Remanence Compensation of Maglev Planar Motor Based on Digital Twin Model

-

摘要:

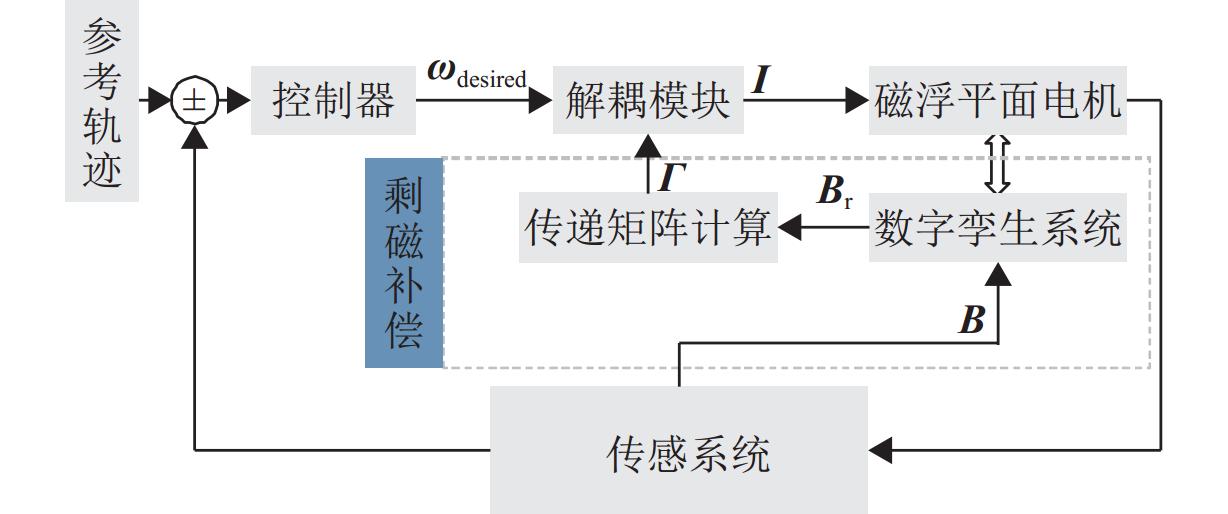

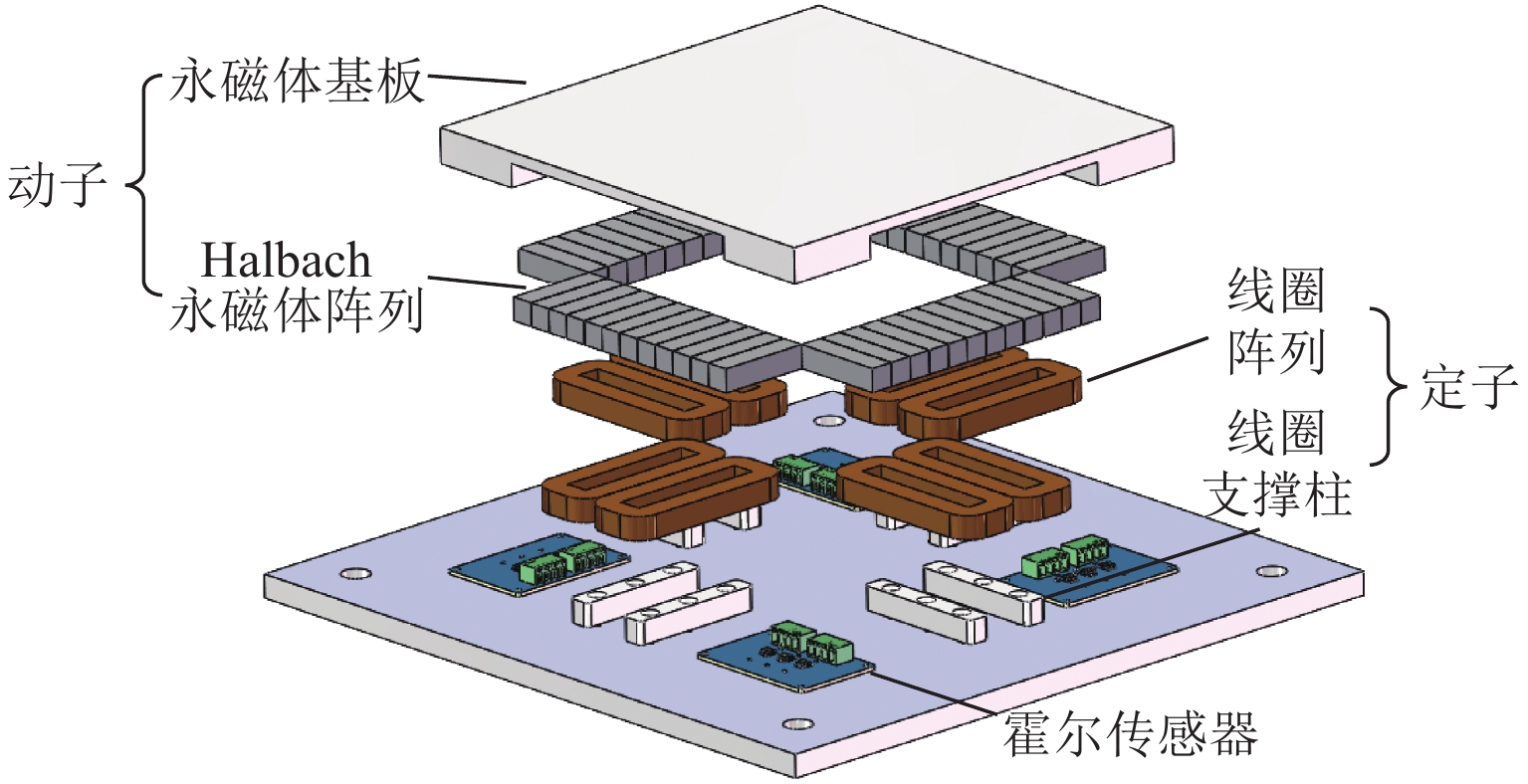

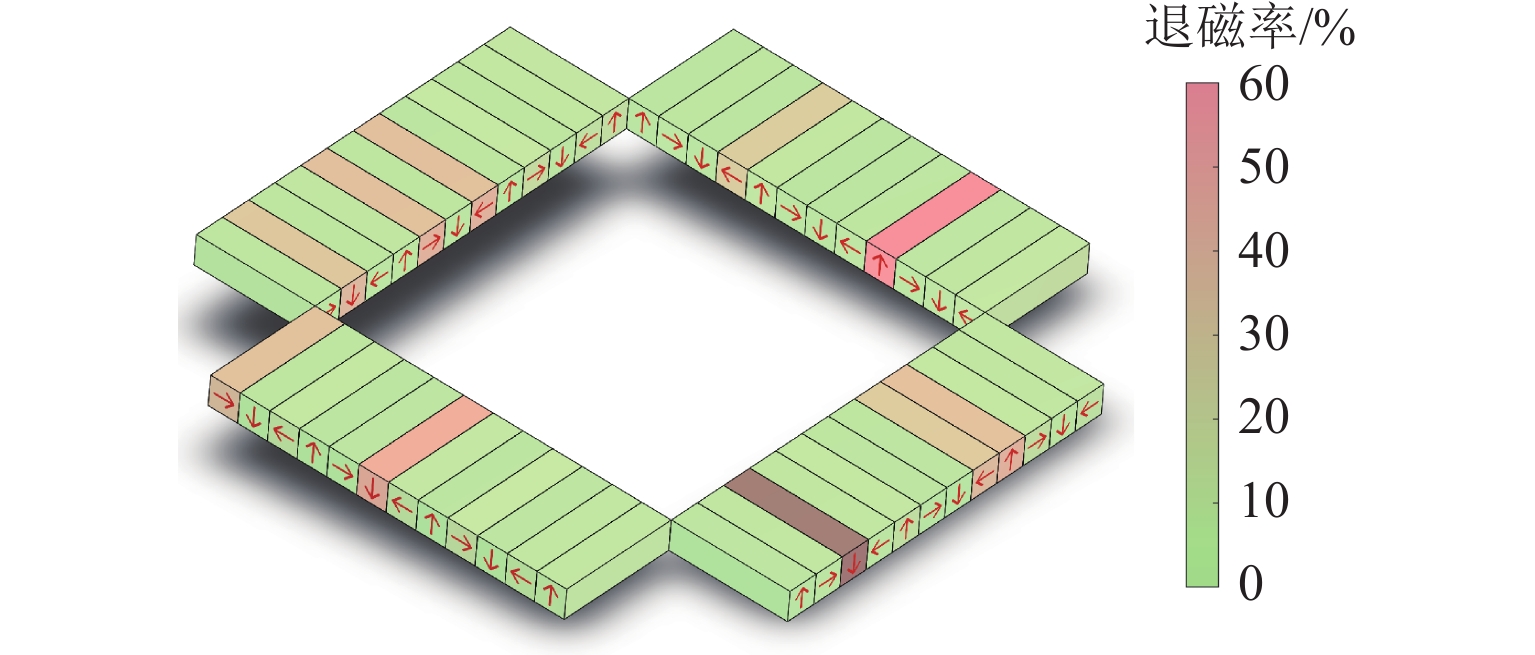

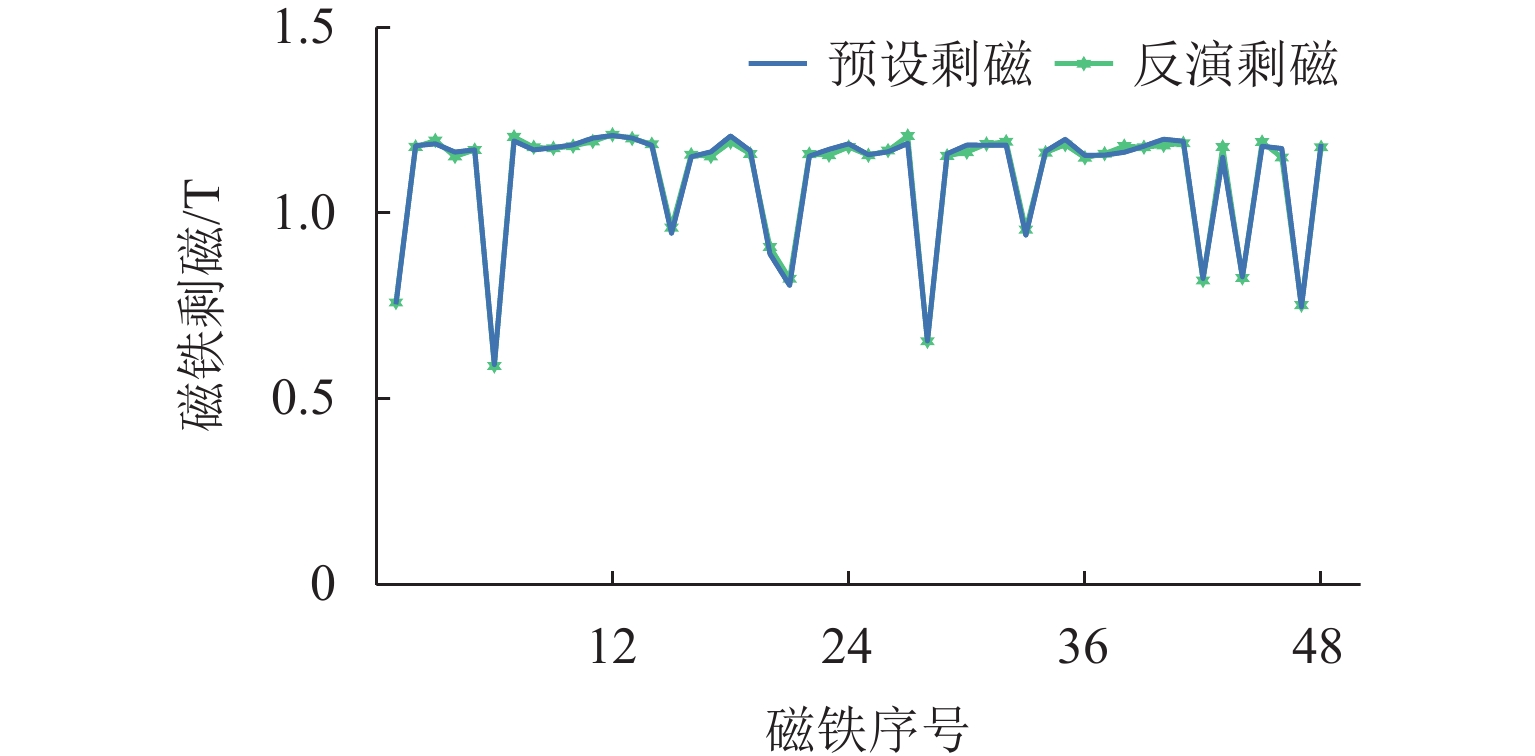

为提升磁浮平面电机发生退磁故障后的控制性能,提出一种针对永磁体阵列的剩磁补偿方法,并通过数字孪生模型对所提方法进行有效性验证. 首先,构建基于数字孪生五维模型的磁浮平面电机数字孪生框架,明确5层架构的组成部分;其次,利用磁荷节点模型探讨动子周围磁场与剩余磁化强度的关系,获得剩磁反演表达式,并在运动解耦过程中引入反演获得的剩磁数据,得出剩磁补偿后的控制电流;最后,利用不同退磁分布的磁浮平面电机孪生体数据,反演得到剩磁数值,通过多组轨迹跟踪仿真实验,对比无退磁、忽视退磁影响、剩磁反演补偿3种情况下的运动模拟. 研究结果表明:与忽视退磁影响相比,采用剩磁反演补偿方法,水平方向上进行斜坡轨迹跟踪的均方根误差减小56.5%,最大误差减小40.9%;平面运动阶跃响应稳定时间减少41.3%,超调量减少15.7%;圆轮廓跟踪时,轮廓误差的均方根减小85.0%,最大误差减小38.9%.

Abstract:A remanence compensation method for permanent magnet arrays was proposed to enhance the control performance of maglev planar motors after demagnetization faults, and the effectiveness of the proposed method was verified by a digital twin model. Firstly, a digital twin framework for maglev planar motors based on a five-dimensional digital twin model was constructed, and the components of the five-layer architecture were clarified. Secondly, the relationship between the magnetic field around the mover and the residual magnetization intensity was explored by using a magnetic charge node model to obtain a remanence inversion expression. Then, the inverted remanence data were introduced into the motion decoupling process to derive the control current after remanence compensation. Digital twin data of maglev planar motors with different demagnetization distributions were used to obtain remanence values through inversion. Multiple trajectory tracking simulation experiments were conducted to compare motion simulations under three conditions: no demagnetization, neglecting demagnetization effects, and remanence inversion compensation. The results show that compared with neglecting demagnetization effects, the remanence inversion compensation method reduces the root mean square error of horizontal ramp trajectory tracking by 56.5% and the maximum error by 40.9%. The setting time in planar motion step response is decreased by 41.3%, and the overshoot is reduced by 15.7%. When a circle contour is tracked, the root mean square of contour error is decreased by 85.0%, and the maximum error is reduced by 38.9%.

-

Key words:

- maglev planar motor /

- digital twin /

- remanence compensation /

- trajectory tracking

-

表 1 磁浮平面电机结构参数

Table 1. Structural parameters of maglev planar motor

参数 数值 Lm/mm

Wm/mm

Hm/mm40

10

10动子质量/kg 2.37 Lc/mm

Wc/mm

Hc/mm

Rc/mm60

10

10

10线圈匝数/匝 300 Ix/(×10−3 kg•m2)

Iy/(×10−3 kg•m2)

Iz/(×10−3 kg•m2)9.38

9.38

18.70表 2 永磁体退磁率分布

Table 2. Demagnetization rate distribution of permanent magnets

阵列 基本无退磁 轻度退磁 重度退磁 阵列 1 2,3,4,5,7,8,9,10,11,12 1 6 阵列 2 1,2,4,5,6,7,10,11,12 3,8,9 阵列 3 1,2,3,5,6,7,8,10,11,12 9 4 阵列 4 1,2,3,4,5,7,9,10,12 6,8,11 表 3 剩磁反演误差分析

Table 3. Error analysis of remanence inversion

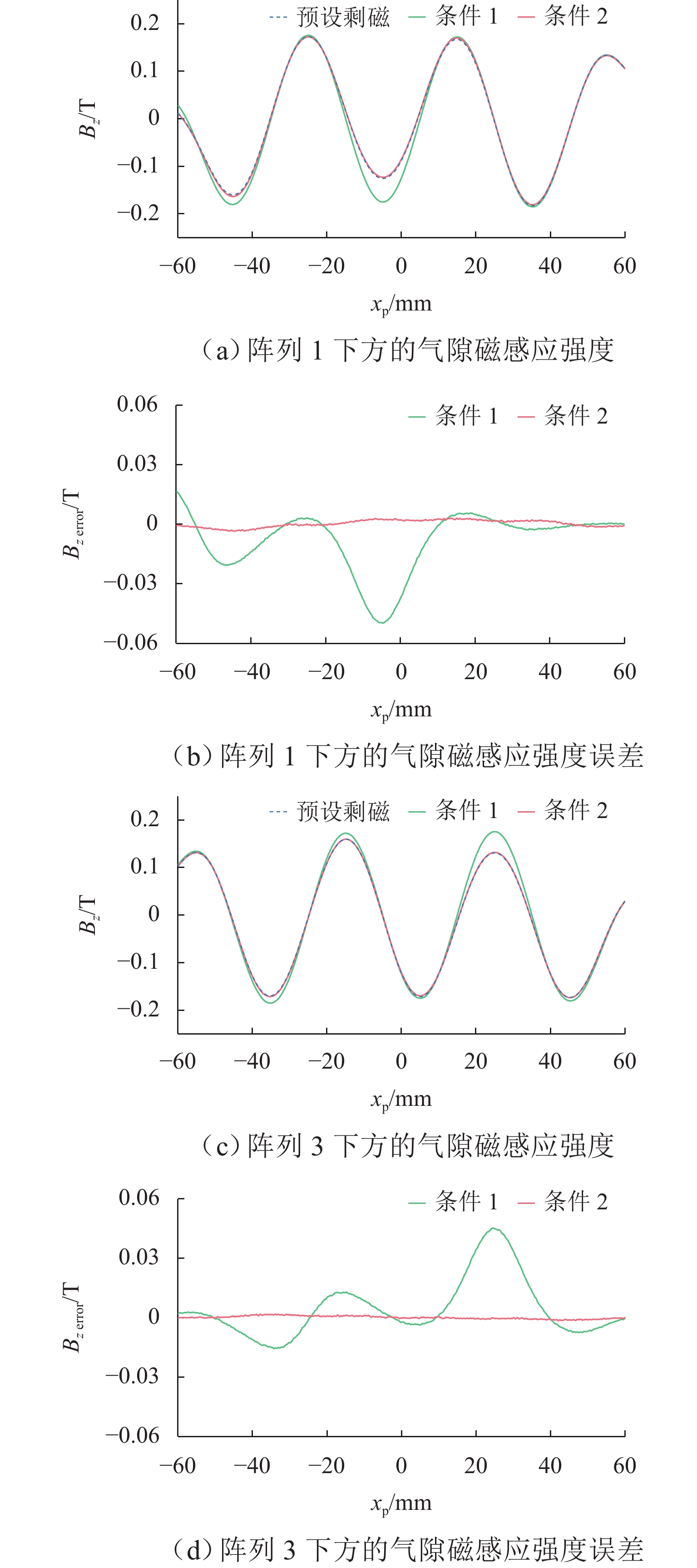

参数 erms,B/T emap/% R2 取值 0.011 0.67738 0.99549 表 4 气隙磁感应强度误差分析

Table 4. Error analysis of air gap magnetic flux density

阵列位置 条件 erms,B/T emap/% 阵列 1 条件 1 0.016939 45.1079 条件 2 0.001293 3.6183 阵列 3 条件 1 0.015386 28.4291 条件 2 0.001790 3.9413 表 5 斜坡轨迹跟踪控制性能

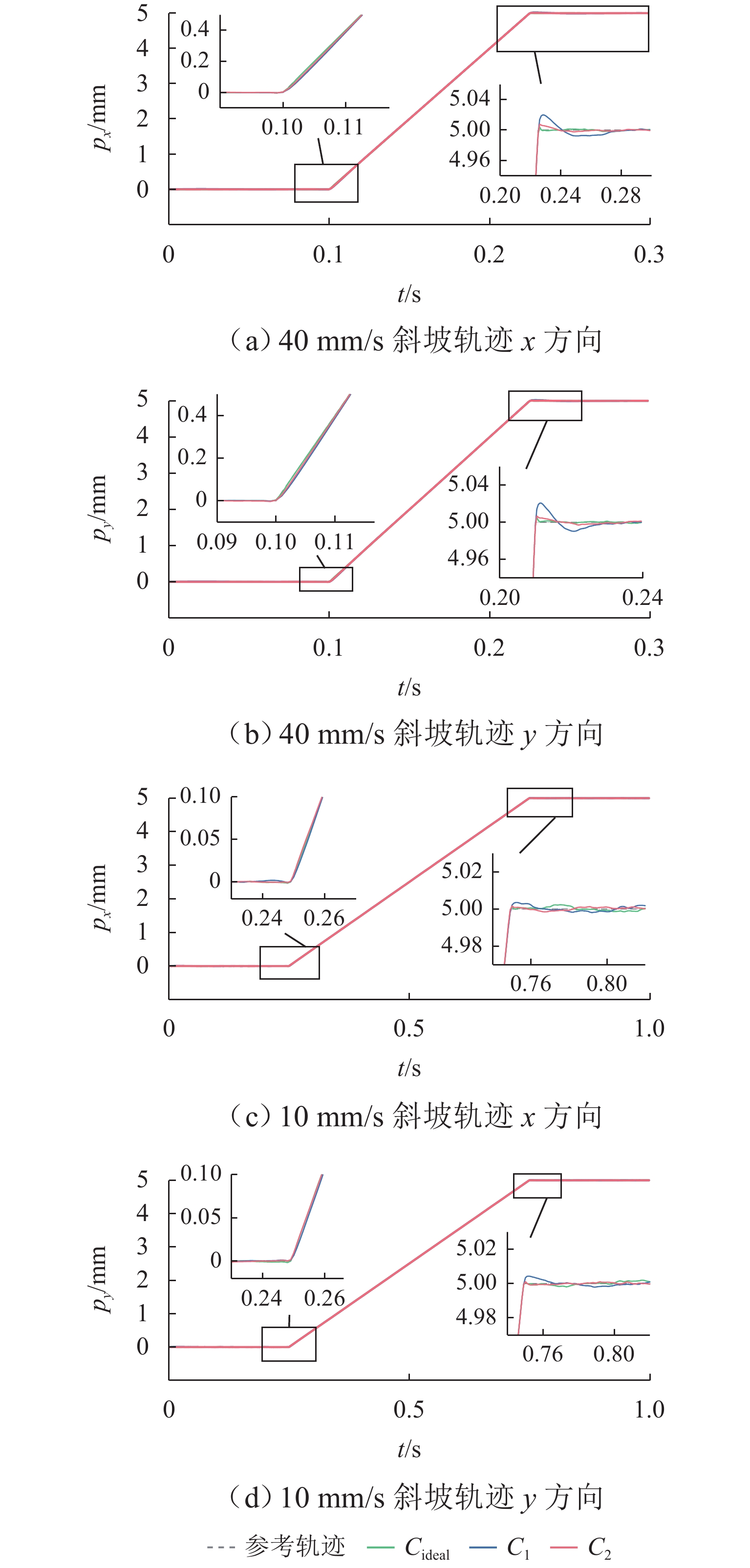

Table 5. Control performance for ramp trajectory tracking

mm 速度/(mm·s−1) 情况 x 方向 y 方向 erms emax erms emax 40 Cideal 0.00099 0.00527 0.00074 0.00224 C1 0.00586 0.02266 0.00171 0.00699 C2 0.00265 0.01344 0.00079 0.00236 10 Cideal 0.00089 0.00551 0.00070 0.00221 C1 0.00616 0.02436 0.00160 0.00702 C2 0.00268 0.01440 0.00091 0.00223 表 6 阶跃响应性能指标

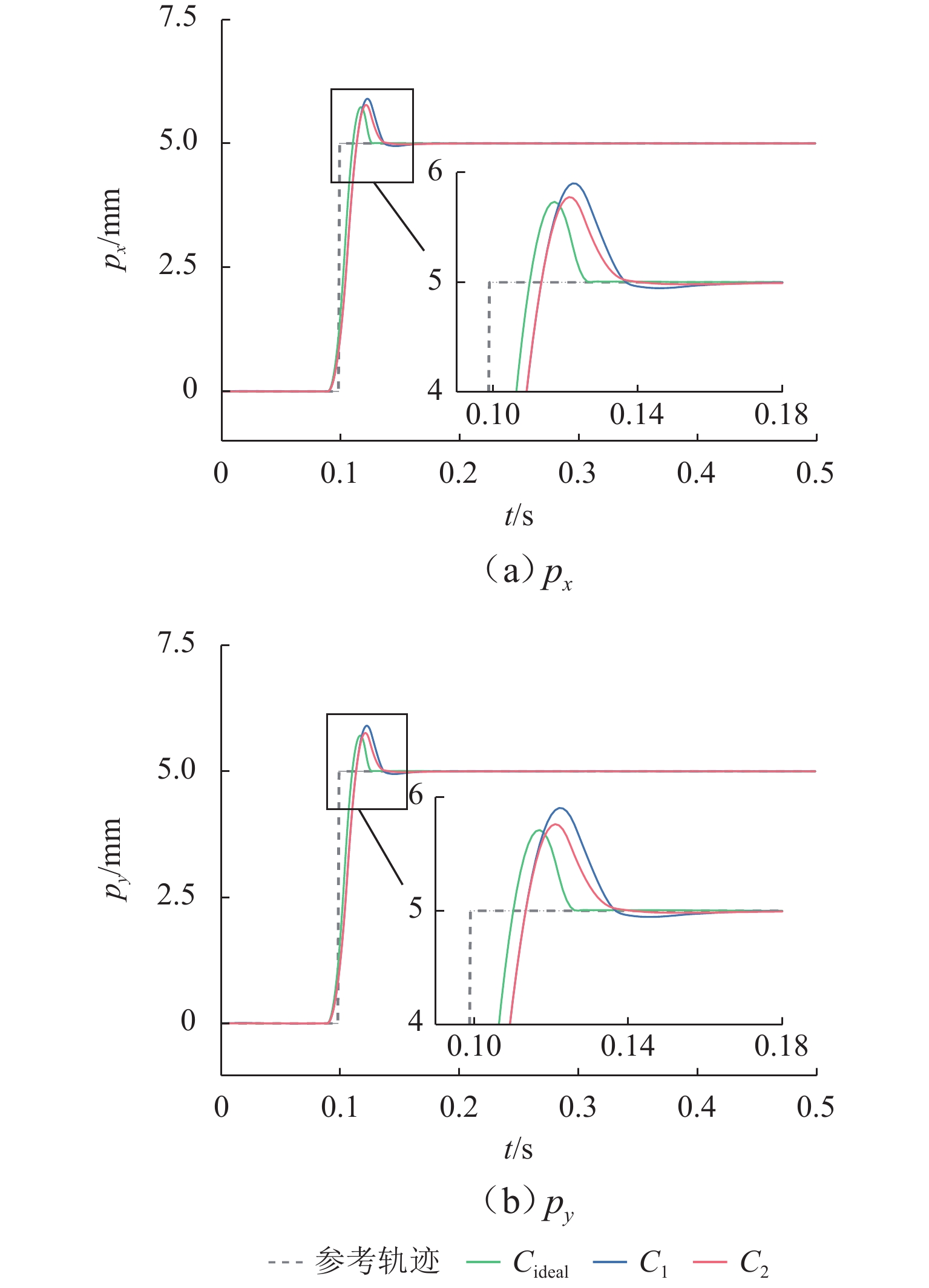

Table 6. Performance metrics for step response

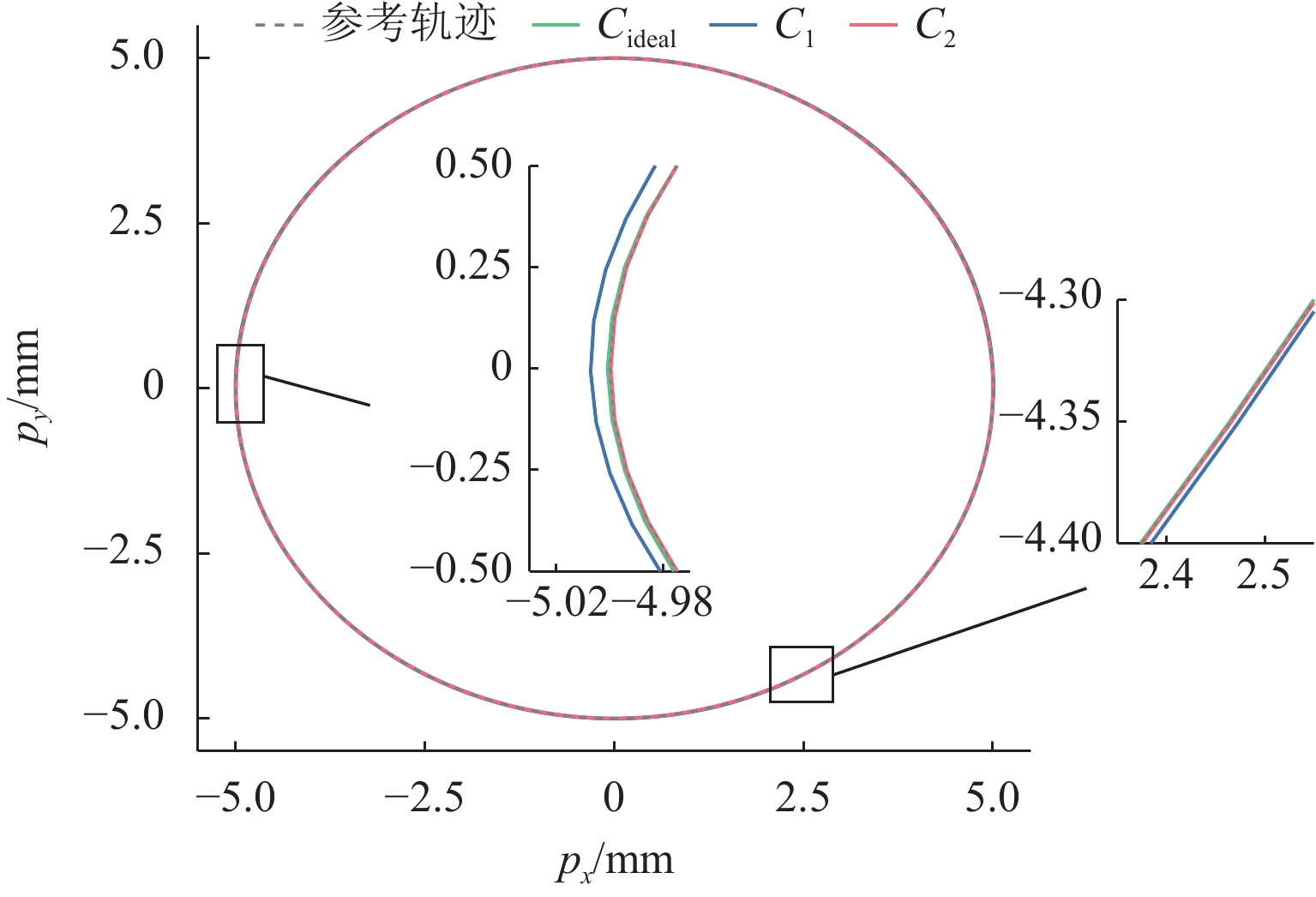

情况 方向 响应时间/ms 超调量/mm Cideal x 24 0.7327 y 27 0.7077 C1 x 63 0.9007 y 63 0.9034 C2 x 37 0.7758 y 39 0.7616 表 7 圆轮廓跟踪性能

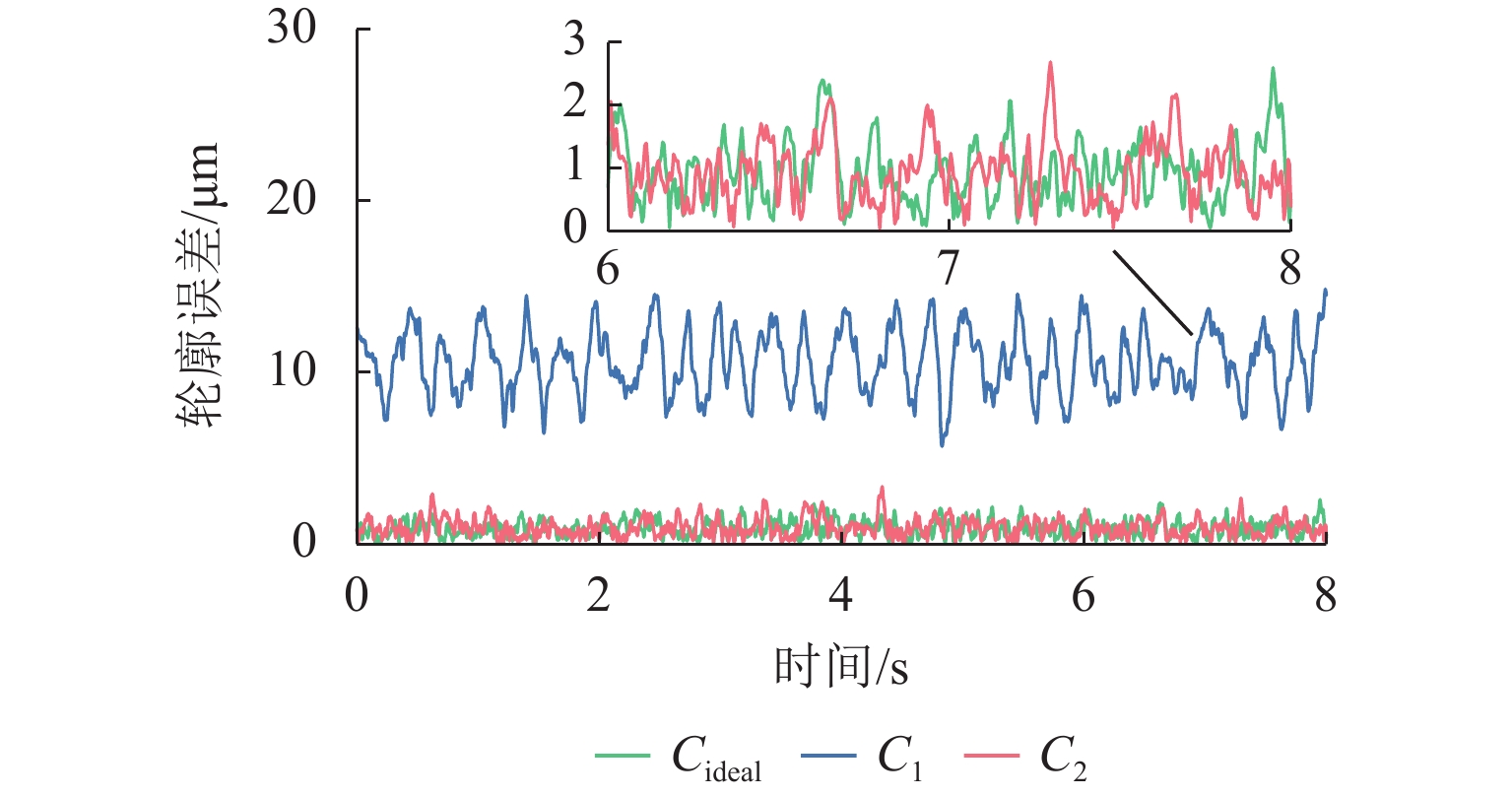

Table 7. Performance of circular contour tracking

性能指标 εrms/mm εmax/mm Cideal 0.0015 0.0156 C1 0.0113 0.0275 C2 0.0017 0.0168 -

[1] 郭东明. 高性能制造[J]. 机械工程学报,2022,58(21): 225-242. doi: 10.3901/JME.2022.21.225GUO Dongming. High performance manufacturing[J]. Journal of Mechanical Engineering, 2022, 58(21): 225-242. doi: 10.3901/JME.2022.21.225 [2] ZHOU L, WU J J. Magnetic levitation technology for precision motion systems: a review and future perspectives[J]. International Journal of Automation Technology, 2022, 16(4): 386-402. doi: 10.20965/ijat.2022.p0386 [3] FU H, HU C X, YU D D, et al. Cascaded iterative learning motion control of precision maglev planar motor with experimental investigation[J]. ISA Transactions, 2023, 139: 463-474. doi: 10.1016/j.isatra.2023.03.031 [4] FAIZ J, NEJADI-KOTI H. Demagnetization fault indexes in permanent magnet synchronous motors: an overview[J]. IEEE Transactions on Magnetics, 2016, 52(4): 1-11. [5] NAIR S S, PATEL V I, WANG J B. Post-demagnetization performance assessment for interior permanent magnet AC machines[J]. IEEE Transactions on Magnetics, 2016, 52(4): 1-10. [6] WOO D K, JEONG B H. Irreversible demagnetization of permanent magnet in a surface-mounted permanent magnet motor with overhang structure[J]. IEEE Transactions on Magnetics, 2016, 52(4): 1-6. [7] JANSEN J W, VAN LIEROP C M M, LOMONOVA E A, et al. Modeling of magnetically levitated planar actuators with moving magnets[J]. IEEE Transactions on Magnetics, 2007, 43(1): 15-25. [8] HUANG S D, LIN Z X, CAO G Z, et al. Nonlinear dynamic model-based position control parameter optimization method of planar switched reluctance motors[J]. Mathematics, 2023, 11(19): 4067.1-4067.19. [9] 周扬,周瑾,王艺宇,等. 考虑界面接触的磁悬浮轴承-转子系统建模及鲁棒控制[J]. 西南交通大学学报,2024,59(4): 755-765.ZHOU Yang, ZHOU Jin, WANG Yiyu, et al. Modeling and robust control of magnetic bearing-rotor system considering interface contact[J]. Journal of Southwest Jiaotong University, 2024, 59(4): 755-765. [10] HUANG S D, XU Z H, CAO G Z, et al. Nonlinear-disturbance-observer-based predictive control for trajectory tracking of planar motors[J]. IET Electric Power Applications, 2024, 18(4): 389-399. doi: 10.1049/elp2.12398 [11] PARK Y, FERNANDEZ D, LEE S B, et al. Online detection of rotor eccentricity and demagnetization faults in PMSMs based on Hall-effect field sensor measurements[J]. IEEE Transactions on Industry Applications, 2019, 55(3): 2499-2509. [12] BRAUN J, DOPPELBAUER M, BRAUN J, et al. Calculation of the demagnetization for permanent magnet synchronous machines[C]//2016 XXII International Conference on Electrical Machines (ICEM). Lausanne: ACM, 2016: 173-179. [13] HUANG L, ZHOU F L, WANG W, et al. Digital twin method and application practice of spacecraft system driven by mechanism data[J]. Digital Twin, 2024, 4: 1-16. doi: 10.12688/digitaltwin.17918.1 [14] 丁国富,何旭,张海柱,等. 数字孪生在高速列车生命周期中的应用与挑战[J]. 西南交通大学学报,2023,58(1): 58-73. doi: 10.3969/j.issn.0258-2724.20210573DING Guofu, HE Xu, ZHANG Haizhu, et al. Application and challenges of digital twin in life cycle of high-speed trains[J]. Journal of Southwest Jiaotong University, 2023, 58(1): 58-73. doi: 10.3969/j.issn.0258-2724.20210573 [15] TUEGEL E J, INGRAFFEA A R, EASON T G, et al. Reengineering aircraft structural life prediction using a digital twin[J]. International Journal of Aerospace Engineering, 2011, 2011: 154798.1-154798.14. [16] 陶飞,程颖,程江峰,等. 数字孪生车间信息物理融合理论与技术[J]. 计算机集成制造系统,2017,23(8): 1603-1611.TAO Fei, CHENG Ying, CHENG Jiangfeng, et al. Theories and technologies for cyber-physical fusion in digital twin shop-floor[J]. Computer Integrated Manufacturing Systems, 2017, 23(8): 1603-1611. [17] KOHTZ S, ZHAO J H, RENTERIA A, et al. Optimal sensor placement for permanent magnet synchronous motor condition monitoring using a digital twin-assisted fault diagnosis approach[J]. Reliability Engineering & System Safety, 2024, 242: 109714.1-109714.12. [18] 陶飞,刘蔚然,刘检华,等. 数字孪生及其应用探索[J]. 计算机集成制造系统,2018,24(1): 1-18.TAO Fei, LIU Weiran, LIU Jianhua, et al. Digital twin and its potential application exploration[J]. Computer Integrated Manufacturing Systems, 2018, 24(1): 1-18. [19] BANCEL F. Magnetic nodes[J]. Journal of Physics D: Applied Physics, 1999, 32(17): 2155-2161. doi: 10.1088/0022-3727/32/17/304 [20] MAHMOUDITABAR F, VAHEDI A, MARIGNETTI F. The demagnetization phenomenon in PM machines: principles, modeling, and design considerations[J]. IEEE Access, 2023, 11: 47750-47773. doi: 10.1109/ACCESS.2023.3274701 [21] LI W L, ZHANG M W, ZHAO X, et al. Effect of demagnetization fault on electromagnetic field and related parameters in permanent magnet wind generator[C]//2019 22nd International Conference on Electrical Machines and Systems (ICEMS). Harbin: ACM, 2019: 1-7. [22] CHOI G, JAHNS T M. Investigation of key factors influencing the response of permanent magnet synchronous machines to three-phase symmetrical short-circuit faults[J]. IEEE Transactions on Energy Conversion, 2019, 31(4): 1488-1497. [23] ZHAN H L, WU L J, LYU Z K, et al. Uneven demagnetization fault diagnosis in dual three-phase permanent magnet machines based on electrical signal difference[J]. IEEE Transactions on Transportation Electrification, 2023, 9(2): 3026-3039. [24] XU F Q, PENG R T, ZHENG T, et al. Development and validation of numerical magnetic force and torque model for magnetically levitated actuator[J]. IEEE Transactions on Magnetics, 2022, 55(1): 1-9. [25] XU F Q, SHI Y, ZHANG K Y, et al. Real-time application of robust offset-free MPC in maglev planar machine[J]. IEEE Transactions on Industrial Electronics, 2023, 70(6): 6121-6130. -

下载:

下载: