Study on Hydraulic Interconnected Damper and Dynamic Performance of High-Speed Electric Multiple Units

-

摘要:

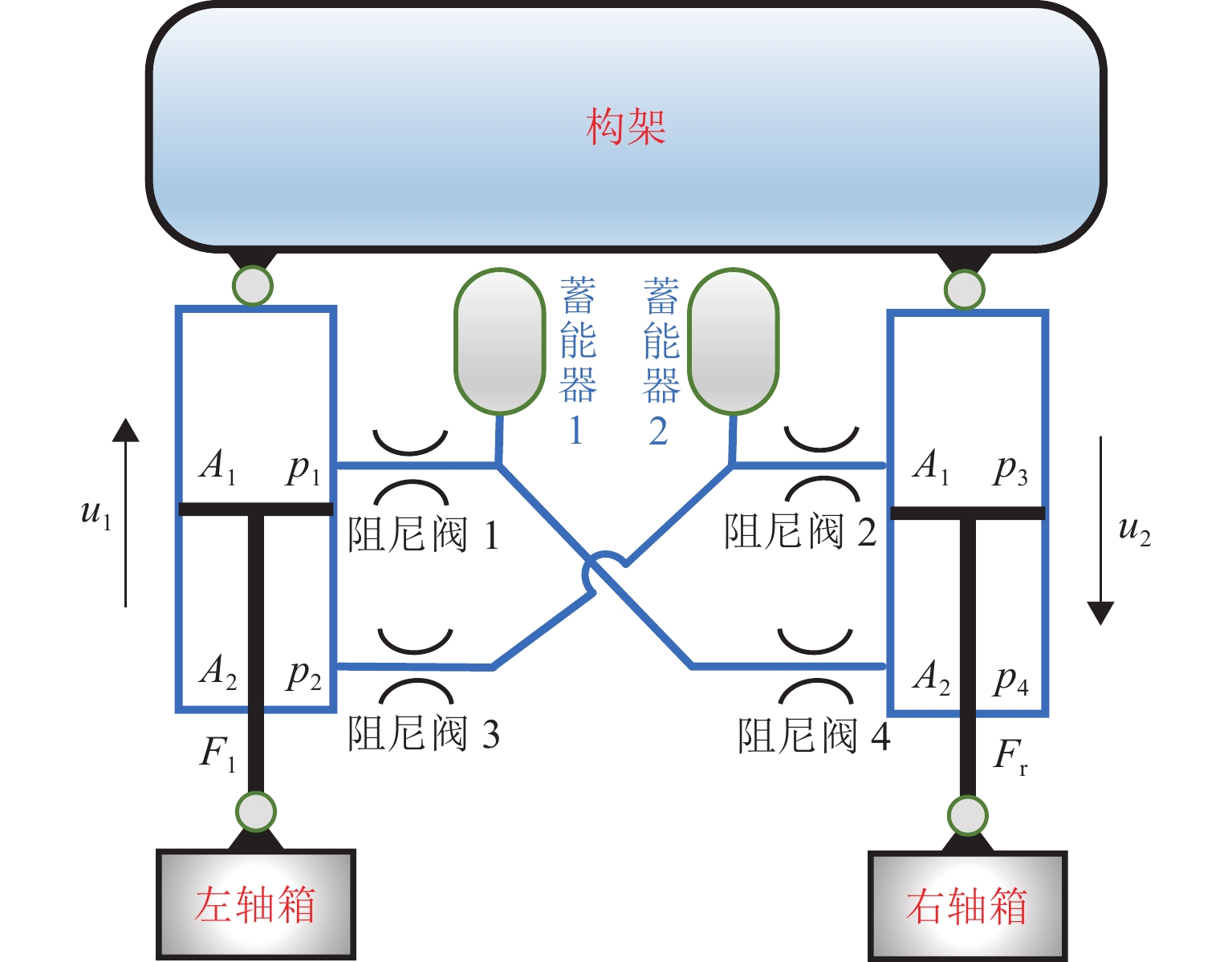

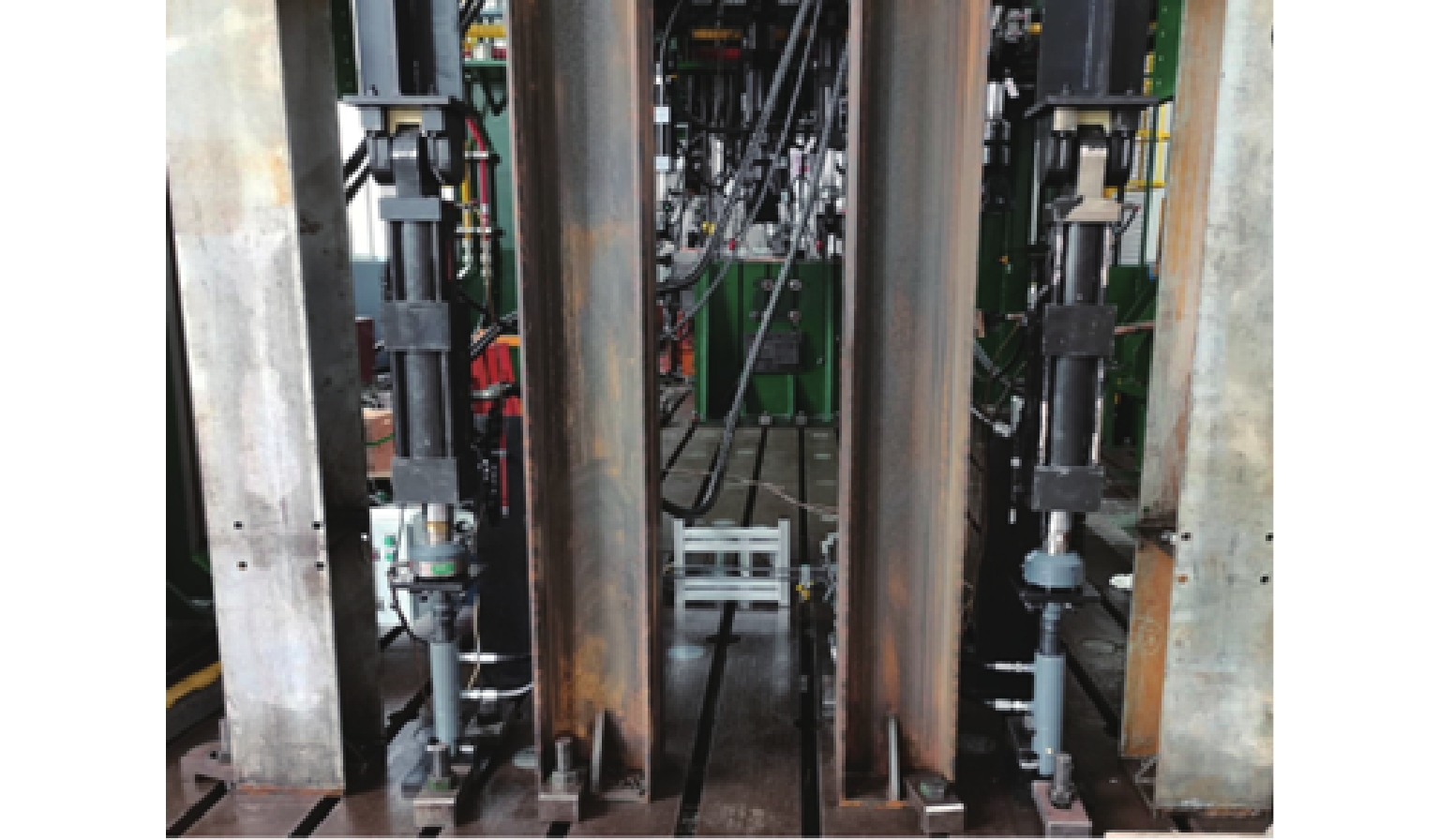

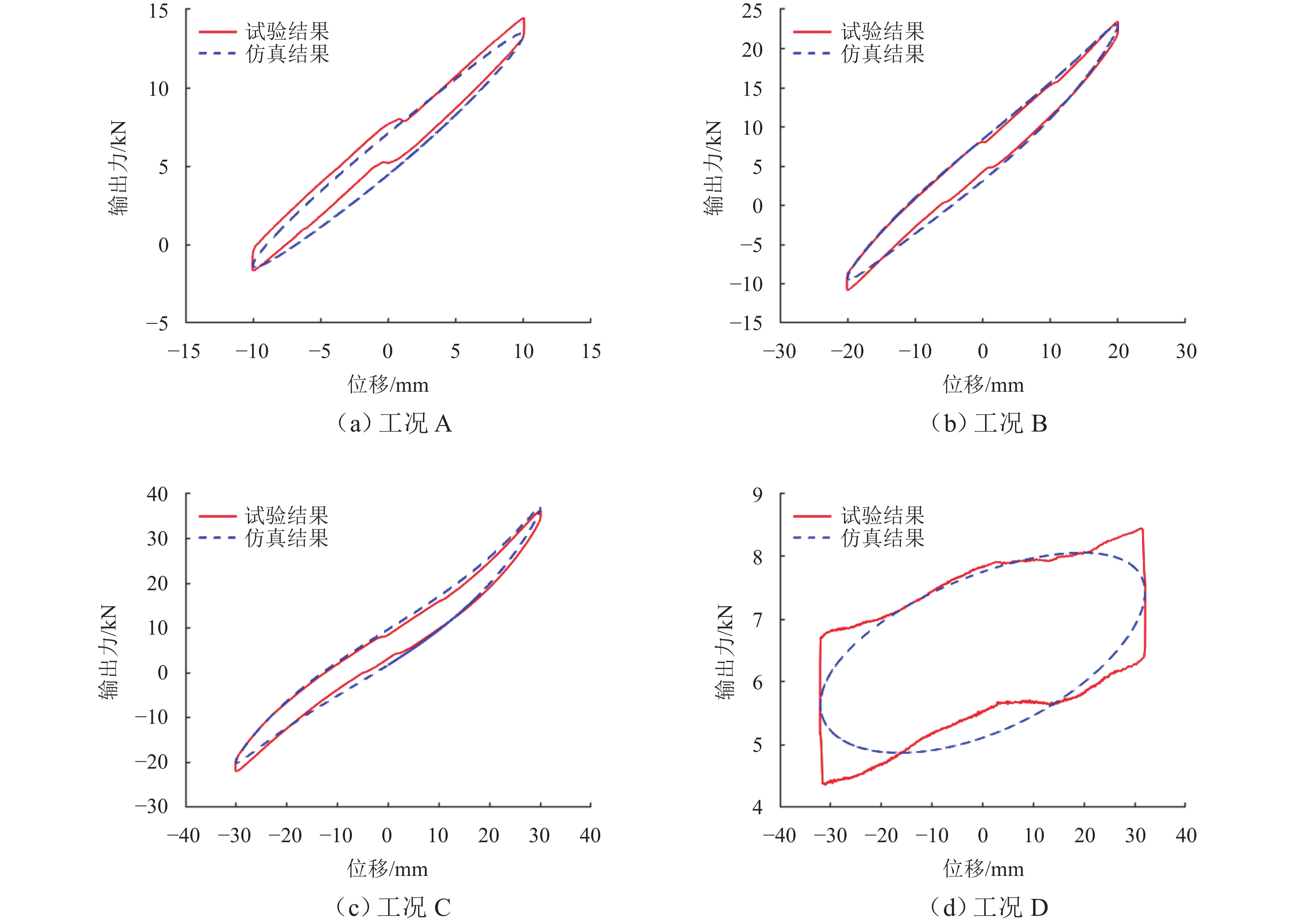

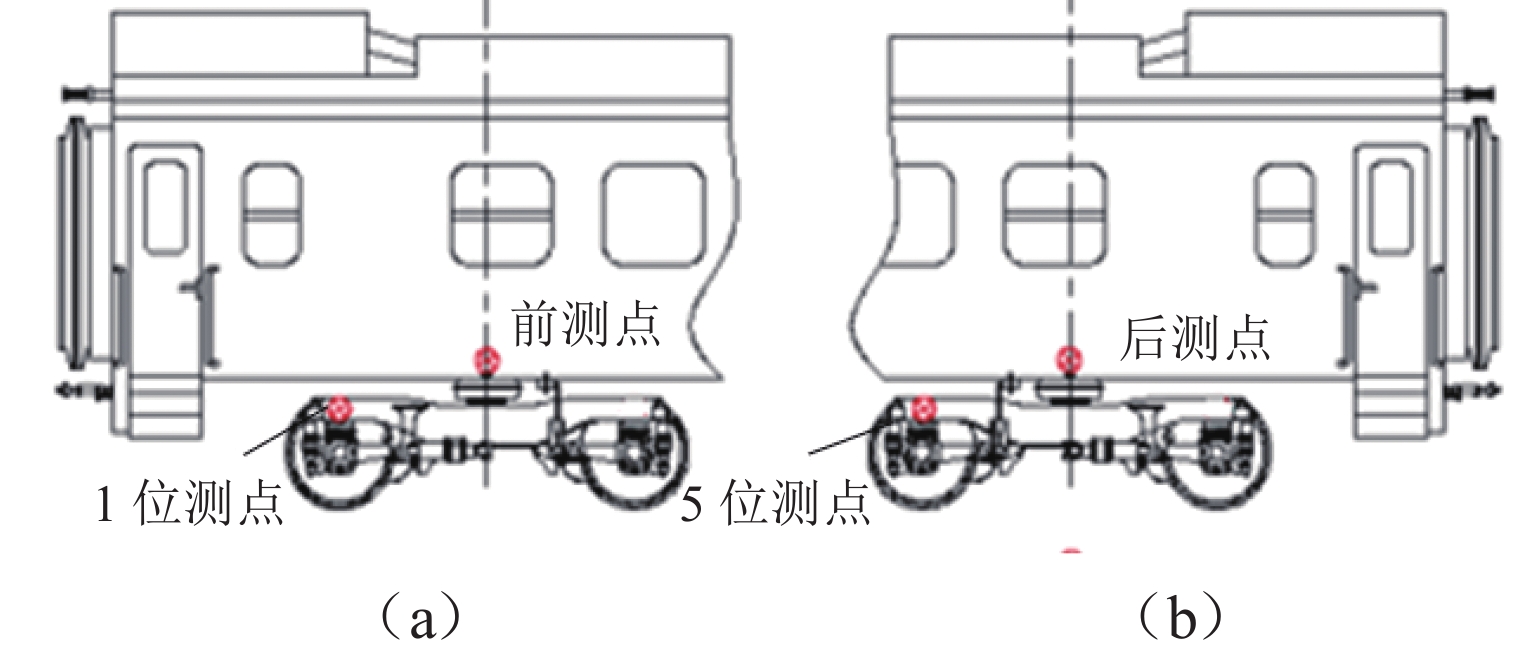

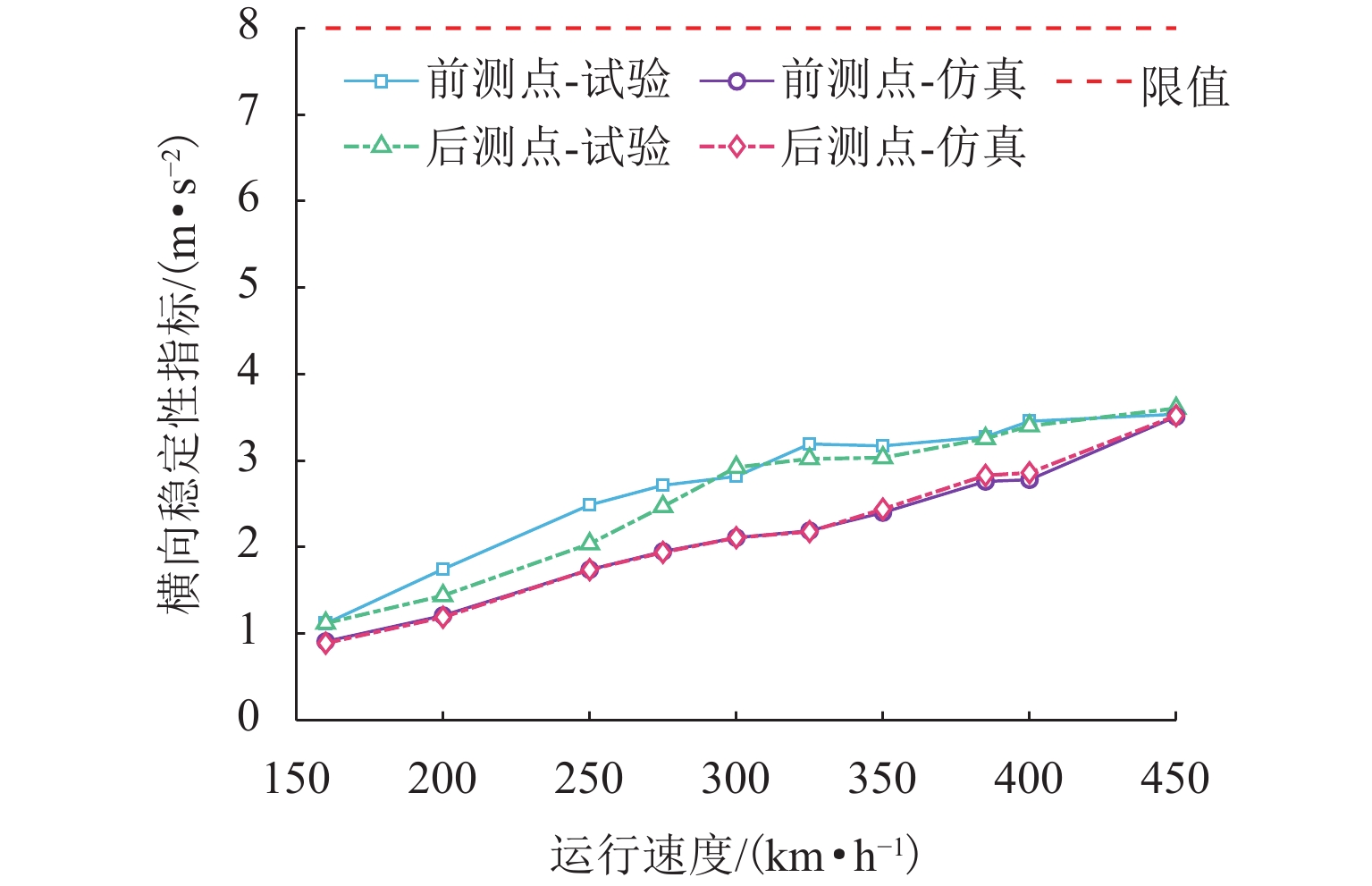

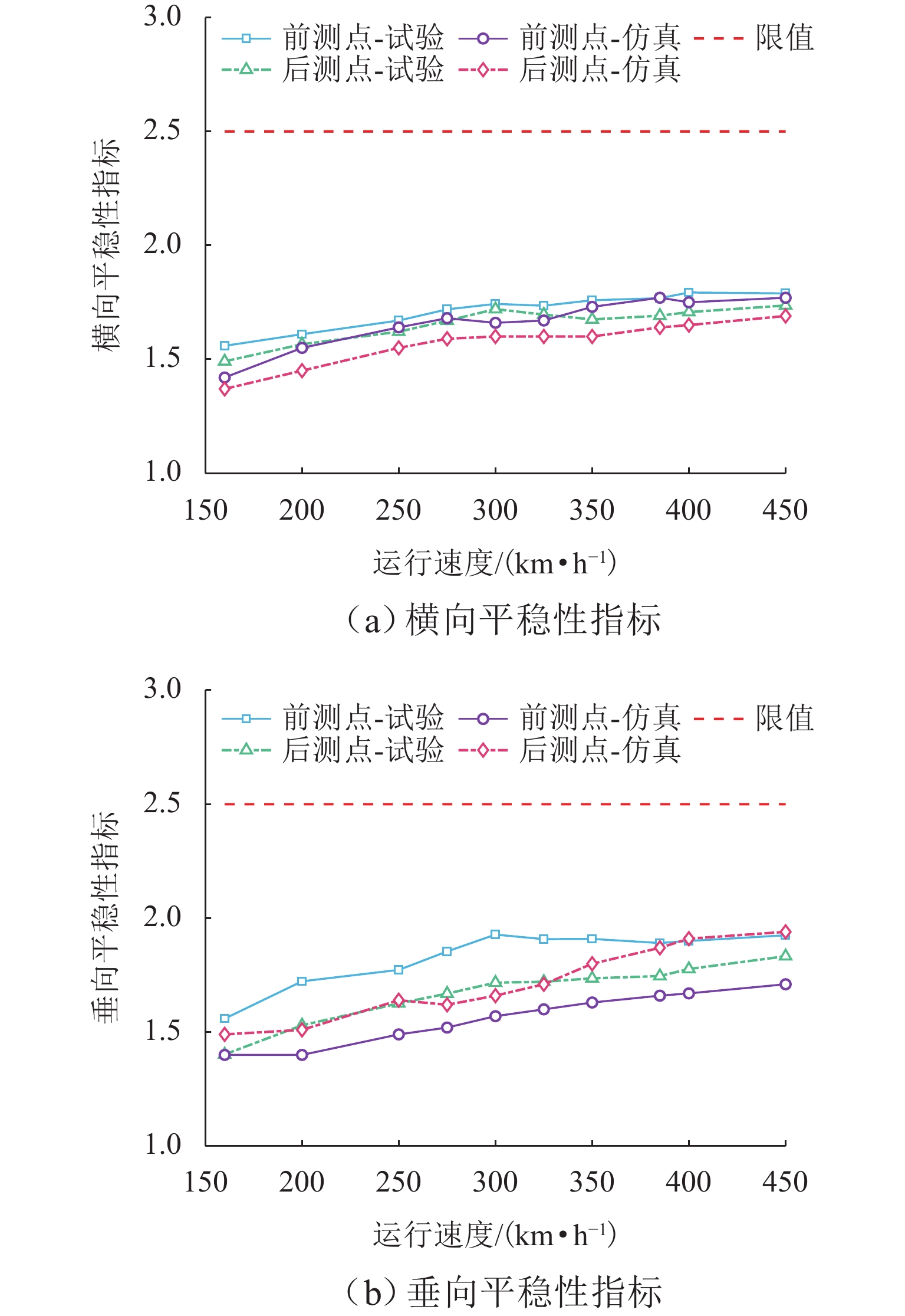

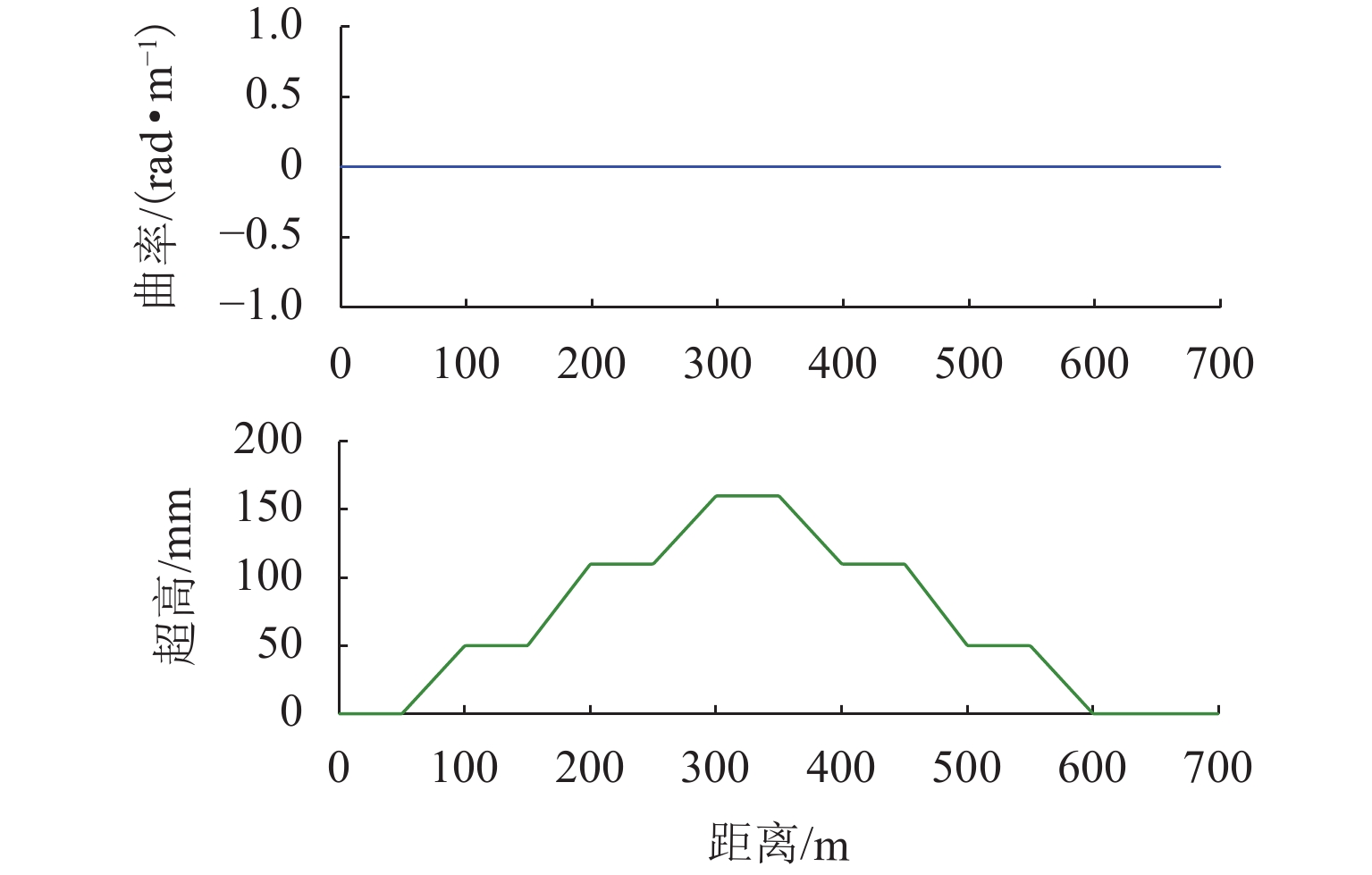

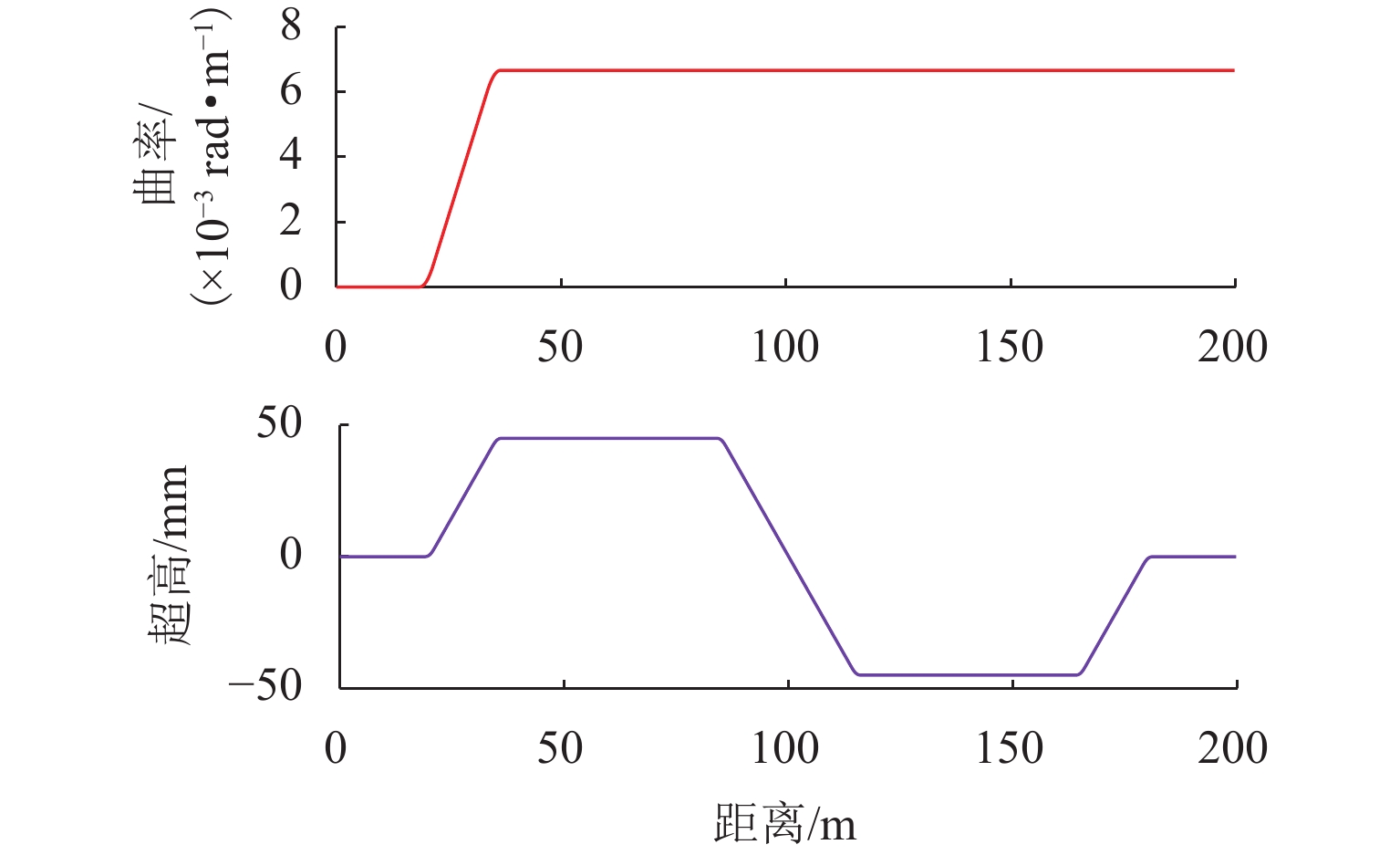

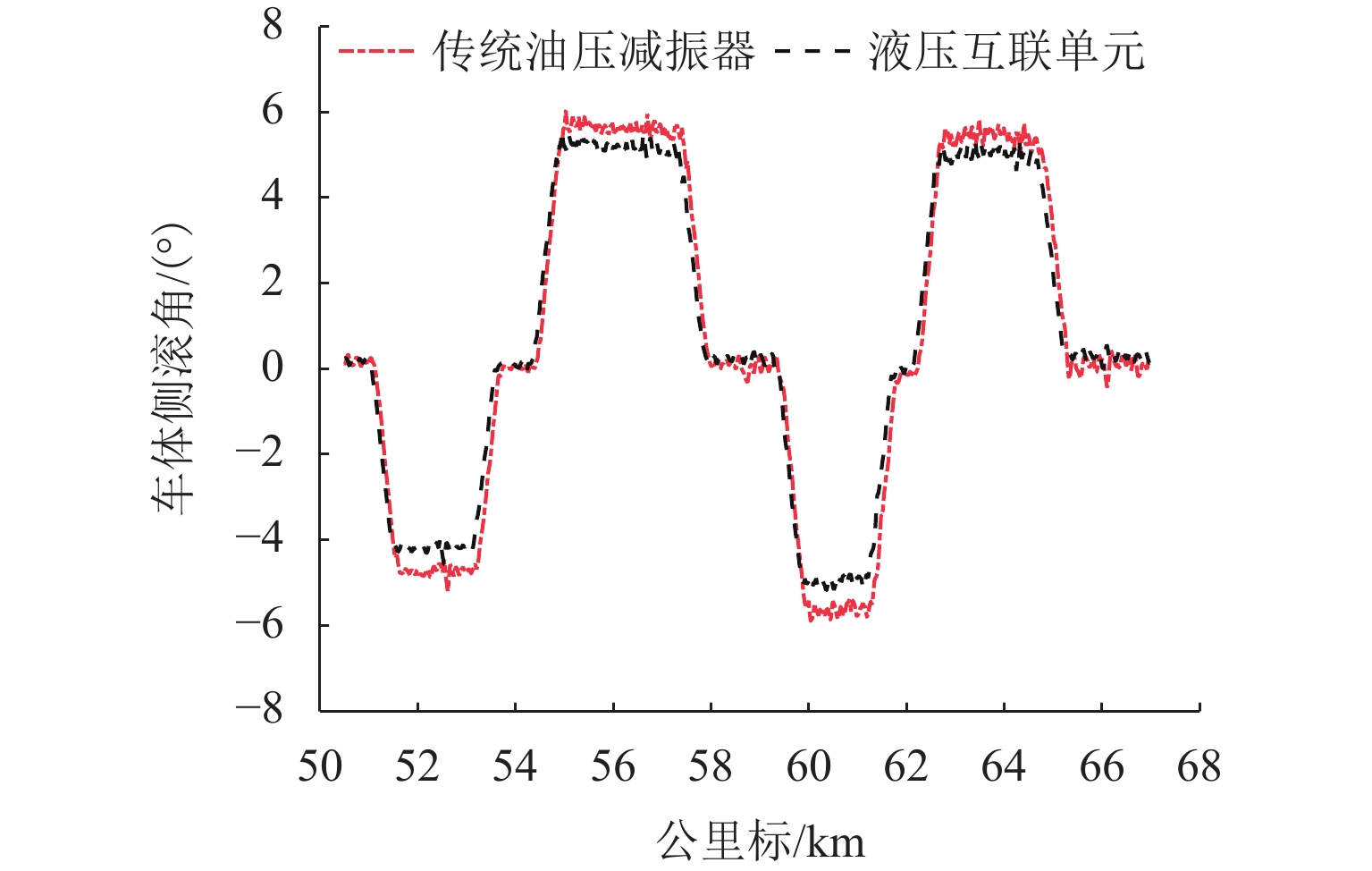

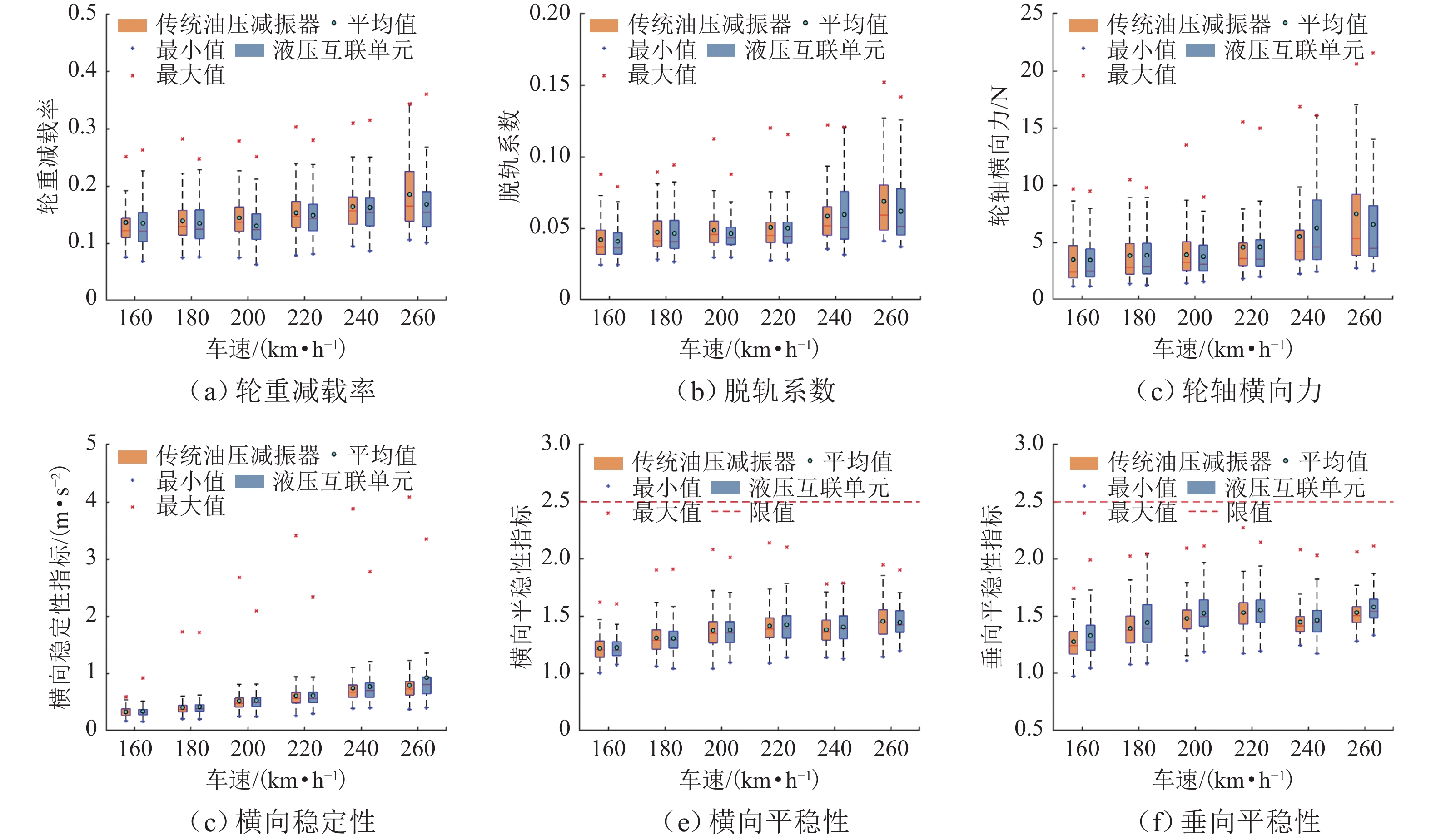

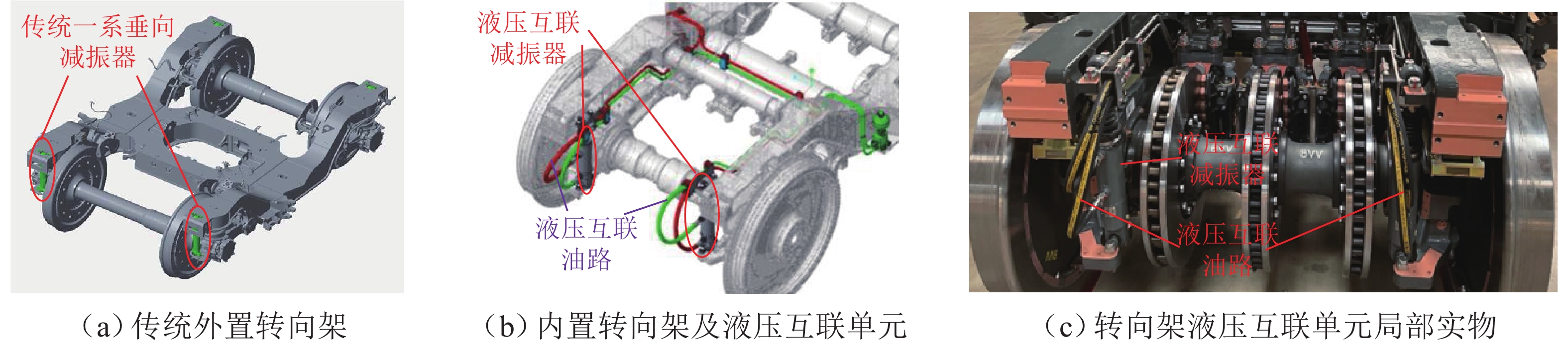

针对高速动车组轴箱内置式转向架抗侧滚刚度不足问题,提出采用液压互联单元替代传统减振器的一系悬挂构型,可在不增加悬挂垂向刚度的前提下提升抗侧滚刚度. 首先,推导油液压力、流量和输出力平衡方程,基于SIMPACK建立车辆系统非线性动力学模型,并通过MATLAB/Simulink建立液压互联单元仿真模型,实现车辆-液压互联单元系统的联合仿真;开展液压互联单元准静态特性测试和整车滚振台架动力学试验,验证了仿真模型的准确性;针对车辆多种运行工况,仿真分析液压互联单元关键参数对车体侧滚角、脱轨系数和平稳性指标的影响规律;开展线路动力学试验,验证车辆通过曲线时动力学性能的改善效果. 研究结果表明:液压互联单元的侧滚刚度明显大于传统液压减振器,车辆曲线通过时车体侧滚角可降低0.5°以上,有利于缩窄动态限界和保障倾覆安全性;线路试验表明,液压互联单元与传统油压减振器两种方案的各项动力学指标相当,通过液压互联单元解决转向架抗侧滚能力不足问题是可行的.

Abstract:To address the inadequate anti-roll stiffness of the axle box in-board bogies of high-speed electric multiple units (EMUs), a primary suspension configuration was proposed to replace the traditional hydraulic damper with hydraulic interconnected units. The configuration could increase the anti-roll stiffness without increasing the vertical stiffness. Firstly, the equilibrium equations of oil pressure, flow rate, and output force were derived. A nonlinear dynamic model of the vehicle system was established using SIMPACK, and a simulation model of the hydraulic interconnected units was created in MATLAB/Simulink to facilitate co-simulation of the vehicle-hydraulic interconnected unit coupling system. Subsequently, the accuracy of the simulation model was validated based on the quasi-static characteristic test of the hydraulic interconnected units and the dynamic tests of the roller rig of the entire vehicle. The simulation analysis was conducted to ascertain the impact of pivotal parameters associated with the hydraulic interconnected units on the roll angle of the car body, derailment coefficient, and riding index for various operation conditions of vehicles. Finally, the field dynamic tests were conducted to verify the improvement in the dynamic performance of vehicles during curve negotiation. The results have shown that the roll stiffness of the interconnection unit is significantly greater than that of the traditional hydraulic dampers. The roll angle of the car body can be reduced by more than 0.5°, which is conducive to narrowing the dynamic limit and ensuring overturning safety. The field test results demonstrate that the dynamic indexes of hydraulic interconnected units are comparable to those of traditional oil pressure dampers. It is viable to address the issue of inadequate anti-roll capability of axle box in-board bogies by adopting hydraulic interconnected units.

-

表 1 液压互联减振器台架试验工况

Table 1. Conditions of roller rig tests for hydraulic interconnected dampers

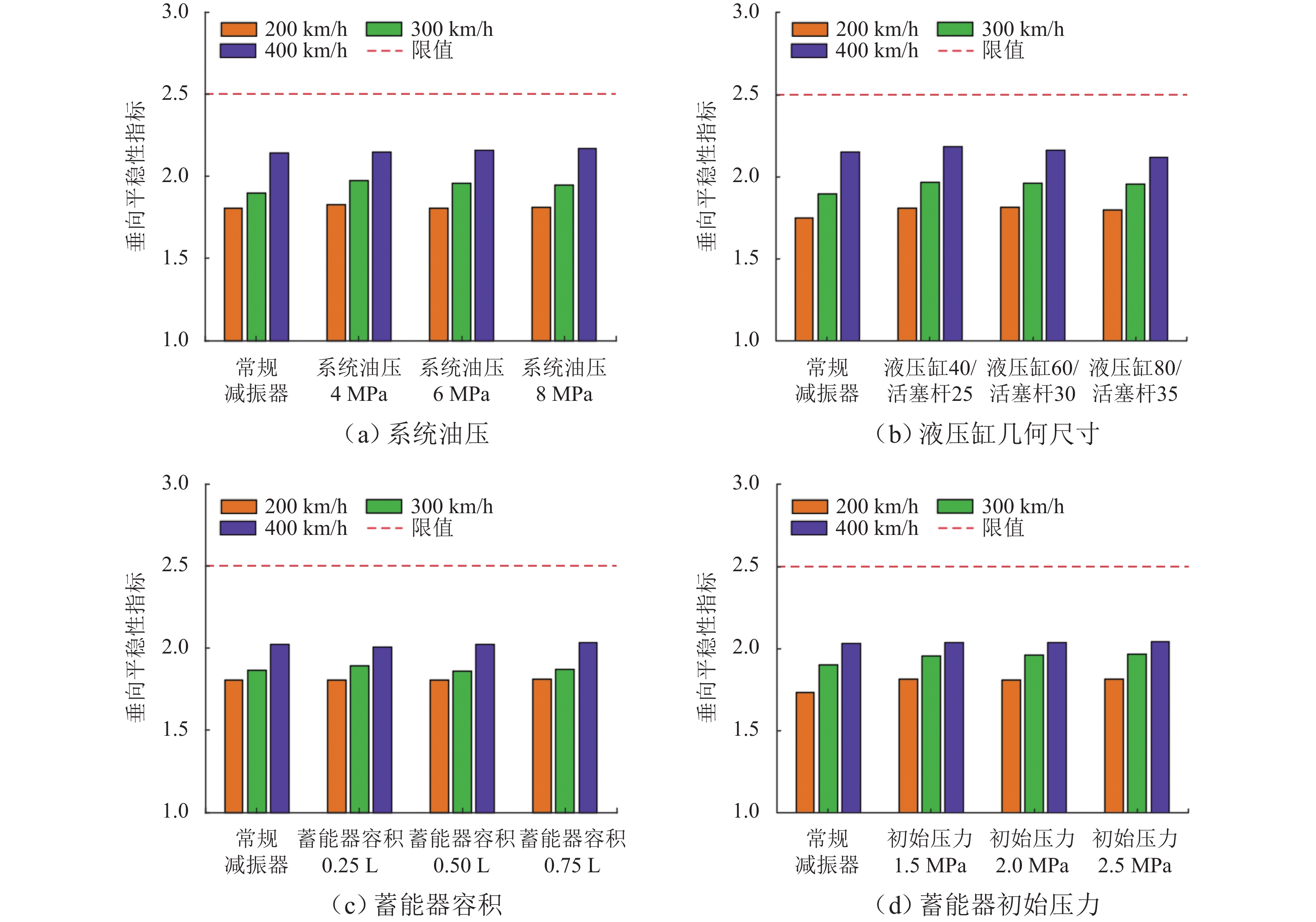

工况 载荷模式 振幅/mm 频率/Hz 速度/(mm·s−1) A 侧滚 10 0.1 6.3 B 侧滚 20 0.1 12.6 C 侧滚 30 0.1 18.5 D 浮沉 33 0.25 51.8 表 2 车体侧滚角随系统关键参数变化

Table 2. Changes of roll angles of car body under various key system parameters

关键参数 参数取值 车体侧滚角/(°) 系统油压 常规减振器 1.629 系统油压 4 MPa 1.291 系统油压 6 MPa 1.162 系统油压 8 MPa 1.073 液压缸几何尺寸 常规减振器 1.629 液压缸 40/活塞杆 25 1.472 液压缸 60/活塞杆 30 1.351 液压缸 80/活塞杆 35 1.212 蓄能器容积 常规减振器 1.629 蓄能器容积 0.25 L 1.036 蓄能器容积 0.50 L 1.162 蓄能器容积 0.75 L 1.240 蓄能器初始压力 常规减振器 1.629 初始压力 1.5 MPa 1.162 初始压力 2.0 MPa 1.200 初始压力 2.5 MPa 1.229 表 3 车体横移量随系统关键参数变化

Table 3. Changes of lateral displacement of car body under various key system parameters

关键参数 参数取值 车体横移量/mm 系统油压 常规减振器 52.57 系统油压 4 MPa 46.16 系统油压 6 MPa 45.56 系统油压 8 MPa 45.14 液压缸几何尺寸 常规减振器 52.57 液压缸 40/活塞杆 25 47.00 液压缸 60/活塞杆 30 46.44 液压缸 80/活塞杆 35 45.79 蓄能器容积 常规减振器 52.57 蓄能器容积 0.25 L 44.98 蓄能器容积 0.50 L 45.56 蓄能器容积 0.75 L 45.92 蓄能器初始压力 常规减振器 52.57 初始压力 1.5 MPa 45.56 初始压力 2.0 MPa 45.74 初始压力 2.5 MPa 45.87 表 4 车辆脱轨系数随系统关键参数变化

Table 4. Changes of derailment coefficients under various key system parameters

关键参数 参数取值 脱轨系数 系统

油压常规减振器 0.630 系统油压 4 MPa 0.681 系统油压 6 MPa 0.703 系统油压 8 MPa 0.760 液压缸

几何尺寸常规减振器 0.630 液压缸 40/活塞杆 25 0.646 液压缸 60/活塞杆 30 0.667 液压缸 80/活塞杆 35 0.703 蓄能器

容积常规减振器 0.630 蓄能器容积 0.25 L 0.784 蓄能器容积 0.5 L 0.721 蓄能器容积 0.75 L 0.694 蓄能器

初始压力常规减振器 0.630 初始压力 1.5 MPa 0.721 初始压力 2.0 MPa 0.707 初始压力 2.5 MPa 0.698 -

[1] PERIS E, GOIKOETXEA J. Roll2Rail: new dependable rolling stock for a more sustainable, intelligent and comfortable rail transport in Europe[J]. Transportation Research Procedia, 2016, 14: 567-574. doi: 10.1016/j.trpro.2016.05.294 [2] David Briginshaw. 西门子公司Velaro系列高速列车的新进展[J]. 国外铁道机车与动车, 2020(3): 9-12.David Briginshaw. Velaro evolution[J]. Foreign Railway Locomotive and Motor Car, 2020(3): 9-12. [3] 丁叁叁, 陈大伟, 刘加利. 中国高速列车研发与展望[J]. 力学学报, 2021, 53(1): 35-50.DING Sansan, CHEN Dawei, LIU Jiali. Research, development and prospect of China high-speed train[J]. Chinese Journal of Theoretical and Applied Mechanics, 2021, 53(1): 35-50. [4] 张隶新. 轴箱内置和外置高速转向架的动力学性能对比[J]. 铁道科学与工程学报, 2021, 18(3): 581-587.ZHANG Lixin. Dynamics analysis of high-speed railway bogies with inner bearing and outer bearing suspensions[J]. Journal of Railway Science and Engineering, 2021, 18(3): 581-587. [5] 缪炳荣, 张卫华, 池茂儒, 等. 下一代高速列车关键技术特征分析及展望[J]. 铁道学报, 2019, 41(3): 58-70.MIAO Bingrong, ZHANG Weihua, CHI Maoru, et al. Analysis and prospects of key technical features of next generation high speed trains[J]. Journal of the China Railway Society, 2019, 41(3): 58-70. [6] 刘秀梅, 李永涛. 车辆油气悬架技术研究综述[J]. 西南交通大学学报, 2025, 60(2): 374-394.LIU Xiumei, LI Yongtao. Review of research on vehicle hydro-pneumatic suspension technology[J]. Journal of Southwest Jiaotong University, 2025, 60(2): 374-394. [7] SMITH W A, ZHANG N, JEYAKUMARAN J. Hydraulically interconnected vehicle suspension: theoretical and experimental ride analysis[J]. Vehicle System Dynamics, 2010, 48(1): 41-64. doi: 10.1080/00423110903243190 [8] SMITH W A, ZHANG N, HU W. Hydraulically interconnected vehicle suspension: handling performance[J]. Vehicle System Dynamics, 2011, 49(1/2): 87-106. [9] CAO D P, RAKHEJA S, SU C Y. Roll- and pitch-plane-coupled hydro-pneumatic suspension. part 2: dynamic response analyses[J]. Vehicle System Dynamics, 2010, 48(4): 507-528. doi: 10.1080/00423110902923461 [10] DAMAVANDI A D, MASIH-TEHRANI M, MASHADI B. Configuration development and optimization of hydraulically interconnected suspension for handling and ride enhancement[J]. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2022, 236(2/3): 381-394. [11] JAFARI B, MASHADI B. Valve control of a hydraulically interconnected suspension system to improve vehicle handling qualities[J]. Vehicle System Dynamics, 2023, 61(4): 1011-1027. doi: 10.1080/00423114.2022.2056490 [12] QI H M, CHEN Y C, ZHANG N, et al. Improvement of both handling stability and ride comfort of a vehicle via coupled hydraulically interconnected suspension and electronic controlled air spring[J]. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2020, 234(2/3): 552-571. [13] ZHU H J, YANG J, ZHANG Y Q. Dual-chamber pneumatically interconnected suspension: modeling and theoretical analysis[J]. Mechanical Systems and Signal Processing, 2021, 147: 107125. doi: 10.1016/j.ymssp.2020.107125 [14] 陈盛钊, 张农, 张邦基, 等. 液压互联悬架关键参数对车辆频响特性的影响[J]. 湖南大学学报(自然科学版), 2017, 44(2): 16-25.CHEN Shengzhao, ZHANG Nong, ZHANG Bangji, et al. Influence of key parameters of hydraulically interconnected suspension on frequency domain characteristics of vehicles[J]. Journal of Hunan University (Natural Sciences), 2017, 44(2): 16-25. [15] 陈盛钊, 钟义旭, 张邦基, 等. 液压互联悬架系统关键参数对车辆动力学响应影响及试验验证[J]. 机械工程学报, 2017, 53(14): 39-48. doi: 10.3901/JME.2017.14.039CHEN Shengzhao, ZHONG Yixu, ZHANG Bangji, et al. Influence of key parameters of hydraulically interconnected suspension on vehicle dynamics and experimental validation[J]. Journal of Mechanical Engineering, 2017, 53(14): 39-48. doi: 10.3901/JME.2017.14.039 [16] DI GIALLEONARDO E, FACCHINETTI A, BRUNI S. Control of an integrated lateral and roll suspension for a high-speed railway vehicle[J]. Vehicle System Dynamics, 2023, 61(2): 472-498. doi: 10.1080/00423114.2022.2049319 [17] DI GIALLEONARDO E, SANTELIA M, BRUNI S, et al. A simple active carbody roll scheme for hydraulically actuated railway vehicles using internal model control[J]. ISA Transactions, 2022, 120: 55-69. doi: 10.1016/j.isatra.2021.03.003 [18] COLOMBO E F, DI GIALLEONARDO E, FACCHINETTI A, et al. Active carbody roll control in railway vehicles using hydraulic actuation[J]. Control Engineering Practice, 2014, 31: 24-34. doi: 10.1016/j.conengprac.2014.05.010 [19] LI H X, LI S W, SUN W C. Vibration and handling stability analysis of articulated vehicle with hydraulically interconnected suspension[J]. Journal of Vibration and Control, 2019, 25(13): 1899-1913. doi: 10.1177/1077546319844092 [20] ZHANG J, DENG Y W, ZHANG N, et al. Vibration performance analysis of a mining vehicle with bounce and pitch tuned hydraulically interconnected suspension[J]. Chinese Journal of Mechanical Engineering, 2019, 32(1): 1-17. doi: 10.1186/s10033-018-0313-7 [21] 索雪峰, 刘湘, 杜腾, 等. 三轴车中后桥液压互联悬架减振特性研究[J/OL]. 西南交通大学学报, 2024: 1-9. (2024-05-10). https://kns.cnki.net/kcms/detail/51.1277.u.20240509.1402.004.html.SUO Xuefeng, LIU Xiang, DU Teng, et al. Research on vibration reduction characteristics of hydraulic interconnecting suspension in middle and rear axle of three-axle vehicle[J/OL]. Journal of Southwest Jiaotong University, 2024: 1-9. (2024-05-10). https://kns.cnki.net/kcms/detail/51.1277.u.20240509.1402.004.html. [22] LUO R, LIU C D. Dynamics simulation of the high-speed train using interconnected hydro-pneumatic suspension as a self-steering system[J]. Vehicle System Dynamics, 2022, 60(6): 2055-2074. doi: 10.1080/00423114.2021.1892156 [23] LUO R, LIU C D, SHI H L. Dynamic simulation of a high-speed train with interconnected hydro-pneumatic secondary suspension[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2022, 236(5): 570-581. doi: 10.1177/09544097211031334 [24] 苏瑞. 内轴箱悬挂高速动车组转向架抗倾覆稳定性研究[D]. 成都: 西南交通大学, 2023. [25] 唐羽. 轴箱内置高速列车一系油气互联抗侧滚装置动力学研究[D]. 成都: 西南交通大学, 2022. [26] 童钧耕, 王平阳, 叶强. 热工基础[M]. 3版. 上海: 上海交通大学出版社, 2016. [27] 罗仁, 石怀龙. 铁道车辆系统动力学及应用[M]. 成都: 西南交通大学出版社, 2018. [28] 翟婉明. 车辆-轨道耦合动力学[M]. 3版. 北京: 科学出版社, 2007. [29] 中华人民共和国国家市场监督管理总局, 中国国家标准化管理委员会. 机车车辆动力学性能评定及试验鉴定规范: GB/T 5599—2019[S]. 北京: 中国标准出版社, 2019. [30] IX-CEN. Railway applications-testing and simulation for the acceptance of running characteristics of railway vehicles-running behaviour and stationary tests: BS EN 14363: 2016[S]. [S. l. ]: BSI, 2016. [31] 石怀龙, 罗仁, 曾京. 国内外高速列车动力学评价标准综述[J]. 交通运输工程学报, 2021, 21(1): 36-58.SHI Huailong, LUO Ren, ZENG Jing. Review on domestic and foreign dynamics evaluation criteria of high-speed train[J]. Journal of Traffic and Transportation Engineering, 2021, 21(1): 36-58. [32] 祁亚运, 李龙, 石怀龙, 等. 高寒动车组温变特性对运行性能的影响分析[J]. 西南交通大学学报, 2025, 60(2): 336-345.QI Yayun, LI Long, SHI Huailong, et al. Influence of temperature-varying characteristics on operating performance of alpine electric multiple units[J]. Journal of Southwest Jiaotong University, 2025, 60(2): 336-345. [33] 陆铭. 时速200公里轴箱内置式转向架动力学性能研究[D]. 成都: 西南交通大学, 2021. -

下载:

下载: