Self-Sensing Performance of Ultra-High Performance Fiber-Reinforced Concrete Under Cyclic Loading

-

摘要:

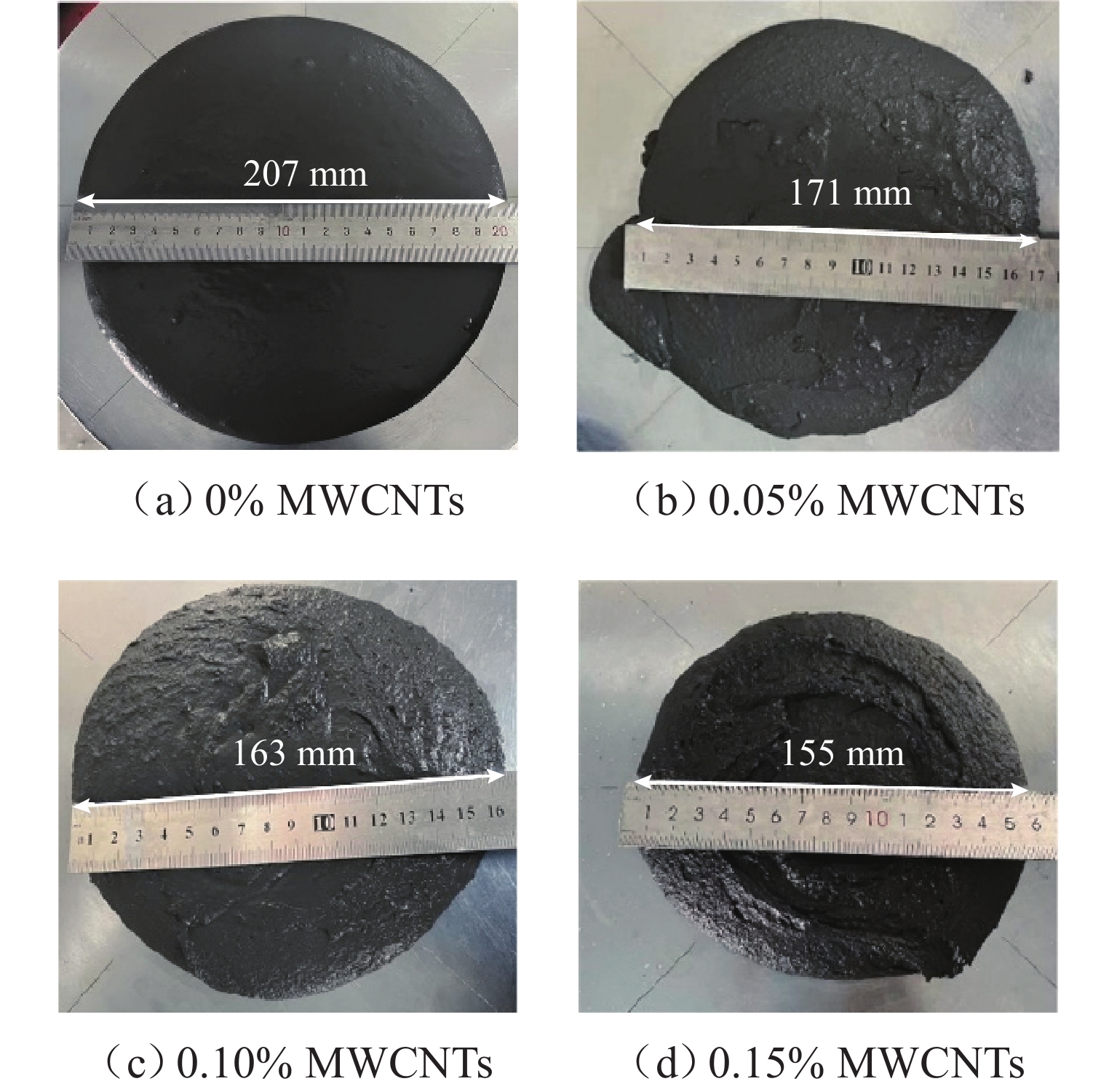

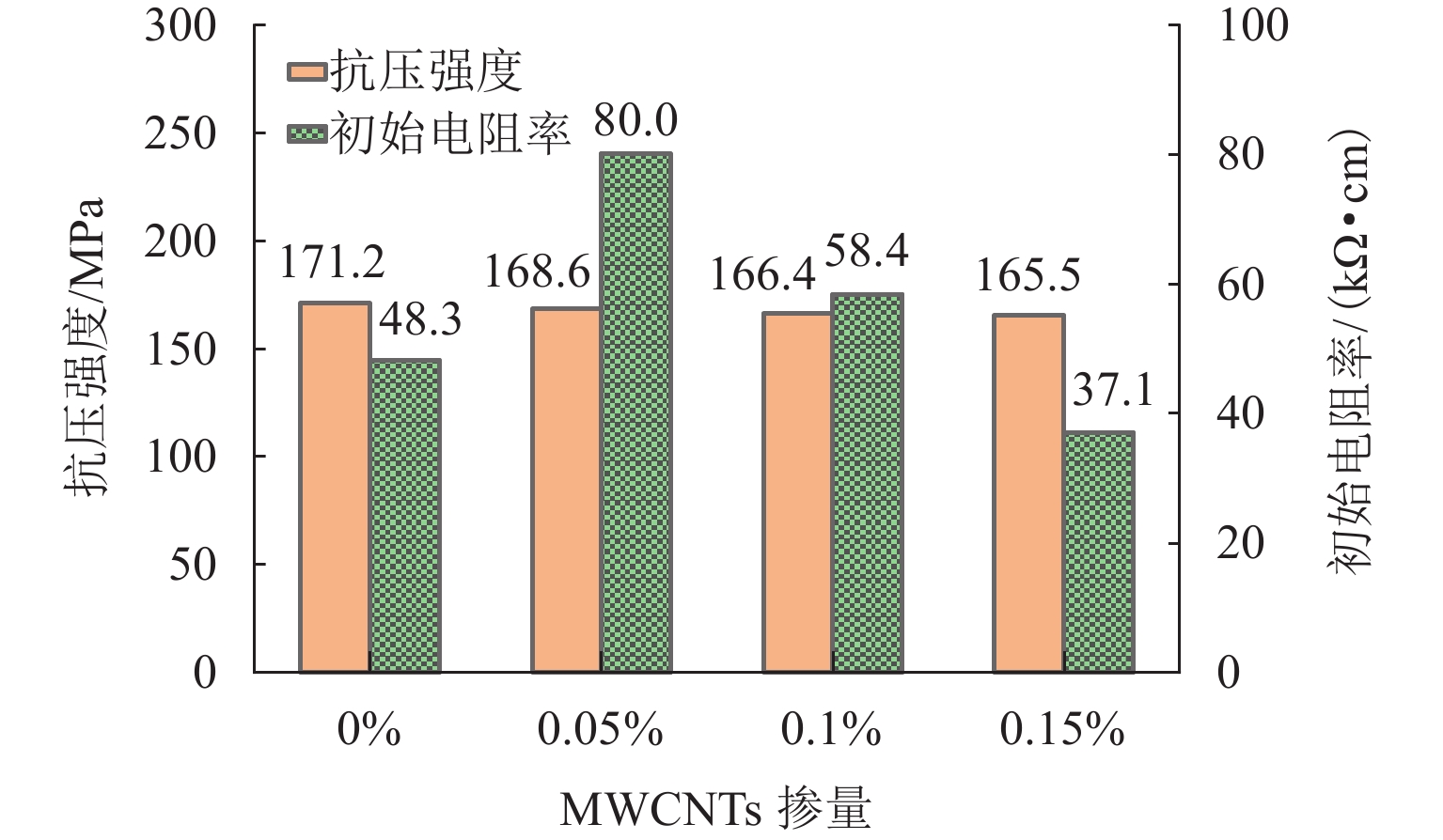

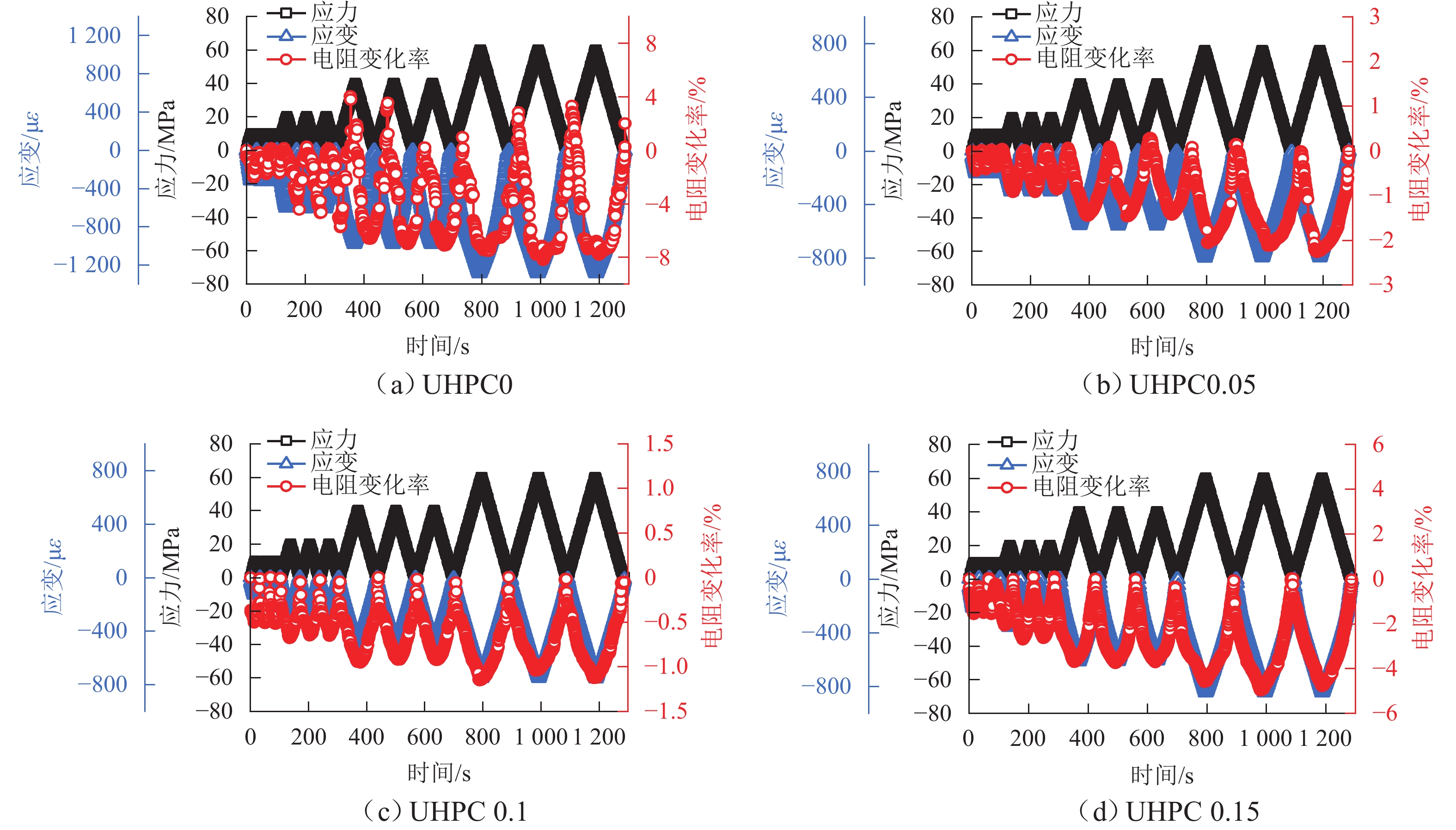

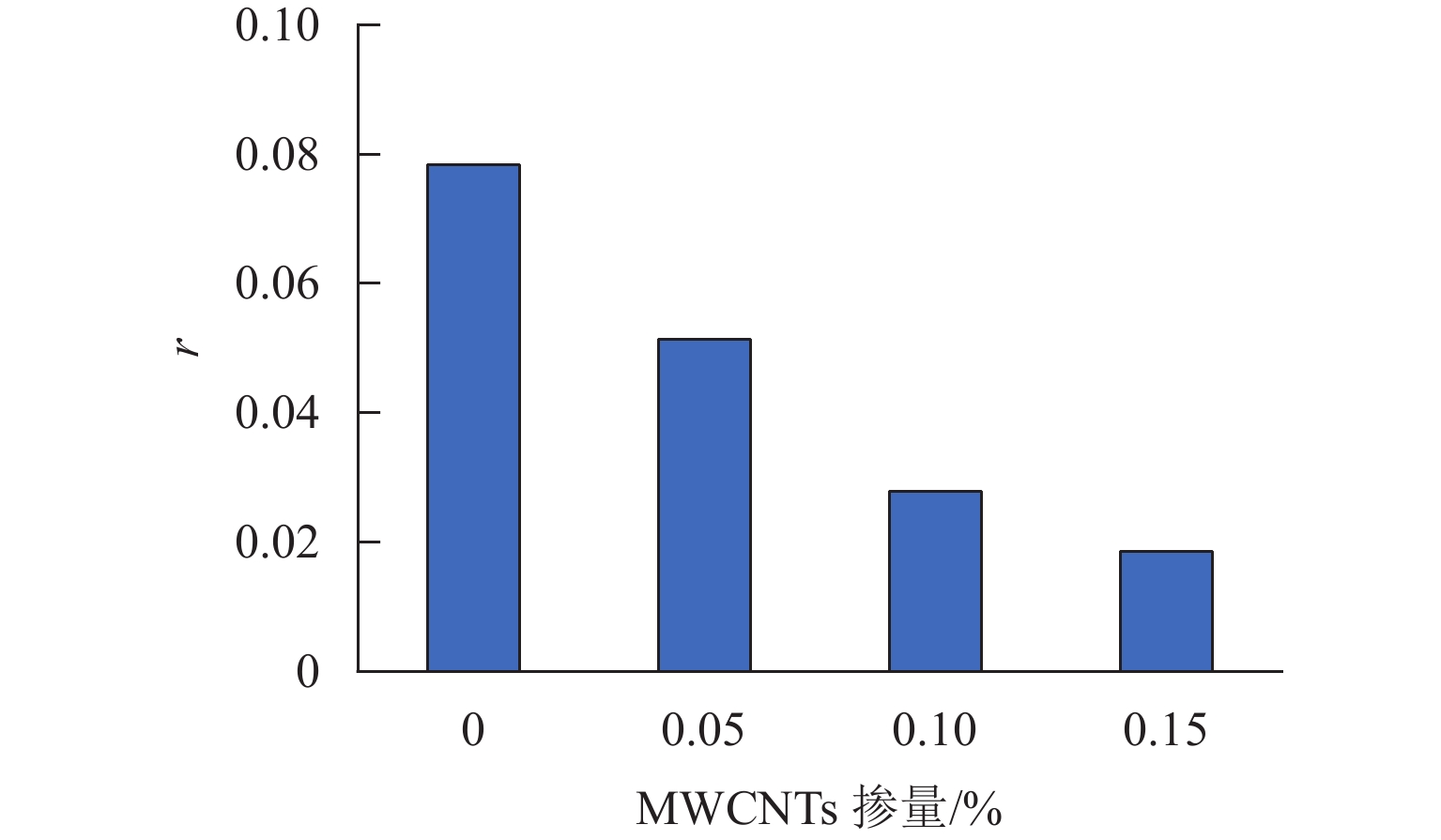

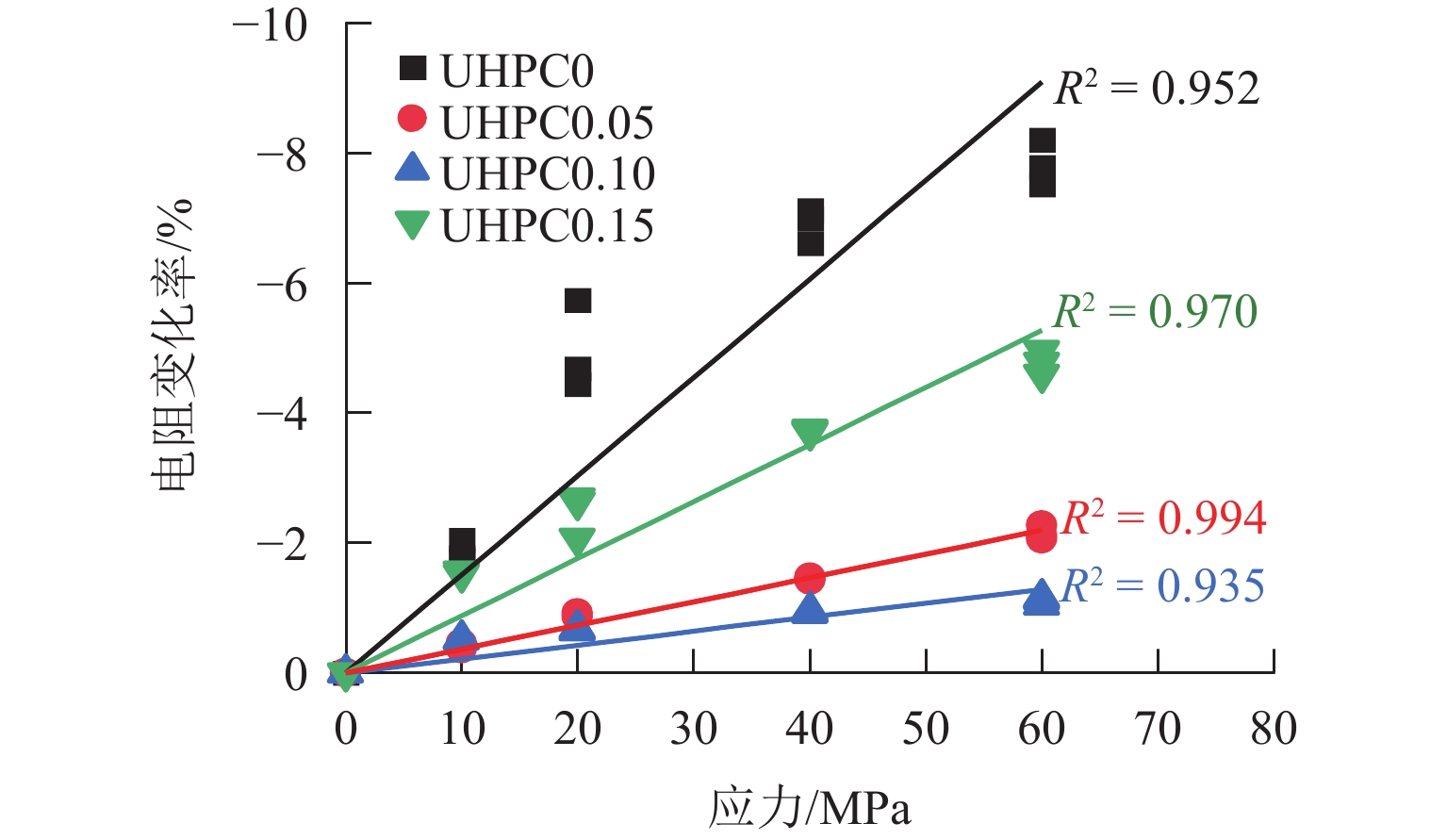

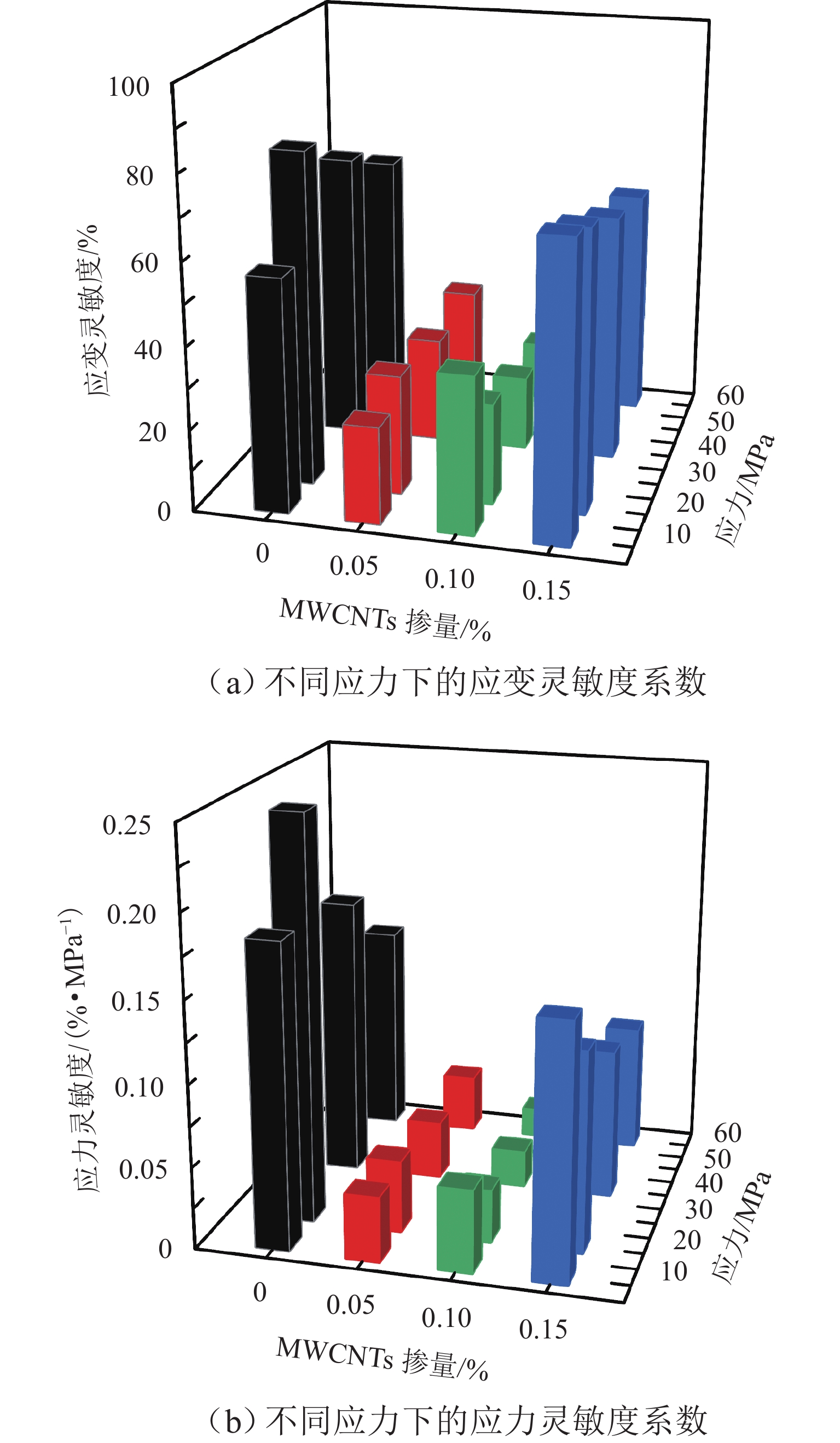

为研究复掺钢纤维和多壁碳纳米管(MWCNTs)的超高性能混凝土(UHPC)在不同循环应力幅值下的自感知性能,对钢纤维体积掺量为2%、不同MWCNTs掺量下的UHPC在不同循环应力幅值下的自感知性能进行试验研究. 结果表明:UHPC的初始电阻率随MWCNTs掺量的增加先升高后降低,加入0.15%的MWCNTs能提高UHPC的导电性;MWCNTs的加入可以提高试样的重复性,当MWCNTs掺量为0.15%时,试样具有最优的重复性,重复性系数为0.019,且交流电阻变化率与应力之间具有较优的线性关系,线性度为0.97;试样 UHPC0、UHPC0.05的应力灵敏度和应变灵敏度随应力的增加先增加后减小,而试样UHPC0.1、UHPC0.15的应力灵敏度和应变灵敏度则随着应力的增加呈逐渐减小的趋势;试样UHPC0.15在不同循环应力幅值下最高应变灵敏度和应力灵敏度分别为71.6%和0.16%/MPa,均出现在应力为10 MPa时;当MWCNTs掺量为0.15%时,UHPC具有最优的自感知性能.

Abstract:To study the self-sensing performance of ultra-high performance concrete (UHPC) mixed with steel fibers and multi-walled carbon nanotubes (MWCNTs) under different cyclic stress amplitudes, experimental studies were conducted on UHPC specimens with a steel fiber volume content of 2% and varying MWCNT contents. The results show that the initial resistivity of UHPC increases first and then decreases with the increase in MWCNT content, and the addition of 0.15% MWCNTs improves the conductivity of UHPC. When the MWCNT content is 0.15%, the sample exhibits optimal repeatability, with a repeatability coefficient of 0.019, and the linearity change of alternating current (AC) resistance presents a strong linear relationship with stress, with a linearity of 0.97. The stress sensitivity and strain sensitivity of the samples UHPC0 and UHPC0.05 first increase and then decrease with the increase in stress, while the stress sensitivity and strain sensitivity of samples UHPC0.1 and UHPC0.15 show a gradually decreasing trend. The maximum strain sensitivity and stress sensitivity of UHPC0.15 are 71.6% and 0.16%/MPa under different cyclic stress amplitudes, both appearing at a stress of 10 MPa. When the content of MWCNTs is 0.15%, UHPC exhibits the best self-sensing performance.

-

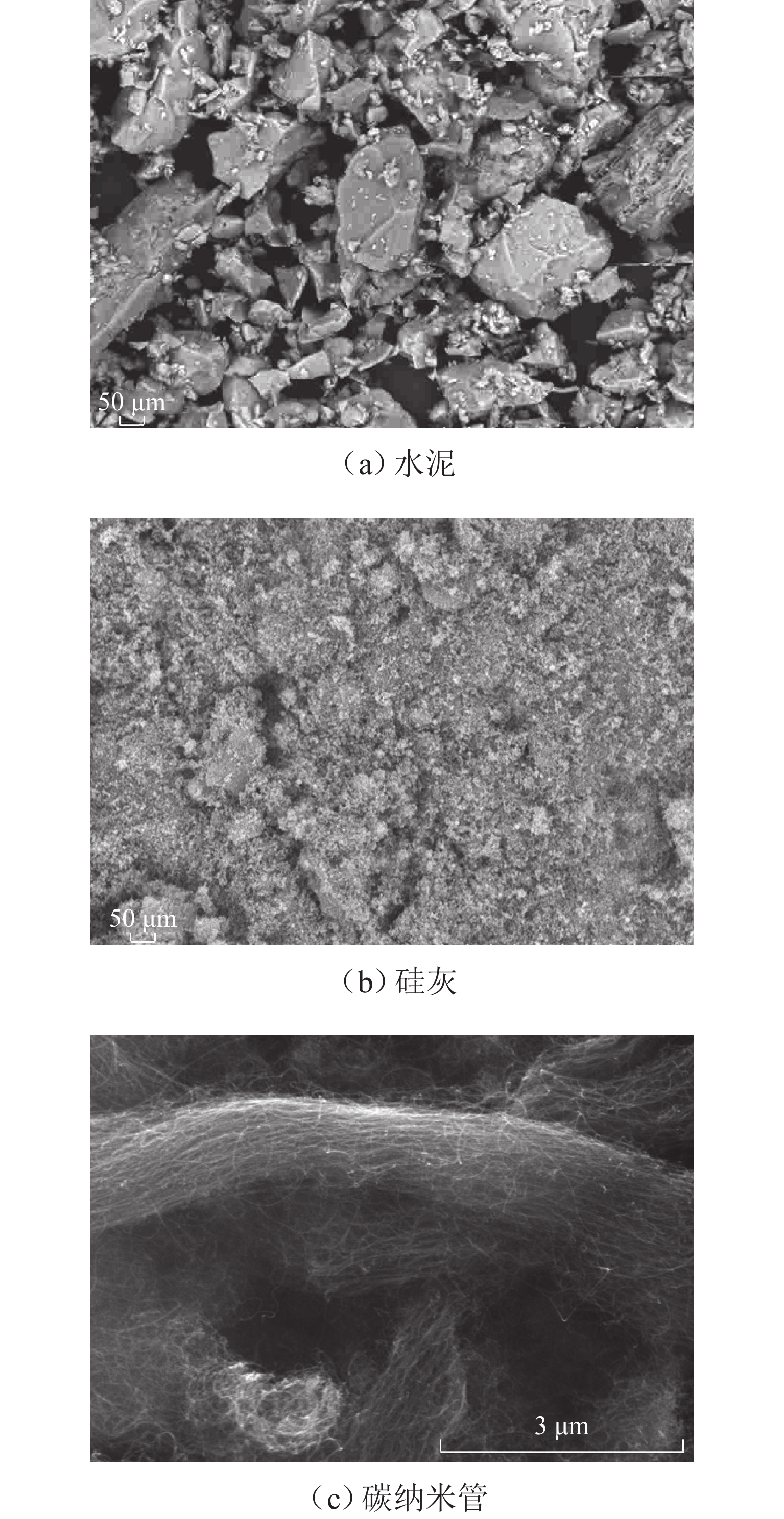

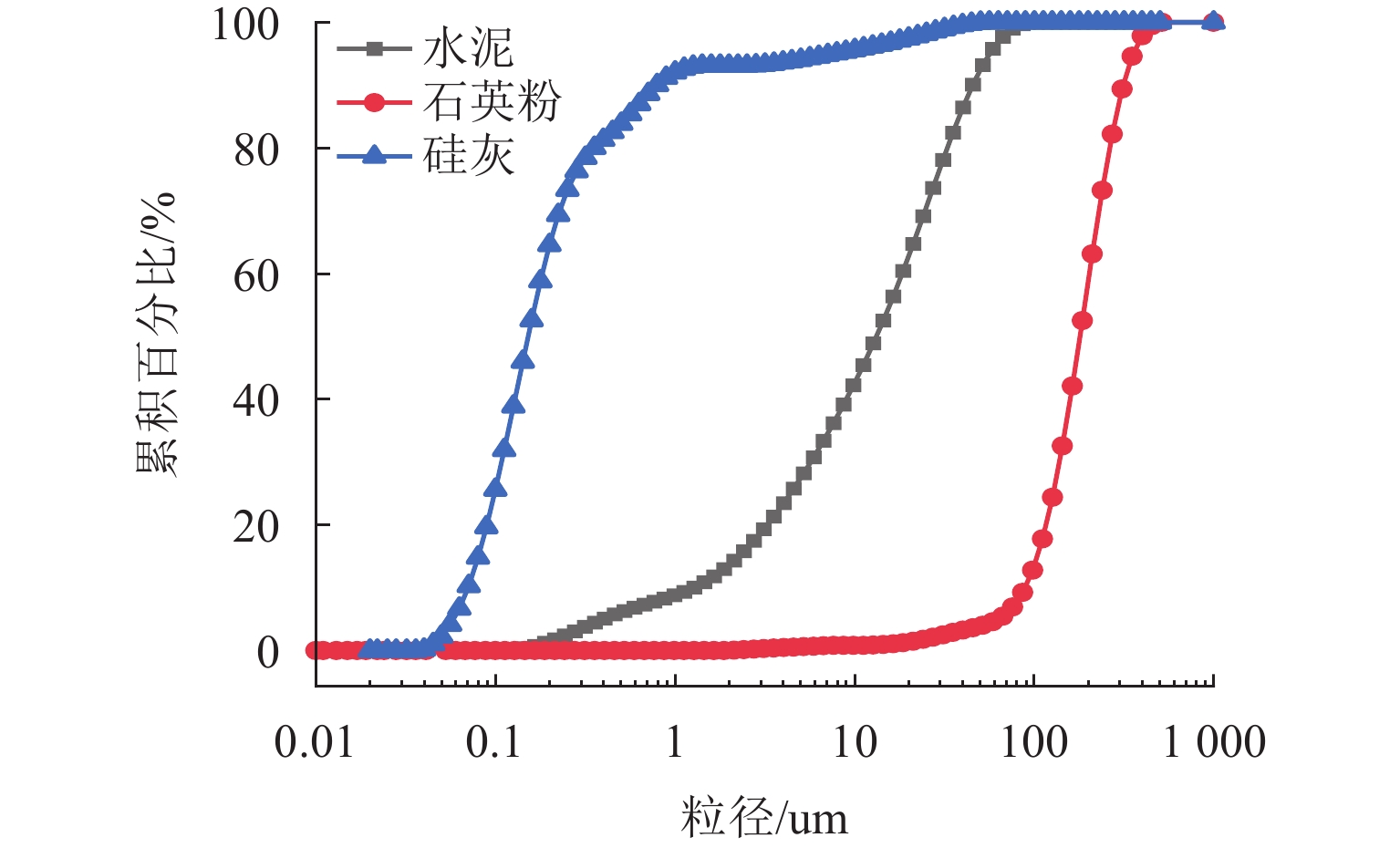

表 1 水泥、硅灰和石英粉的化学组成

Table 1. Chemical composition of cement, silica fume, and quartz powder (Mass fraction)

材料类型 化学成分/% 表面积/(m2·g−1) Al2O3 SiO2 CaO TiO2 MgO Na2O K2O Fe2O3 SO3 L.O.I. 水泥 5.02 19.99 64.47 0.21 1.64 0.21 0.72 2.99 2.82 2.0774 硅灰 0.15 95.15 0.34 0.02 0.49 0.27 0.58 0.08 0.21 2.51 28.3000 石英粉 0.03 99.81 0.02 0.01 0.01 0.019 0.06 0.8445 表 2 MWCNTs物理参数

Table 2. Physical properties of MWCNTs

名称 外径/nm 长度/μm 表面积/(m2•g−1) 纯度/% 颜色 取值 5~15 10~30 220~300 >99 黑色 表 3 钢纤维力学性能

Table 3. Mechanical properties of steel fibers

名称 长度/

mm直径/

μm抗拉强

度/MPa弹性模

量/GPa密度/

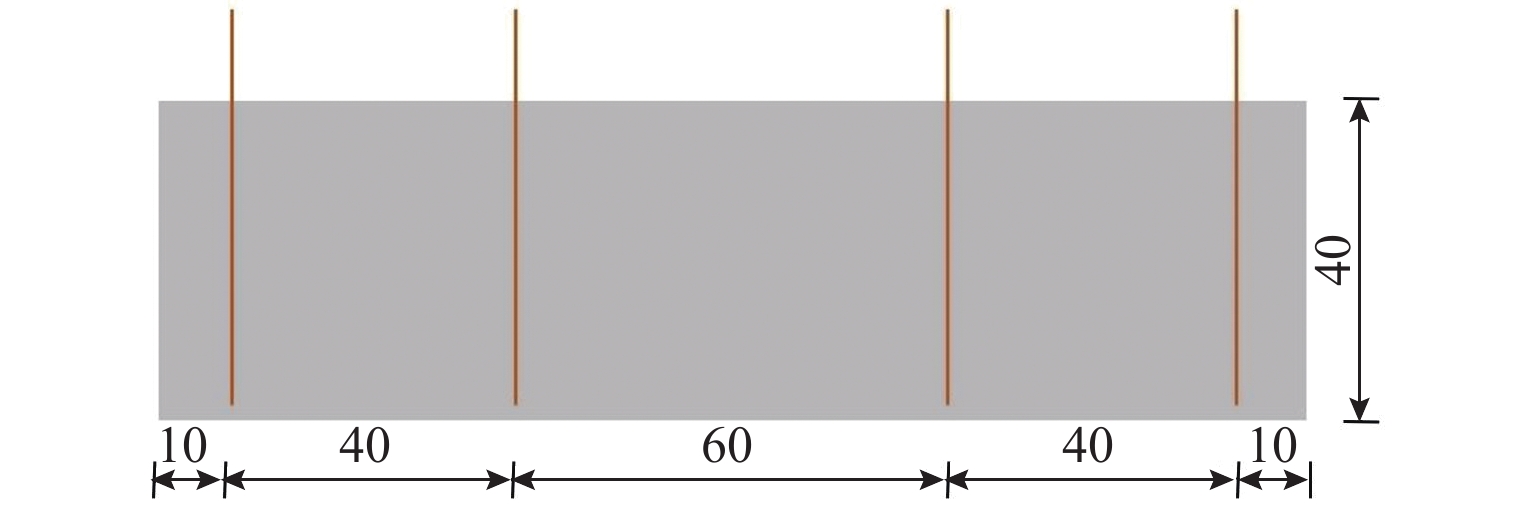

(g•cm−3)取值 13 200 2750 210 7.85 表 4 UHPC配合比

Table 4. Mix proportions of UHPC

kg/m3 试件

编号单位重量 水泥 硅灰 石英粉 水 减水剂 钢纤维 碳纳米管 UHPC0 890 220 980 199.8 55 165 0 UHPC0.05 890 220 980 199.8 55 165 0.445 UHPC0.1 890 220 980 199.8 55 165 0.89 UHPC0.15 890 220 980 199.8 55 165 1.335 表 5 试样的综合评价指标(归一化)

Table 5. Comprehensive evaluation index of samples (normalization)

试样编号 Gε Gσ r L S UHPC0 1.00 1.00 0 0.29 0.629 UHPC0.05 0 0 0.45 1.00 0.235 UHPC0.10 0.17 0.03 0.83 0 0.309 UHPC0.15 0.81 0.54 1.00 0.59 0.764 -

[1] YOO D Y, BANTHIA N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: a review[J]. Cement and Concrete Composites, 2016, 73: 267-280. doi: 10.1016/j.cemconcomp.2016.08.001 [2] HE B, ZHU X P, REN Q, et al. Effects of fibers on flexural strength of ultra-high-performance concrete subjected to cryogenic attack[J]. Construction and Building Materials, 2020, 265: 120323.1-120323.8. [3] GOMAA E, GHENI A, ELGAWADY M A. Repair of ordinary Portland cement concrete using ambient-cured alkali-activated concrete: interfacial behavior[J]. Cement and Concrete Research, 2020, 129: 105968.1-105968.17. [4] WANG Y S, PENG K D, ALREFAEI Y, et al. The bond between geopolymer repair mortars and OPC concrete substrate: Strength and microscopic interactions[J]. Cement and Concrete Composites, 2021, 119: 103991.1-103991.12. [5] TAYEH B A, ABU BAKAR B H, MEGAT JOHARI M A, et al. Utilization of ultra-high performance fibre concrete (UHPFC) for rehabilitation—a review[J]. Procedia Engineering, 2013, 54: 525-538. doi: 10.1016/j.proeng.2013.03.048 [6] TAHERI S. A review on five key sensors for monitoring of concrete structures[J]. Construction and Building Materials, 2019, 204: 492-509. doi: 10.1016/j.conbuildmat.2019.01.172 [7] BAE Y, PYO S. Effect of steel fiber content on structural and electrical properties of ultra high performance concrete (UHPC) sleepers[J]. Engineering Structures, 2020, 222: 111131. doi: 10.1016/j.engstruct.2020.111131 [8] YOO D Y, YOON Y S. A review on structural behavior, design, and application of ultra-high-performance fiber-reinforced concrete[J]. International Journal of Concrete Structures and Materials, 2016, 10(2): 125-142. doi: 10.1007/s40069-016-0143-x [9] YOO D Y, KIM S, LEE S H. Self-sensing capability of ultra-high-performance concrete containing steel fibers and carbon nanotubes under tension[J]. Sensors and Actuators A: Physical, 2018, 276: 125-136. doi: 10.1016/j.sna.2018.04.009 [10] SUN M Q, LIEW R J Y, ZHANG M H, et al. Development of cement-based strain sensor for health monitoring of ultra high strength concrete[J]. Construction and Building Materials, 2014, 65: 630-637. doi: 10.1016/j.conbuildmat.2014.04.105 [11] DONG S F, HAN B G, OU J P, et al. Electrically conductive behaviors and mechanisms of short-cut super-fine stainless wire reinforced reactive powder concrete[J]. Cement and Concrete Composites, 2016, 72: 48-65. doi: 10.1016/j.cemconcomp.2016.05.022 [12] KIM M K, KIM D J, AN Y K. Electro-mechanical self-sensing response of ultra-high-performance fiber-reinforced concrete in tension[J]. Composites Part B: Engineering, 2018, 134: 254-264. doi: 10.1016/j.compositesb.2017.09.061 [13] YOU I, YOO D Y, KIM S, et al. Electrical and self-sensing properties of ultra-high-performance fiber-reinforced concrete with carbon nanotubes[J]. Sensors, 2017, 17(11): 2481.1-2481.19. [14] LEE S H, KIM S, YOO D Y. Hybrid effects of steel fiber and carbon nanotube on self-sensing capability of ultra-high-performance concrete[J]. Construction and Building Materials, 2018, 185: 530-544. doi: 10.1016/j.conbuildmat.2018.07.071 [15] DONG S F, DONG X F, ASHOUR A, et al. Fracture and self-sensing characteristics of super-fine stainless wire reinforced reactive powder concrete[J]. Cement and Concrete Composites, 2020, 105: 103427.1-103427.15. [16] SONG F C, CHEN Q, ZHENG Q M. Multifunctional ultra-high performance fibre-reinforced concrete with integrated self-sensing and repair capabilities towards in situ structure monitoring[J]. Composite Structures, 2023, 321: 117240.1-117240.17. [17] SONG F C, CHEN Q, JIANG Z W, et al. Piezoresistive properties of ultra-high-performance fiber-reinforced concrete incorporating few-layer graphene[J]. Construction and Building Materials, 2021, 305: 124362.1-124362.14. [18] LE H V, KIM M K, KIM S U, et al. Enhancing self-stress sensing ability of smart ultra-high performance concretes under compression by using nano functional fillers[J]. Journal of Building Engineering, 2021, 44: 102717.1-102717.14. [19] ASTM International. Standard test method for flow of hydraulic cement mortar: ASTM C1437[S]. West Conshohocken: ASTM International, 2015. [20] ASTM International. Standard test method for compressive strength of hydraulic cement mortars (using 2-in. or [50-mm] cube specimens): ASTM C109/C109M-21[S]. West Conshohocken: ASTM International, 2021. [21] AZHARI F, BANTHIA N. Cement-based sensors with carbon fibers and carbon nanotubes for piezoresistive sensing[J]. Cement and Concrete Composites, 2012, 34(7): 866-873. doi: 10.1016/j.cemconcomp.2012.04.007 [22] PELED A, T ORRENTSJ M, MASON T, et al. Electrical impedance spectra to monitor damage during tensile loading of cement composites[J]. ACI Materials Journal, 2001, 98(4): 313-322. [23] DEMIREL B, YAZICIOĞLU S, ORHAN N. Electrical behaviour of carbon fibre-reinforced concrete with increasing loading in varying and constant frequencies[J]. Magazine of Concrete Research, 2006, 58(10): 691-697. doi: 10.1680/macr.2006.58.10.691 [24] HAN B G, YU X, KWON E, et al. Effects of CNT concentration level and water/cement ratio on the piezoresistivity of CNT/cement composites[J]. Journal of Composite Materials, 2012, 46(1): 19-25. doi: 10.1177/0021998311401114 [25] TEOMETE E, KOCYIGIT O I. Tensile strain sensitivity of steel fiber reinforced cement matrix composites tested by split tensile test[J]. Construction and Building Materials, 2013, 47: 962-968. doi: 10.1016/j.conbuildmat.2013.05.095 [26] CHEN P W, CHUNG D D L. Carbon fiber reinforced concrete for smart structures capable of non-destructive flaw detection[J]. Smart Materials and Structures, 1993, 2(1): 22-30. doi: 10.1088/0964-1726/2/1/004 [27] HAN B G, GUAN X C, OU J P. Electrode design, measuring method and data acquisition system of carbon fiber cement paste piezoresistive sensors[J]. Sensors and Actuators A: Physical, 2007, 135(2): 360-369. doi: 10.1016/j.sna.2006.08.003 [28] 罗健林. 碳纳米管水泥基复合材料制备及功能性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2009. [29] CHUNG D D L, WANG Y L. Capacitance-based stress self-sensing in cement paste without requiring any admixture[J]. Cement and Concrete Composites, 2018, 94: 255-263. doi: 10.1016/j.cemconcomp.2018.09.017 [30] MCCARTER W J, BROUSSEAU R. The A. C. response of hardened cement paste[J]. Cement and Concrete Research, 1990, 20(6): 891-900. doi: 10.1016/0008-8846(90)90051-X [31] KIM M K, LE H V, KIM D J. Electromechanical response of smart ultra-high performance concrete under external loads corresponding to different electrical measurements[J]. Sensors, 2021, 21(4): 1281.1-1281.18. [32] LEE S Y, LE H V, KIM D J. Self-stress sensing smart concrete containing fine steel slag aggregates and steel fibers under high compressive stress[J]. Construction and Building Materials, 2019, 220: 149-160. doi: 10.1016/j.conbuildmat.2019.05.197 [33] LE H V, LEE D H, KIM D J. Effects of steel slag aggregate size and content on piezoresistive responses of smart ultra-high-performance fiber-reinforced concretes[J]. Sensors and Actuators A: Physical, 2020, 305: 111925.1-111925.14. [34] LE H V, KIM M K, KIM D J, et al. Electrical properties of smart ultra-high performance concrete under various temperatures, humidities, and age of concrete[J]. Cement and Concrete Composites, 2021, 118: 103979.1-103979.14. [35] SHI K R, CHUNG D D L. Piezoelectricity-based self-sensing of compressive and flexural stress in cement-based materials without admixture requirement and without poling[J]. Smart Materials and Structures, 2018, 27(10): 105011.1-105011.21. -

下载:

下载: