Pressure Arch and Surrounding Rock Pressure in Mechanized Tunnels with Drilling and Blasting Method

-

摘要:

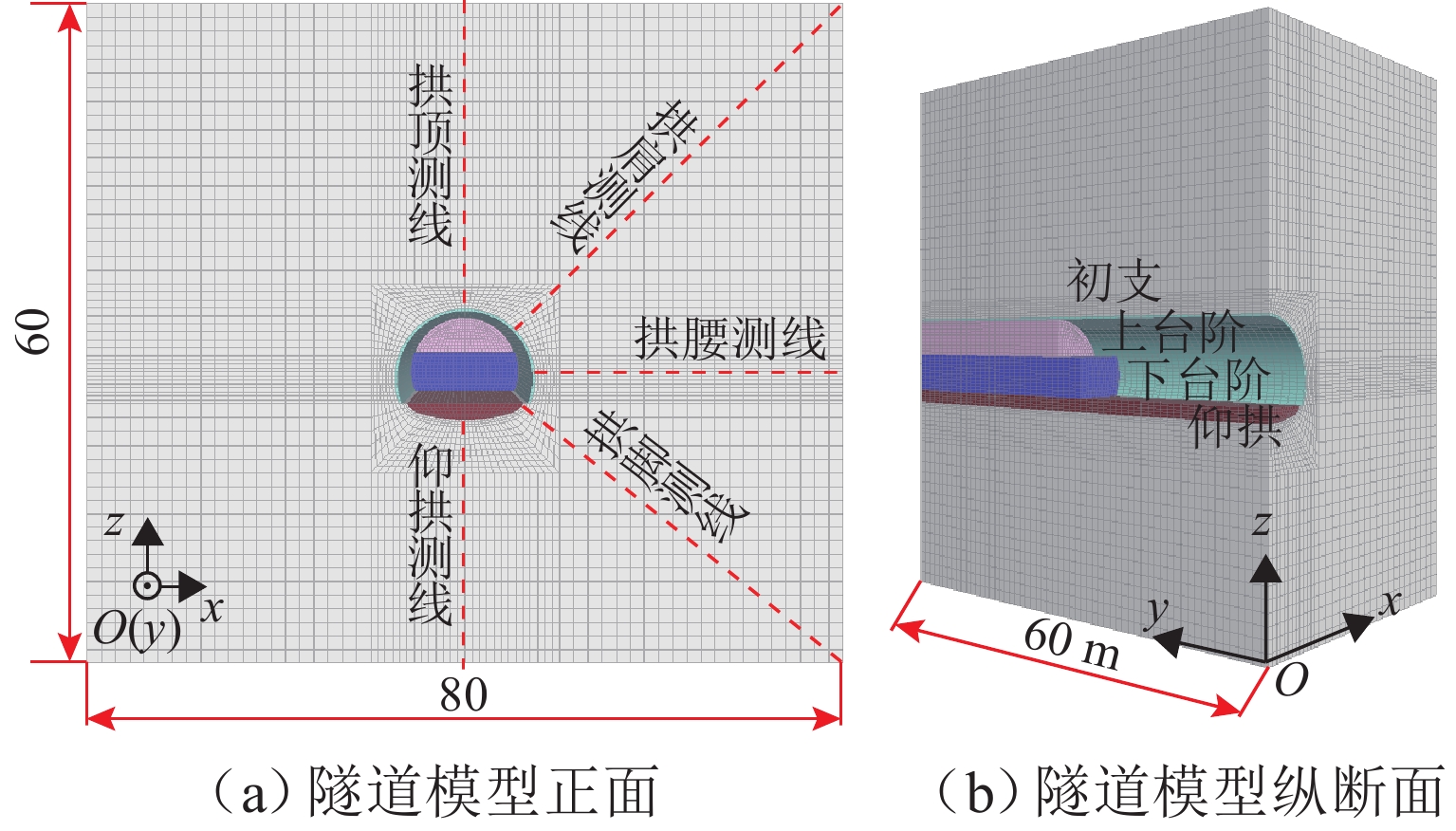

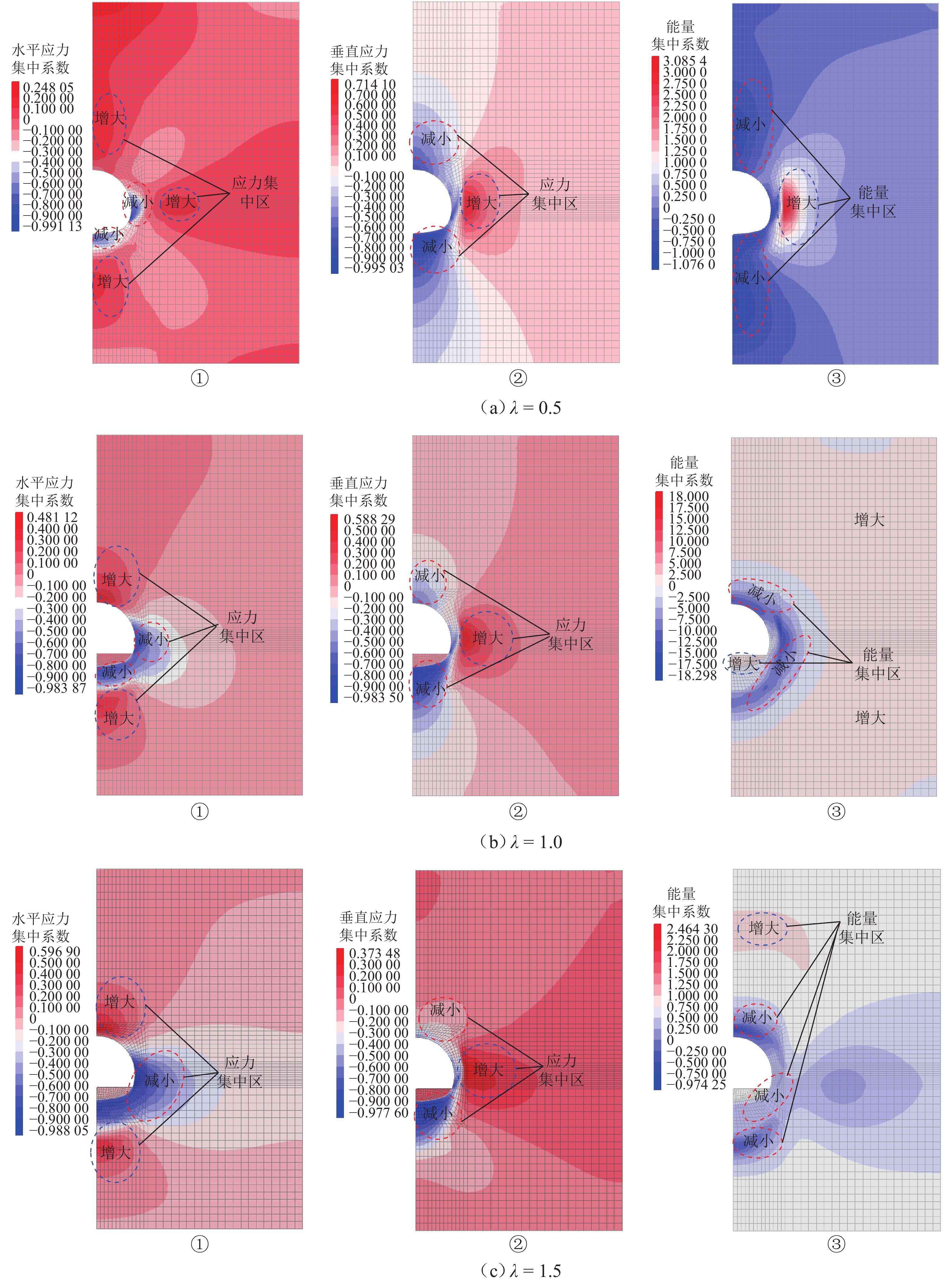

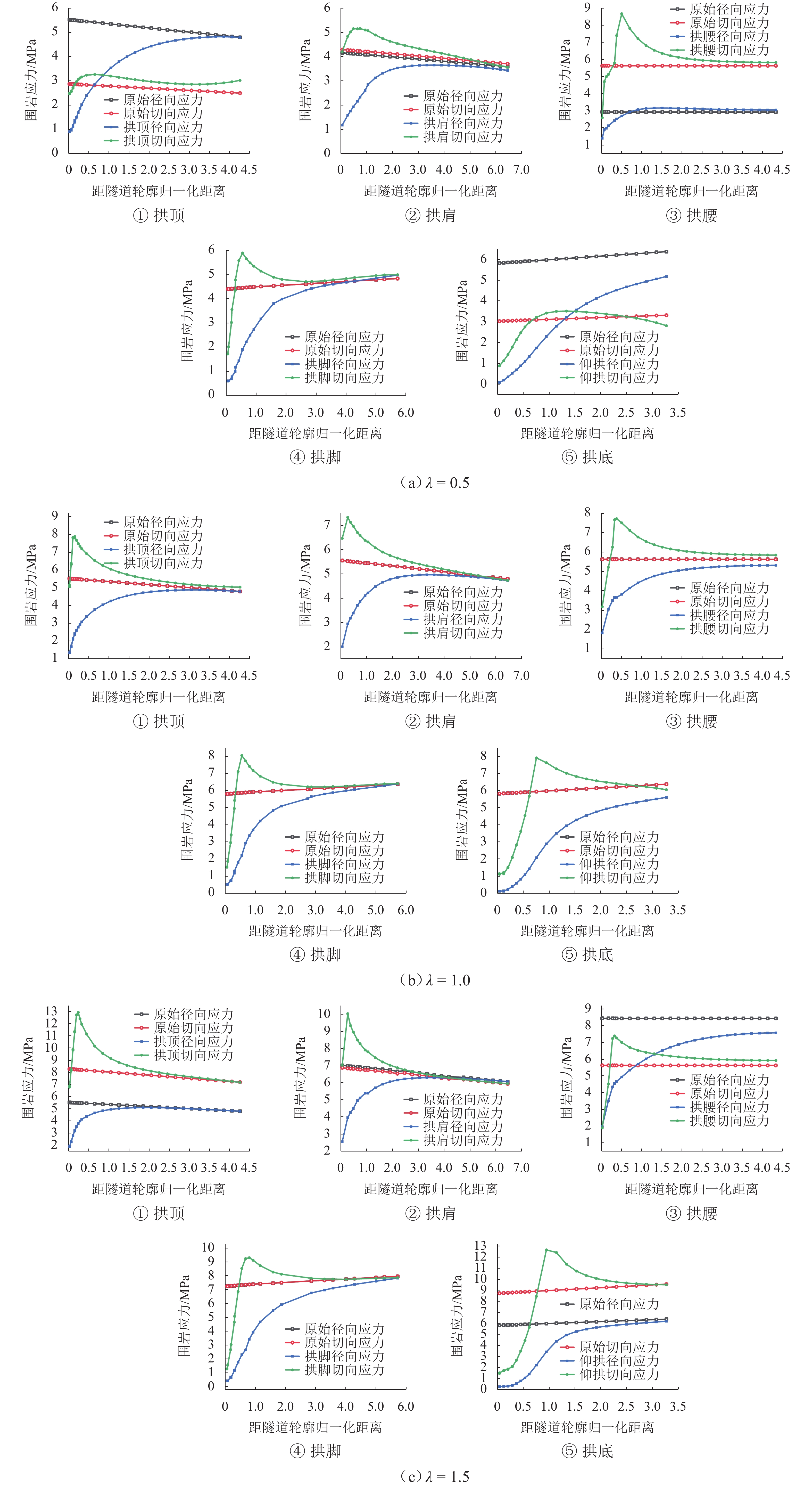

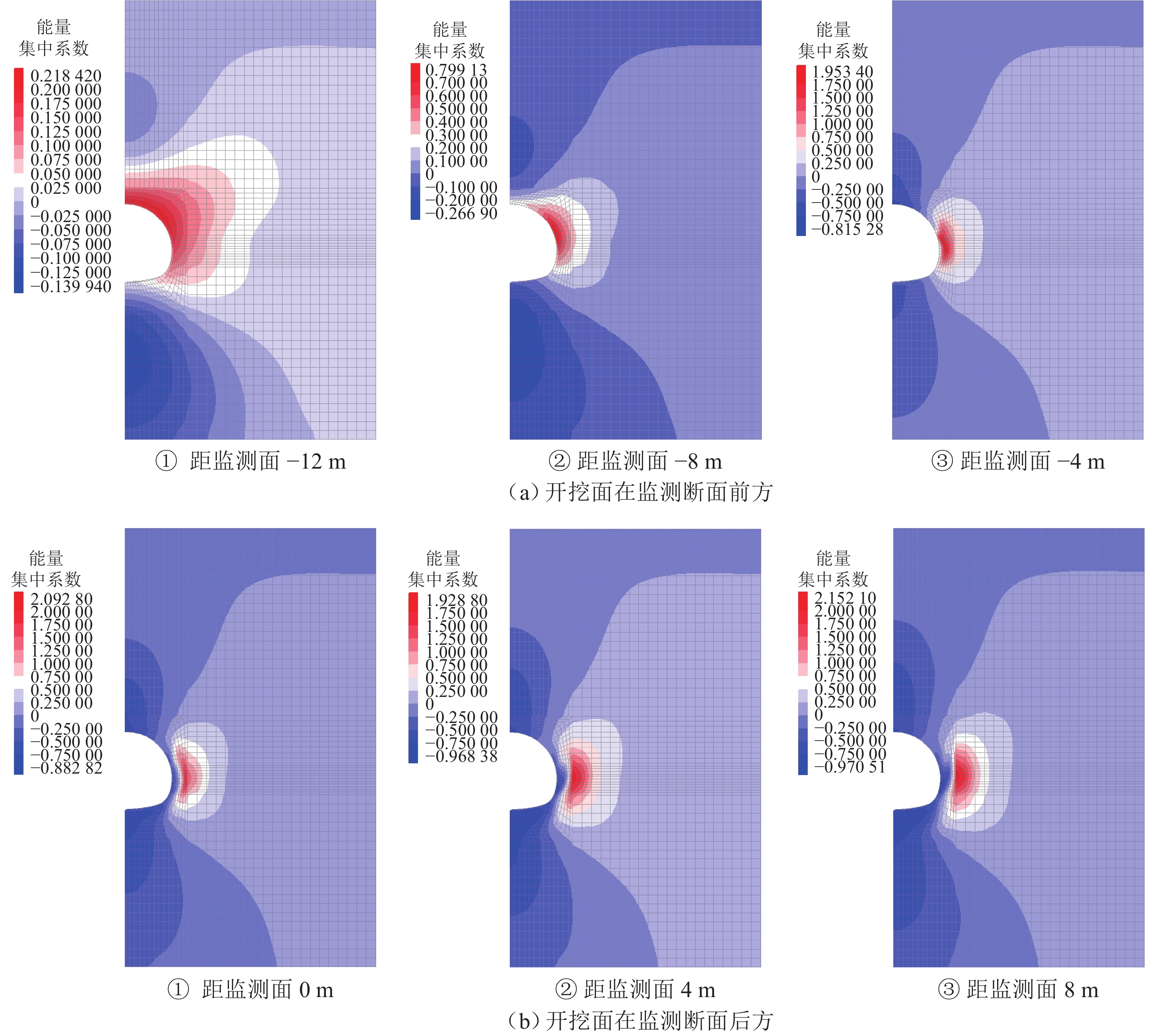

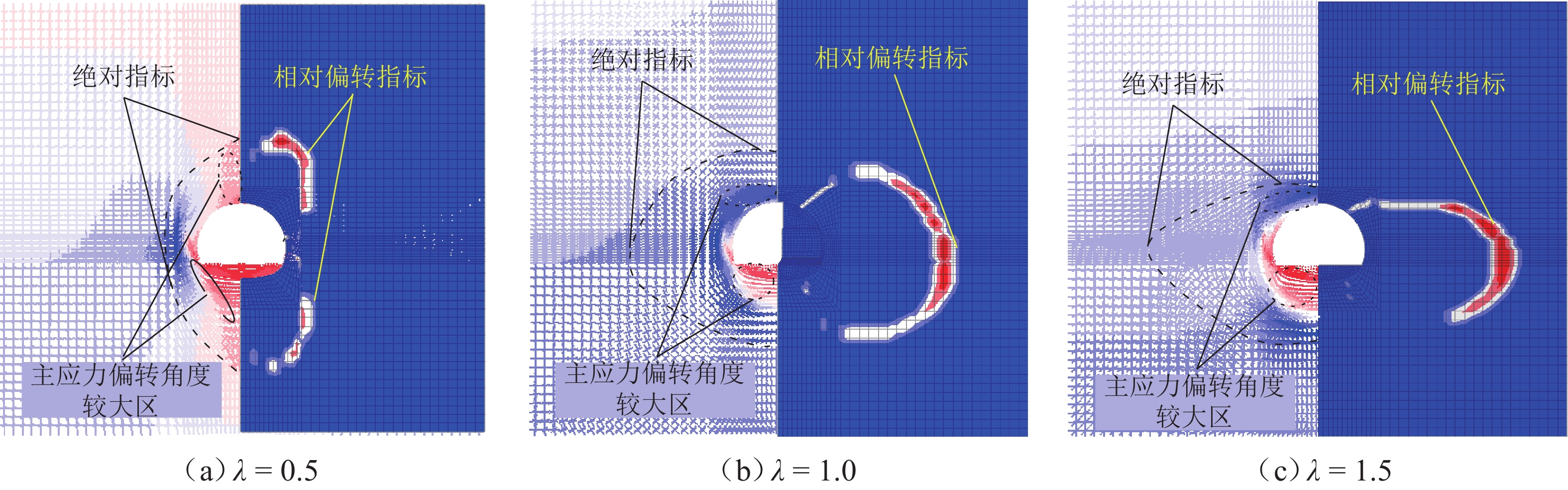

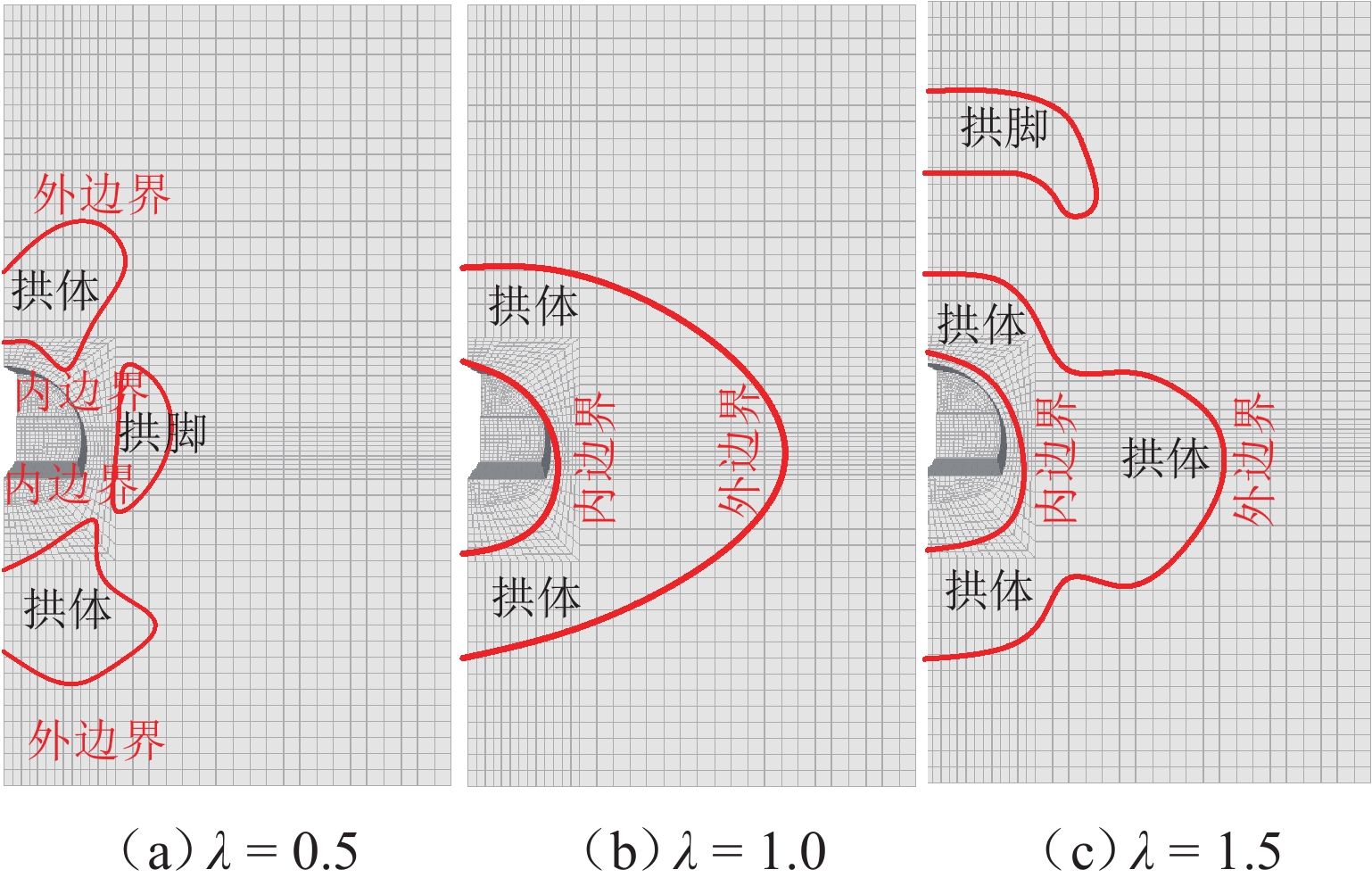

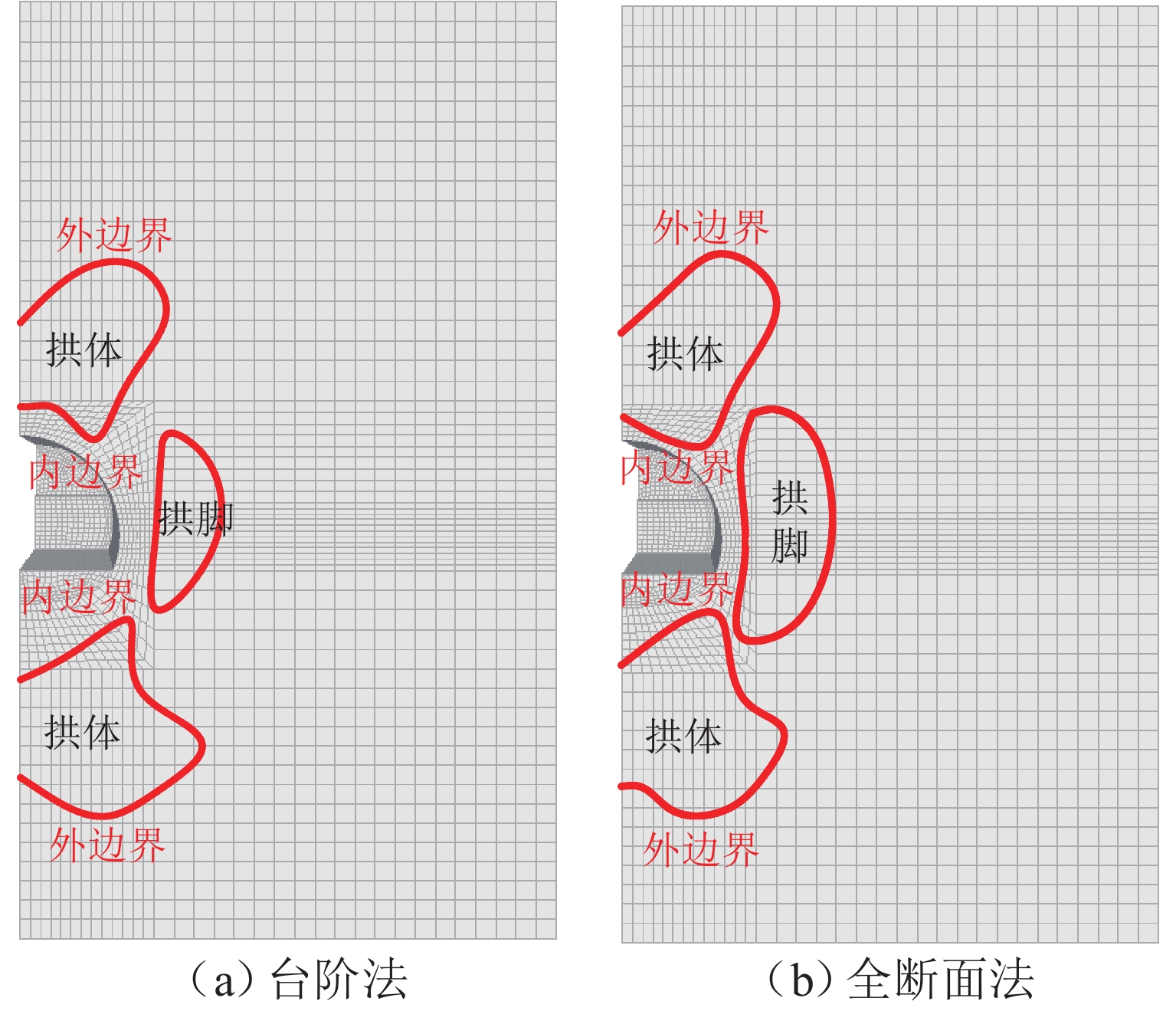

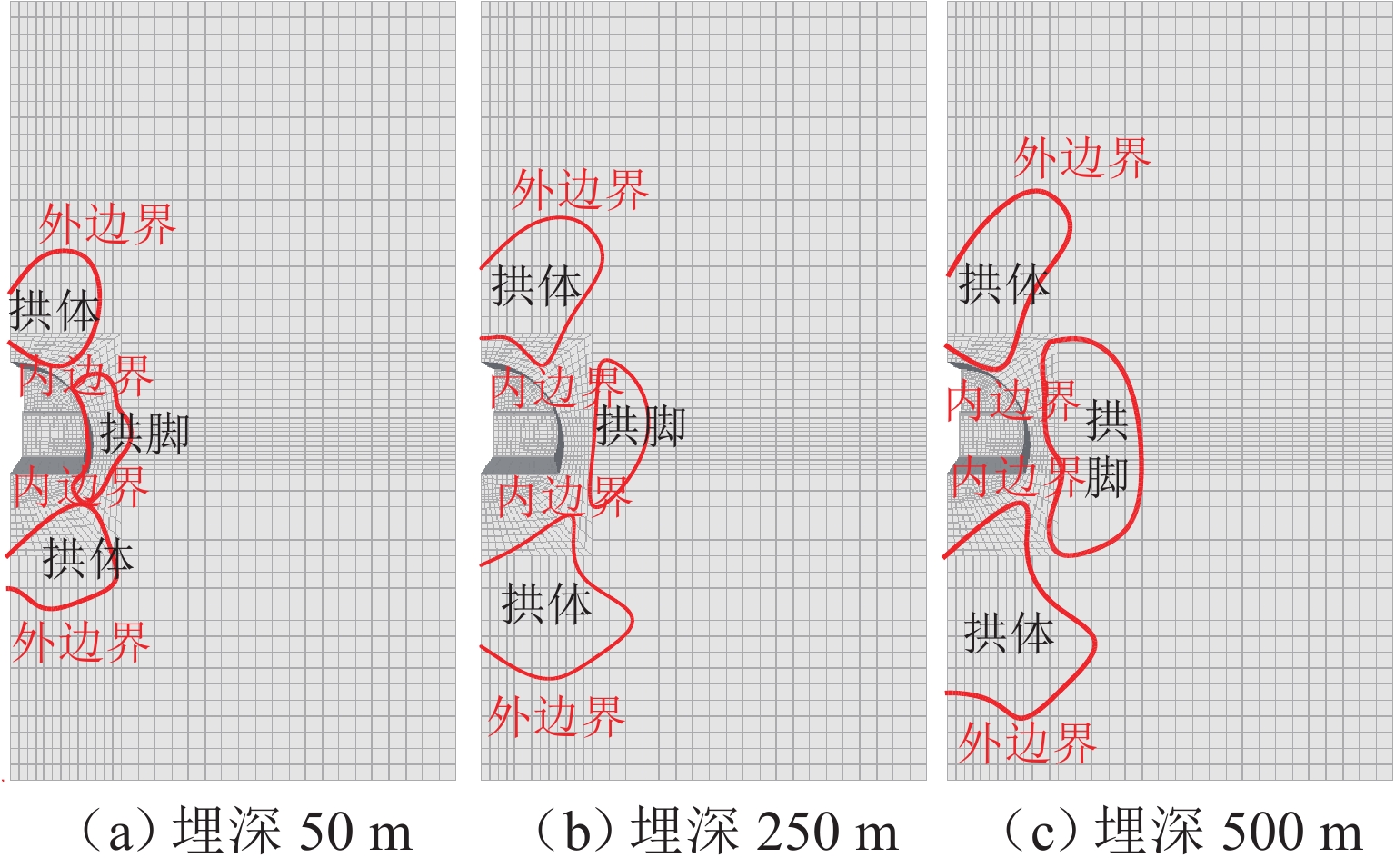

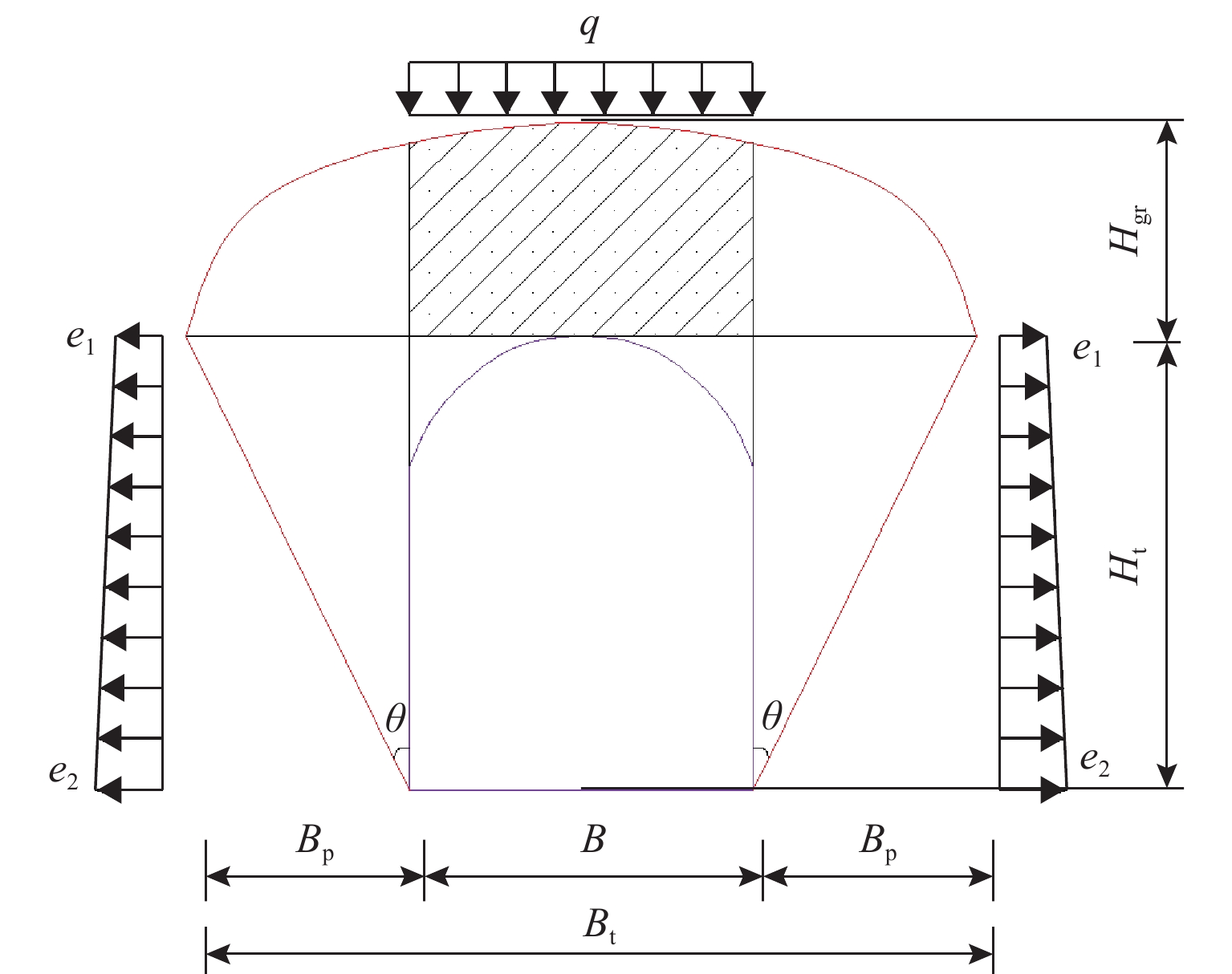

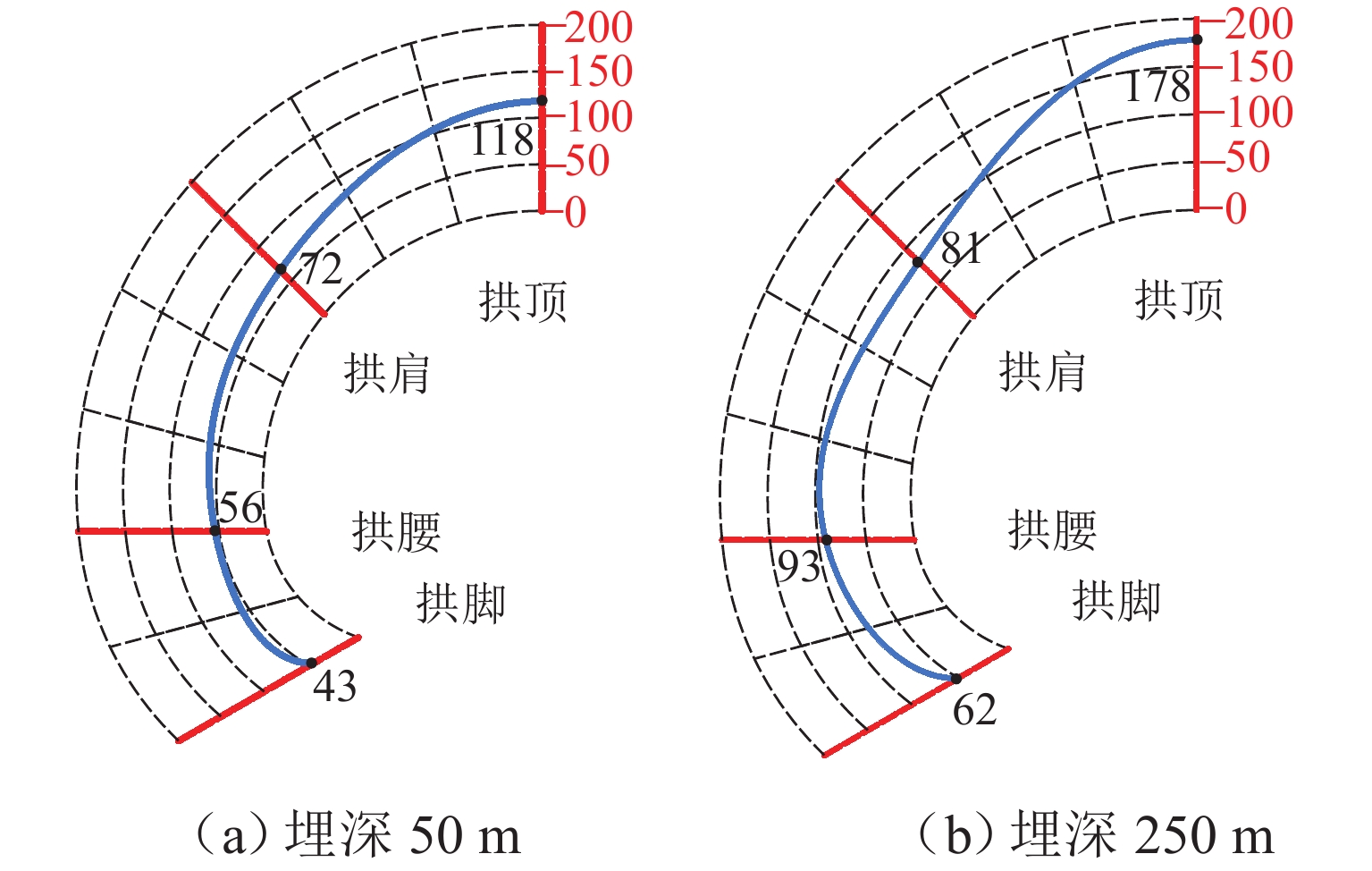

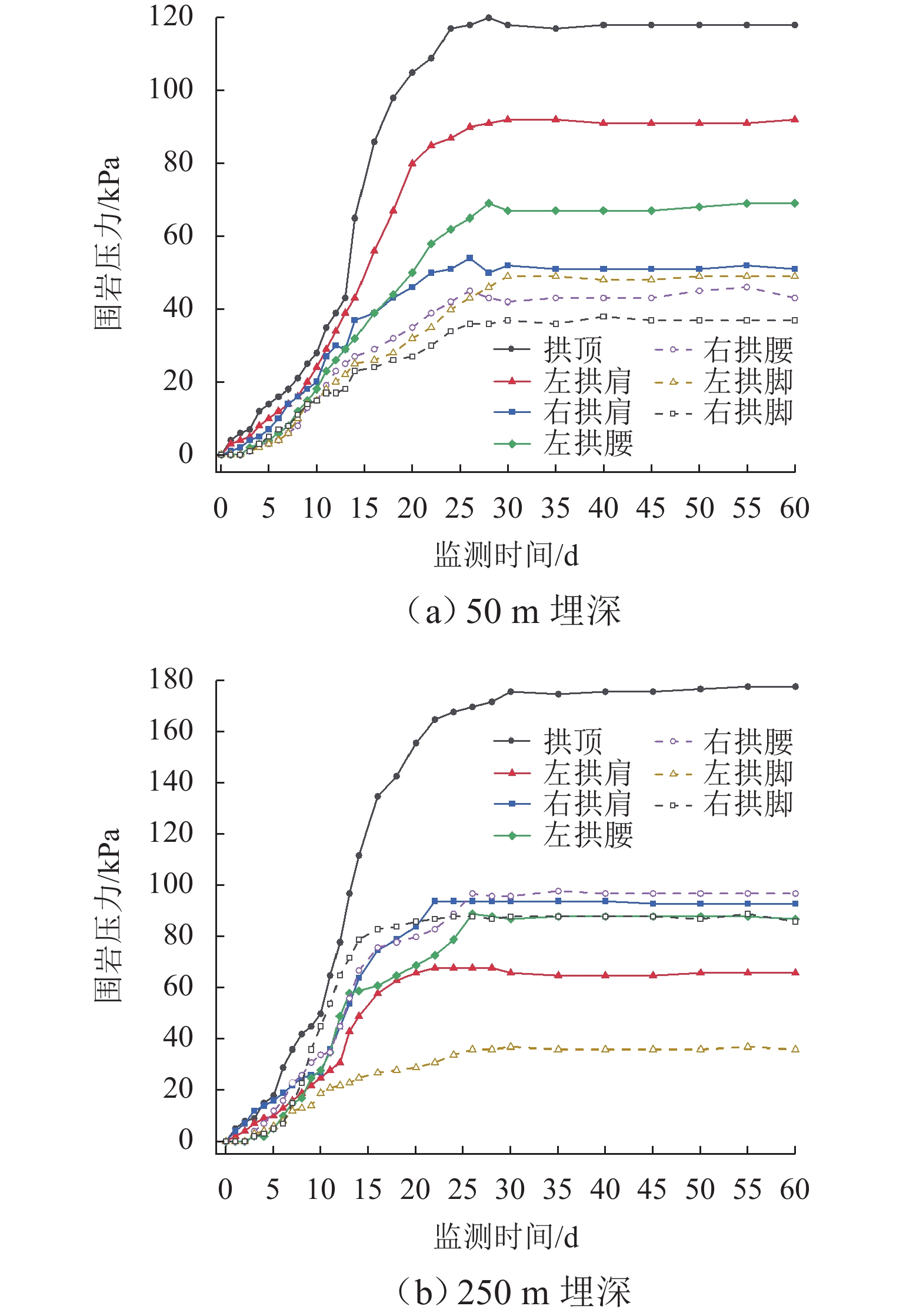

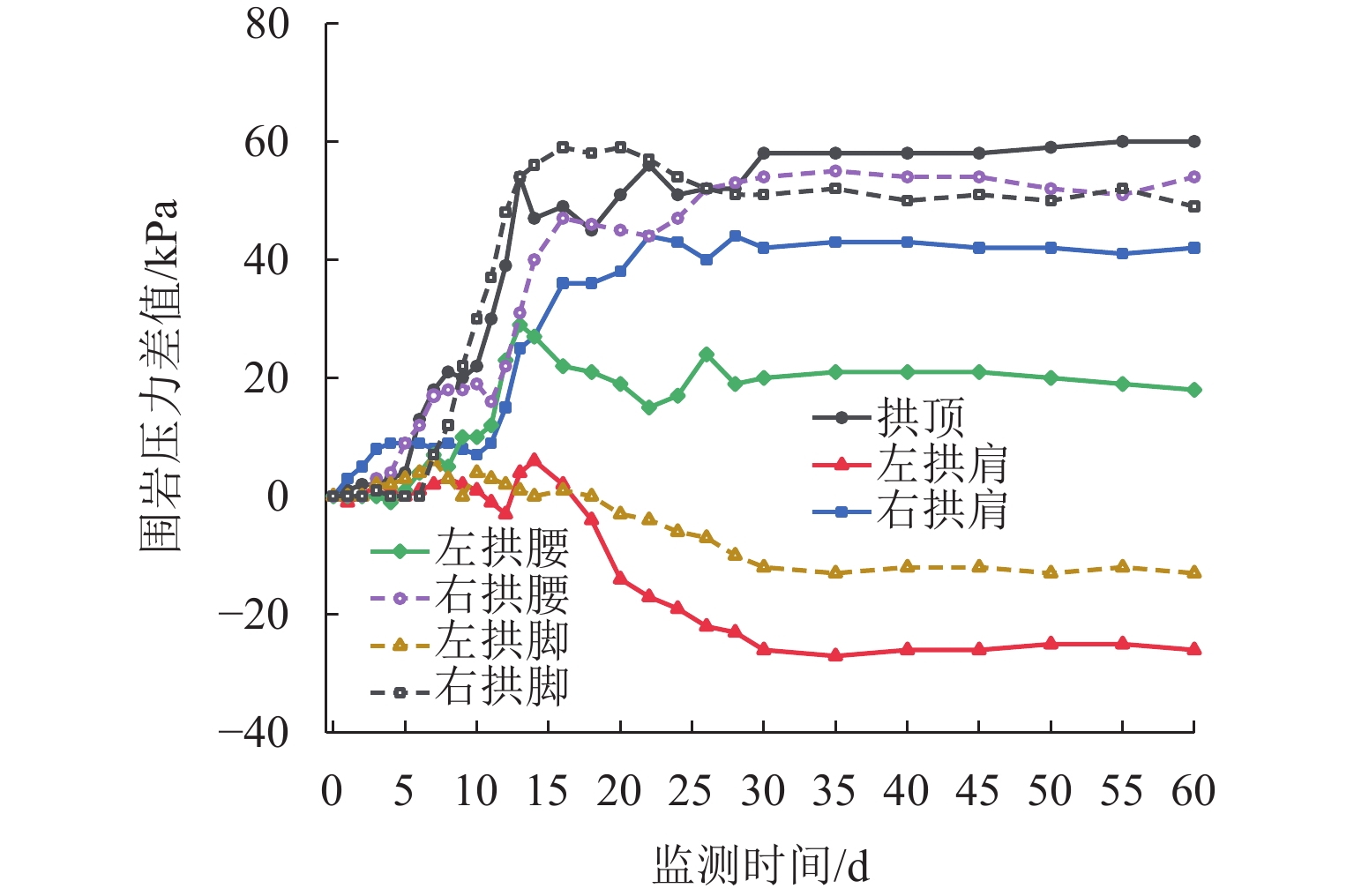

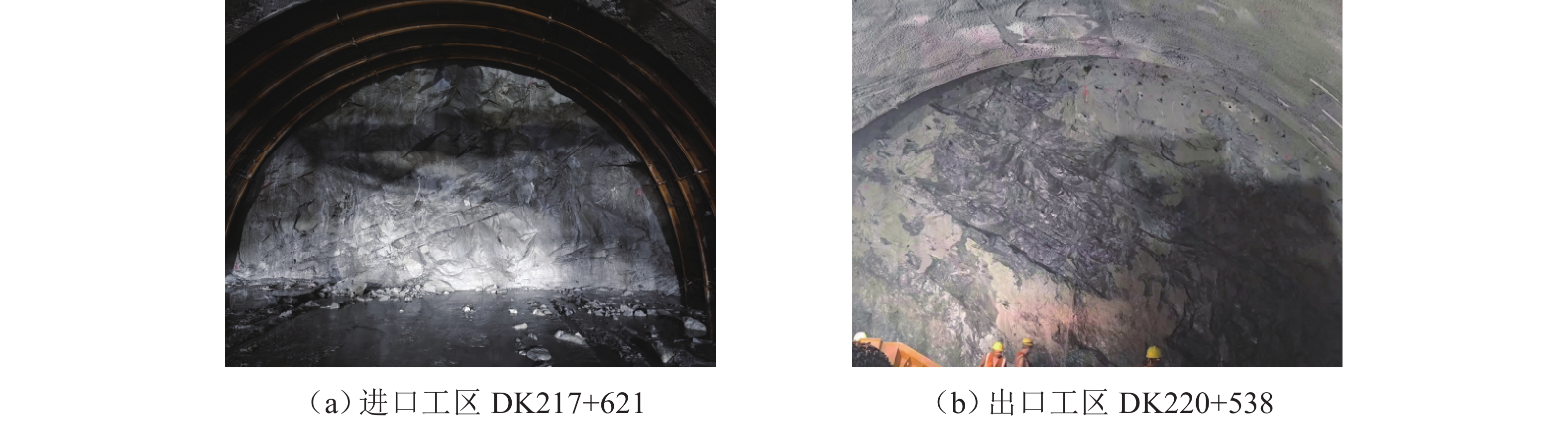

隧道钻爆法机械化开挖过程中,压力拱演化机制和发展规律对隧道荷载计算和稳定性判定有着重要的意义. 选取渝昆高铁典型双线隧道为研究对象,应用数值模拟和现场试验等方法,通过拟合压力拱内边界点、外边界点、起拱线和“拱脚”所对应位置的控制点,实现机械化隧道压力拱边界的综合判定,探明钻爆法机械化隧道开挖过程中压力拱的形成及发展规律;同时,基于压力拱特征,推导围岩压力理论计算模型. 结果表明:随着侧压力系数$\lambda $的增大,机械开挖过程中围岩应变能增大区呈现从边墙(侧压力系数$ \lambda = 0.5 $)→洞周开挖轮廓($ \lambda = 1.0 $)→拱顶($ \lambda = 1.5 $,距开挖轮廓较远)转移的演化规律;隧道开挖过程中围岩径向与切向应力变化总体呈“缩口喇叭”形状,当$ \lambda = 0.5 $时,洞室开挖面轮廓附近应变能会产生聚集并最终集聚至拱腰围岩内;拱顶围岩压力计算值与现场测试结果误差小于10%;与《铁路隧道设计规范》推荐公式对比,在埋深50 m时,计算值小于隧规值,随着埋深逐渐增大,围岩压力也逐渐增大,这与现场试验结果趋于一致.

Abstract:The evolution mechanism and development patterns of the pressure arch during the mechanized excavation process of tunnels using the drilling and blasting method hold significant importance for tunnel load calculation and stability assessment. A typical double-track tunnel on the Chongqing–Kunming High Speed Railway was selected as the research subject. By employing methods such as numerical simulation and field tests and fitting the control points corresponding to the inner boundary points, outer boundary points, arch springing line, and the positions of the “arch springing” of the pressure arch, a comprehensive determination of the pressure arch boundary in mechanized tunnels was achieved. Additionally, the formation and development patterns of the pressure arch during the excavation of mechanized tunnels using the drilling and blasting method were ascertained. Meanwhile, based on the characteristics of the pressure arch, a theoretical calculation model for surrounding rock pressure was derived. The conclusions are as follows: As the lateral pressure coefficient $\lambda $ increases, the area of increased strain energy in the surrounding rock during mechanical excavation shows an evolutionary pattern of transition from the side wall (lateral pressure coefficient $ \lambda = 0.5 $), the excavation contour around the tunnel ($ \lambda = 1.0 $), and the vault ($ \lambda = 1.5 $, farther away from the excavation contour). During tunnel excavation, the overall changes in radial and tangential stresses in the surrounding rock exhibit a narrowing trumpet shape. When $ \lambda = 0.5 $, the strain energy accumulates near the contour of the excavation face of the tunnel and eventually concentrates within the surrounding rock of the haunch. The error between the calculated value of the vault surrounding rock pressure and the field test result is less than 10%. Compared with the recommended formula in the

Code for Design of Railway Tunnel , the calculated value is smaller than the tunnel code value at a buried depth of 50 m. As the buried depth gradually increases, the surrounding rock pressure also increases, which is consistent with field test results. -

表 1 围岩及支护结构物理力学参数

Table 1. Physical and mechanical parameters of surrounding rock and supporting structure

类别 岩性 弹性模量/GPa 内摩擦角/(°) 黏聚力/MPa 泊松比 抗拉强度/MPa 密度/(kN·cm−3) 围岩 Ⅳ 级泥岩夹砂岩 1.90 35 0.20 0.34 1.20 2300 初期支护 25.68 0.20 2285 表 2 不同侧压力系数下围岩压力拱厚度

Table 2. Thickness of pressure arch of surrounding rock under different lateral pressure coefficients

m λ 拱部 边墙 仰拱 0.5 13.1 5.1 13.3 1.0 7.9 19.1 9.7 1.5 7.4 23.3 8.6 表 3 本文与其他研究对比

Table 3. Comparison between this study and other research

表 4 不同埋深时竖向围岩压力计算值

Table 4. Calculation values of vertical surrounding rock pressure at different burial depths

kPa 隧道埋深/m 规范计算值 普氏压力拱理论值 计算值 50 152.5 179.2 127.70 250 152.5 179.2 176.73 500 152.5 179.2 191.78 -

[1] 童建军, 刘大刚, 张霄, 等. 大断面隧道机械化施工支护结构设计方法: 以郑万高铁湖北段隧道为例[J]. 隧道建设(中英文), 2021, 41(1): 116-125.TONG Jianjun, LIU Dagang, ZHANG Xiao, et al. Design method for support structure of large cross-section tunnels in Hubei on Zhengzhou-Wanzhou railway constructed by mechanized means[J]. Tunnel Construction, 2021, 41(1): 116-125. [2] 中华人民共和国行业编写组. 铁路隧道设计规范: TB 10003—2016[S]. 北京: 中国铁道出版社, 2016. [3] 台启民, 张顶立, 王剑晨, 等. 软弱破碎围岩高铁隧道压力拱演化规律分析[J]. 北京交通大学学报, 2015, 39(6): 62-68.TAI Qimin, ZHANG Dingli, WANG Jianchen, et al. Analysis on pressure arch evolution law of high-speed railway tunnel under unfavourable rock conditions[J]. Journal of Beijing Jiaotong University, 2015, 39(6): 62-68. [4] 姚艺玮. 深埋黄土隧道围岩压力分布规律、形成机理及计算方法研究[D]. 西安: 西安理工大学, 2023. [5] 安永林, 李佳豪, 周进, 等. 某不等跨分岔隧道力学特性与三维空间压力拱分析[J]. 铁道科学与工程学报, 2022, 19(12): 3705-3714.AN Yonglin, LI Jiahao, ZHOU Jin, et al. Mechanical characteristics and three-dimensional pressure arch of a branch-out tunnel with unequal-span[J]. Journal of Railway Science and Engineering, 2022, 19(12): 3705-3714. [6] 晏莉, 吕超慧, 喻少华, 等. 近邻双孔隧道围岩联合压力拱试验与数值分析[J]. 北京交通大学学报, 2022, 46(3): 103-109.YAN Li, LYU Chaohui, YU Shaohua, et al. Test and numerical analysis on combined pressure arch of surrounding rock in adjacent twin tunnels[J]. Journal of Beijing Jiaotong University, 2022, 46(3): 103-109. [7] 梁晓丹, 刘刚, 赵坚. 地下工程压力拱拱体的确定与成拱分析[J]. 河海大学学报(自然科学版), 2005, 33(3): 314-317.LIANG Xiaodan, LIU Gang, ZHAO Jian. Definition and analysis of arching action in underground rock engineering[J]. Journal of Hohai University (Natural Sciences), 2005, 33(3): 314-317. [8] 李奎. 水平层状隧道围岩压力拱理论研究[D]. 成都: 西南交通大学, 2010. [9] 曹利强, 张顶立, 李新宇, 等. 浅埋盾构穿越渗透性地层时极限支护压力分析[J]. 西南交通大学学报, 2019, 54(3): 507-515. doi: 10.3969/j.issn.0258-2724.20180482CAO Liqiang, ZHANG Dingli, LI Xinyu, et al. Analysis of limit support pressure due to shield tunnelling with shallow overburden under seepage[J]. Journal of Southwest Jiaotong University, 2019, 54(3): 507-515. doi: 10.3969/j.issn.0258-2724.20180482 [10] 王明年, 王志龙, 桂登斌, 等. 开挖方法影响下的深埋隧道形变压力计算方法[J]. 西南交通大学学报, 2021, 56(5): 1116-1124.WANG Mingnian, WANG Zhilong, GUI Dengbin, et al. Calculation method of deformation load of deep-buried tunnel under influence of excavation method[J]. Journal of Southwest Jiaotong University, 2021, 56(5): 1116-1124. [11] 严涛, 李坤杰, 牟智恒, 等. 变坡条件下浅埋偏压隧道围岩压力解析法[J]. 西南交通大学学报, 2020, 55(3): 531-536.YAN Tao, LI Kunjie, MOU Zhiheng, et al. Analytical method for calculation of surrounding rock pressure of shallow-buried and unsymmetrically loaded tunnel adjacent to variable slope[J]. Journal of Southwest Jiaotong University, 2020, 55(3): 531-536. [12] 孙振宇, 皇甫楠琦, 张顶立, 等. 大跨度隧道预应力锚固体系协同承载的压力拱效应[J]. 铁道标准设计, 2023, 67(1): 10-16, 24.SUN Zhenyu, HUANGFU Nanqi, ZHANG Dingli, et al. Pressure arch effect of the synergetic bearing of pre-stressed anchorage system in large-span tunnel[J]. Railway Standard Design, 2023, 67(1): 10-16, 24. [13] 宋玉香, 张亚辉, 刘勇. 基于压力拱理论的围岩压力计算研究[J]. 防灾减灾学报, 2017, 33(2): 45-51.SONG Yuxiang, ZHANG Yahui, LIU Yong. Calculation of the surrounding rock pressure based on pressure arch theory[J]. Journal of Disaster Prevention and Reduction, 2017, 33(2): 45-51. [14] 郑康成, 丁文其, 金威, 等. 特大断面隧道分步施工动态压力拱分析研究[J]. 岩土工程学报, 2015, 37(增1): 72-77.ZHENG Kangcheng, DING Wenqi, JIN Wei, et al. Analysis and research on dynamic pressure arch in step-by-step construction of extra-large cross-section tunnel[J]. Chinese Journal of Geotechnical Engineering, 2015, 37(S1): 72-77. [15] 杜晓丽. 采矿岩石压力拱演化规律及其应用的研究[D]. 徐州: 中国矿业大学, 2011. [16] 安永林, 李佳豪, 刘文娟, 等. 隧道压力拱边界统一判定方法及其空间演化特征[J]. 中国安全科学学报, 2022, 32(8): 84-90.AN Yonglin, LI Jiahao, LIU Wenjuan, et al. Unified boundary determination method of pressure arch in tunnels and its spatial evolution characteristics[J]. China Safety Science Journal, 2022, 32(8): 84-90. [17] 王明年, 郭军, 罗禄森, 等. 高速铁路大断面深埋黄土隧道围岩压力计算方法[J]. 中国铁道科学, 2009, 30(5): 53-58. doi: 10.3321/j.issn:1001-4632.2009.05.009WANG Mingnian, GUO Jun, LUO Lusen, et al. Calculation method for the surrounding rock pressure of deep buried large sectional loess tunnel of high-speed railway[J]. China Railway Science, 2009, 30(5): 53-58. doi: 10.3321/j.issn:1001-4632.2009.05.009 [18] 李英杰. 软弱深埋隧道围岩结构特性及支护荷载确定方法研究[D]. 北京: 北京交通大学, 2012. [19] 范文, 俞茂宏, 孙萍, 等. 硐室形变围岩压力弹塑性分析的统一解[J]. 长安大学学报(自然科学版), 2003, 23(3): 1-4.FAN Wen, YU Maohong, SUN Ping, et al. Unified solution of elastic-plastic analysis for surrounding rock mass stress under cave deformation[J]. Journal of Xi’an Highway University, 2003, 23(3): 1-4. [20] 郑颖人, 王永甫. 隧道稳定性分析与设计方法讲座之一: 隧道围岩压力理论进展与破坏机制研究[J]. 隧道建设, 2013, 33(6): 423-430.ZHENG Yingren, WANG Yongfu. Evolution of rock mass pressure theory and researches on tunnel failure mechanism[J]. Tunnel Construction, 2013, 33(6): 423-430. [21] 李鹏飞, 赵勇, 张顶立, 等. 基于现场实测数据统计的隧道围岩压力分布规律研究[J]. 岩石力学与工程学报, 2013, 32(7): 1392-1399.LI Pengfei, ZHAO Yong, ZHANG Dingli, et al. Study of distribution laws of tunnel surrounding rock pressure based on field measured data statistics[J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(7): 1392-1399. [22] PARDO G S, SÁEZ E. Experimental and numerical study of arching soil effect in coarse sand[J]. Computers and Geotechnics, 2014, 57: 75-84. doi: 10.1016/j.compgeo.2014.01.005 [23] MA K M, ZHANG J C, ZHANG J R, et al. Determination of the rock mass bearing mechanism following excavation of circular tunnels[J]. Rock Mechanics and Rock Engineering, 2024, 57(8): 5783-5800. doi: 10.1007/s00603-024-03840-7 [24] 李鹏飞, 周烨, 伍冬. 隧道围岩压力计算方法及其适用范围[J]. 中国铁道科学, 2013, 34(6): 55-60.LI Pengfei, ZHOU Ye, WU Dong. Calculation methods for surrounding rock pressure and application Scopes[J]. China Railway Science, 2013, 34(6): 55-60. [25] HE L, ZHANG Q B. Numerical investigation of arching mechanism to underground excavation in jointed rock mass[J]. Tunnelling and Underground Space Technology, 2015, 50: 54-67. doi: 10.1016/j.tust.2015.06.007 [26] 孙河川, 张鏖, 施仲衡. 喷锚支护与隧道自承拱的机理[J]. 岩土工程学报, 2004, 26(4): 490-494. doi: 10.3321/j.issn:1000-4548.2004.04.013SUN Hechuan, ZHANG Ao, SHI Zhongheng. Mechanism of grouted rockbolting and self-supporting arch of tunnels[J]. Chinese Journal of Geotechnical Engineering, 2004, 26(4): 490-494. doi: 10.3321/j.issn:1000-4548.2004.04.013 [27] 甄利兵, 贾敬锎. 基于正交试验的采场压力拱形态因素敏感性分析[J]. 地下空间与工程学报, 2022, 18(增1): 82-87, 96.ZHEN Libing, JIA Jingkai. Sensitivity analysis of stope pressure arch form factors based on orthogonal test[J]. Chinese Journal of Underground Space and Engineering, 2022, 18(S1): 82-87, 96. [28] 昝文博, 赖金星, 邱军领, 等. 松散堆积体隧道压力拱效应试验与数值模拟[J]. 岩土工程学报, 2021, 43(9): 1666-1674.ZAN Wenbo, LAI Jinxing, QIU Junling, et al. Experiments and numerical simulations on pressure-arch effect for a tunnel in loose deposits[J]. Chinese Journal of Geotechnical Engineering, 2021, 43(9): 1666-1674. [29] 王明年, 王志龙, 张霄, 等. 深埋隧道围岩形变压力计算方法研究[J]. 岩土工程学报, 2020, 42(1): 81-90. doi: 10.11779/CJGE202001009WANG Mingnian, WANG Zhilong, ZHANG Xiao, et al. Method for calculating deformation pressure of surrounding rock of deep-buried tunnels[J]. Chinese Journal of Geotechnical Engineering, 2020, 42(1): 81-90. doi: 10.11779/CJGE202001009 -

下载:

下载: