Experimental Study on a New Clamping Anchor for Carbon Fiber Reinforced Polymer Plate

-

摘要:

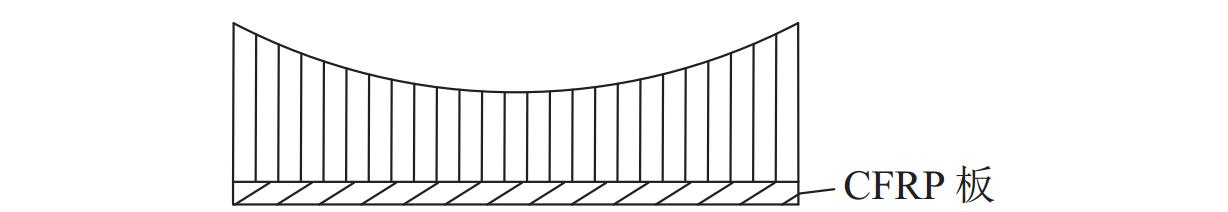

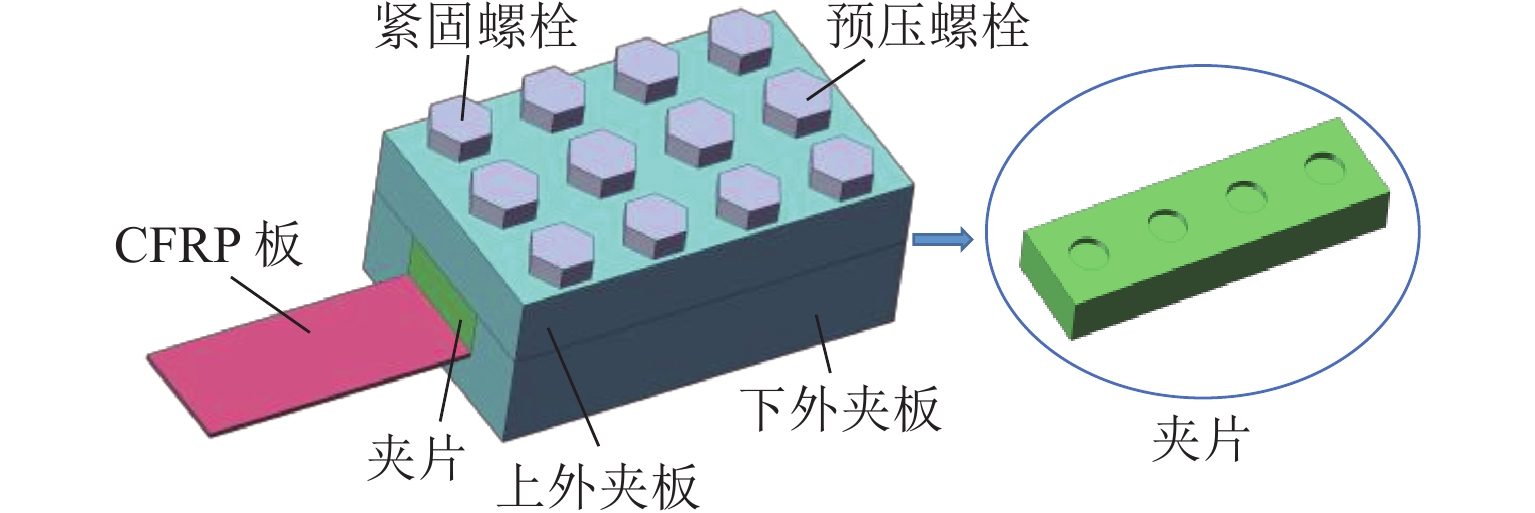

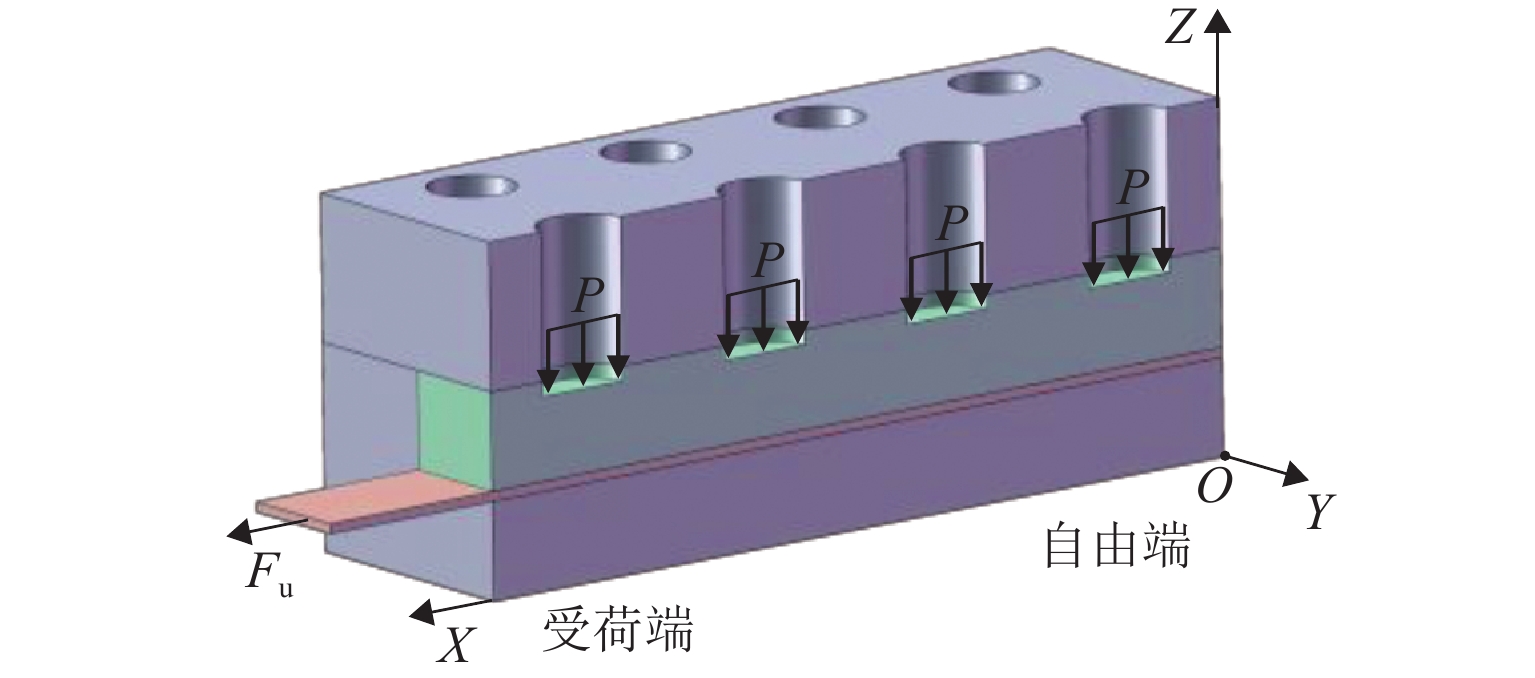

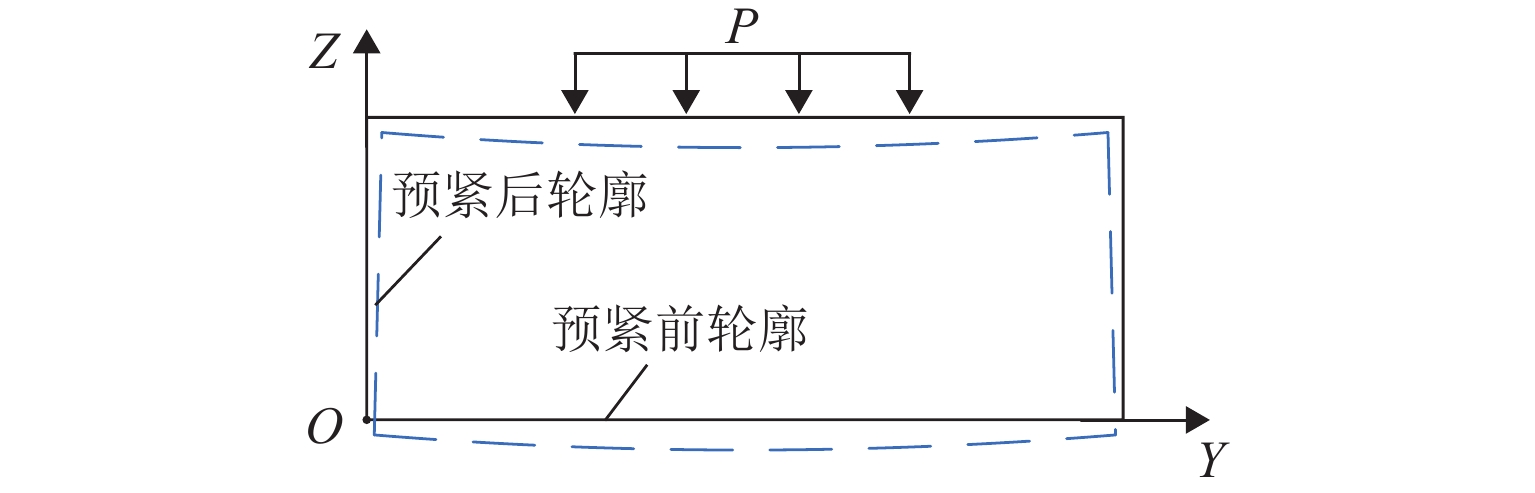

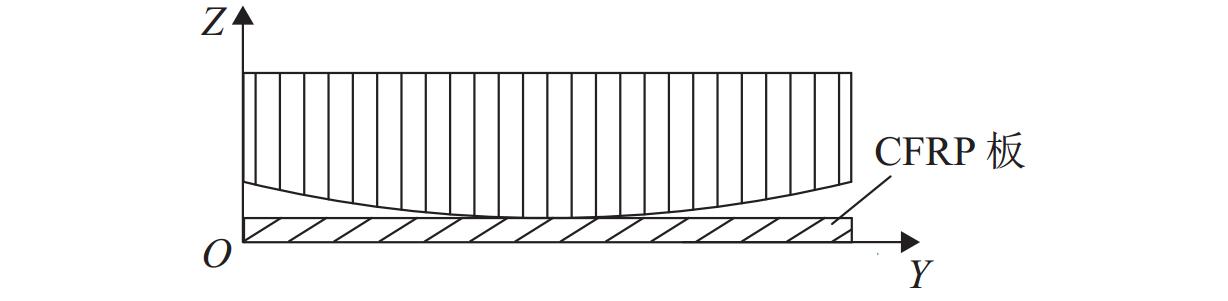

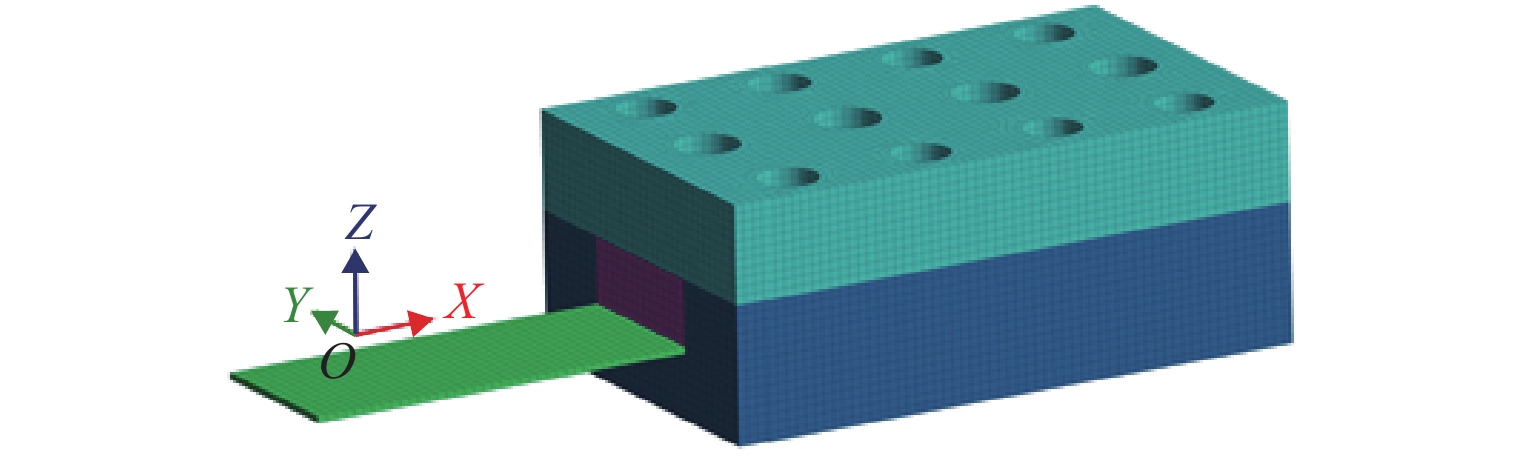

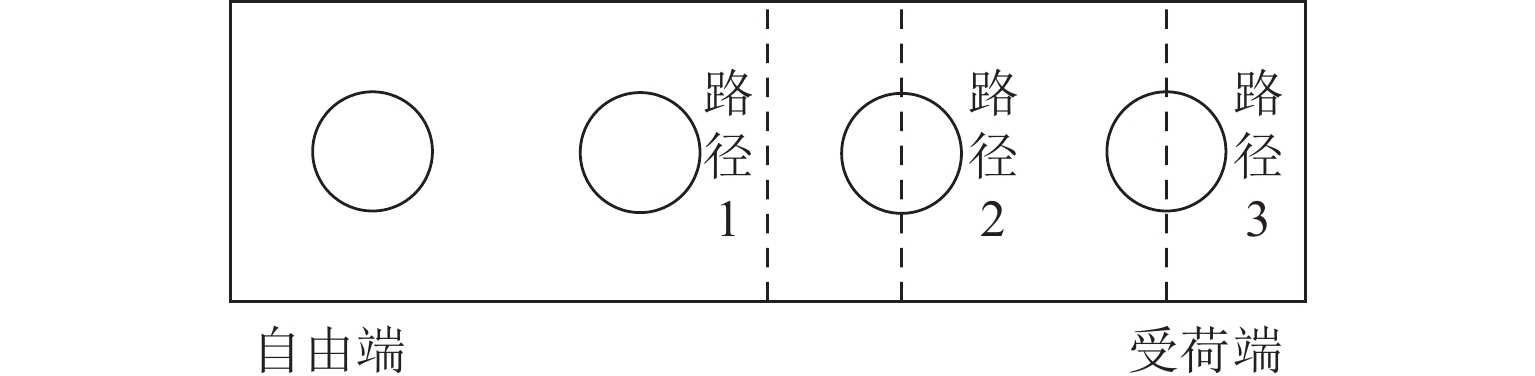

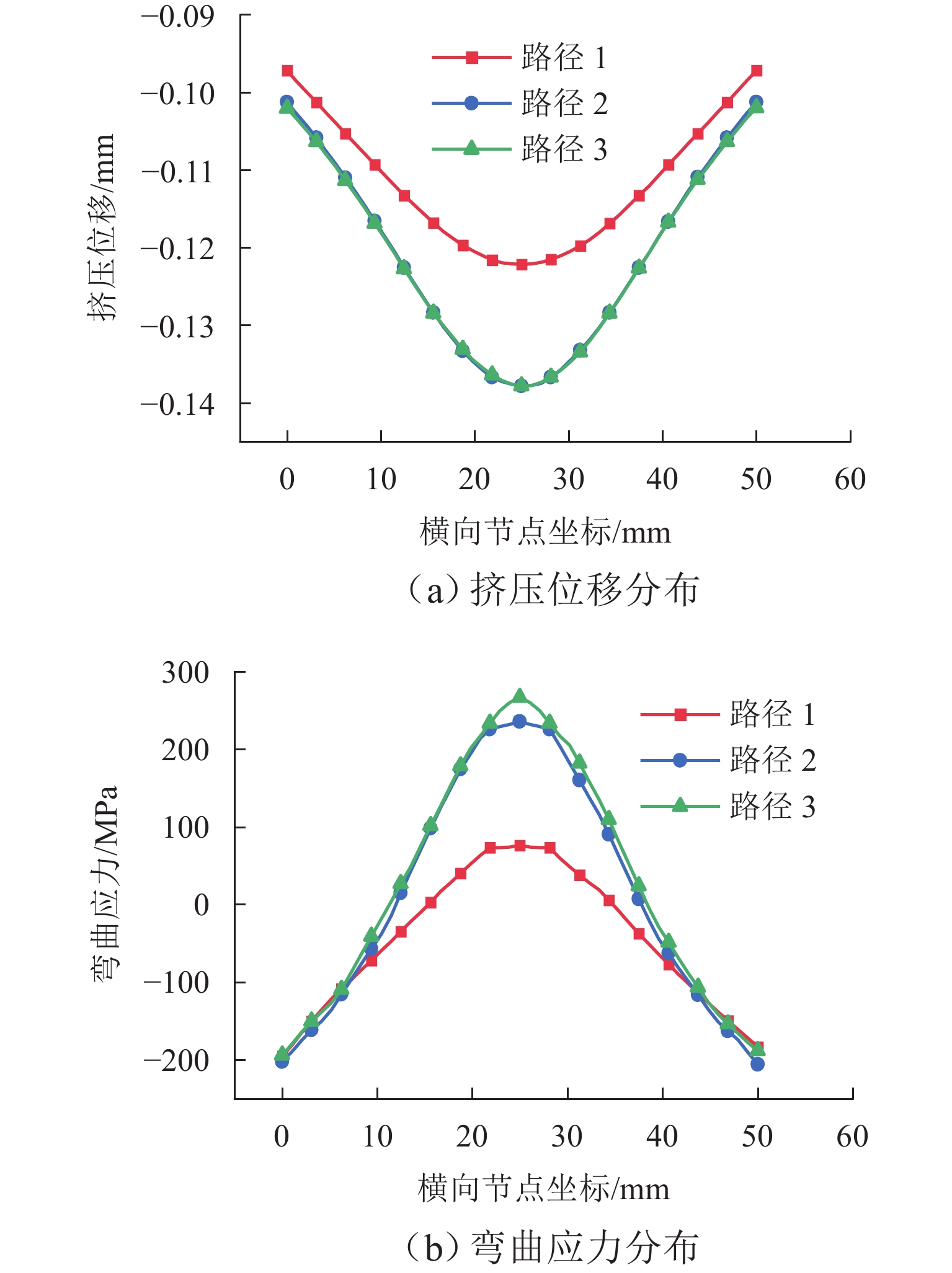

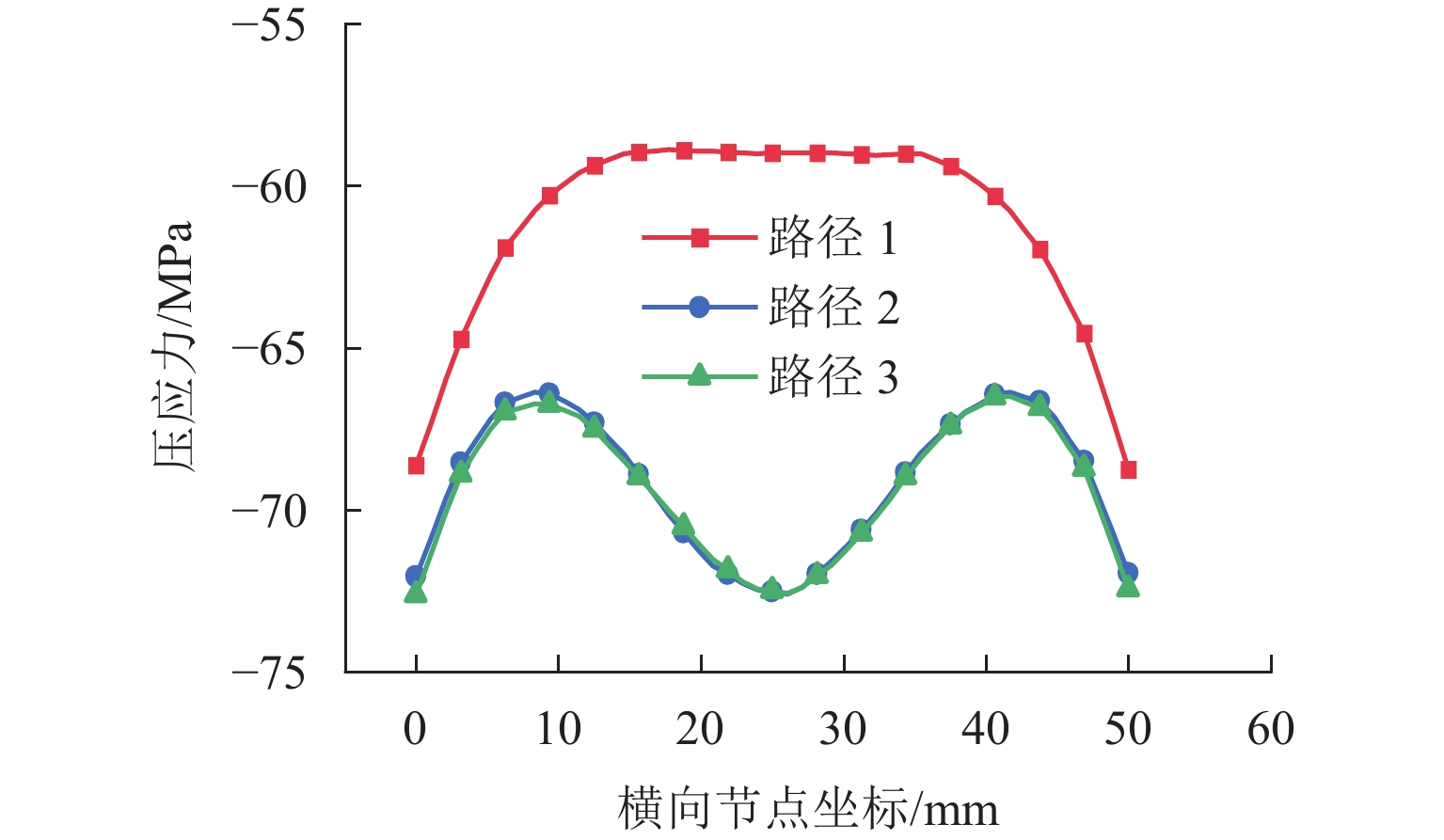

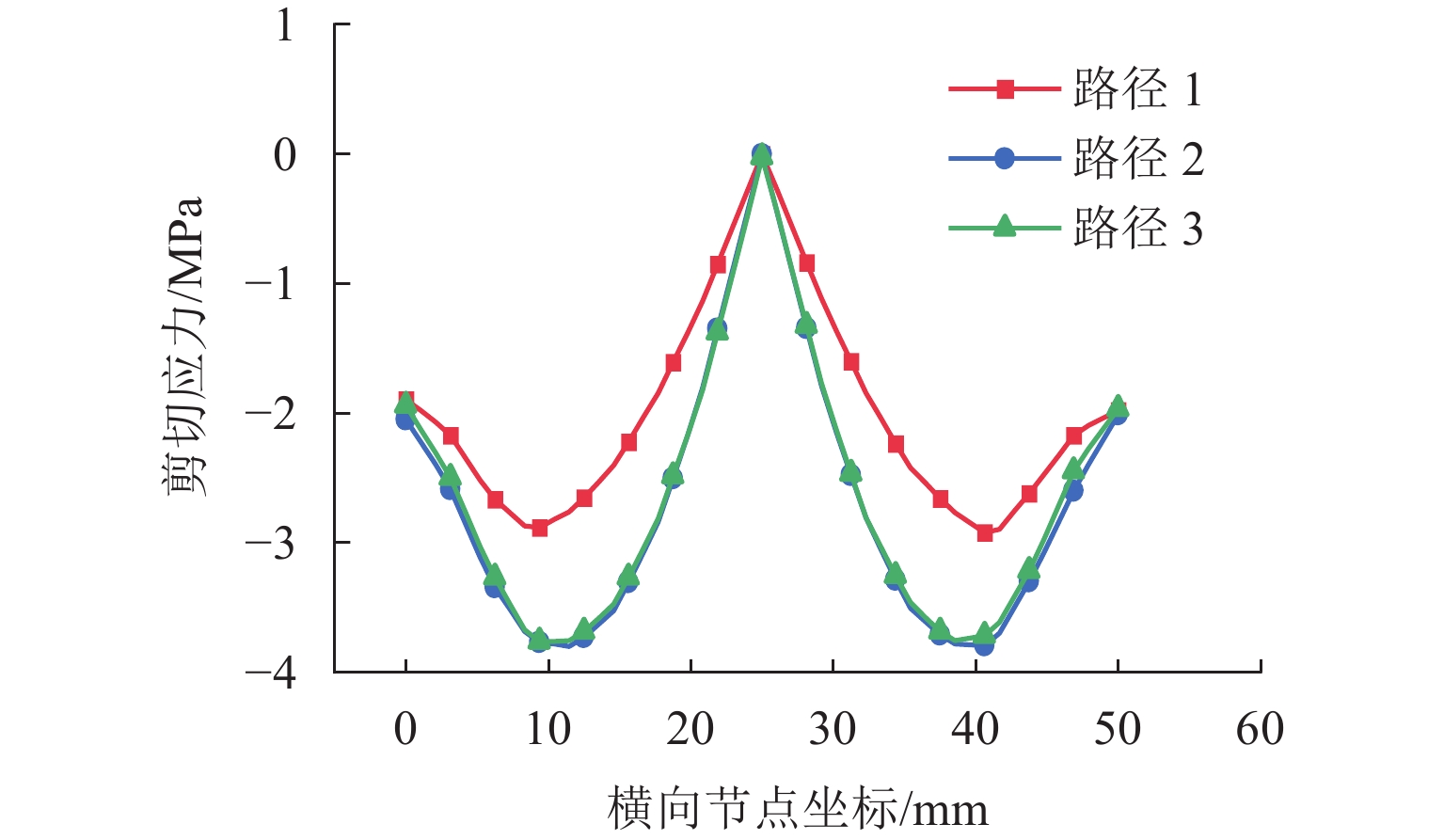

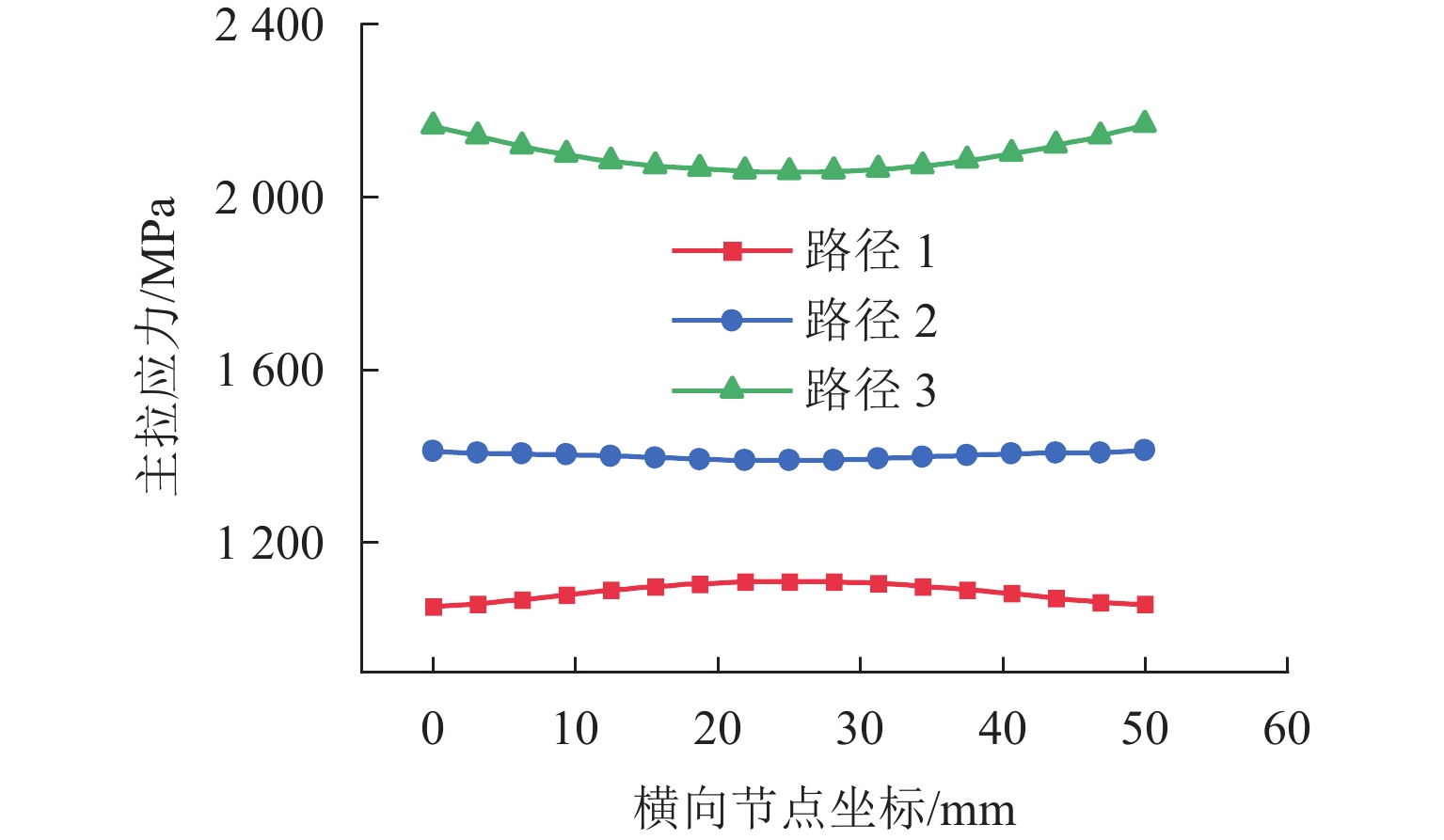

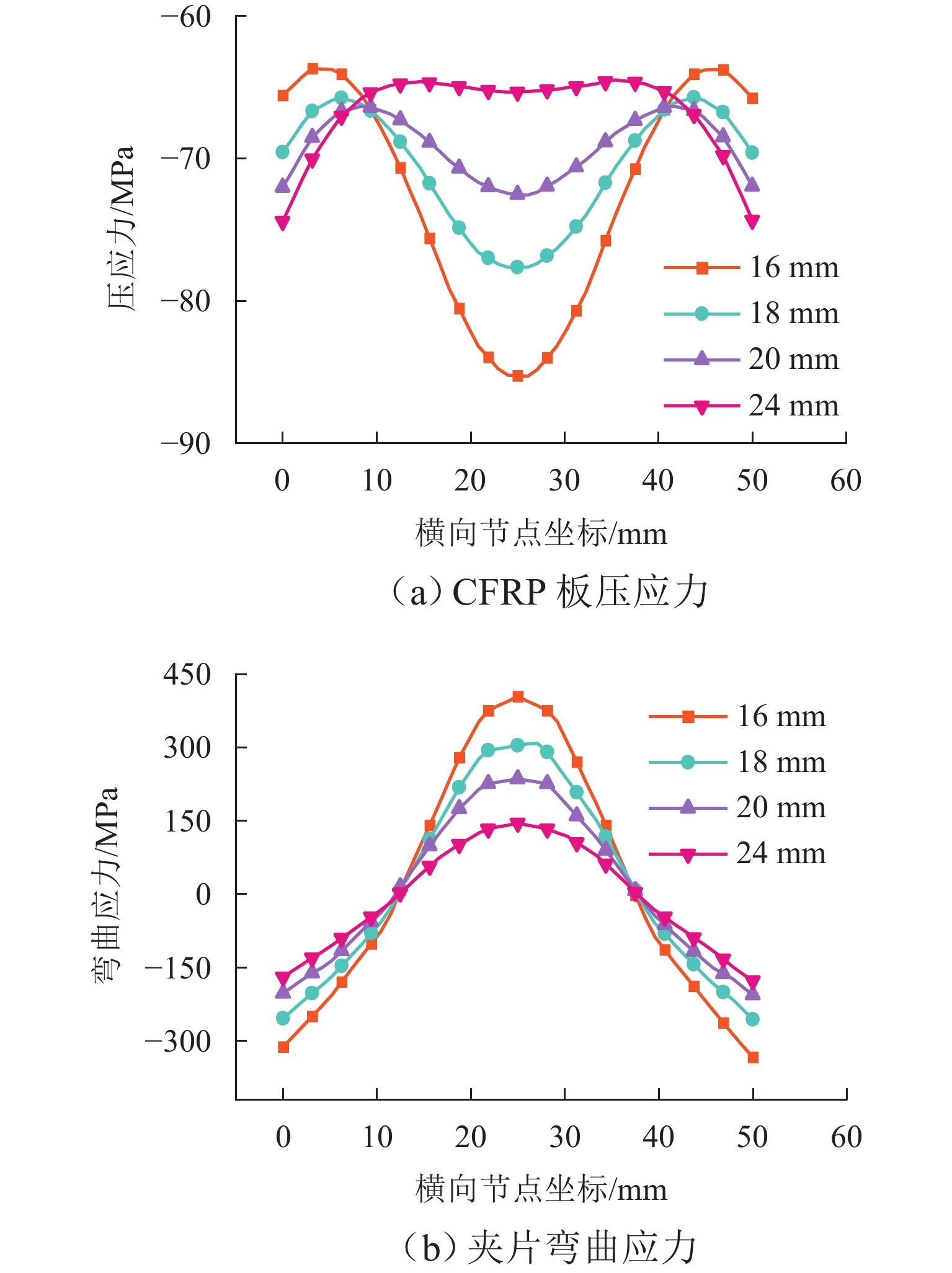

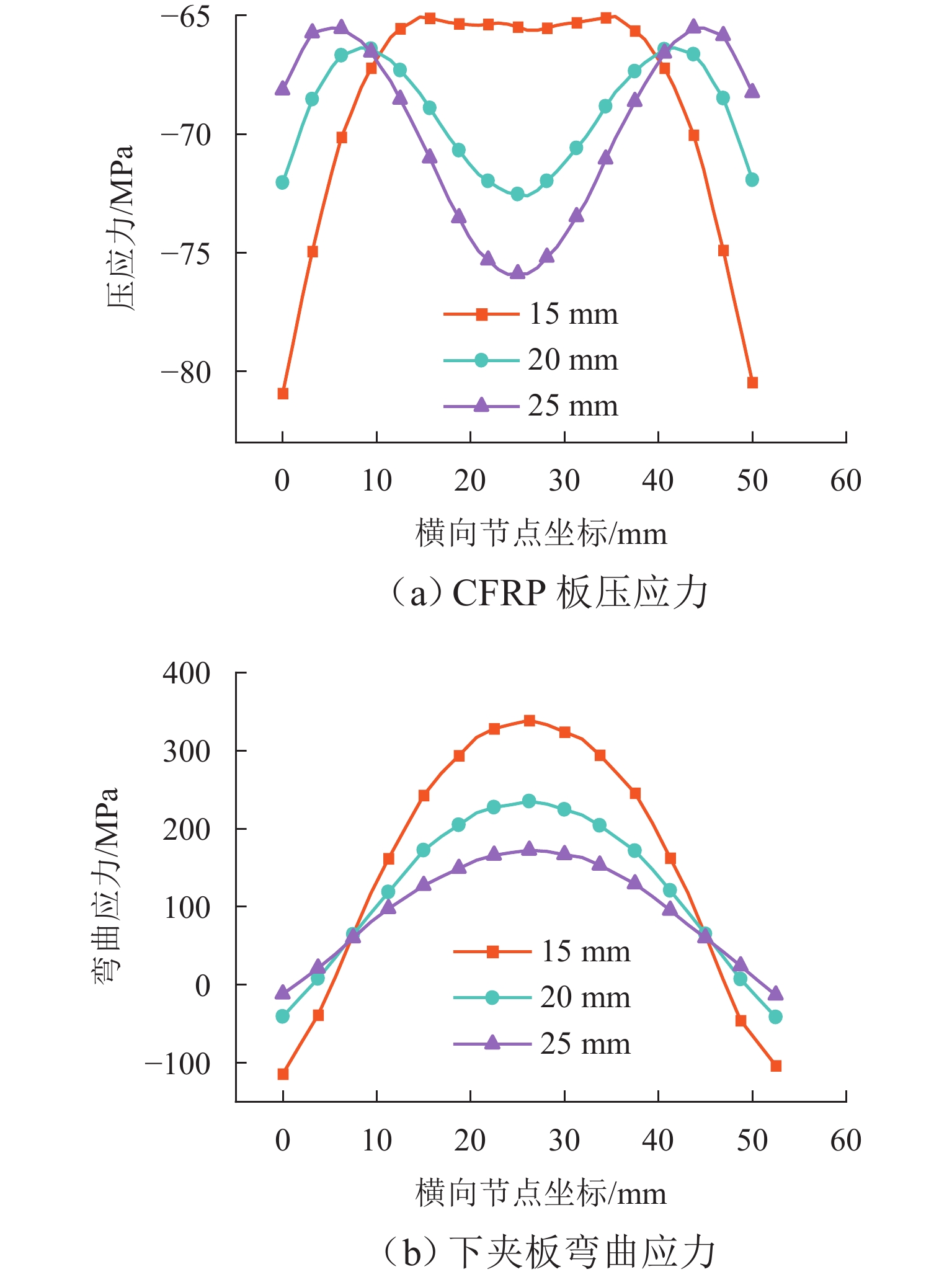

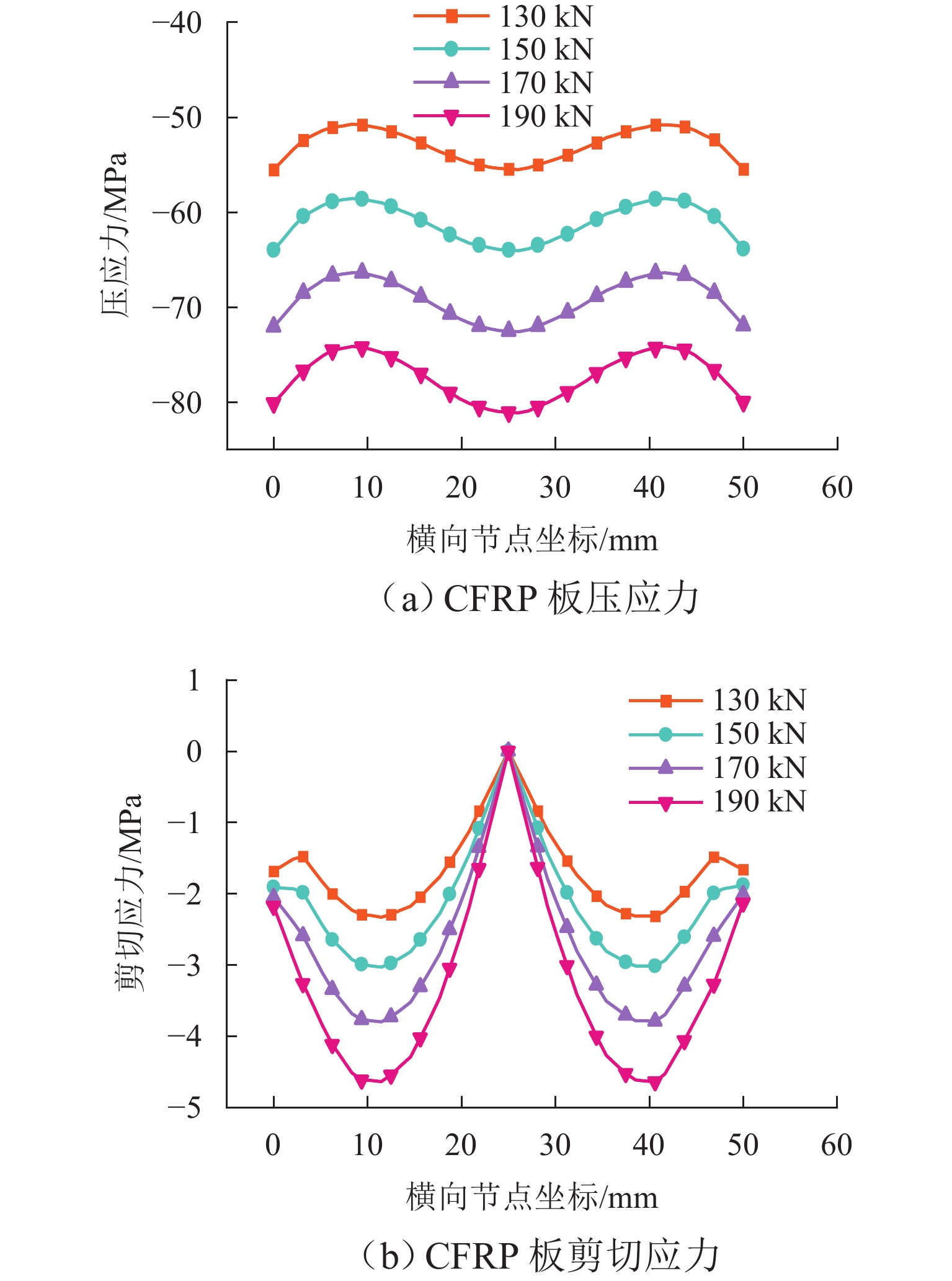

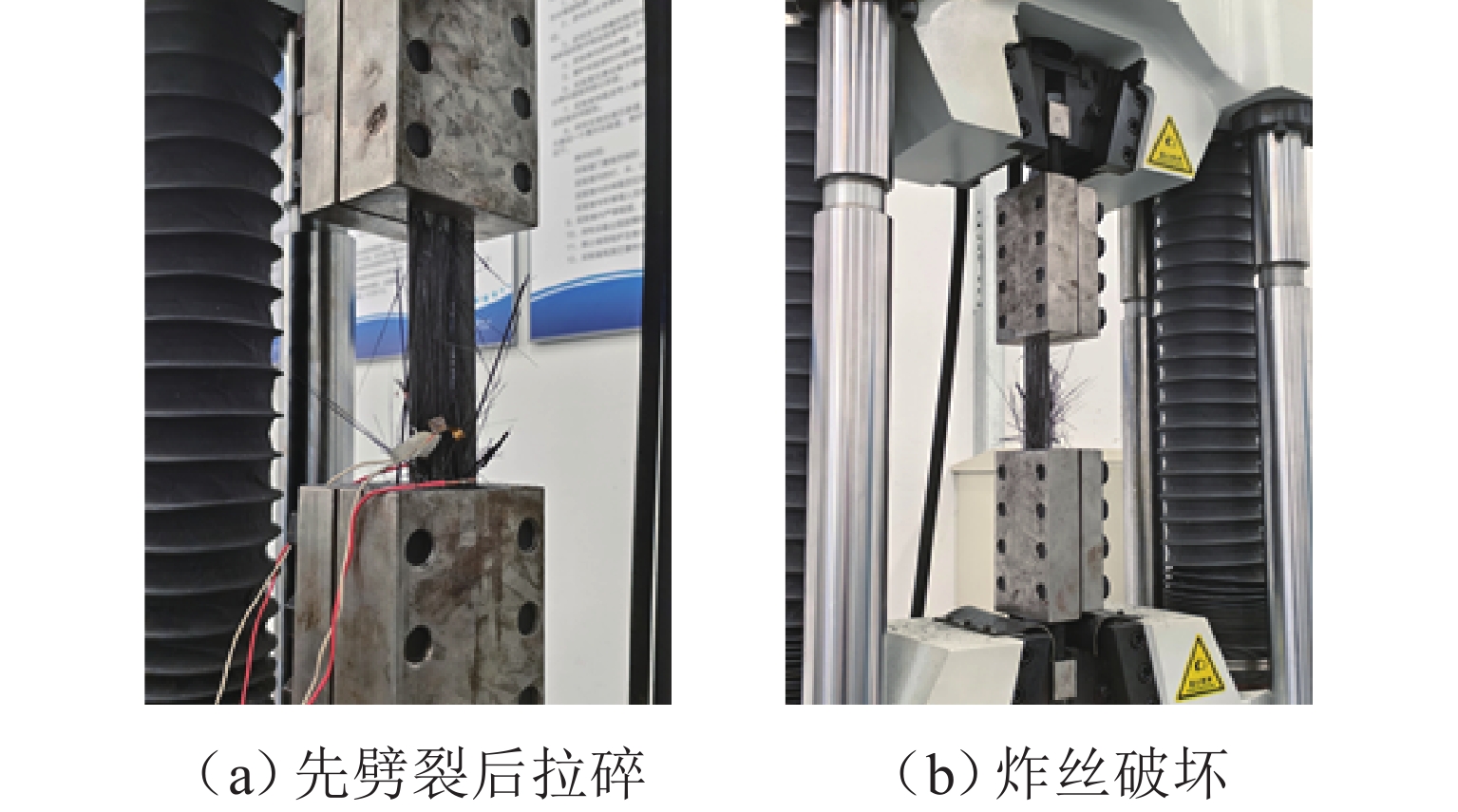

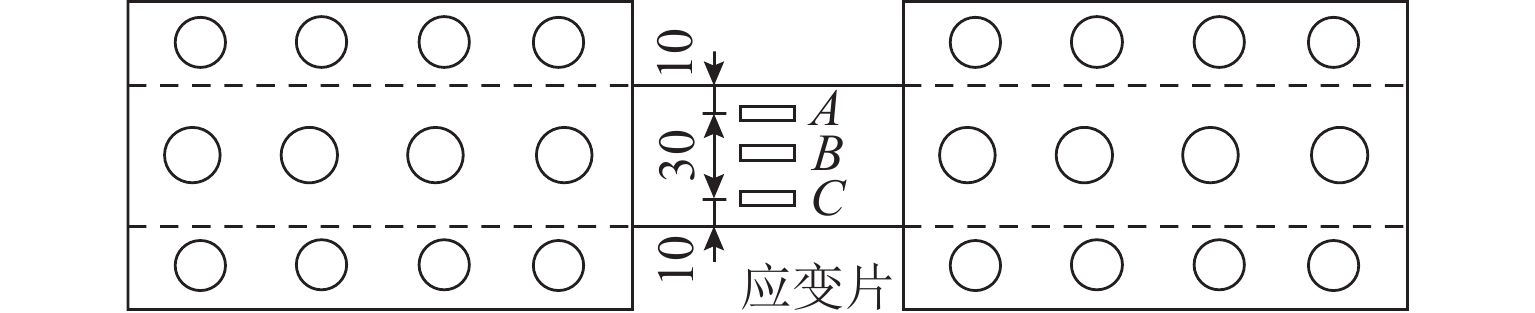

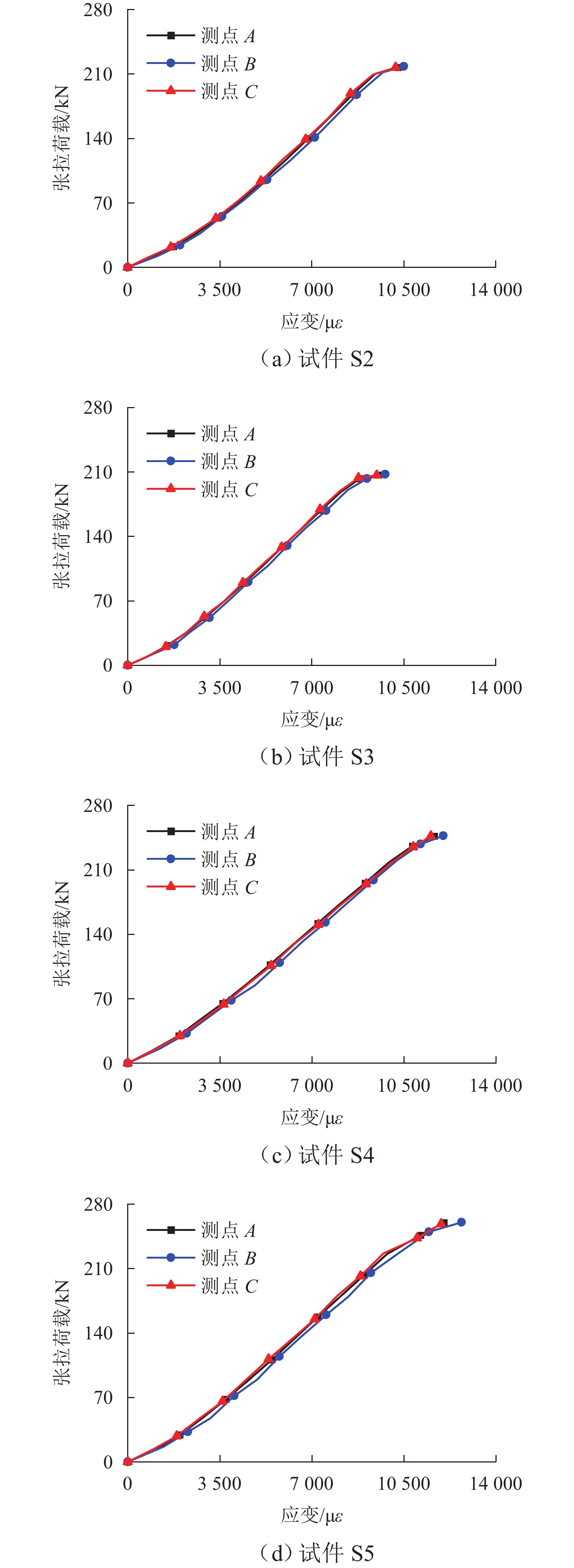

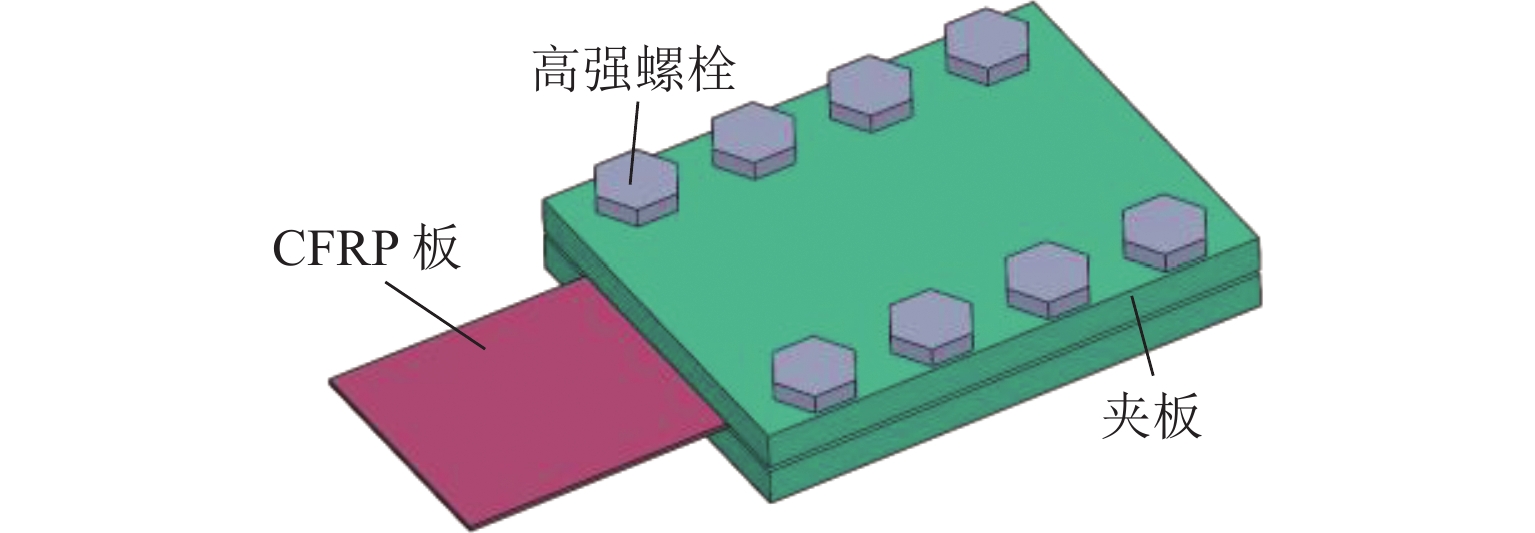

针对传统碳纤维增强复合材料(CFRP)板锚具压应力沿横向分布不均匀,导致张拉过程中板材易发生撕裂破坏的问题,研制了一种CFRP板新型夹持式锚具. 新型锚具在中轴线上布置预压螺栓,同时设定螺栓长度,通过控制螺栓的位移量对CFRP板施加定量的压紧力,分析新型锚具的受力机理;使用有限元软件ANSYS进行模拟,分析影响锚固性能的关键因素;对厚度为2 mm、宽度为50 mm的CFRP板进行静载张拉试验. 研究结果表明:1) 新型锚具的锚固性能与夹片厚度、外夹板厚度及螺栓预紧力密切相关;当夹片厚度为20 mm时,横向上CFRP板的压应力分布较均匀,最大与最小压应力之差仅为9.8 MPa;当上、下外夹板的厚度分别为30 mm和20 mm时,各构件的弯曲应力均保持在安全范围内;当螺栓预紧力为170 kN时,CFRP板的压应力水平显著提高,而剪切应力始终处于较低水平. 2) 在静载张拉试验中,新型锚具承受的最大张拉力为260.7 kN,锚固效率达到了108.63%;CFRP板的破坏形式为炸丝破坏,未出现撕裂等异常破坏形式,锚具的静载锚固性能优异.

Abstract:To address the problem of uneven transverse compressive stress distribution in traditional carbon fiber reinforced polymer (CFRP) plate anchors, which makes the plate prone to tearing failure during the tensioning process, a new clamping anchor for CFRP plates was developed. The new anchor features a preloaded bolt arranged along the central axis. By setting the bolt length and controlling its displacement, a quantified compressive force was applied to the CFRP plate, and the force mechanism of the new anchor was analyzed. Next, finite element software ANSYS was used for simulation, and the key factors affecting anchorage performance were analyzed. Finally, a static tensile test was performed on a CFRP plate with a thickness of 2 mm and a width of 50 mm. The results are as follows: 1) The anchorage performance of the new anchor is closely related to the clamp thickness, the outer clamp plate thicknesses, and the bolt preload force. When the clamp thickness is 20 mm, the transverse compressive stress distribution of the CFRP plate is relatively uniform, with a difference between the maximum and minimum compressive stresses of only 9.8 MPa. When the thicknesses of the upper and lower outer clamp plates are 30 mm and 20 mm, respectively, the bending stress of each component remains within a safe range. When the preload force of the bolt is 170 kN, the compressive stress level in the CFRP plate significantly increases, while the shear stress remains consistently low. 2) In the static tensile test, the new anchor withstands a maximum tensile force of 260.7 kN, achieving an anchoring efficiency of 108.63%. The failure mode of the CFRP plate is fiber rupture, with no tearing or other abnormal failure modes observed. The anchor demonstrates excellent static anchorage performance.

-

表 1 锚具各部件主要设计参数

Table 1. Main design parameters of anchor components

部件 设计参数/mm CFRP 板 横截面厚/宽 2/50 上夹板 长/宽/厚 180/110/30 下夹板 整体长/宽/厚 180/110/42 凹槽宽度 50 底部厚度 20 夹片 长/宽/厚 180/50/20 圆槽厚度 3 表 2 CFRP板材料性能

Table 2. Material properties of CFRP plate

CFRP 尺寸/mm 极限抗拉

强度/MPa极限承

载力/kN弹性模

量/GPa极限延

伸率/%厚 宽 2 50 2400 240 160 1.5 表 3 钢材材料性能

Table 3. Material properties of steel

材质 抗拉强

度/MPa屈服强

度/MPa弹性模

量/GPa泊松比 Q355B 600 355 206 0.32 表 4 螺栓材料性能

Table 4. Material properties of bolt

螺栓等级 公称直

径/mm抗拉强

度/MPa屈服强

度/MPa屈强比 12.9 20 1200 1080 0.9 表 5 静载张拉试验结果汇总

Table 5. Summary of static load tension test results

试件

编号理论最大

承载力/kN实际最大

承载力/kN锚固

效率/%CFRP 板最终

破坏形式S1 240 213.22 88.84 先劈裂后拉碎 S2 240 218.37 90.99 先劈裂后拉碎 S3 240 207.65 86.52 先劈裂后拉碎 S4 240 246.90 102.88 炸丝破坏 S5 240 260.70 108.63 炸丝破坏 S6 240 240.63 100.26 炸丝破坏 S7 240 249.38 103.91 炸丝破坏 S8 240 242.53 101.05 炸丝破坏 -

[1] 《中国公路学报》编辑部. 中国桥梁工程学术研究综述•2021[J]. 中国公路学报, 2021, 34(2): 1-97. doi: 10.3969/j.issn.1001-7372.2021.02.002Editorial Department of China Journal of Highway and Transport. Review on China’s bridge engineering research: 2021[J]. China Journal of Highway and Transport, 2021, 34(2): 1-97. doi: 10.3969/j.issn.1001-7372.2021.02.002 [2] 梅葵花, 王凤轩, 孙胜江. 纤维增强复合材料加固混凝土桥梁结构研究进展[J]. 建筑科学与工程学报, 2024, 41(1): 31-51.MEI Kuihua, WANG Fengxuan, SUN Shengjiang. Research progress of fiber reinforced polymer in strengthening concrete bridge structure[J]. Journal of Architecture and Civil Engineering, 2024, 41(1): 31-51. [3] 王海涛, 朱长玉, 熊浩, 等. 锚固方法和预应力水平对CFRP板加固钢筋混凝土梁抗弯性能的影响[J]. 河海大学学报(自然科学版), 2023, 51(5): 104-110. doi: 10.3876/j.issn.1000-1980.2023.05.014WANG Haitao, ZHU Changyu, XIONG Hao, et al. Effects of anchorage method and prestressing level on flexural behavior of reinforced concrete beams strengthened with CFRP plates[J]. Journal of Hohai University (Natural Sciences), 2023, 51(5): 104-110. doi: 10.3876/j.issn.1000-1980.2023.05.014 [4] WANG H T, BIAN Z N, WU Q, et al. Development of a novel anchorage and tensioning system for strengthening steel beams with unbonded prestressed CFRP plates[J]. Engineering Structures, 2024, 312: 118234. doi: 10.1016/j.engstruct.2024.118234 [5] MOHEE F M, AL-MAYAH A, PLUMTREE A. Anchors for CFRP plates: State-of-the-art review and future potential[J]. Composites Part B: Engineering, 2016, 90: 432-442. doi: 10.1016/j.compositesb.2016.01.011 [6] YE H W, WU C J, LIU D J, et al. Friction and wear behavior of CFRP plate in contact with roughened mould steel under high normal pressure[J]. Construction and Building Materials, 2019, 220: 308-319. doi: 10.1016/j.conbuildmat.2019.06.007 [7] DUO Y Y, YANG Y, LIU X G, et al. Experimental investigation on the friction behavior of CFRP plate in contact with sandblasted steel plate[J]. Structures, 2023, 55: 2491-2503. doi: 10.1016/j.istruc.2023.06.073 [8] 诸葛萍, 强士中, 侯苏伟. 碳纤维筋夹片式锚具参数试验研究[J]. 西南交通大学学报, 2010, 45(4): 514-520. doi: 10.3969/j.issn.0258-2724.2010.04.005ZHUGE Ping, QIANG Shizhong, HOU Suwei. Experimental investigation of wedge-anchor parameters for CFRP tendons[J]. Journal of Southwest Jiaotong University, 2010, 45(4): 514-520. doi: 10.3969/j.issn.0258-2724.2010.04.005 [9] 吴刚. 预应力碳纤维板楔形夹片式锚具的受力仿真分析与优化[D]. 南昌: 南昌大学, 2021. [10] 储焙宇, 钱登朝, 诸葛萍, 等. 预应力CFRP板平板锚具承载力评估理论与试验研究[J]. 宁波大学学报(理工版), 2020, 33(4): 41-48. doi: 10.3969/j.issn.1001-5132.2020.04.008CHU Beiyu, QIAN Dengchao, ZHUGE Ping, et al. Theoretical and experimental study on load-carrying capacity evaluation of CFRP plates bond-type anchors[J]. Journal of Ningbo University (Natural Science & Engineering Edition), 2020, 33(4): 41-48. doi: 10.3969/j.issn.1001-5132.2020.04.008 [11] 许颢迈. CFRP板新型夹持式锚固系统性能研究[D]. 北京: 北京建筑大学, 2019. [12] KIANMOFRAD F, GHAFOORI E, ELYASI M M, et al. Strengthening of metallic beams with different types of pre-stressed un-bonded retrofit systems[J]. Composite Structures, 2017, 159: 81-95. doi: 10.1016/j.compstruct.2016.09.020 [13] MOHEE F M, AL-MAYAH A, PLUMTREE A. Friction characteristics of CFRP plates in contact with copper plates under high contact pressure[J]. Journal of Composites for Construction, 2016, 20(5): 04016022. doi: 10.1061/(ASCE)CC.1943-5614.0000673 [14] MOHEE F M, AL-MAYAH A. Development of an innovative prestressing CFRP plate anchor: numerical modelling and parametric study[J]. Composite Structures, 2017, 177: 1-12. doi: 10.1016/j.compstruct.2016.12.039 [15] MOHEE F M, AL-MAYAH A, PLUMTREE A. Development of a novel prestressing anchor for CFRP plates: experimental investigations[J]. Composite Structures, 2017, 176: 20-32. doi: 10.1016/j.compstruct.2017.05.011 [16] YE H W, LIU C M, HOU S W, et al. Design and experimental analysis of a novel wedge anchor for prestressed CFRP plates using pre-tensioned bolts[J]. Composite Structures, 2018, 206: 313-325. doi: 10.1016/j.compstruct.2018.08.075 [17] YE H W, ZHANG Q, LIU C M, et al. Failure mechanisms governing anchoring force of friction-based wedge anchorage for prestressed CFRP plate[J]. Composite Structures, 2019, 225: 111142. doi: 10.1016/j.compstruct.2019.111142 [18] DUO Y Y, QI L G, HUANG S D, et al. Planar clamping anchorage for CFRP plate: experimental research, friction-adhesion synergistic mechanism and theoretical model[J]. Construction and Building Materials, 2024, 441: 137540. doi: 10.1016/j.conbuildmat.2024.137540 [19] 齐艺佳, 肖丹, 王中强. 夹片外伸式CFRP板锚具设计优化与试验研究[J/OL]. 中外公路, 2024[2024-06-17]. https://link.cnki.net/urlid/43.1363.U.20240614.1746.013. [20] 龙佩恒, 史文浩, 侯苏伟, 等. 基于位移控制CFRP板新型锚具锚固性能研究[J]. 中国公路学报, 2021, 34(5): 76-85.LONG Peiheng, SHI Wenhao, HOU Suwei, et al. Anchorage performance of a new carbon fiber board anchor based on displacement control[J]. China Journal of Highway and Transport, 2021, 34(5): 76-85. [21] 姜艳. 双曲面CFRP板锚具性能研究[D]. 北京: 北京建筑大学, 2023. [22] 中华人民共和国交通运输部. 桥梁用预应力碳纤维板-夹持式锚具: JT/T 1267—2019[S]. 北京: 人民交通出版社, 2019. -

下载:

下载: