Vibration Characteristics of Riser Induced by Gas-Liquid-Solid Three-Phase Flow in Deep-Sea Hydrate Extraction Under VIV Effect

-

摘要:

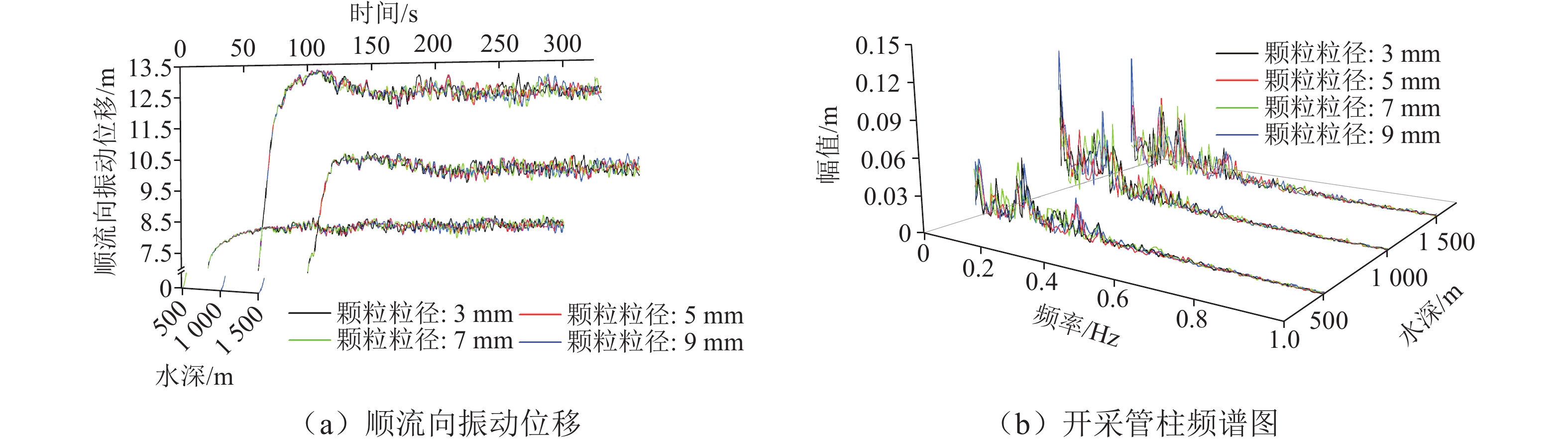

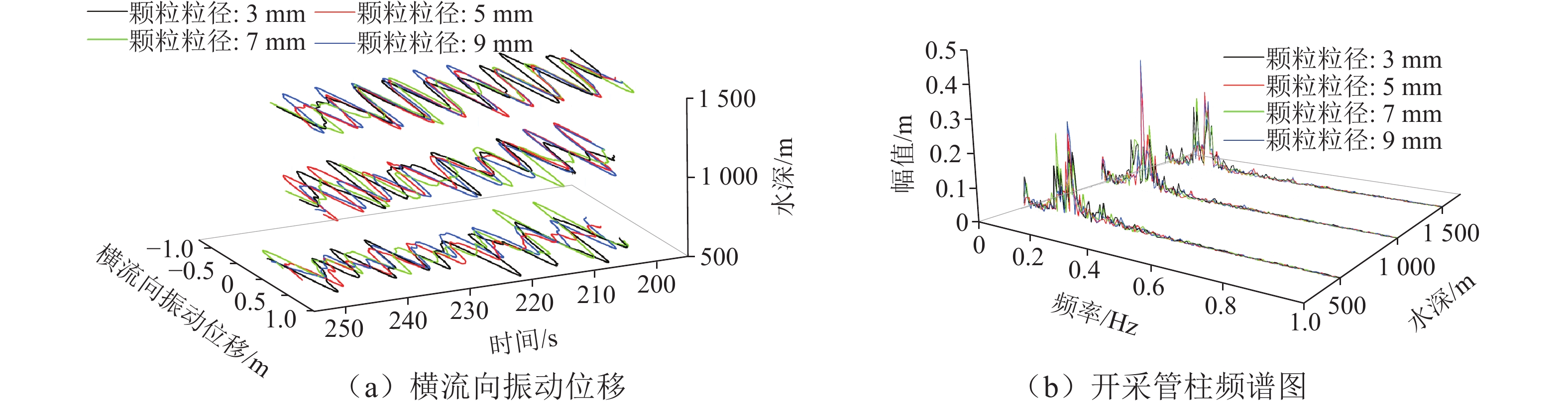

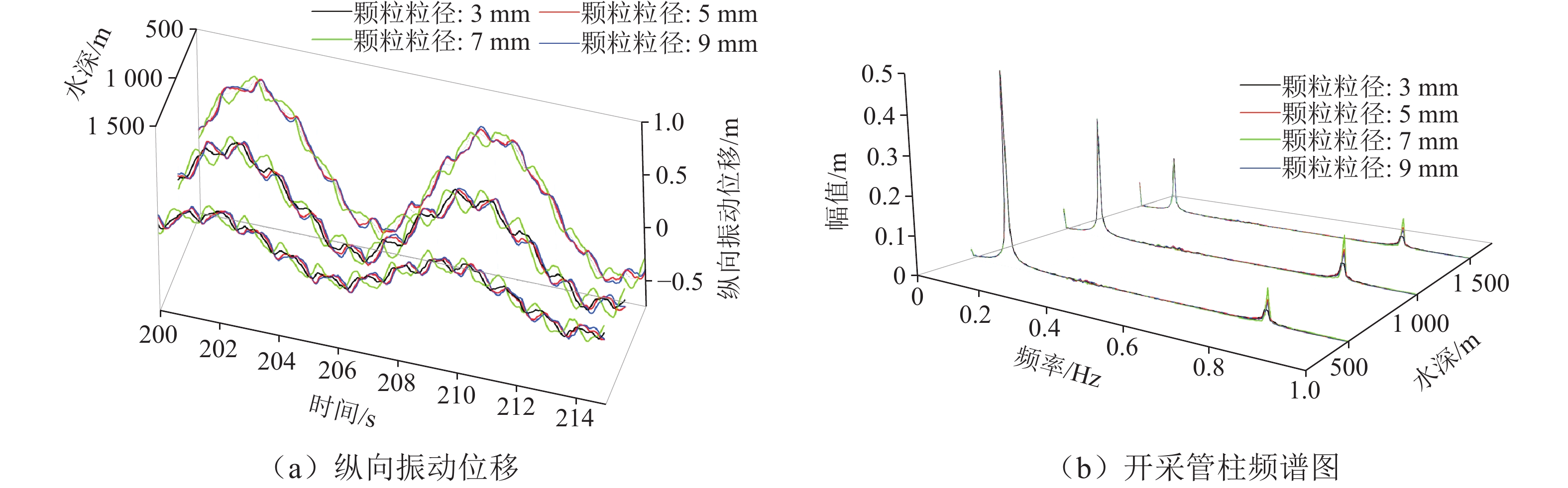

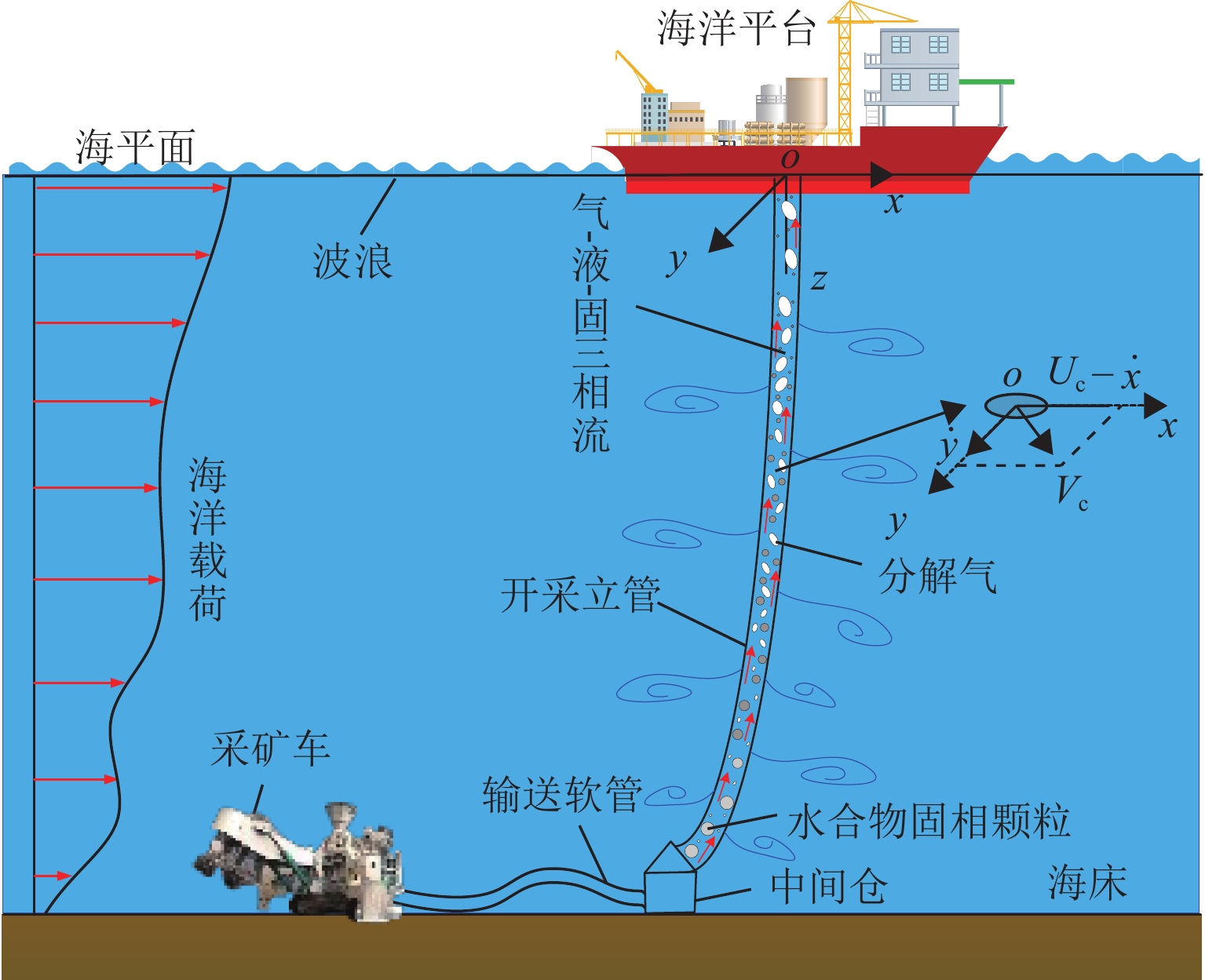

为研究深海水合物开采立管由内部气-液-固三相流和外部海洋载荷耦合作用下非线性振动失效问题,首先,采用有限元法、哈密顿原理和能量法建立深海水合物开采立管气-液-固三相流致振动模型,该模型考虑了海洋涡激效应、气-液-固三相流致效应、水合物动态分解以及海洋平台升沉等多因素的联合作用;其次,采用相似原理研制内外流激励下开采管柱非线性振动模拟实验装置,验证非线性振动模型的正确性;最后,利用频域和时域分析方法探讨外部环境参数和多相流参数对立管非线性振动响应的影响规律. 研究结果表明:立管的横流向振动幅值比顺流向振动幅值更高,同时内流参数的变化对横流向振动的影响更显著;立管纵向振动由重力与平台升沉导致的低频高幅振动和内外流场载荷诱发的高频低幅振动组成;剪切流流速的增大会大幅增加立管的顺流向位移,从而抑制立管的横流向振动;内流排量和水合物丰度的增大会增强内流对立管的激励作用,使其振动更加剧烈;水合物粒径的增大会减弱内流对立管的激励作用,使其顺流向振动幅值减小;当剪切流流速达到1.4 m/s,水合物丰度达到80%以及水合物粒径达到7 mm时,立管将产生共振现象,振动幅度显著增强.

Abstract:Objective Natural gas hydrate, as a low-carbon unconventional energy source, is increasingly receiving attention from the scientific community. It is considered the most promising alternative energy source in the 21st century. At present, the extraction of deep-sea hydrates is mainly carried out through riser transportation. Due to the state instability of the hydrate, it is easy to decompose during migration, forming a typical vibration phenomenon induced by gas-liquid-solid three-phase flow, which can easily lead to nonlinear vibration of the riser. This nonlinear vibration mechanism is completely different from the vibration mechanisms induced by single-phase and two-phase flows. It is particularly important to reveal the vibration mechanism of the riser in gas-liquid-solid three-phase flow.

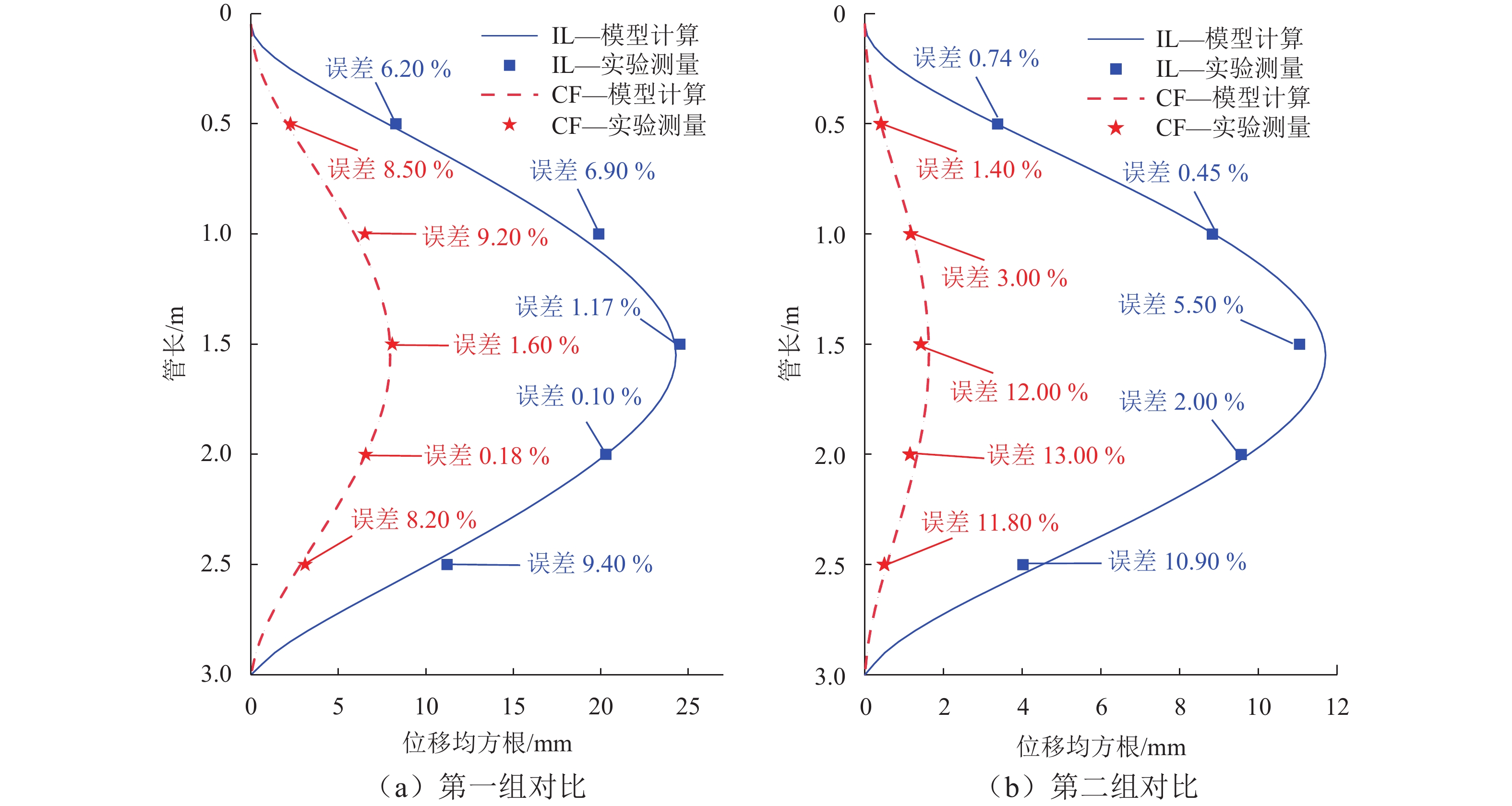

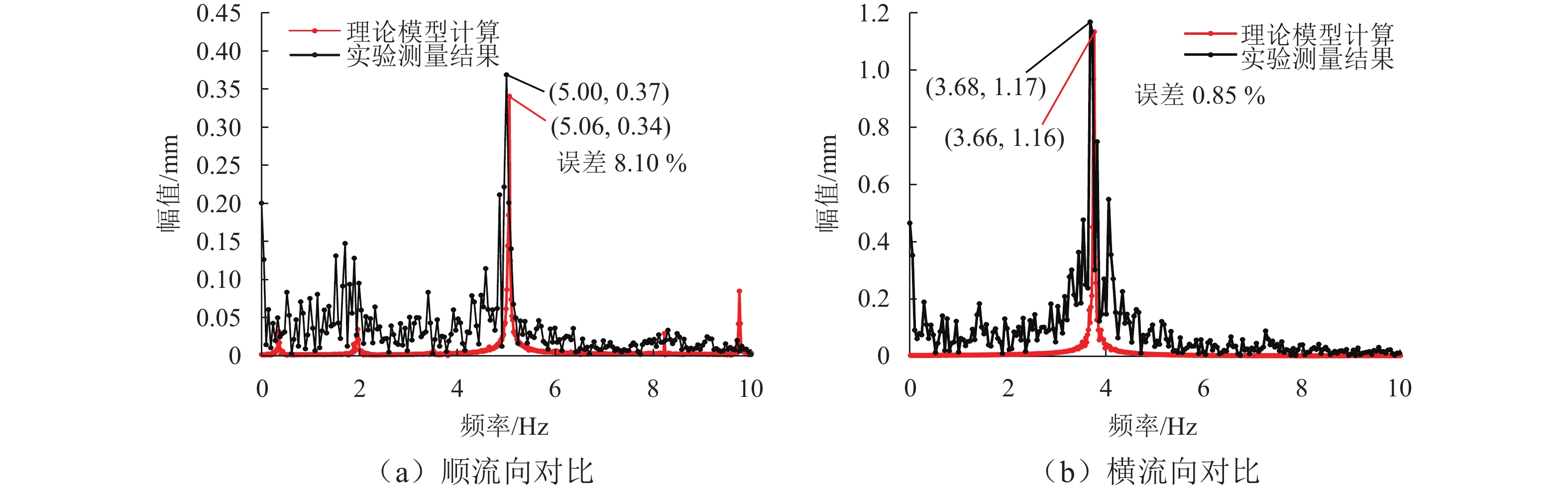

Method Due to external ocean loads during the process of mining riser operations, it is easy to cause vortex-induced vibrations (VIV). The riser was subjected to the action of internal gas-liquid-solid three-phase flow of hydrate. Moreover, the upper end of the riser was subjected to the heave motion of the ocean platform. These factors require the use of multiple methods in combination for the nonlinear vibration model of the riser. Therefore, the gas-liquid-solid three-phase FIV model for deep-sea hydrate extraction riser was established using the finite element method, Hamiltonian principle, and energy method. The fluid structure coupling effect between ocean flow field and mining riser was achieved through the wake oscillator model. The coupling effect between internal multiphase flow and mining riser was achieved through additional mass, collision energy loss, and flow velocity changes. Simultaneously, a dynamic decomposition model for hydrates was established to identify changes in the content of gas, solid, and liquid phases. The platform was prone to six degrees of freedom motion under the action of wind, waves, and currents. However, during the process of hydrate extraction, the platform was most prone to heave movement. With the help of previous research, a platform heave motion model was established, which can effectively obtain the displacement boundary of the upper end of the mining riser. Then, in order to achieve a numerical solution of the model, the vibration model was solved using the combined iterative method of the incrementally applied Newmark-

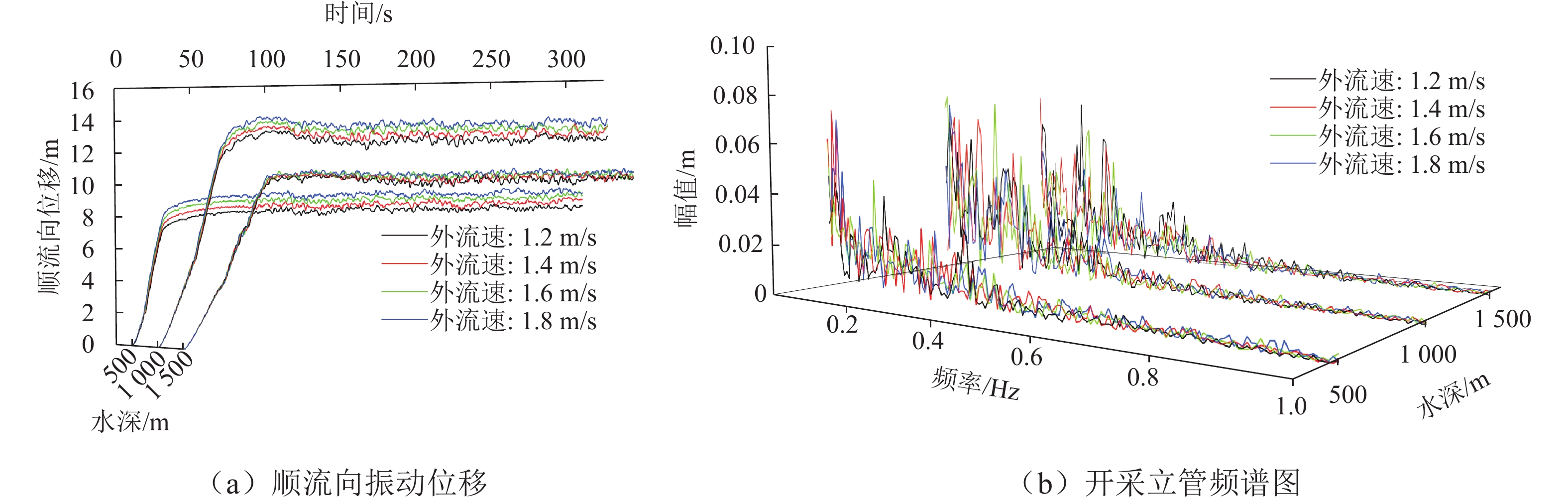

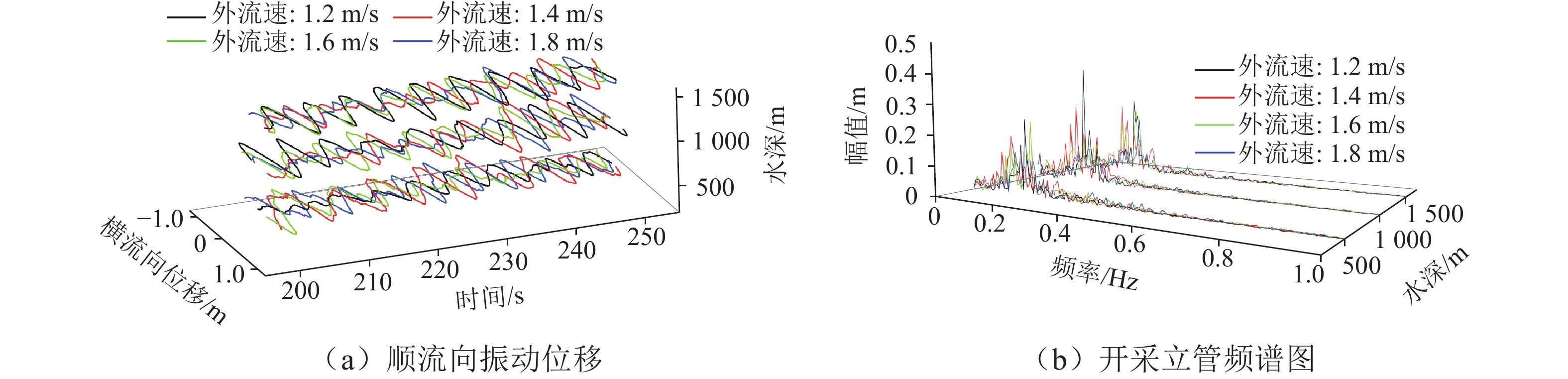

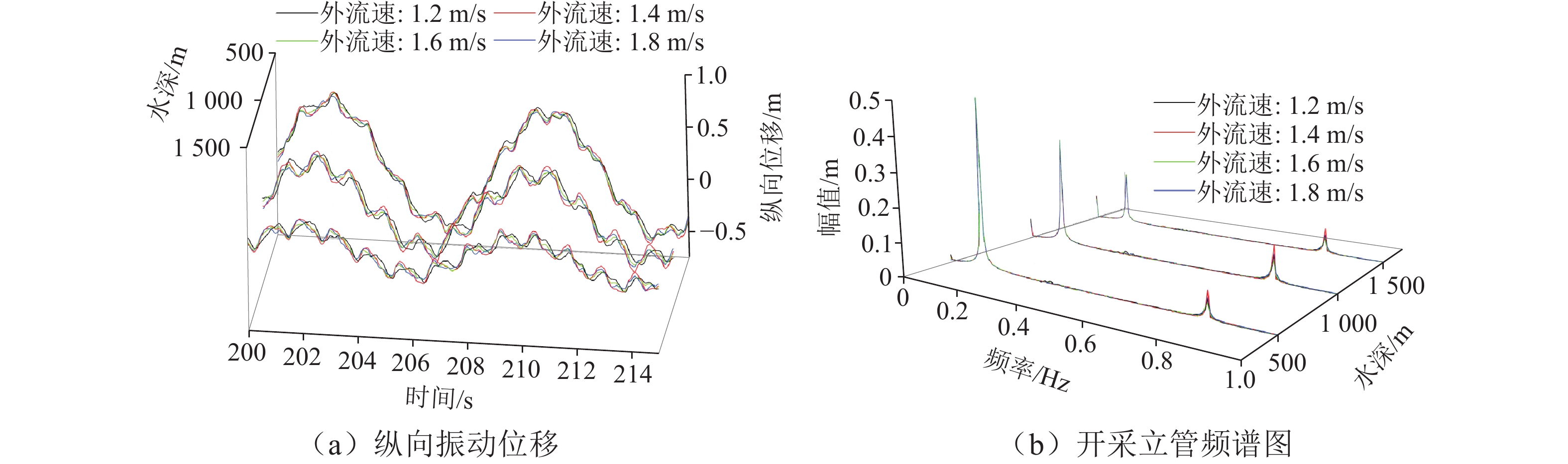

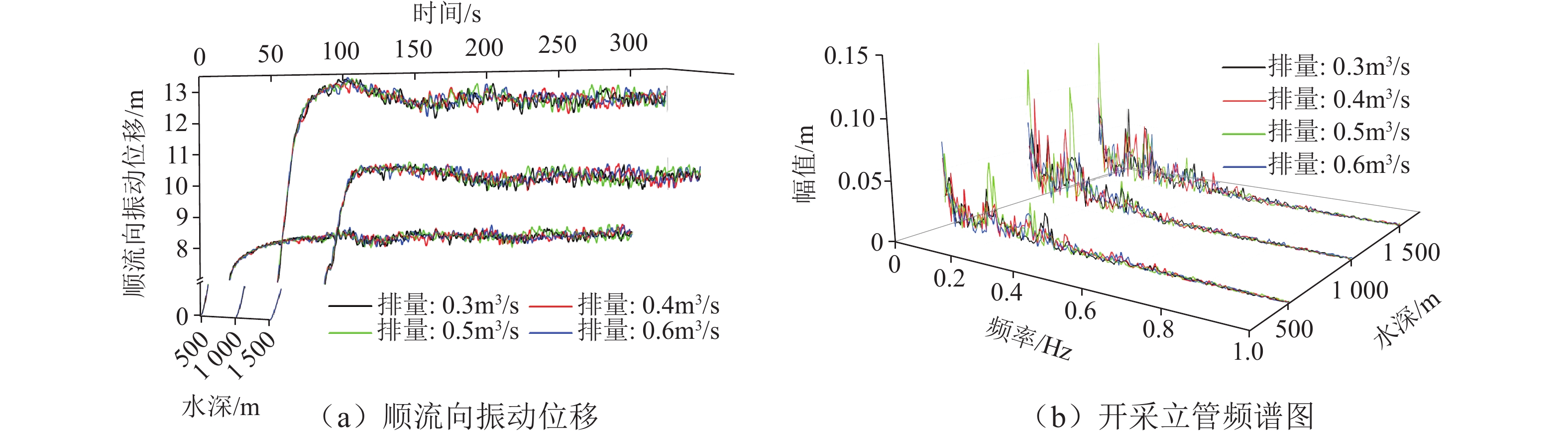

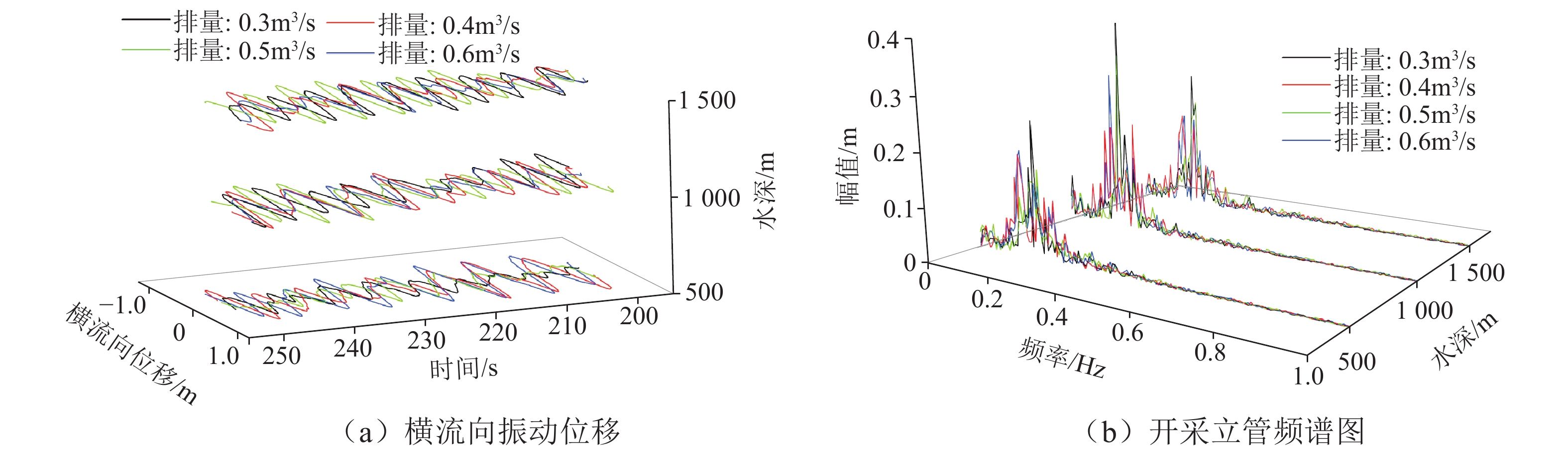

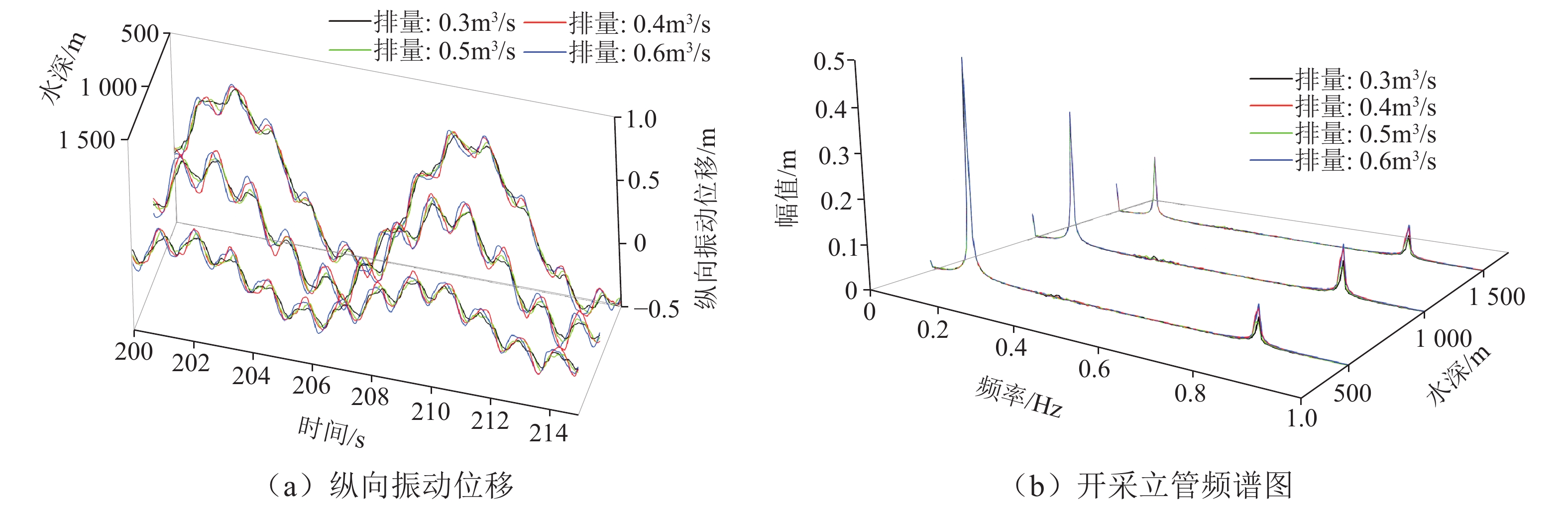

β method and Newton-Raphson method, obtaining the vibration response of the mining riser. Due to the excessive consideration of nonlinear factors in the model, the correctness and effectiveness of its numerical solution need to be rigorously verified. However, the actual vibration data on site could not be obtained. The simulation experiment of the water tank was particularly important. Therefore, by using the principle of similarity, a nonlinear vibration simulation experiment system for a hydrate mining riser under internal and external flow excitation was developed. The root mean square of the vibration displacement and amplitude frequency curves of the mining riser were experimentally measured. At the same time, the calculation parameters of the theoretical model were set exactly the same as the experimental parameters to compare the theoretical calculation results and the experimental test results. On this basis, the root mean square of the vibration displacement and the amplitude frequency curve of the mining riser were calculated. Comparing the experimental results with the model calculation results, the correctness of the established model was verified, and the comparison accuracy could be higher than 90%. By using frequency domain and time domain analysis methods, the influence of external environmental parameters and multiphase flow parameters on the nonlinear FIV response of the riser was explored.Result The results show that the vibration amplitude of the riser in the cross-flow (CF) direction is higher than that in the in-line flow (IL) direction, and the variation of internal flow parameters has a more significant impact on the CF vibration of the riser. This phenomenon indicates a close relationship between the internal gas-liquid-solid three-phase flow and the vortex-induced effect. The axial vibration of the riser mainly consists of two parts: One part is dominated by gravity and platform heave motion, exhibiting low-frequency and high-amplitude vibration characteristics, which may cause the strength failure of the riser. The other part is induced by internal and external flow field loads, exhibiting high-frequency and low-amplitude vibration characteristics, which may accelerate the fatigue failure of the riser. With the shear flow velocity increases, the displacement of the riser in the IL direction gradually increases, and the axial second-order main frequency amplitude increases accordingly. However, in the CF direction, the amplitude and root mean square of displacement show a decreasing trend, indicating that the increase in displacement in the IL direction has a certain inhibitory effect on the CF vibration. With the increase of internal output volume, the flow velocity of each phase increases, resulting in an increase in displacement and amplitude of the riser in the IL direction, as well as an increase in amplitude in the CF direction. This widens the frequency band, expands the displacement envelope range, and reduces the number of modes in the CF direction. As the particle size of hydrates increases, the solid-phase flow velocity decreases, and the collision energy loss increases, resulting in a decrease in the vibration amplitude of the riser in the IL direction, a narrowing of the vibration frequency band, and an increase in amplitude in the CF direction. The characteristic of more concentrated energy makes it possible to control it more effectively in the future. When the shear flow velocity reaches 1.4 m/s, the hydrate abundance reaches 80%, or the hydrate particle size reaches 7 mm, the vibration amplitude of the riser in two or three directions will significantly increase, and the vibration response of the riser will not change with the variation of other parameter values. At these specific values, the frequency of the interaction between the internal and external fluids on the riser tends to approach the natural frequency of the riser system, resulting in resonance phenomena. In the actual operation process, these parameter values should be avoided to ensure the safety and stability of the riser.

Conclusion Once commercial exploitation of deep-sea hydrates is achieved, the nonlinear vibration model of deep-sea hydrate mining riser can effectively guide the parameter configuration in the later hydrate mining process. It can evaluate the safety and service life of deep-sea hydrate mining risers, ensuring the safe operation of commercial mining cycles of hydrate.

-

表 1 立管实际与实验参数对比表

Table 1. Comparison of actual and experimental parameters of riser

参数 长度/

m外径/

m内径/

m材料

类型密度/

(kg•m−3)弹性模量/

GPa实际值 2000 0.440 0.400 13Cr-L80 7850 207.0 实验值 3 0.022 0.020 PVC 1600 2.1 表 2 变量实际与实验参数对比

Table 2. Comparison of actual variables and experimental parameters

表 3 水合物颗粒实际参数与实验参数对比表

Table 3. Comparison of actual and experimental parameters of hydrate particles

参数 直径/m 材料类型 密度(kg•m−3) 实际值 6 × 10−3 ~ 40 × 10−3 天然气水合物颗粒 880 ~ 1350 实验值 10目、20目、30目40目(1.7 × 10−3、8.3 × 10−4、5.5 × 10−4、3.8 × 10−4) 橡胶颗粒 900 表 4 立管系统模型基本参数

Table 4. Basic parameters of riser system model

参数 数值 参数 数值 管长/m 2000 平台升沉周期

与幅值8-1.448 外径/m 0.44 海水密度/

(kg•m−3)1025 壁厚/m 0.02 结构阻尼系数 0.01 管柱密度/

(kg•m−3)7850 斯特劳哈尔系数 0.2 弹性模量/GPa 207 水合物密度/

(kg•m−3)900 顶张力/kN 571.438 内流排量/

(m3•s−1)0.3 剪切流流速/

(m•s−1)0.15 ~ 1.35 井口回压/MPa 0.1 水合物颗粒

直径/mm5 水合物丰度 70% -

[1] 周守为, 陈伟, 李清平. 深水浅层天然气水合物固态流化绿色开采技术[J]. 中国海上油气, 2014, 26(5): 1-7.ZHOU Shouwei, CHEN Wei, LI Qingping. The green solid fluidization development principle of natural gas hydrate stored in shallow layers of deep water[J]. China Offshore Oil and Gas, 2014, 26(5): 1-7. [2] KAEWUNRUEN S, CHIRAVATCHRADEJ J, CHUCHEEPSAKUL S. Nonlinear free vibrations of marine risers/pipes transporting fluid[J]. Ocean Engineering, 2005, 32(3/4): 417-440. doi: 10.1016/j.oceaneng.2004.07.007 [3] MONPRAPUSSORN T, ATHISAKUL C, CHUCHEEPSAKUL S. Nonlinear vibrationsof an extensible flexible marine riser carrying a PulsatileFlow[J]. Journal of Applied Mechanics, 2007, 74(4): 754-769. doi: 10.1115/1.2711226 [4] 黄林, 董佳慧, 廖海黎, 等. 基于CFD与风洞试验的边主梁涡振气动措施[J]. 西南交通大学学报, 2024, 59(2): 343-352. doi: 10.3969/j.issn.0258-2724.20220208HUANG Lin, DONG Jiahui, LIAO Haili, et al. Vortex-induced vibration(VIV) aerodynamic measures of girder with side beam based on computation fluid dynamics(CFD) and wind tunnel test[J]. Journal of Southwest Jiaotong University, 2024, 59(2): 343-352. doi: 10.3969/j.issn.0258-2724.20220208 [5] 黄林, 董佳慧, 王骑, 等. 检修车轨道位置与导流板对扁平箱梁涡振的影响[J]. 西南交通大学学报, 2023, 58(3): 535-545. doi: 10.3969/j.issn.0258-2724.20210474HUANG Lin, DONG Jiahui, WANG Qi, et al. Influence of maintenance rail position and guide vanes on vortex-induced vibration performance of flat box girders[J]. Journal of Southwest Jiaotong University, 2023, 58(3): 535-545. doi: 10.3969/j.issn.0258-2724.20210474 [6] 李永乐, 潘俊志, 遆子龙, 等. 设置分段式声屏障桥梁的涡振幅值反演方法[J]. 西南交通大学学报, 2023, 58(1): 183-190.LI Yongle, PAN Junzhi, TI Zilong, et al. Inversion method of vortex-induced vibration amplitude for long-span bridges with partially installed noise barrier[J]. Journal of Southwest Jiaotong University, 2023, 58(1): 183-190. [7] 宋彦宏, 张天翔, 马李, 等. 弹性变径管对于内流振动影响的仿真研究[J]. 人民黄河, 2022, 44(10): 122-126.SONG Yanhong, ZHANG Tianxiang, MA Li, et al. Simulation study on the influence of elastic reducer to the internal flow vibration[J]. Yellow River, 2022, 44(10): 122-126. [8] 王天林, 郭长青, 漆发辉, 等. 单边约束下受脉动内流激励作用简支输流管的碰振响应研究[J]. 振动与冲击, 2023, 42(22): 210-219. doi: 10.13465/j.cnki.jvs.2023.22.024WANG Tianlin, GUO Changqing, QI Fahui, et al. Research on impact vibration response of a simply supported fluid conveying pipe excited by pulsating internal flow under unilateral constraint[J]. Journal of Vibration and Shock, 2023, 42(22): 210-219. doi: 10.13465/j.cnki.jvs.2023.22.024 [9] HARA F. Two-phase flow induced vibrations in a horizontal piping system[J]. Transactions of the Japan Society of Mechanical Engineers, 1976, 42(360): 2400-2411. doi: 10.1299/kikai1938.42.2400 [10] SAKAGUCHI T, OZAWA M, HAMAGUCHI H, et al. Analysis of the impact force by a transient liquid slug flowing out of a horizontal pipe[J]. Nuclear Engineering and Design, 1987, 99: 63-71. doi: 10.1016/0029-5493(87)90108-7 [11] 许超洋. 气液两相流混输管道振动分析研究[D]. 东营: 中国石油大学(华东), 2007. [12] 赵金睿. 悬链线立管中多相流流动特征研究[D]. 东营: 中国石油大学(华东), 2012. [13] 唐有波. 海洋立管内部气液段塞流动特性及其流致振动研究[D]. 成都: 西南石油大学, 2017. [14] KIM T W, AYDIN T B, PEREYRA E, et al. Detailed flow field measurements and analysis in highly viscous slug flow in horizontal pipes[J]. International Journal of Multiphase Flow, 2018, 106: 75-94. doi: 10.1016/j.ijmultiphaseflow.2018.05.005 [15] MOHMMED A O, AL-KAYIEM H H, NASIF M S, et al. Effect of slug flow frequency on the mechanical stress behavior of pipelines[J]. International Journal of Pressure Vessels and Piping, 2019, 172: 1-9. doi: 10.1016/j.ijpvp.2019.03.012 [16] 张宇祥, 夏利娟, 李琳依. 基于流固耦合的气液两相流竖直弯管振动特性数值仿真[J]. 舰船科学技术, 2022, 44(17): 17-22. doi: 10.3404/j.issn.1672-7649.2022.17.004ZHANG Yuxiang, XIA Lijuan, LI Linyi. Fluid-solid coupling numerical simulation of gas-liquid two-phase flow induced vibration in the vertical elbows[J]. Ship Science and Technology, 2022, 44(17): 17-22. doi: 10.3404/j.issn.1672-7649.2022.17.004 [17] 马晓旭, 刘帅, 张政, 等. U形管内气液两相流诱导振动特性的试验研究[J]. 振动与冲击, 2023, 42(14): 76-83. doi: 10.13465/j.cnki.jvs.2023.014.009MA Xiaoxu, LIU Shuai, ZHANG Zheng, et al. Experimental study on the gas-liquid two-phase flow-induced vibration in a U-tube[J]. Journal of Vibration and Shock, 2023, 42(14): 76-83. doi: 10.13465/j.cnki.jvs.2023.014.009 [18] 高岳, 朱红钧, 颜知音, 等. 变工况气液段塞流诱导的柔性立管振动响应[J]. 振动工程学报, 2023, 36(4): 1044-1053.GAO Yue, ZHU Hongjun, YAN Zhiyin, et al. Slug flow-induced vibration of a flexible catenary riser model with variable gas-liquid flows[J]. Journal of Vibration Engineering, 2023, 36(4): 1044-1053. [19] XIA J X, NI J R, MENDOZA C. Upward flow of large size particles–water mixtures through swaying pipes[J]. Journal of Transportation Engineering, 2004, 130(4): 535-543. doi: 10.1061/(ASCE)0733-947X(2004)130:4(535) [20] XU X P, LIU M Y, MA Y, et al. Effects of fluidized solid particles on vibration behaviors of a graphite tube evaporator with an internal vapor–liquid flow[J]. Applied Thermal Engineering, 2016, 100: 1229-1244. doi: 10.1016/j.applthermaleng.2015.12.126 [21] 刘勇, 陈炉云. 涡激振动对管道液固两相流流场的影响[J]. 上海交通大学学报, 2017, 51(4): 485-489. doi: 10.16183/j.cnki.jsjtu.2017.04.016LIU Yong, CHEN Luyun. Influence of vortex induced vibration on the liquid-solid two-phase flow in pipeline[J]. Journal of Shanghai Jiao Tong University, 2017, 51(4): 485-489. doi: 10.16183/j.cnki.jsjtu.2017.04.016 [22] 徐海良, 饶星, 杨放琼. 横向摆动对深海采矿扬矿管输送特性的影响[J]. 中南大学学报(自然科学版), 2019, 50(10): 2395-2402. doi: 10.11817/j.issn.1672-7207.2019.10.008XU Hailiang, RAO Xing, YANG Fangqiong. Influence of lateral swing on transportation characteristics of deep sea mining pipeline[J]. Journal of Central South University (Science and Technology), 2019, 50(10): 2395-2402. doi: 10.11817/j.issn.1672-7207.2019.10.008 [23] ZHANG F W, CRONIN K, LIN Y H, et al. Sealing pipe top enhancing transportation of particulate solids inside a vertically vibrating pipe[J]. Powder Technology, 2019, 343: 383-391. doi: 10.1016/j.powtec.2018.11.069 [24] 宋龙波, 滕爽, 曹骞, 等. 大尺寸固体颗粒提升过程中管道内的固液两相流动特征[J]. 排灌机械工程学报, 2021, 39(11): 1111-1117. doi: 10.3969/j.issn.1674-8530.20.0278SONG Longbo, TENG Shuang, CAO Qian, et al. Solid-liquid two-phase flow characteristics in pipe during large solid particles lifting[J]. Journal of Drainage and Irrigation Machinery Engineering, 2021, 39(11): 1111-1117. doi: 10.3969/j.issn.1674-8530.20.0278 [25] 王明. 携砂压裂液颗粒群碰撞破碎及管道耦合振动的数值分析方法研究[D]. 大庆: 东北石油大学, 2022. [26] 马维祥. 固液两相流诱发变径及T型管道振动实验研究及数值模拟[J]. 石油化工设备, 2023, 52(4): 12-18. doi: 10.3969/j.issn.1000-7466.2023.04.003MA Weixiang. Experimental study and numerical simulation of vibration of variable diameter and T-shaped pipes by solid-liquid two-phase flow[J]. Petro-Chemical Equipment, 2023, 52(4): 12-18. doi: 10.3969/j.issn.1000-7466.2023.04.003 [27] MONTOYA-HERNÁNDEZ D J, VÁZQUEZ-HERNÁNDEZ A O, CUAMATZI R, et al. Natural frequency analysis of a marine riser considering multiphase internal flow behavior[J]. Ocean Engineering, 2014, 92: 103-113. doi: 10.1016/j.oceaneng.2014.09.039 [28] 马亚成, 唐文勇, 王晋. 多相流作用下水下刚性跨接管流致振动特性数值模拟方法研究[J]. 船海工程, 2014, 43(4): 96-100. doi: 10.3963/j.issn.1671-7953.2014.04.023MA Yacheng, TANG Wenyong, WANG Jin. On the numerical simulation methods of internal multiphase flow-induced vibration in subsea rigid jumper[J]. Ship & Ocean Engineering, 2014, 43(4): 96-100. doi: 10.3963/j.issn.1671-7953.2014.04.023 [29] BALAKIN B V, LO S, KOSINSKI P, et al. Modelling agglomeration and deposition of gas hydrates in industrial pipelines with combined CFD-PBM technique[J]. Chemical Engineering Science, 2016, 153: 45-57. doi: 10.1016/j.ces.2016.07.010 [30] 梁维兴. 含水合物相变多相内流海洋立管动力分析[D]. 东营: 中国石油大学(华东), 2021. [31] 陈国庆. 考虑水合物相变的柔性立管内流动特性及振动分析[D]. 杭州: 中国计量大学, 2022. [32] 周洪利. 天然气水合物输送管道气液固流动特性的CFD-PBM数值模拟[D]. 大庆: 东北石油大学, 2022. [33] 黄鑫, 寇鉴, 毛良杰, 等. 天然气水合物开采立管力学特性研究[J]. 西南石油大学学报(自然科学版), 2023, 45(4): 143-154.HUANG Xin, KOU Jian, MAO Liangjie, et al. Mechanical characteristics of natural gas hydrate production riser[J]. Journal of Southwest Petroleum University (Science & Technology Edition), 2023, 45(4): 143-154. [34] 孙万通. 海洋天然气水合物藏固态流化采掘多相非平衡管流研究[D]. 成都: 西南石油大学, 2016. [35] 夏建新. 大洋多金属结核水力提升两相流体动力学及应用研究[D]. 徐州: 中国矿业大学, 2000. [36] GUO X Q, LI X, HE Y F, et al. Investigation on three-dimensional vibration model and response characteristics of deep-water riser-test pipe system[J]. Communications in Nonlinear Science and Numerical Simulation, 2022, 109: 106296. doi: 10.1016/j.cnsns.2022.106296 [37] 杨建民, 肖龙飞, 盛振邦. 海洋工程水动力学试验研究[M]. 上海: 上海交通大学出版社, 2008: 1-70. [38] 谢武德. 顶张力立管外流涡激-内流密度变化的动力特性研究[D]. 天津: 天津大学, 2020. -

下载:

下载: