Temperature Prediction of Key Chips in Nuclear Power Instrumentation and Control System Based on Machine Learning

-

摘要:

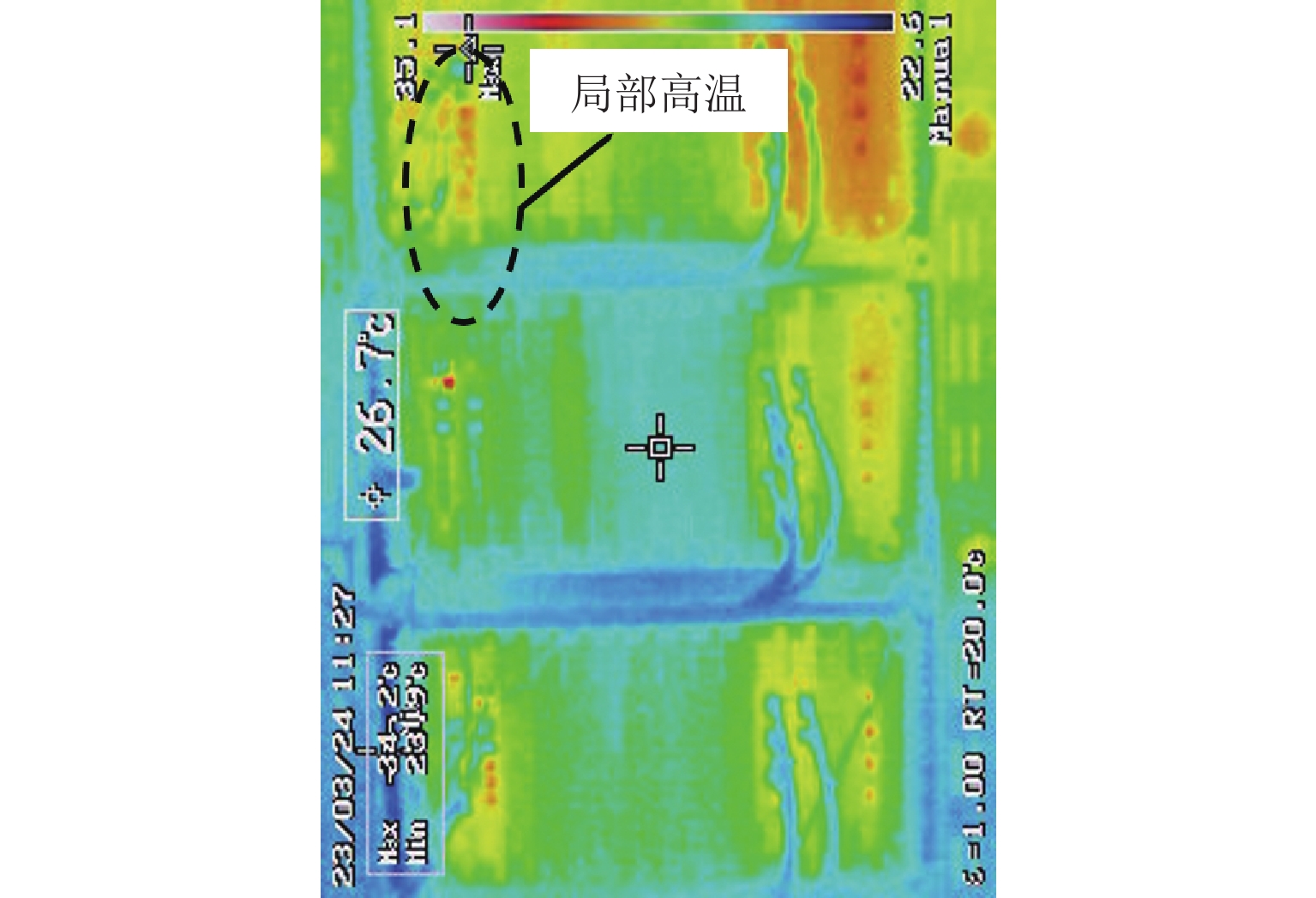

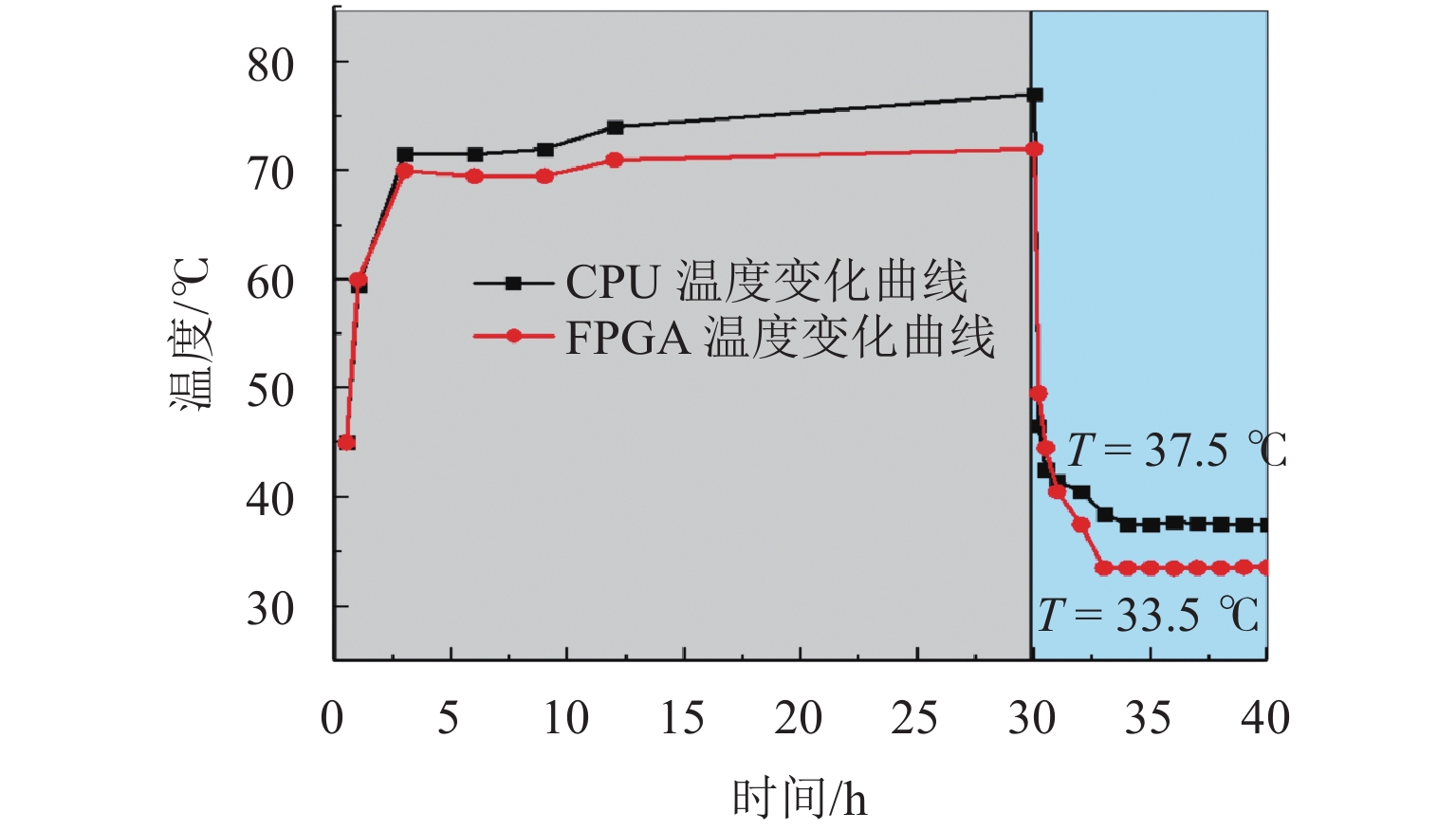

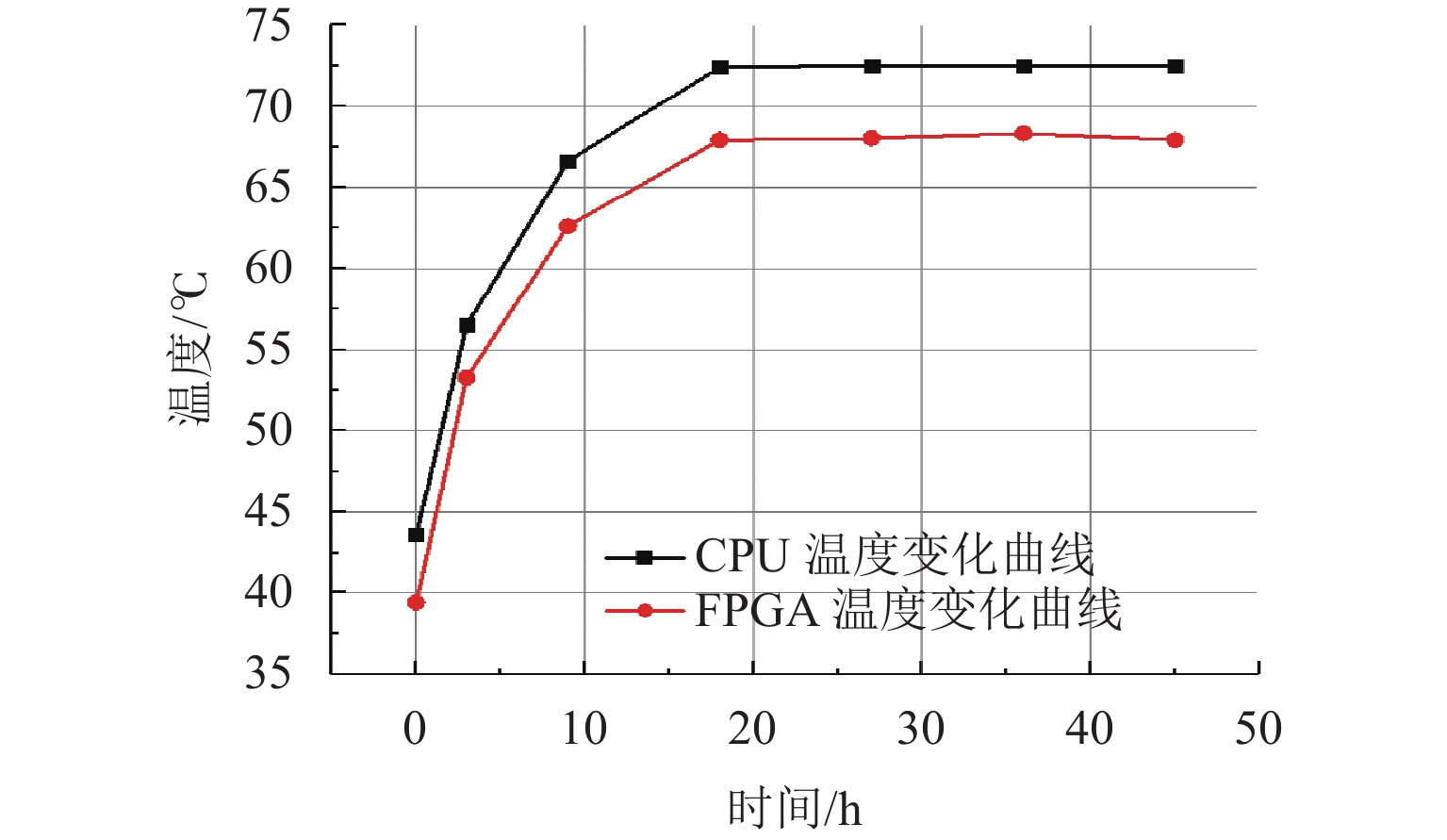

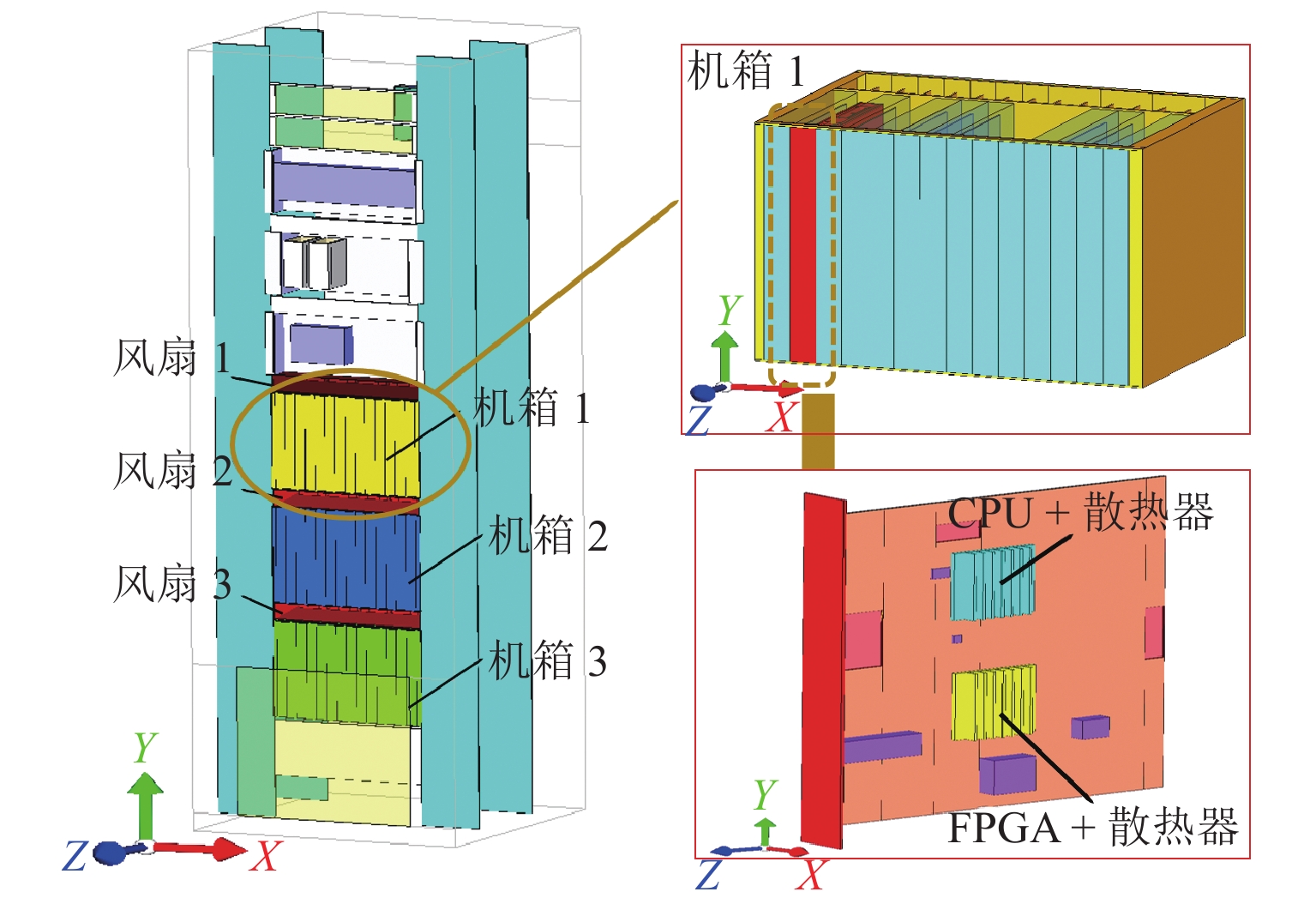

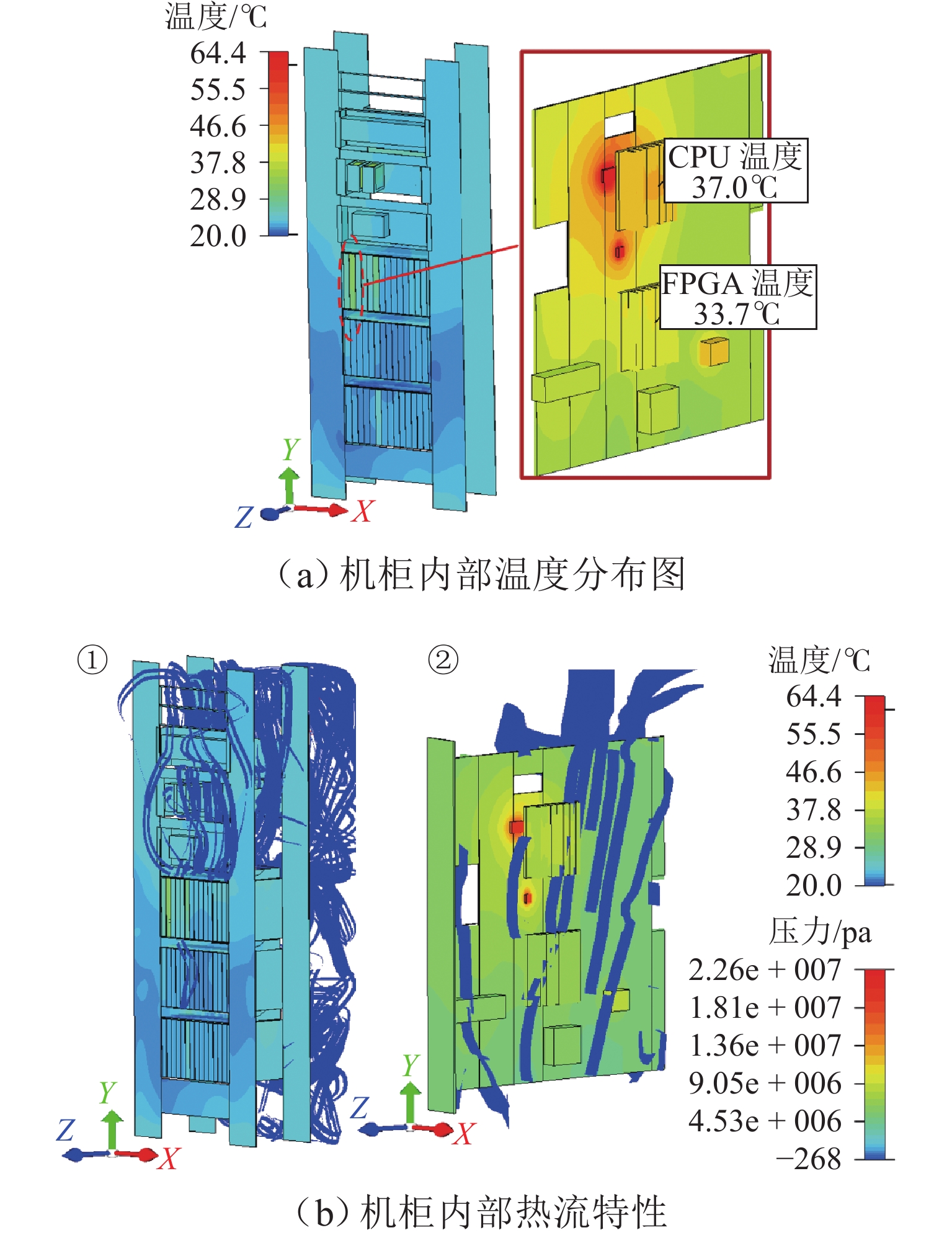

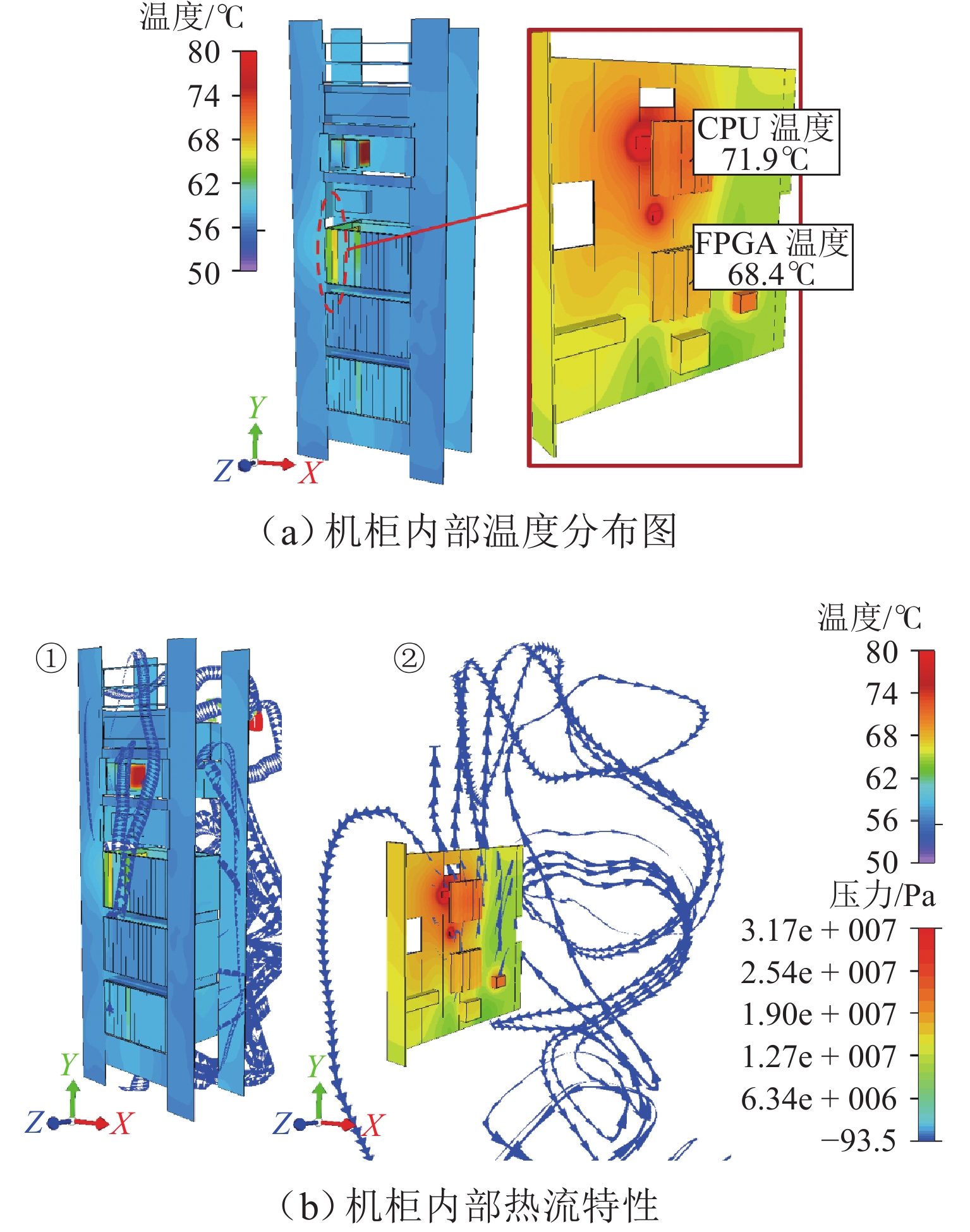

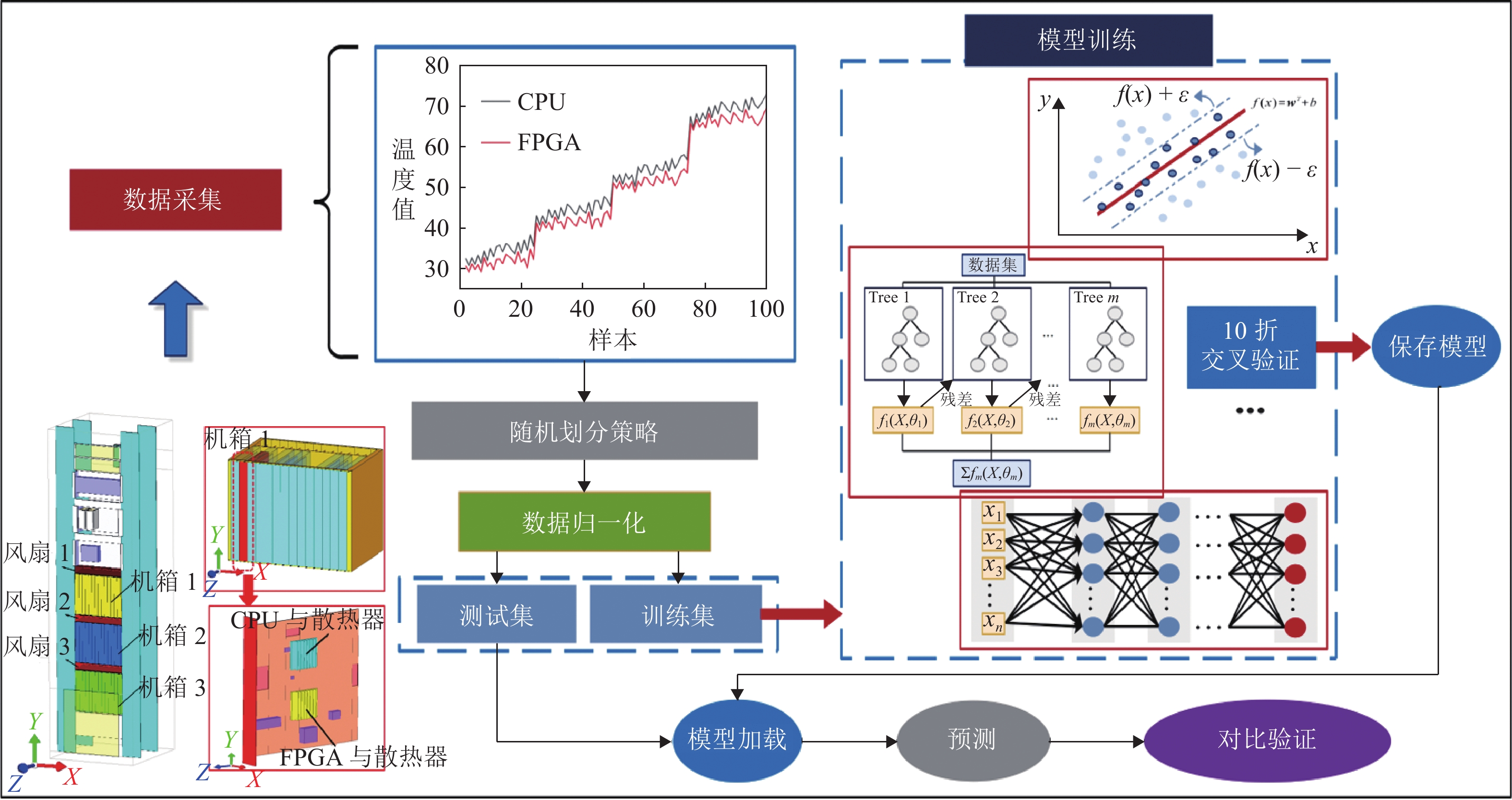

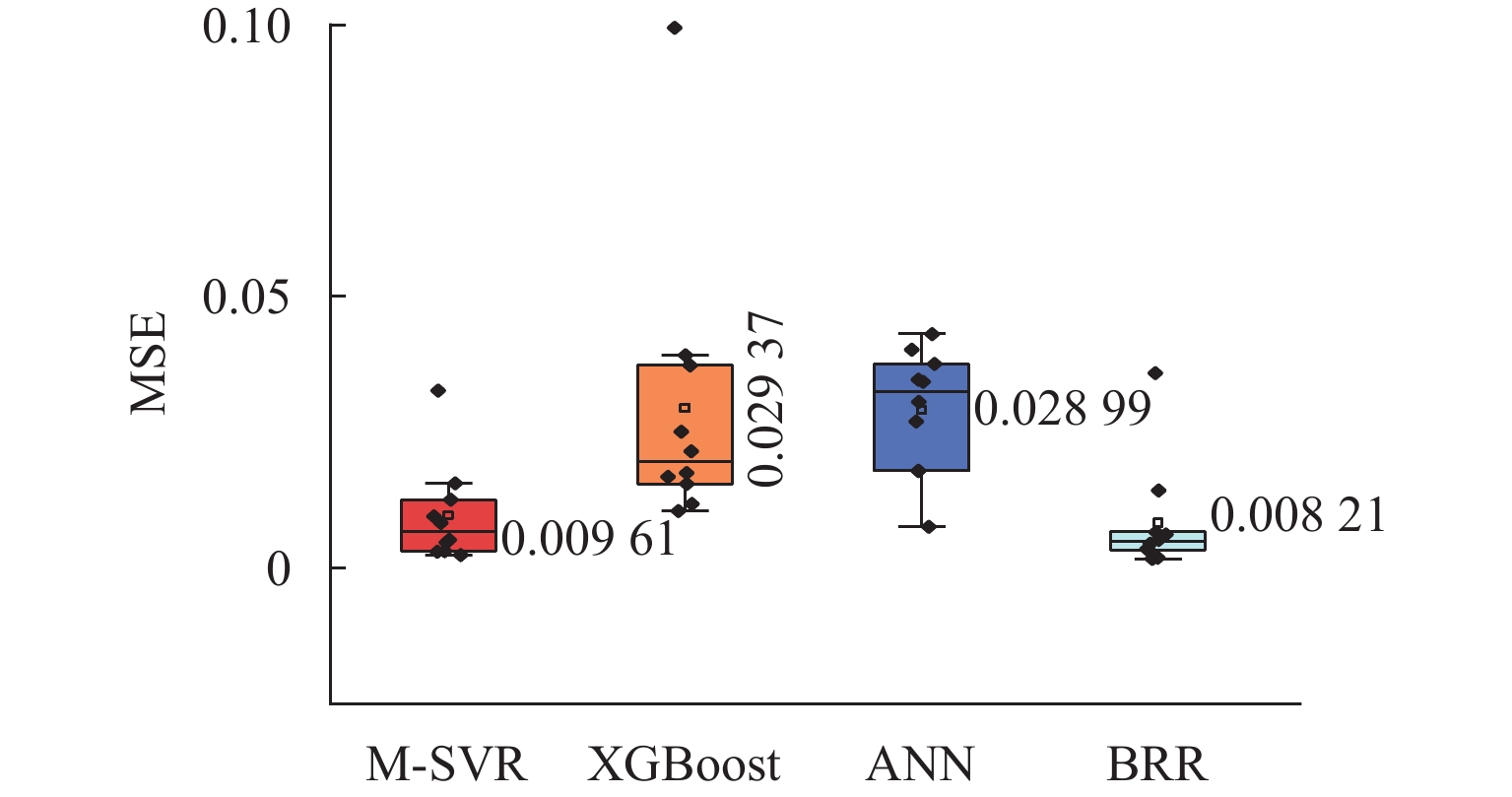

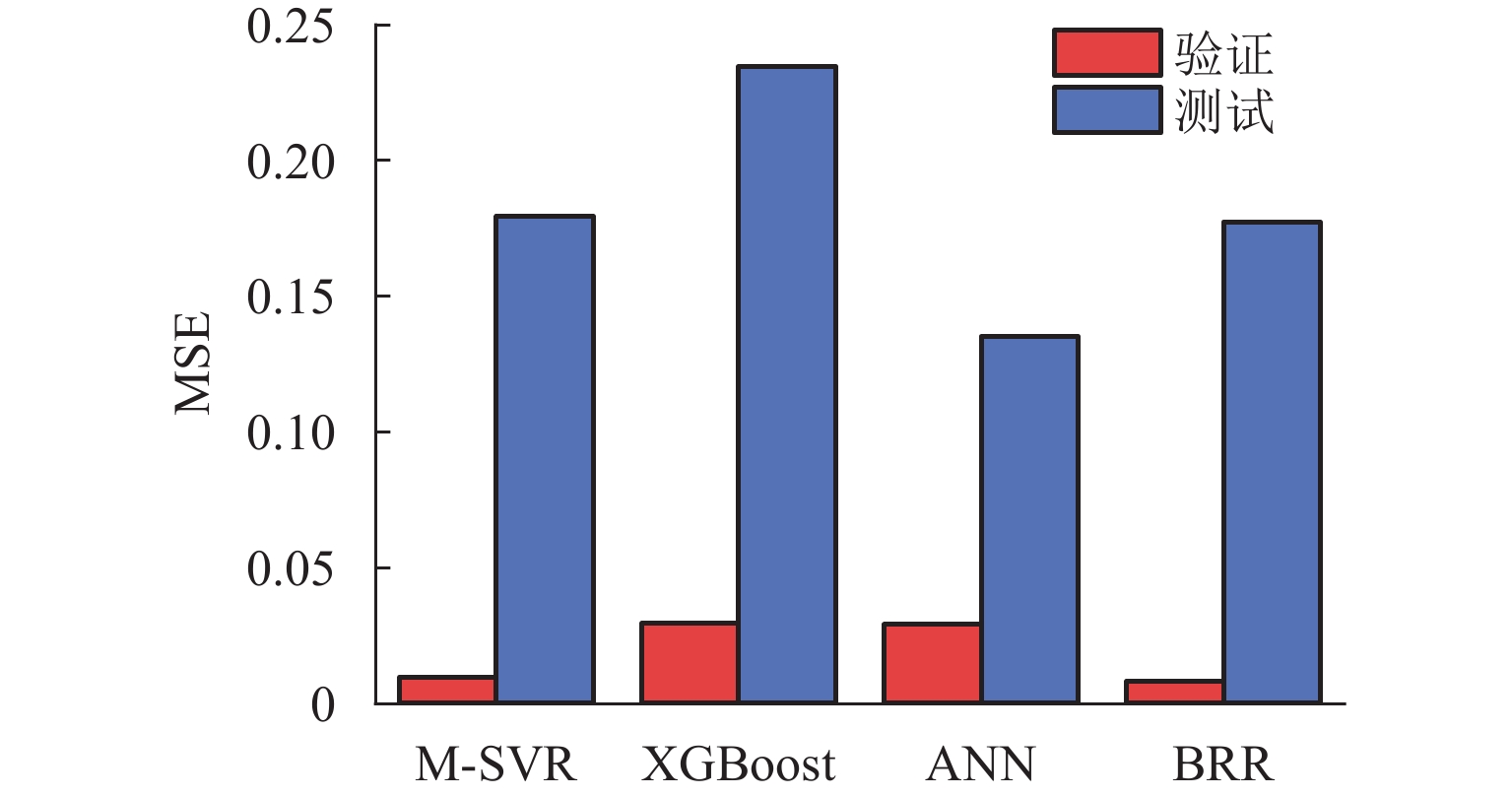

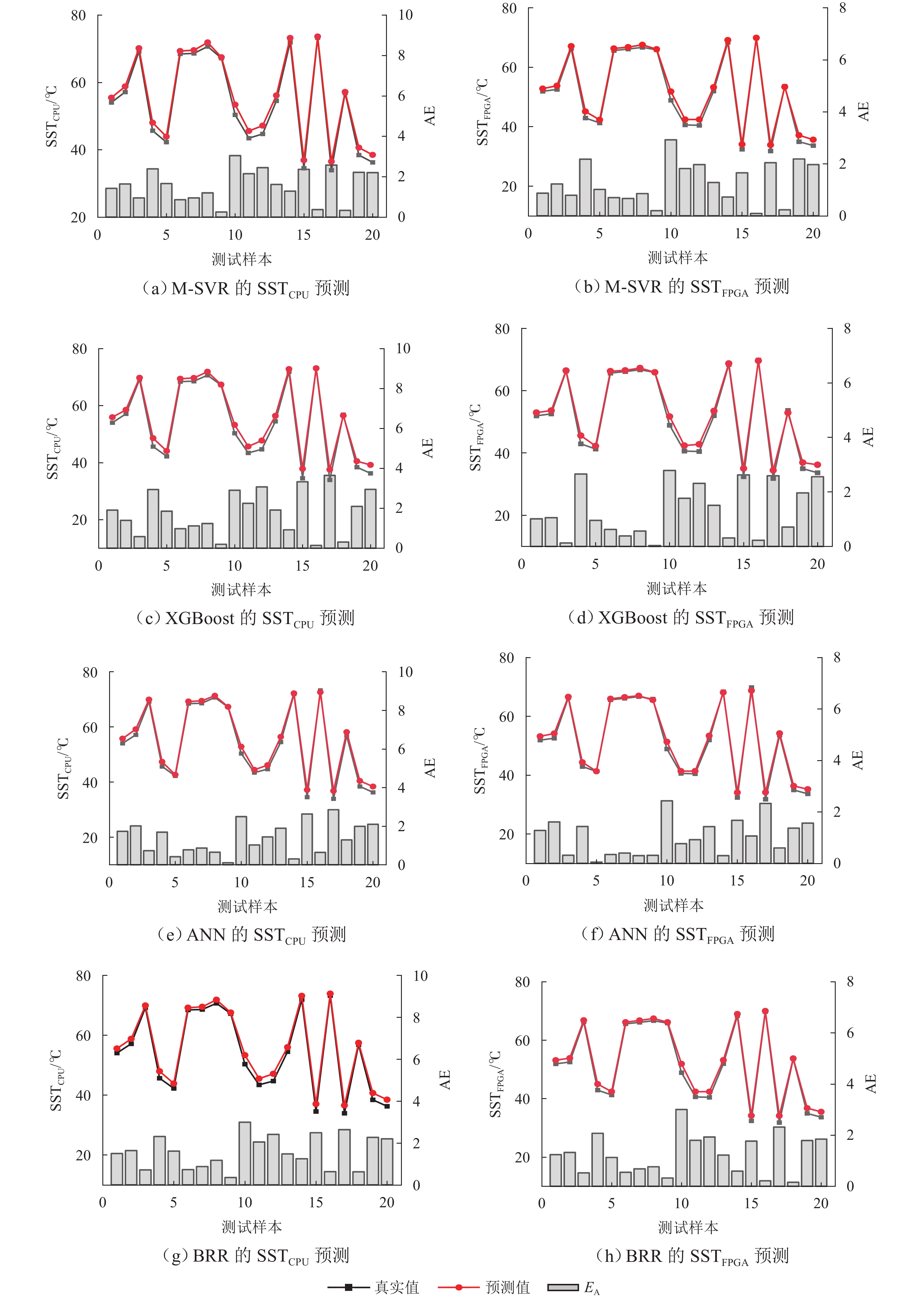

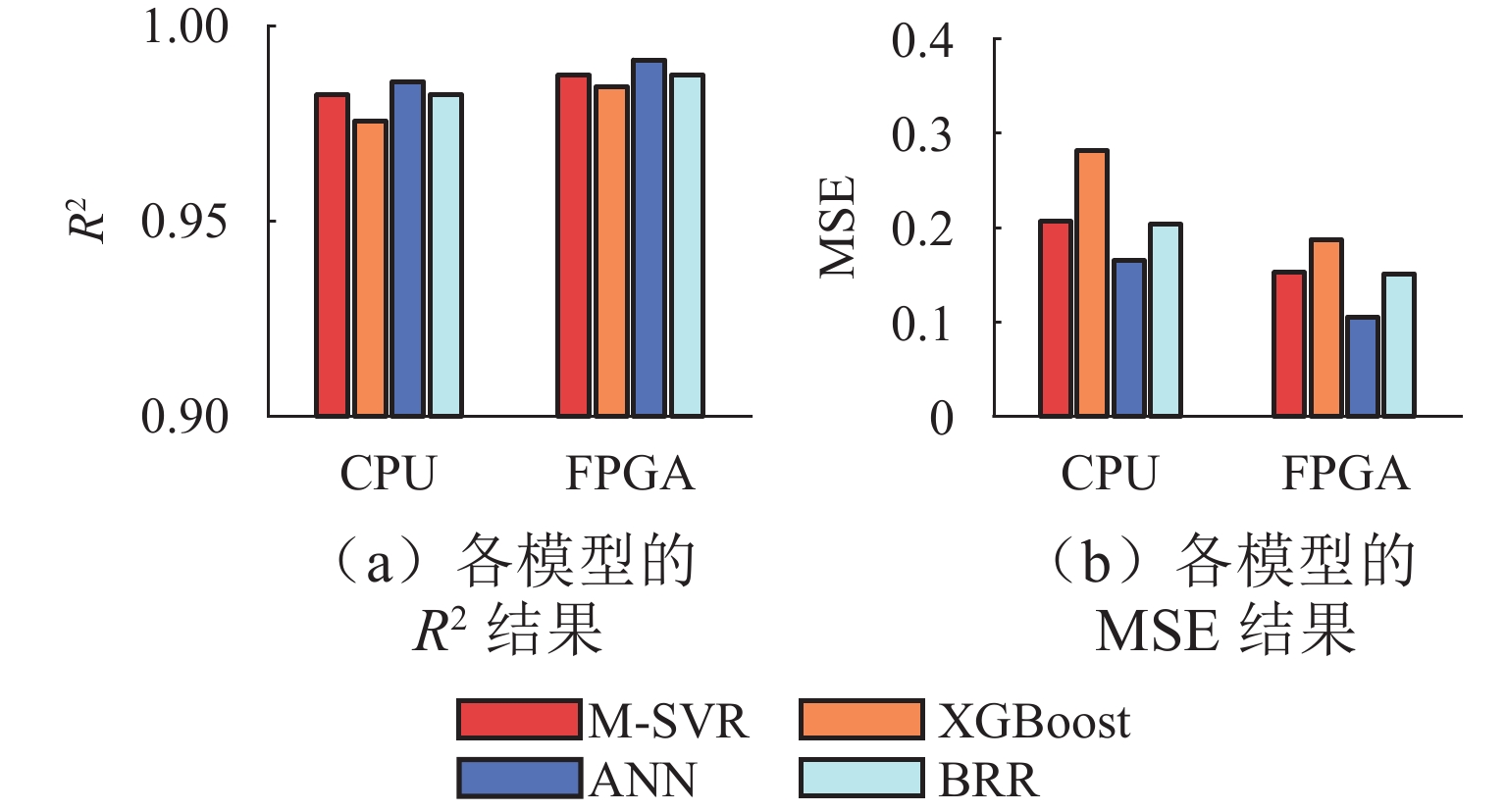

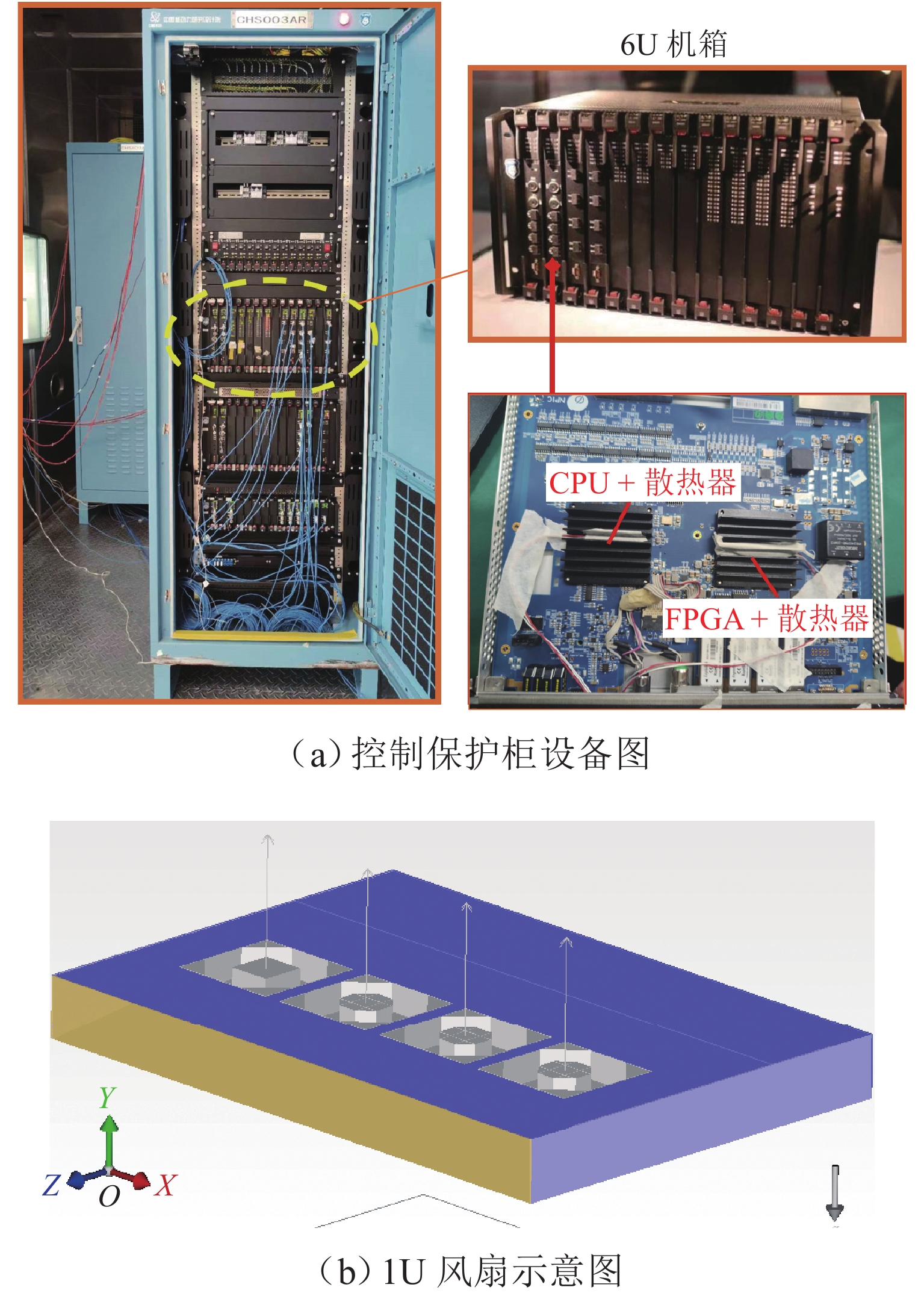

为研究核安全级仪控系统中控制保护柜的内部热学特性及其关键芯片(CPU与FPGA)的稳态温度(SST)变化规律,在不同环境温度下对该控制保护柜开展了试验研究,并采用有限元方法模拟试验过程,通过对比试验结果验证了数值模型的准确性;在此基础上,利用有限元模型计算得到100组随机工况下CPU和FPGA的SST值,并采用M-SVR、XGBoost、ANN及BRR 4种算法对不同工况下CPU和FPGA的SST进行学习预测. 研究结果表明:1) 在环境温度为20 ℃时,CPU和FPGA的SST分别为37.5 ℃和33.5 ℃;当环境温度为55 ℃时,相应的SST上升至为72 ℃和68 ℃;有限元分析结果能够很好地模拟试验现象,计算所得芯片的SST同试验结果吻合较好. 2) 4种算法模型均能够对芯片SST进行预测,其中ANN算法在测试集上的预测性能最佳,其MSE值小于0.15%,

R 2大于0.99,泛化能力最强;相比之下,其他3种模型对高SST样本表现出较好的预测性能,但对低SST样本的预测误差较大,尤其是XGBoost模型,其预测误差高达3.65 ℃. 本研究为核安全级控制系统的芯片SST预测提供了一种新方法.Abstract:To investigate the thermal characteristics inside the control and protection cabinet of nuclear safety-class instrumentation and control (I&C) systems and the variation patterns of the steady-state temperature (SST) of key chips (CPU and field programmable gate array (FPGA)), experimental studies were conducted on the cabinet under different ambient temperatures. The finite element method was employed to simulate the experimental process, and the accuracy of the numerical model was validated by comparing the experimental results. Furthermore, the SST values of CPU and FPGA under 100 sets of random working conditions were calculated by the finite element model, and the SST values of CPU and FPGA under different working conditions were learned and predicted using four algorithms of multi-output support vector regression (M-SVR), extreme gradient boosting (XGBoost), artificial neural network (ANN), and Bayesian ridge regression (BRR). Results show that when the ambient temperature is 20 ℃, the SST of CPU and FPGA is 37.5 ℃ and 33.5 ℃, respectively. When the ambient temperature is 55 ℃, the SST of the CPU and FPGA rises to 72 ℃ and 68 ℃, respectively. Finite element analysis can well simulate the test phenomenon, and the calculated chip SSTs are in good agreement with the experimental results. All the four algorithm models can be used to predict chip SST, among which the ANN algorithm exhibits the best prediction performance on the test set. It has a mean squared error (MSE) less than 0.15% and an

R 2 value greater than 0.99 and exhibits the strongest generalization ability. In contrast, although the other three models show good prediction performance for samples with high SSTs, the prediction error for samples with low SSTs is large, especially for the XGBoost model, whose prediction error is as high as 3.65 ℃. The research provides a new method for SST prediction of chips in nuclear safety-class control systems. -

表 1 部件材料参数值

Table 1. Material parameters of components

部件 材料 热导率/

(W·mK−1)比热容/

(J/Kg·K)密度/

(kg·m−3)机柜 Q235 50.2 460 7860 内部支撑件 不锈钢 16.3 500 7900 机箱 Al 6061 180 963 2700 PCB FR4 0.3 880 1200 CPU 金属封装 15 395 2000 FPGA 金属封装 15 395 2000 表 2 特征的详细参数值

Table 2. Detailed parameter values of features

特征项 参数值 环境温度/℃ 20, 30, 40, 55 CPU功耗/W 5, 6, 8, 10 FPGA功耗/W 3, 4, 5, 6 风扇风量/(m3·h−1) 0.015, 0.018, 0.025, 0.030 表 3 4个模型的最优超参数

Table 3. Optimal hyperparameters of the four models

模型 参数值 M-SVR kernel=“RBF”,C=700,gamma=0.03 XGBoost learning_rate=0.1,n_estimators=300,

max_depth=3,subsample=0.8,

reg_alpha=0,reg_lambda=10ANN Dense (8, activation='sigmoid'),

Dense (4, activation='sigmoid'),

optimizer = “rmsprop”,

batch_size = 5,epochs = 300BRR alpha_1=100,alpha_init=1,

lambda_1=10,lambda_init=0.001表 4 4种模型的10折交叉验证结果

Table 4. 10-fold cross validation results of the four models

验证

次数/次MSE/% M-SVR XGBoost ANN BRR 1 0.0326 0.0994 0.0178 0.0358 2 0.0030 0.0167 0.0342 0.0051 3 0.0082 0.0372 0.0075 0.0061 4 0.0023 0.0117 0.0375 0.0032 5 0.0094 0.0104 0.0305 0.0065 6 0.0125 0.0391 0.0401 0.0034 7 0.0046 0.0154 0.0178 0.0016 8 0.0029 0.0174 0.0269 0.0018 9 0.0051 0.0214 0.0430 0.0044 10 0.0155 0.0250 0.0346 0.0142 表 5 测试集样本数据

Table 5. Sample data of the test set

环境温

度/℃CPU功

耗/WFPGA

功耗/W风扇风量/

(m3·h−1)TCPU/℃ TFPGA/℃ 20 8 5 0.015 36.29 33.65 20 8 5 0.025 34.54 32.41 20 8 6 0.030 33.95 31.83 20 10 6 0.015 38.43 34.95 30 6 5 0.030 42.25 41.28 30 8 4 0.030 43.44 40.60 30 8 5 0.015 45.66 42.93 30 10 3 0.030 44.71 40.46 40 6 5 0.030 50.35 48.91 40 8 5 0.025 54.51 51.97 40 8 6 0.030 54.05 51.92 40 10 3 0.015 57.15 52.55 40 10 6 0.030 56.84 53.62 55 6 5 0.030 67.21 65.85 55 8 4 0.025 69.20 66.30 55 8 4 0.030 68.46 65.62 55 8 5 0.030 68.6 66.11 55 10 4 0.025 70.66 66.68 55 10 5 0.018 71.90 68.40 55 10 6 0.015 73.24 69.80 表 6 4种模型的预测性能对比

Table 6. Comparison of prediction performance of the four models

模型 MSE/% R2 M-SVR 0.1793 0.9847 XGBoost 0.2346 0.9800 ANN 0.1352 0.9885 BRR 0.1773 0.9849 表 7 4种模型的详细性能指标

Table 7. Detailed performance metrics of the four models

模型 MSE/% R2 CPU FPGA CPU FPGA M-SVR 0.2063 0.1524 0.9822 0.9873 XGBoost 0.2816 0.1875 0.9756 0.9844 ANN 0.1651 0.1053 0.9857 0.9912 BRR 0.2035 0.1511 0.9824 0.9874 -

[1] 王丛林, 柴晓明, 杨博, 等. 先进核能技术发展及展望[J]. 核动力工程, 2023, 44(5): 1-5.WANG Conglin, CAI Xiaoming, YANG Bo, et al. Development and prospect of advanced nuclear energy technology[J]. Nuclear Power Engineering, 2023, 44(5): 1-5. [2] 张军, 张犁, 成瑜. IGBT模块寿命评估研究综述[J]. 电工技术学报, 2021, 36(12): 2560-2575.ZHANG Jun, ZHANG Li, CHENG Yu. Review of the lifetime evaluation for the IGBT module[J]. Transactions of China Electrotechnical Society, 2021, 36(12): 2560-2575. [3] DING B, ZHANG Z H, GONG L, et al. A novel thermal management scheme for 3D-IC chips with multi-cores and high power density[J]. Applied Thermal Engineering, 2020, 168: 114832. doi: 10.1016/j.applthermaleng.2019.114832 [4] 薛志虎, 艾邦成, 曲伟. 基于LHP的数据中心服务器芯片级散热技术[J/OL]. 华中科技大学学报(自然科学版), https://doi.org/10.13245/j.hust.240339.XUE Zhihu, AI Bangcheng, QU Wei. Server chip-level cooling technology in data center based on LHP[J/OL]. Journal of Huazhong University of Science and Technology, https://doi.org/10.13245/j.hust.240339. [5] 李宇婷, 徐超, 陆规. 极高热流密度的降级散热及耦合优化[J]. 工程热物理学报, 2022, 43(6): 1580-1587.LI Yuting, XU Chao, LU Gui. Degraded heat dissipation and coupling optimization with extremely high heat flux density[J]. Journal of Engineering Thermophysics, 2022, 43(6): 1580-1587. [6] ALSHEHRY A H, ALSHAHRY S M, ALHAZMI A K, et al. A study on the effect of temperature variations on FPGA-based multi-channel time-to-digital converters[J]. Sensors, 2023, 23(18): 7672. doi: 10.3390/s23187672 [7] 盘朝奉, 刘兵, 陈龙, 等. 锂离子电池温升特性分析及液冷结构设计[J]. 西南交通大学学报, 2020, 55(1): 68-75.PAN Chaofeng, LIU Bing, CHEN Long, et al. Temperature rise characteristic analysis and liquid cooling structure design of lithium battery[J]. Journal of Southwest Jiaotong University, 2020, 55(1): 68-75. [8] 赵泽宇, 杜明星. 多数据驱动人工神经网络的IGBT结温在线估计方法[J]. 电子测量与仪器学报, 2022, 36(7): 223-229.ZHAO Zeyu, DU Mingxing. On line estimation of IGBT junction temperature based on multi data driven artificial neural network[J]. Journal of Electronic Measurement and Instrumentation, 2022, 36(7): 223-229. [9] BHATASANA M, MARCONNET A. Deep learning for real-time chip temperature and power predictions[C]//2023 22nd IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm). Orlando: IEEE, 2023: 1-7. [10] WANG C, VAFAI K. Heat transfer enhancement for 3D chip thermal simulation and prediction[J]. Applied Thermal Engineering, 2024, 236: 121499. doi: 10.1016/j.applthermaleng.2023.121499 [11] SADIQBATCHA S I, ZHANG J W, AMROUCH H, et al. Real-time full-chip thermal tracking: a post-silicon, machine learning perspective[J]. IEEE Transactions on Computers, 2021, 71(6): 1411-1424. [12] RAJPUT D, WANG W J, CHEN C C. Evaluation of a decided sample size in machine learning applications[J]. BMC Bioinformatics, 2023, 24(1): 48. doi: 10.1186/s12859-023-05156-9 [13] DOU B Z, ZHU Z L, MERKURJEV E, et al. Machine learning methods for small data challenges in molecular science[J]. Chemical Reviews, 2023, 123(13): 8736-8780. doi: 10.1021/acs.chemrev.3c00189 [14] BAO Y K, XIONG T, HU Z Y. Multi-step-ahead time series prediction using multiple-output support vector regression[J]. Neurocomputing, 2014, 129: 482-493. doi: 10.1016/j.neucom.2013.09.010 [15] JOHNSTONE C, SULUNGU E D. Application of neural network in prediction of temperature: a review[J]. Neural Computing and Applications, 2021, 33(18): 11487-11498. doi: 10.1007/s00521-020-05582-3 [16] ASSELMAN A, KHALDI M, AAMMOU S. Enhancing the prediction of student performance based on the machine learning XGBoost algorithm[J]. Interactive Learning Environments, 2023, 31(6): 3360-3379. doi: 10.1080/10494820.2021.1928235 [17] MASSAOUDI M, REFAAT S S, ABU-RUB H, et al. A hybrid Bayesian ridge regression-CWT-catboost model for PV power forecasting[C]//2020 IEEE Kansas Power and Energy Conference (KPEC). Manhattan: IEEE, 2020: 1-5. -

下载:

下载: