Vibration and Stability Evaluation of Magnetically Suspended Fluid Machinery Based on API 617

-

摘要:

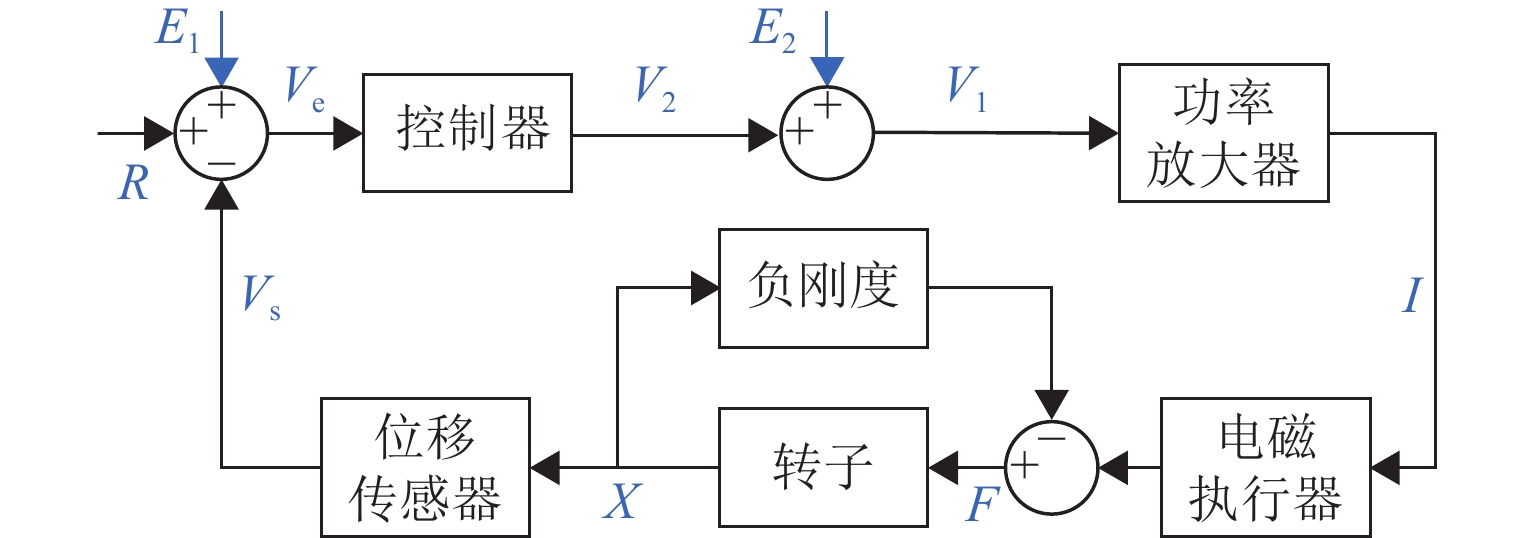

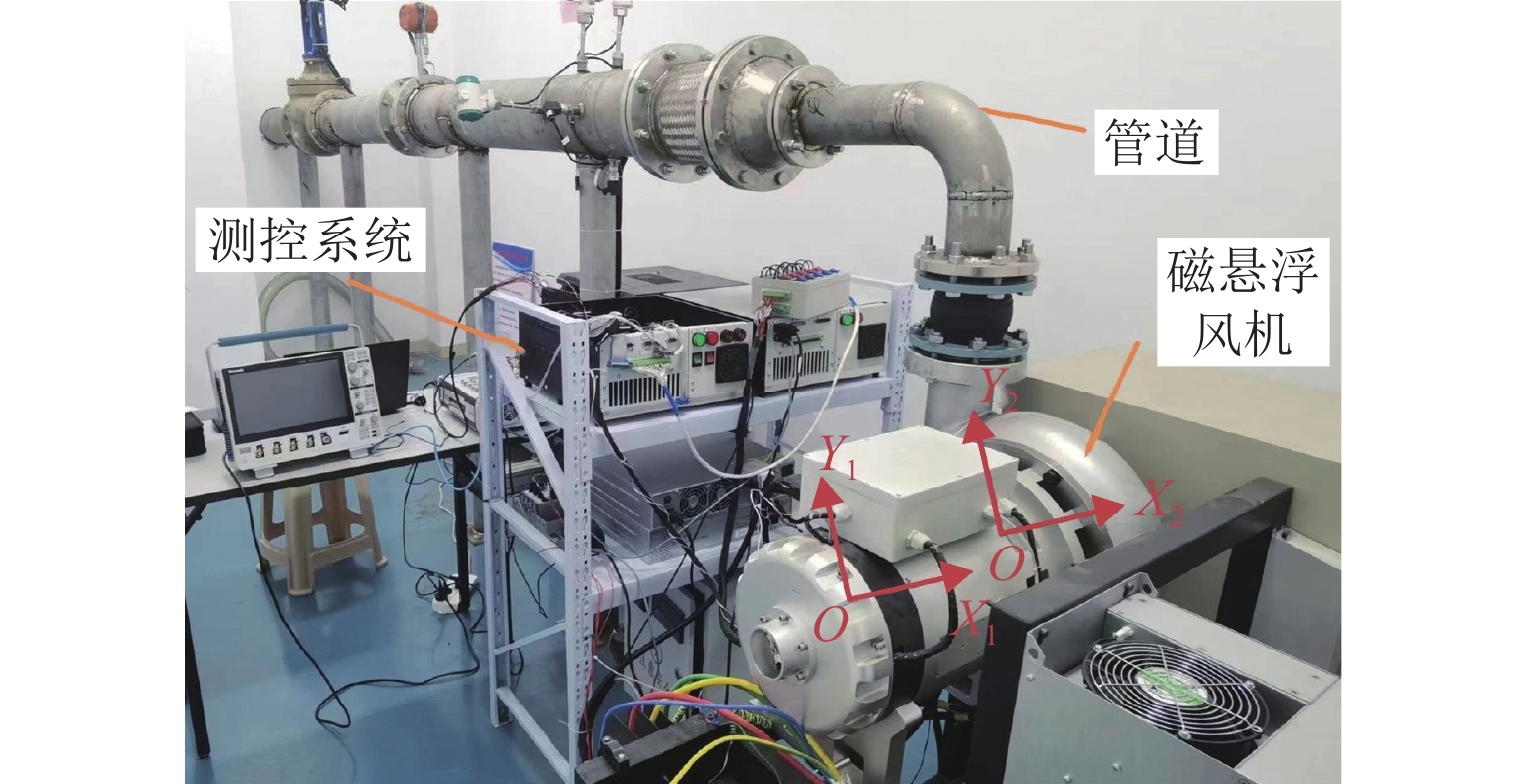

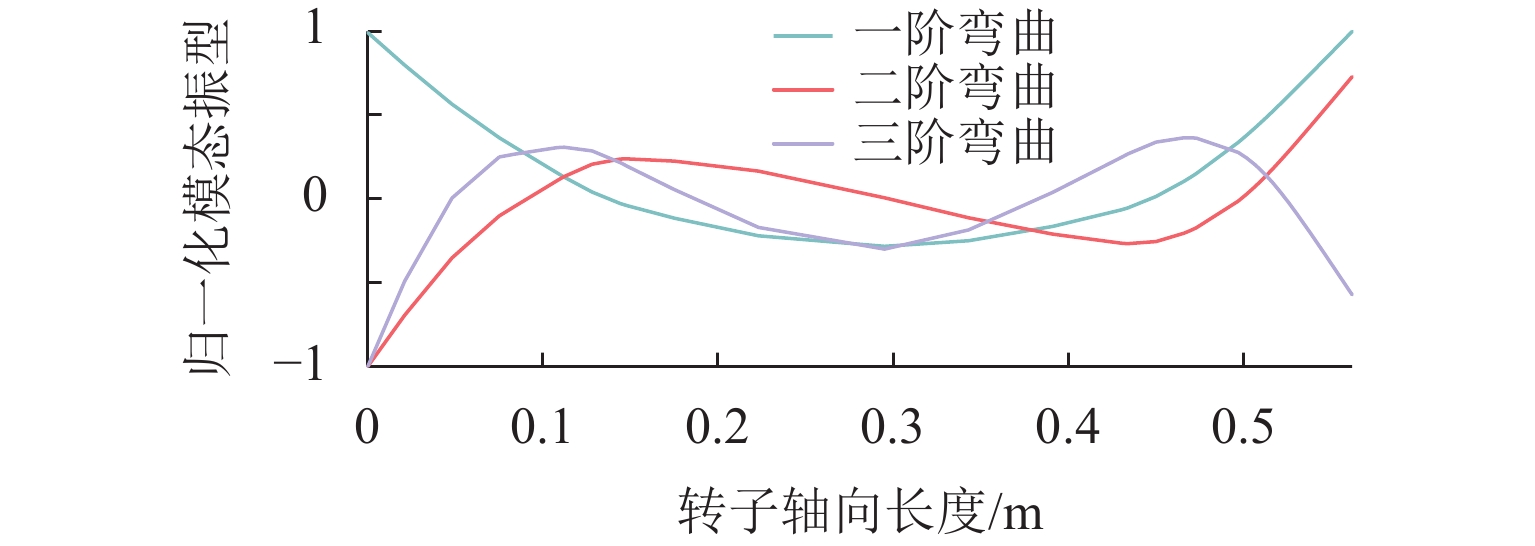

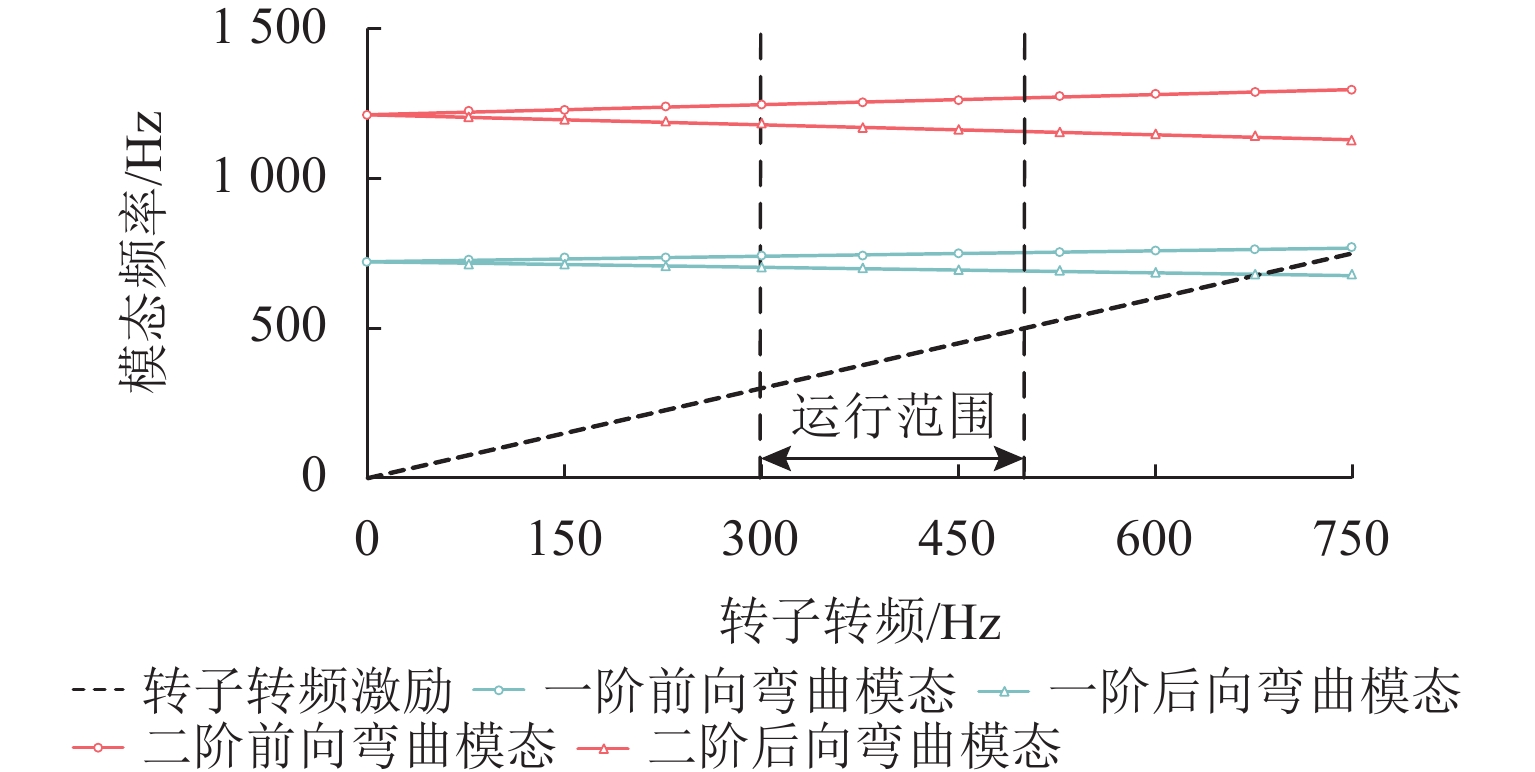

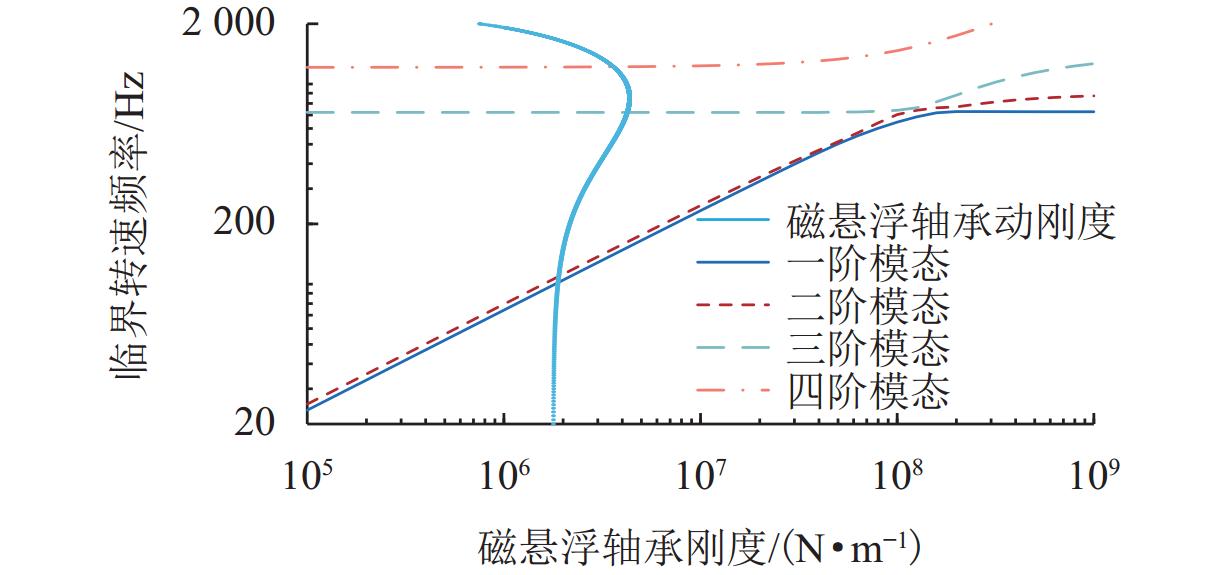

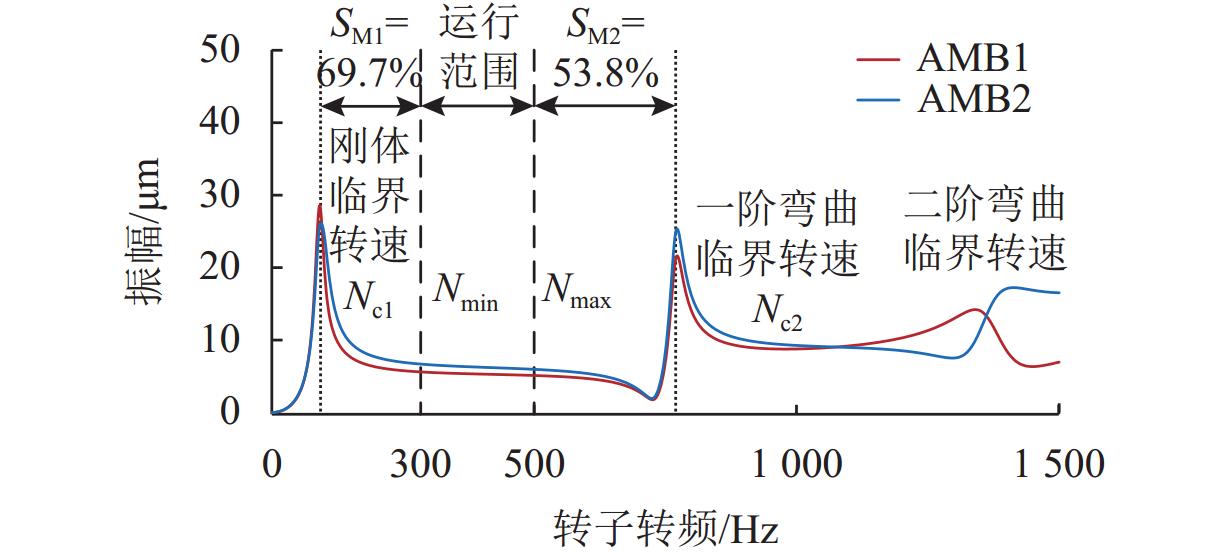

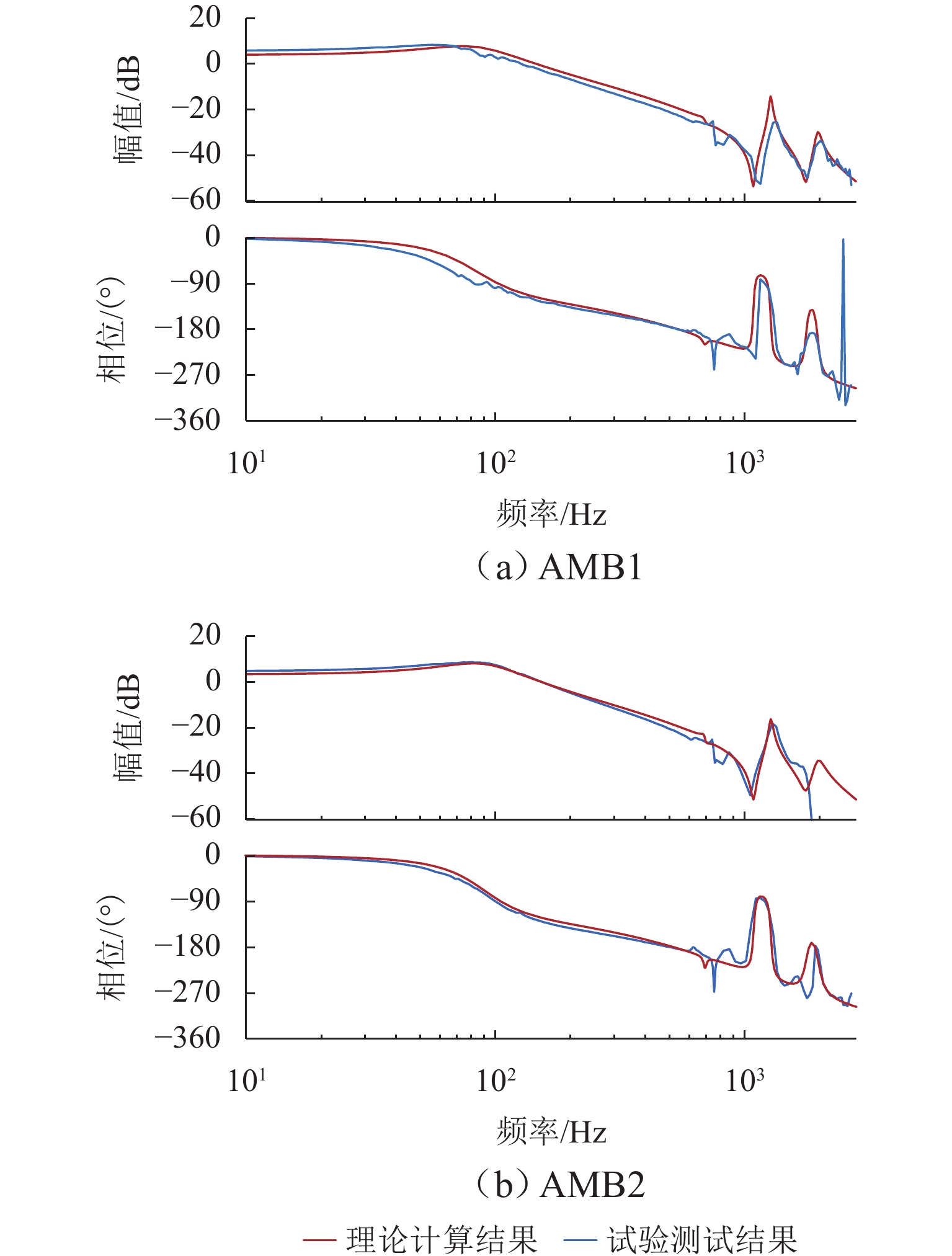

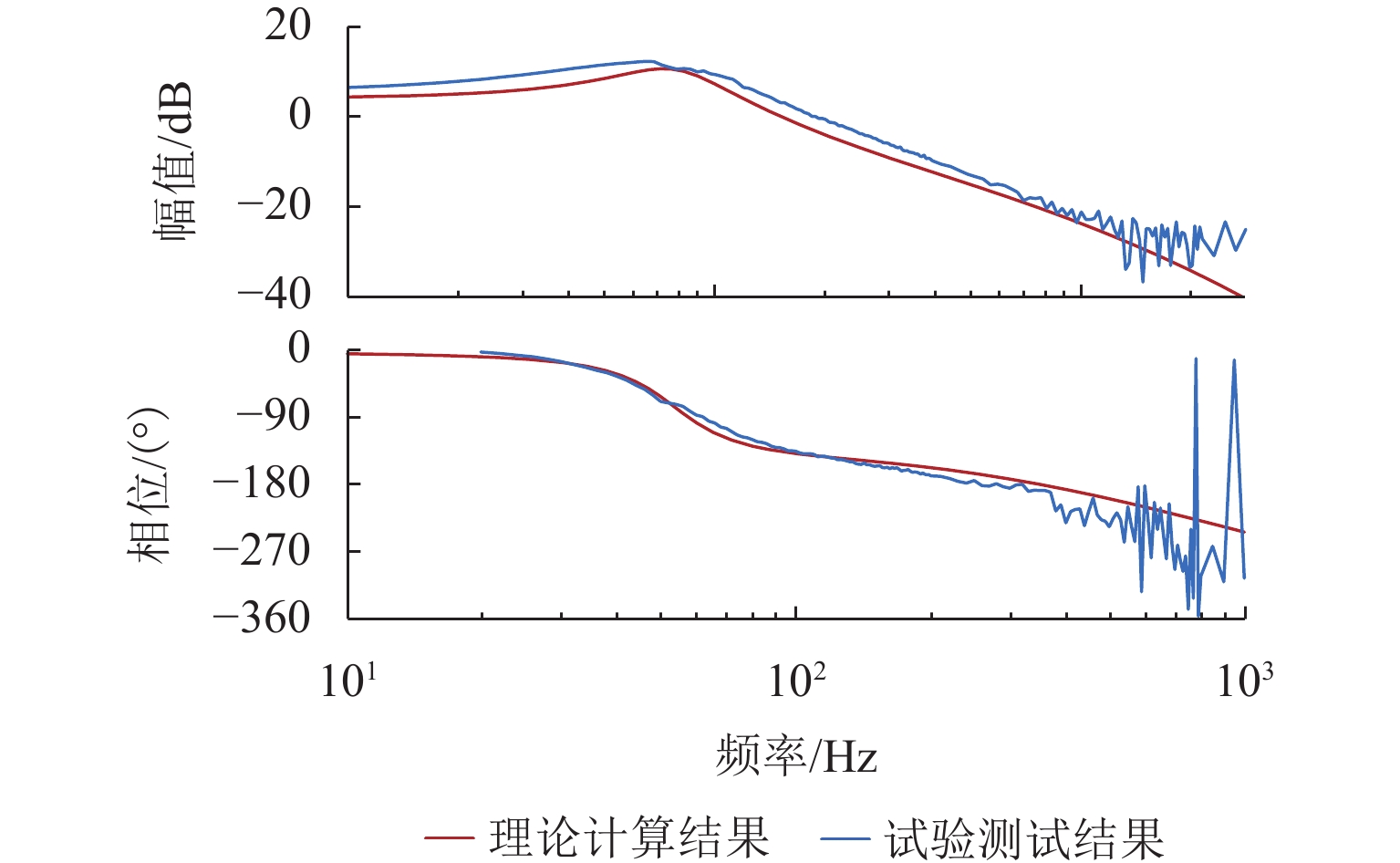

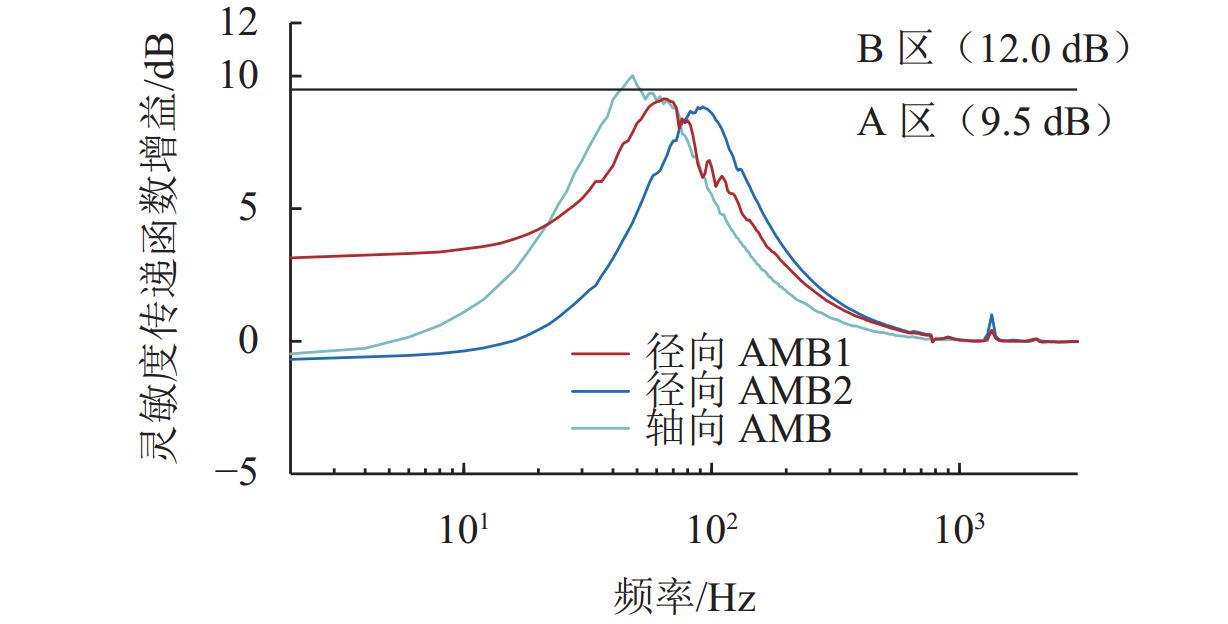

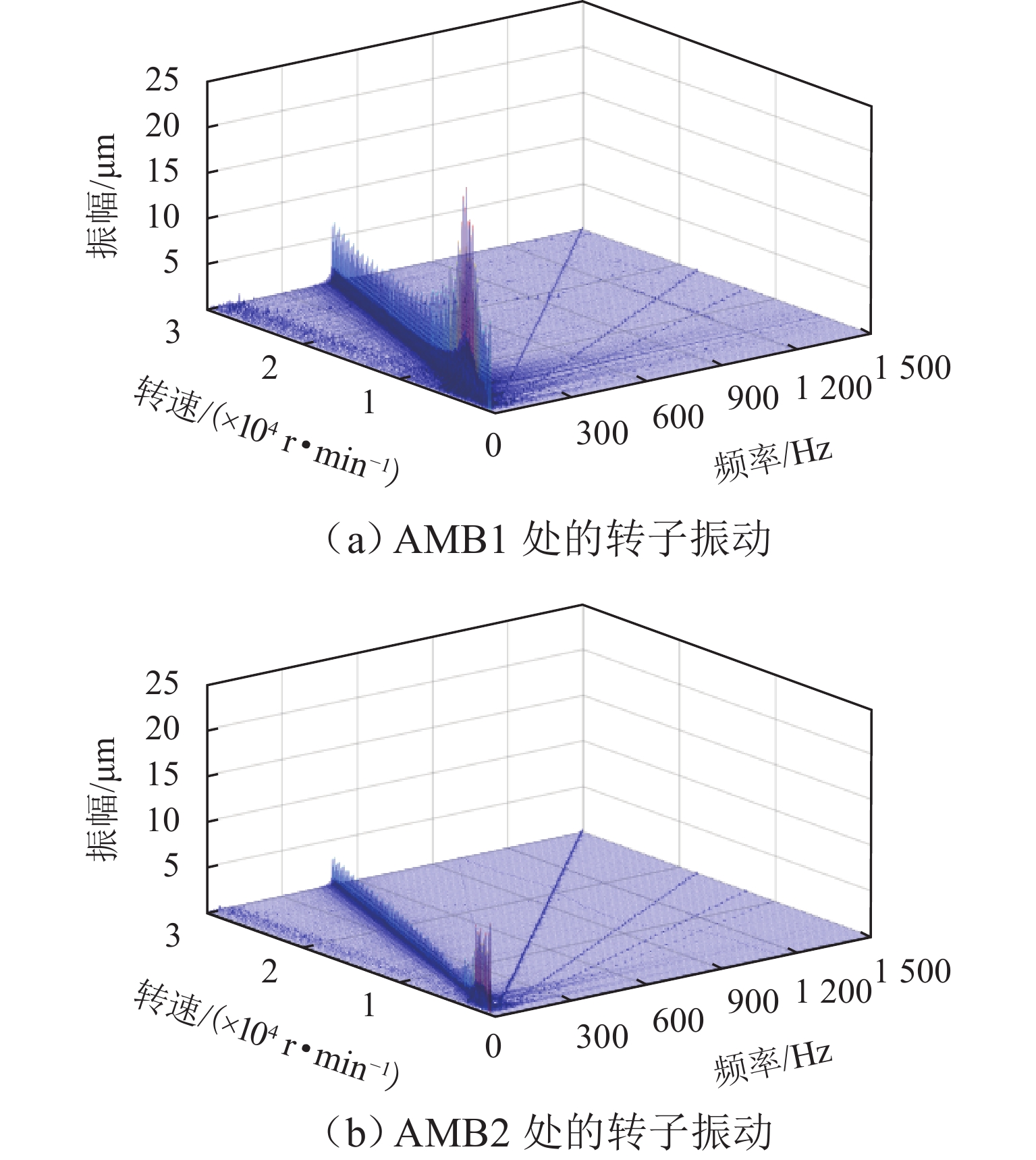

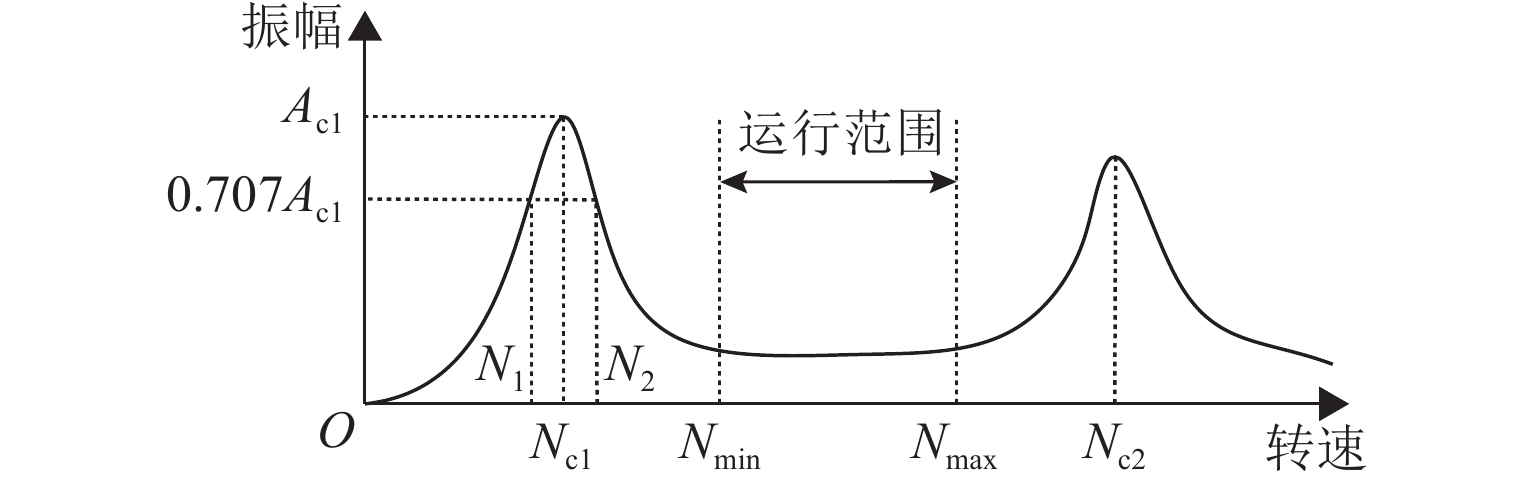

为评估磁悬浮流体机械设计的合理性和运行的可靠性,应用API 617标准对其振动和稳定性进行分析. 首先,对API 617标准中关于磁悬浮流体机械的相关规范和要求进行介绍;然后,以一台磁悬浮风机为研究对象,基于API 617标准开展转子动力学分析、闭环传递函数测试、振动分析、稳定性评估等工作. 结果表明:各项指标均满足API 617标准要求,转子运行转速与刚体临界转速、一阶弯曲临界转速之间的分离裕度分别为69.7%和53.8%,设计合理;磁悬浮转子系统建模准确,可用于预测转子的动力学行为;径向磁悬浮轴承系统灵敏度传递函数峰值均处于等级A范围内,轴向磁悬浮轴承处于等级B范围内,满足长期稳定运行要求;运行转速范围内转子振动小于10 μm,远小于振动极限要求.

Abstract:To evaluate the design rationality and operation reliability of the magnetically suspended fluid machinery, the API 617 standard was applied to analyze its vibration and stability. Firstly, the relevant specifications and requirements for magnetically suspended fluid machinery in the API 617 standard were introduced. Then, a magnetically suspended blower was taken as the research object, and rotor dynamics analysis, closed-loop transfer function testing, vibration analysis, stability evaluation, and other work were carried out based on the API 617 standard. The results indicate that all indicators meet the API 617 standard requirements. The separation margins between the rotor operating speed and the rigid body critical speed and the first-order bending critical speed are 69.7% and 53.8%, respectively, and the design is reasonable. The modelling of the magnetically suspended rotor system is accurate and can be used to predict the dynamic behavior of the rotor; the peak sensitivity transfer function values of the radial active magnetic bearing (AMB) system are all in zone A, while those of the axial AMB are in zone B, meeting the requirements for long-term and stable operation. The rotor vibration within the operating speed range is less than 10 μm, far below the vibration limit requirement.

-

表 1 磁悬浮轴承转子系统振动等级

Table 1. Vibration level of AMB-rotor system

等级 Ar/Cmin 描述 A <0.3 新调试设备一般都处于此等级 B [0.3, 0.4) 设备可长时间运行 C [0.4, 0.5) 需要定期维护以保持稳定运行 D ≥0.5 设备失稳的可能性较大 表 2 磁悬浮轴承转子系统灵敏度峰值等级(ISO 14839-3)

Table 2. Peak sensitivity level of AMB-rotor system (ISO 14839-3)

等级 最大增益/dB 描述 A <9.5 新调试设备一般都处于此等级 B [9.5,12.0) 是可接受的、可长时间运行的 C [12.0,14.0) 不满足长时间连续运行要求 D ≥14.0 可能会导致设备的损坏 表 3 径向磁悬浮轴承和转子的主要参数

Table 3. Main parameters of radial AMB and rotor

参数 数值 保护间隙/mm 0.25 偏置电流/A 2.5 磁极面积/mm2 270 线圈匝数/匝 80 转子长度/mm 562 轴颈轴径/mm 56 -

[1] JASTRZEBSKI R P, LIUKKONEN O. Analysis of a segmented axial active magnetic bearing for multi-MW compressor applications[J]. IEEE/ASME Transactions on Mechatronics, 2023, 28(5): 2799-2809. doi: 10.1109/TMECH.2023.3254812 [2] 贺艳晖,甘杨俊杰,周亮. 主动磁悬浮轴承在余热发电机的应用研究[J]. 西南交通大学学报,2022,57(3): 657-664. doi: 10.3969/j.issn.0258-2724.20210860HE Yanhui, GAN Yangjunjie, ZHOU Liang. Application of active magnetic bearing in waste heat generator[J]. Journal of Southwest Jiaotong University, 2022, 57(3): 657-664. doi: 10.3969/j.issn.0258-2724.20210860 [3] International Organization for Standardization. Mechanical vibration—vibration of rotating machinery equipped with active magnetic bearings: part 1: vocabulary: ISO 14839-1: 2018[S]. Geneva: [s.n.], 2018. [4] International Organization for Standardization. Mechanical vibration—vibration of rotating machinery equipped with active magnetic bearings: part 2: evaluation of vibration: ISO 14839-2: 2004[S]. Geneva: [s.n.], 2004. [5] International Organization for Standardization. Mechanical vibration—vibration of rotating machinery equipped with active magnetic bearings: part 3: evaluation of stability margin: ISO 14839-3: 2006[S]. Geneva: [s.n.], 2006. [6] International Organization for Standardization. Mechanical vibration—vibration of rotating machinery equipped with active magnetic bearings: part 4: technical guidelines: ISO 14839-4: 2012[S]. Geneva: [s.n.], 2012. [7] International Organization for Standardization. Mechanical vibration—vibration of rotating machinery equipped with active magnetic bearings: part 5: touch-down bearings: ISO 14839-5: 2022[S]. Geneva: [s.n.], 2022. [8] American Petroleum Institute. Axial and centrifugal compressors and expanders-compressors for petroleum, chemical and gas industry services: API 617. 9th Edition[S]. Washington D. C.: API Publishing Services, 2022. [9] 崔恒斌,周瑾,董继勇,等. 磁悬浮旋转机械振动稳定性实例研究[J]. 浙江大学学报(工学版),2018,52(4): 635-640,686.CUI Hengbin, ZHOU Jin, DONG Jiyong, et al. Case study on vibration stability of rotating machinery equipped with active magnetic bearings[J]. Journal of Zhejiang University (Engineering Science), 2018, 52(4): 635-640,686. [10] KHATRIA R, HAWKINS L. Applicability of API 617 8th ed. and ISO 14839-3 in evaluating the dynamic stability of AMB-supported compressors[C]// Proceedings of the 16th International Symposium on Magnetic Bearings. Beijing: [s.n.], 2018. [11] SMITHANI J, PAUL Y. Applying API 617, 8th edition to expander-compressors with active magnetic bearings[C]//Proceedings of the 44th Turbomachinery & 31st Pump Symposium. Houston: [s.n.], 2015. [12] SWANSON E, HAWKINS L, MASALA A. New active magnetic bearing requirements for compressors in API 617 eight edition[C]//Proceedings of the 43rd Turbomachinery Symposium. Houston: [s.n.], 2014. [13] 胡永,肖忠会,王玉旌,等. 电磁轴承支撑系统转子动力学分析[C]//第十六届沈阳科学学术年会论文集:理工农医. 沈阳:[出版社不详], 2019. [14] 张越,周瑾,金超武,等. 一种磁悬浮旋转机械系统在线频率响应测试方法:中国,ZL202110545692.8[P]. 2022-08-12. [15] ZHANG Y, ZHOU J, ZHANG Y B, et al. Modelling and vibration response of a magnetically suspended flexible rotor considering base motion[J]. Applied Mathematical Modelling, 2023, 118: 518-540. doi: 10.1016/j.apm.2023.01.020 [16] 周扬,周瑾,王艺宇,等. 考虑界面接触的磁悬浮轴承-转子系统建模及鲁棒控制[J]. 西南交通大学学报,2024,59(4): 755-765. doi: 10.3969/j.issn.0258-2724.20230510ZHOU Yang, ZHOU Jin, WANG Yiyu, et al. Modeling and robust control of magnetic bearing-rotor system considering interface contact[J]. Journal of Southwest Jiaotong University, 2024, 59(4): 755-765. doi: 10.3969/j.issn.0258-2724.20230510 [17] 金超武,辛宇,周扬,等. 高温磁悬浮轴承-转子系统建模与动力学分析[J]. 西南交通大学学报,2024,59(4): 746-754,822. doi: 10.3969/j.issn.0258-2724.20230667JIN Chaowu, XIN Yu, ZHOU Yang, et al. Modeling and dynamics analysis of high-temperature magnetic bearing-rotor system[J]. Journal of Southwest Jiaotong University, 2024, 59(4): 746-754,822. doi: 10.3969/j.issn.0258-2724.20230667 [18] XU Y P, ZHOU J, DI L, et al. Active magnetic bearings dynamic parameters identification from experimental rotor unbalance response[J]. Mechanical Systems and Signal Processing, 2017, 83: 228-240. doi: 10.1016/j.ymssp.2016.06.009 -

下载:

下载: