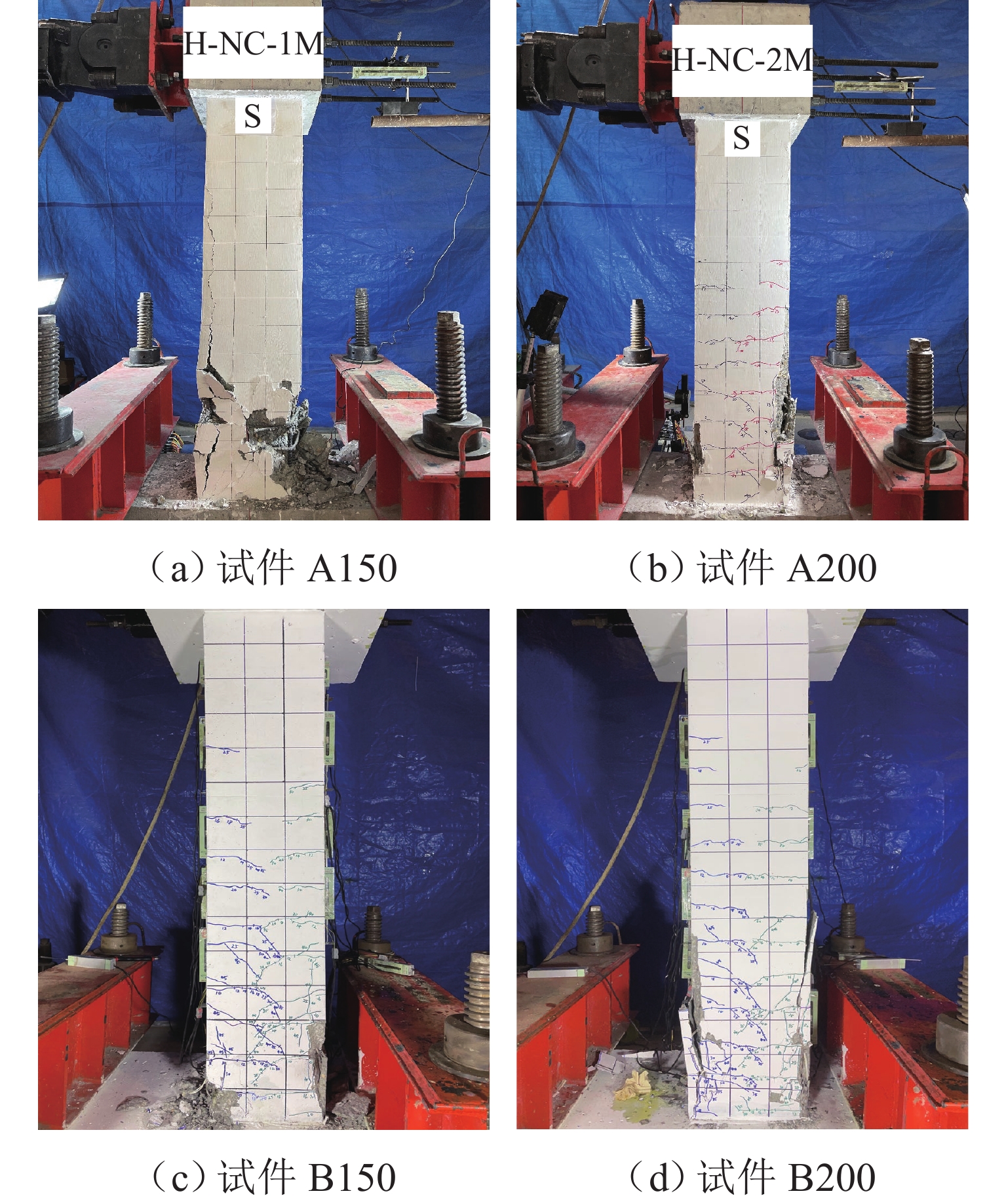

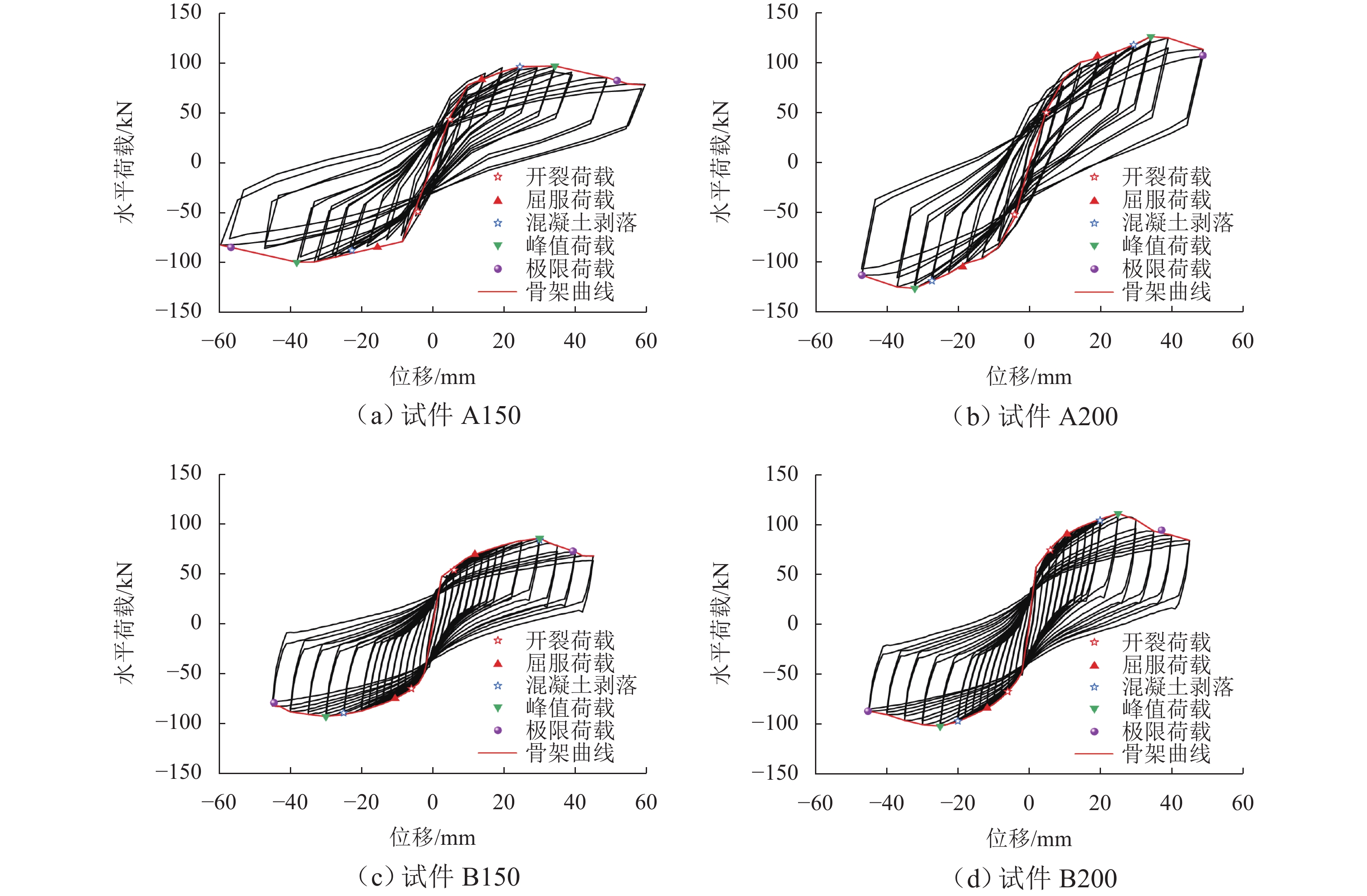

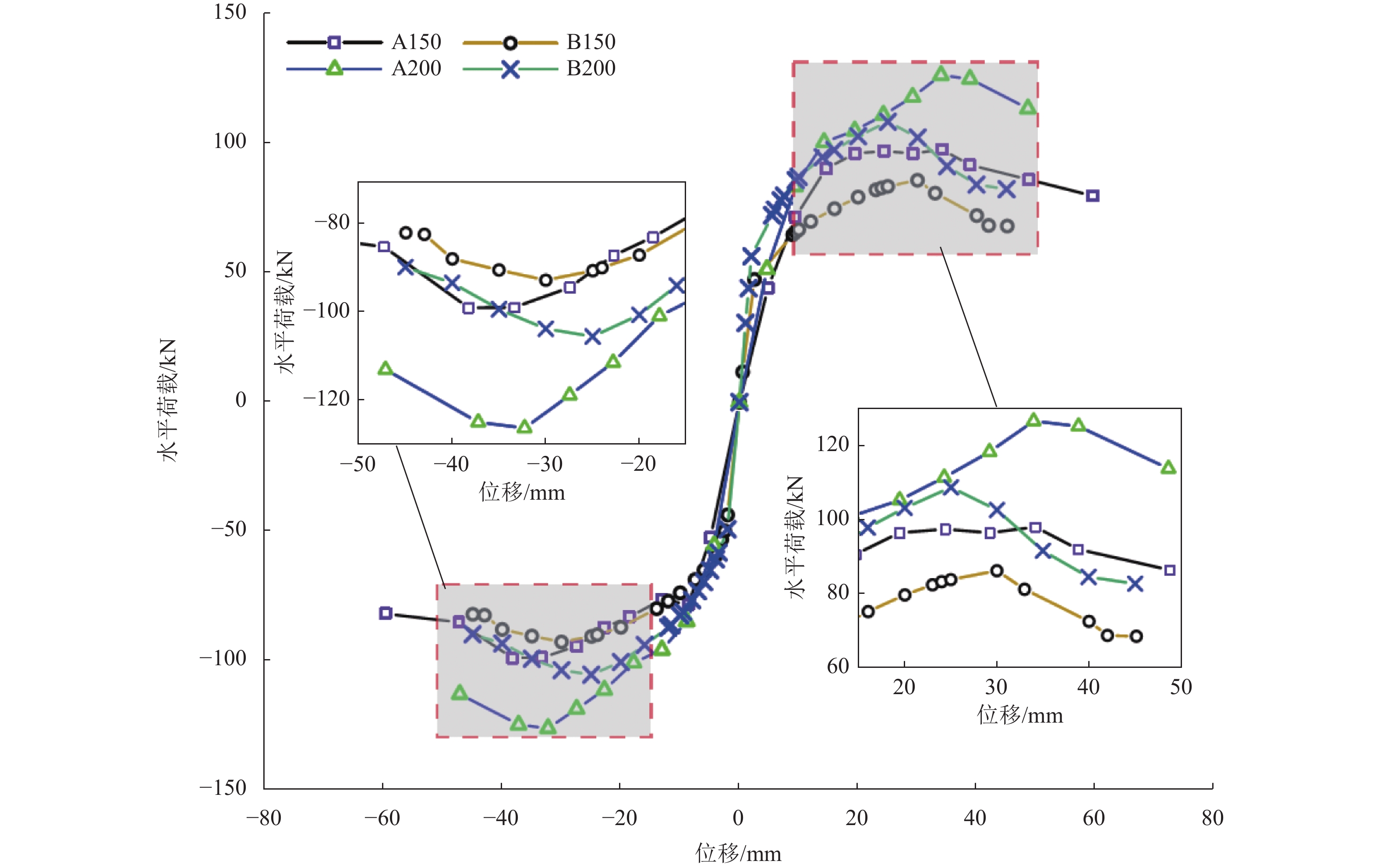

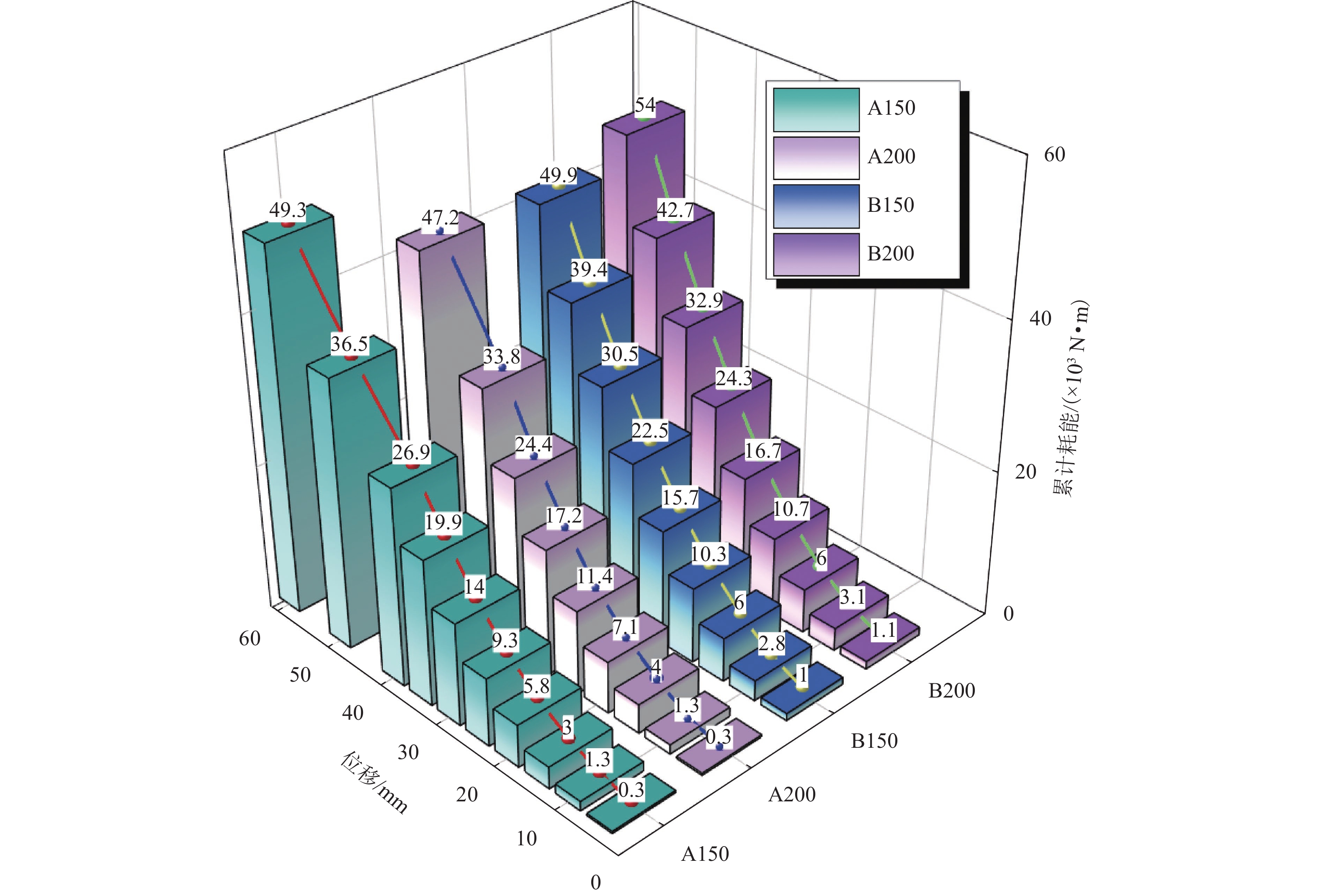

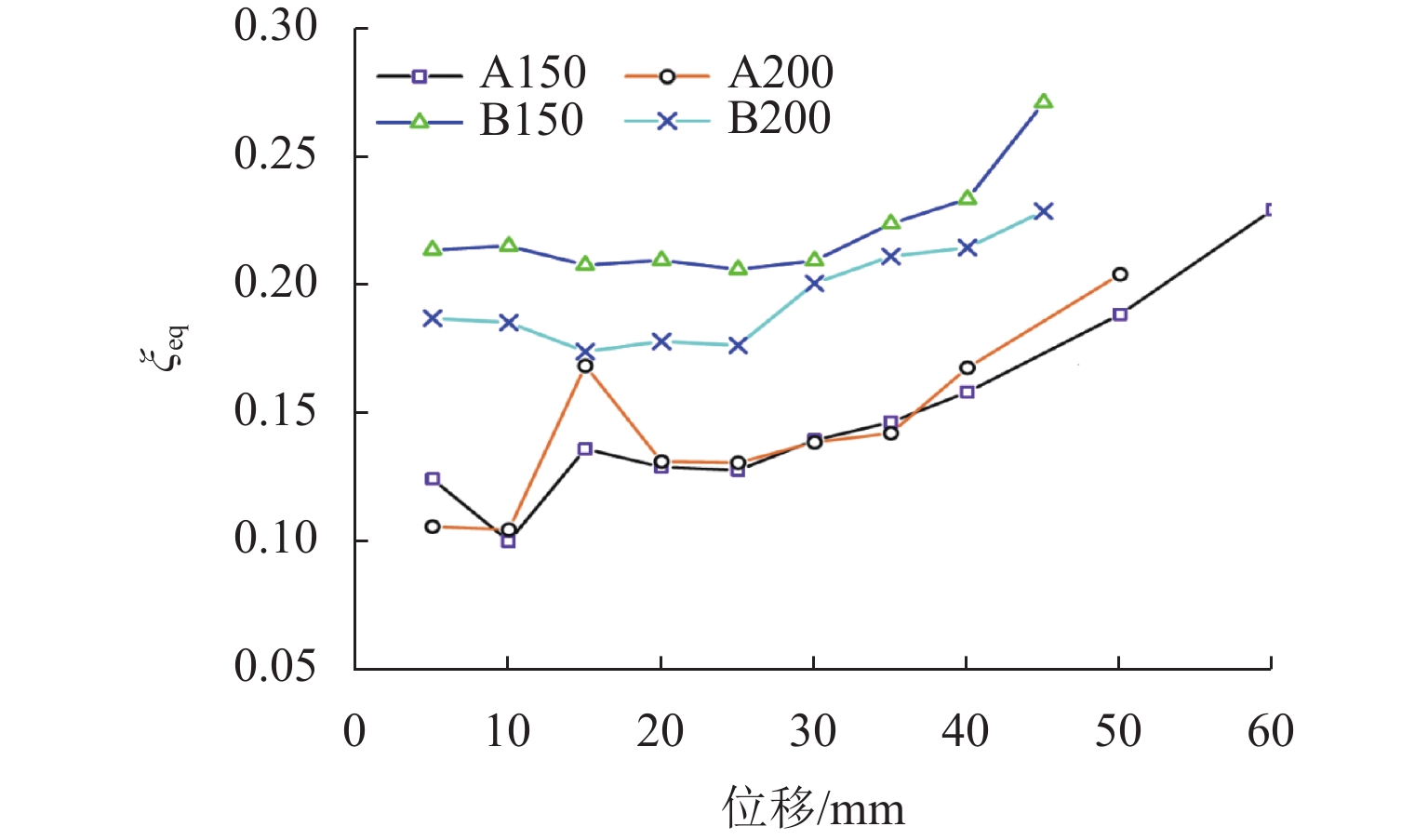

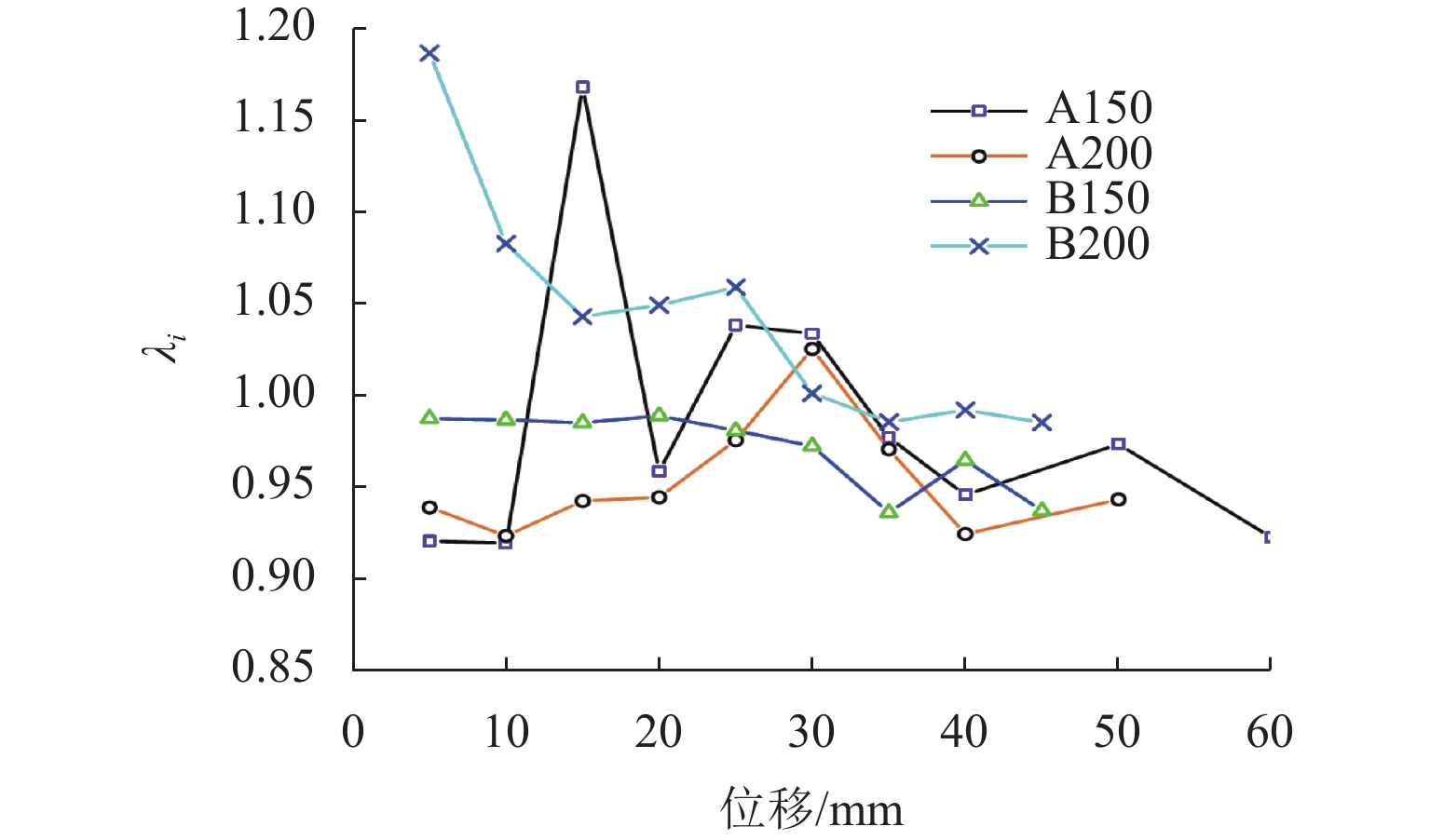

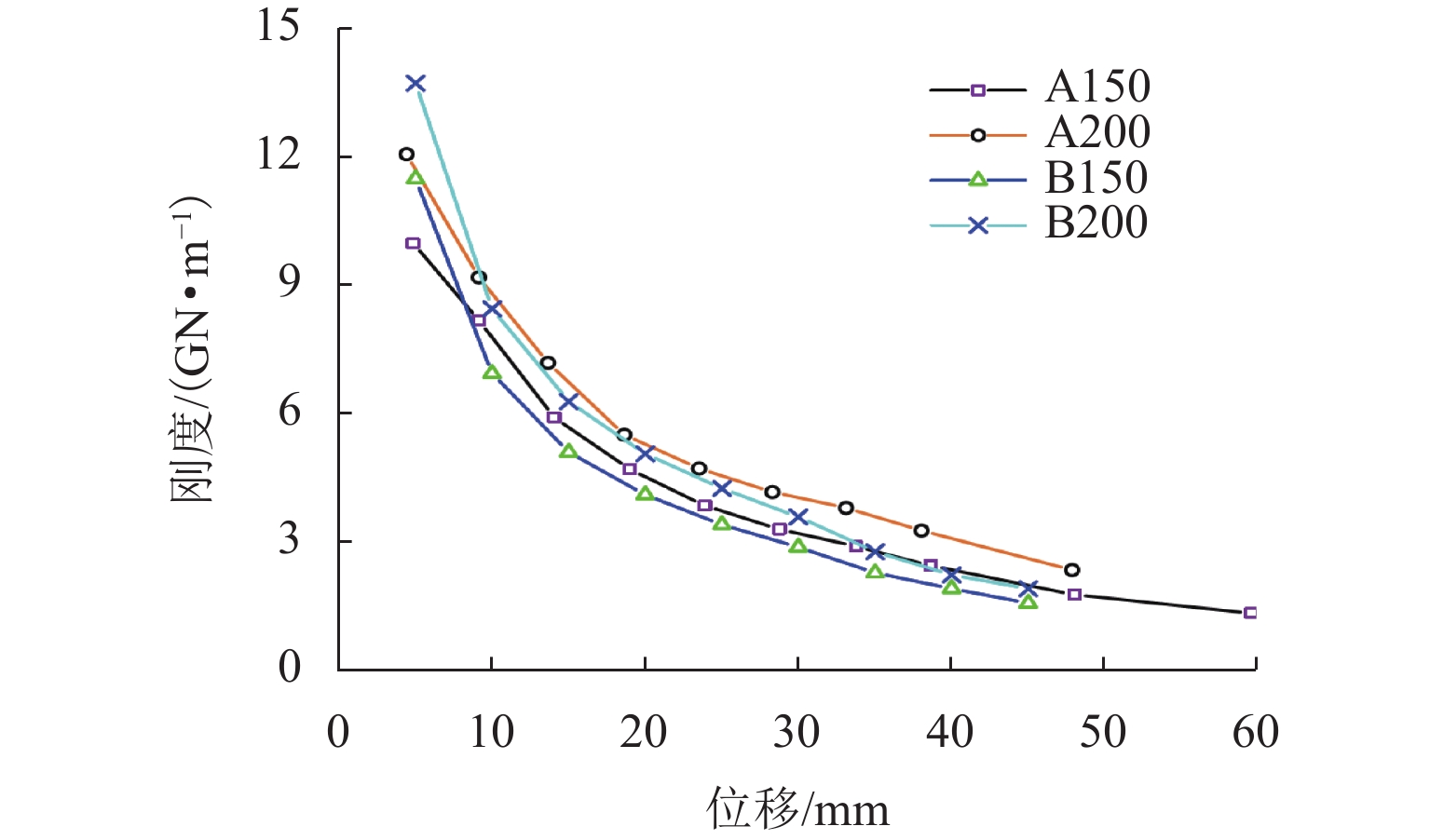

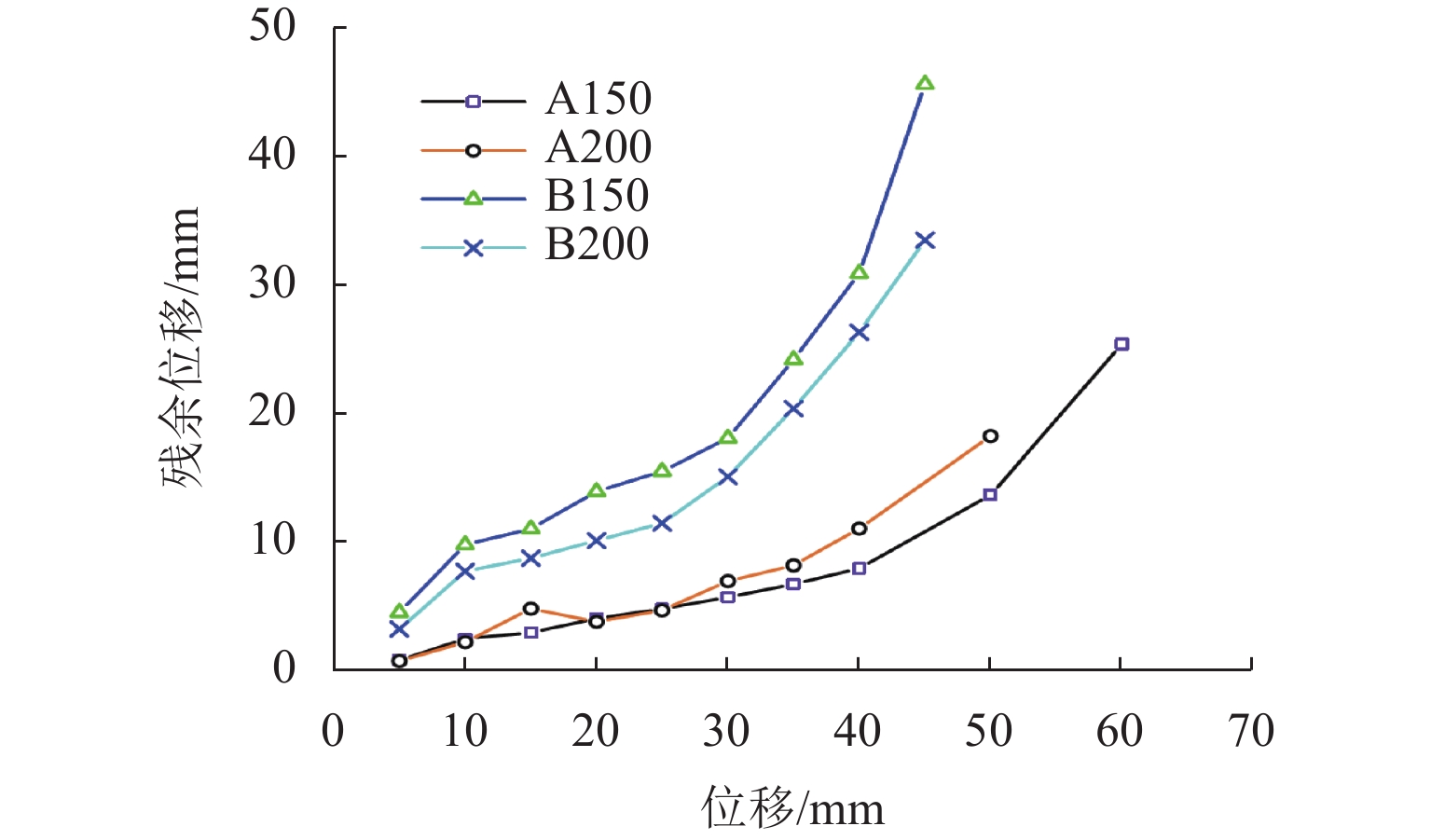

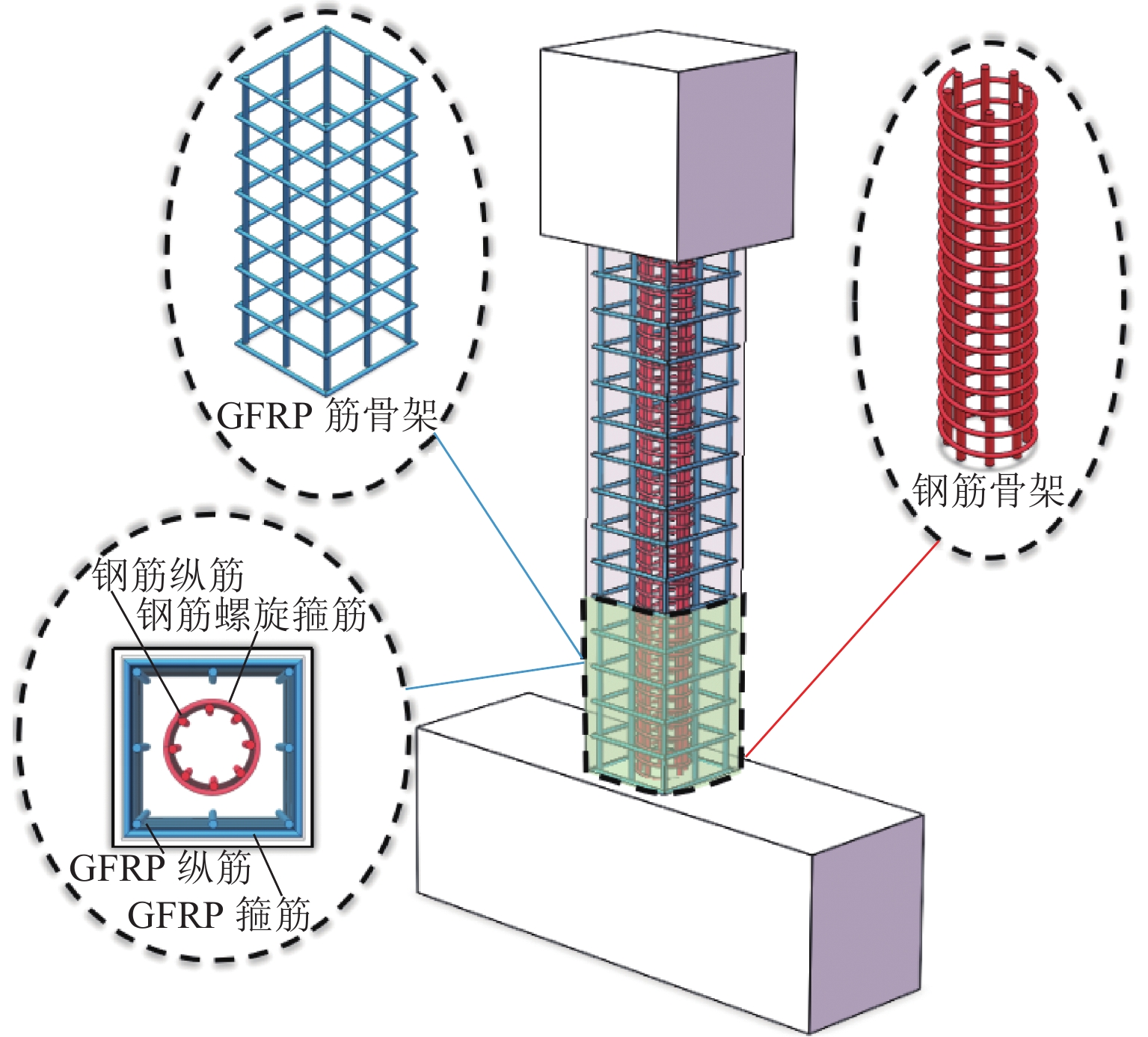

基于提高构件耐久性并保证构件延性的需求,提出一种新型内置螺旋箍筋芯柱的玻璃纤维增强复合材料(GFRP)-钢筋混合配筋(HRBS)柱. 开展4个HRBS柱的拟静力试验,其中,2个HRBS柱进行复合盐干湿循环试验,得到HRBS柱在复合盐干湿循环前后的破坏过程和最终破坏模式、滞回曲线、骨架曲线、耗能能力、性能退化和残余位移等. 结果表明:HRBS柱在复合盐干湿循环前后均表现出良好的抗震性能,破坏类型均为弯曲破坏;常规环境下,随着芯柱直径的增大,HRBS柱的屈服荷载和峰值荷载提升了25.77%和28.68%;复合盐环境下,芯柱直径的增大有利于提升HRBS 柱的承载能力、位移延性系数、强度退化系数、耗能能力、整体刚度和自复位能力;经过复合盐侵蚀后,200 mm芯柱直径试件的屈服荷载和峰值荷载分别降低了17.65%和15.77%,而耗能能力和位移延性系数分别提升14.41%和32.61%;通过设计合理的芯柱直径,可保证HRBS柱在常规环境和腐蚀环境下均具备良好的耐久性能和整体抗震性能.

Abstract:To enhance the durability of structural members while ensuring ductility, a new glass fiber-reinforced polymer (GFRP)-steel hybrid reinforced (HRBS) column with a built-in spiral stirrup core column was proposed. Four HRBS columns were subjected to quasi-static loading tests, among which two HRBS columns underwent composite salt dry-wet cycling tests. The failure process, ultimate failure mode, hysteresis curves, skeleton curves, energy dissipation capacity, performance degradation, and residual displacement of the HRBS columns before and after composite salt dry-wet cycling were investigated. The results indicate that HRBS columns demonstrate good seismic performance both before and after composite salt dry-wet cycling, and all specimens exhibit flexural failure. Under conventional environments, the yield load and peak load of HRBS columns increase by 25.77% and 28.68%, respectively, with an increase in the core column diameter. In a composite salt environment, increasing the core column diameter improves the load-bearing capacity, displacement ductility factor, strength degradation factor, energy dissipation capacity, overall stiffness, and self-centering ability of the HRBS columns. After composite salt erosion, the yield load and peak load of specimens with a 200 mm core column diameter decrease by 17.65% and 15.77%, respectively, while the energy dissipation capacity and displacement ductility factor increase by 14.41% and 32.61%, respectively. Therefore, by designing an appropriate core column diameter, HRBS columns ensure good durability and overall seismic performance in both conventional and corrosive environments.

-

表 1 试件设计参数

Table 1. Specimen design parameters

试件

编号外侧

纵筋内部

纵筋外侧

箍筋螺旋

箍筋芯柱直

径/mm腐蚀时

间/dA150 8G14 8S14 G8@100 S8@40 150 0 A200 8G14 8S14 G8@100 S8@40 200 0 B150 8G14 8S14 G8@100 S8@40 150 90 B200 8G14 8S14 G8@100 S8@40 200 90 表 2 试件破坏过程

Table 2. Failure process of specimens

试件 开裂 屈服 峰值 极限 A150 -4.24 mm(-48.40 kN)位移时,东侧混凝土出现初始裂缝,裂缝水平贯穿并延伸至南北两侧 两侧裂缝加速发展,新裂缝逐渐从横向裂缝转变为纵向受压裂缝 34.16 mm和-38.24 mm位移时达到正、负向峰值荷载,为97.9 kN和-99.15 kN,混凝土开始压溃 51.61 mm(83.21 kN)位移时,正向荷载急剧下降至峰值荷载的85%,东西两侧的混凝土平均剥落高度在550 mm左右. A200 -4.24 mm(-52.09 kN)位移时,东侧混凝土出现初始裂缝,裂缝水平贯穿并延伸至南北两侧 从20 mm位移开始,东西两面裂缝进一步发展,30 mm时出现混凝土剥落 33.97 mm和-32.24 mm位移时达到正、负向峰值荷载,126.62 kN和−126.29 kN,混凝土开始压溃 53.79 mm(107.62 kN)位移时,正向荷载急剧下降至峰值荷载的85%,东西两侧混凝土平均剥落高度在550 mm左右. B150 6.00 mm(54.10 kN)位移时,东侧沿着出现0.02 mm的初始腐蚀裂缝,宽度为0.03 mm,东、西侧裂缝高度为150 mm和200 mm 每个位移级别下均会产生新裂缝,裂缝高度开展到900 mm,西侧和东侧的初始裂缝逐渐形成主裂缝,宽度均达到0.24 mm 29.98 mm(86.02 kN)和−29.98 mm(−92.88 kN)位移时达到正、负向峰值荷载,水平裂缝发展速度放缓,出现竖向黏结裂缝 39.33 mm位移时,正向荷载急剧下降至峰值荷载的85%(73.12 kN),混凝土大量剥落,斜向裂缝开始大量产生(最大宽度达到0.6 mm) B200 6.00 mm位移(75.06 kN)时,东西侧150 mm处出现初始裂缝,宽度均为0.02 mm 每级位移均会产生新裂缝,裂缝高度开展到900 mm,西侧和东侧的初始裂缝逐渐形成主裂缝,宽度分别为0.22 mm和0.14 mm 25.01 mm(111.88 kN)和−24.97 mm(−101.76 kN)位移时达到正、负向峰值荷载,混凝土保护层大面积剥落,竖向裂缝开始大量出现 37.20 mm位移时,正向荷载急剧下降至峰值荷载的85%(95.10 kN),35 ~ 45 mm位移期间,荷载呈现稳定的下降趋势,具备良好的承载力稳定性 表 3 试件特征点试验结果

Table 3. Test results of characteristic points of specimens

试件编号 方向 屈服荷

载/kN屈服位

移/mm峰值荷

载/kN峰值位

移/mm极限荷

载/kN极限位

移/mmA150 正 84.2 13.6 97.9 38.2 83.2 51.6 负 84.2 15.6 99.1 34.1 84.2 56.7 A200 正 106.9 18.9 126.6 33.9 107.6 53.7 负 104.9 18.8 126.9 32.2 107.3 51.9 B150 正 70.1 12.0 84.1 29.9 73.1 39.3 负 75.8 11.2 92.8 29.9 78.9 44.5 B200 正 91.2 10.7 111.8 25.0 95.1 37.2 负 83.1 11.4 101.7 24.9 86.5 45.2 表 4 试件位移延性系数

Table 4. Displacement ductility factor of specimens

试件编号 A150 A200 B150 B200 延性系数 3.70 2.79 3.61 3.70 表 5 刚度退化特征值

Table 5. Characteristic values of stiffness degradation

试件 起始刚度/

(kN•mm−1)最终刚度/

(kN•mm−1)刚度退化/

%A150 10.01 1.36 86.41 A200 12.09 2.37 80.39 B150 11.51 1.59 86.18 B200 13.74 1.93 85.95 -

[1] WEI J, WANG C G, WEI X, et al. Corrosion evolution of steel reinforced concrete under simulated tidal and immersion zones of marine environment[J]. Acta Metallurgica Sinica (English Letters), 2019, 32(7): 900-912. doi: 10.1007/s40195-018-0867-5 [2] YIN G J, ZUO X B, SUN X H, et al. Macro-microscopically numerical analysis on expansion response of hardened cement paste under external sulfate attack[J]. Construction and Building Materials, 2019, 207: 600-615. doi: 10.1016/j.conbuildmat.2019.02.159 [3] 李国满, 李浩然, 邱国斌, 等. 混凝土氯盐-硫酸盐耦合侵蚀机理、模型及数值模拟研究进展[J]. 硅酸盐通报, 2024, 43(11): 3935-3946, 3967.LI Guoman, LI Haoran, QIU Guobin, et al. Research progress on chloride-sulfate coupling erosion mechanism, model and numerical simulation of concrete[J]. Bulletin of the Chinese Ceramic Society, 2024, 43(11): 3935-3946,3967. [4] LI Y, YIN S P, LV H L. Combined effects of dry-wet cycles and sustained loads on the seismic behavior of TRC-strengthened RC columns[J]. Structures, 2021, 33: 2226-2237. doi: 10.1016/j.istruc.2021.05.089 [5] AHMAD SAWPAN M, ALSHAHRANI H, KAFI A. Durability of pultruded GFRP rebar subjected to natural weathering in alkaline solution for 10 years[J]. Journal of Polymers and the Environment, 2023, 31(3): 1090-1101. doi: 10.1007/s10924-022-02667-z [6] HOMAN S M. Durability of fibre-reinforced polymers (FRP) used in concrete structures[D]. Toronto: University of Toronto, 2000. [7] AL-SALLOUM Y A, EL-GAMAL S, ALMUSALLAM T H, et al. Effect of harsh environmental conditions on the tensile properties of GFRP bars[J]. Composites Part B: Engineering, 2013, 45(1): 835-844. doi: 10.1016/j.compositesb.2012.05.004 [8] WU G, WANG X, WU Z, et al. Durability of basalt fibers and composites in corrosive environments[J]. Journal of Composite Materials, 2015, 49(7): 873-887. doi: 10.1177/0021998314526628 [9] WANG Z H, XIE J H, MAI Z H, et al. Durability of GFRP bar-reinforced seawater–sea sand concrete beams: coupled effects of sustained loading and exposure to a chloride environment[J]. Engineering Structures, 2023, 283: 115814.1-115814.13. doi: 10.1016/j.engstruct.2023.115814 [10] ABDALLAH A E, EL-SALAKAWY E F. Seismic performance of GFRP-RC circular columns with different aspect ratios and concrete strengths[J]. Engineering Structures, 2022, 257: 114092.1-114092.16. doi: 10.1016/j.engstruct.2022.114092 [11] ALI M A, El-SALAKAWY E. Seismic performance of GFRP-reinforced concrete rectangular columns[J]. Journal of Composites for Construction, 2016, 20(3): 04015074.1-04015074.12. doi: 10.1061/(asce)cc.1943-5614.0000637 [12] KHARAL Z, SHEIKH S A. Seismic behavior of square and circular concrete columns with GFRP reinforcement[J]. Journal of Composites for Construction, 2020, 24(1): 04019059.1-04019059.17. doi: 10.1061/(asce)cc.1943-5614.0000988 [13] CHEN Y D, LI P D. Anti-corrosion performance of a novel ECC-GFRP spiral-confined RC column[J]. Case Studies in Construction Materials, 2024, 20: e03241.1-e03241.17. doi: 10.1016/j.cscm.2024.e03241 [14] GE W J, ZHANG S K, ZHANG Z W, et al. Eccentric compression behavior of Steel-FRP composite bars RC columns under coupling action of chloride corrosion and load[J]. Structures, 2023, 50: 1051-1068. doi: 10.1016/j.istruc.2023.02.090 [15] ACI Committee 440. Guide for The Design and Construction of Concrete Reinforced with fiber-reinforced polymer (FRP) Bars[S]. Farmington Hill: American Concrete Institute, 2015. [16] TOBBI H, FARGHALY A S, BENMOKRANE B. Concrete columns reinforced longitudinally and transversally with glass fiber-reinforced polymer bars[J]. ACI Structural Journal, 2012, 109(4): 551-558 doi: 10.14359/51683874 [17] SUN L, WEI M H, ZHANG N. Experimental study on the behavior of GFRP reinforced concrete columns under eccentric axial load[J]. Construction and Building Materials, 2017, 152: 214-225. doi: 10.1016/j.conbuildmat.2017.06.159 [18] XIN Q, NIU Q L, ZHANG M, et al. Effect of chlorine salt erosion on flexural performance of GFRP and steel bars hybrid reinforced beams[J]. Structures, 2024, 59: 105779.1-105779.12. doi: 10.1016/j.istruc.2023.105779 [19] 周满清, 张智梅, 魏久燚. 钢筋与FRP筋混合配筋混凝土梁最大裂缝宽度计算[J]. 复合材料科学与工程, 2022(3): 73-80. doi: 10.19936/j.cnki.2096-8000.20220328.011ZHOU Manqing, ZHANG Zhimei, WEI Jiuyi. Calculation for maximum crack width of concrete beams reinforced with hybrid steel and FRP bars[J]. Composites Science and Engineering, 2022(3): 73-80. doi: 10.19936/j.cnki.2096-8000.20220328.011 [20] 王坦, 李立巍, 周志杰, 等. GFRP筋与钢筋混合配筋柱偏心受压性能试验研究[J]. 建筑结构学报, 2023, 44(增1): 248-255.WANG Tan, LI Liwei, ZHOU Zhijie, et al. Experimental study on eccentric compression performance of column with hybrid of GFRP and steel bars[J]. Journal of Building Structures, 2023, 44(S1): 248-255. [21] 邓宗才, 高磊, 王献云. 配置GFRP筋的混凝土矩形截面柱抗震试验研究[J]. 应用基础与工程科学学报, 2019, 27(5): 1065-1076. doi: 10.16058/j.issn.1005-0930.2019.05.011DENG Zongcai, GAO Lei, WANG Xianyun. Experiments on seismic behavior of rectangular glass fiber-reinforced polymer-reinforced concrete columns[J]. Journal of Basic Science and Engineering, 2019, 27(5): 1065-1076. doi: 10.16058/j.issn.1005-0930.2019.05.011 [22] 袁方, 赵修远. FRP筋-钢筋增强ECC-混凝土组合柱抗震性能研究[J]. 工程力学, 2021, 38(8): 55-65, 144. doi: 10.6052/j.issn.1000-4750.2020.08.0532YUAN Fang, ZHAO Xiuyuan. Seismic behaviors of hybrid frp-steel reinforced ecc-concrete composite columns[J]. Engineering Mechanics, 2021, 38(8): 55-65,144. doi: 10.6052/j.issn.1000-4750.2020.08.0532 [23] 王作虎, 罗义康, 刘杜, 等. CFRP筋-高强钢筋/高强混凝土柱的抗震性能[J]. 复合材料学报, 2021, 38(10): 3463-3473. doi: 10.13801/j.cnki.fhclxb.20201222.001WANG Zuohu, LUO Yikang, LIU Du, et al. Seismic behavior of high-strength concrete columns reinforced with CFRP tendons and high-strength steels[J]. Acta Materiae Compositae Sinica, 2021, 38(10): 3463-3473. doi: 10.13801/j.cnki.fhclxb.20201222.001 [24] JING D H, YU T, LIU X D. New configuration of transverse reinforcement for improved seismic resistance of rectangular RC columns: Concept and axial compressive behavior[J]. Engineering Structures, 2016, 111: 383-393. doi: 10.1016/j.engstruct.2015.12.014 [25] FANG S, LI L J, LIN L H, et al. FRP interlocking multi-spiral reinforced square concrete columns: a promising compression application for marine engineering[J]. Engineering Structures, 2021, 244: 112733.1-112733.23. doi: 10.1016/j.engstruct.2021.112733 [26] 李明翰, 周威, 刘明建, 等. 复合螺旋箍筋约束混凝土柱偏压性能试验[J]. 哈尔滨工业大学学报, 2019, 51(12): 113-120. doi: 10.11918/j.issn.0367-6234.201812034LI Minghan, ZHOU Wei, LIU Mingjian, et al. Experimental investigation of reinforced concrete columns with composite spiral stirrups under eccentric loading[J]. Journal of Harbin Institute of Technology, 2019, 51(12): 113-120. doi: 10.11918/j.issn.0367-6234.201812034 [27] YANG Y F, ZHANG Y Q, FU F. Behaviour of axially compressed CTHST stub columns with inner spiral stirrup[J]. Structures, 2022, 45: 372-389. doi: 10.1016/j.istruc.2022.09.038 [28] 中华人民共和国住房和城乡建设部. 混凝土物理力学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国建筑工业出版社, 2019. [29] 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 金属材料 拉伸试验 第1部分: 室温试验方法: GB/T 228.1—2010[S]. 北京: 中国标准出版社, 2011. [30] 周志杰. 装配式带螺旋箍筋芯柱的混合配筋柱抗震性能研究[D]. 长春: 长春工程学院, 2023. [31] 郑跃, 郑山锁, 董立国, 等. 酸雨环境下腐蚀RC剪力墙抗震性能试验研究[J]. 工程力学, 2020, 37(5): 190-198, 227.ZHENG Yue, ZHENG Shansuo, DONG Liguo, et al. Experimental study on the seismic behavior of rc shear walls in a simulated acid environment[J]. Engineering Mechanics, 2020, 37(5): 190-198,227. [32] 金伟良, 薛文, 陈驹. 海岸及近海混凝土材料耐久性设计指标的影响参数分析[J]. 建筑结构学报, 2011, 32(12): 86-97.JIN Weiliang, XUE Wen, CHEN Ju. Effecting coefficients for concrete structure durability design index[J]. Journal of Building Structures, 2011, 32(12): 86-97. [33] 中国建筑科学研究院. 建筑抗震试验方法规程: JGJ/T 101—2015[S]. 北京: 中国建筑工业出版社, 2015. [34] ZHOU J, CHEN Z P, LIU D Y, et al. Experimental and numerical investigations on eccentric compression behavior of square CFST columns with inner spiral stirrup[J]. Structures, 2023, 57: 105196.1-105196.19. doi: 10.1016/j.istruc.2023.105196 [35] Guan D, Chen Z, Liu J, et al. Seismic performance of precast concrete columns with prefabricated UHPC jackets in plastic hinge zone[J]. Engineering Structures, 2021, 245: 112776. doi: 10.1016/j.engstruct.2021.112776 [36] 李涛, 朱鹏涛, 张彬, 等. 硫酸盐侵蚀下混凝土内腐蚀反应-扩散过程的实验研究[J]. 硅酸盐通报, 2020, 39(1): 50-55. doi: 10.16552/j.cnki.issn1001-1625.2020.01.006LI Tao, ZHU Pengtao, ZHANG Bin, et al. Experimental study on corrosion reaction-diffusion process of concrete under sulfate attack[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(1): 50-55. doi: 10.16552/j.cnki.issn1001-1625.2020.01.006 -

下载:

下载: