Compression Performance of Cold-Formed Steel T-Shaped Composite Edge Columns with Web Stiffeners

-

摘要:

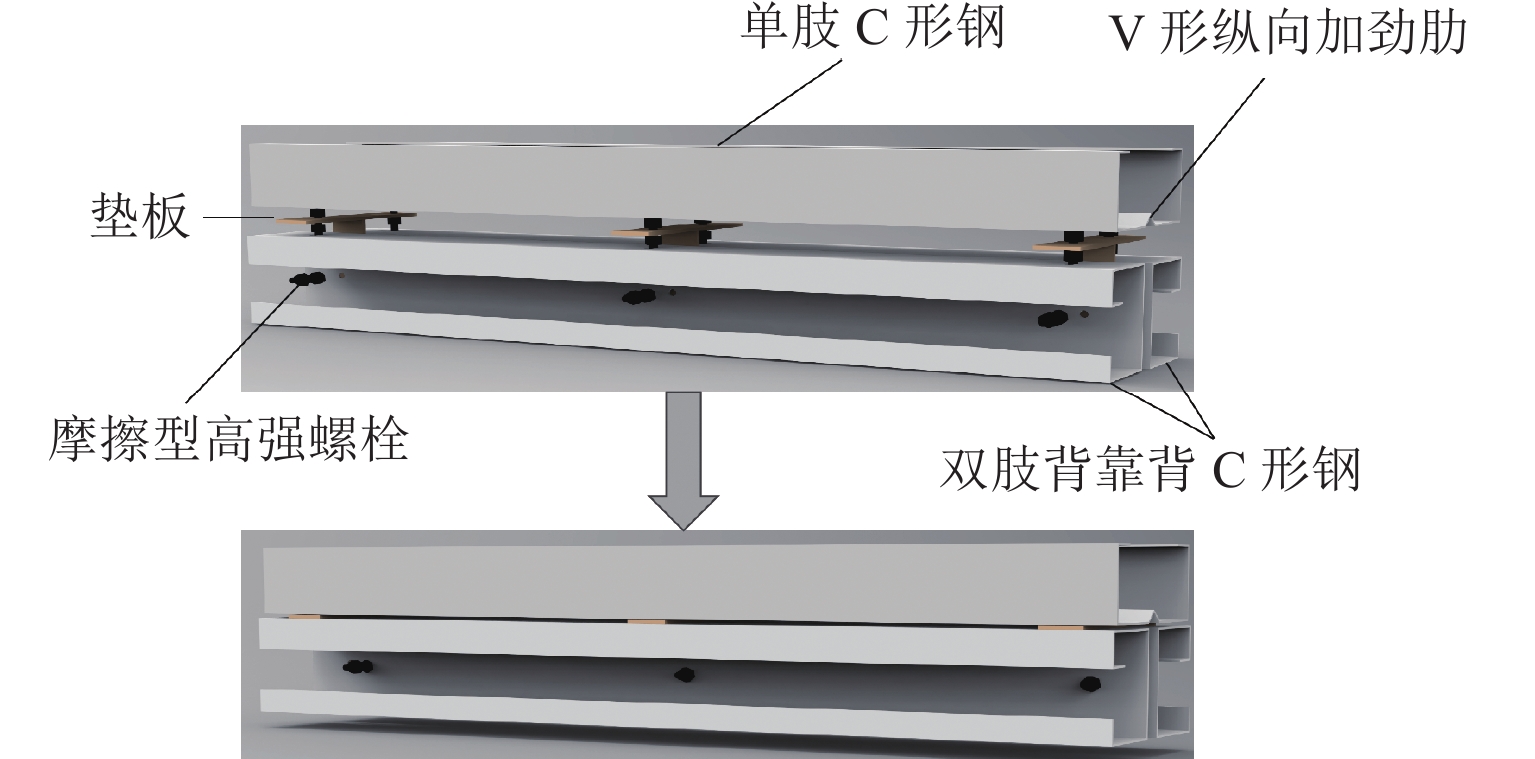

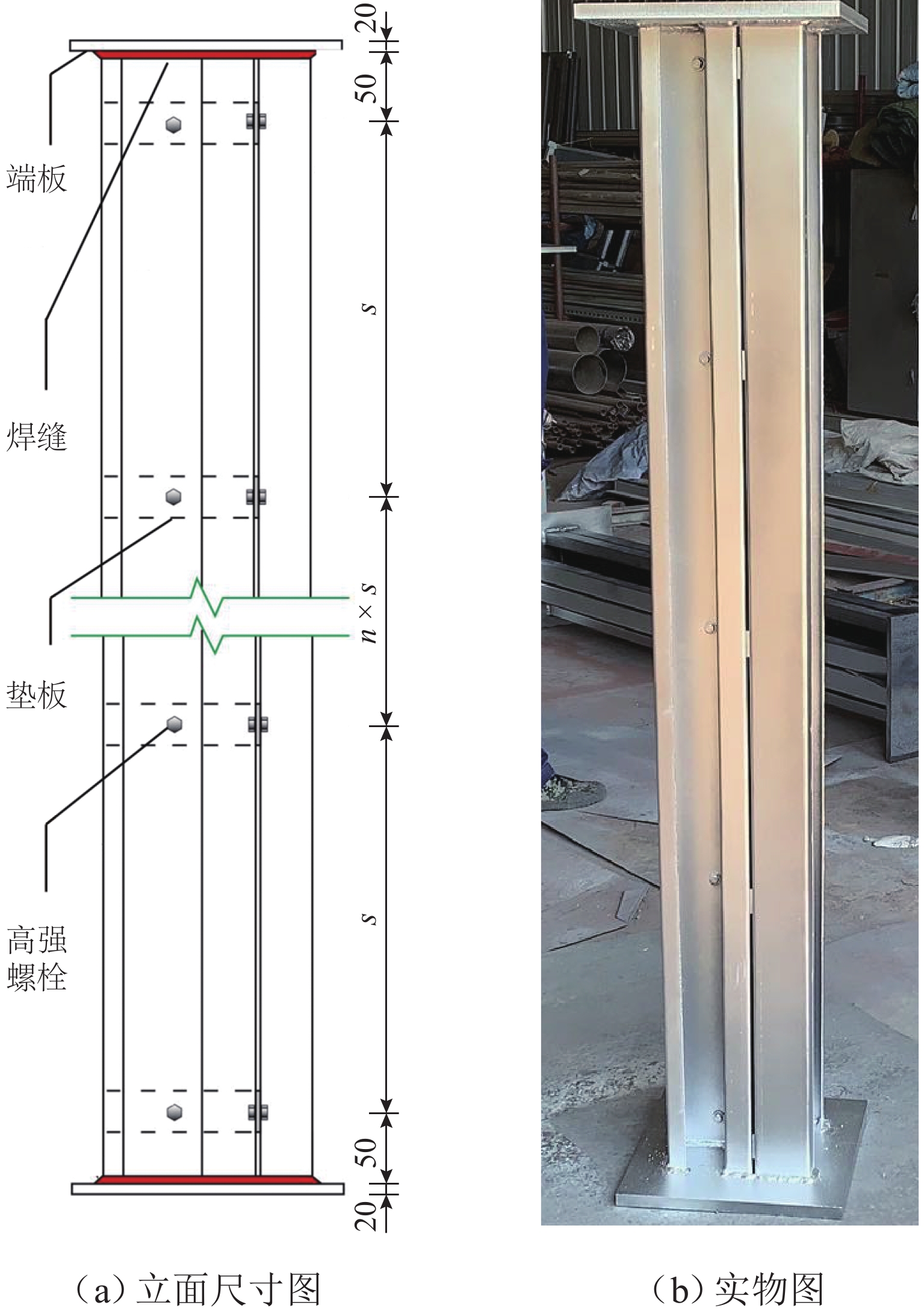

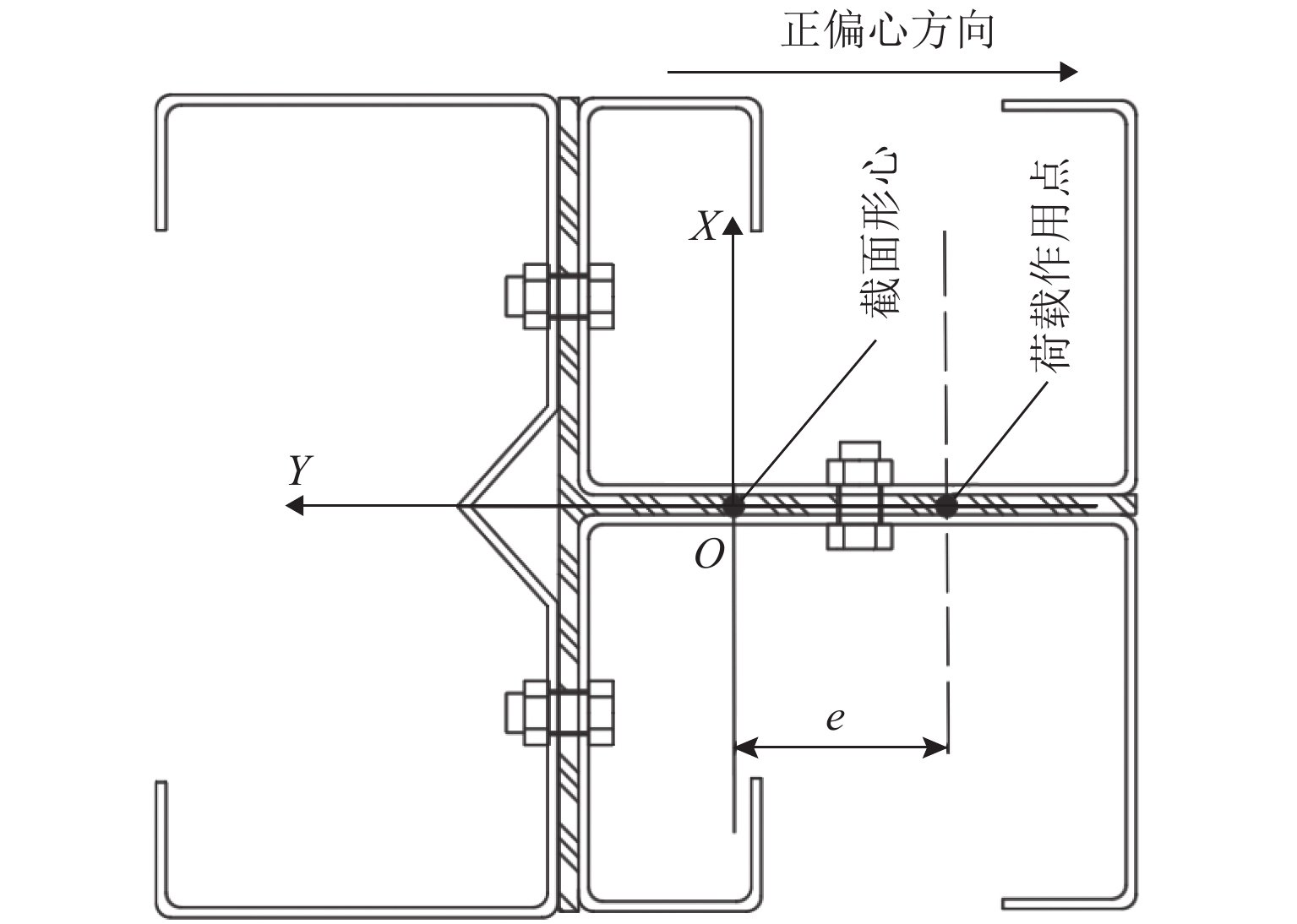

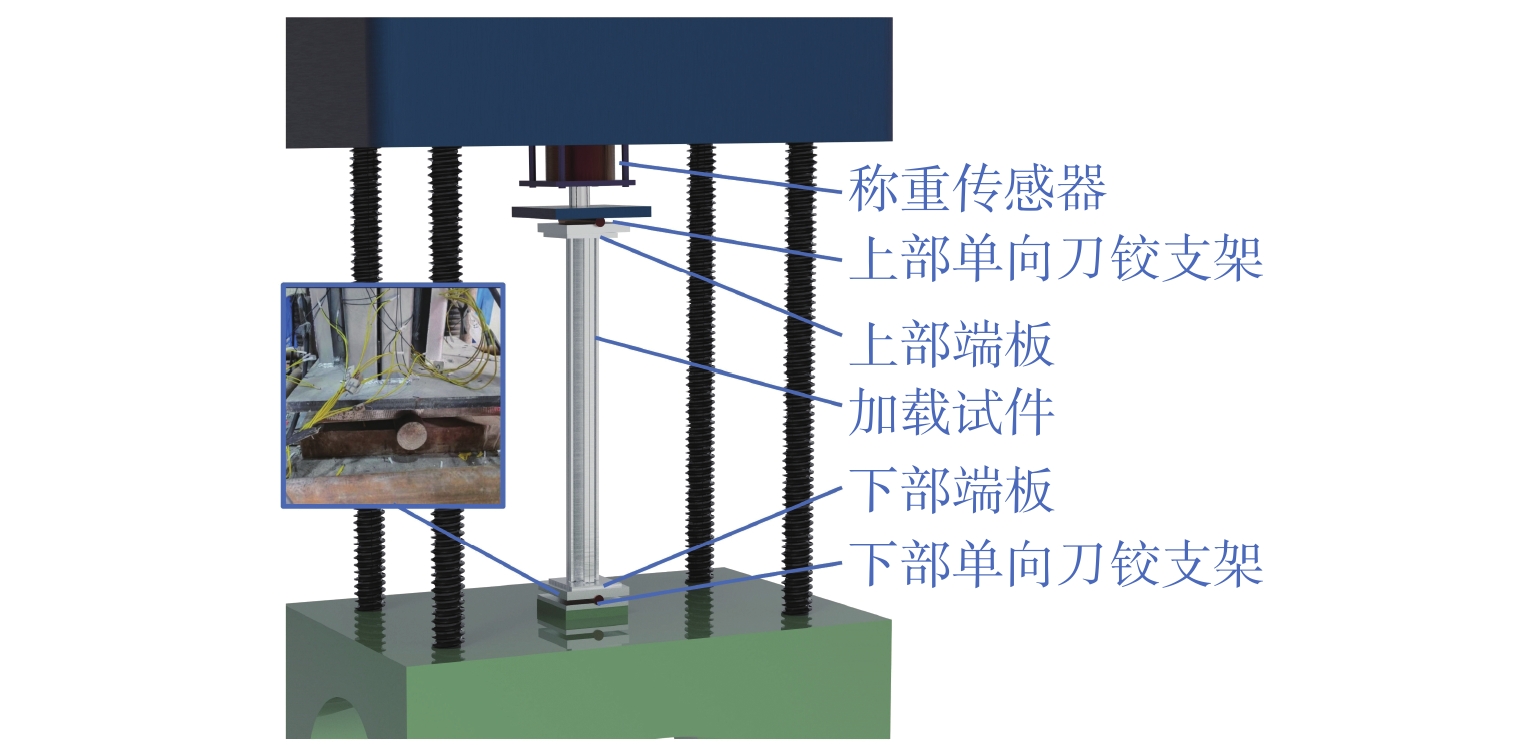

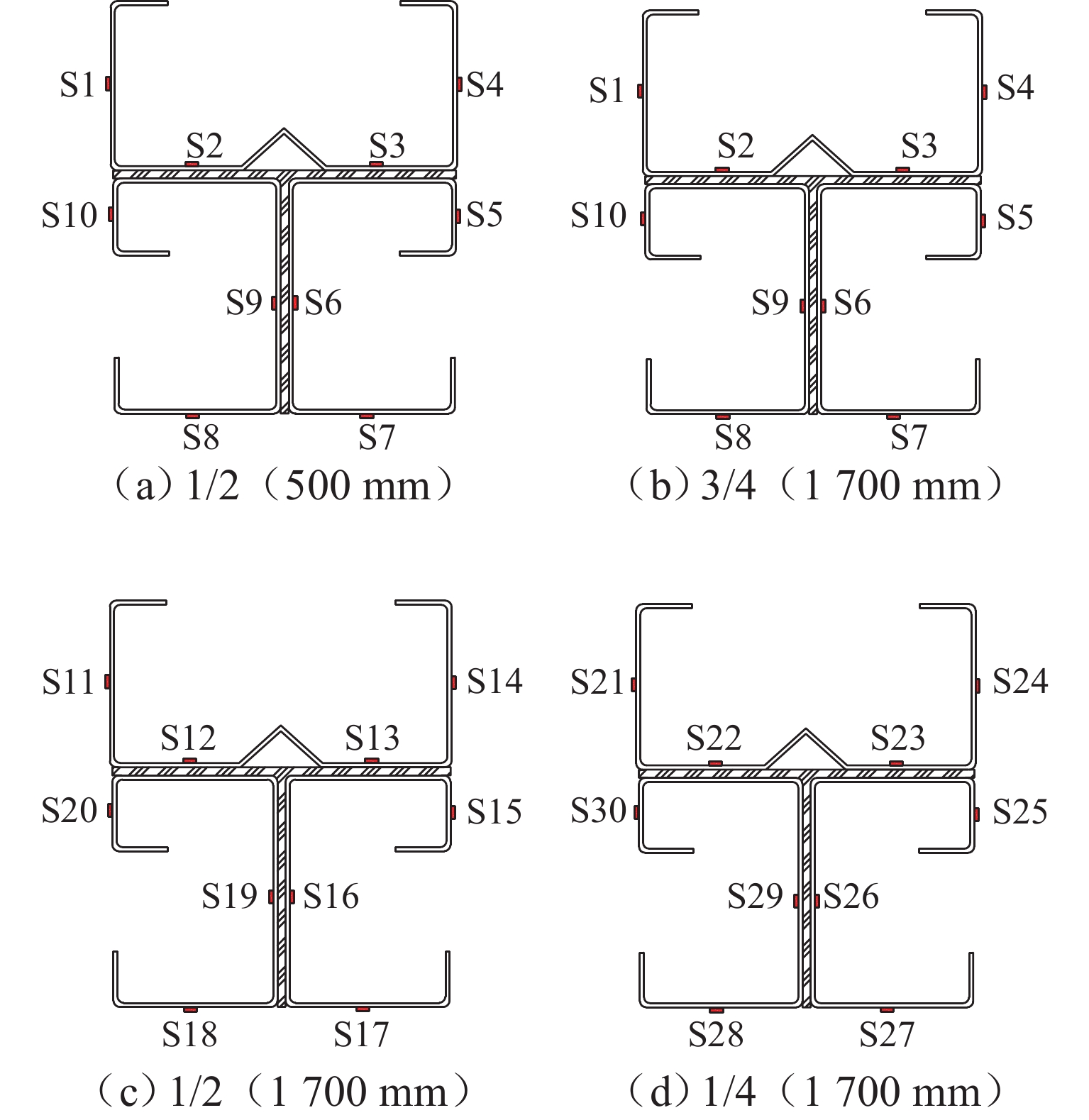

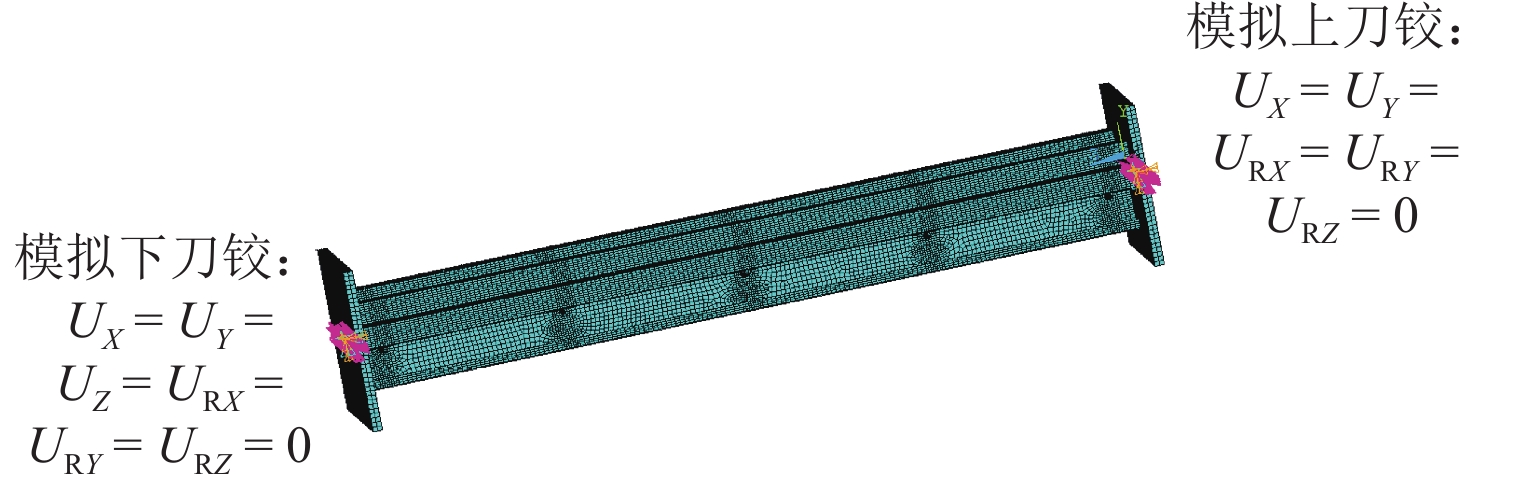

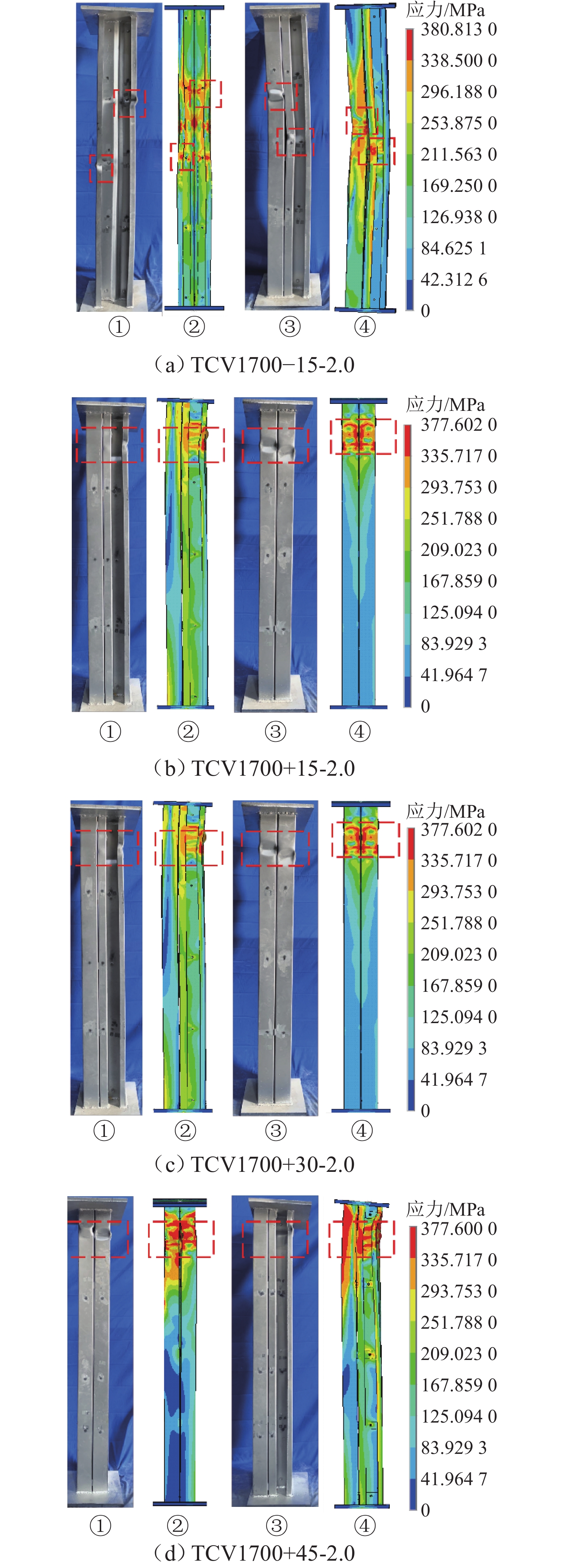

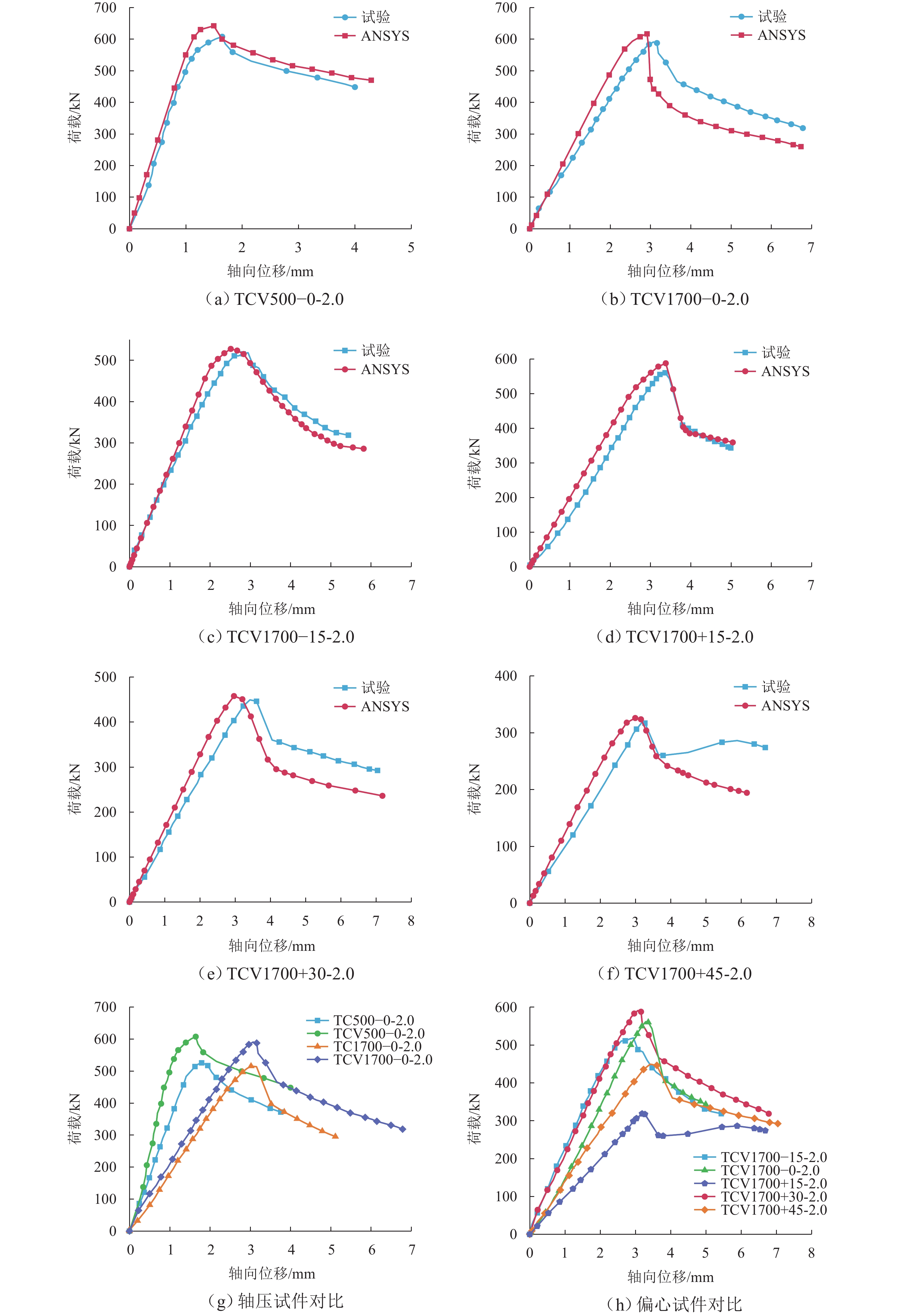

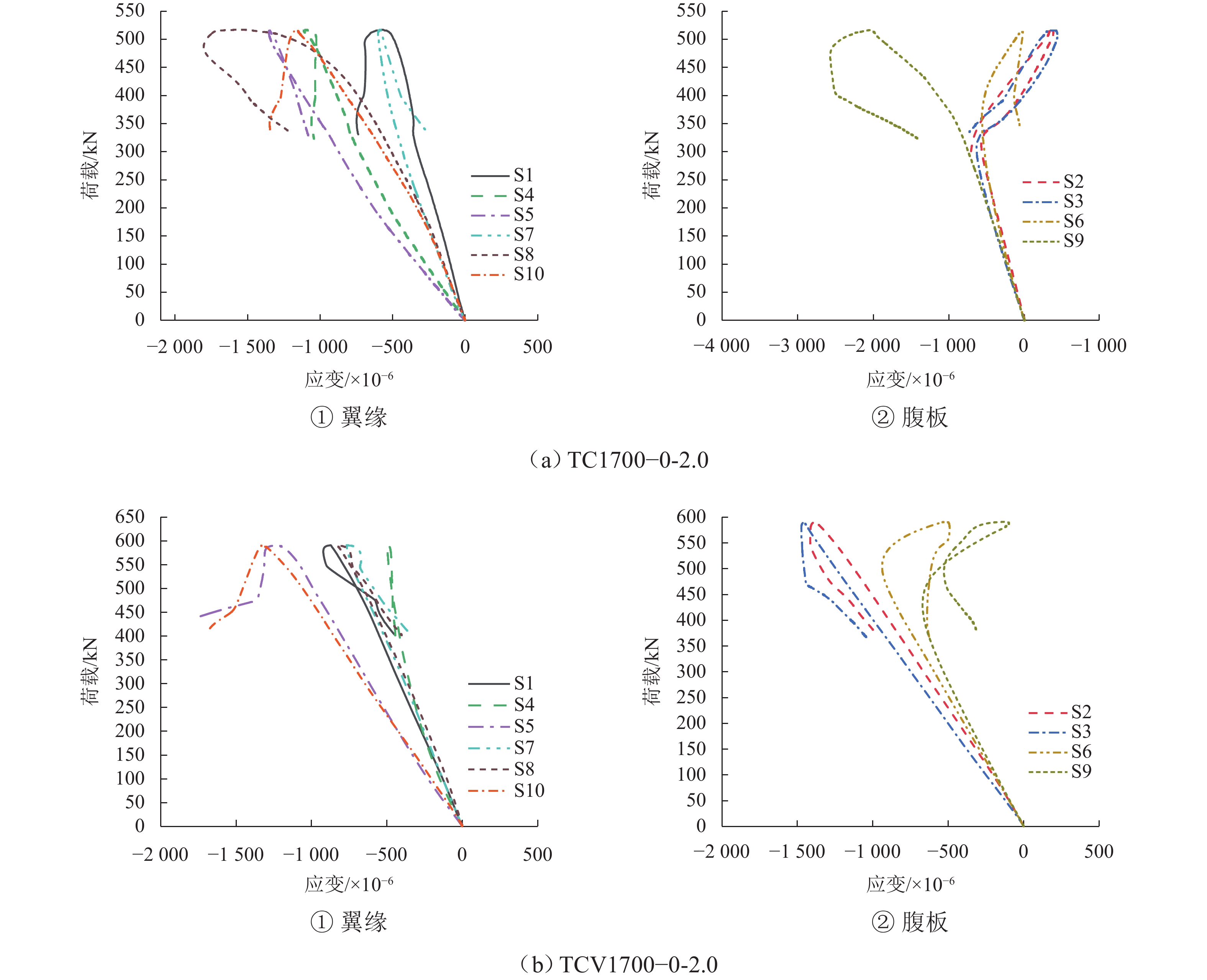

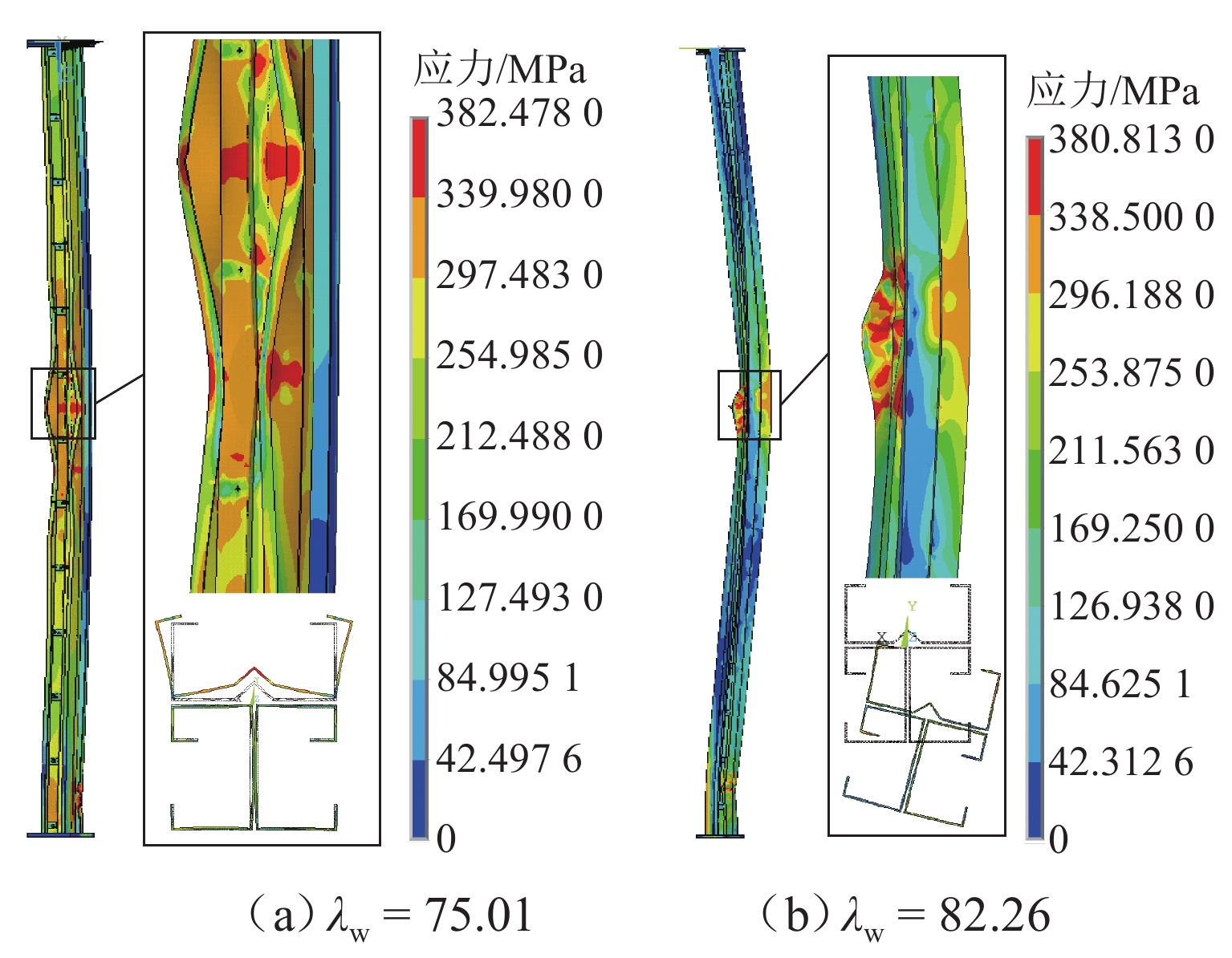

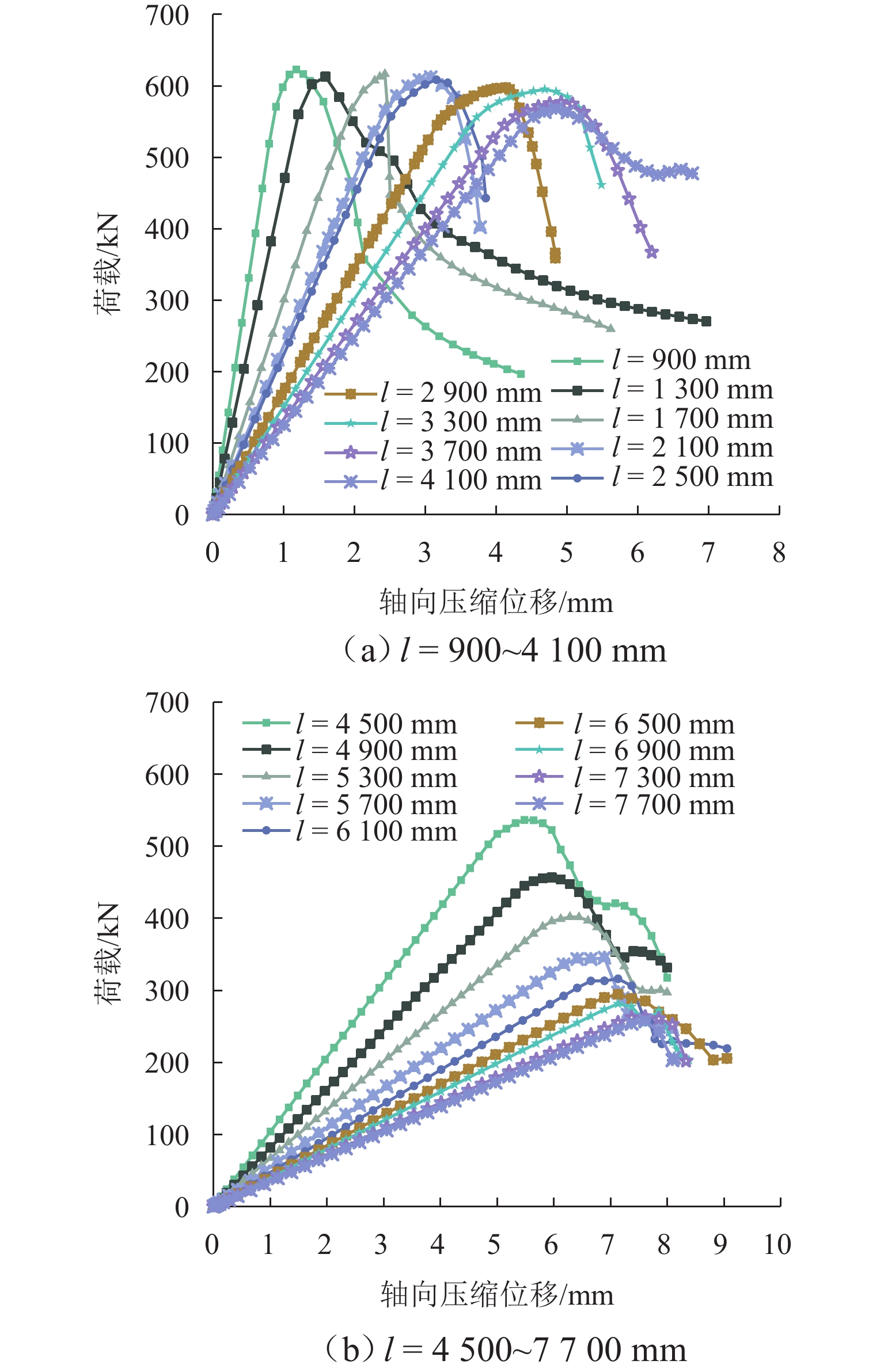

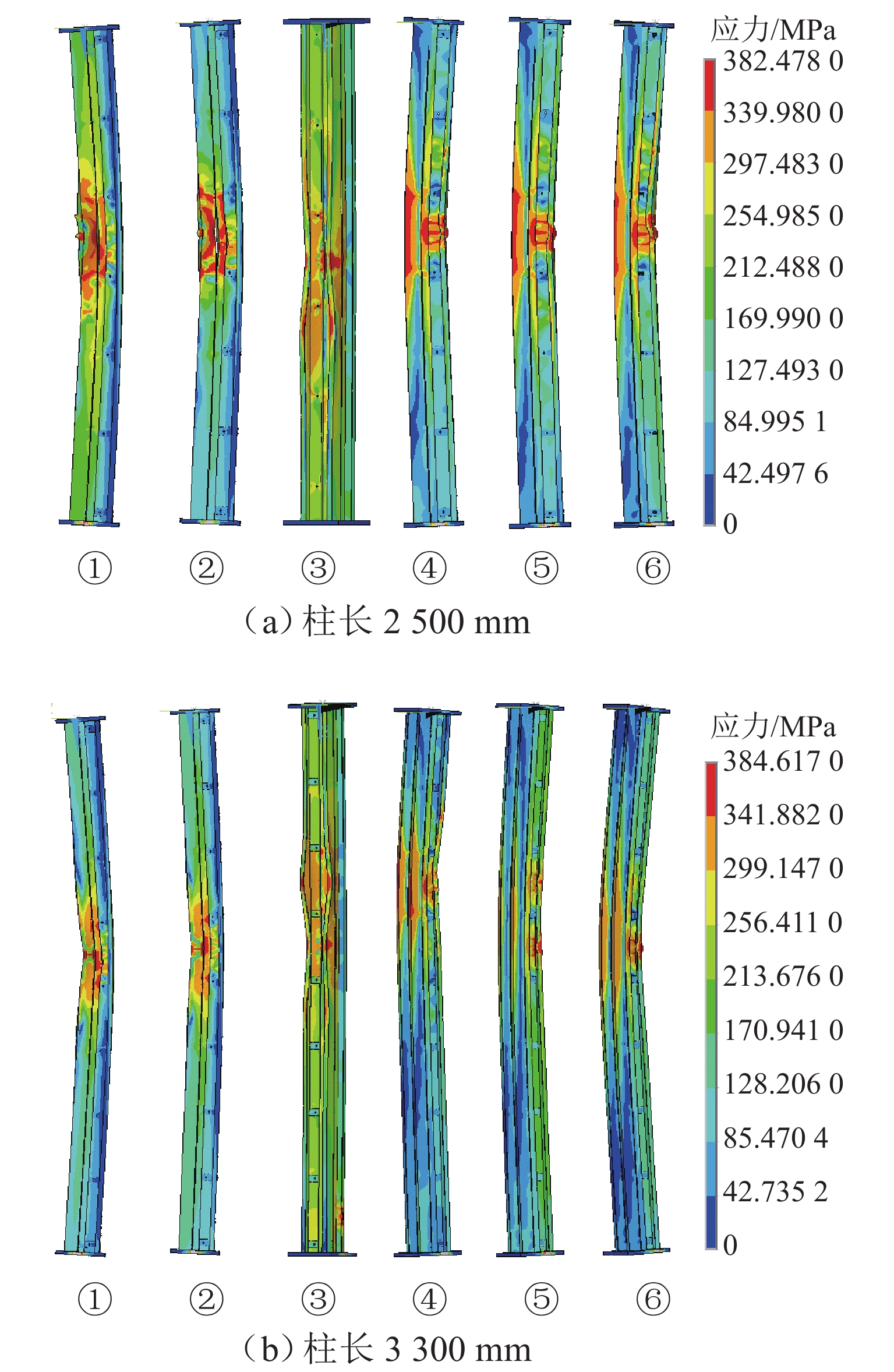

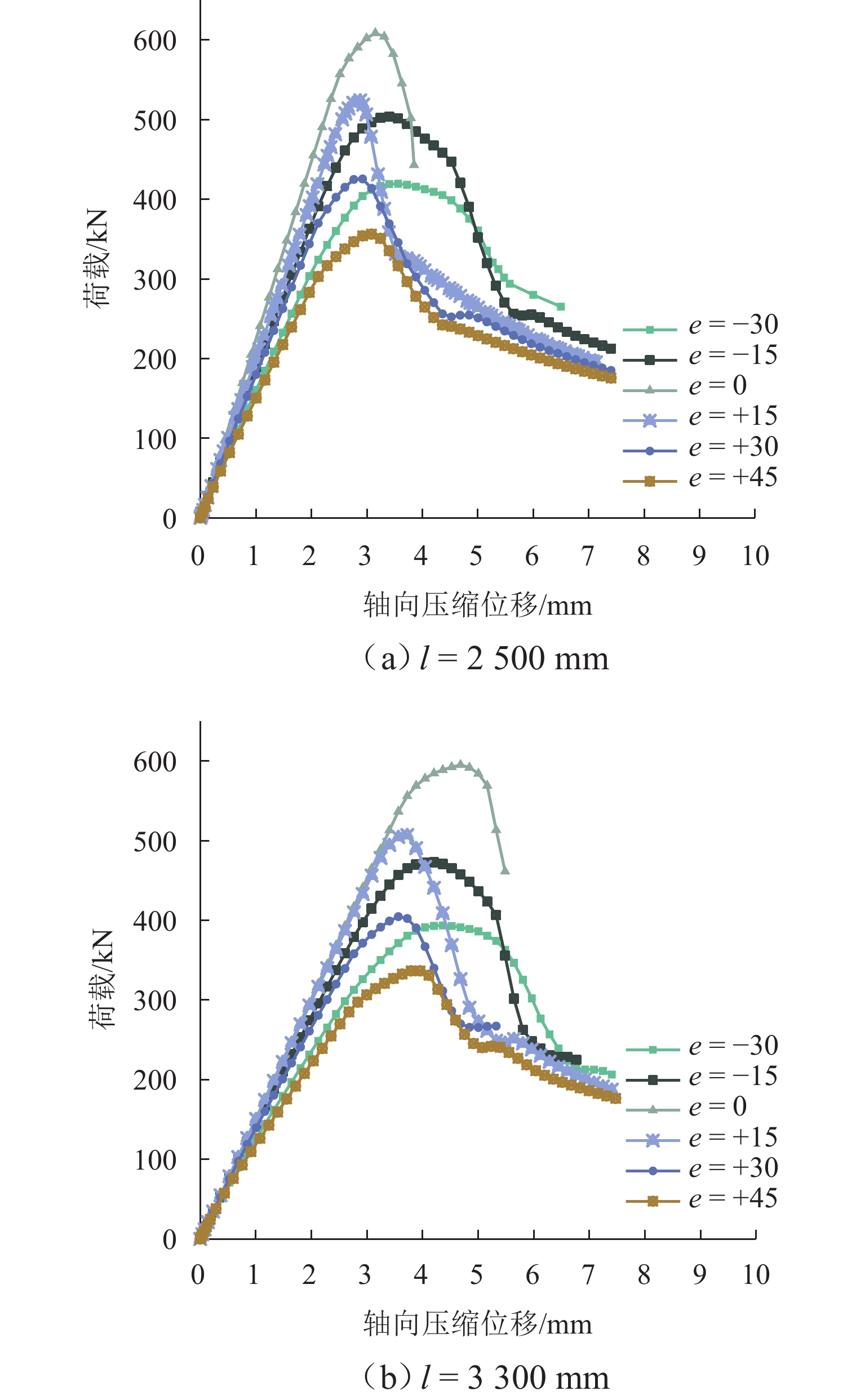

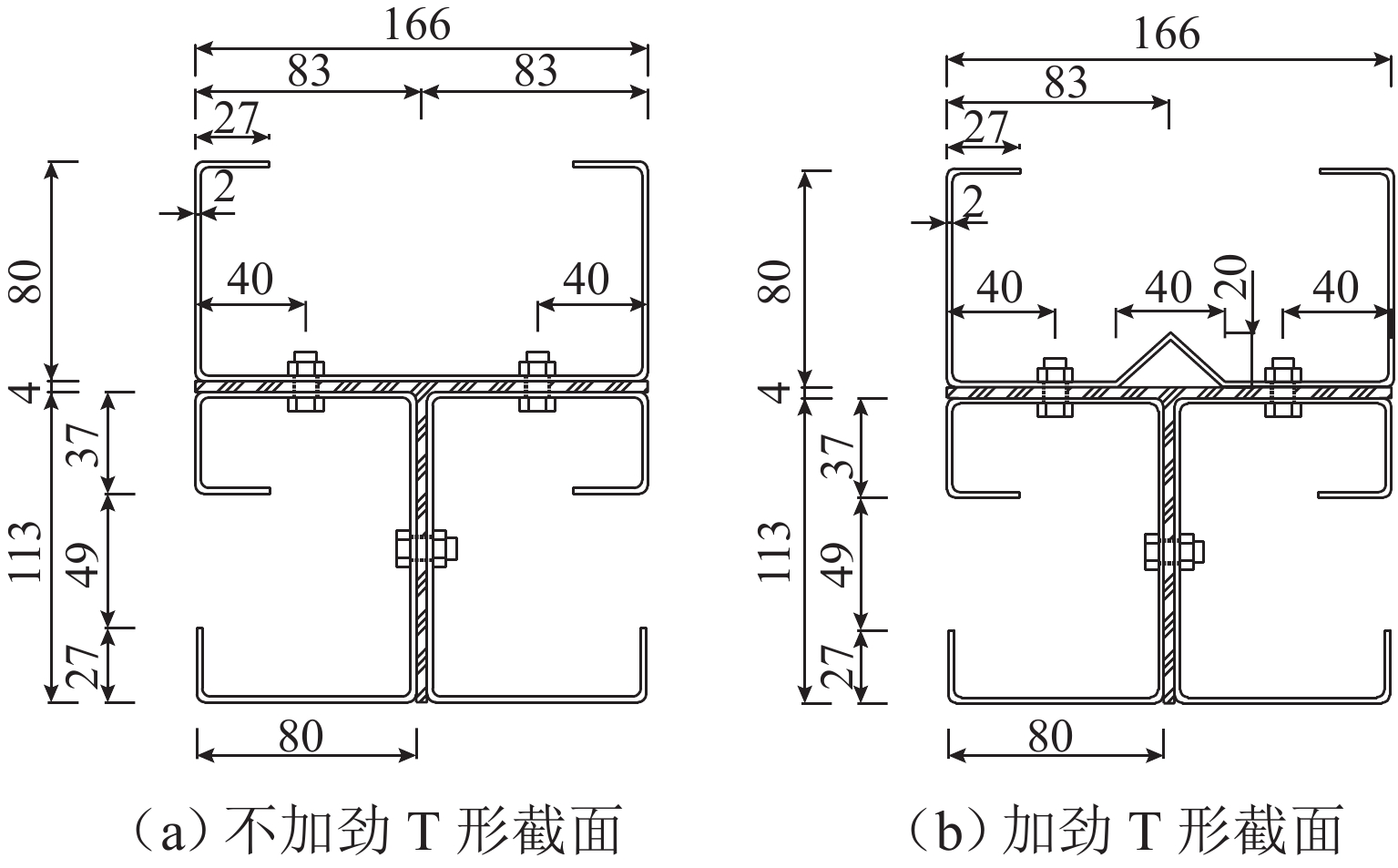

为研究腹板加劲冷弯薄壁型钢T形拼合边柱的受压性能,对8组试件开展轴压与偏压试验,结合有限元模型验证及参数分析,揭示“V”形纵向加劲肋对构件破坏模式和承载力的影响规律,并提出改进的承载力计算方法. 研究结果表明:轴压作用下未设加劲肋的T形拼合边柱单肢腹板率先出现局部屈曲,最终导致整体压溃破坏;增设“V”形加劲肋后,可以提高单肢C形钢腹板刚度,改善T形拼合边柱的局部屈曲模式,承载力提高约15%;随着偏心距增大,试件破坏模式基本相同,极限承载力呈下降趋势;基于有效宽度法预测轴压和偏压承载力结果均较保守,有限元结果和试验结果均大于计算结果,二者比值的平均值分别为1.238和1.143;修正后的有效宽度法预测结果与模拟值比值在1.000~1.074,预测结果较为准确.

Abstract:To investigate the compression performance of cold-formed thin-walled steel T-shaped composite edge columns with web stiffeners, axial and eccentric compression tests were conducted on eight groups of specimens. The influence of “V”-shaped longitudinal stiffening ribs on the failure modes and bearing capacity of the components were revealed through finite element model validation and parameter analysis, and an improved calculation method for bearing capacity was proposed. The results indicate that under axial compression, local buckling first appears in the web of the T-shaped composite edge column without stiffening ribs, ultimately leading to overall crushing failure. After adding “V”-shaped stiffening ribs, the stiffness of the single-limb C-shaped steel web is enhanced; the local buckling mode of the T-shaped composite edge column is improved, and the bearing capacity increases by approximately 15%. As the eccentricity increases, the failure modes of the specimens remain similar, and the ultimate bearing capacity shows a decreasing trend. The bearing capacities under axial and eccentric compression predicted by the effective width method are conservative. Both the finite element results and the test results are greater than the calculated results, with the average ratios being 1.238 and 1.143, respectively. After modification, the ratio of the results predicted by the effective width method to the simulated values ranges from 1.000 to 1.074, indicating high prediction accuracy.

-

表 1 试件编号

Table 1. Specimen number

试件编号 l/mm 受压类型 e/mm TC500−0-2.0 500 轴心受压 0 TCV500−0-2.0 500 轴心受压 0 TC1700−0-2.0 1 700 轴心受压 0 TCV1700−0-2.0 1 700 轴心受压 0 TCV1700−15-2.0 1 700 偏心受压 −15 TCV1700+15-2.0 1 700 偏心受压 +15 TCV1700+30-2.0 1 700 偏心受压 +30 TCV1700+45-2.0 1 700 偏心受压 +45 注:试件编号依次为是否加劲(V表示加劲)、l、e、板件厚度. 表 2 试件极限承载力对比

Table 2. Comparison of ultimate bearing capacity of specimens

试件编号 Pcr/kN Pt/kN PA/kN PA/Pt TC500−0-2.0 520.16 525.04 536.29 1.02 TCV500−0-2.0 600.08 607.61 641.90 1.06 TC1700−0-2.0 500.41 515.38 543.29 1.05 TCV1700−0-2.0 580.29 590.71 616.44 1.04 TCV1700−15-2.0 512.06 518.35 527.65 1.02 TCV1700+15-2.0 550.17 561.54 587.87 1.05 TCV1700+30-2.0 450.65 449.23 457.63 1.02 TCV1700+45-2.0 348.38 318.84 325.92 1.02 表 3 不同长细比试件承载力计算结果对比

Table 3. Comparison of bearing capacity calculation results for specimens with different slenderness ratios

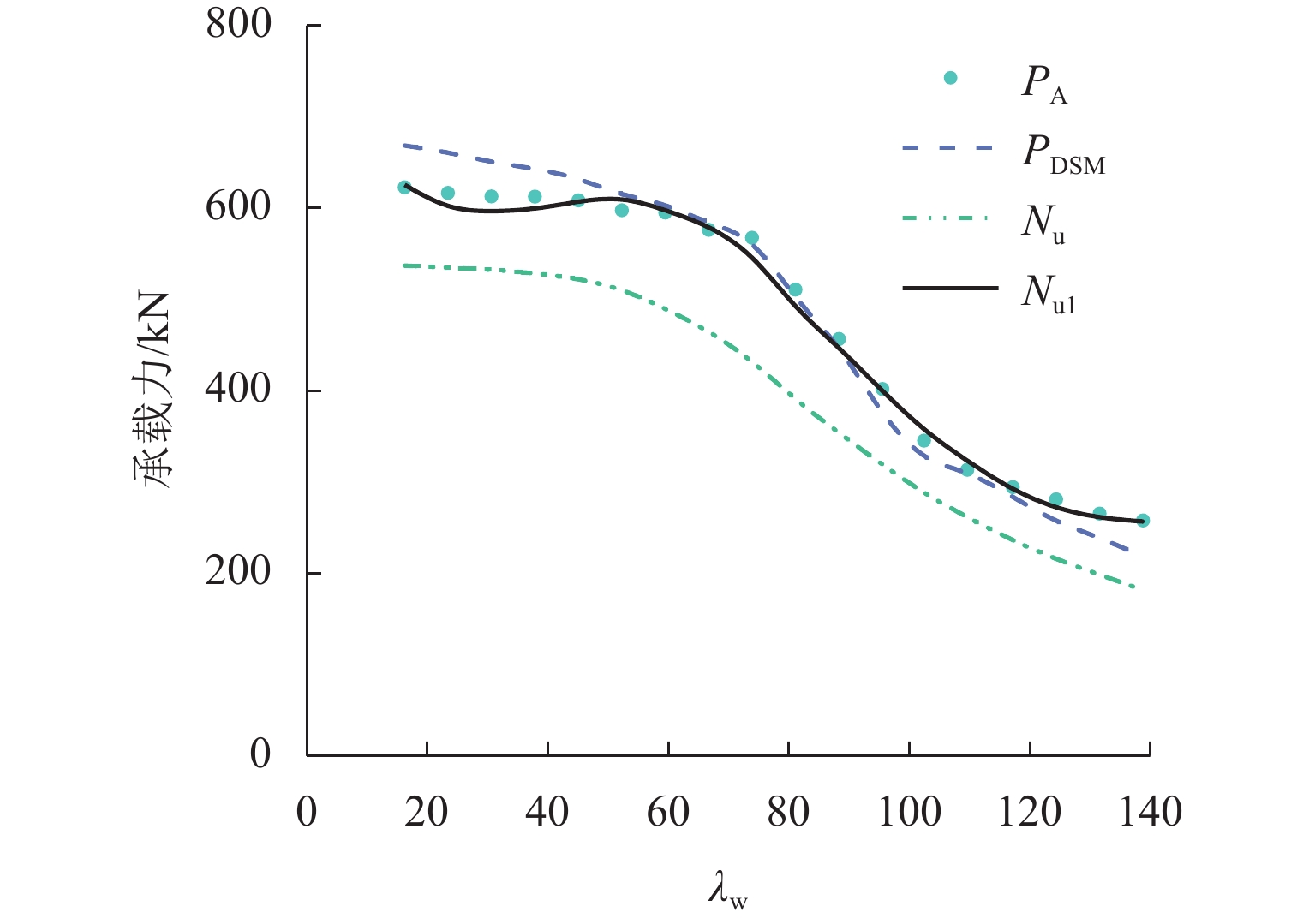

试件编号 λw Nu/kN PDSM/kN Nu1/kN PA/kN PA/Nu PA/PDSM PA/Nu1 TCV900−0-2.0 17.03 536.99 668.59 615.58 622.71 1.159 0.931 1.012 TCV1300−0-2.0 24.28 534.67 661.19 602.44 616.66 1.153 0.933 1.024 TCV1700−0-2.0 31.52 532.70 650.19 596.69 612.90 1.150 0.943 1.027 TCV2100−0-2.0 38.78 528.56 643.35 599.57 612.47 1.158 0.952 1.021 TCV2500−0-2.0 46.02 523.01 633.27 606.92 608.57 1.163 0.961 1.001 TCV2900−0-2.0 53.27 511.64 613.40 594.24 597.51 1.167 0.974 1.006 TCV3300−0-2.0 60.52 489.95 605.34 587.70 595.05 1.214 0.983 1.013 TCV3700−0-2.0 67.76 465.62 582.49 570.92 576.09 1.237 0.989 1.009 TCV4100−0-2.0 75.01 433.45 569.81 545.52 567.53 1.309 0.996 1.040 TCV4500−0-2.0 82.26 389.53 498.90 498.65 510.70 1.311 1.024 1.024 TCV4900−0-2.0 89.51 353.65 451.45 446.59 456.56 1.291 1.011 1.022 TCV5300−0-2.0 96.76 318.75 371.70 388.79 401.92 1.261 1.081 1.034 TCV5700−0-2.0 104.00 287.54 321.82 337.80 345.24 1.201 1.073 1.022 TCV6100−0-2.0 111.25 261.24 312.39 303.82 313.23 1.199 1.003 1.030 TCV6500−0-2.0 118.50 235.65 283.69 292.48 294.31 1.249 1.037 1.001 TCV6900−0-2.0 125.75 215.33 255.89 272.33 280.82 1.304 1.097 1.031 TCV7300−0-2.0 132.00 198.40 239.22 261.56 265.29 1.337 1.109 1.014 TCV7700−0-2.0 140.24 181.55 218.08 256.78 257.92 1.421 1.183 1.004 平均值 1.238 1.021 1.027 表 4 不同偏心距试件承载力计算结果对比

Table 4. Comparison of bearing capacity calculation results for specimens with different eccentric distances

试件编号 l/mm E/mm N/kN N1/kN Pt/PA/kN PA/N PA/N1 TCV1700-15-2.0 1700 −15 458.72 516.57 518.35 1.129 1.022 TCV1700-0-2.0 1700 0 532.70 596.69 590.71 1.089 1.015 TCV1700 + 15-2.0 1700 + 15 527.76 552.48 561.54 1.064 1.001 TCV1700 + 30-2.0 1700 + 30 407.65 443.87 449.23 1.102 1.028 TCV1700 + 45-2.0 1700 + 45 303.37 316.92 318.84 1.051 1.026 TCV2500-30-2.0 2500 −30 390.41 410.42 419.30 1.074 1.051 TCV2500-15-2.0 2500 −15 446.05 496.05 503.59 1.129 1.000 TCV2500-0-2.0 2500 0 523.01 606.92 608.57 1.164 1.004 TCV2500 + 15-2.0 2500 + 15 459.63 509.63 523.98 1.140 1.013 TCV2500 + 30-2.0 2500 + 30 384.97 414.87 425.39 1.105 1.009 TCV2500 + 45-2.0 2500 + 45 330.89 338.86 356.04 1.076 1.011 TCV3300-30-2.0 3300 −30 356.43 393.33 393.50 1.104 1.018 TCV3300-15-2.0 3300 −15 399.27 470.87 472.74 1.184 1.021 TCV3300-0-2.0 3300 0 489.95 587.70 595.02 1.214 1.041 TCV3300 + 15-2.0 3300 + 15 435.53 502.34 506.96 1.164 1.040 TCV3300 + 30-2.0 3300 + 30 363.75 400.09 404.49 1.112 1.002 TCV3300 + 45-2.0 3300 + 45 310.75 330.62 336.47 1.084 1.017 TCV4100-30-2.0 4100 −30 319.89 363.79 371.39 1.161 1.074 TCV4100-15-2.0 4100 −15 367.71 430.38 447.87 1.219 1.022 TCV4100-0-2.0 4100 0 433.45 545.52 567.53 1.309 1.015 TCV4100 + 15-2.0 4100 + 15 380.75 480.34 481.27 1.264 1.001 TCV4100 + 30-2.0 4100 + 30 319.45 377.64 383.98 1.202 1.028 TCV4100 + 45-2.0 4100 + 45 276.73 296.57 318.52 1.151 1.026 平均值 1.143 1.019 -

[1] 陈明, 黄骥辉, 赵根田. 组合截面冷弯薄壁型钢结构研究进展[J]. 工程力学, 2016, 33(12): 1-11. doi: 10.6052/j.issn.1000-4750.2016.05.ST03CHEN Ming, HUANG Jihui, ZHAO Gentian. Research progress of compound section cold-formed thin-wall steel structures[J]. Engineering Mechanics, 2016, 33(12): 1-11. doi: 10.6052/j.issn.1000-4750.2016.05.ST03 [2] YU C, SCHAFER B W. Distortional buckling tests on cold-formed steel beams[A]. Proceedings of the seventeenth international specialty conference on cold-formed steel structures, Orlando FL, 2004: 1-27. [3] YU C, SCHAFER B W. Distortional buckling tests on cold-formed steel beams[J]. Journal of Structural Engineering, 2006, 132(4): 515-528. doi: 10.1061/(ASCE)0733-9445(2006)132:4(515) [4] MOEN C D, SCHAFER B W. Direct strength method for design of cold-formed steel columns with holes[J]. Journal of Structural Engineering, 2011, 137(5): 559-570. doi: 10.1061/(ASCE)ST.1943-541X.0000310 [5] 石宇, 周绪红, 刘永健. 冷弯薄壁卷边槽钢偏心受压构件承载力计算的折减强度法[J]. 建筑科学与工程学报, 2011, 28(3): 40-48.SHI Yu, ZHOU Xuhong, LIU Yongjian. Strength-reduction method for load-carrying capacity of cold-formed thin-walled lipped channel members under eccentric compression[J]. Journal of Architecture and Civil Engineering, 2011, 28(3): 40-48. [6] 周绪红, 何子奇. 冷成型钢轴压构件畸变屈曲承载力计算公式研究[J]. 土木工程学报, 2015, 48(2): 1-9.ZHOU Xuhong, HE Ziqi. Research on design formula of distortional buckling capacity of cold-formed steel columns under axial compression[J]. China Civil Engineering Journal, 2015, 48(2): 1-9. [7] 刘占科, 周绪红. 基于直接强度法的薄壁轴压构件局部屈曲临界荷载实用计算式[J]. 建筑结构学报, 2016, 37(6): 219-227.LIU Zhanke, ZHOU Xuhong. Practical formula of critical local buckling load of thin-walled members under axial compression based on direct strength method[J]. Journal of Building Structures, 2016, 37(6): 219-227. [8] 周天华, 聂少锋, 刘向斌. 冷弯薄壁型钢开口三肢拼合柱轴压性能试验研究[J]. 建筑结构学报, 2012, 3(5): 22-29.ZHOU Tianhua, NIE Shaofeng, LIU Xiangbin. Experimental study on cold-formed steel three limbs built-up section members under axial compression[J]. Journal of Building Structures, 2012, 3(5): 22-29. [9] 李艳春, 周天华, 丁嘉豪, 等. 冷弯薄壁型钢拼合箱形柱的畸变屈曲性能研究[J]. 湖南大学学报(自然科学版), 2021, 48(11): 91-100.LI Yanchun, ZHOU Tianhua, DING Jiahao, et al. Investigation on distortion buckling behavior of cold-formed thin-walled steel built-up box-section columns[J]. Journal of Hunan University (Natural Sciences), 2021, 48(11): 91-100. [10] LIU X B, ZHOU T H. Research on axial compression behavior of cold-formed triple-lambs built-up open T-section columns[J]. Journal of Constructional Steel Research, 2017, 134: 102-113. doi: 10.1016/j.jcsr.2017.03.015 [11] LIAO F F, WU H H, WANG R Z, et al. Compression test and analysis of multi-limbs built-up cold-formed steel stub columns[J]. Journal of Constructional Steel Research, 2017, 128: 405-415. doi: 10.1016/j.jcsr.2016.09.005 [12] 何子奇, 杨光, 周绪红, 等. 腹板加劲冷弯薄壁拼合H形钢压弯构件畸变性能试验研究[J]. 建筑结构学报, 2022, 43(10): 237-248.HE Ziqi, YANG Guang, ZHOU Xuhong, et al. Experimental investigation on distortional performance of cold-formed steel built-up channel columns with web-stiffeners under eccentric compression[J]. Journal of Building Structures, 2022, 43(10): 237-248. [13] ZHANG J H, YOUNG B. Experimental investigation of cold-formed steel built-up closed section columns with web stiffeners[J]. Journal of Constructional Steel Research, 2018, 147: 380-392. doi: 10.1016/j.jcsr.2018.04.008 [14] ZHANG J H, YOUNG B. Finite element analysis and design of cold-formed steel built-up closed section columns with web stiffeners[J]. Thin-Walled Structures, 2018, 131: 223-237. doi: 10.1016/j.tws.2018.06.008 [15] HE Z Q, ZHOU X H, LIU Z K, et al. Post-buckling behaviour and DSM design of web-stiffened lipped channel columns with distortional and local mode interaction[J]. Thin-Walled Structures, 2014, 84: 189-203. doi: 10.1016/j.tws.2014.07.001 [16] ZHANG P, ALAM M S. Compression tests of thin-walled cold-formed steel columns with Σ-shaped sections and patterned perforations distributed along the length[J]. Thin-Walled Structures, 2022, 174: 109082.1-109082.28. [17] CHEN M T, YOUNG B, MARTINS A D, et al. Experimental investigation on cold-formed steel stiffened lipped channel columns undergoing local-distortional interaction[J]. Thin-Walled Structures, 2020, 150: 106682.1-106682.20. [18] 姚永红, 武振宇. 冷弯薄壁卷边槽钢柱弹性畸变屈曲数值分析[J]. 科学技术与工程, 2012, 12(6): 1436-1438, 1444. doi: 10.3969/j.issn.1671-1815.2012.06.053YAO Yonghong, WU Zhenyu. Numerical analysis of elastic distortional buckling for cold-formed thin-walled steel lipped channel columns[J]. Science Technology and Engineering, 2012, 12(6): 1436-1438, 1444. doi: 10.3969/j.issn.1671-1815.2012.06.053 [19] 何子奇, 杨光, 周绪红, 等. 腹板并合双肢冷弯薄壁Σ型钢压弯构件畸变性能试验研究[J]. 工程力学, 2023, 40(2): 25-35. doi: 10.6052/j.issn.1000-4750.2021.08.0626HE Ziqi, YANG Guang, ZHOU Xuhong, et al. Experimental research on distortional behavior of cold-formed thin-walled-shaped steel built-up sections under eccentric compression[J]. Engineering Mechanics, 2023, 40(2): 25-35. doi: 10.6052/j.issn.1000-4750.2021.08.0626 [20] SELVARAJ S, MADHAVAN M. Design of cold-formed steel built-up columns subjected to local-global interactive buckling using direct strength method[J]. Thin-Walled Structures, 2021, 159: 107305.1-107305.20. [21] SELVARAJ S, MADHAVAN M. Design of cold-formed steel built-up closed section columns using direct strength method[J]. Thin-Walled Structures, 2022, 171: 108746.1-108746.18. [22] CHEN M, GENG Y, LI B S, et al. Compressive behavior study of cruciform cold-formed steel built-up columns with web stiffeners[J]. Structures, 2025, 71: 108090.1-108090.23. [23] CHEN M, GENG Y, GUO Y H, et al. Research on axial compression behavior of cold-formed steel built-up T-shaped columns[J]. Structures, 2024, 70: 107765.1-107765.18. [24] 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 金属材料 拉伸试验第1部分: 室温试验方法: GB/T 228.1—2021[S]. 北京: 中国标准出版社, 2021. [25] LU W B, CHEN M, SHI Y, et al. Numerical simulation and specification provisions for cruciform cold-formed steel built-up columns[J]. Structures, 2023, 51: 484-497. doi: 10.1016/j.istruc.2023.03.043 [26] CHEN M, GENG Y, LI B S, et al. Research on lateral load-resisting performance of cruciform cold-formed steel built-up columns[J]. Journal of Constructional Steel Research, 2025, 229: 109529.1-109529.19. [27] 湖北省发展计划委员会, 中南建筑设计院. 冷弯薄壁型钢结构技术规范: GB 50018—2002[S]. 北京: 中国标准出版社, 2003. [28] North American Specification (NAS). North American specification for the design of cold-formed steel structural members[S]. Washington D. C.: American Iron and Steel Institute, 2016 -

下载:

下载: