Transient Respons Analysis of Wheel-Rail Contact and Impact in Welded Joint Area of High-Speed Turnouts

-

摘要:

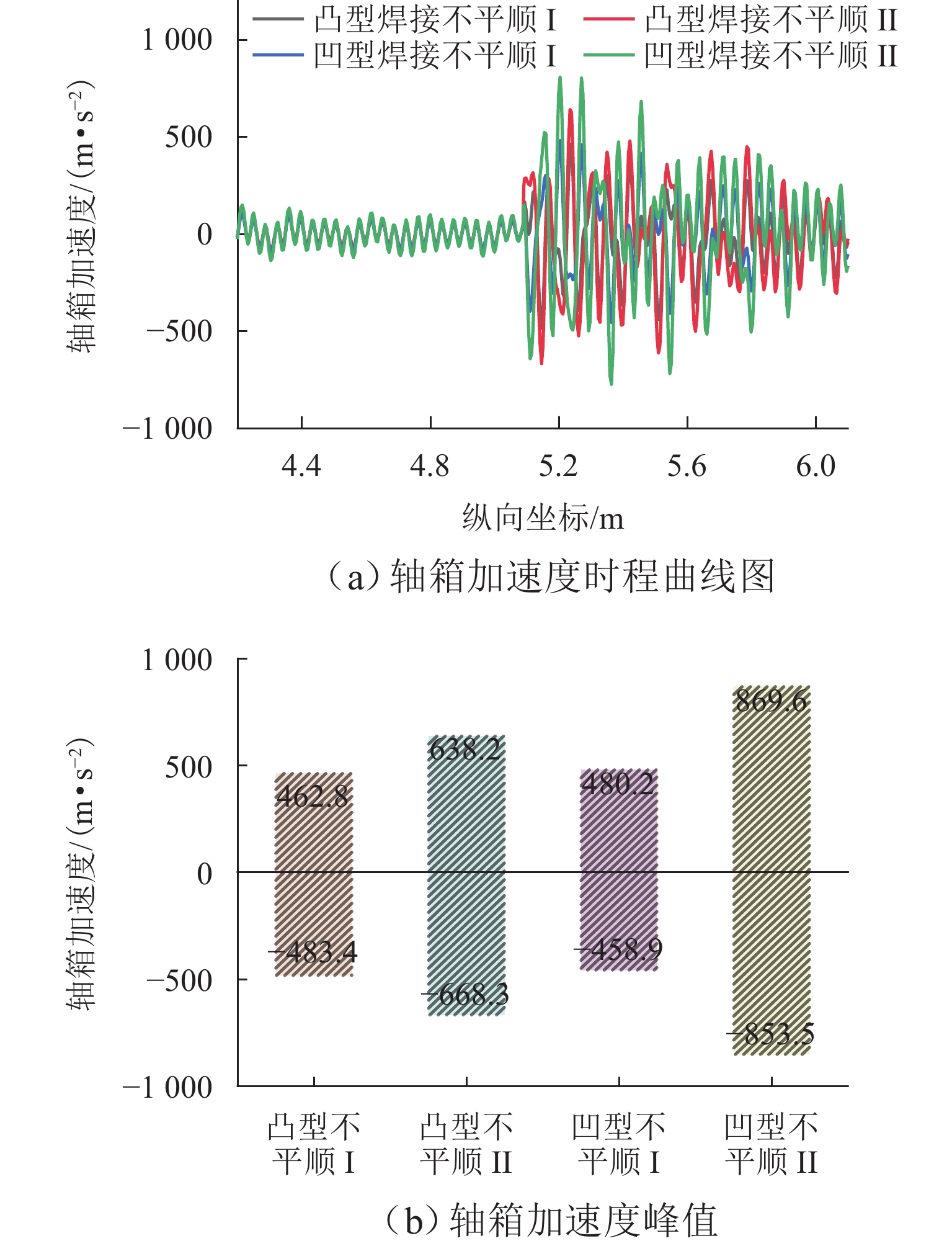

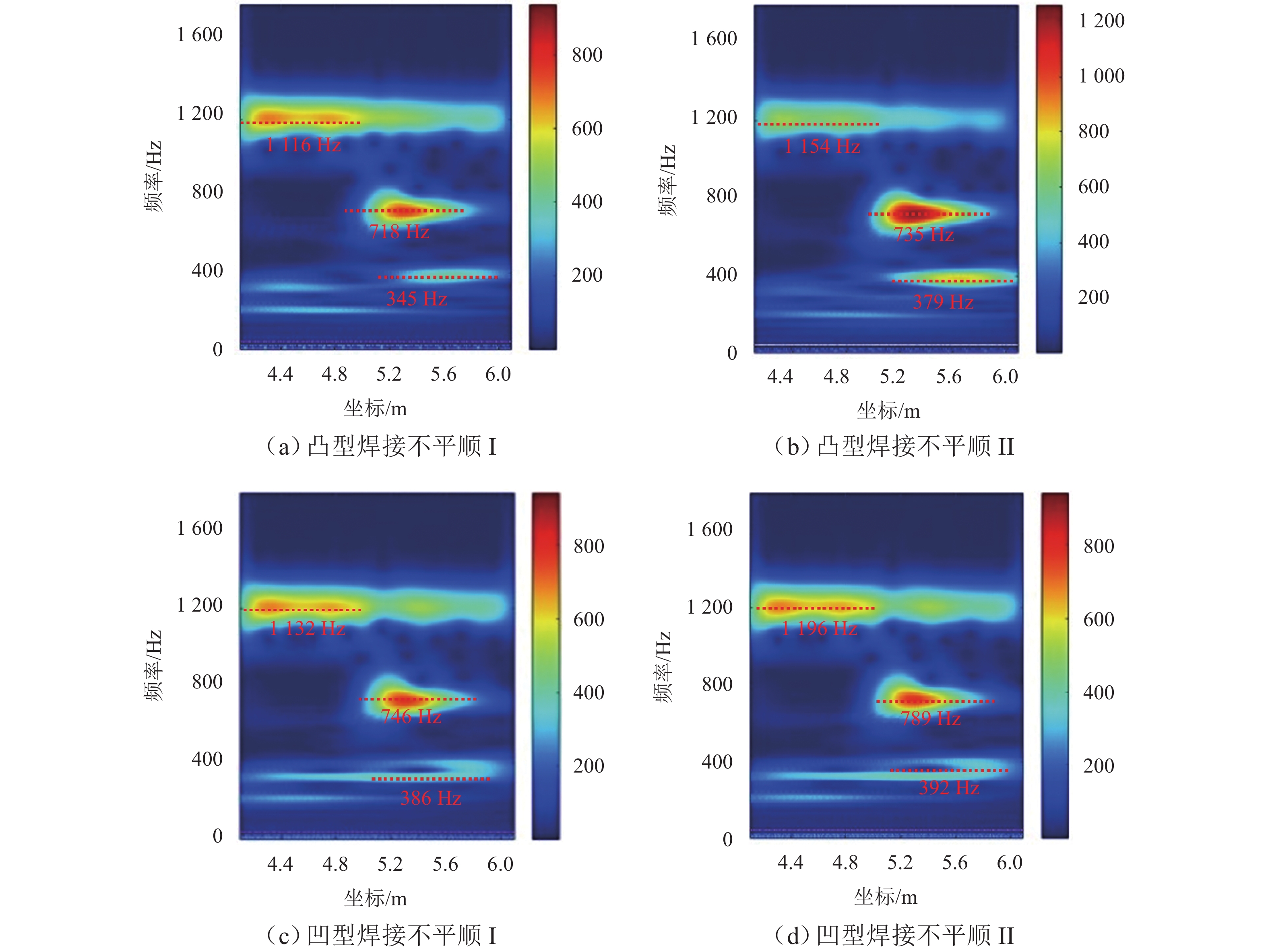

高速铁路无缝道岔与相邻轨条的连接质量是确保列车平稳运行的关键结构,而焊接是广泛存在于高速道岔区的主要连接方式之一. 为研究焊接不平顺引起的轮轨冲击问题对高速道岔行车安全性和稳定性的影响,基于显示积分算法构建了考虑实际焊接接头不平顺的轮轨冲击模型;分析了不同焊接不平顺下的轮轨动态响应在时、频域的分布特性,并结合现场试验对仿真结果进行了验证;探明了高速条件下焊接接头几何不平顺对轮轨动态冲击行为和钢轨受力特性的影响. 研究结果表明:轴箱加速度时频图主要存在三个明显的高频振动能量峰,其频率主要集中在300、750 Hz和

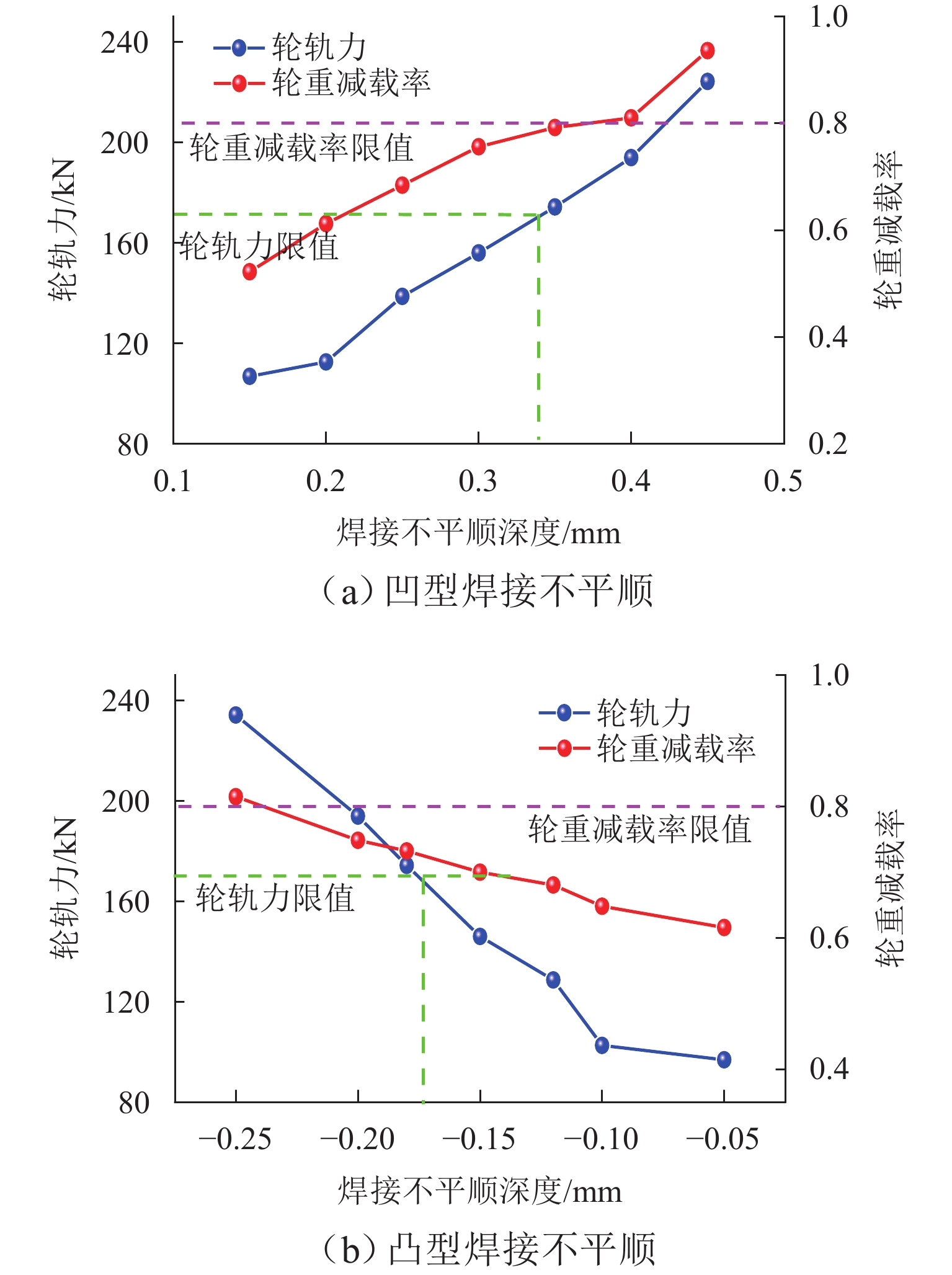

1200 Hz附近;结合高速铁路维修规则,基于动力学仿真结果确定了400公里时速条件下高速铁路焊缝限值,1 m直尺测量矢度条件下,凸型焊接接头不平顺限值为0.174 mm,凹形焊接接头不平顺限值为0.34 mm.Abstract:Objective The rail welding joint is a critical component in ensuring the safety and stability of the vehicle on continuously welded rails in high-speed railways, which can decrease the dynamic response between wheel and rail. However, the significant impact loads, varying operation conditions, and diverse types of defects remain key factors limiting its service life, As a result, welding joints are considered vulnerable areas in high-speed railway lines and pose significant challenges in maintenance and repair work. Therefore, the transient response of wheel-rail contact and impact in the welded joint area of high-speed turnouts is studied, and corresponding limits for weld irregularity are proposed.

Method In order to recognize the wheel-rail impact behavior in the welded joint area and propose the irregularity limits, the distribution laws of geometric irregularities in welded joints, the wheel-rail impact mechanism, and its influencing factors were first reviewed. Meanwhile, two main types of welded joints and their geometrical characteristics were generalized, and the prospects of subsequent research were elucidated in view of the necessity of joint maintenance and repair work. Based on the joint irregularities under different wavelengths and amplitudes, a transient wheel-rail rolling contact model considering the actual joint geometry and nonlinear material constitutive was established to investigate the wheel-rail dynamic responses and impact during the passage of a vehicles through the joint. The model was solved using an implicit-explicit algorithm, and measures were implemented to mitigate boundary wave reflections. The simulation results were verified by field tests. By using this transient model, the axle box acceleration in the time domain was analyzed. By applying the wavelet transform, the time-domain signals were converted into frequency-domain results, revealing the high-frequency vibration energy peak of the axle box acceleration during impact. By combining critical parameters specified in high-speed railway maintenance regulations such as the wheel load reduction rate and wheel-rail force, the weld limits for high-speed railways were determined based on the dynamic simulation results. The proposed weld limits for high-speed railways are intended to support research on rolling contact fatigue and wear of welded joints and provide valuable references for the maintenance or damage detection of welded joints.

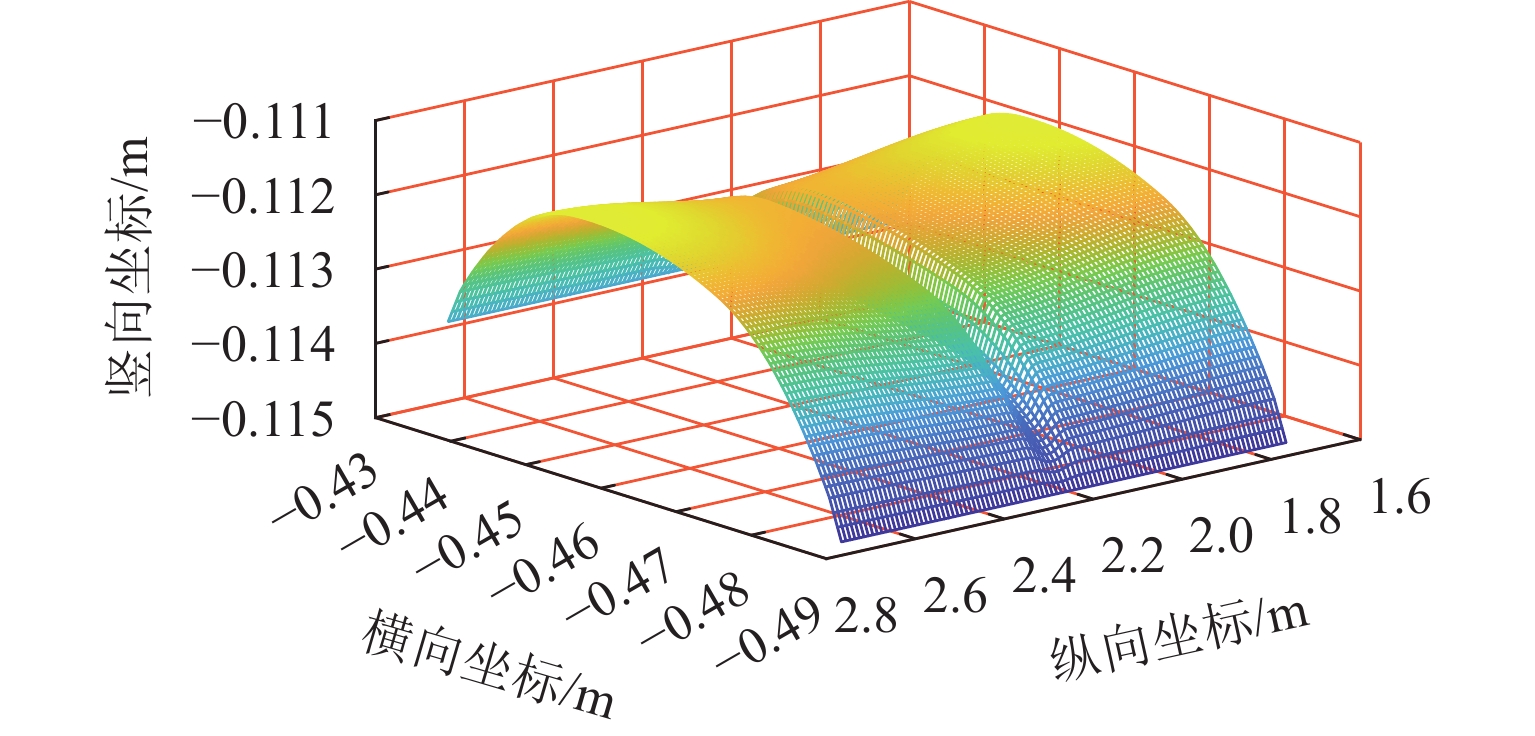

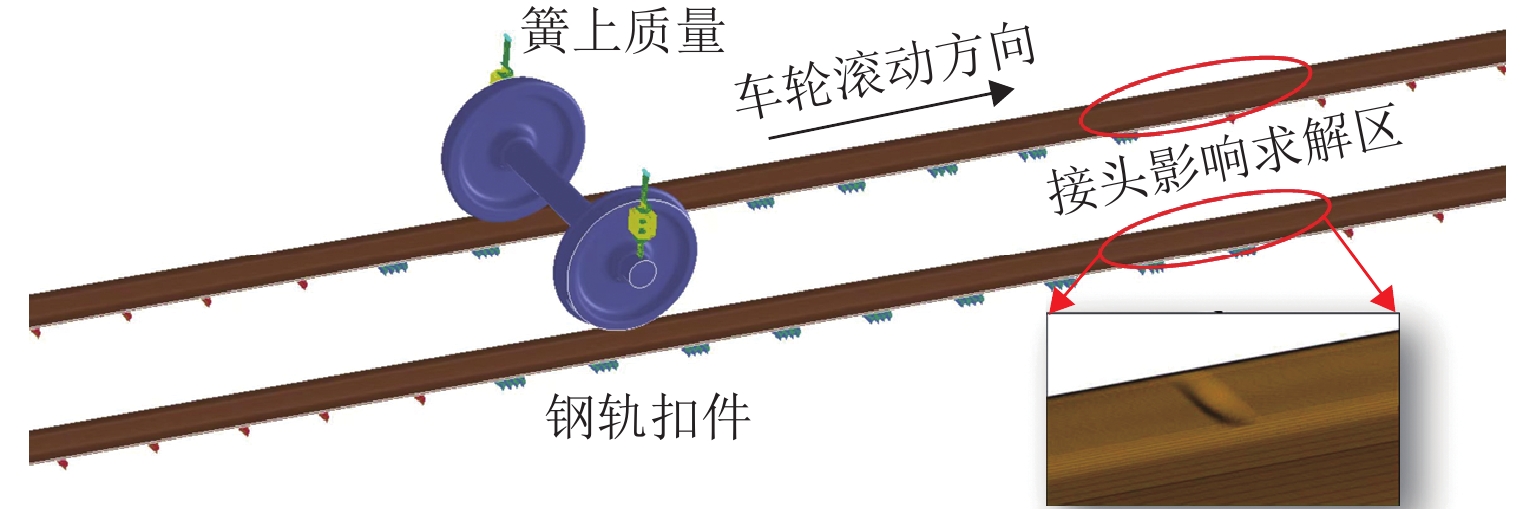

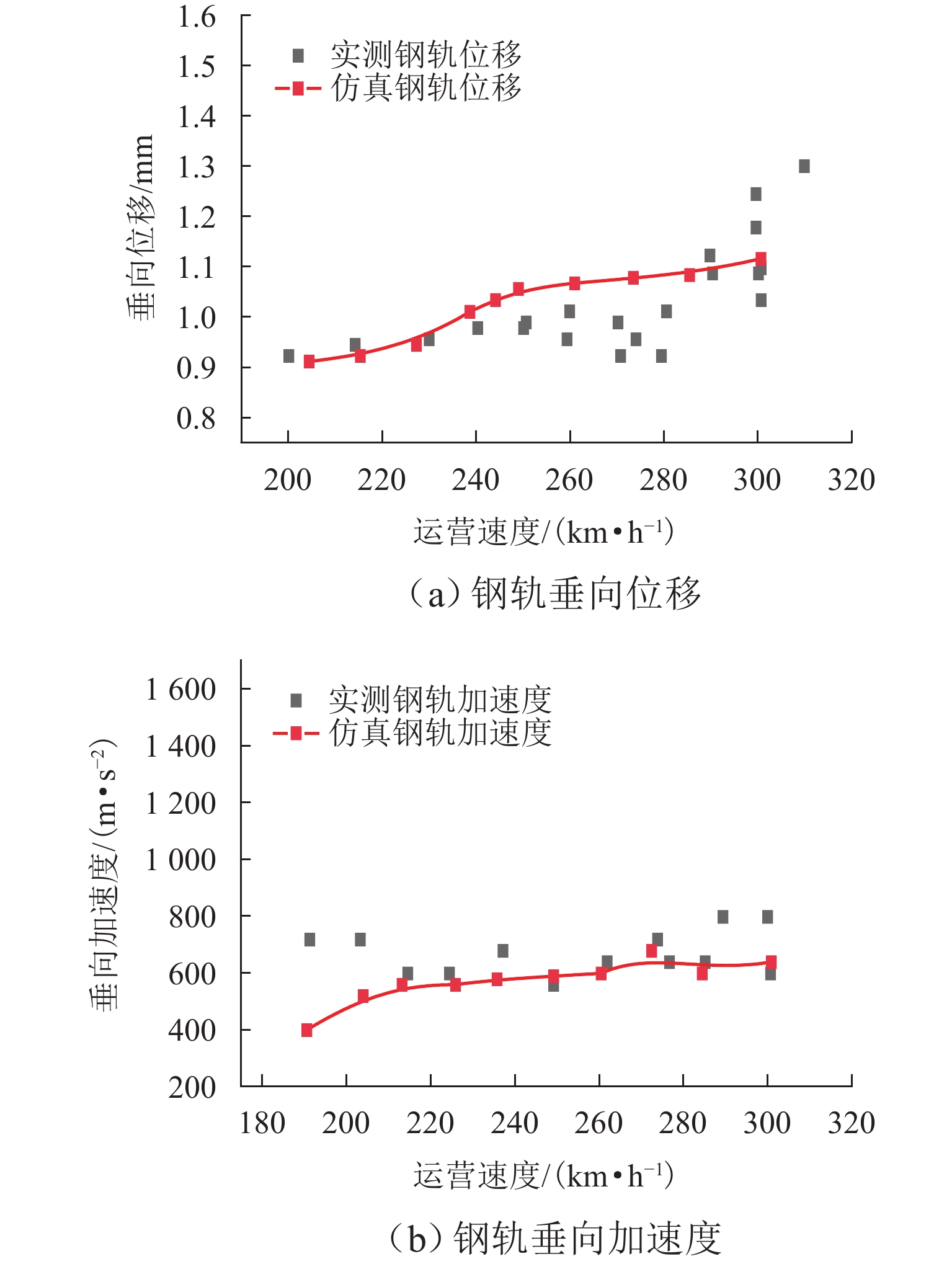

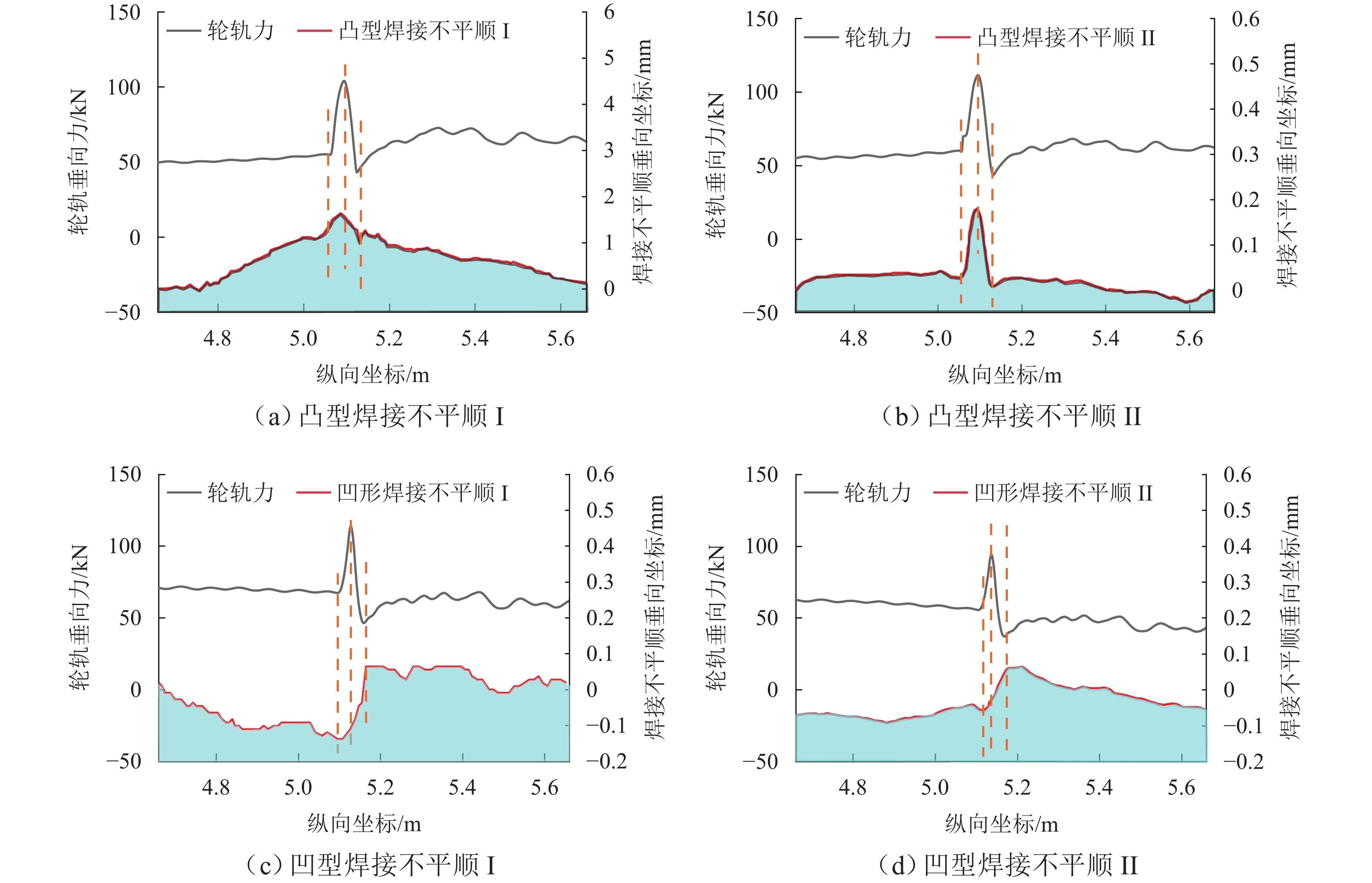

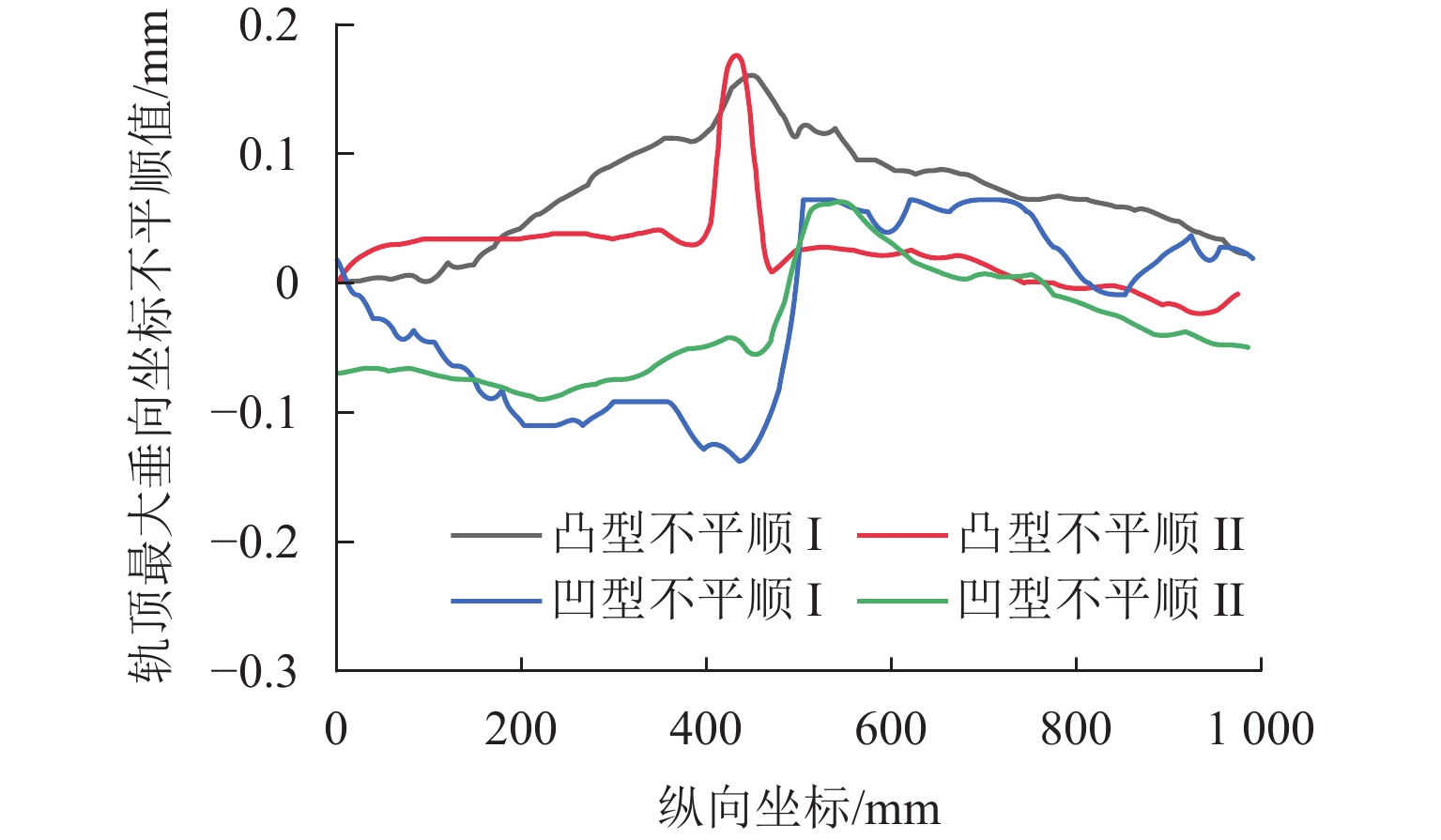

Result Within the 1-meter-long influence zone of the welded joint, two primary types of irregularities are present: convex and concave irregularities. Convex irregularities are geometrically characterized as either a single-peak protrusion or a gentler convex profile. These are typically caused by the inward displacement of the base metal during welding, combined with insufficient post-weld grinding. The concave welding irregularity is mainly caused by two reasons. One is that there may be a low joint or excessive grinding during the welding process; the other is that during the long-term service process, due to the tensile strength and fatigue performance of the joint material being less than that of the base metal, the concave welding irregularity phenomenon occurs. Consequently, the geometric irregularity at the joint is a critical factor influencing the wheel-rail dynamic response.In this paper, a three-dimensional explicit finite element dynamic model of the rail’s welded joint in the high-speed turnout area was established, incorporating actual geometric irregularities measured in the field. The three-dimensional model considered four typical joint geometric irregularity profiles. Subsequently, an explicit integration algorithm was employed in the wheel-rail finite element model to simulate the wheel-rail impact contact process as a train passes at high speed over different welded joints. During the transition from static to dynamic motion of the wheelset, the sudden change in the wheel-rail state will excite wheel-rail disturbances. To mitigate this, approximately 1.2 m of ordinary section rail was set in front of the weld as a dynamic relaxation area to slowly consume energy and ensure that the wheel is in a stable state when entering the welded joint. To further reduce the influence of the rail boundary wave on the stress of the wheel-rail material, stiffness and damping elements were set at the rail end and rail bottom to reduce the influence of the boundary reflection wave.The model was verified by comparing simulation and field test results of wheel-rail dynamic responses. The maximum vertical displacements and accelerations in the simulation were close to the measured values. For wheel-rail contact forces, convex and concave welding irregularities caused significant impacts. The maximum wheel-rail forces were within limits. The dynamic responses were related to the geometric characteristics of the irregularities. The analysis of wheel-rail high-frequency responses using axle box acceleration showed three main resonance energy peaks in the time-frequency diagram. The vibration energy amplitude was affected by the joint’s geometric irregularity, while the frequency distribution was primarily determined by the physical properties of the wheel. By analyzing how different depths of convex and concave irregularities affect wheel-rail dynamics, safety limits for convex and concave weld irregularities were determined as 0.174 mm and 0.34 mm, respectively.

Conclusion The three-dimensional explicit finite element model accurately captures the dynamic wheel-rail impact forces induced by welding irregularities. The results demonstrate that the peak impact force is governed primarily by the geometric gradient of the irregularity, while its depth (wave depth) significantly influences the overall dynamic response. The proposed limits for welding irregularities provide a critical theoretical foundation for ensuring the operational safety and stability of high-speed railways. Furthermore, these limits can directly inform maintenance protocols and guide the damage detection processes for rail welds.

-

Key words:

- high-speed railway /

- rail weld /

- explicit integral method /

- wheel-rail transient impact /

- safety limit

-

表 1 材料参数表

Table 1. Parameters of materails

类型 弹性模量/

GPa密度/

(kg•m−3)泊松比 屈服强度/

MPa抗拉强度/

MPa母材 245 7850 0.308 584 1004 焊缝材料 240 7850 0.308 602 866 表 2 模型参数

Table 2. Parameters of model

模型参数 数值 簧上质量/(kg) 8000 一系悬挂系统 刚度系数/(MN•m−1) 0.88 阻尼系数/(kN•s•m−1) 4 簧下车轮质量/(kg) 356.4 阻尼常数 0.0001 轨底扣件胶垫 刚度系数(MN•m−1) 27 阻尼系数(kN•s•m−1) 0.17 表 3 焊接接头不平顺计算工况

Table 3. Calculation conditions of welded joint irregularities

mm 工况 凸型波深/mm 凹型波深/mm 1 −0.05 0.15 2 −0.10 0.20 3 −0.12 0.25 4 −0.15 0.30 5 −0.18 0.35 6 −0.20 0.40 7 −0.25 0.45 -

[1] 王平, 陈嵘, 徐井芒, 等. 高速铁路道岔系统理论与工程实践研究综述[J]. 西南交通大学学报, 2016, 51(2): 357-372. doi: 10.3969/j.issn.0258-2724.2016.02.015WANG Ping, CHEN Rong, XU Jingmang, et al. Theories and engineering practices of high-speed railway turnout system: survey and review[J]. Journal of Southwest Jiaotong University, 2016, 51(2): 357-372. doi: 10.3969/j.issn.0258-2724.2016.02.015 [2] 龚继军, 赵冠闯, 李建辉, 等. 高速铁路道岔打磨对钢轨平顺性及轮轨动力学性能的影响[J]. 铁道建筑, 2023, 63(5): 39-44. doi: 10.3969/j.issn.1003-1995.2023.05.08GONG Jijun, ZHAO Guanchuang, LI Jianhui, et al. Influence of high speed railway turnout grinding on rail irregularity and wheel-rail dynamic performance[J]. Railway Engineering, 2023, 63(5): 39-44. doi: 10.3969/j.issn.1003-1995.2023.05.08 [3] 徐井芒, 郑兆光, 赖军, 等. 轨道参数对高速道岔轮轨接触行为的影响[J]. 西南交通大学学报, 2022, 57(5): 990-999.XU Jingmang, ZHENG Zhaoguang, LAI Jun, et al. Influence of track parameters on wheel/rail contact behavior of high-speed turnout[J]. Journal of Southwest Jiaotong University, 2022, 57(5): 990-999. [4] CHEN J Y, WANG P, XU J M, et al. Simulation of vehicle-turnout coupled dynamics considering the flexibility of wheelsets and turnouts[J]. Vehicle System Dynamics, 2023, 61(3): 739-764. doi: 10.1080/00423114.2021.2014898 [5] LIAO T, SONG J, LAI J, et al. Numerical investigation of the transient wheel-rail impact behaviour in high-speed turnouts caused by a bonded insulated rail joint[J]. Vehicle System Dynamics, 2023, 61(12): 3025-3046. doi: 10.1080/00423114.2022.2152193 [6] 冯仲伟. CR450动车组新技术部件换装科学研究试验[R]. 北京: 中国铁道科学研究院集团有限公司铁道建筑研究所, 2023. [7] SARIKAVAK Y, TURKBAS O S, COGUN C. Influence of welding on microstructure and strength of rail steel[J]. Construction and Building Materials, 2020, 243: 118220. doi: 10.1016/j.conbuildmat.2020.118220 [8] HOELZL C, ARCIERI G, ANCU L, et al. Fusing expert knowledge with monitoring data for condition assessment of railway welds[J]. Sensors, 2023, 23(5): 2672. doi: 10.3390/s23052672 [9] ZHAO J Z, PANG X, FU P L, et al. Dynamic constitutive model of U75VG rail flash-butt welded joint and its application in wheel-rail transient rolling contact simulation[J]. Engineering Failure Analysis, 2022, 134: 106078. doi: 10.1016/j.engfailanal.2022.106078 [10] LULU G B, CHEN R, WANG P, et al. Influence of out-of-round wheels on the vehicle–flexible track interaction at rail welds[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2021, 235(3): 313-327. doi: 10.1177/0954409720924300 [11] CHEN Y C, KUANG J H. Contact stress variations near the insulated rail joints[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2002, 216(4): 265-273. doi: 10.1243/095440902321029217 [12] CHEN Y C, CHEN L W. Effects of insulated rail joint on the wheel/rail contact stresses under the condition of partial slip[J]. Wear, 2006, 260(11/12): 1267-1273. doi: 10.1016/j.wear.2005.08.005 [13] SU H, PUN C L, MUTTON P, et al. Numerical study on the ratcheting performance of rail flash butt welds in heavy haul operations[J]. International Journal of Mechanical Sciences, 2021, 199: 106434. doi: 10.1016/j.ijmecsci.2021.106434 [14] YANG Y F, LING L, YANG Y F, et al. Effects of wheelset flexibility on locomotive–track interaction due to rail weld irregularities[J]. Vehicle System Dynamics, 2022, 60(9): 3088-3108. doi: 10.1080/00423114.2021.1939063 [15] YANG Z, DENG X Y, LI Z L. Numerical modeling of dynamic frictional rolling contact with an explicit finite element method[J]. Tribology International, 2019, 129: 214-231. doi: 10.1016/j.triboint.2018.08.028 [16] YANG Z, BOOGAARD A, CHEN R, et al. Numerical and experimental study of wheel-rail impact vibration and noise generated at an insulated rail joint[J]. International Journal of Impact Engineering, 2018, 113: 29-39. doi: 10.1016/j.ijimpeng.2017.11.008 [17] 邢丽贤. 提速条件下钢轨伤损特点及钢轨伤损分类的研究[D]. 北京: 中国铁道科学研究院, 2008. [18] 金学松, 刘启跃. 轮轨摩擦学[M]. 北京: 中国铁道出版社, 2004: 169. [19] 张玉华, 李澳, 胡伟平. 钢轨铝热焊焊缝材料与母材力学性能对比分析[J]. 高速铁路新材料, 2023, 2(2): 79-84. doi: 10.3969/j.issn.2097-0846.2023.02.015ZHANG Yuhua, LI Ao, HU Weiping. Comparative analysis of mechanical properties of Thermit welding material and base material[J]. Advanced Materials of High Speed Railway, 2023, 2(2): 79-84. doi: 10.3969/j.issn.2097-0846.2023.02.015 [20] 高建敏, 翟婉明. 高速铁路钢轨焊接区不平顺的动力效应及其安全限值研究[J]. 中国科学: 技术科学, 2014, 44(7): 697-706. doi: 10.1360/N092014-00081GAO Jianmin, ZHAI Wanming. Dynamic effect and safety limits of rail weld irregularity on high-speed railways[J]. Scientia Sinica (Technologica), 2014, 44(7): 697-706. doi: 10.1360/N092014-00081 [21] AN B Y, WANG P, XIAO J L, et al. Dynamic response of wheel-rail interaction at rail weld in high-speed railway[J]. Shock and Vibration, 2017, 2017(1): 5634726. [22] YANG Z, BOOGAARD A, WEI Z L, et al. Numerical study of wheel-rail impact contact solutions at an insulated rail joint[J]. International Journal of Mechanical Sciences, 2018, 138: 310-322. doi: 10.1016/j.ijmecsci.2018.02.025 [23] XU J M, WANG K, LIANG X Y, et al. Influence of viscoelastic mechanical properties of rail pads on wheel and corrugated rail rolling contact at high speeds[J]. Tribology International, 2020, 151: 106523. doi: 10.1016/j.triboint.2020.106523 [24] KAEWUNRUEN S, CHIENGSON C. Railway track inspection and maintenance priorities due to dynamic coupling effects of dipped rails and differential track settlements[J]. Engineering Failure Analysis, 2018, 93: 157-171. doi: 10.1016/j.engfailanal.2018.07.009 [25] 徐井芒, 梁新缘, 王凯, 等. 扣件刚度非线性对波磨区轮轨瞬态滚动接触行为的影响[J]. 西南交通大学学报, 2024, 59(2): 247-255.XU Jingmang, LIANG Xinyuan, WANG Kai, et al. Influence of fastener stiffness nonlinearity on wheel–rail transient rolling contact behavior in corrugated area[J]. Journal of Southwest Jiaotong University, 2024, 59(2): 247-255. [26] 胡晓依, 成棣, 孟凡迪, 等. 时速400公里高速铁路轮轨周期性短波不平顺的安全限值研究[J]. 西南交通大学学报, 2025, 60(6): 1581-1592. doi: 10.3969/j.issn.0258-2724.20230676HU Xiaoyi, CHENG Di, MENG Fandi, et al. Safety limit for periodic short-wave irregularity of wheel and rail for high-speed railways at 400 km/h[J]. Journal of Southwest Jiaotong University, 2025, 60(6): 1581-1592. doi: 10.3969/j.issn.0258-2724.20230676 -

下载:

下载: