Mechanical Characteristics of Large-Diameter Shield Tunnel Segment Structure under High Water Pressure

-

摘要:

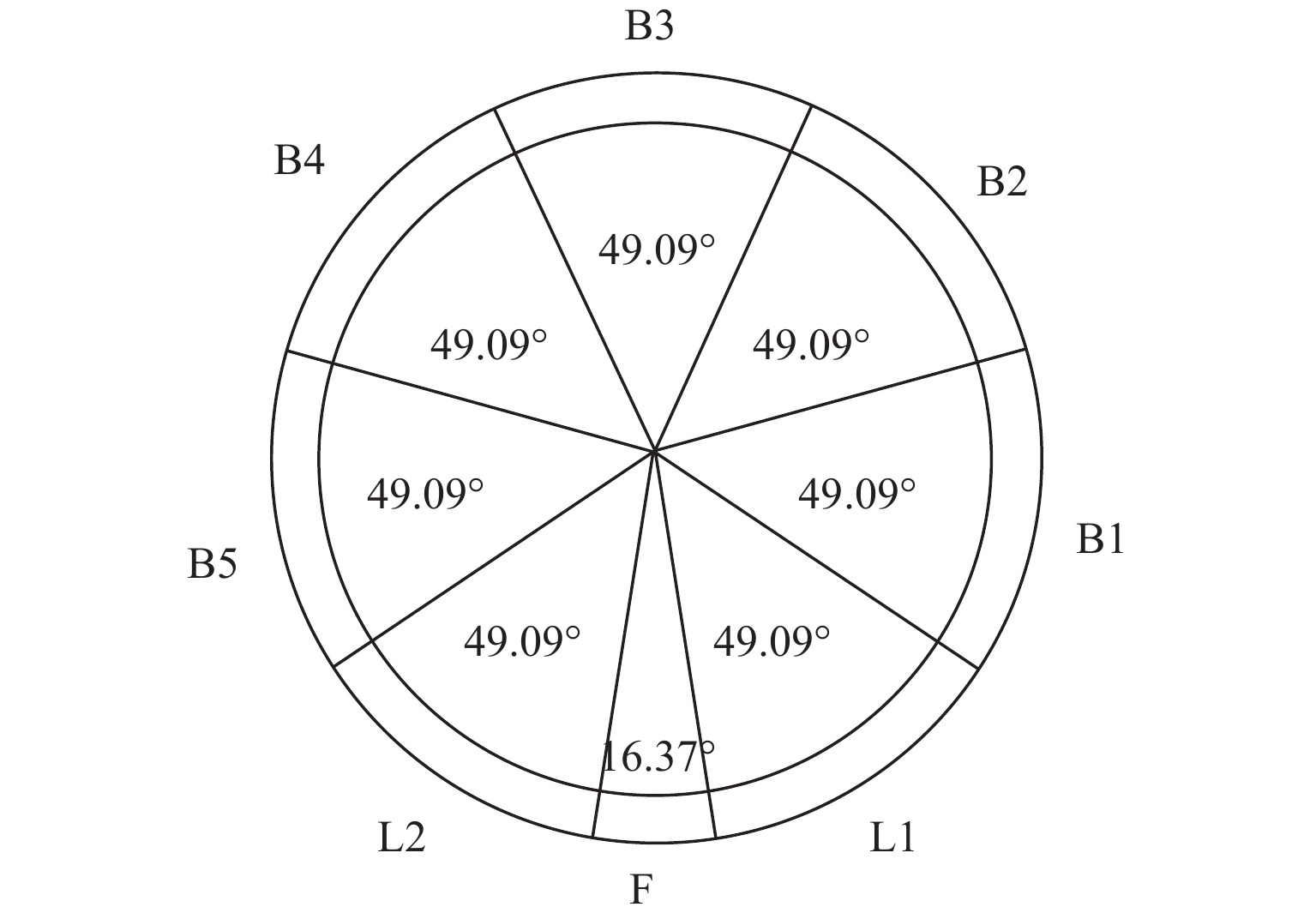

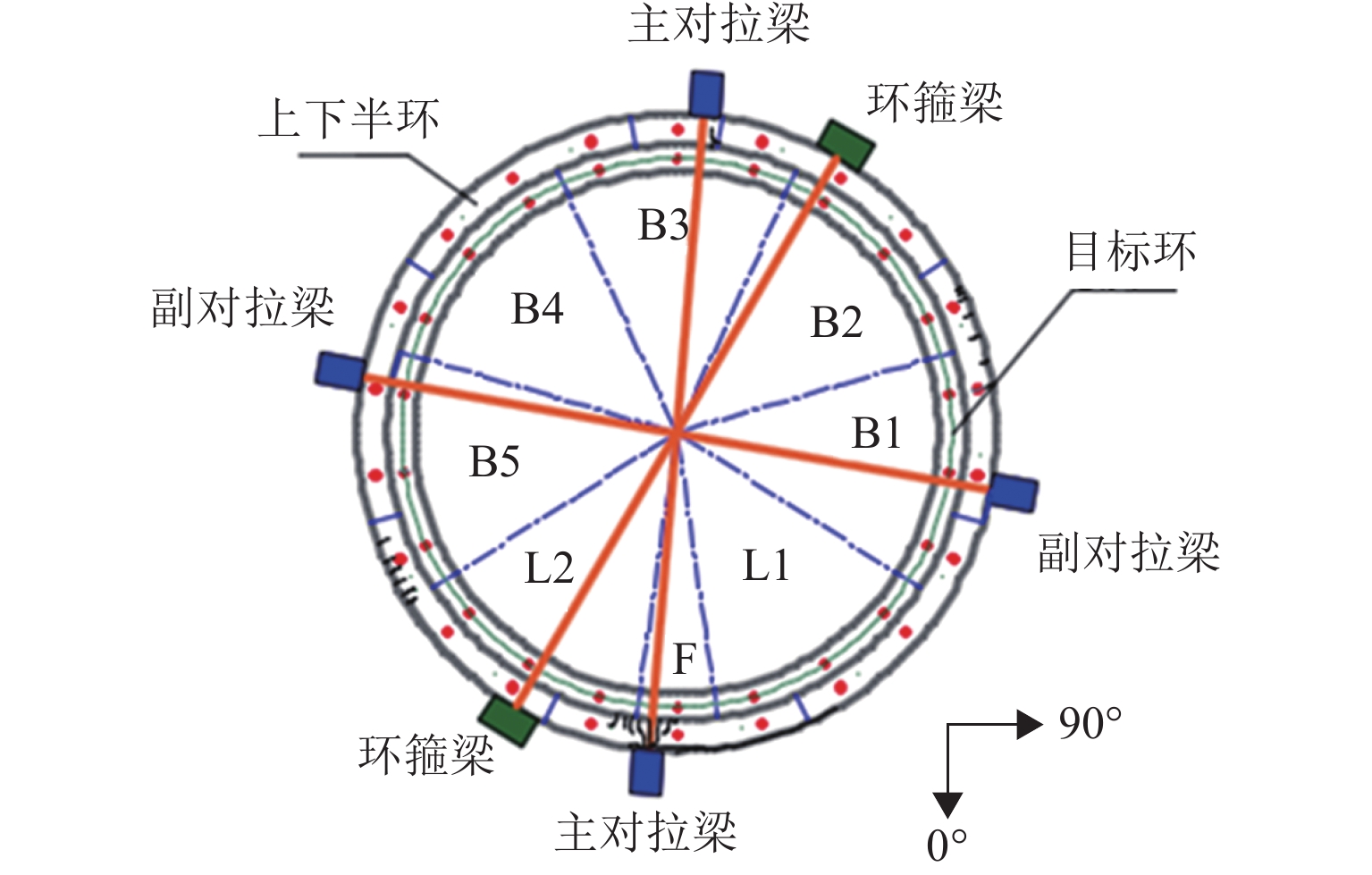

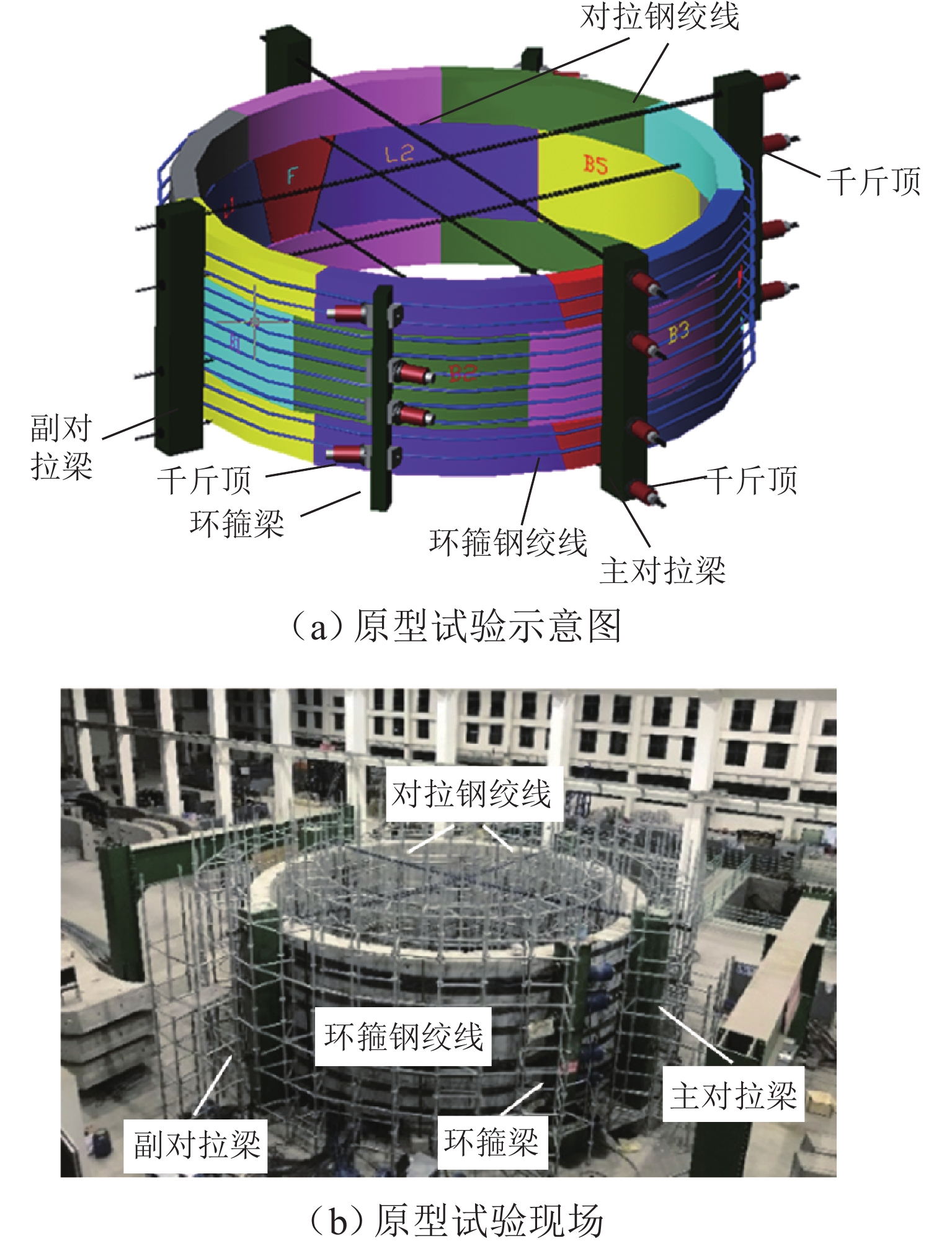

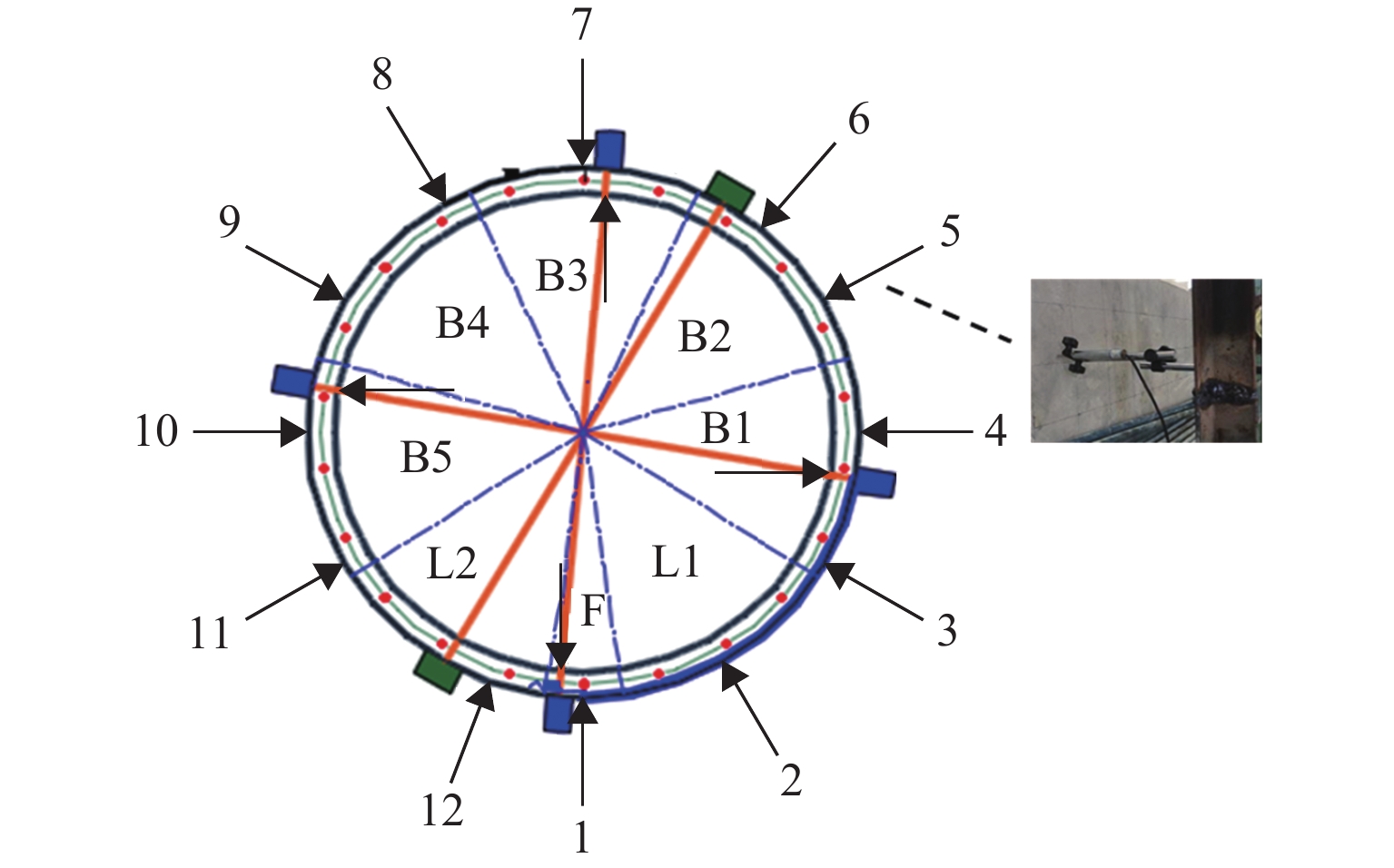

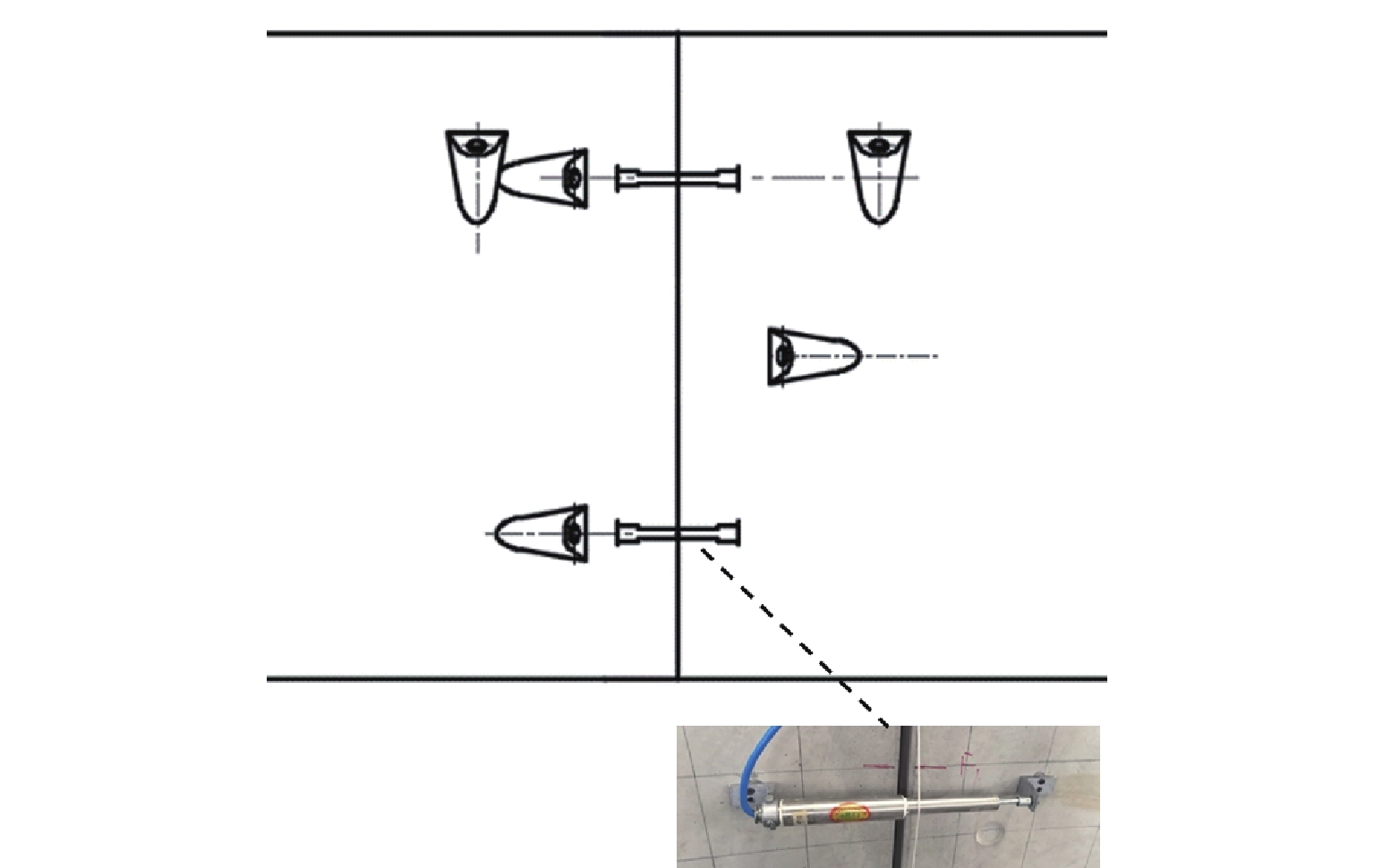

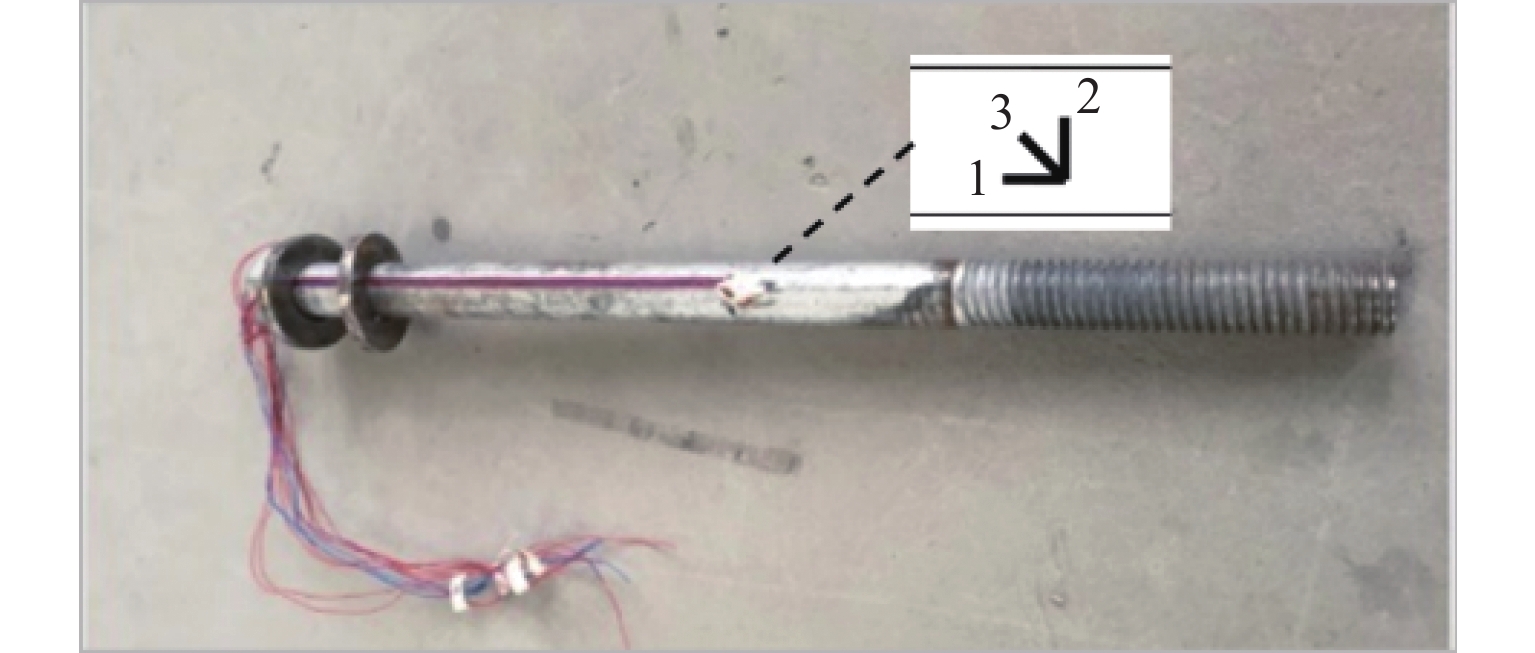

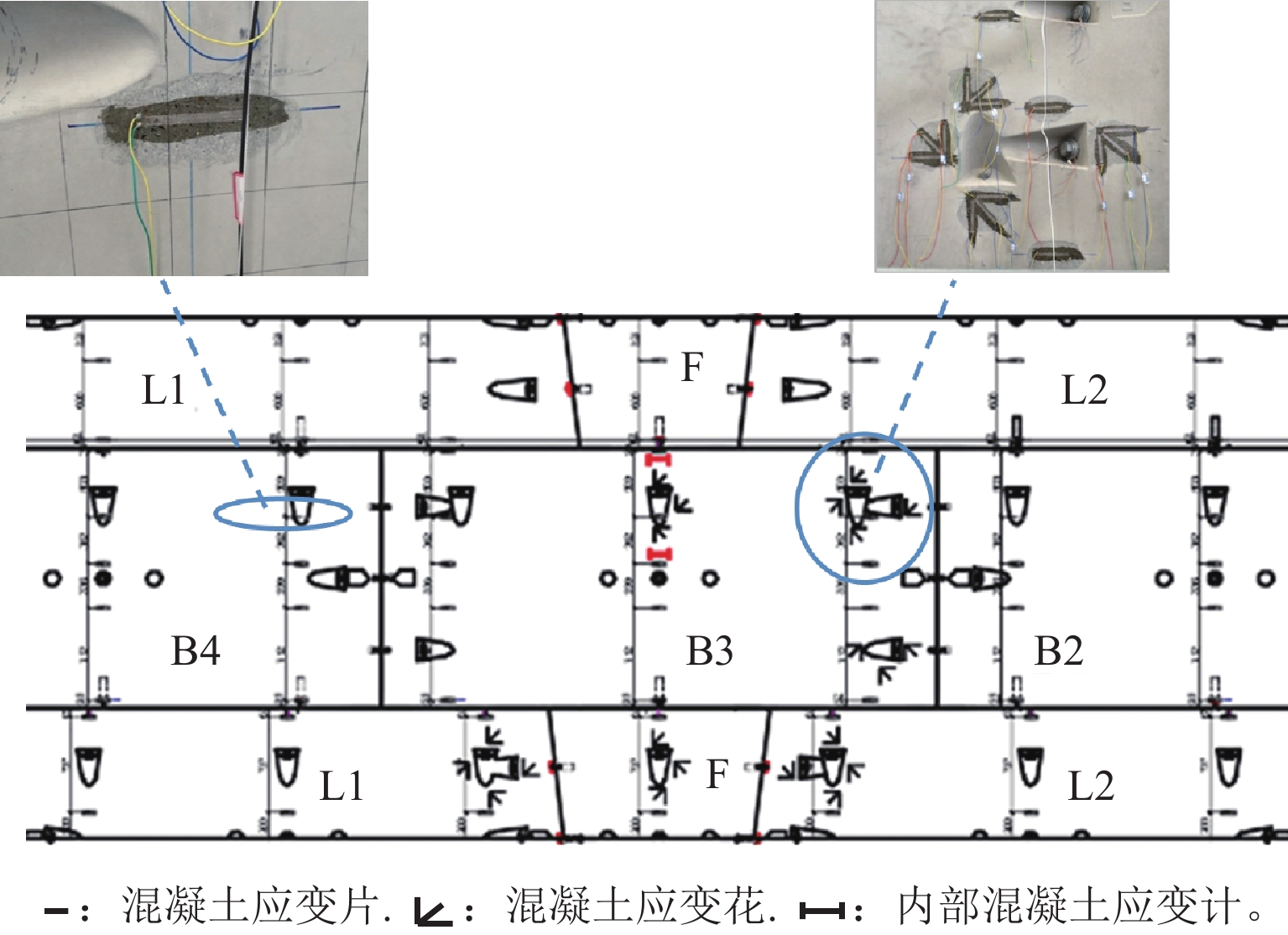

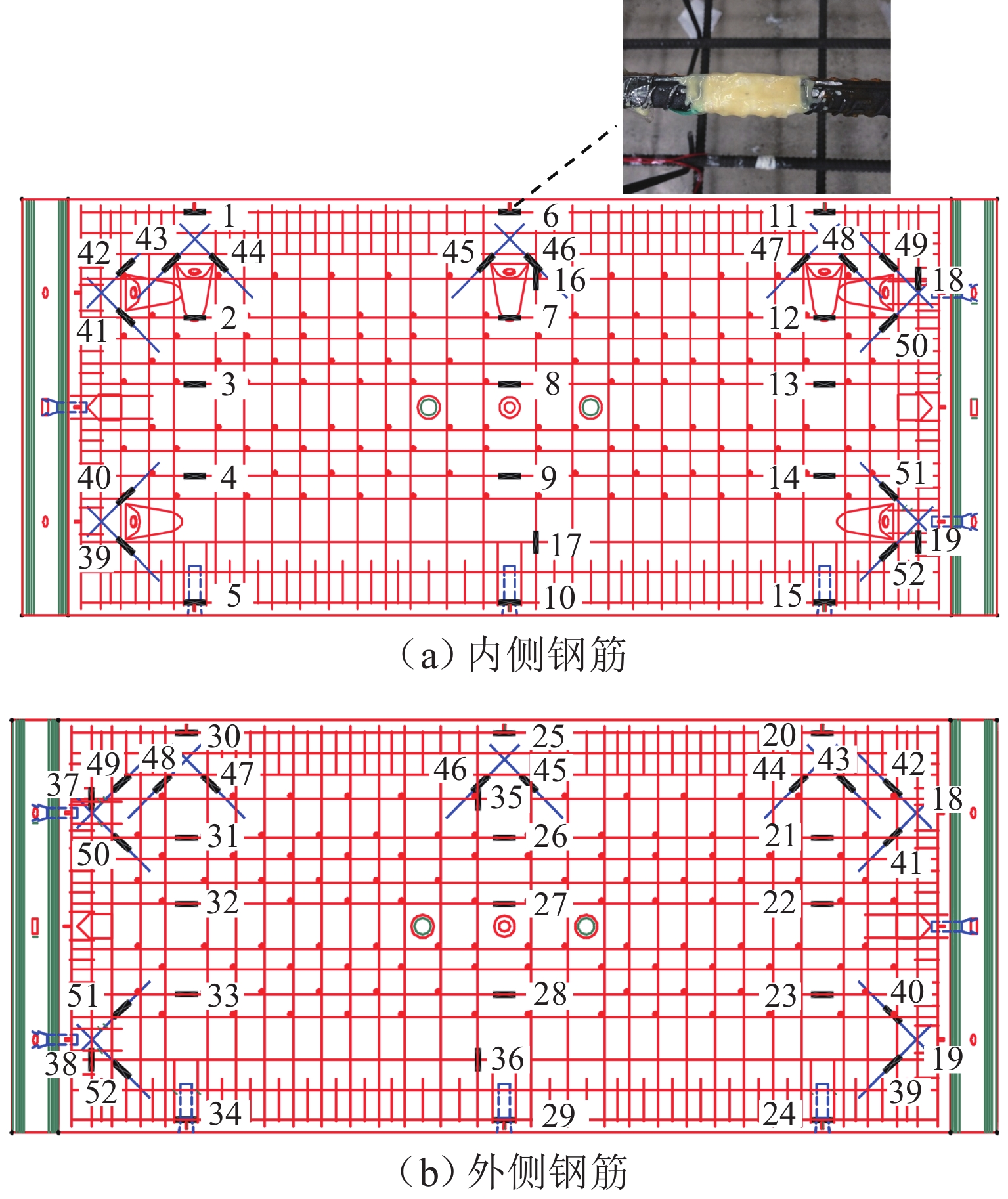

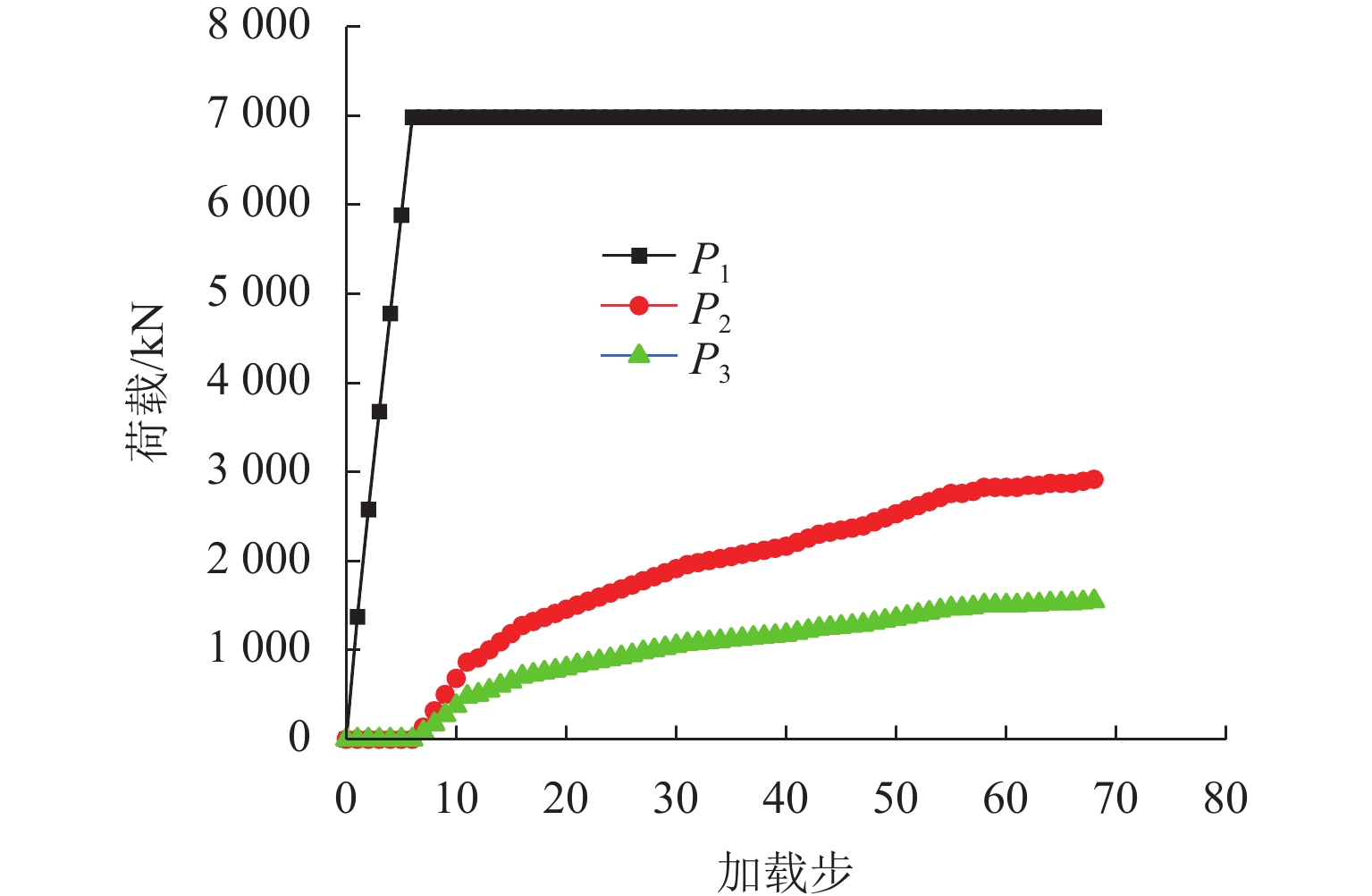

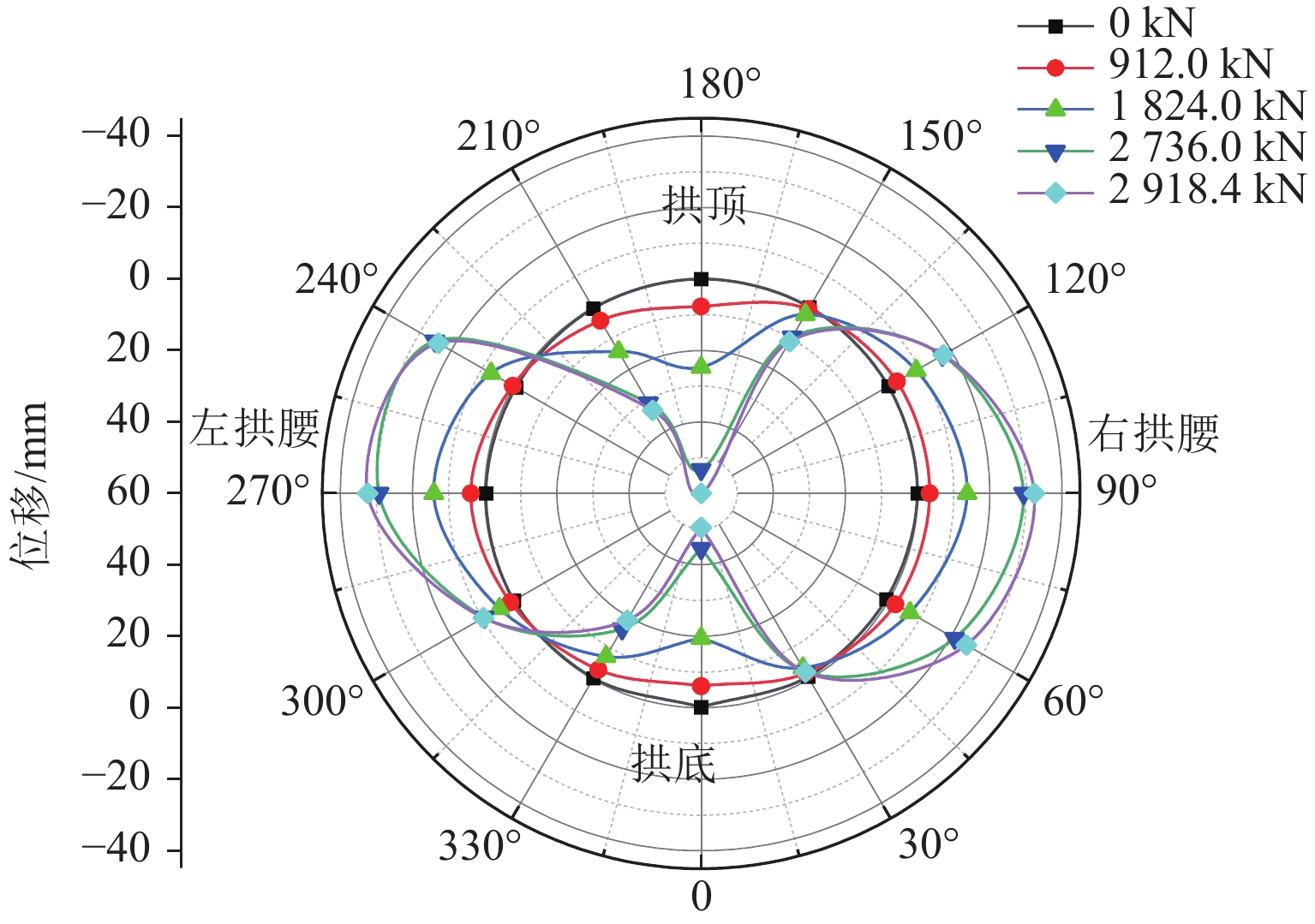

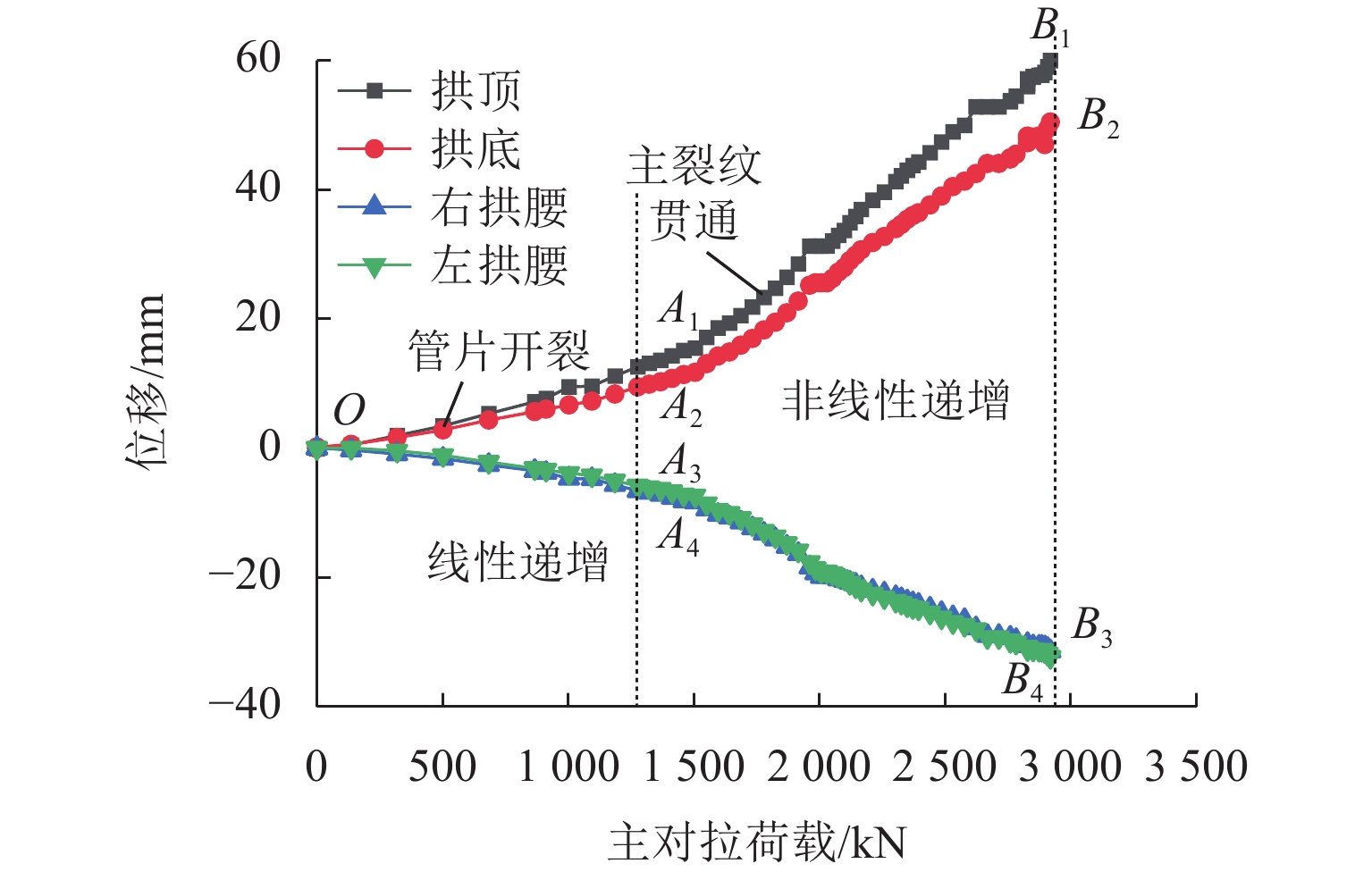

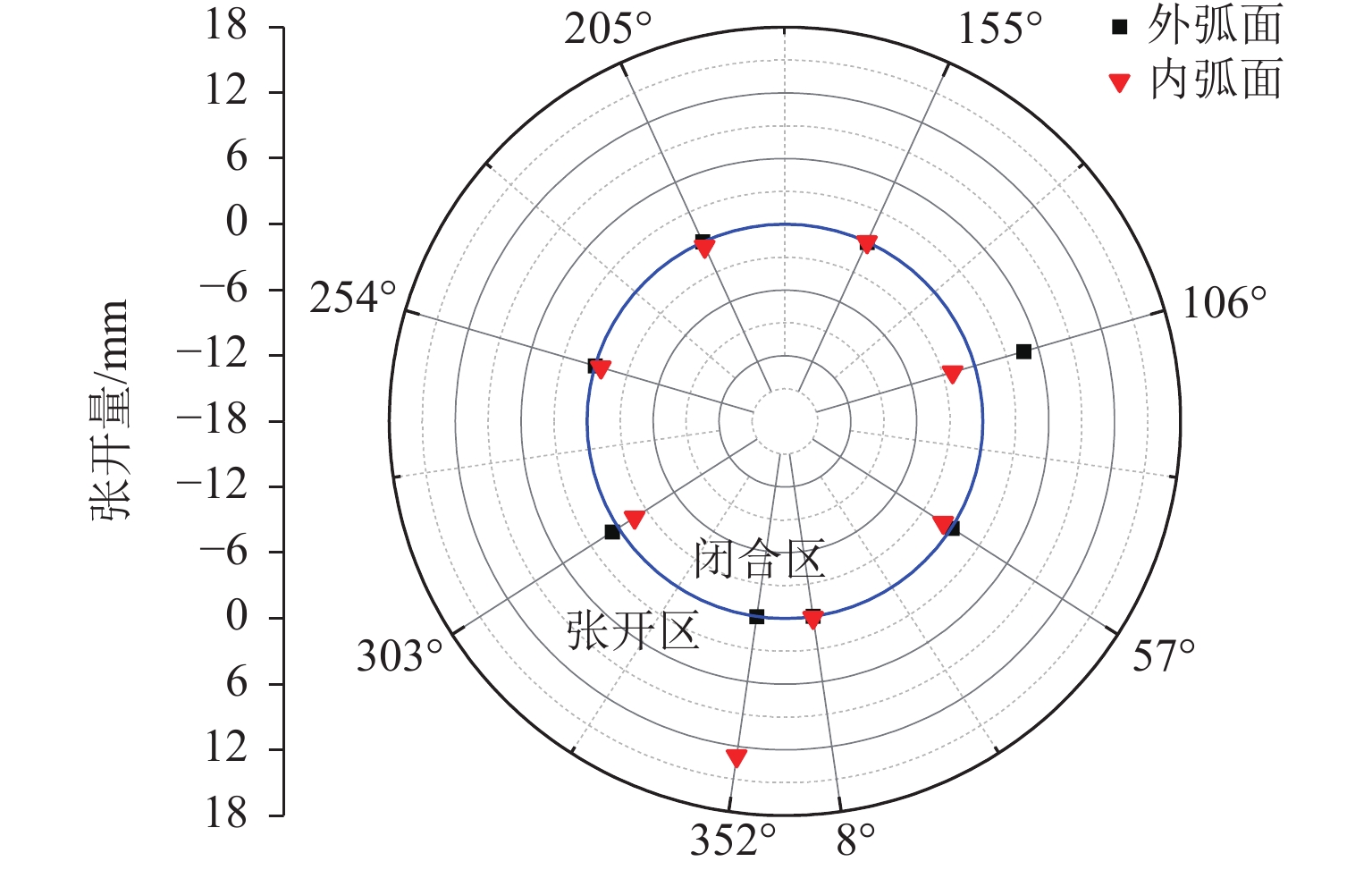

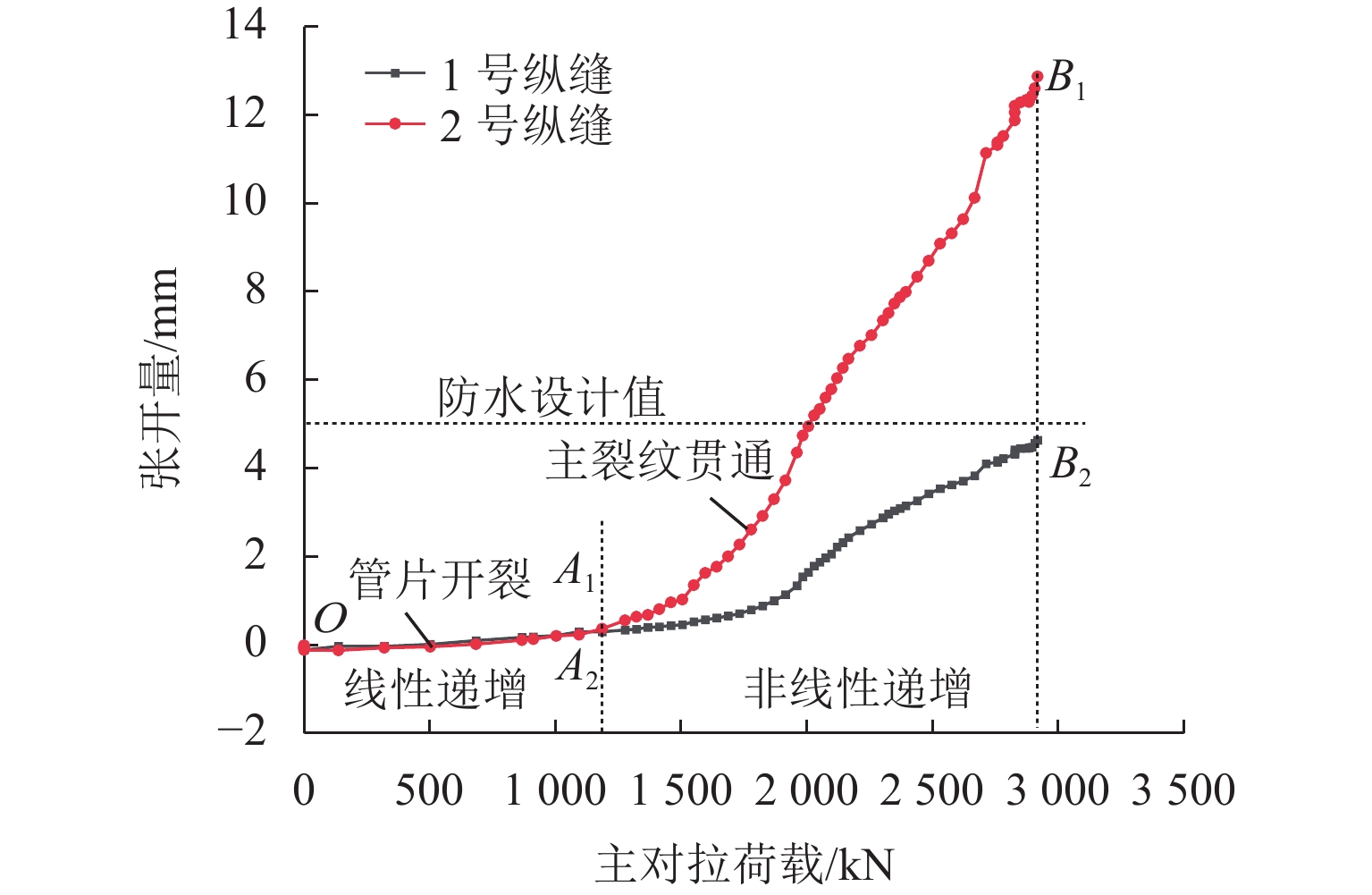

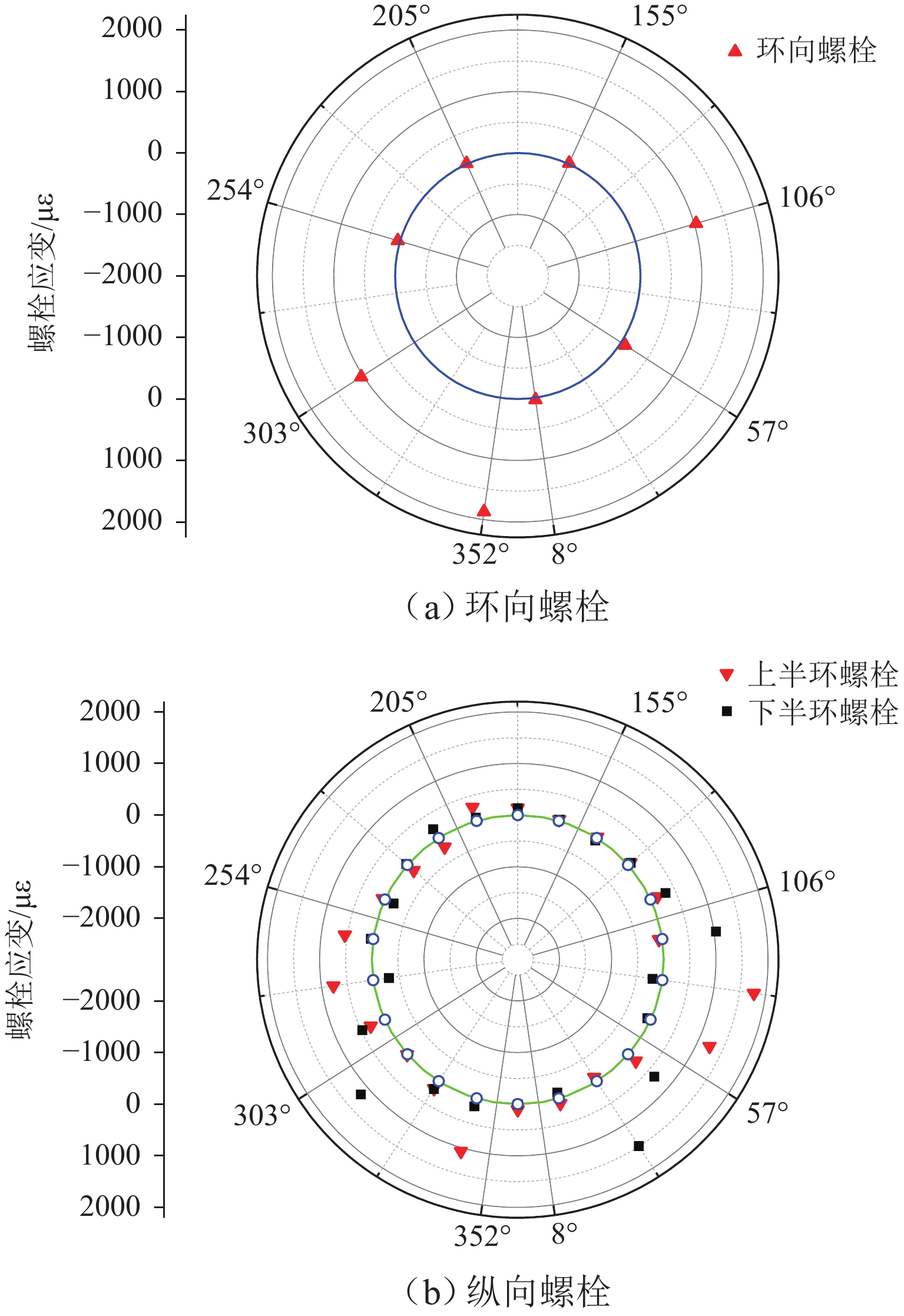

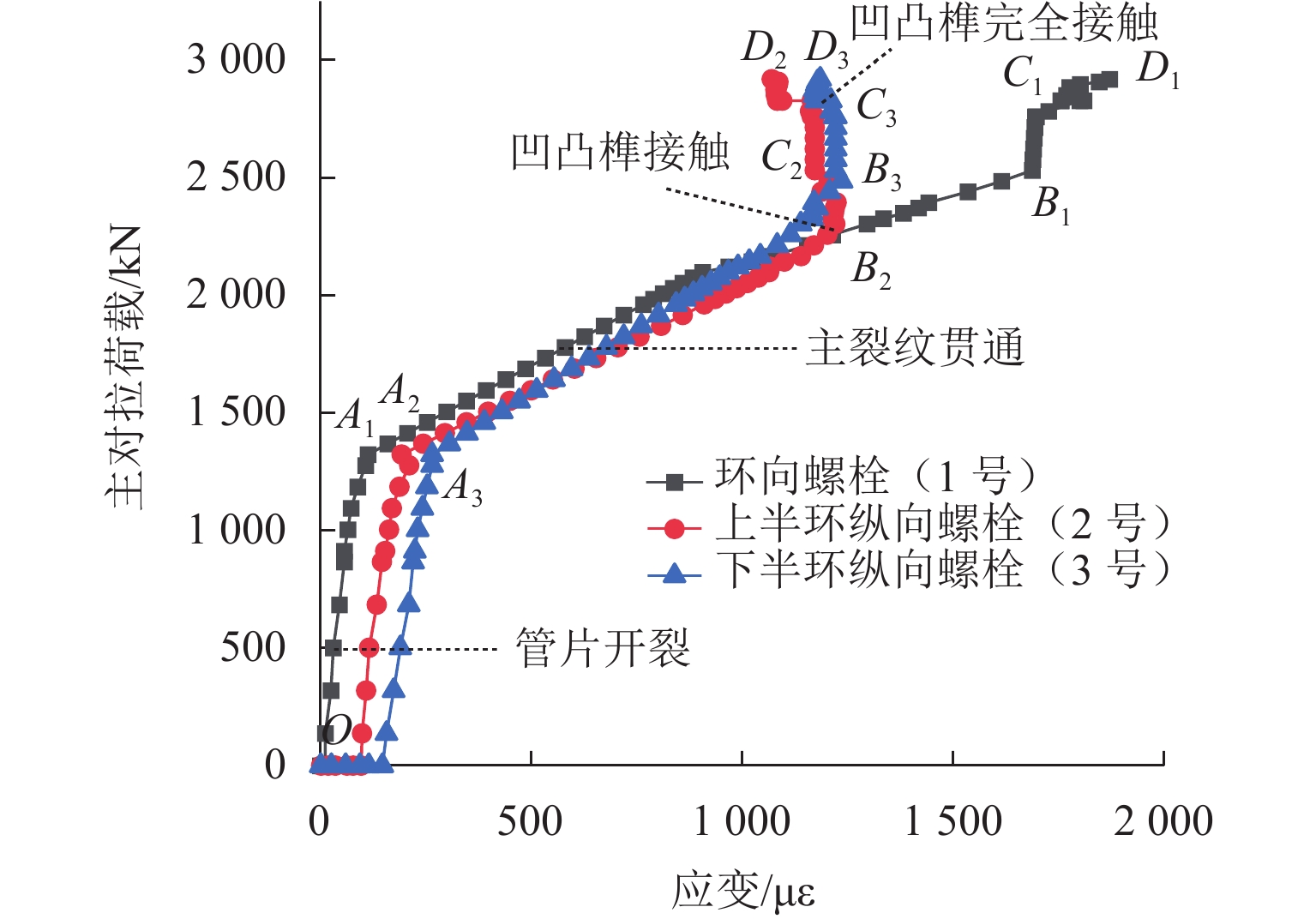

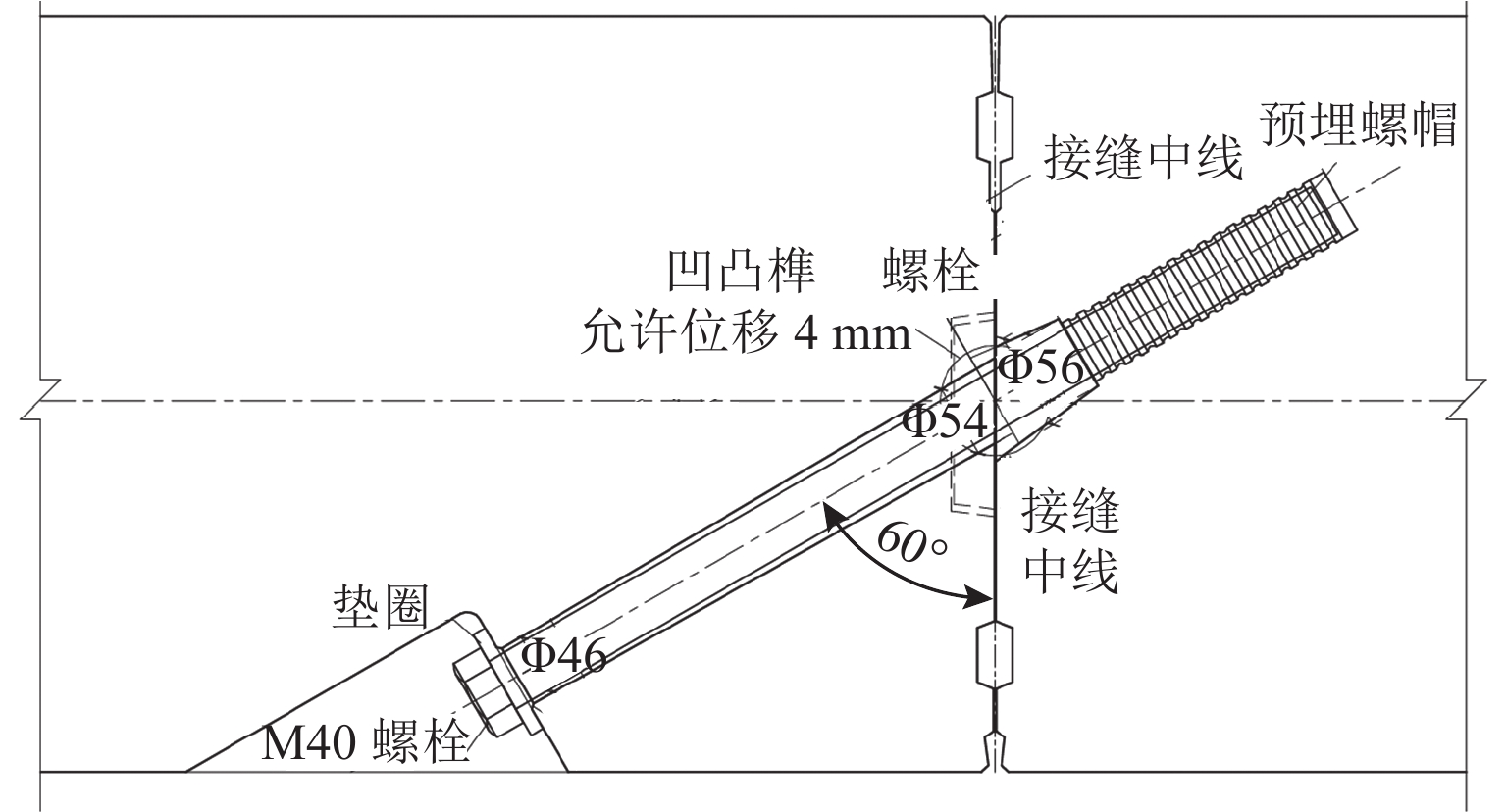

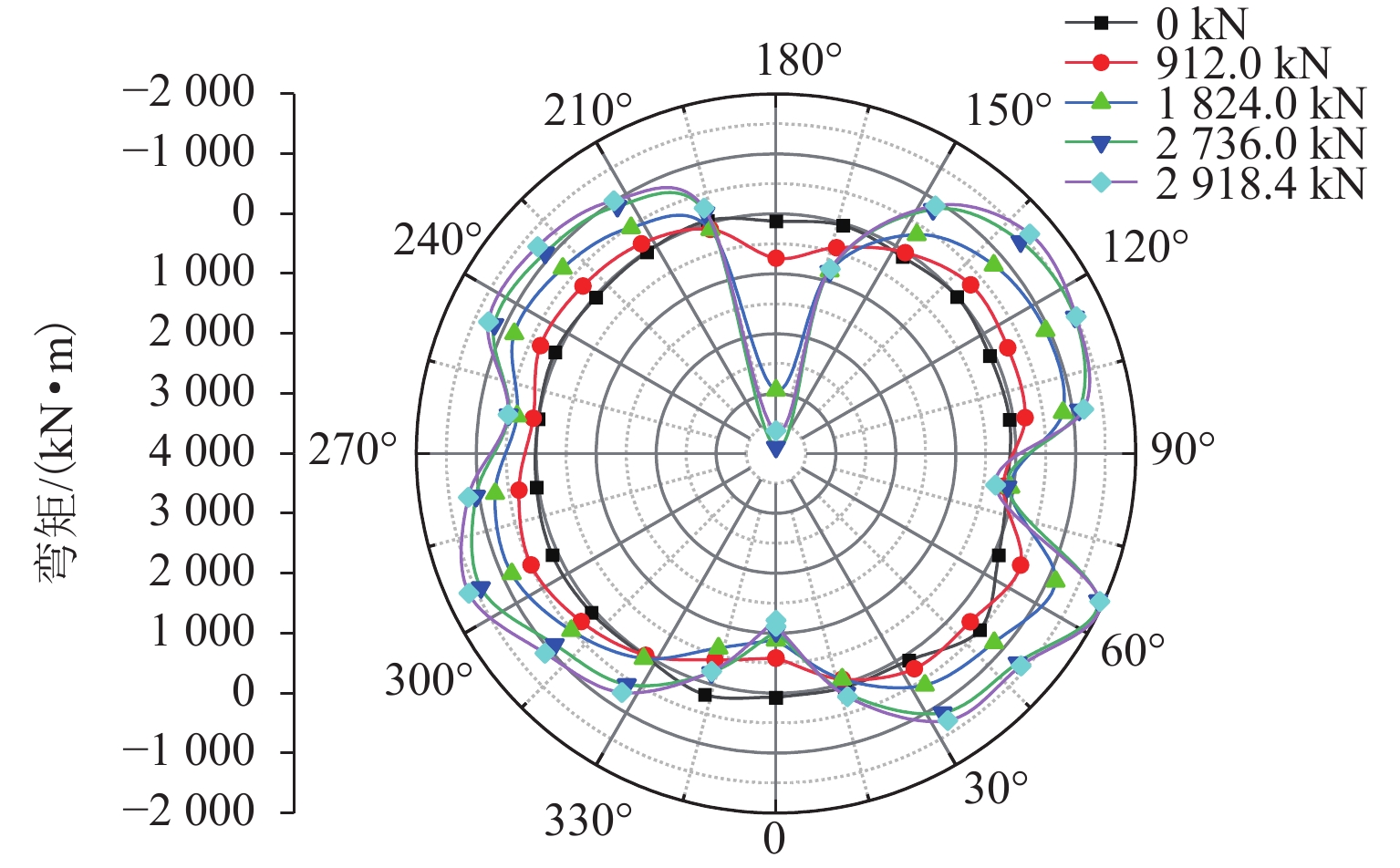

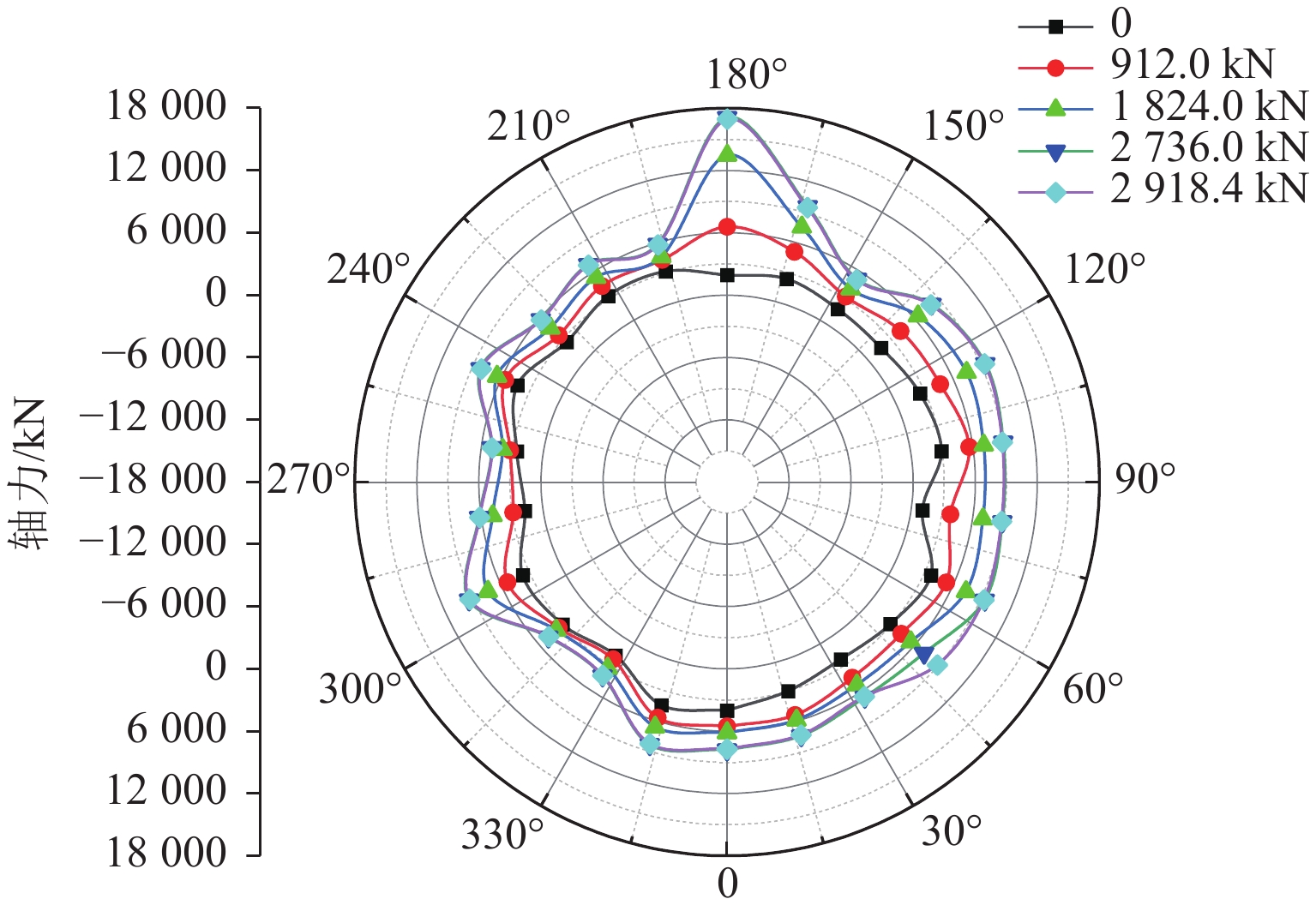

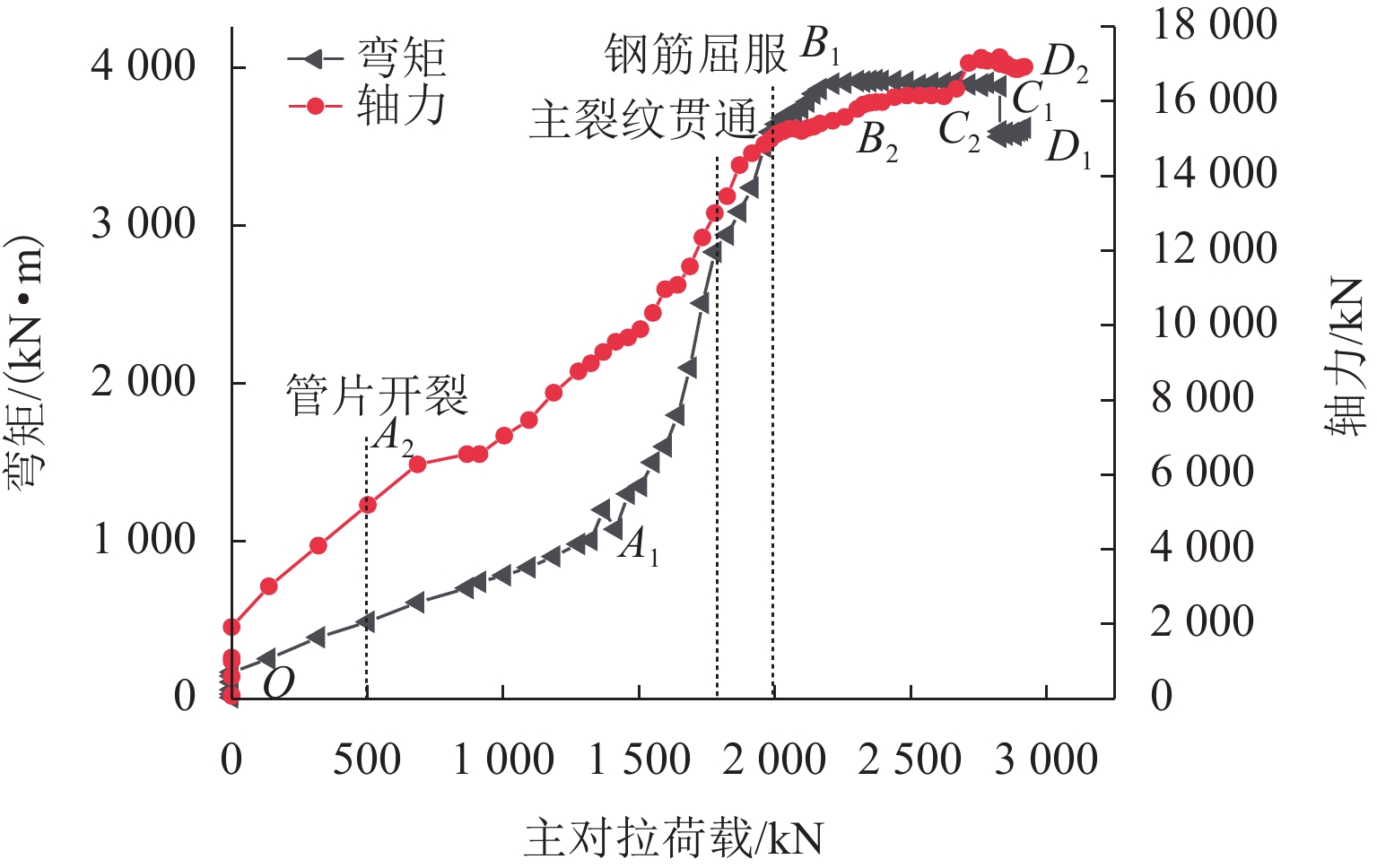

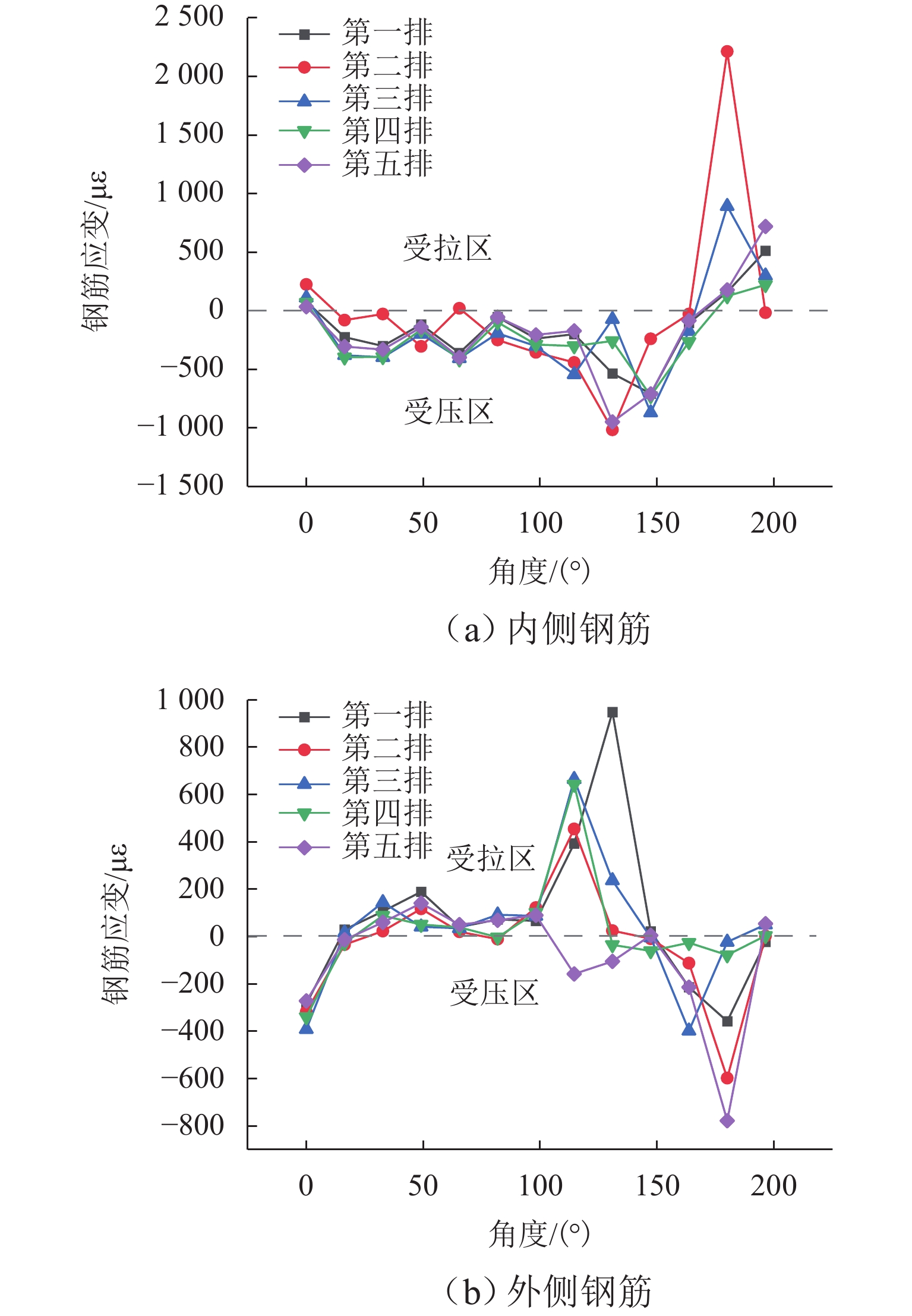

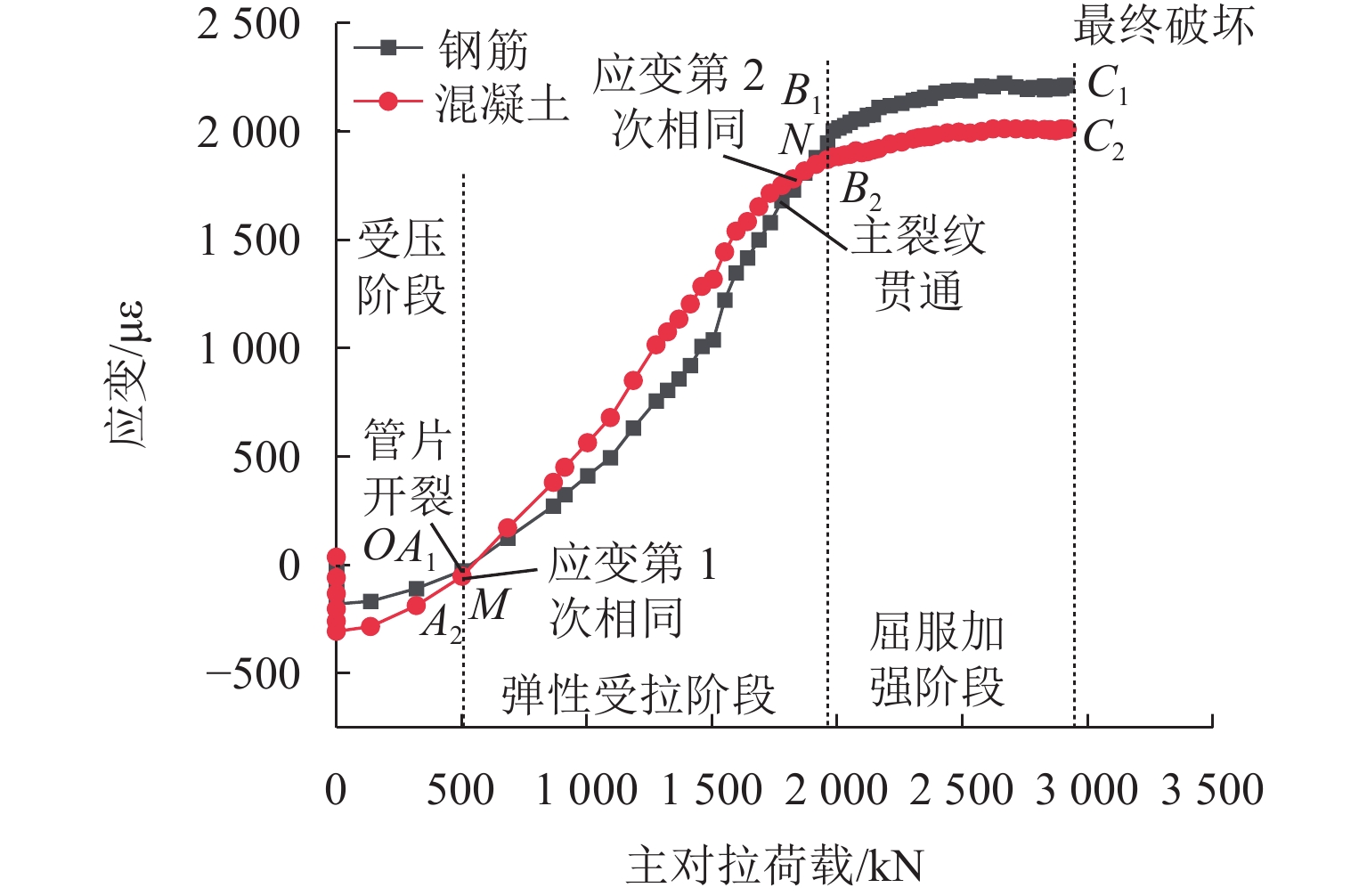

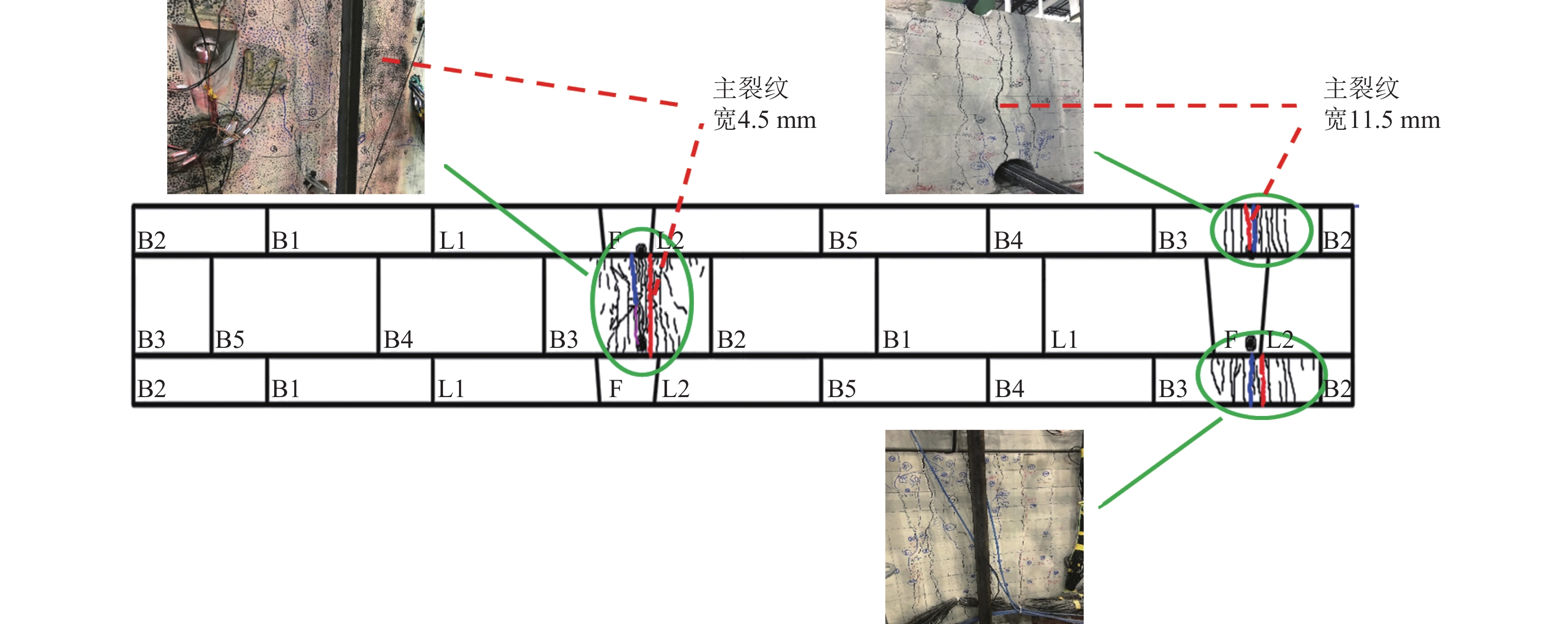

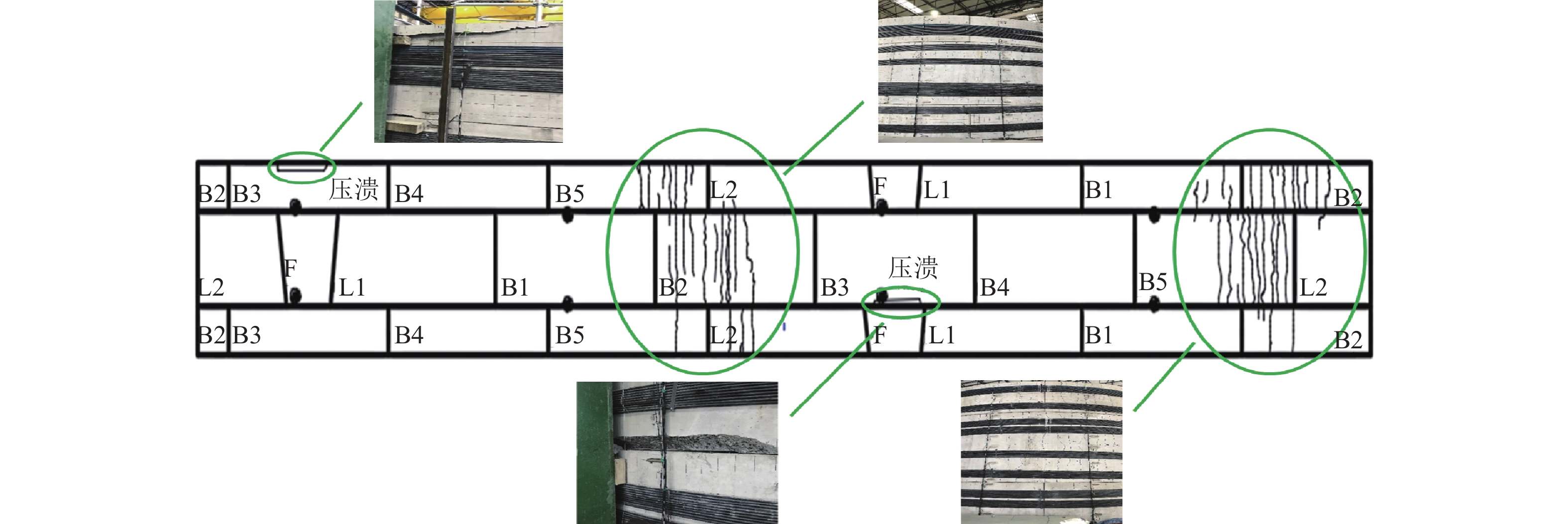

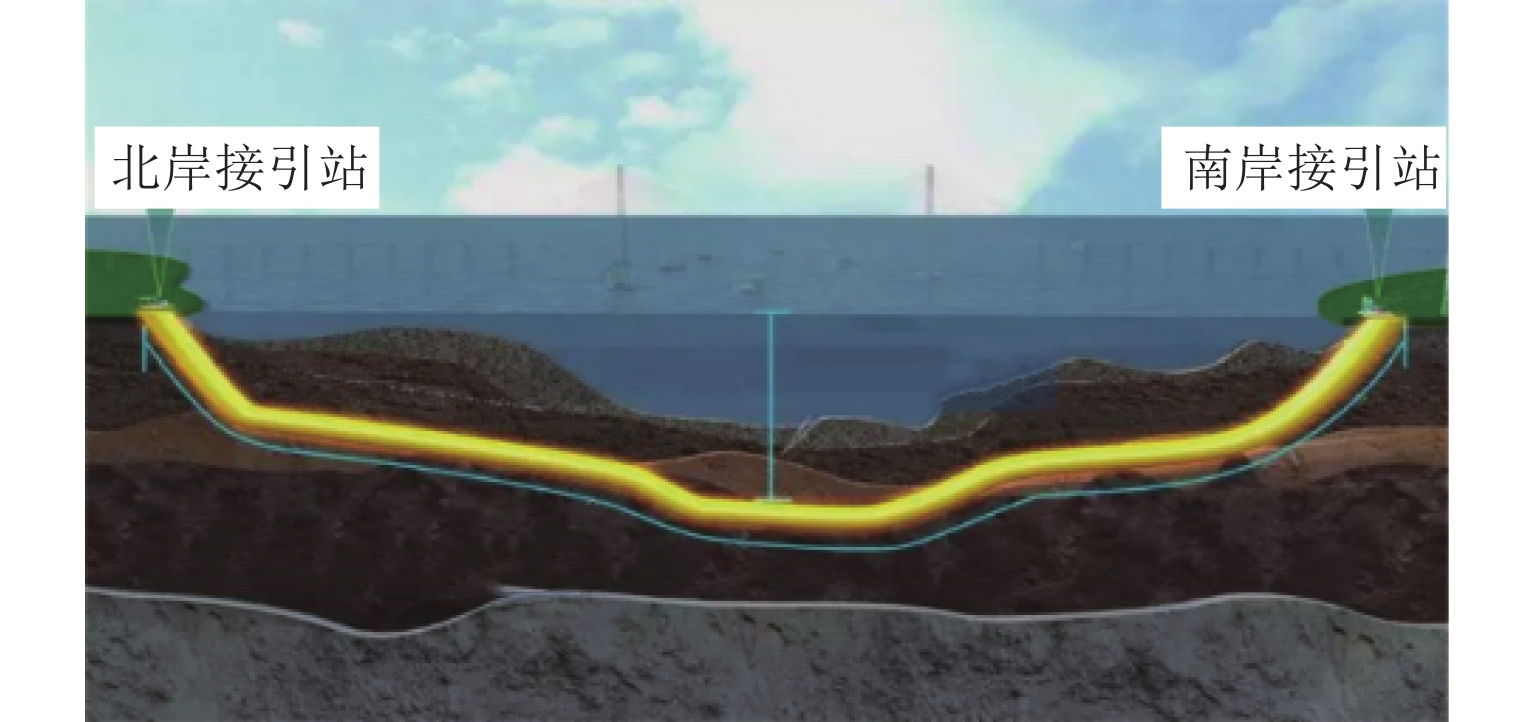

为探明大直径盾构隧道管片结构在极限荷载下的力学特性,首先,采用多功能盾构隧道结构体加载装置对苏通GIL综合管廊工程盾构管片结构开展原型加载破坏试验;其次,分析极限荷载下管片结构变形、内力、接缝变形、螺栓和钢筋应变等力学响应规律;最后,结合裂纹形态,揭示管片结构的破坏特征及机理. 研究结果表明:管片结构的变形呈“横鸭蛋”形态,弯矩呈现“蝶”形态,轴力呈现“圆”形态,最大单点变化率为10.3‰,最大正弯矩为

3896 kN•m,最大轴力为17099.28 kN;螺栓最大应变为1871 με,远小于屈服应变,钢筋最大应变为2213 με,超过其屈服应变;管片的形变指标安全余量为0.92~1.72,强度指标安全余量为0.10~0.16,强度指标先于形变指标达到极限破坏值,建议以钢筋屈服或主裂纹贯通作为管片结构正常使用承载能力极限状态的判断标准;管片裂纹开始于B3块管片中部,当荷载为1778.4 kN时,拱顶、拱底内外弧面多处裂纹贯通,内外弧面裂纹最大宽度分别达到4.5、11.5 mm,B3块管片钢筋屈服,管片结构因局部失稳发生破坏.Abstract:To investigate the mechanical characteristics of large-diameter shield tunnel segment structures under ultimate loads, a multifunctional shield tunnel structure loading device was used to conduct a prototype loading failure test on the shield tunnel segment structure of the Sutong gas-insulated metal-enclosed transmission line (GIL) utility tunnel project. The mechanical response laws of deformation, internal force, joint deformation, bolt and steel bar strain of the segment structure under ultimate load were analyzed. Based on the crack morphology, the failure characteristics and mechanisms of the segment structure were revealed. The results show that the deformation of the segment structure presents a horizontal duck egg shape, the bending moment presents a butterfly shape, and the axial force presents a circular shape. The maximum single point change rate is 10.3‰, the maximum positive bending moment is

3896 kN•m, and the maximum axial force is17099.28 kN. The maximum bolt strain is1871 με, far less than the yield strain, and the maximum steel bar strain is2213 με, exceeding its yield strain. The safety margin for the deformation indicator of the segment structure is between 0.92 and 1.72, while for the strength indicator, it is between 0.10 and 0.16. The strength indicator reaches the ultimate failure value before the deformation indicator. Reinforcement yielding or the main crack penetration is recommended as the judgment criterion of the ultimate limit state for the normal serviceability of the segment structure. Cracks of the segment structure first appear in the middle of the segment B3. When the load is1778.4 kN, multiple cracks penetrate through the inner and outer arc surfaces of the arch crown and arch bottom, with the maximum widths of the cracks on the inner and outer arc surfaces reaching 4.5 mm and 11.5 mm, respectively. The steel bar of the segment B3 reaches the yield condition, and the segment structure is damaged due to local instability. -

表 1 转折点螺栓应变

Table 1. Strain of turning point bolts

转折点 1号螺栓 2号螺栓 3号螺栓 荷载/

kN应变/

με荷载/

kN应变/

με荷载/

kN应变/

μεAi 1322.4 113 1322.4 193 1322.4 265 Bi 2530.8 1687 2257.2 1202 2485.2 1236 Ci 2758.8 1695 2827.2 1165 2827.2 1210 表 2 转折点弯矩、轴力

Table 2. Bending moment and axial force at turning points

转折点 弯矩 轴力 荷载/

kN弯矩/

(kN•m)荷载/

kN轴力/

kNAi 1413.6 1076.3 684.0 6281.6 Bi 2211.6. 3902.3 2439.6 16117.2 Ci 2827.2 3885.9 2667.6 16335.0 表 3 转折点钢筋、混凝土应变

Table 3. Strain of steel bars and concrete at turning points

转折点 钢筋 混凝土 荷载/

kN应变/

με荷载/

kN应变/

μεAi 501.6 0 501.6 0 Bi 1983.6 2003 1983.6 1882 表 4 管片结构力学指标

Table 4. Mechanical indicators of the segment structure

序号 力学指标 量值 最大值 安全

余量1 结构形变最大值T1/mm 31.29 59.99 0.92 2 纵缝张开量最大值T2/mm 4.74.00 12.87 1.72 3 螺栓应变最大值T3/με 935.91 1871.00 1.00 4 弯矩最大值T4/kN•m 3595.52 3924.03 0.09 5 轴力最大值T5/kN 14988.60 17186.40 0.15 6 钢筋应变最大值T6/με 2003.00 2213.00 0.10 -

[1] 何川, 封坤. 大型水下盾构隧道结构研究现状与展望[J]. 西南交通大学学报, 2011, 46(1): 1-11. doi: 10.3969/j.issn.0258-2724.2011.01.001HE Chuan, FENG Kun. Review and prospect of structure research of underwater shield tunnel with large cross-section[J]. Journal of Southwest Jiaotong University, 2011, 46(1): 1-11. doi: 10.3969/j.issn.0258-2724.2011.01.001 [2] 封坤, 何川, 肖明清. 高速铁路水下盾构隧道管片衬砌主体结构受力分析研究[J]. 现代隧道技术, 2008, 45(增1): 129-133.FENG Kun, HE Chuan, XIAO Mingqing. Study on stress analysis of the main structure of segment lining in underwater shield tunnels for high-speed rail[J]. Modern Tunnelling Technology, 2008, 45(S1): 129-133. [3] 方勇, 何川, 齐春, 等. 砂卵石地层下伏膨胀岩土盾构隧道结构内力特征[J]. 西南交通大学学报, 2014, 49(3): 386-392. doi: 10.3969/j.issn.0258-2724.2014.03.003FANG Yong, HE Chuan, QI Chun, et al. Structural internal force of shield tunnel in expansive soil underlying sandy pebble layer[J]. Journal of Southwest Jiaotong University, 2014, 49(3): 386-392. doi: 10.3969/j.issn.0258-2724.2014.03.003 [4] 郭瑞, 何川. 盾构隧道管片衬砌结构稳定性研究[J]. 中国公路学报, 2015, 28(6): 74-81. doi: 10.19721/j.cnki.1001-7372.2015.06.011GUO Rui, HE Chuan. Study on stability of segment lining structure for shield tunnel[J]. China Journal of Highway and Transport, 2015, 28(6): 74-81. doi: 10.19721/j.cnki.1001-7372.2015.06.011 [5] 张伟列, 晏启祥, 张川, 等. 盾构千斤顶不良顶推作用下地铁管片衬砌开裂特性[J]. 西南交通大学学报, 2023, 58(5): 1073-1082. doi: 10.3969/j.issn.0258-2724.20220235ZHANG Weilie, YAN Qixiang, ZHANG Chuan, et al. Cracking behavior of segmental lining in subways under adverse jacking force during shield tunneling[J]. Journal of Southwest Jiaotong University, 2023, 58(5): 1073-1082. doi: 10.3969/j.issn.0258-2724.20220235 [6] 鲁志鹏, 付佳卉, 张心源, 等. 大直径盾构隧道单环结构安全性评价分析[J]. 铁道标准设计, 2024, 68(11): 117-125.LU Zhipeng, FU Jiahui, ZHANG Xinyuan, et al. Analysis on safety evaluation of single-ring structures in large-diameter shield tunnels[J]. Railway Standard Design, 2024, 68(11): 117-125. [7] 刘洋, 龚振华, 梁敏飞, 等. 考虑变荷载影响的水下盾构隧道双层衬砌力学特性分析[J]. 铁道标准设计, 2022, 66(7): 101-107. doi: 10.13238/j.issn.1004-2954.202103060001LIU Yang, GONG Zhenhua, LIANG Minfei, et al. Analysis of mechanical characteristics of shield tunnel with double-layer lining considering variable loads[J]. Railway Standard Design, 2022, 66(7): 101-107. doi: 10.13238/j.issn.1004-2954.202103060001 [8] 赵金虎. 纵向力对盾构隧道管片结构力学性能的影响分析[J]. 铁道建筑技术, 2023(8): 155-159. doi: 10.3969/j.issn.1009-4539.2023.08.038ZHAO Jinhu. Analysis of the effect of longitudinal force on the mechanical properties of segment structures of shield tunnel[J]. Railway Construction Technology, 2023(8): 155-159. doi: 10.3969/j.issn.1009-4539.2023.08.038 [9] 王士民, 申兴柱, 彭博, 等. 侧压力系数对盾构隧道管片衬砌受力及破坏形态的影响研究[J]. 铁道学报, 2019, 41(7): 102-109.WANG Shimin, SHEN Xingzhu, PENG Bo, et al. Analysis of effect of lateral strata pressure coefficient on mechanical characteristics and failure modes of segment lining of shield tunnel[J]. Journal of the China Railway Society, 2019, 41(7): 102-109. [10] 鲁选一, 封坤, 漆美霖, 等. 纵向力作用下的盾构隧道管片结构纵向弯曲变形性能研究[J]. 工程力学, 2023, 40(7): 205-216. doi: 10.6052/j.issn.1000-4750.2021.12.0945LU Xuanyi, FENG Kun, QI Meilin, et al. Study on longitudinal bending deformation behavior of shield tunnel segments regarding the action of longitudinal force[J]. Engineering Mechanics, 2023, 40(7): 205-216. doi: 10.6052/j.issn.1000-4750.2021.12.0945 [11] 刘川昆, 何川, 王士民, 等. 裂缝长度对盾构隧道管片结构破坏模式模型试验研究[J]. 中南大学学报(自然科学版), 2019, 50(6): 1447-1456. doi: 10.11817/j.issn.1672-7207.2019.06.024LIU Chuankun, HE Chuan, WANG Shimin, et al. Model test study on failure mode of segment structure of shield tunnel with crack length[J]. Journal of Central South University (Science and Technology), 2019, 50(6): 1447-1456. doi: 10.11817/j.issn.1672-7207.2019.06.024 [12] ZHOU J M, HE C, FENG K, et al. Model test on structural behaviour of underwater shield tunnel with large cross-section considering assembling modes[J]. Advanced Materials Research, 2011, 243/244/245/246/247/248/249: 3560-3564. [13] CARATELLI A, MEDA A, RINALDI Z, et al. Structural behaviour of precast tunnel segments in fiber reinforced concrete[J]. Tunnelling and Underground Space Technology, 2011, 26(2): 284-291. doi: 10.1016/j.tust.2010.10.003 [14] 张子新, 朱叶艇, 朱雁飞, 等. 粘土地层大断面异形盾构隧道结构力学特征数值试验研究[J]. 现代隧道技术, 2018, 55(4): 106-113. doi: 10.13807/j.cnki.mtt.2018.04.015ZHANG Zixin, ZHU Yeting, ZHU Yanfei, et al. Mechanical characteristics of the segment lining for a large specially shaped cross-section shield tunnel in clay strata[J]. Modern Tunnelling Technology, 2018, 55(4): 106-113. doi: 10.13807/j.cnki.mtt.2018.04.015 [15] 杨成永, 马文辉, 费腾, 等. 考虑轴力和剪切效应的盾构隧道纵向变形分析[J]. 西南交通大学学报, 2022, 57(1): 139-147. doi: 10.3969/j.issn.0258-2724.20200134YANG Chengyong, MA Wenhui, FEI Teng, et al. Analysis of longitudinal deformation of shield tunnel structures with consideration of axial force and shear effect[J]. Journal of Southwest Jiaotong University, 2022, 57(1): 139-147. doi: 10.3969/j.issn.0258-2724.20200134 [16] 何川, 封坤, 苏宗贤. 大断面水下盾构隧道原型结构加载试验系统的研发与应用[J]. 岩石力学与工程学报, 2011, 30(2): 254-266.HE Chuan, FENG Kun, SU Zongxian. Development and application of loading test system of prototype structure for underwater shield tunnel with large cross-section[J]. Chinese Journal of Rock Mechanics and Engineering, 2011, 30(2): 254-266. [17] 封坤, 何川, 苏宗贤. 南京长江隧道原型管片结构破坏试验研究[J]. 西南交通大学学报, 2011, 46(4): 564-571. doi: 10.3969/j.issn.0258-2724.2011.04.007FENG Kun, HE Chuan, SU Zongxian. Prototype test on failure characteristics of segmental lining structure for Nanjing Yangtze River tunnel[J]. Journal of Southwest Jiaotong University, 2011, 46(4): 564-571. doi: 10.3969/j.issn.0258-2724.2011.04.007 [18] 邱月, 封坤, 何川, 等. 盾构隧道错缝拼装管片衬砌局部原型结构破坏试验[J]. 土木工程学报, 2019, 52(4): 98-108. doi: 10.15951/j.tmgcxb.2019.04.009QIU Yue, FENG Kun, HE Chuan, et al. Local prototype failure test on staggered assembled segmental lining for shield tunnel[J]. China Civil Engineering Journal, 2019, 52(4): 98-108. doi: 10.15951/j.tmgcxb.2019.04.009 [19] 柳献, 黄晓冬. 通缝拼装盾构隧道衬砌结构抗倒塌性能的试验研究[J]. 岩石力学与工程学报, 2015, 34(增2): 3703-3714. doi: 10.13722/j.cnki.jrme.2015.0989LIU Xian, HUANG Xiaodong. Experimental study of collapse capacity of straight joint segmental tunnel lining structure[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(S2): 3703-3714. doi: 10.13722/j.cnki.jrme.2015.0989 [20] 毕湘利, 柳献, 王秀志, 等. 通缝拼装盾构隧道结构极限承载力的足尺试验研究[J]. 土木工程学报, 2014, 47(10): 117-127. doi: 10.15951/j.tmgcxb.2014.10.028BI Xiangli, LIU Xian, WANG Xiuzhi, et al. Experimental investigation on the ultimate bearing capacity of continuous-jointed segmental tunnel linings[J]. China Civil Engineering Journal, 2014, 47(10): 117-127. doi: 10.15951/j.tmgcxb.2014.10.028 [21] 朱瑶宏, 朱雁飞, 叶宇航, 等. 类矩形盾构隧道衬砌结构受力性能的足尺试验研究[J]. 现代隧道技术, 2016, 53(增1): 108-117. doi: 10.13807/j.cnki.mtt.2016.S1.016ZHU Yaohong, ZHU Yanfei, YE Yuhang, et al. Full-scale experiment study on mechanical behavior of quasi-rectangular shield tunnel lining[J]. Modern Tunnelling Technology, 2016, 53(S1): 108-117. doi: 10.13807/j.cnki.mtt.2016.S1.016 [22] 梁坤, 封坤, 肖明清, 等. 水压作用对通缝拼装管片结构力学性能的影响研究[J]. 岩土工程学报, 2019, 41(11): 2037-2045. doi: 10.11779/CJGE201911008LIANG Kun, FENG Kun, XIAO Mingqing, et al. Water-pressure action on structural behaviors of straight assembling segmental linings of underwater shield tunnels[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(11): 2037-2045. doi: 10.11779/CJGE201911008 [23] 封坤, 何川, 苏宗贤. 南京长江隧道管片衬砌结构原型加载试验[J]. 中国公路学报, 2013, 26(1): 135-143. doi: 10.19721/j.cnki.1001-7372.2013.01.019FENG Kun, HE Chuan, SU Zongxian. Prototype loading test on segmental lining structure of Nanjing Yangtze River tunnel[J]. China Journal of Highway and Transport, 2013, 26(1): 135-143. doi: 10.19721/j.cnki.1001-7372.2013.01.019 [24] 夏松林. 狮子洋隧道通缝式拼装管片衬砌结构的原型试验研究[D]. 成都: 西南交通大学, 2010. [25] 曹淞宇, 封坤, 刘迅, 等. 纵向力对带榫管片环缝剪切破坏机制影响研究[J]. 中国公路学报, 2021, 34(9): 273-284. doi: 10.3969/j.issn.1001-7372.2021.09.023CAO Songyu, FENG Kun, LIU Xun, et al. Experimental investigation of the shear mechanism on mortise and tenon segment lining[J]. China Journal of Highway and Transport, 2021, 34(9): 273-284. doi: 10.3969/j.issn.1001-7372.2021.09.023 -

下载:

下载: