Influence Analysis of Traction Rods on Locomotive Axle Load Transfer

-

摘要:

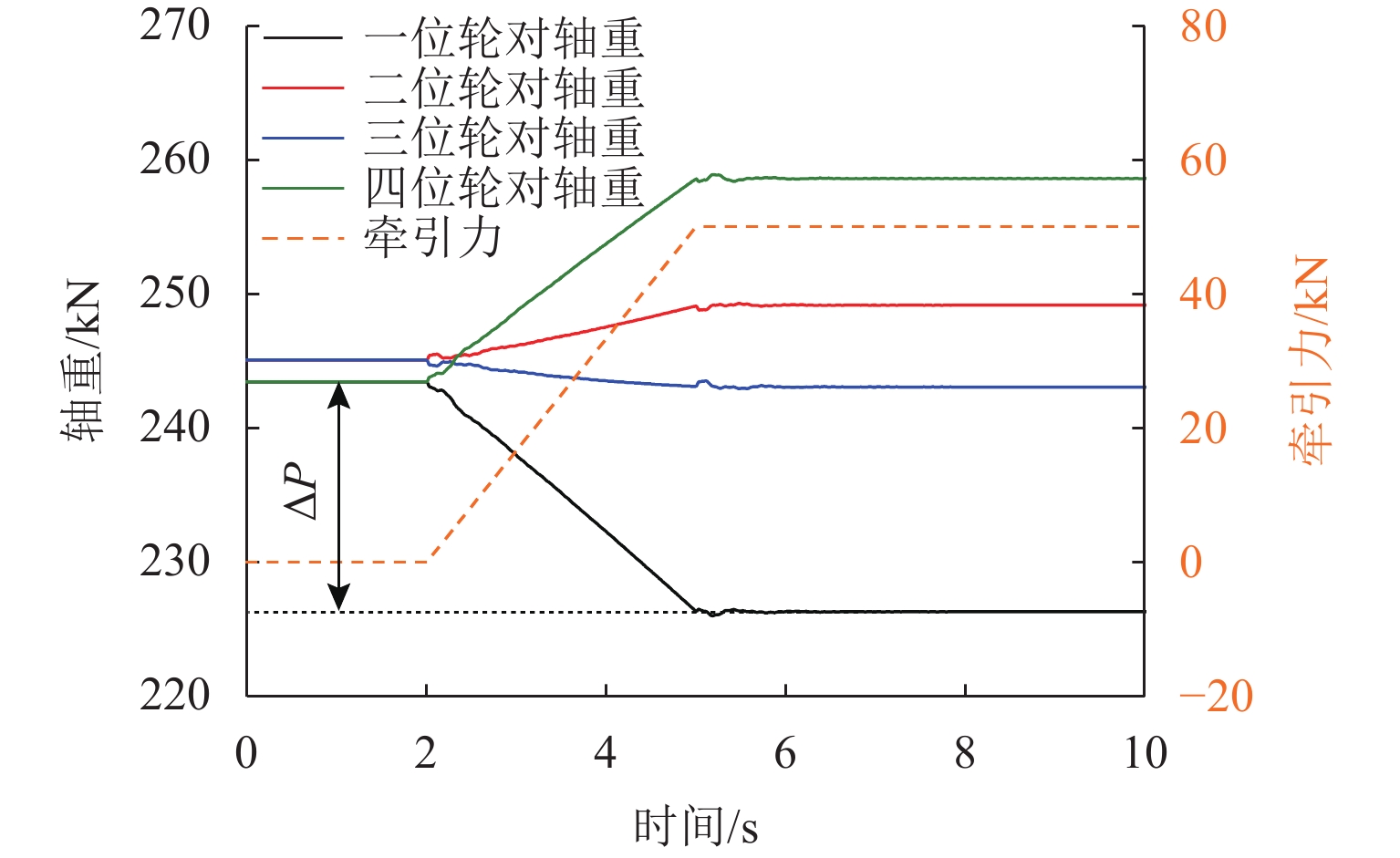

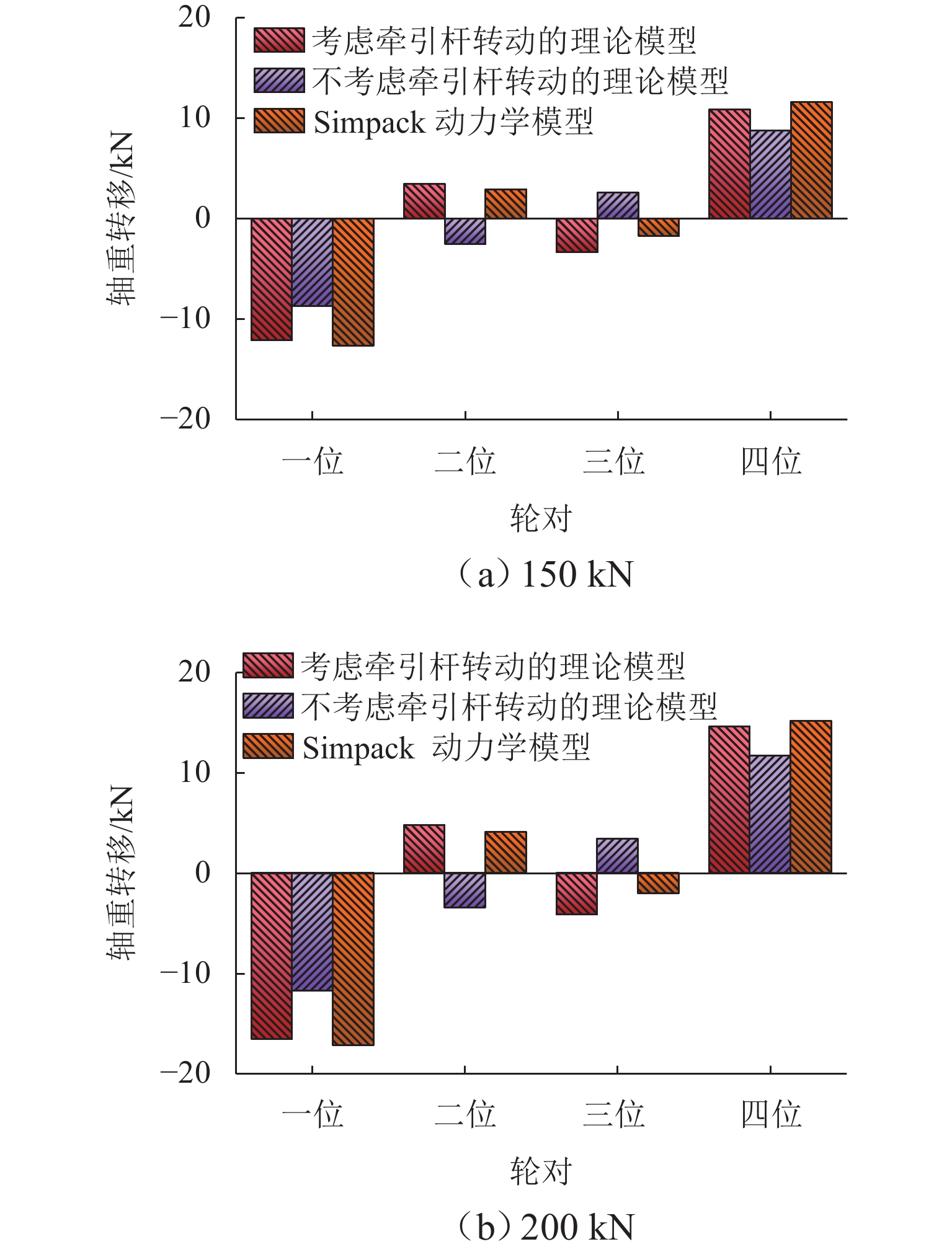

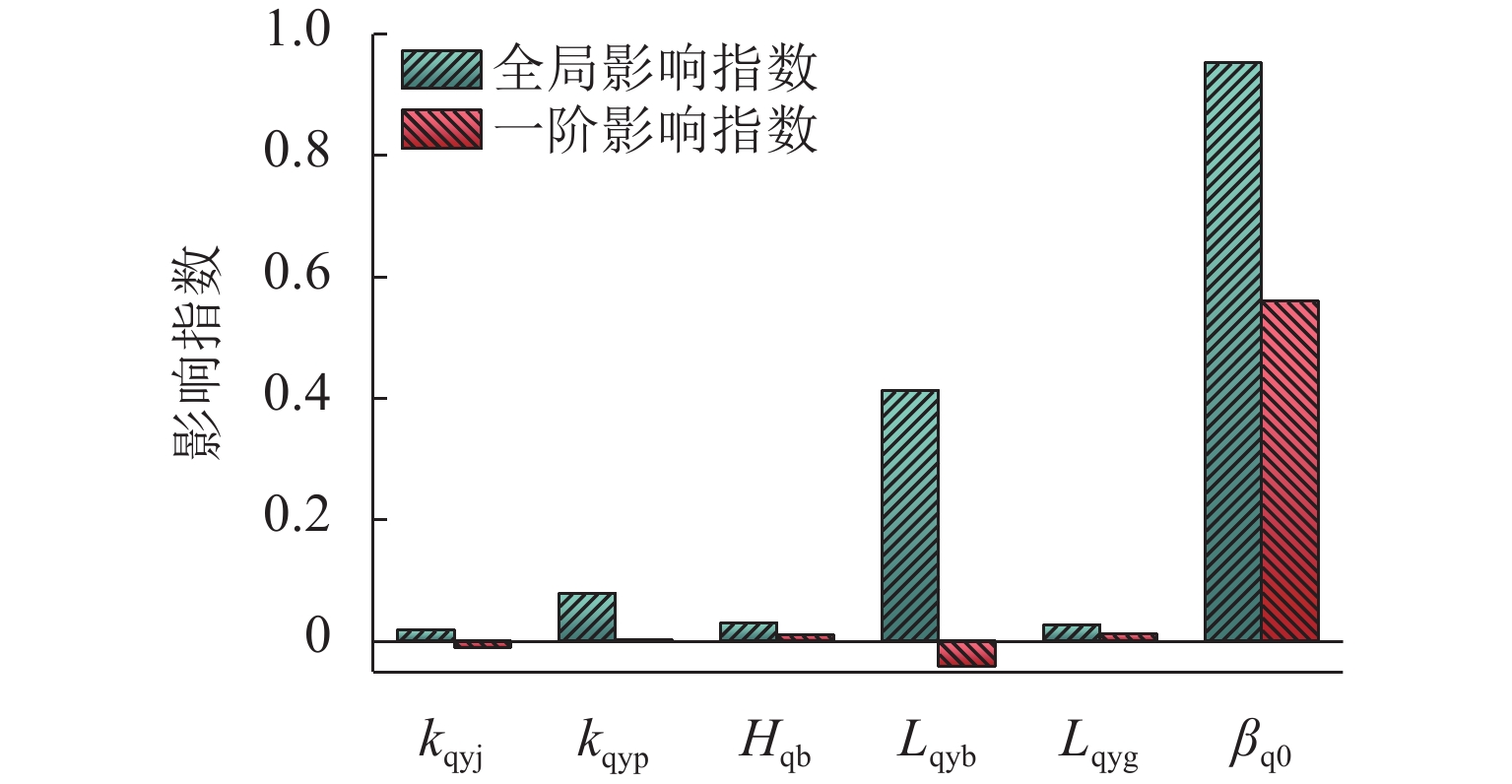

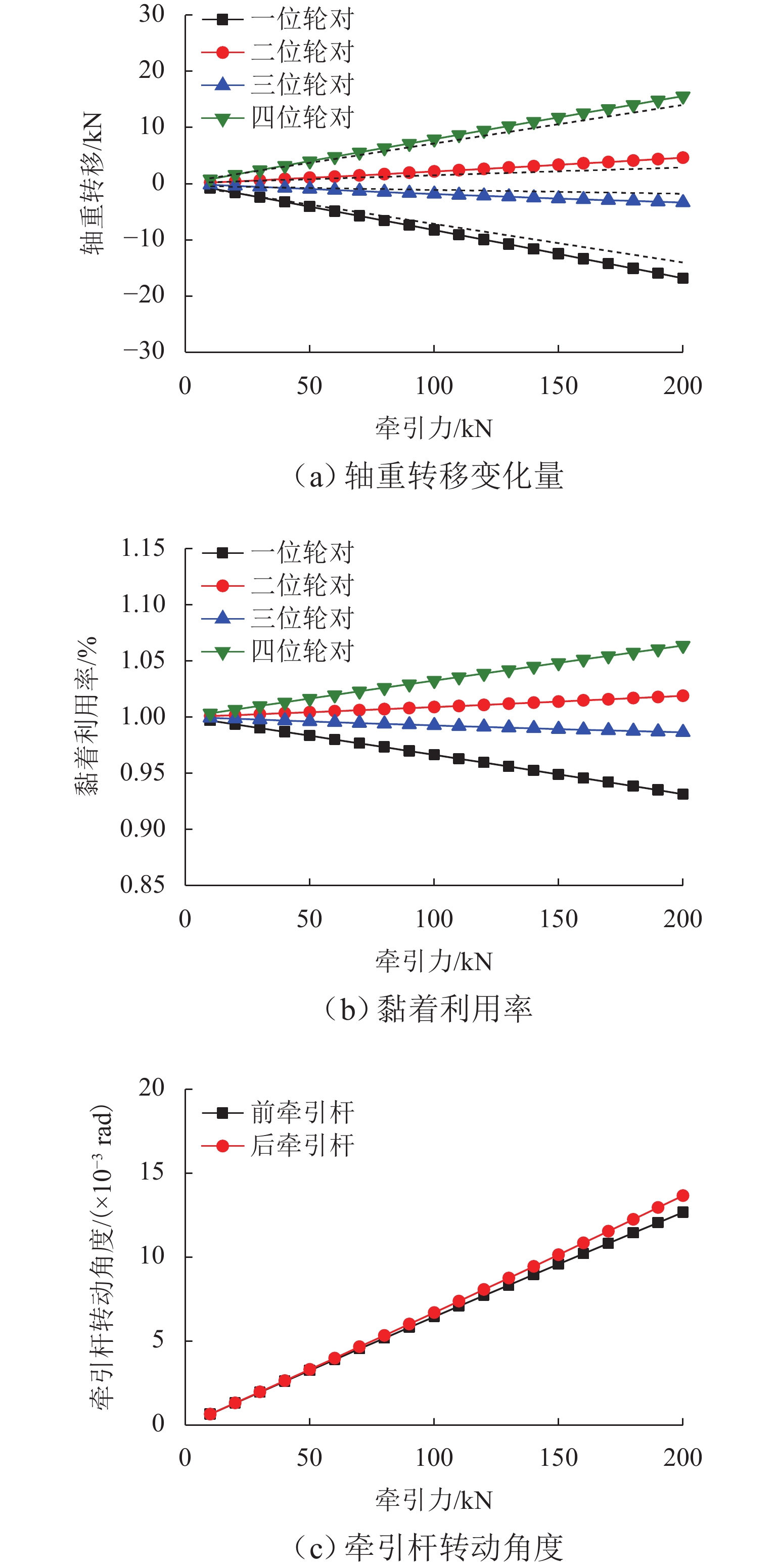

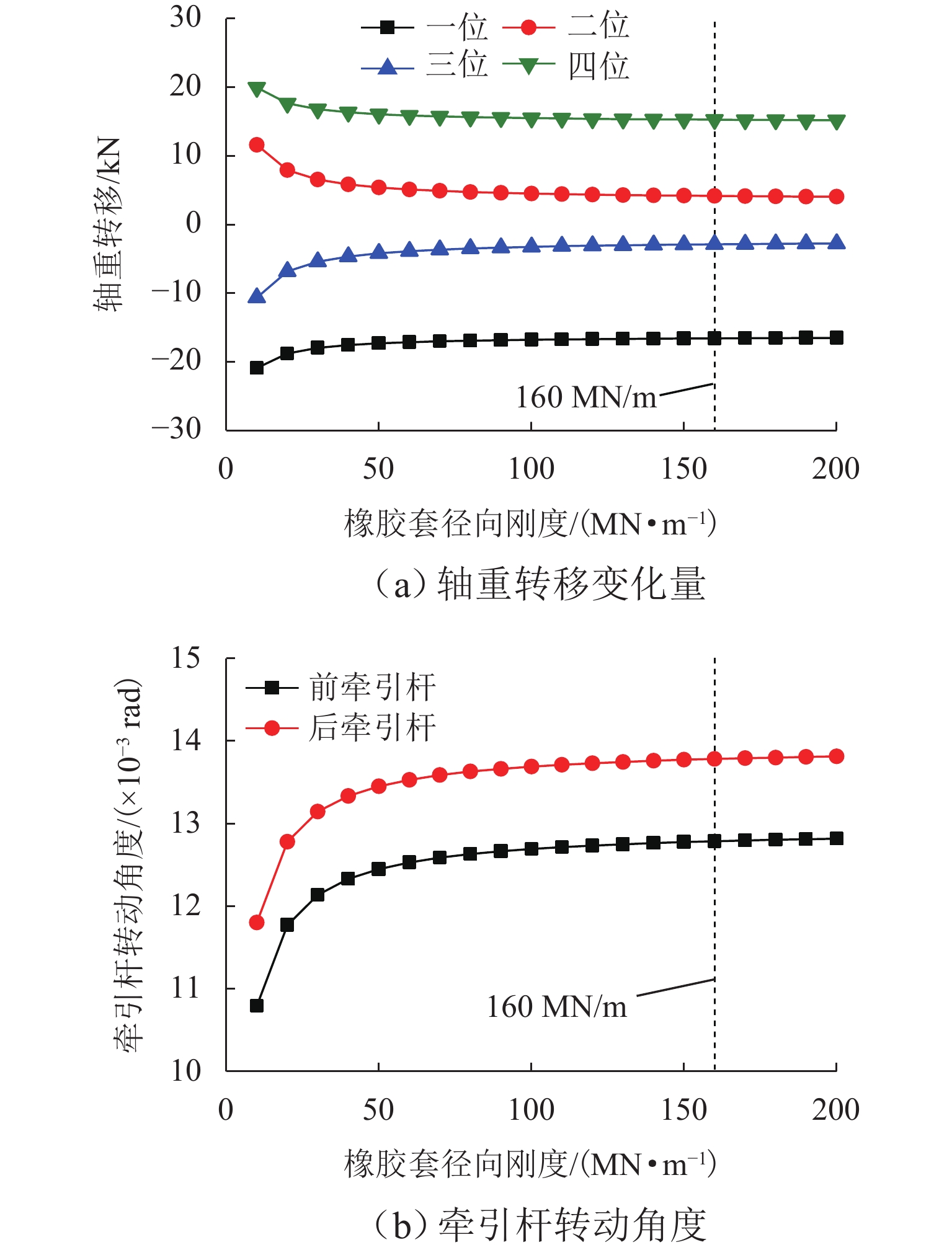

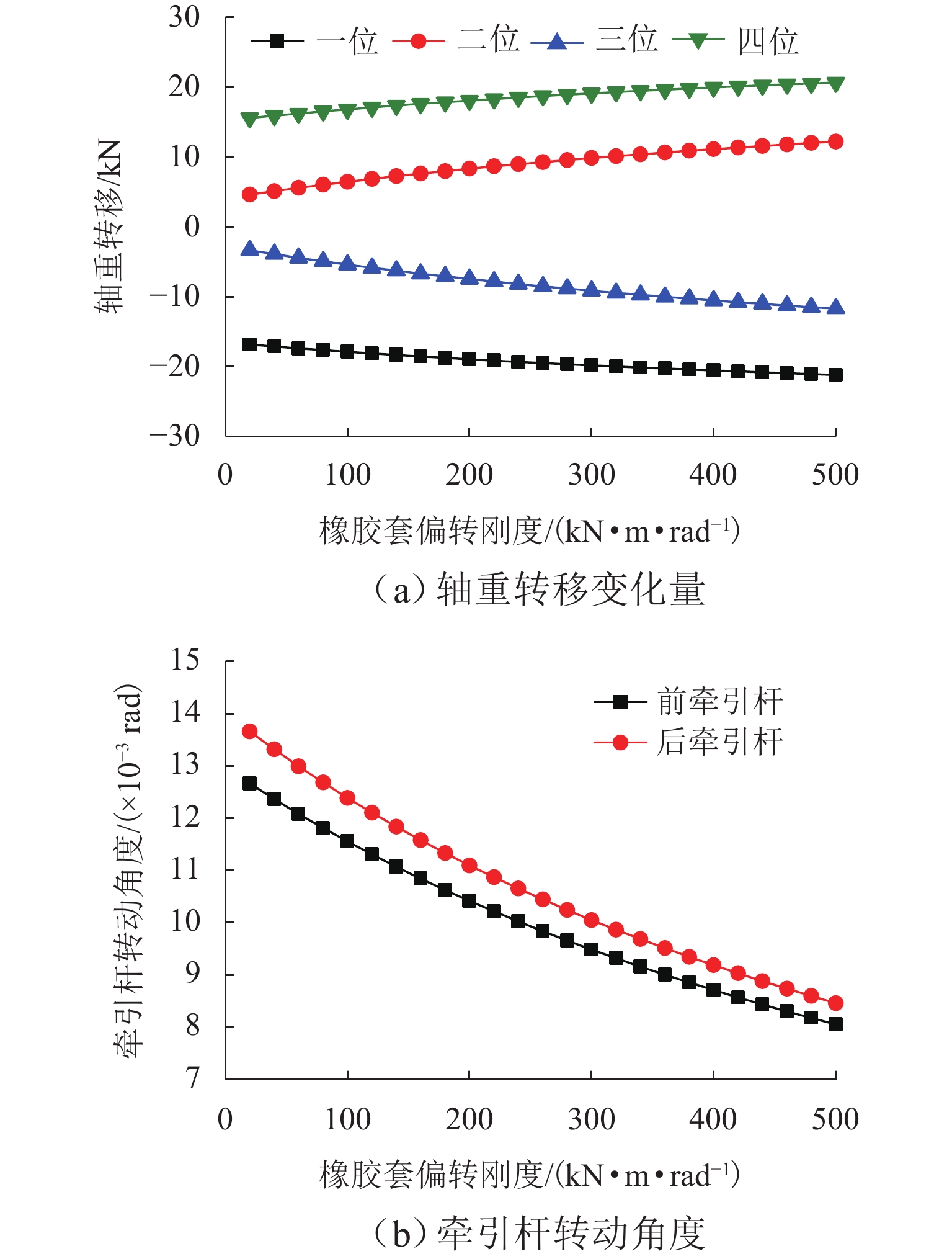

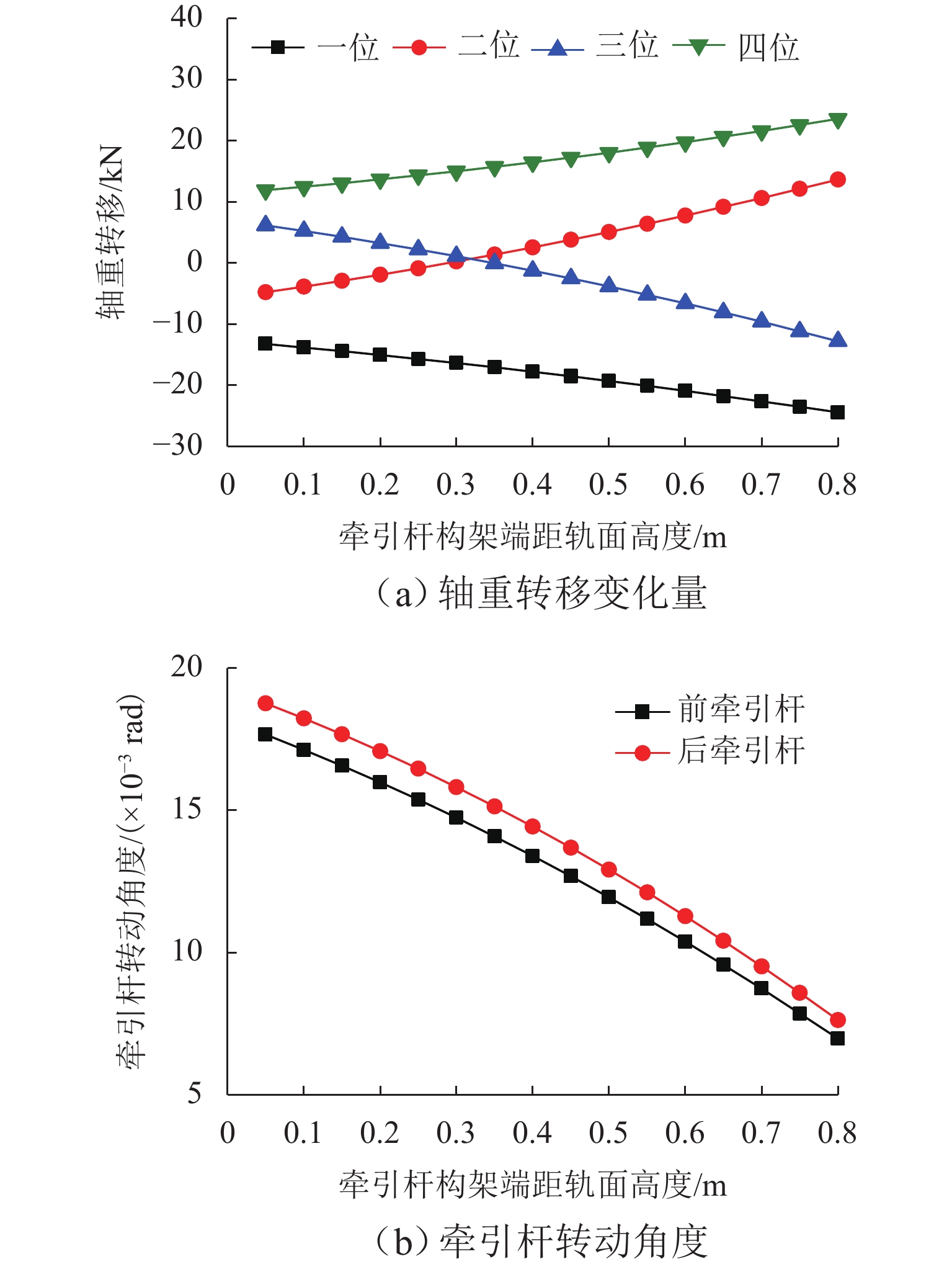

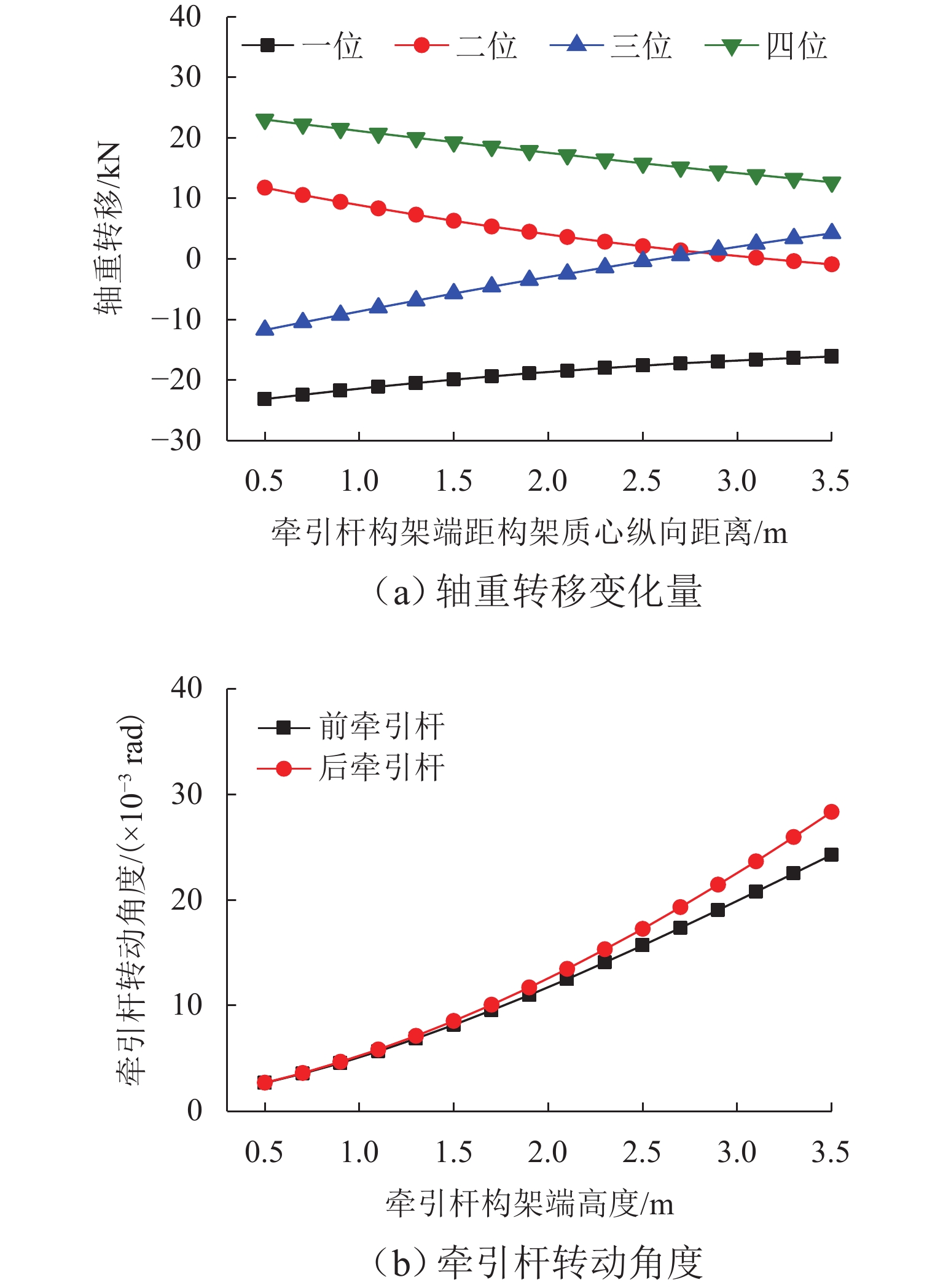

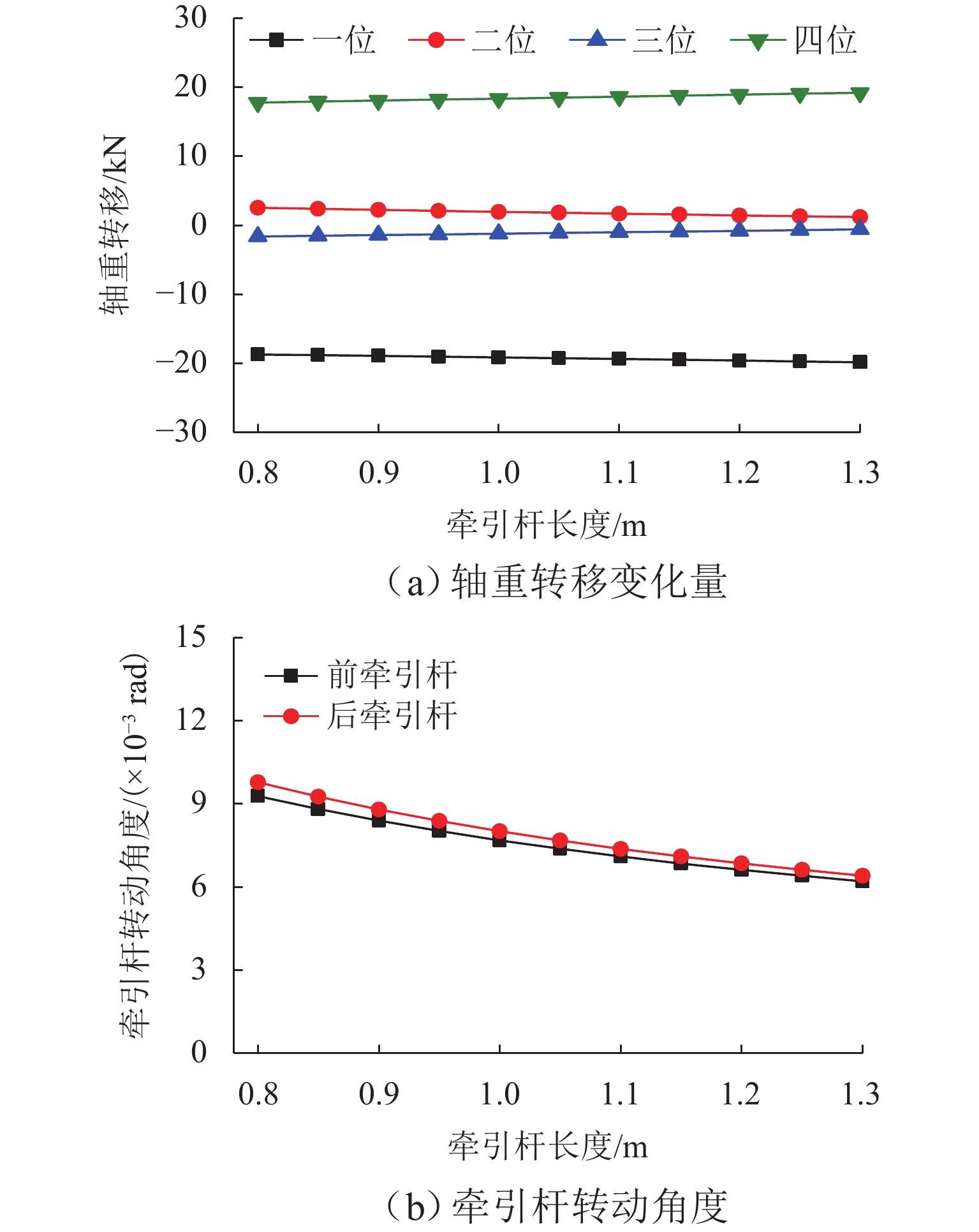

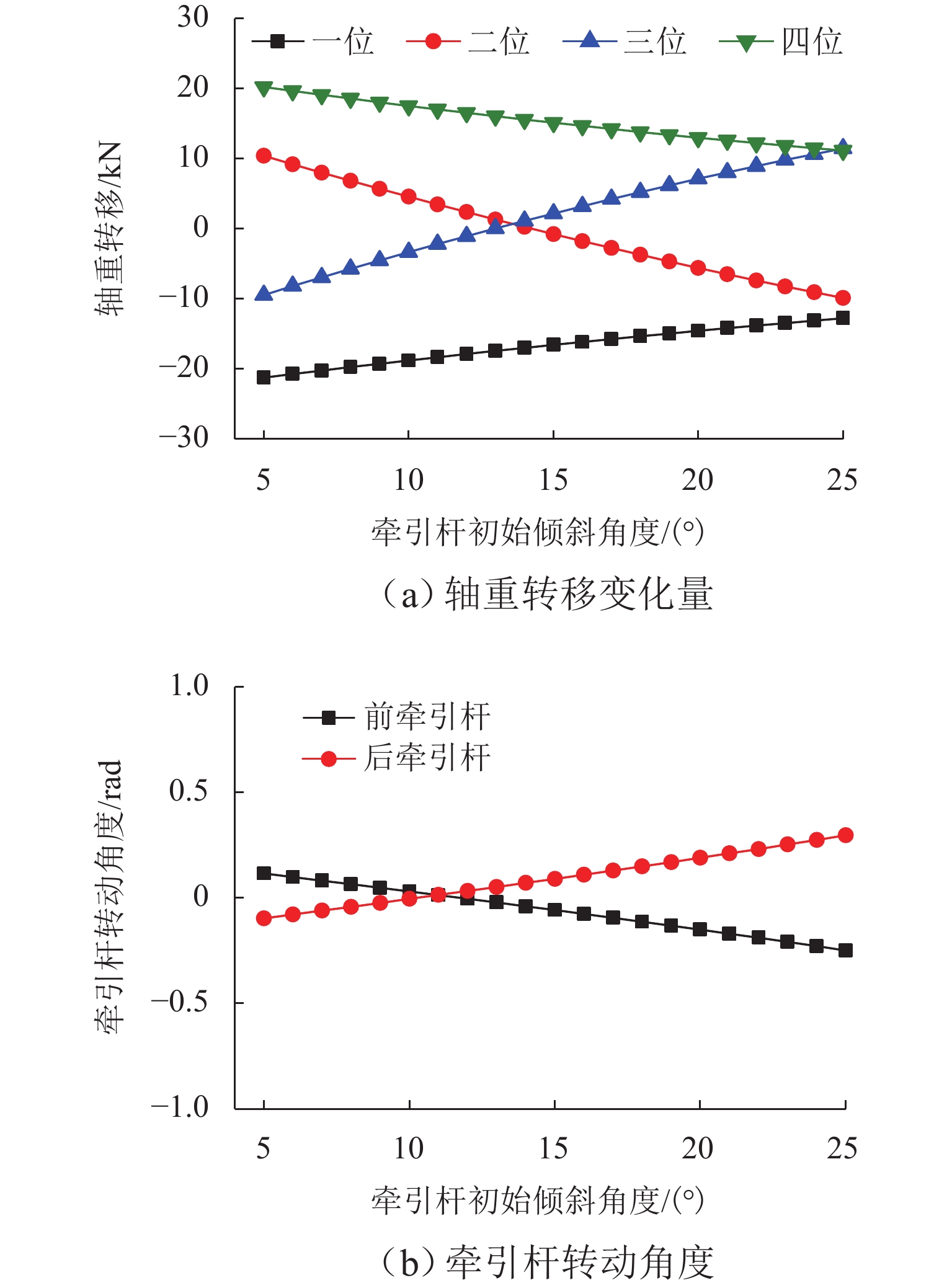

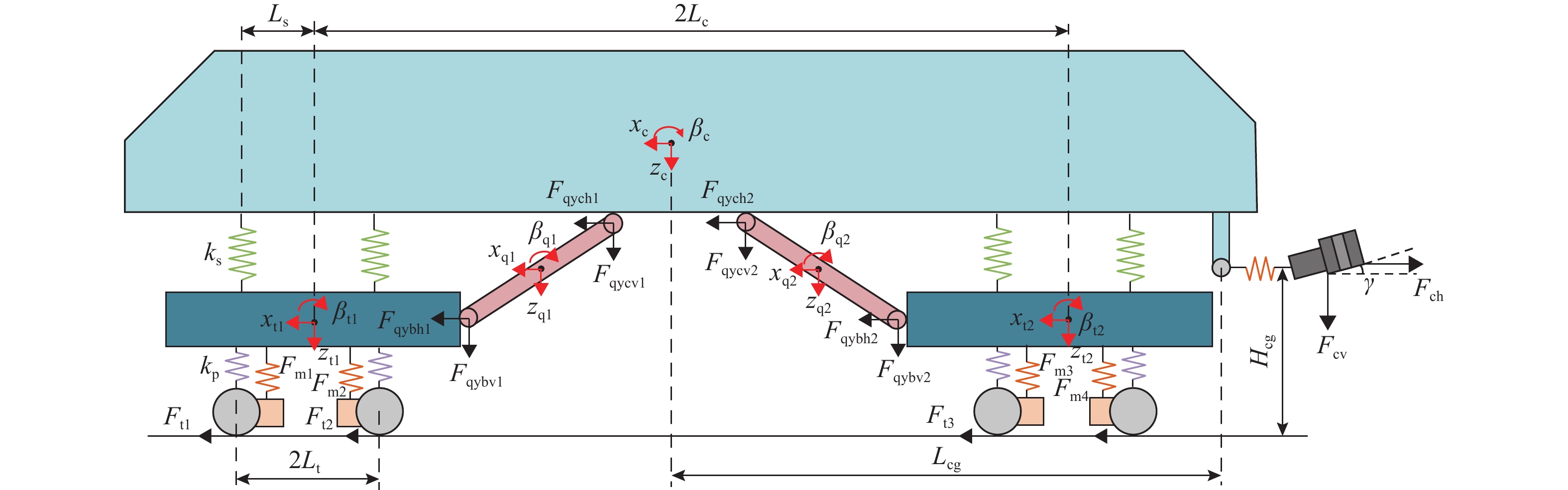

优化机车结构参数以减轻轴重转移是提高机车黏着利用率的主要手段. 针对某型机车牵引杆结构参数对轴重转移影响机理尚不明晰的问题,本文基于准静态平衡建立考虑牵引杆转动的轴重转移理论计算模型,并基于Sobol灵敏度分析方法探明牵引杆各个参数对轴重转移的影响程度,进一步分析牵引力大小、牵引杆橡胶套刚度和牵引杆位形参数对机车轴重转移的影响. 结果表明:考虑牵引杆转动时,理论模型计算结果与Simpack动力学模型计算结果更接近,理论模型计算效率显著高于动力学模型;牵引杆初始倾斜角度对轴重转移的影响较其他牵引杆参数更大,牵引杆的转动导致各轴的轴重随牵引力非线性变化;牵引杆橡胶套径向刚度超过160 MN/m后,机车轴重转移变化趋于平缓;牵引杆橡胶套偏转刚度由20 N m/rad增加至500 N m/rad,机车轴重转移量增大了25.7%;牵引杆构架端距轨面高度由0.05 m增加至0.8 m时,机车轴重转移量增大了84.3%;牵引杆构架端距构架质心纵向距离由0.5 m增加至3.5 m时,机车轴重转移量减小了30.4%;牵引杆初始倾斜角度在11°左右时,牵引杆的转动角度接近于0;牵引杆初始倾斜角度在13 ~ 14°时,二位和三位轮对的轴重转移接近于0.

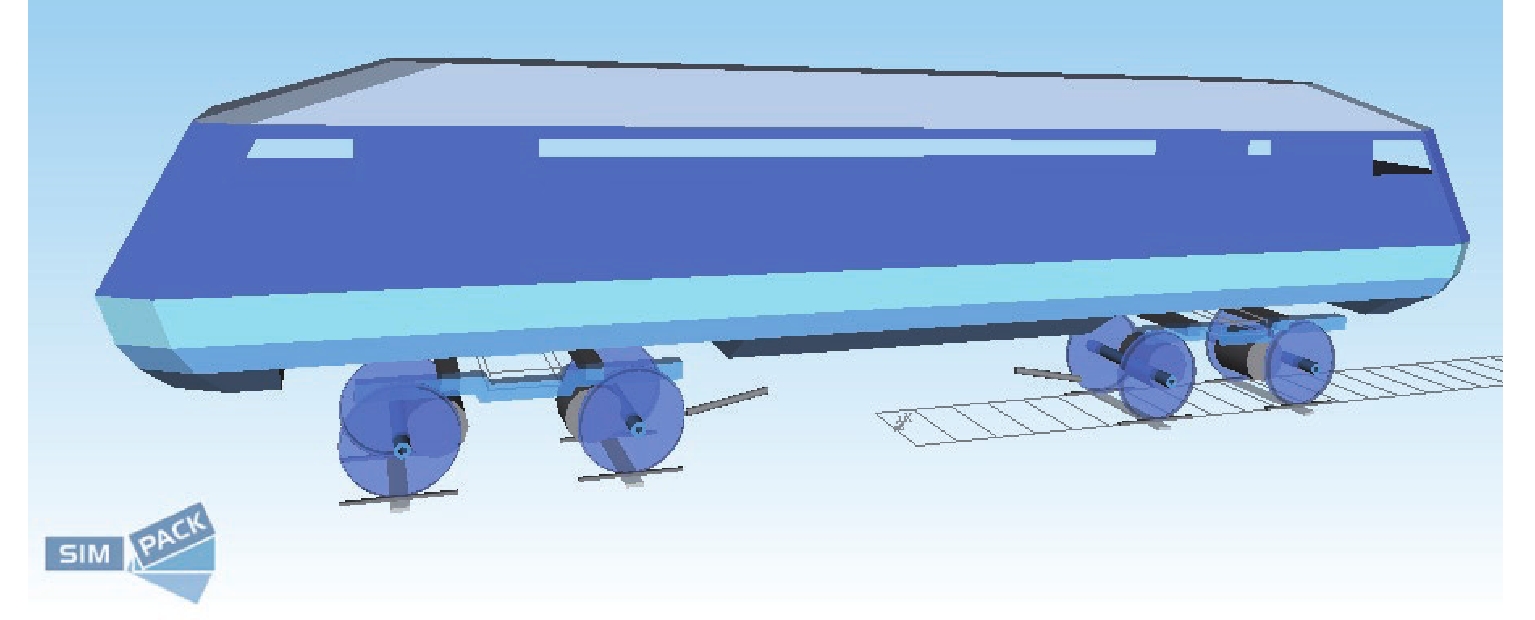

Abstract:Mitigating axle load transfer by optimizing structural parameters of locomotives is a primary strategy for enhancing adhesion utilization. To address the unclear mechanism by which the traction rod of a locomotive affects axle load transfer, a theoretical calculation model for axle load transfer given the rotation of the traction rod was established based on quasi-static equilibrium. The influence of the traction rod parameters on axle load transfer was explored based on the Sobol sensitivity analysis. Further analysis investigated the influence of traction force magnitude, stiffness of rubber sleeves, and position of the traction rod on axle load transfer. The results show that when the rotation of the traction rod is considered, the calculation results of the theoretical model are closer to those of the Simpack model, and the theoretical model exhibits significantly higher computational efficiency than the dynamics model. The initial tilt angle of the traction rod has a greater effect on axle load transfer than other traction rod parameters, and the rotation of the traction rod causes the load on each axle to vary nonlinearly with the traction force. As the radial stiffness of rubber sleeves of the traction rod exceeds 160 MN/m, the change in the locomotive’s axle load transfer tends to be gentle. As the deflection stiffness of rubber sleeves of the traction rod increases from 20 N m/rad to 500 N m/rad, the locomotive’s axle load transfer increases by 25.7%. As the height between the end of the traction rod frame and the rail surface increases from 0.05 m to 0.8 m, the locomotive’s axle load transfer increases by 84.3%. As the longitudinal distance between the end of the traction rod frame and the frame centroid increases from 0.5 m to 3.5 m, the locomotive’s axle load transfer decreases by 30.4%. The rotation angle of the traction rod approaches 0 when the initial tilt angle of the traction rod is around 11°. The axle load transfer of the second and third wheelsets approaches 0 when the initial tilt angle of the traction rod is between 13° and 14°.

-

Key words:

- locomotive /

- axle load transfer /

- traction rod /

- parameter effect analysis /

- sensitivity analysis

-

表 1 模型自由度

Table 1. Freedom degrees of model

纵向 垂向 点头 车体 xc zc βc 构架(j=1 ~ 2) xtj ztj βtj 牵引杆(j=1 ~ 2) xqj zqj βqj 表 2 轴重转移分析中部件受力

Table 2. Forces of components in axle load transfer analysis

符号 具体含义 Fsk 第k个二系悬挂垂向分力(k=1 ~ 4) Fsix 第k个二系悬挂纵向分力(k=1 ~ 4) Fpi 第i位轮对的一系悬挂垂向分力 Fpix 第i位轮对的一系悬挂纵向分力 Fqyc(b)vj 第j个牵引杆在车体端和构架端受到的垂向分力 Fqyc(b)hj 第j个牵引杆在车体端和构架端受到的纵向分力 Mqyc(b)j 第j个牵引杆在车体端和构架端受到的转矩 Fmi 第i个电机受到的吊挂力 Fti 第i位轮对的轮周牵引力 Fgh 车体受到的钩缓作用力 Fghv 车体受到的钩缓作用力垂向分力 Lc 车辆定距的一半 Ls 二系弹簧距构架质心纵向间距的一半 Lcg 为钩缓力作用点距离车体质心的纵向距离 Hcg 为车钩距离轨面的垂向间距 Lt 轴距的一半 -

[1] 王晨, 罗世辉, 马卫华, 等. 启动工况下2C0机车粘着利用率分析[J]. 机械设计与制造, 2015(11): 236-238, 242.WANG Chen, LUO Shihui, MA Weihua, et al. Analysis on adhesion availability of 2C0 locomotive under starting working condition[J]. Machinery Design & Manufacture, 2015(11): 236-238,242. [2] 陈清华, 杨云帆, 凌亮, 等. 复杂轮轨摩擦条件下的重载机车防滑控制研究[J]. 机械工程学报, 2023, 59(10): 179-186. doi: 10.3901/JME.2023.10.179CHEN Qinghua, YANG Yunfan, LING Liang, et al. Study on anti-slip control for heavy-haul locomotives under complex wheel/rail friction conditions[J]. Journal of Mechanical Engineering, 2023, 59(10): 179-186. doi: 10.3901/JME.2023.10.179 [3] 杨宁, 蒋威, 谢冰若, 等. 电力机车牵引黏着控制半实物仿真研究[J]. 铁道机车车辆, 2021, 41(3): 9-14. doi: 10.3969/j.issn.1008-7842.2021.03.02YANG Ning, JIANG Wei, XIE Bingruo, et al. Semi-physical simulation research on traction adhesion control of electric locomotive[J]. Railway Locomotive & Car, 2021, 41(3): 9-14. doi: 10.3969/j.issn.1008-7842.2021.03.02 [4] 高文, 靳春雷, 陆静. 基于需求的多样化轴重转移算法及面向对象的实现[J]. 机械制造, 2024, 62(8): 25-29, 33.GAO Wen, JIN Chunlei, LU Jing. Diversified axle load transfer algorithm based on demand and object-oriented achievement[J]. Machinery, 2024, 62(8): 25-29,33. [5] 伍泓桦, 邹瑞明, 马卫华. 33t轴重重载机车轴重转移研究[J]. 铁道机车车辆, 2016, 36(1): 1-5. doi: 10.3969/j.issn.1008-7842.2016.01.01WU Honghua, ZOU Ruiming, MA Weihua. Research on axle load transfer on 33t axle load heavy haul locomotive[J]. Railway Locomotive & Car, 2016, 36(1): 1-5. doi: 10.3969/j.issn.1008-7842.2016.01.01 [6] 罗洪文, 罗赟, 钟文生. 8轴机车轴重转移计算分析[J]. 铁道机车车辆, 2007(6): 9-11, 22. doi: 10.3969/j.issn.1008-7842.2007.06.003LUO Hongwen, LUO Yun, ZHONG Wensheng. Axle load transfer calculation and analysis of eight-axle locomotive[J]. Railway Locomotive & Car, 2007(6): 9-11,22. doi: 10.3969/j.issn.1008-7842.2007.06.003 [7] 黄志辉, 丁凤铁. 电机架悬及轴悬对机车轴重转移的影响[J]. 内燃机车, 2006(4): 18-21, 49-50. doi: 10.3969/j.issn.1003-1820.2006.04.007HUANG Zhihui, DING Fengtie. Effect of motor suspended on frame or wheelset on locomotive axle load transfer[J]. Railway Locomotive and Motor Car, 2006(4): 18-21,49-50. doi: 10.3969/j.issn.1003-1820.2006.04.007 [8] 刘陆洲. 基于多体动力学的电力机车轴重转移仿真研究[J]. 兰州交通大学学报, 2015, 34(4): 137-140. doi: 10.3969/j.issn.1001-4373.2015.04.026LIU Luzhou. Simulation of locomotive axle load transfer based on multi-body dynamics[J]. Journal of Lanzhou Jiaotong University, 2015, 34(4): 137-140. doi: 10.3969/j.issn.1001-4373.2015.04.026 [9] 魏家麒, 张开林, 姚远. 单轴牵引力变化时的机车轴重转移分析[J]. 机车电传动, 2014(3): 40-43. doi: 10.13890/j.issn.1000-128x.2014.03.007WEI Jiaqi, ZHANG Kailin, YAO Yuan. Analysis of locomotive axle load transfer with consideration of adhesive force varying for each axle[J]. Electric Drive for Locomotives, 2014(3): 40-43. doi: 10.13890/j.issn.1000-128x.2014.03.007 [10] 吕凯凯, 王开云, 张志和. 200km/h八轴客运电力机车轴重转移分析[J]. 西南科技大学学报, 2015, 30(4): 25-28, 55. doi: 10.3969/j.issn.1671-8755.2015.04.006LV Kaikai, WANG Kaiyun, ZHANG Zhihe. Axle-load transfer analysis of 200 km/h eight-axle passenger electric locomotive[J]. Journal of Southwest University of Science and Technology, 2015, 30(4): 25-28,55. doi: 10.3969/j.issn.1671-8755.2015.04.006 [11] 曲天威, 罗世辉, 马卫华. 33t轴重内燃机车方案及机车曲线黏着问题研究[J]. 铁道学报, 2020, 42(9): 39-48.QU Tianwei, LUO Shihui, MA Weihua. Study on diesel locomotive concepts with 33 t axle load and its curving adhesion problem[J]. Journal of the China Railway Society, 2020, 42(9): 39-48. [12] 王自超, 陈再刚, 翟婉明, 等. 考虑齿轮传动系统的重载电力机车轴重转移研究[J]. 铁道学报, 2019, 41(10): 24-29.WANG Zichao, CHEN Zaigang, ZHAI Wanming, et al. Research on axle load transfer of heavy-haul electric locomotive considering effect of gear transmission system[J]. Journal of the China Railway Society, 2019, 41(10): 24-29. [13] 皮优政. HXD1D型机车齿轮传动对机车轴重转移影响的分析研究[J]. 机车车辆工艺, 2021(5): 5-8. doi: 10.14032/j.issn.1007-6034.2021.05.002PI Youzheng. Probing into the effect of gear drive of HXD1D locomotive on its axleload shift[J]. Locomotive & Rolling Stock Technology, 2021(5): 5-8. doi: 10.14032/j.issn.1007-6034.2021.05.002 [14] 张志超, 李谷, 储高峰, 等. 考虑车钩垂向约束的机车轴重转移计算方法研究[J]. 工程力学, 2021, 38(11): 212-219.ZHANG Zhichao, LI Gu, CHU Gaofeng, et al. Research on the calculation method of locomotive axle load transfer considering coupler vertical constrain effect[J]. Engineering Mechanics, 2021, 38(11): 212-219. [15] 罗建利. 中低速磁浮牵引车的轴重转移研究[J]. 机车电传动, 2022(1): 79-84.LUO Jianli. Research on axle load transfer of low-medium speed maglev tractor[J]. Electric Drive for Locomotives, 2022(1): 79-84. [16] 张又孔, 沈龙江, 陈国胜. 基于小齿轮空心轴C0转向架的机车轴重/轮重转移分析[J]. 电力机车与城轨车辆, 2023, 46(6): 47-51.ZHANG Youkong, SHEN Longjiang, CHEN Guosheng. Analysis of locomotive axle load/wheel load transfer based on C0 bogie of pinion hollow shaft[J]. Electric Locomotives & Mass Transit Vehicles, 2023, 46(6): 47-51. [17] 冯俞钧, 黄景春, 王会议, 等. 重载机车动态轴重转移补偿仿真研究[J]. 计算机仿真, 2018, 35(8): 115-118. doi: 10.3969/j.issn.1006-9348.2018.08.024FENG Yujun, HUANG Jingchun, WANG Huiyi, et al. Simulation researchon heavy load locomotive dynamic axle loadtransfer compensation[J]. Computer Simulation, 2018, 35(8): 115-118. doi: 10.3969/j.issn.1006-9348.2018.08.024 [18] 张昌凡, 豆兵兵, 何静, 等. 基于轴重转移下的机车防空转仿真研究[J]. 机车电传动, 2017(2): 34-38. doi: 10.13890/j.issn.1000-128x.2017.02.008ZHANG Changfan, DOU Bingbing, HE Jing, et al. Study on locomotive anti-slip simulation based on axle load transfer[J]. Electric Drive for Locomotives, 2017(2): 34-38. doi: 10.13890/j.issn.1000-128x.2017.02.008 [19] YAMASHITA M, SOEDA T. Development of re-adhesion control method considering axle-weight transfer of electric locomotive[J]. Quarterly Report of RTRI, 2011, 52(1): 7-12. doi: 10.2219/rtriqr.52.7 [20] 周海平, 李红利. 重载机车轴重转移与电气补偿对坡起的影响研究[J]. 铁道机车与动车, 2025(4): 29-31, 62.ZHOU Haiping, LI Hongli. Research on the influence of axle load transfer and electrical compensation on hill start of heavy-duty locomotives[J]. Railway Locomotive and Motor Car, 2025(4): 29-31,62. [21] 高珊, 秦佳颖, 温从溪, 等. 基于轴重转移的轴控系统制动力分配研究[J]. 机车车辆工艺, 2023(3): 1-4, 17. doi: 10.14032/j.issn.1007-6034.2023.03.001GAO Shan, QIN Jiaying, WEN Congxi, et al. Research on braking force distribution in axle controlled braking control system based on axle load transfer[J]. Locomotive & Rolling Stock Technology, 2023(3): 1-4,17. doi: 10.14032/j.issn.1007-6034.2023.03.001 [22] 雷孟宇, 张旭辉, 杨文娟, 等. 基于蒙特卡洛随机采样方法与牛顿-拉夫逊迭代方法的钻锚机器人机械臂逆运动学求解方法[J]. 煤炭学报, 2024, 49(增1): 446-456.LEI Mengyu, ZHANG Xuhui, YANG Wenjuan, et al. An integrated approach for inverse kinematics of unconventional manipulators using Monte Carlo random sampling method and Newton iterative method[J]. Journal of China Coal Society, 2024, 49(S1): 446-456. [23] 房明磊, 丁德凤, 王敏, 等. 一种求解非线性方程组的改进Shamanskii-like Levenberg-Marquardt算法[J]. 山东大学学报(理学版), 2023, 58(8): 118-126.FANG Minglei, DING Defeng, WANG Min, et al. A new modified efficient Shamanskii-like Levenberg-Marquardt method for solving systems of nonlinear equations[J]. Journal of Shandong University (Natural Science), 2023, 58(8): 118-126. [24] 王东贤, 赵建雷, 赵伟佳, 等. 基于全局灵敏度的高效一体式隔振超结构不确定性分析[J]. 振动与冲击, 2024, 43(20): 334-342. doi: 10.13465/j.cnki.jvs.2024.20.036WANG Dongxian, ZHAO Jianlei, ZHAO Weijia, et al. Highly efficient uncertainty analysis of an integrated vibration-isolating metastructure based on global sensitivity[J]. Journal of Vibration and Shock, 2024, 43(20): 334-342. doi: 10.13465/j.cnki.jvs.2024.20.036 -

下载:

下载: