Analysis of Impact Effect of Cable Breakage in Half-Through Railway Arch Bridges with CFRP Cables

-

摘要:

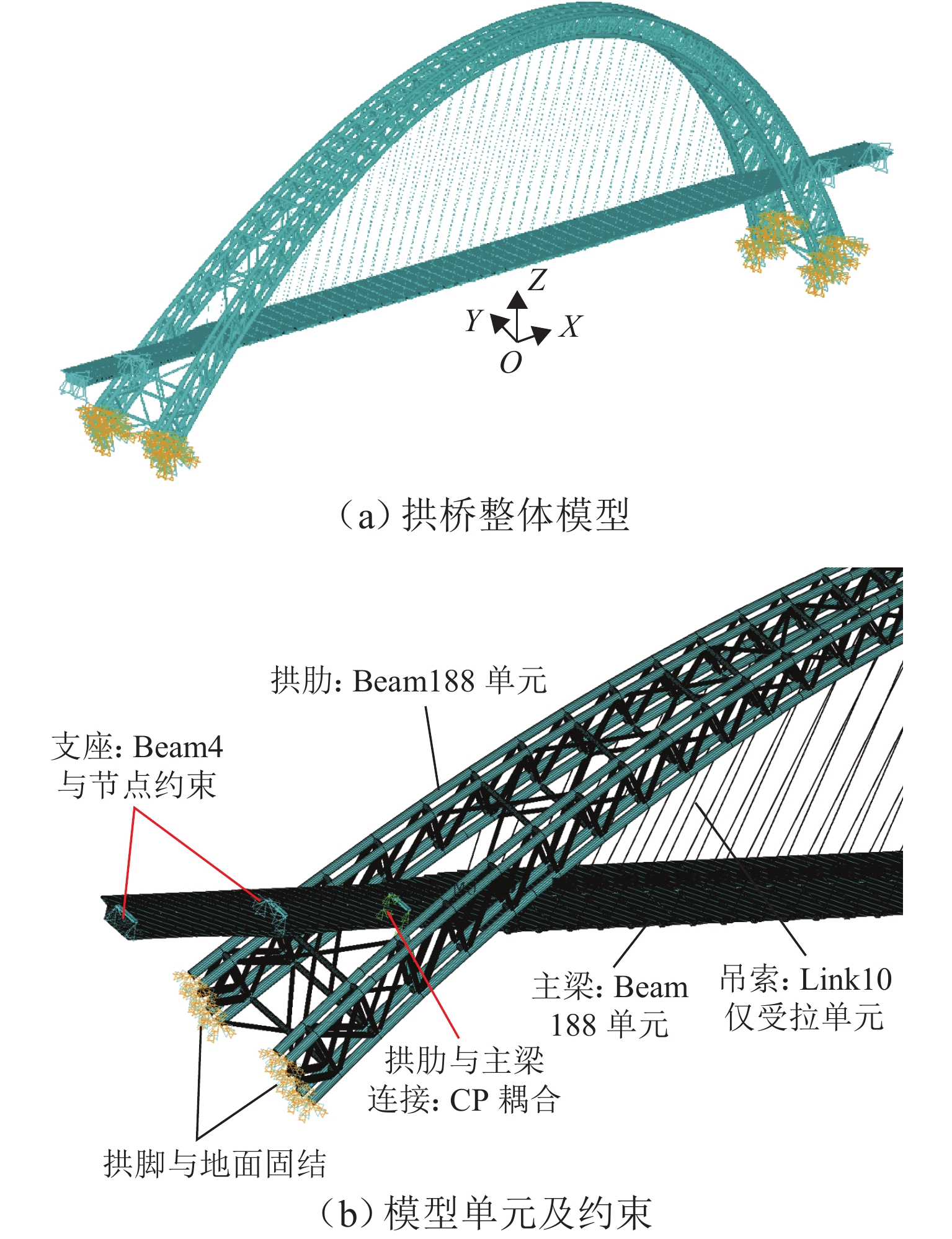

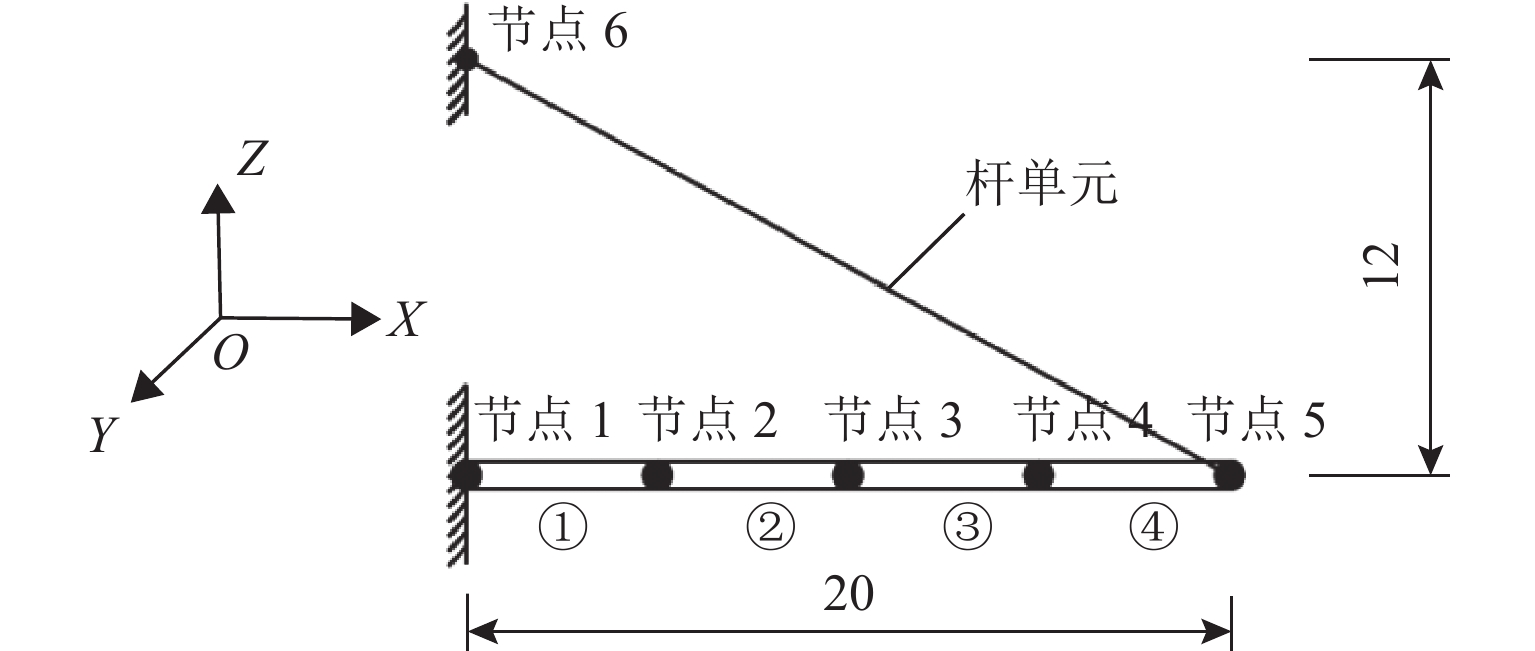

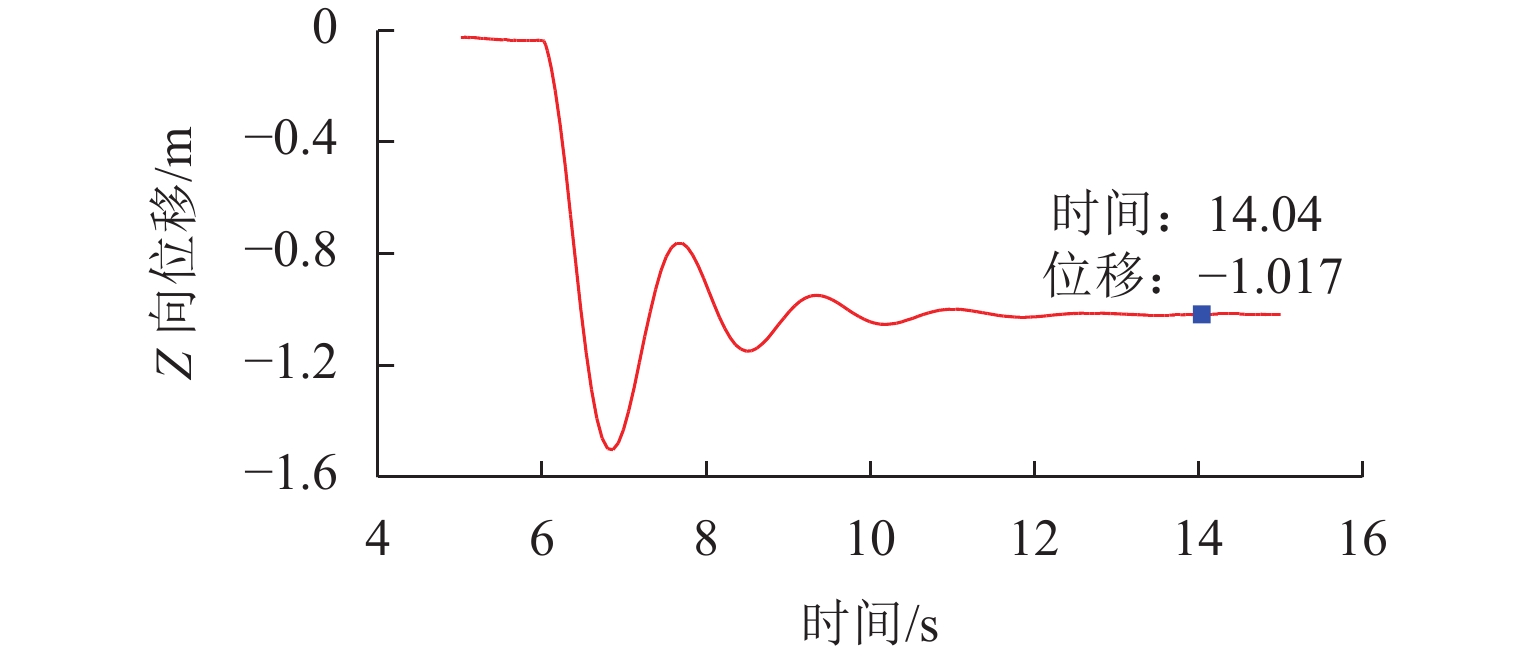

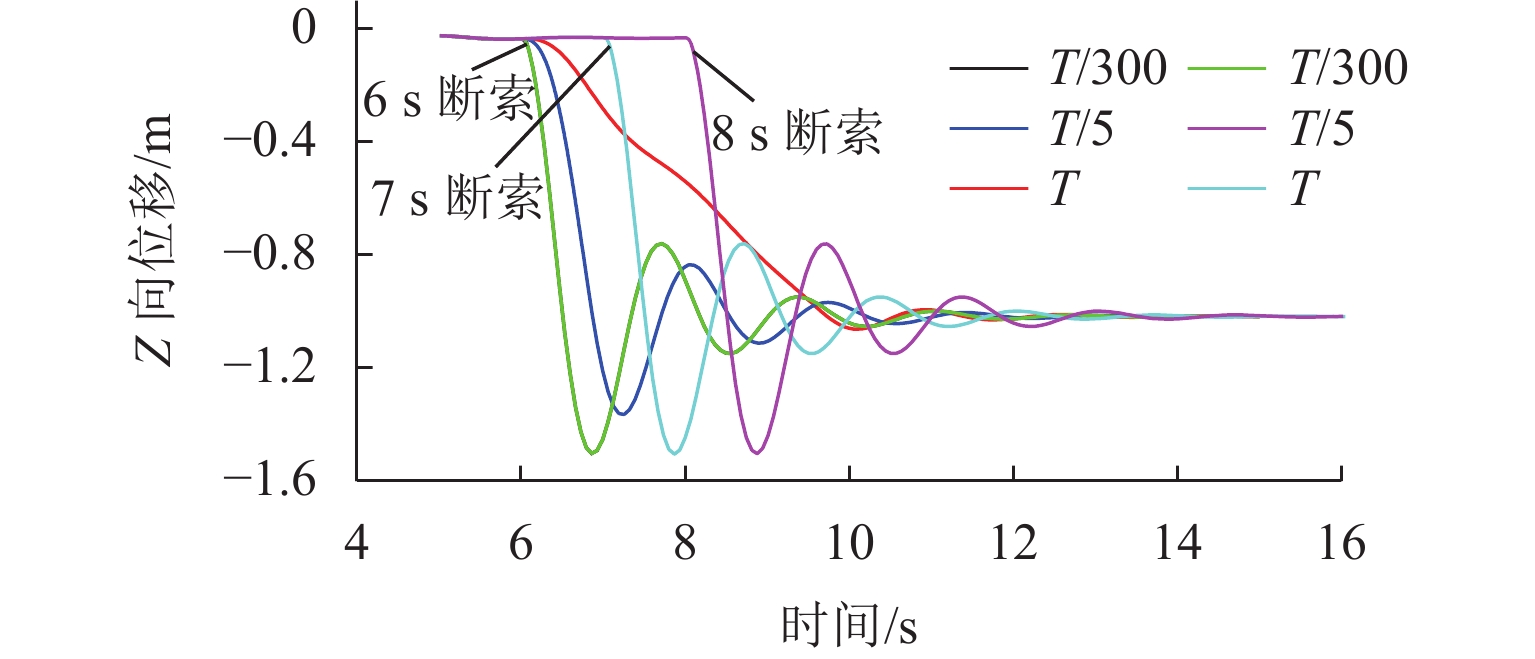

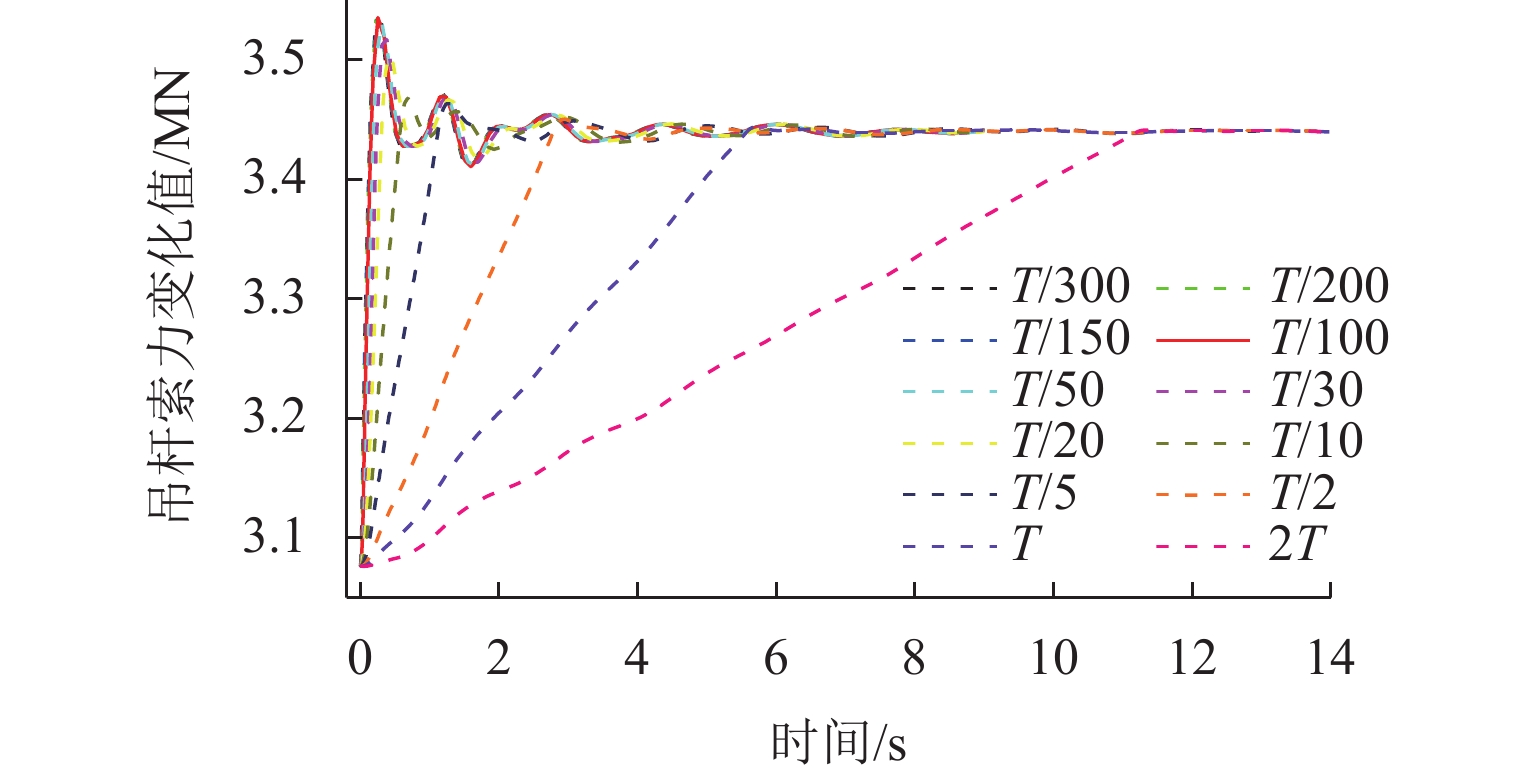

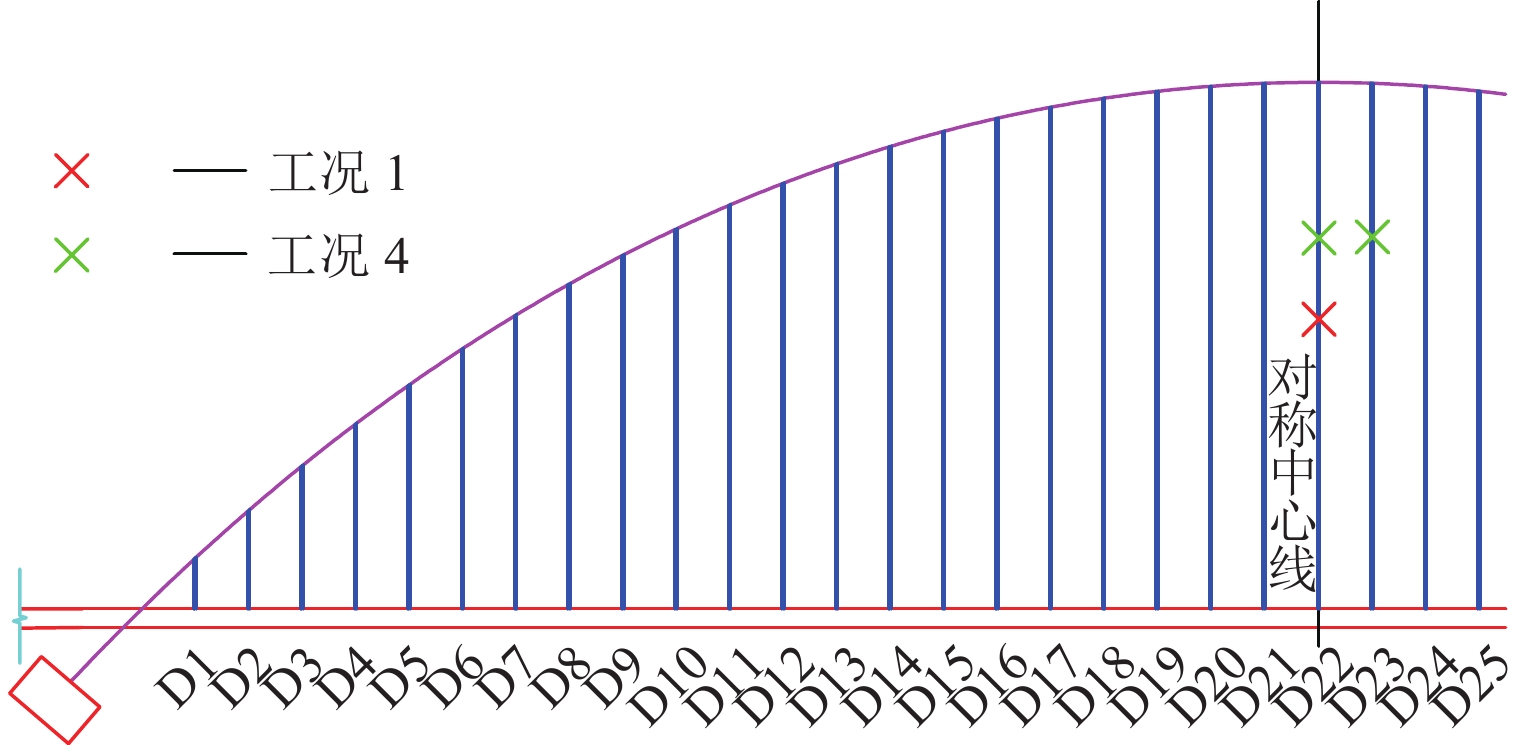

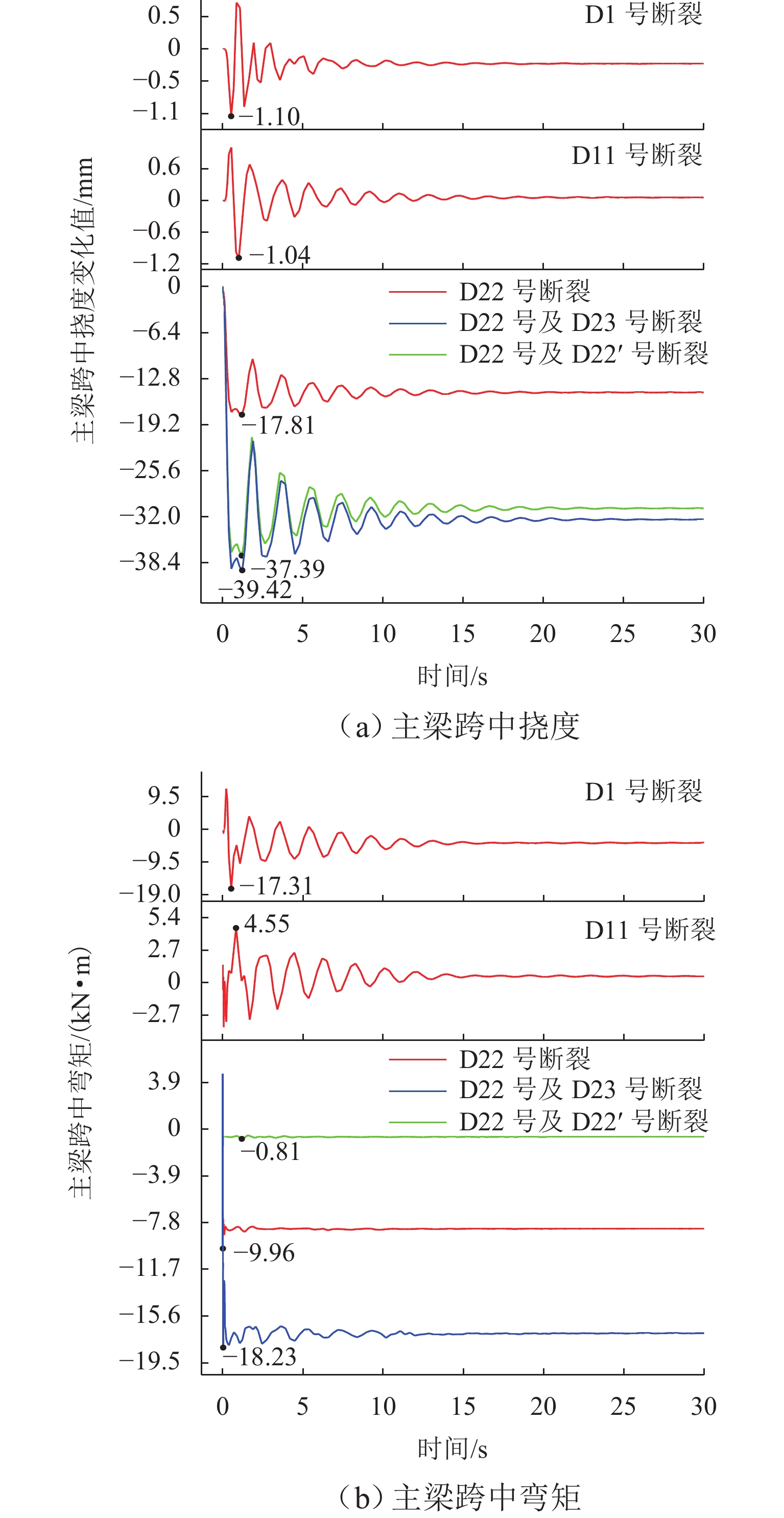

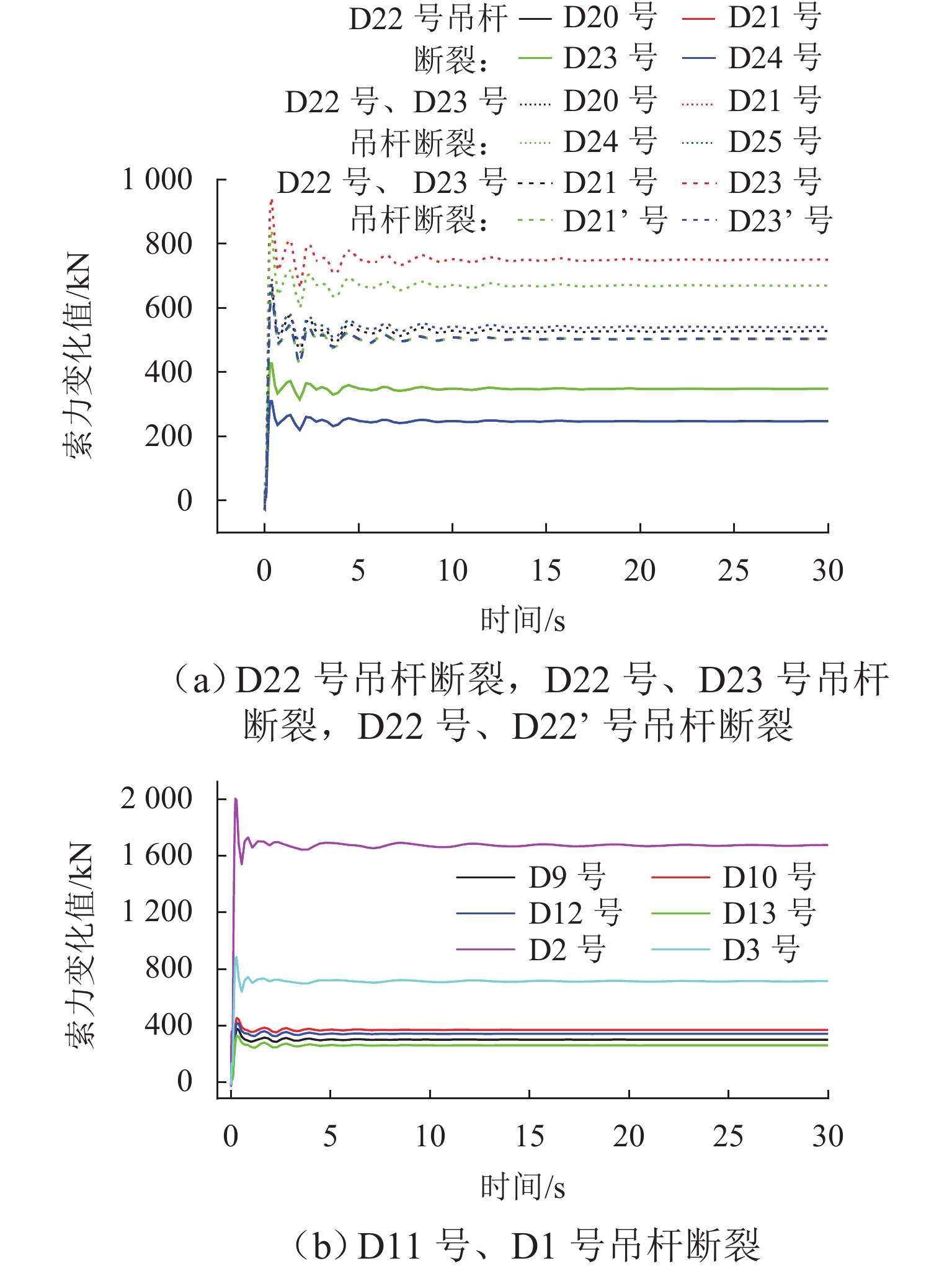

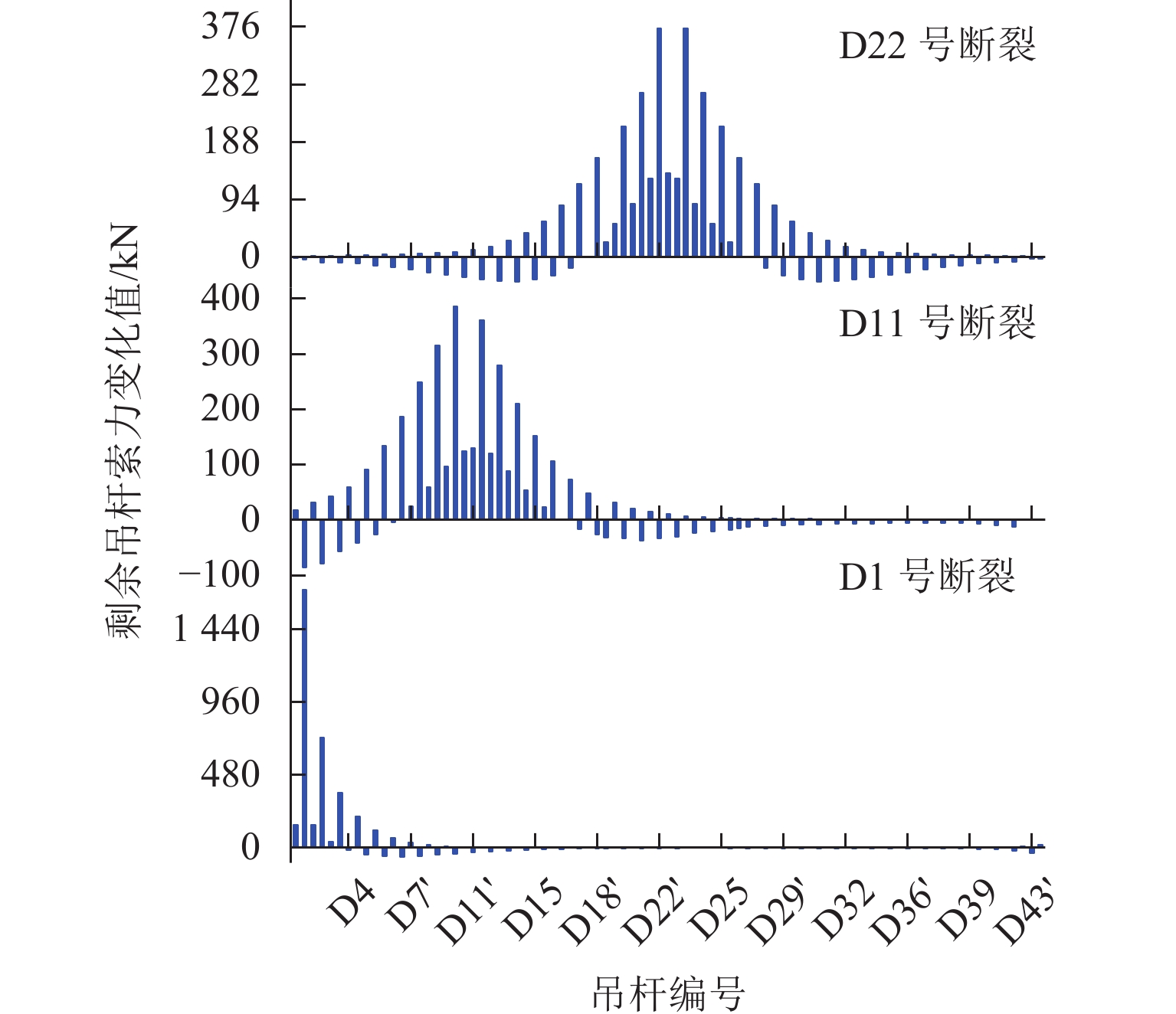

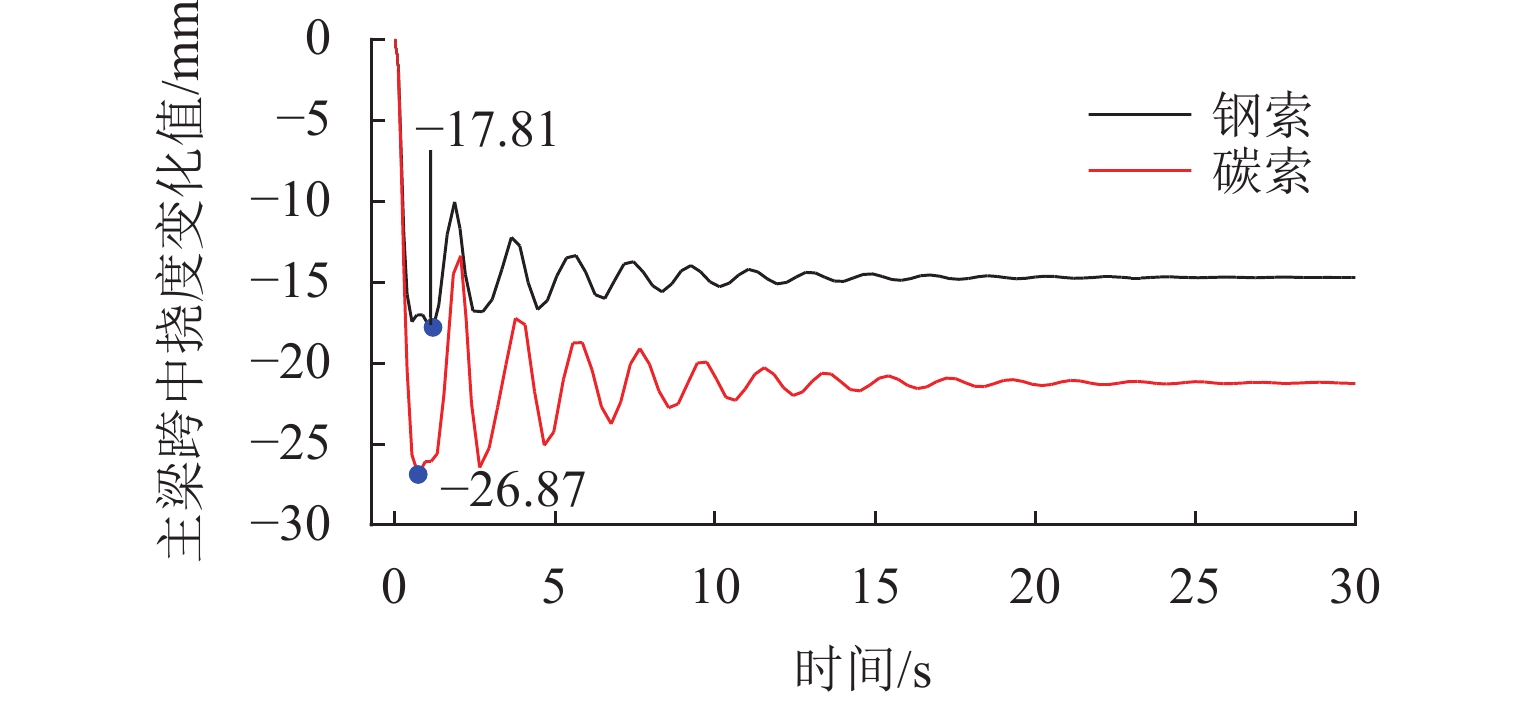

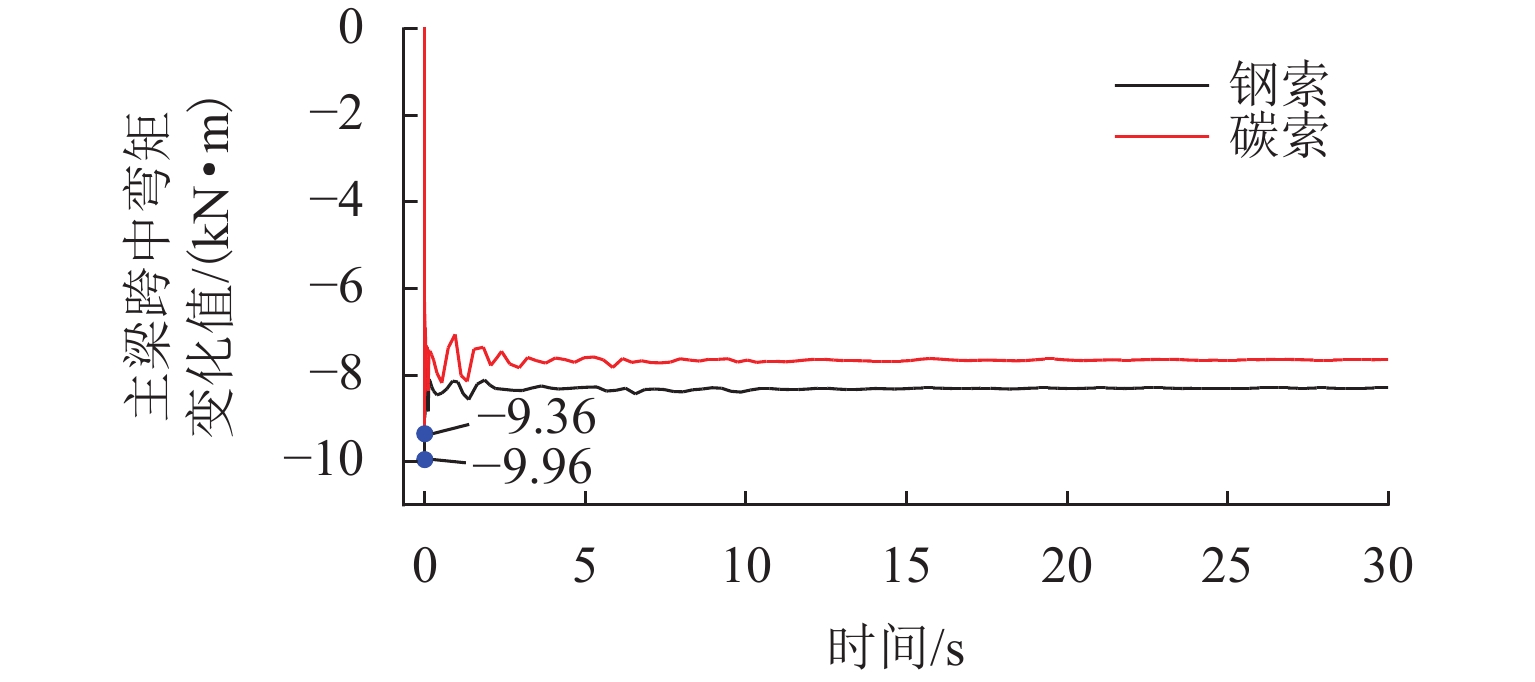

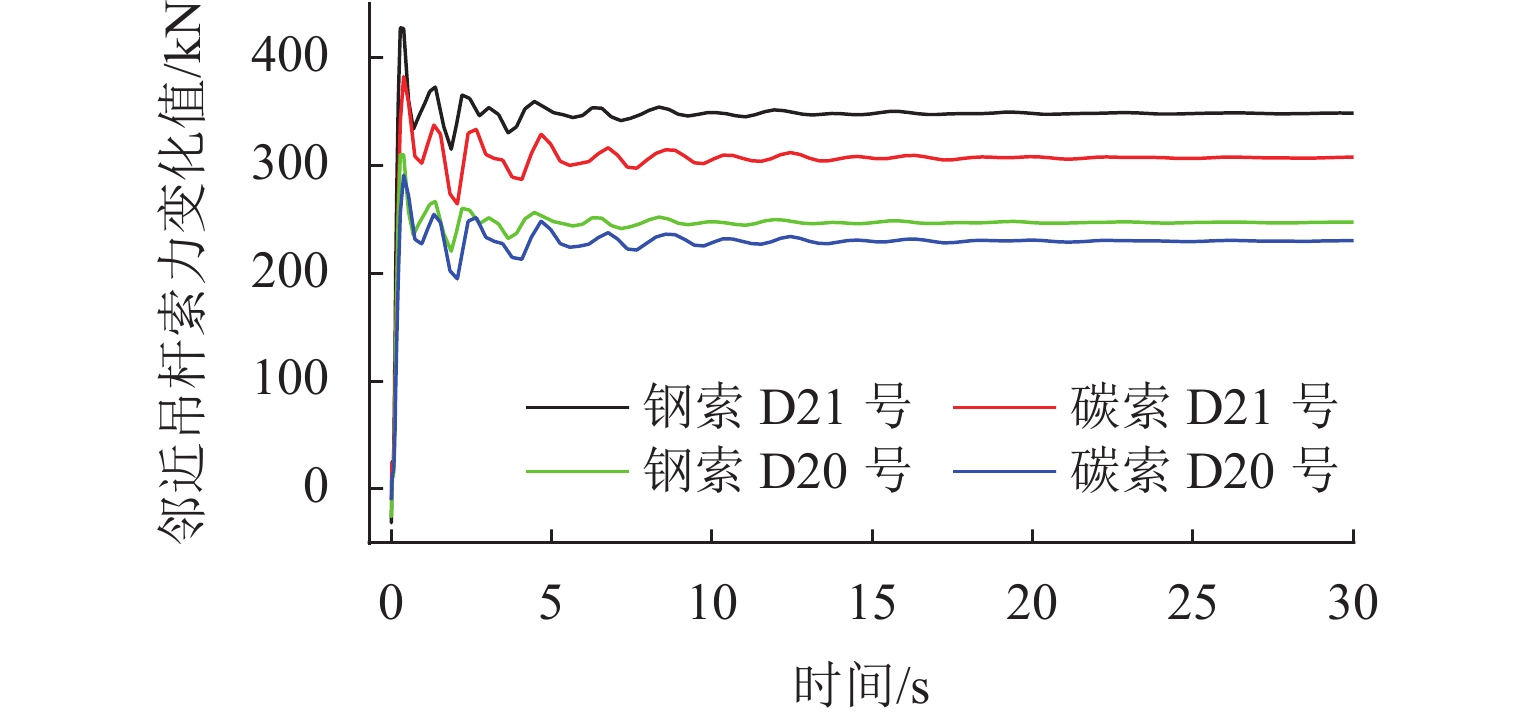

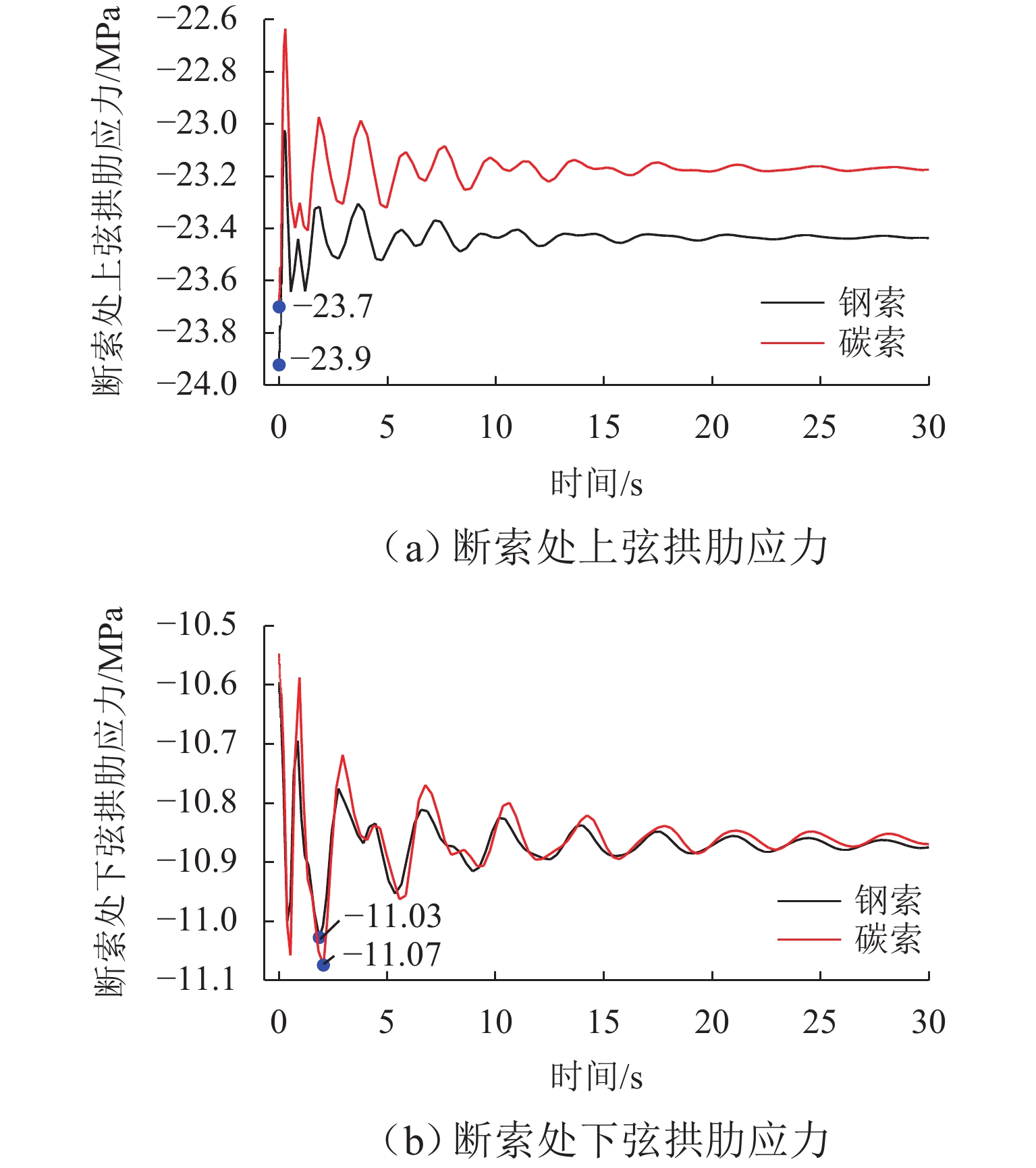

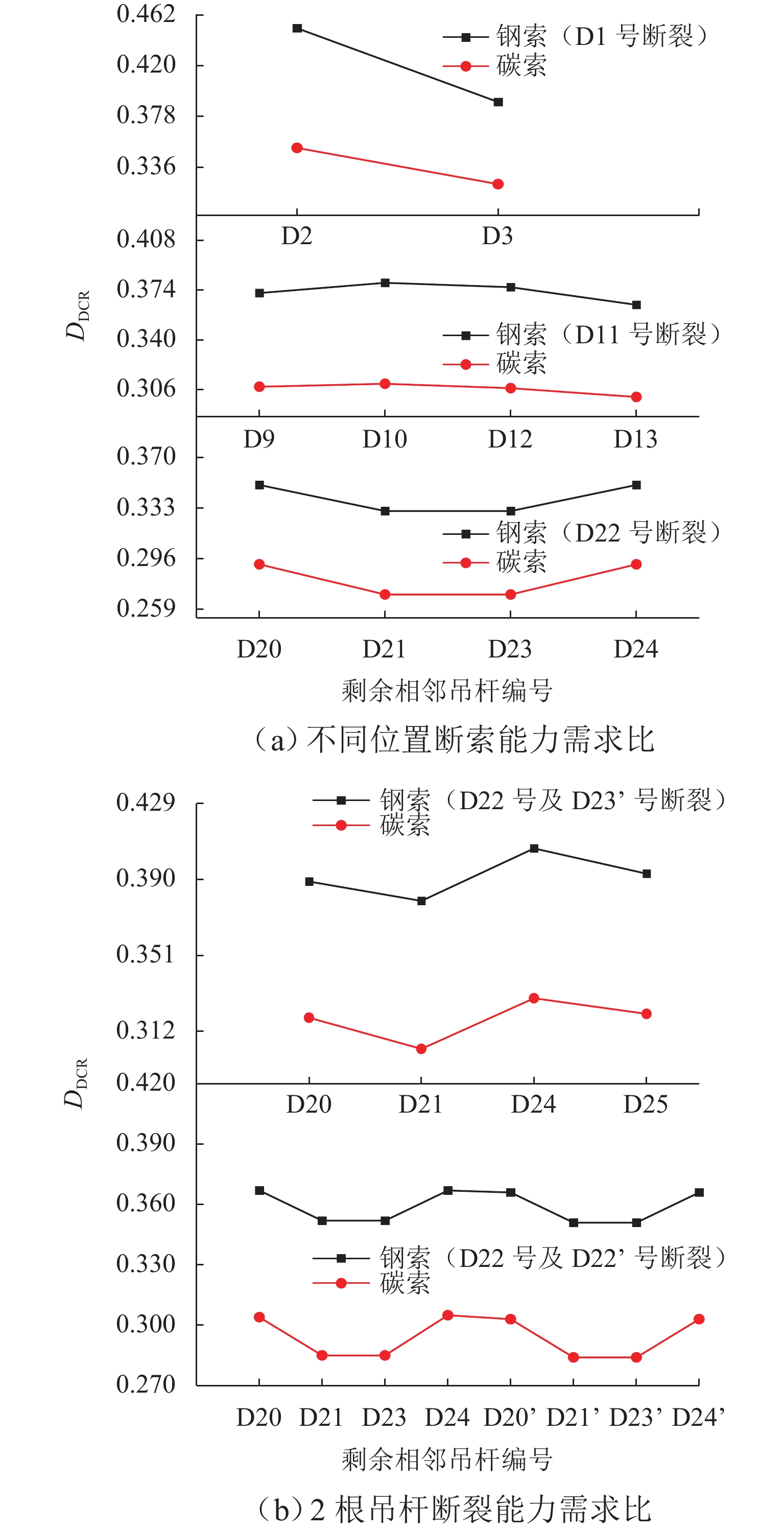

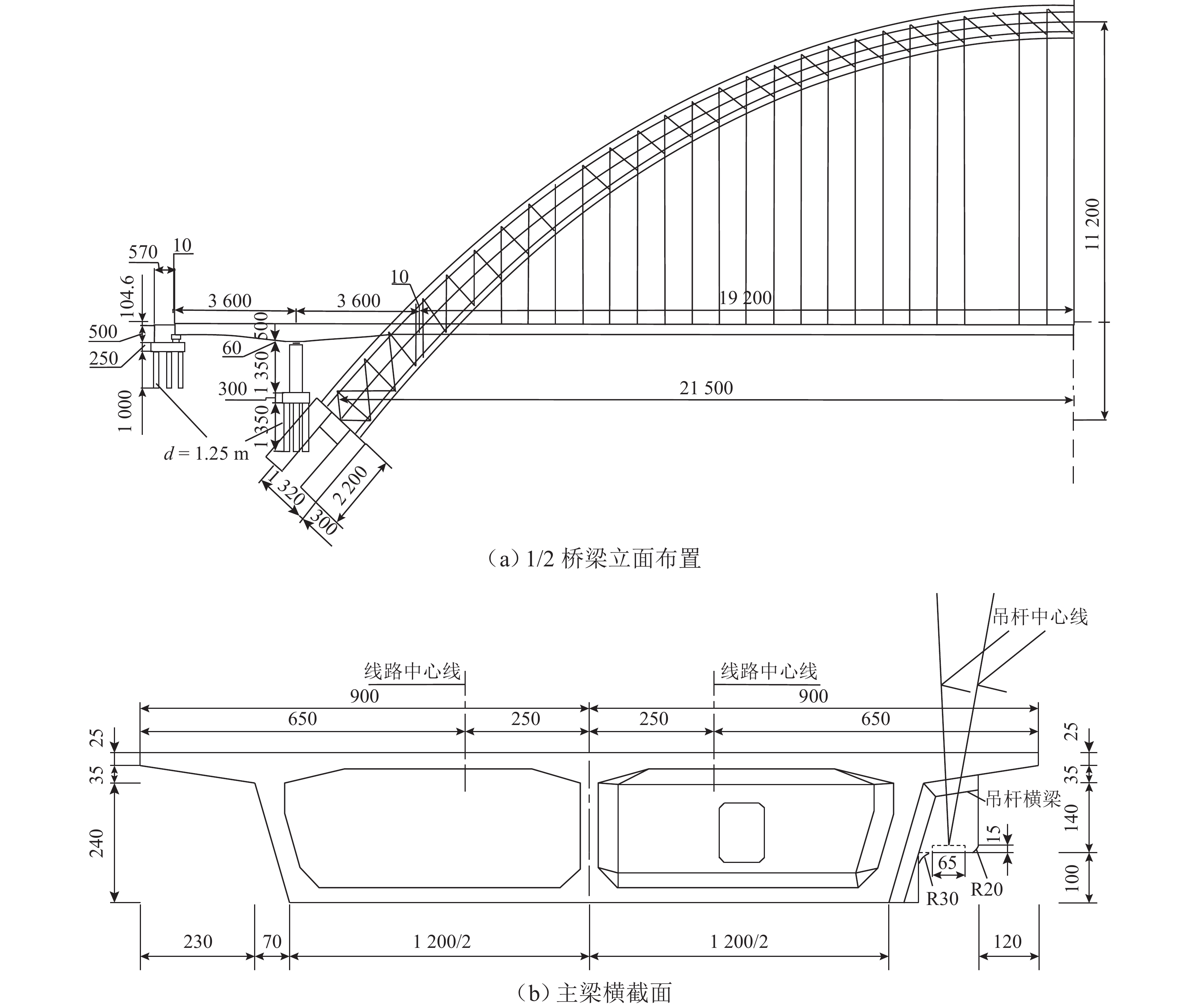

为研究吊杆断裂对钢管混凝土拱桥冲击响应的影响及对碳纤维复合材料索与钢索断索安全系数需求的差异,以某铁路特大桥为研究对象,分析偶然断索时全桥结构的动力响应. 采用ANSYS建立空间有限元模型,基于等效卸载法研究5种断索工况下拱桥剩余结构的受力特性变化规律;通过动力放大系数和能力需求比评估断索后结构的冲击敏感性;对比分析钢索与碳索不同缆索材料对桥梁断索动力响应的影响. 研究结果表明:断索位置和数量对主梁动力响应和拱肋应力影响显著;吊杆索力的重分配比例与距离断索区域的远近和索体长度成反比,与失效吊杆数量成正比;拱桥碳索对应的动力放大系数大于钢索的,均在1.19~1.43内变化;断索后剩余吊杆的应力需求比均未超过1,具有较大冗余;较钢索桥,拱桥碳索断索下的安全系数小,均在1.0~1.5内变化.

Abstract:To study the effect of cable breakage on the impact response of concrete-filled steel tube arch bridges and the difference in safety factor requirements between carbon fiber reinforced polymer (CFRP) cables and steel cables, the dynamic response of a railway bridge under accidental cable breakage was analyzed. A spatial finite element model was established by ANSYS. The force characteristic variations of the residual structure of the arch bridge under five cable breakage conditions were studied based on the equivalent unloading method. The impact sensitivity of the structure after cable breakage was evaluated by dynamic amplification factor (

D DAF) and demand capacity ratio (D DCR). The effects of different cable materials, namely steel cables and carbon cables, on the dynamic response of the arch bridge were compared. The results show that the dynamic response of the main girder and the stress of the arch rib are greatly affected by the position and number of cable breakages. The redistribution ratio of the cable force is inversely proportional to the distance from the broken cable area and the cable length and directly proportional to the number of failed cables. TheD DAF of the arch bridge with carbon cables is higher than that of the arch bridge with steel cables, ranging from 1.19 to 1.43. TheD DCR of the remaining cable after cable breakage does not exceed 1, indicating large redundancy. Compared with bridges with steel cables, arch bridges with carbon cables require smaller safety factors under cable breakage conditions, ranging from 1.0 to 1.5. -

表 1 索材料力学参数

Table 1. Mechanical parameters of cable materials

类型 弹性模量/GPa 强度/MPa 容重/(kN·m−3) 钢索 200 1860 78.5 CFRP索 160 3000 15.3 表 2 拱桥动力特性

Table 2. Dynamic characteristics of arch bridge

阶段 频率/Hz 振型特点 第 1 阶 0.179 主梁横向弯曲振动 第 2 阶 0.302 拱肋横向弯曲振动 第 3 阶 0.416 体系反对称竖向弯曲振动 第 4 阶 0.522 体系横向弯曲振动 第 5 阶 0.601 体系反对称横向弯曲振动 第 6 阶 0.606 体系正对称竖向弯曲振动 第 7 阶 0.826 体系正对称横向弯曲振动 第 8 阶 0.983 体系竖向弯曲振动 第 9 阶 1.043 体系正对称竖向弯曲振动 第 10 阶 1.077 体系正对称横向弯曲振动 表 3 断索工况模拟设置

Table 3. Cable breakage condition simulation

影响因素 断索工况 断索位置 断索位置 D22 号吊杆断裂(工况 1) 主梁跨中 D11 号吊杆断裂(工况 2) 1/4 拱肋 D1 号吊杆断裂(工况 3) 拱脚 断索数量 D22 号、D23 号吊杆断裂(工况 4) 主梁跨中 对称断裂 D22 号、D22’ 号吊杆断裂(工况 5) 主梁跨中 表 4 邻近吊杆索力冲击敏感性评估

Table 4. Impact sensitivity evaluation of adjacent cables’ force

断索工况 邻近吊杆编号 吊杆应力最大值/Mpa DDCR DDAF M 钢索 碳索 钢索 碳索 钢索 碳索 钢索 碳索 D22 号断裂 D20 号 553.4 743.5 0.350 0.349 1.255 1.266 1.104 1.097 D21 号 523.7 689.3 0.331 0.324 1.228 1.246 1.136 1.123 D23 号 523.7 689.5 0.331 0.324 1.228 1.245 1.136 1.123 D24 号 553.3 744.2 0.350 0.350 1.255 1.265 1.104 1.096 D11 号断裂 D9号 587.6 786.5 0.372 0.370 1.258 1.272 1.121 1.110 D10 号 599.8 790.4 0.379 0.372 1.227 1.245 1.145 1.126 D12 号 593.8 782.1 0.376 0.368 1.228 1.244 1.135 1.118 D13 号 575.6 766.3 0.364 0.361 1.257 1.267 1.106 1.097 D1 号断裂 D2 号 713.7 898.0 0.451 0.423 1.198 1.236 1.490 1.388 D3 号 616.8 822.4 0.390 0.387 1.241 1.281 1.268 1.229 D22 号、D23 号断裂 D20 号 614.5 821.8 0.389 0.383 1.281 1.261 1.226 1.199 D21 号 599.3 772.0 0.379 0.363 1.257 1.247 1.300 1.258 D24 号 642.2 839.1 0.406 0.395 1.256 1.246 1.281 1.236 D25 号 621.2 818.4 0.393 0.385 1.279 1.259 1.229 1.201 D22 号、D22’ 号断裂 D21 号 557.0 727.2 0.352 0.342 1.298 1.264 1.209 1.185 D23 号 556.9 727.5 0.352 0.342 1.298 1.265 1.209 1.186 D21’ 号 555.2 723.2 0.351 0.340 1.298 1.266 1.209 1.185 D23’ 号 555.3 723.8 0.351 0.341 1.298 1.266 1.209 1.186 -

[1] LIU Z X, GUO T, YU X M, et al. Corrosion fatigue and electrochemical behaviour of steel wires used in bridge cables[J]. Fatigue & Fracture of Engineering Materials & Structures, 2021, 44(1): 63-73. [2] ZHAO Y, GUO X L, SU B T, et al. Evaluation of flexible central buckles on short suspenders’ corrosion fatigue degradation on a suspension bridge under traffic load[J]. Materials, 2023, 16(1): 290.1-290.17. [3] WANG B T, JIA Y D, ZHAO H J, et al. Research on the dynamic response of a continuous steel box girder bridge based on the ANSYS platform[J]. Sustainability, 2022, 14(17): 10638.1-10638.22. [4] WANG S F, YU L, YANG F, et al. Effect of steel fiber distribution on the mechanical properties of UHPC caused by vehicle-bridge coupling vibration[J]. Composites Part B: Engineering, 2022, 245: 110201.1-110201.1. [5] SU J X, ZHANG J P, ZHOU J Y, et al. Fatigue life assessment of suspenders in tied-arch bridges under random traffic loads and environmental corrosion[J]. International Journal of Civil Engineering, 2023, 21(3): 523-540. doi: 10.1007/s40999-022-00792-3 [6] ZHANG Y, FANG Z, JIANG R N, et al. Static performance of a long-span concrete cable-stayed bridge subjected to multiple-cable loss during construction[J]. Journal of Bridge Engineering, 2020, 25(3): 04020002.1-04020002.16. [7] LIU Z, NARASIMHAN H, KOTSOVINOS P, et al. Enhancing fire resilience of cable-supported bridges: current knowledge and research gaps[J]. Structural Engineering International, 2023, 33(4): 548-557. doi: 10.1080/10168664.2022.2164756 [8] YIN T, SUN X S, WANG Y J, et al. Corrosion investigation of rock anchors served over 10 years in underground powerhouse of a hydropower station[J]. Advances in Materials Science and Engineering, 2022, 13: 4905010.1-4905010.14. [9] ZHANG L G, LIANG Z Z, LI S L. Effect of current density on the cathodic protection efficiency and mechanical properties of pre-stressed high-strength steel wires for stay cable[J]. Construction and Building Materials, 2022, 314: 125671.1-125671.11. [10] SCATTARREGGIA N, ORGNONI A, PINHO R, et al. Failure analysis of the impact of a falling object on a bridge deck[J]. Engineering Failure Analysis, 2023, 148: 107229.1-107229.21. [11] 魏建东. 宜宾小南门大桥的抢修加固与恢复工程[J]. 公路, 2003, 48(4): 34-38. doi: 10.3969/j.issn.0451-0712.2003.04.010WEI Jiandong. Urgent reinforcement and restoration of xiaonanmen bridge in Yibin City[J]. Highway, 2003, 48(4): 34-38. doi: 10.3969/j.issn.0451-0712.2003.04.010 [12] 邢丽丽, 常忠义. 国内近期桥梁垮塌案例分析与启示[J]. 福建建材, 2011(9): 27-28. [13] LIU P, LU H P, CHEN Y X, et al. Fatigue analysis of long-span steel truss arched bridge part II: fatigue life assessment of suspenders subjected to dynamic overloaded moving vehicles[J]. Metals, 2022, 12(6): 1035.1-1035.11. [14] NAKAMURA S, MIYACHI K. Ultimate strength and chain-reaction failure of hangers in tied-arch bridges[J]. Structural Engineering International, 2021, 31(1): 136-146. doi: 10.1080/10168664.2020.1775537 [15] 陈宝春, 范冰辉, 余印根, 等. 钢管混凝土拱桥强健性设计[J]. 桥梁建设, 2016, 46(6): 88-93.CHEN Baochun, FAN Binghui, YU Yingen, et al. Robustness design of concrete-filled steel tube arch bridges[J]. Bridge Construction, 2016, 46(6): 88-93. [16] FAN B H, SU J Z, CHEN B C. Condition evaluation for through and half-through arch bridges considering robustness of suspended deck systems[J]. Advances in Structural Engineering, 2021, 24(5): 962-976. doi: 10.1177/1369433220945835 [17] 曲兆乐, 石雪飞, 李小祥, 等. 斜拉桥拉索断裂损伤的动力过程模拟方法研究[J]. 结构工程师, 2009, 25(6): 89-92. doi: 10.3969/j.issn.1005-0159.2009.06.017QU Zhaole, SHI Xuefei, LI Xiaoxiang, et al. Research on dynamic simulation methodology for cable loss of cable-stayed bridges[J]. Structural Engineers, 2009, 25(6): 89-92. doi: 10.3969/j.issn.1005-0159.2009.06.017 [18] 李岩, 崔石林, 陈逸民. 考虑模态更新的断索作用下斜拉桥动力响应分析方法[J]. 哈尔滨工业大学学报, 2024, 56(3): 1-8. doi: 10.11918/202205002LI Yan, CUI Shilin, CHEN Yimin. Dynamic response analysis method of cable-stayed bridge under cable broken based on modal updating[J]. Journal of Harbin Institute of Technology, 2024, 56(3): 1-8. doi: 10.11918/202205002 [19] 陈康明, 吴庆雄, 罗健平, 等. 考虑吊杆断裂动力作用的钢管混凝土拱桥等效静力计算方法[J]. 土木工程学报, 2023, 56(6): 63-74.CHEN Kangming, WU Qingxiong, LUO Jianping, et al. Equivalent static calculation method for concrete filled steel tubular arch bridges considering dynamic effect of hanger fracture[J]. China Civil Engineering Journal, 2023, 56(6): 63-74. [20] 邱文亮, 吴广润. 悬索桥吊索断裂动力响应分析的有限元模拟方法研究[J]. 湖南大学学报(自然科学版), 2021, 48(11): 22-30.QIU Wenliang, WU Guangrun. Research on simulation method of dynamic response analysis for suspension bridges subjected to hanger-breakage events[J]. Journal of Hunan University (Natural Sciences), 2021, 48(11): 22-30. [21] HUO J H, HUANG Y H, WANG J L, et al. Numerical analysis on the impact effect of cable breaking for a new type arch bridge[J]. Buildings, 2023, 13(3): 753.1-753.23. [22] 吴庆雄, 罗健平, 陈康明, 等. 吊杆断裂破坏安全极限状态下中、下承式拱桥悬吊桥面系简化计算方法[J]. 土木工程学报, 2024, 57(10): 57-70.WU Qingxiong, LUO Jianping, CHEN Kangming, et al. Simplified calculation method for suspension bridge deck system of half-through and through arch bridge under safety limit condition of suspender fracture[J]. China Civil Engineering Journal, 2024, 57(10): 57-70. [23] ZHANG C, HAO H, BI K M, et al. Dynamic amplification factors for a system with multiple-degrees-of-freedom[J]. Earthquake Engineering and Engineering Vibration, 2020, 19(2): 363-375. doi: 10.1007/s11803-020-0567-9 [24] 刘永健, 刘江, 周绪红, 等. 桥梁长寿命设计理论综述[J]. 交通运输工程学报, 2024, 24(3): 1-24.LIU Yongjian, LIU Jiang, ZHOU Xuhong, et al. Review on long-life design theory for bridges[J]. Journal of Traffic and Transportation Engineering, 2024, 24(3): 1-24. [25] RUIZ-TERAN A M, APARICIO A C. Response of under-deck cable-stayed bridges to the accidental breakage of stay cables[J]. Engineering Structures, 2009, 31(7): 1425-1434. doi: 10.1016/j.engstruct.2009.02.027 [26] 霍建宏. 斜拱曲梁异型拱桥断索响应模型试验与有限元分析[D]. 广州: 广州大学, 2023. [27] 黄永辉, 霍建宏, 傅继阳, 等. 拱桥断索冲击响应模型试验与有限元分析[J]. 中国公路学报, 2024, 37(5): 138-150.HUANG Yonghui, HUO Jianhong, FU Jiyang, et al. Model test and finite element analysis of arch bridge response to cable failure[J]. China Journal of Highway and Transport, 2024, 37(5): 138-150. -

下载:

下载: