Cutter Load Characteristics and Effect of Cutter Profile in Multi-Cutter Rock-Breaking Condition

-

摘要:

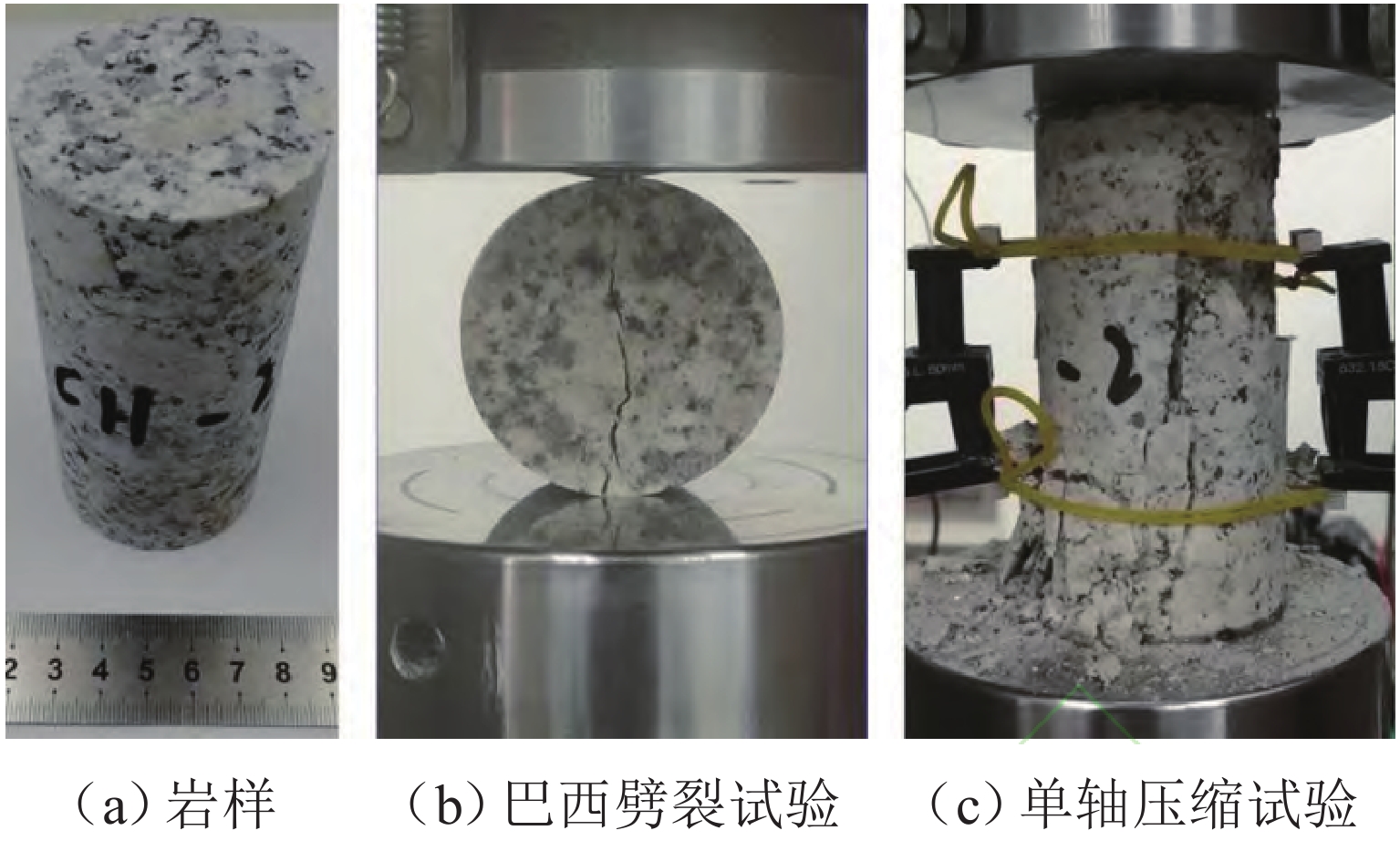

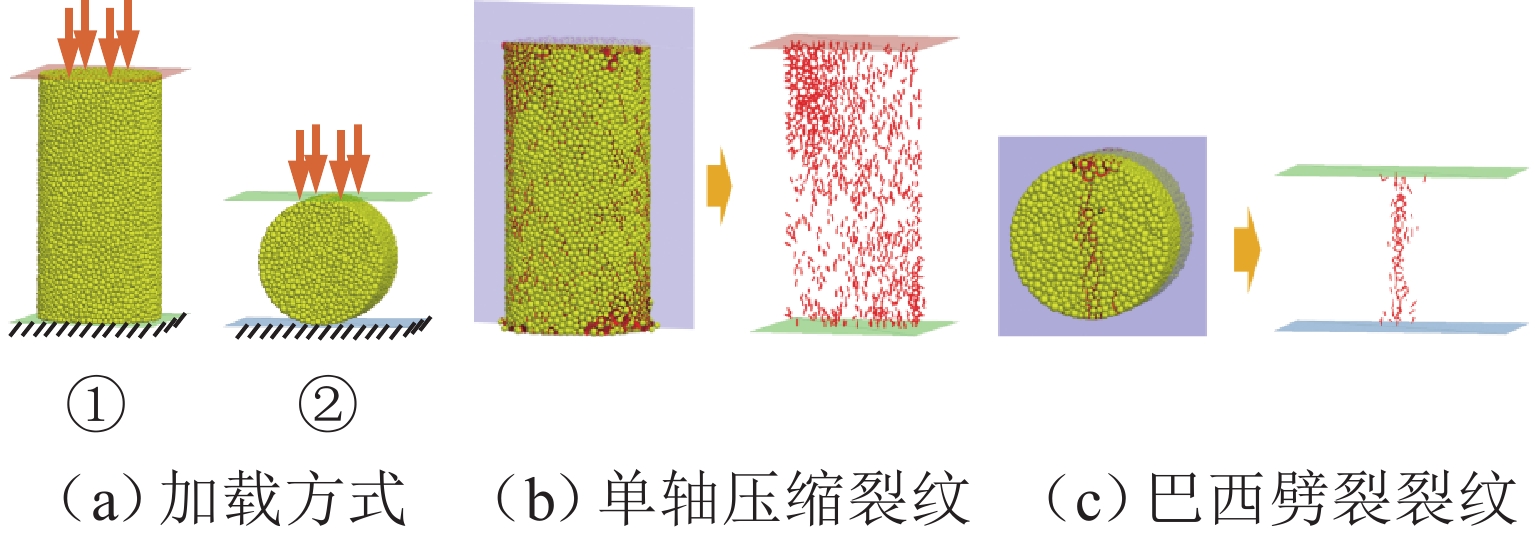

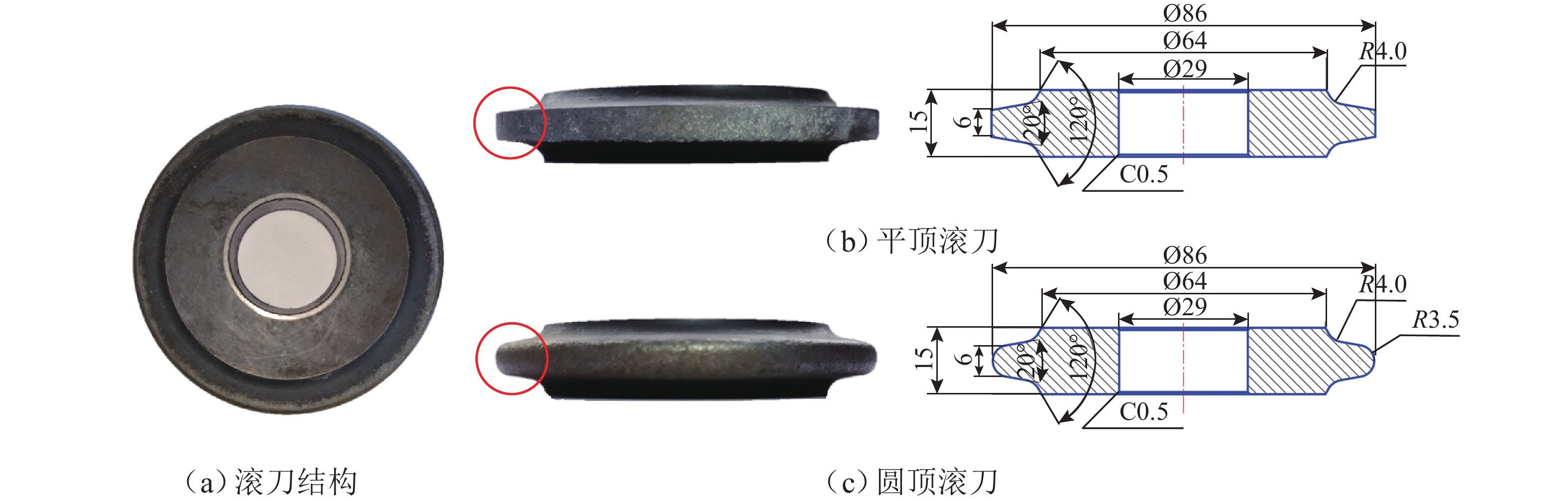

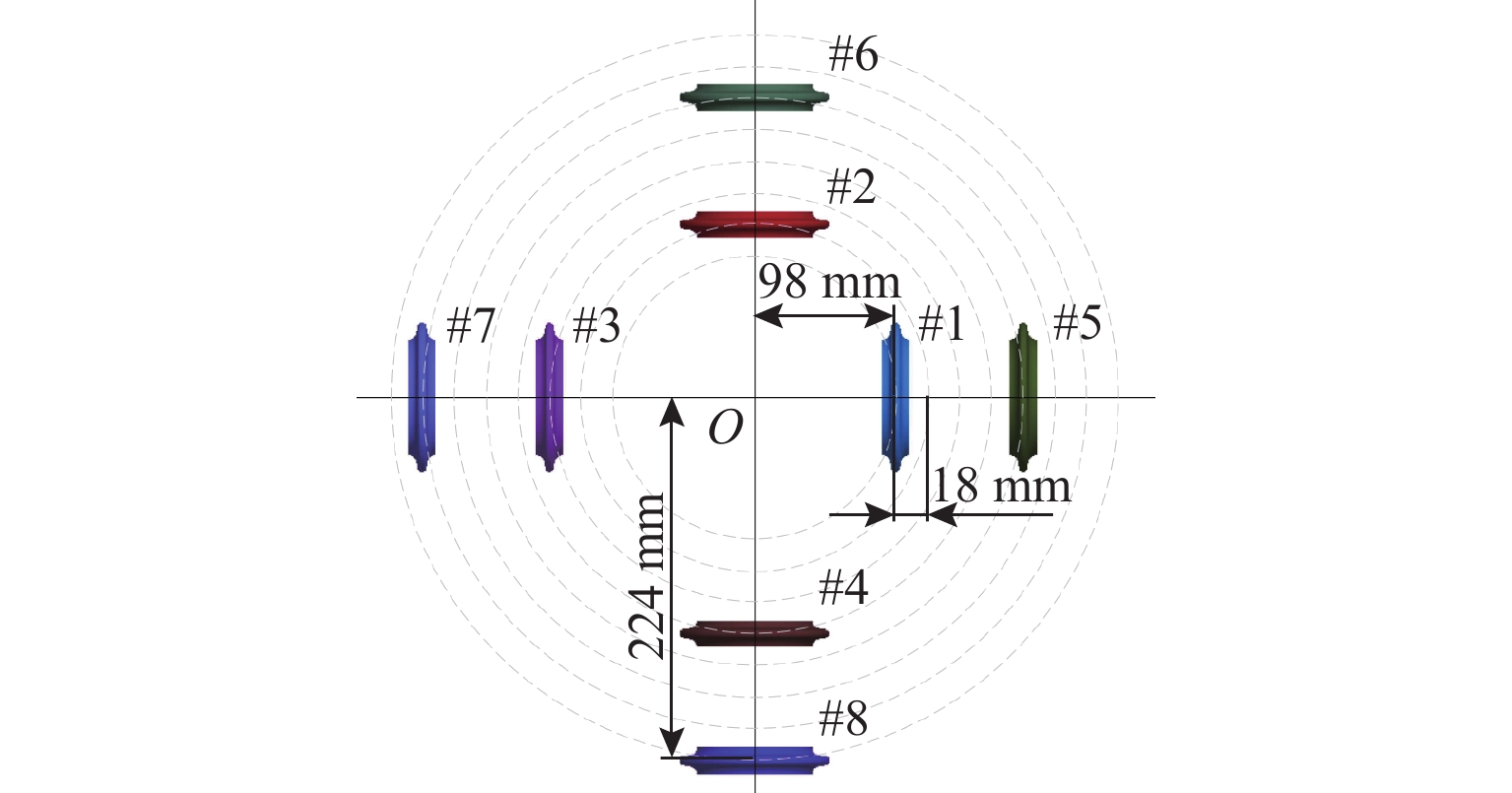

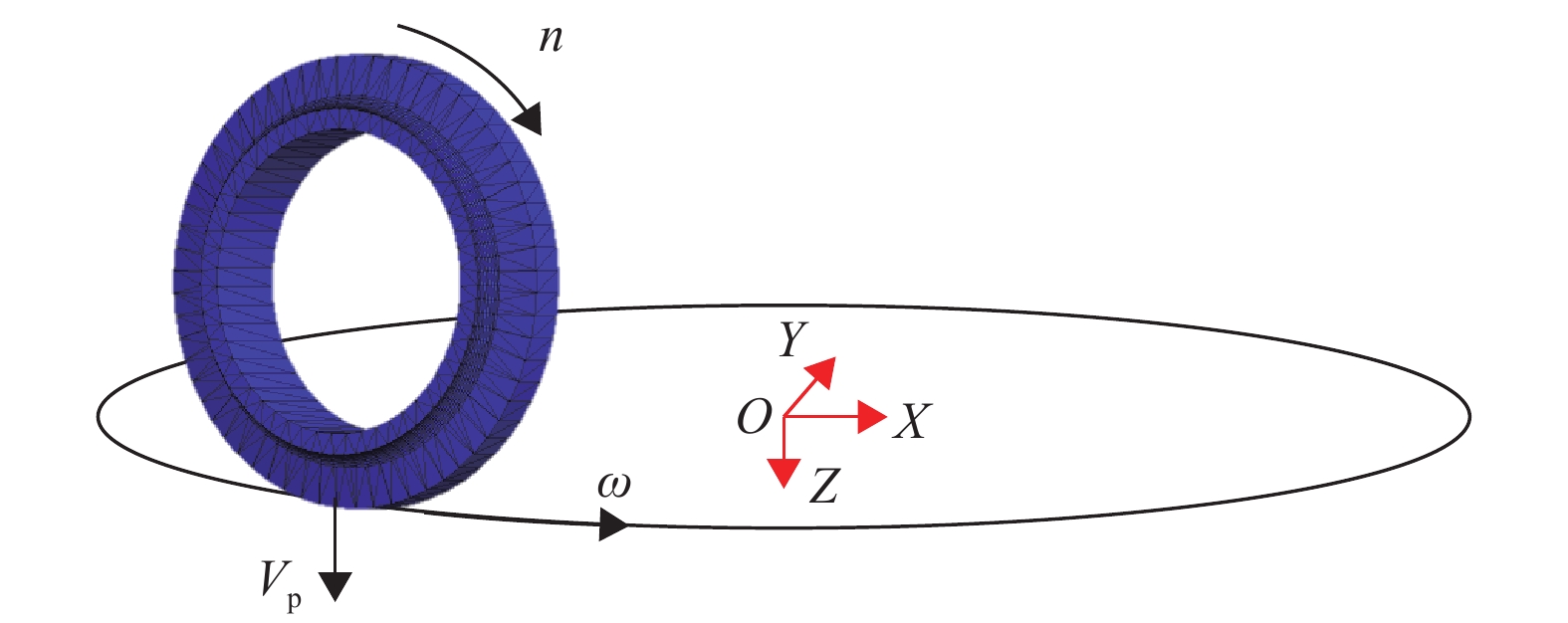

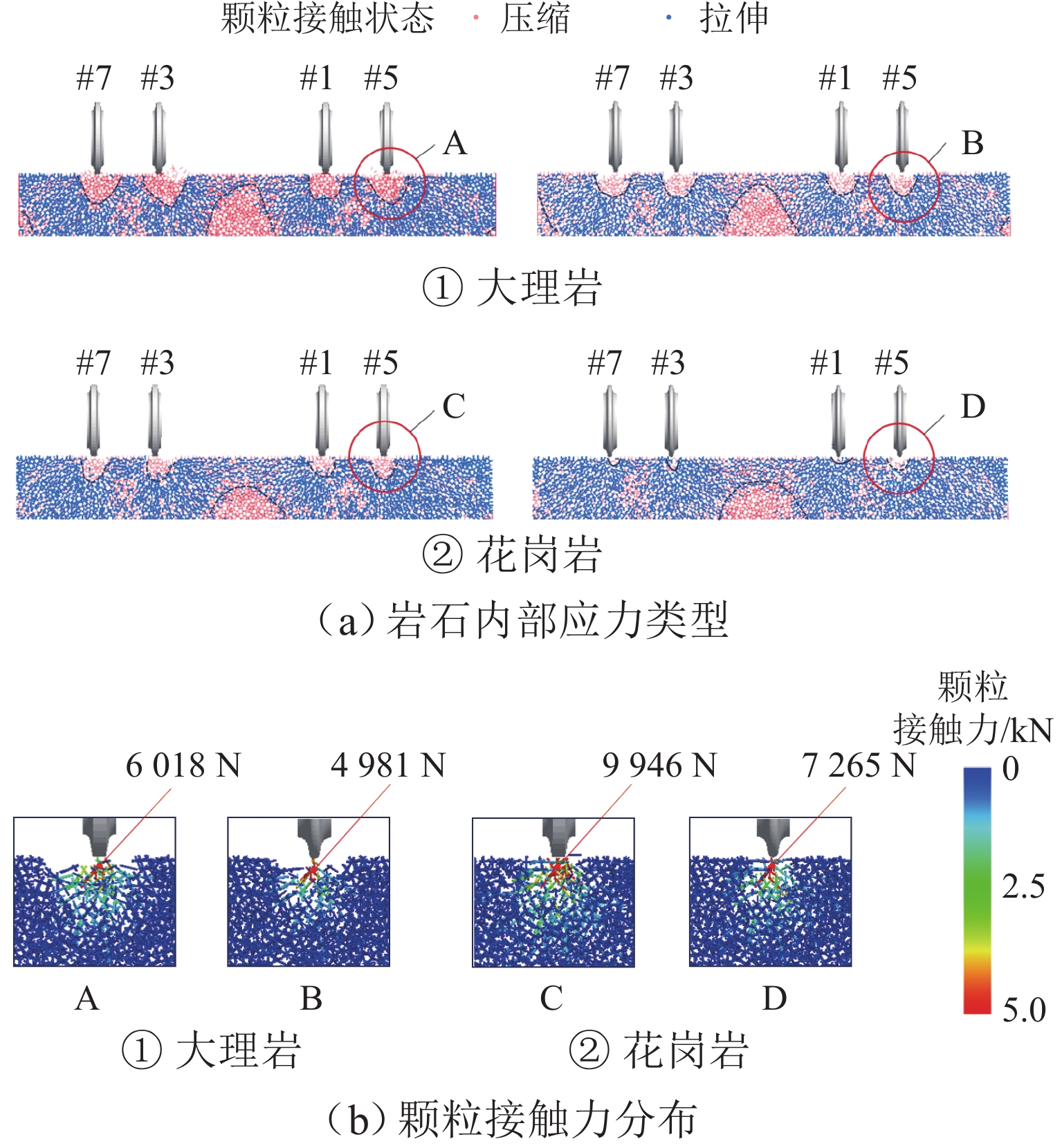

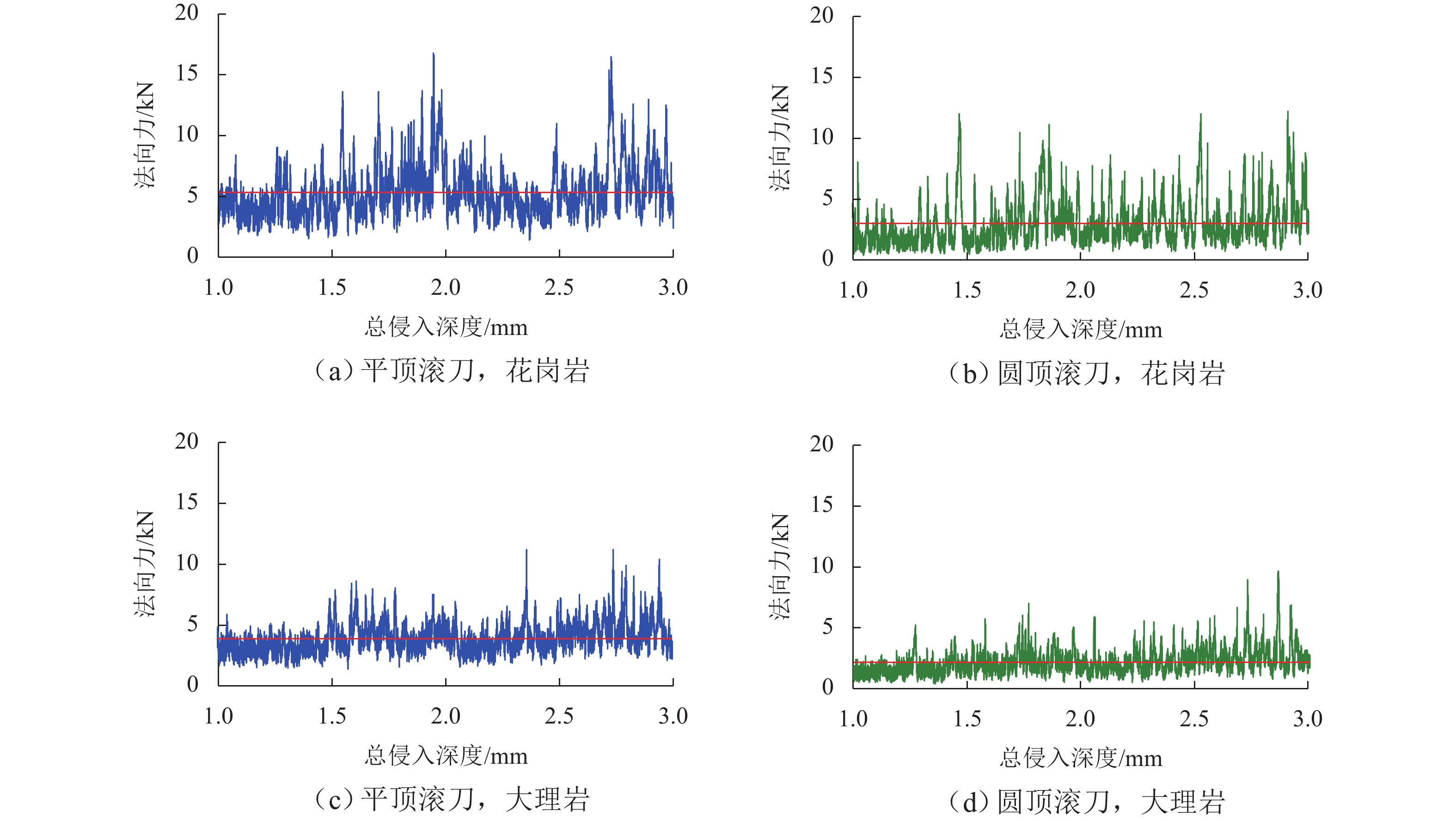

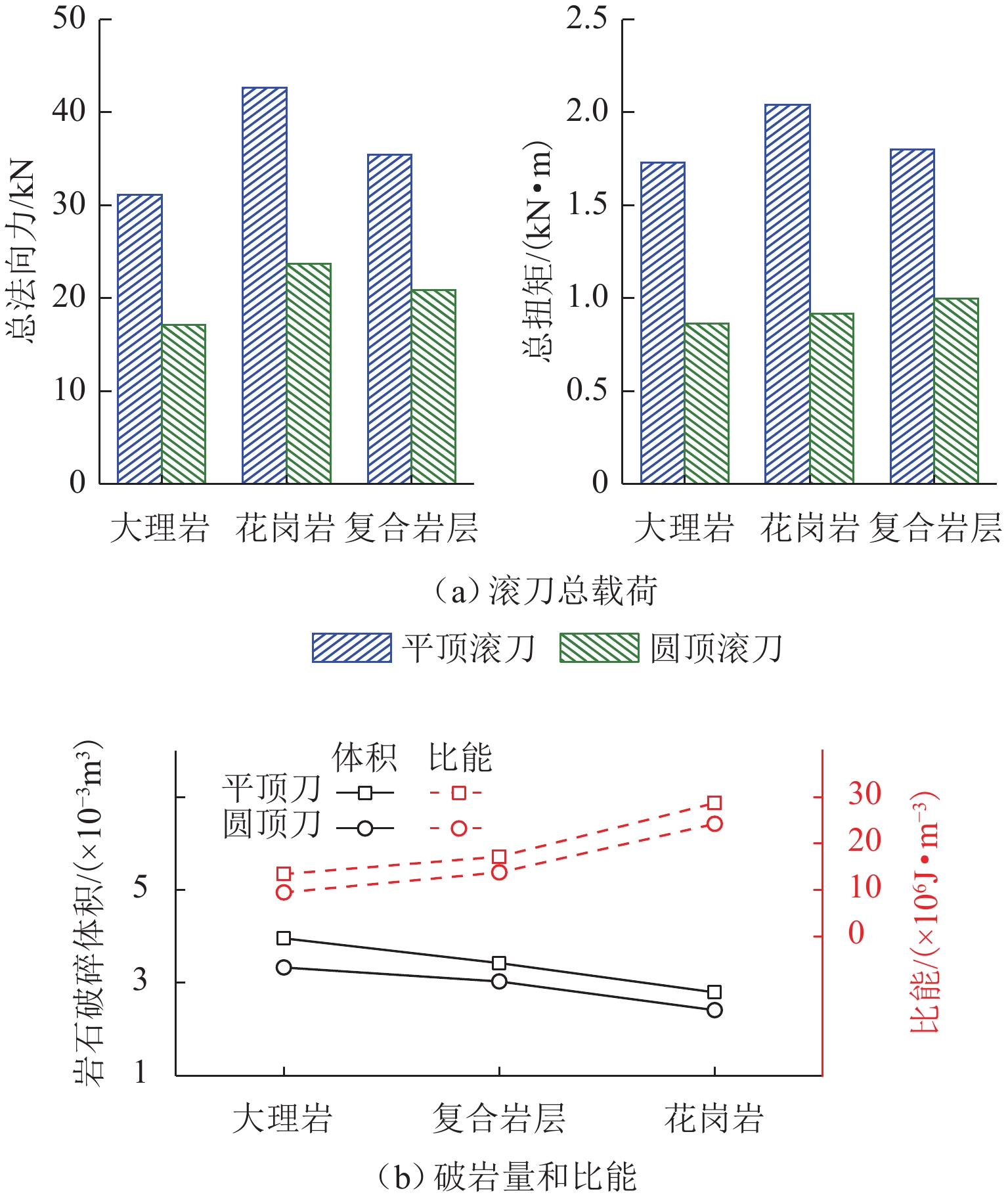

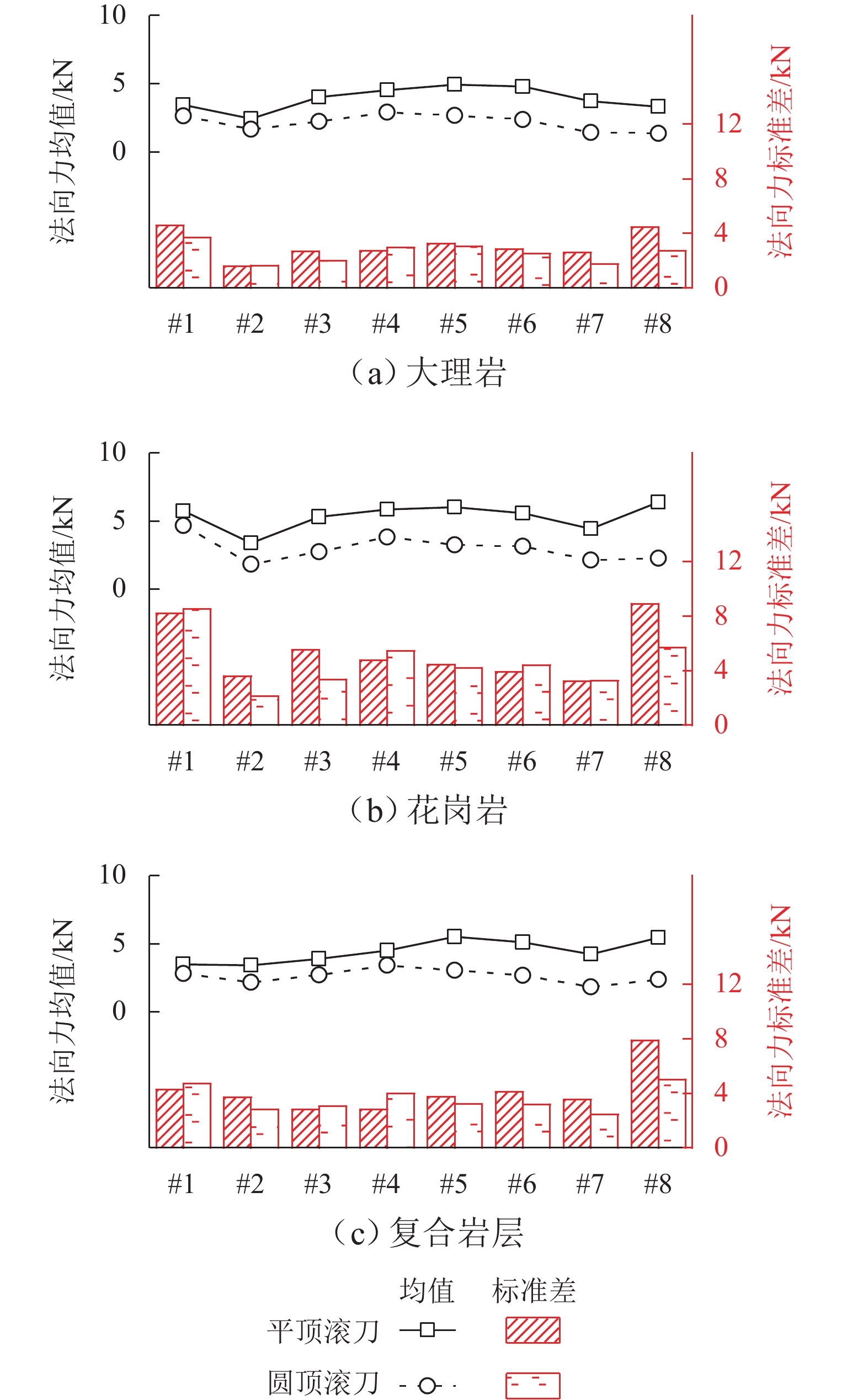

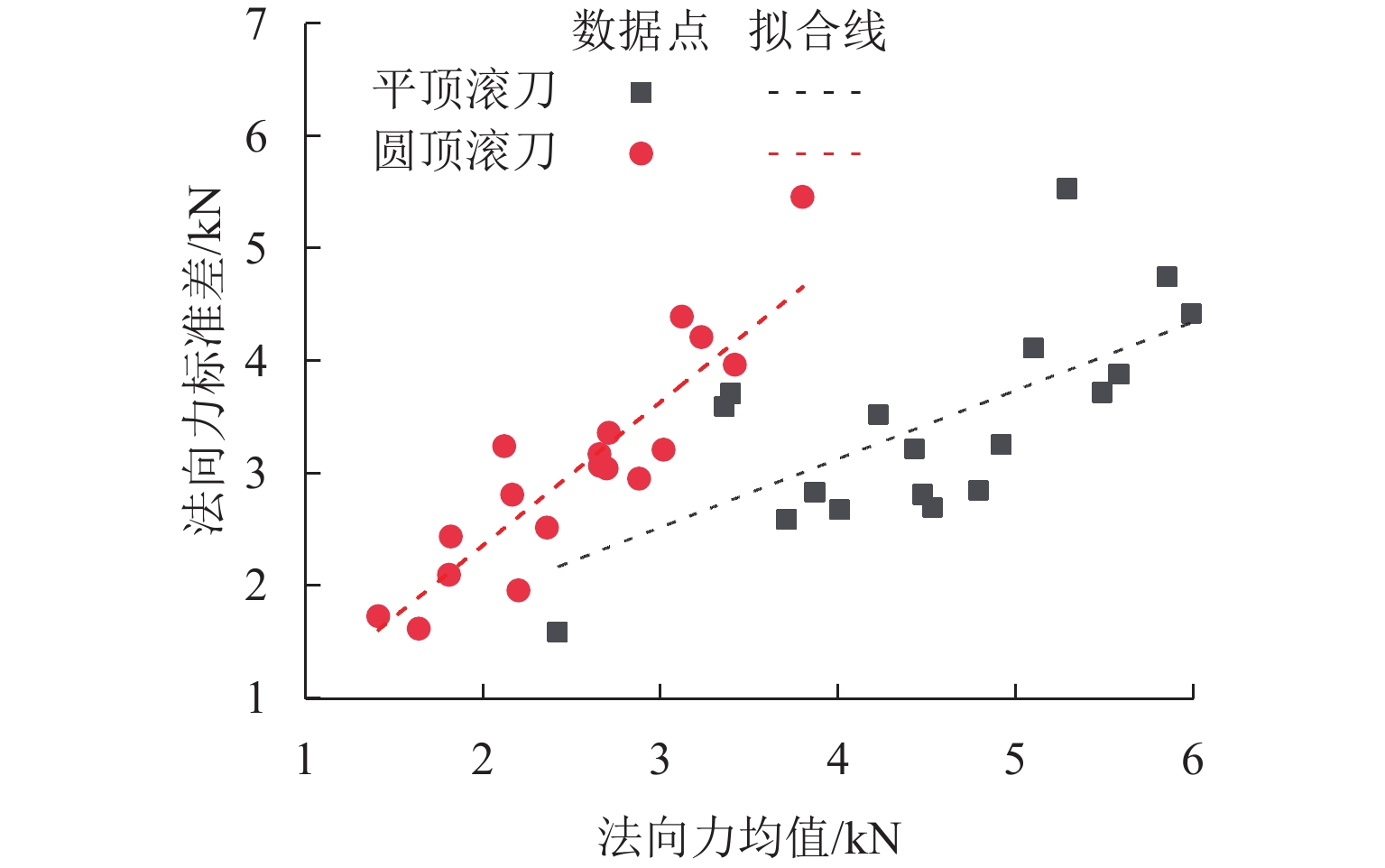

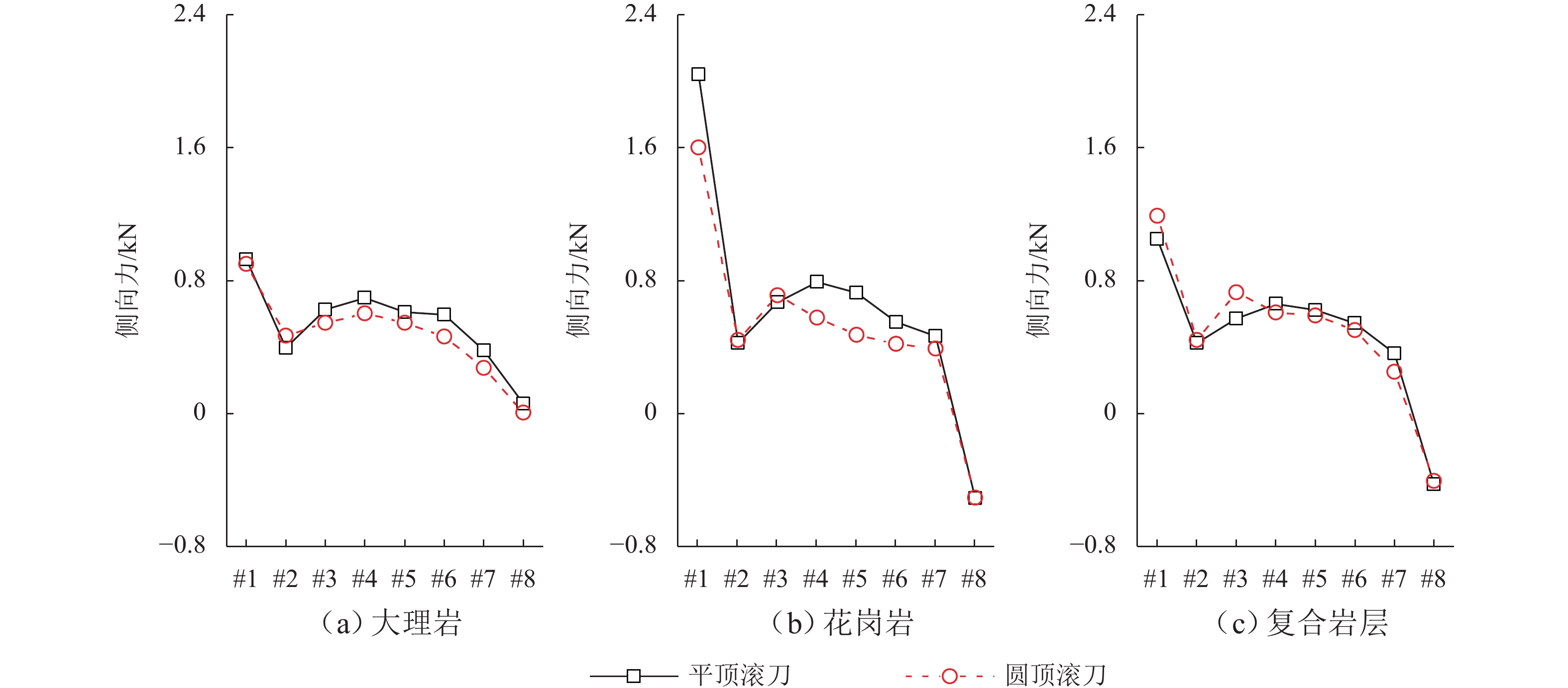

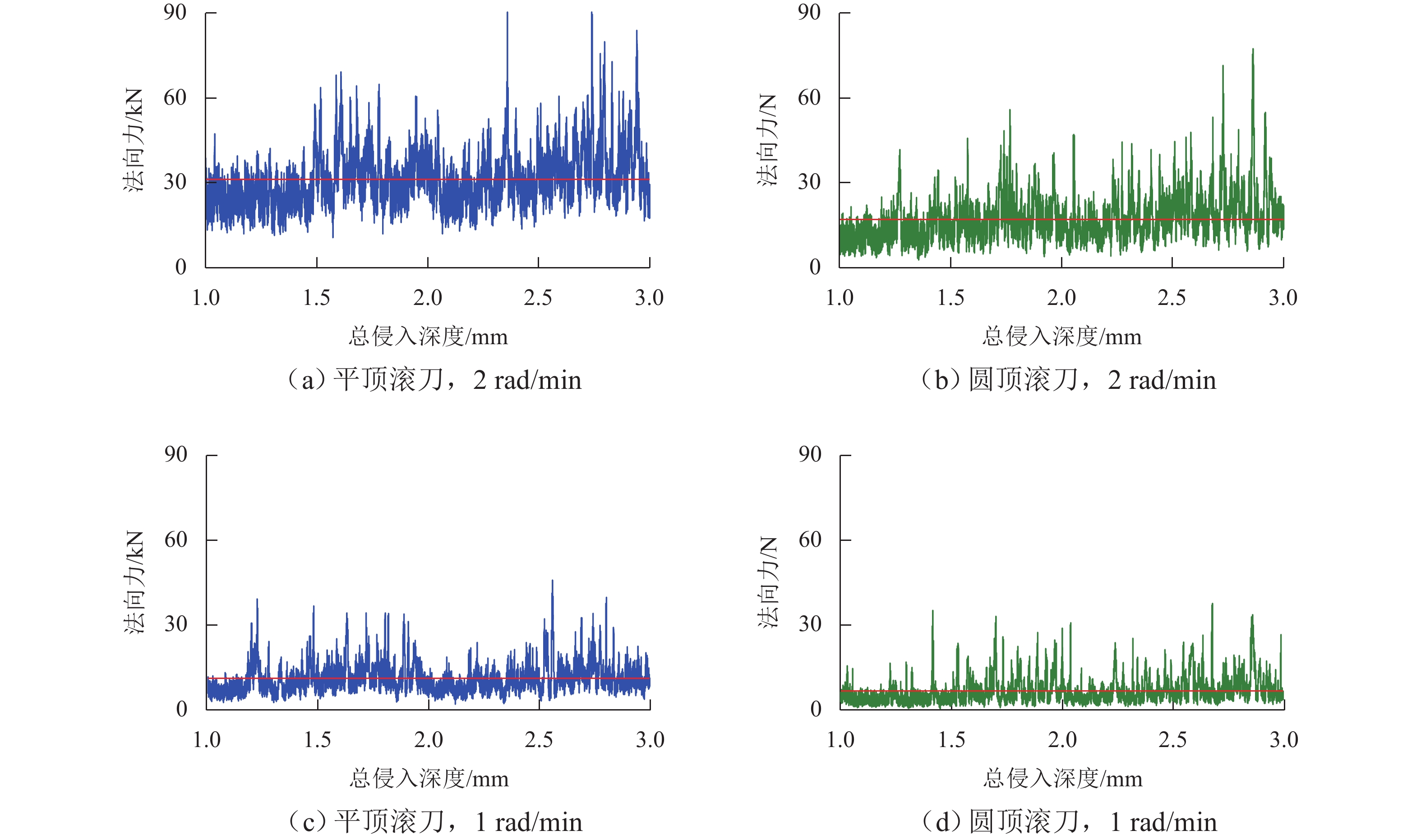

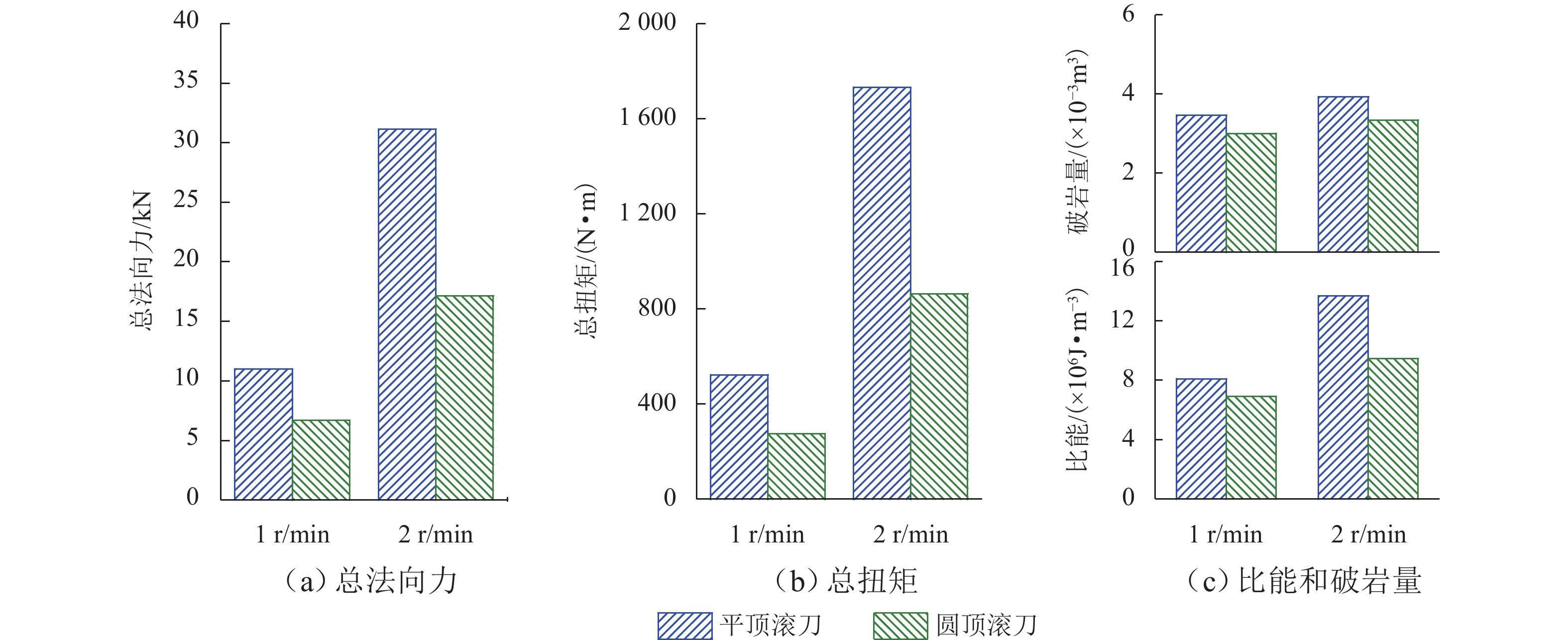

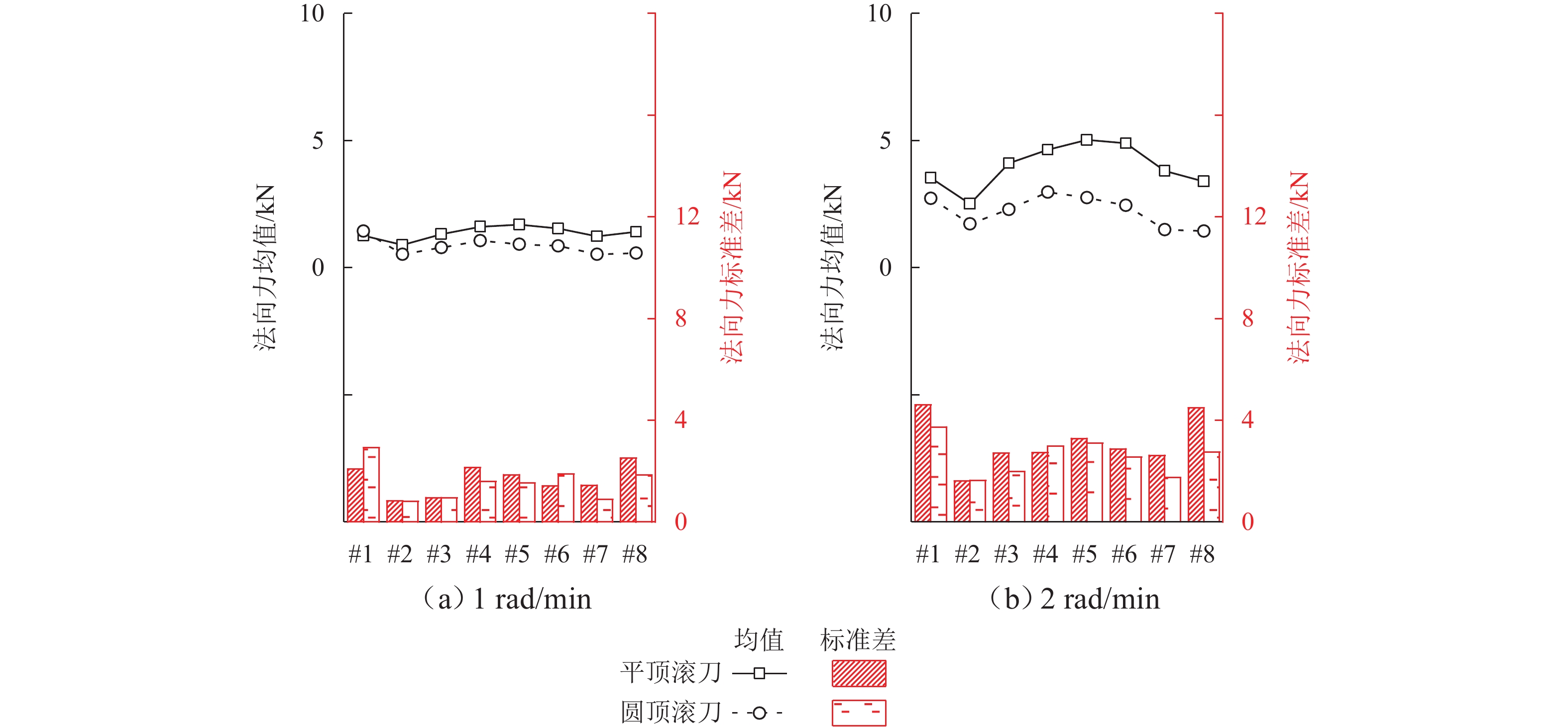

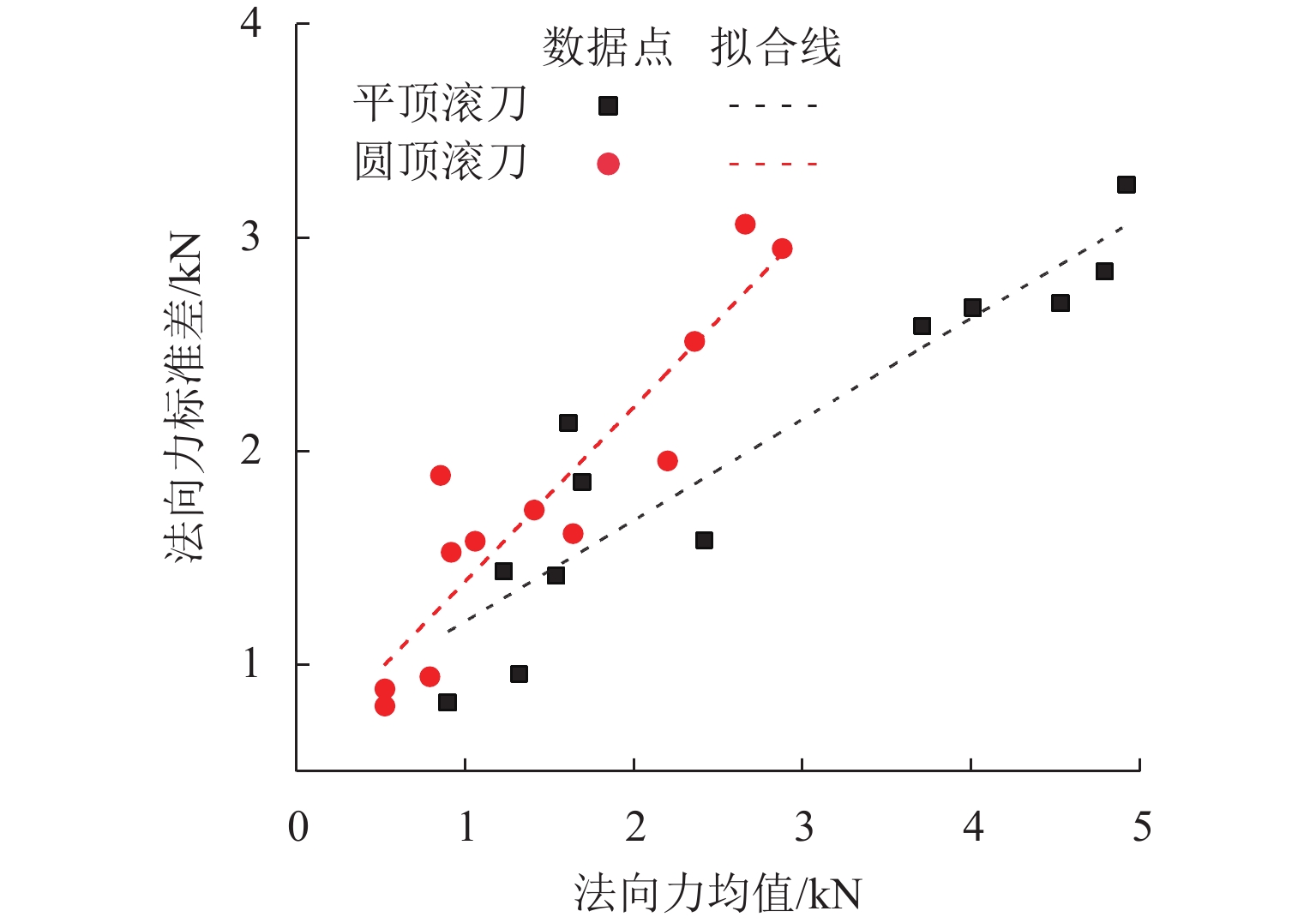

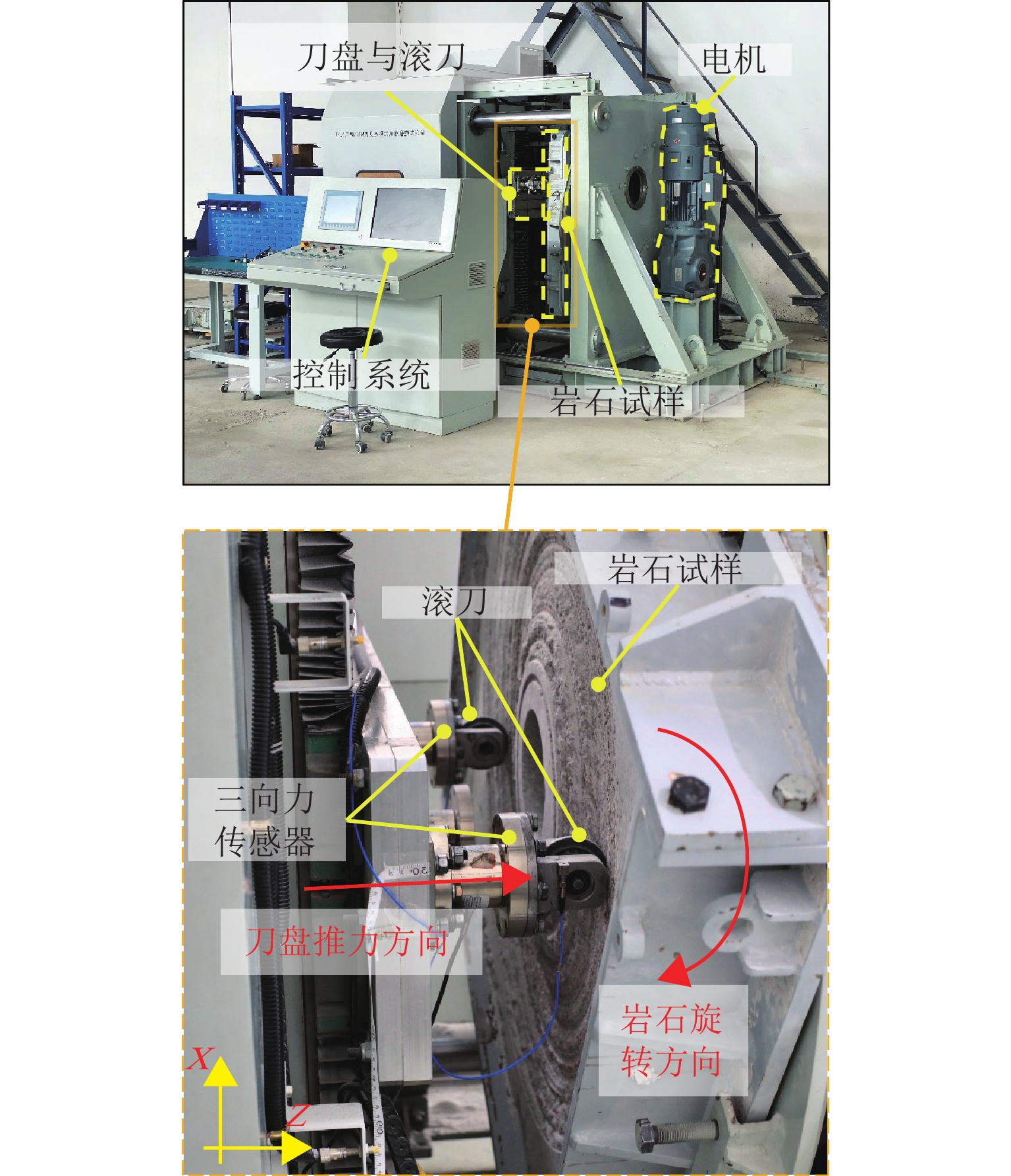

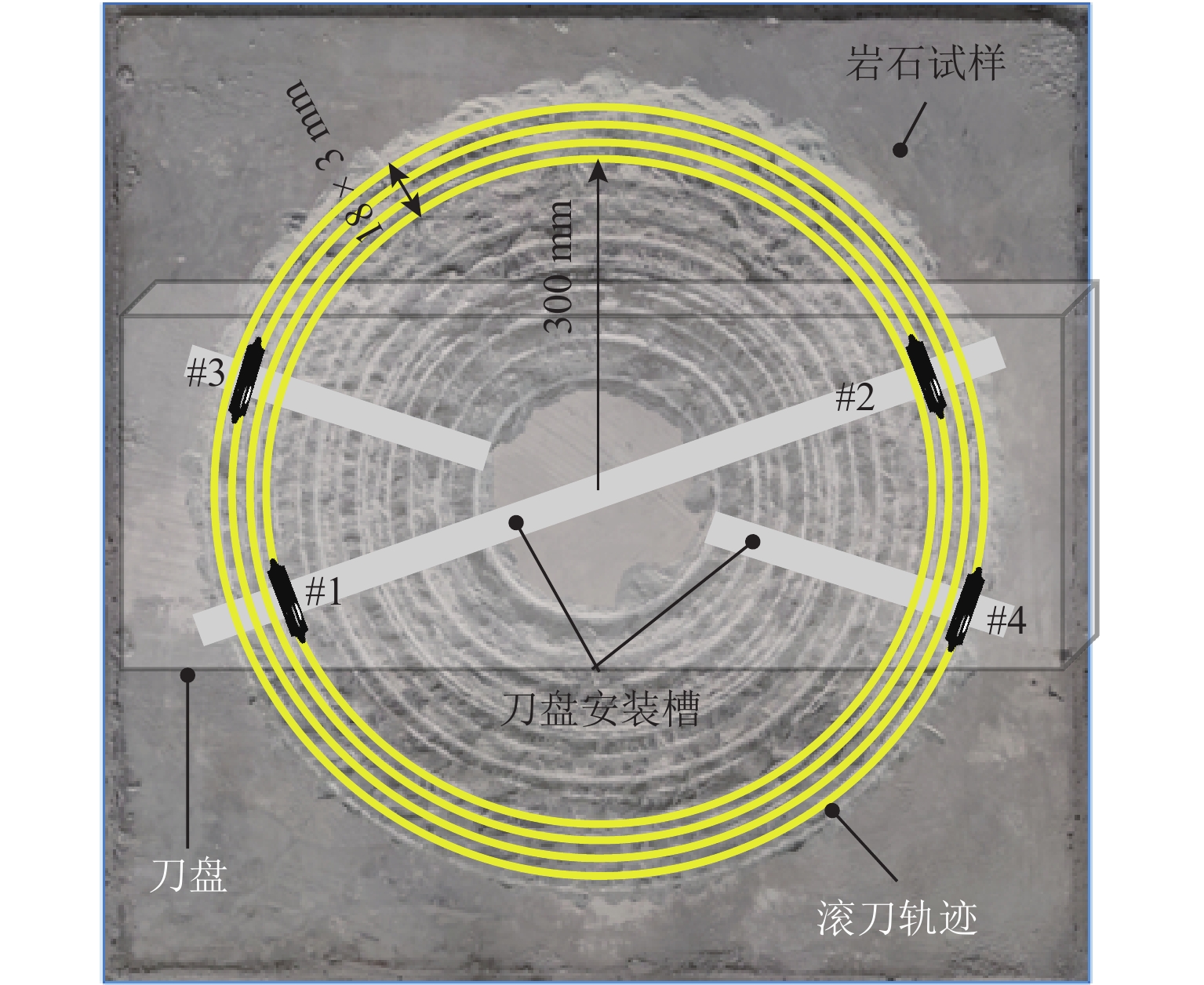

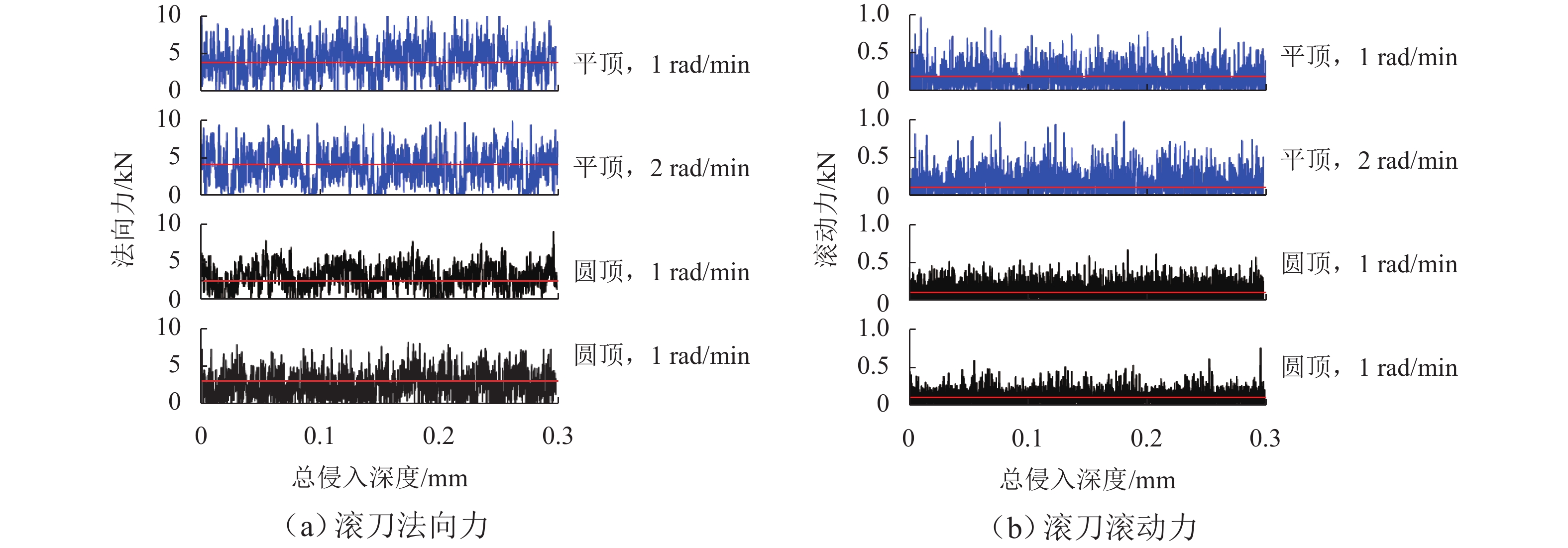

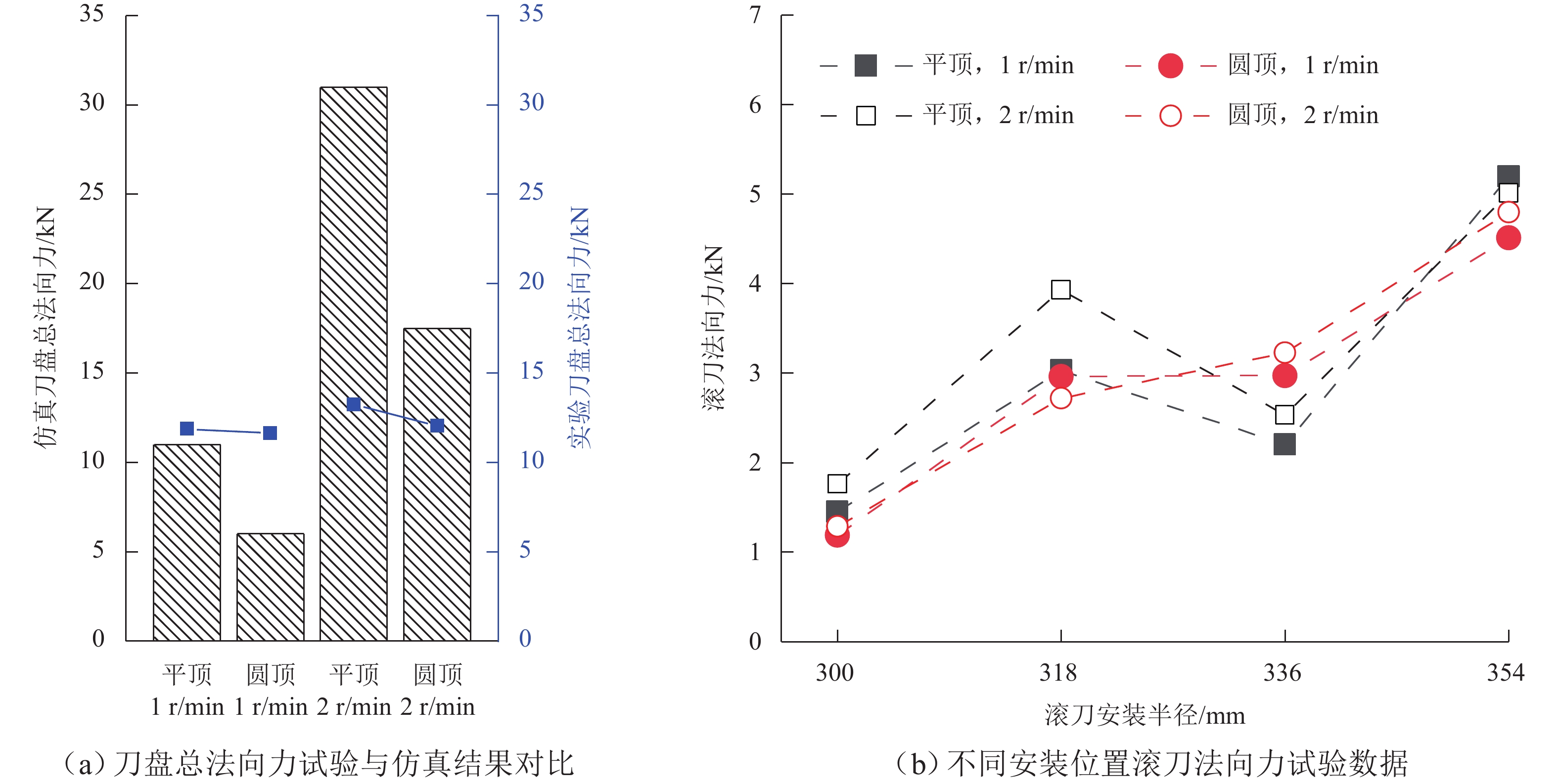

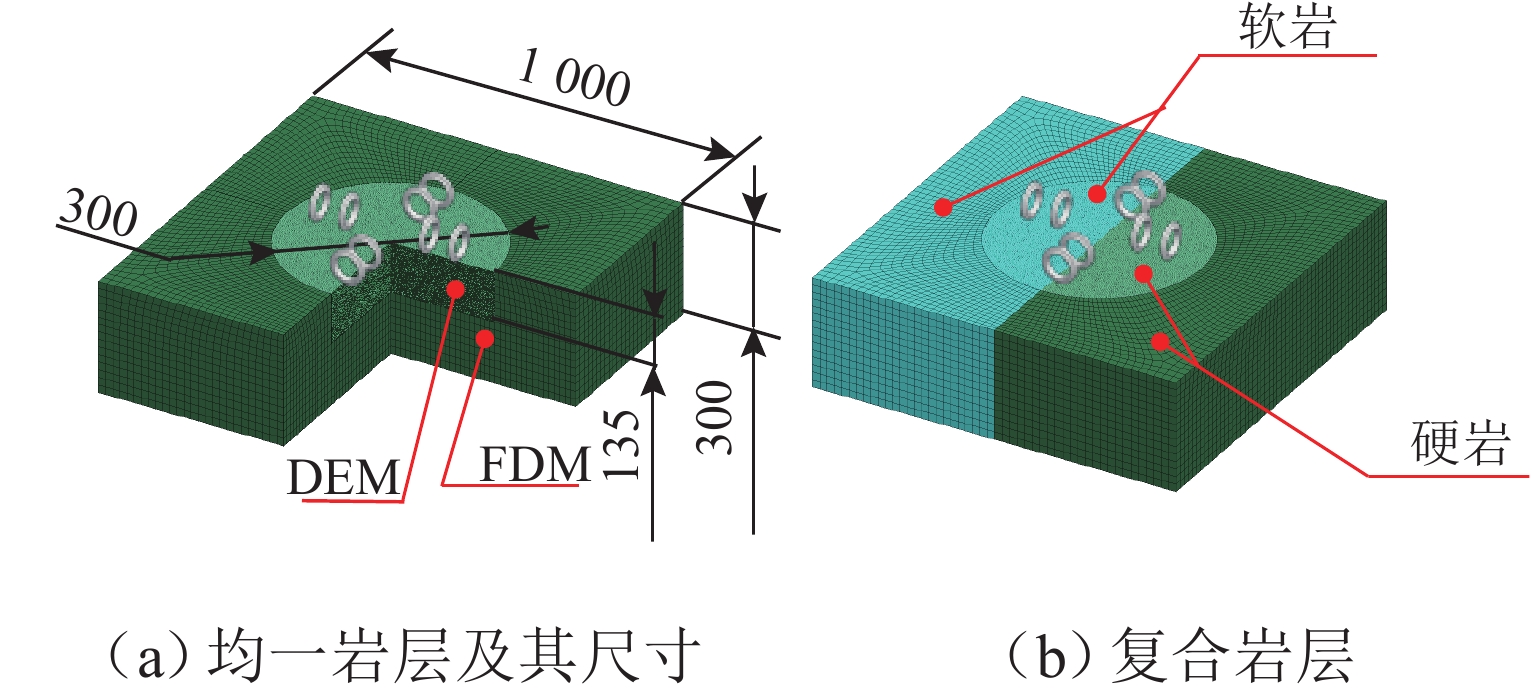

为保障全断面隧道掘进机(TBM,Tunnel Boring Machines)在复杂地形下安全、高效运行,需明确多滚刀协同破岩时滚刀的载荷特性,并分析各种刃形滚刀在不同地层中的性能表现. 为此,建立多滚刀协同破岩的颗粒流离散元数值模型,分析平顶、圆顶2种刃形滚刀在不同岩石强度、刀盘转速下的载荷特性,并通过多刀破岩试验对数值分析主要结果加以验证. 结果表明:在给定贯入度条件下,圆顶滚刀所需法向总推力较平顶滚刀低23%~50%,其破岩体积与比能亦低10%~20%;不同安装半径滚刀所受载荷有所差异,最内、最外侧滚刀仅与相邻单侧滚刀形成协同破岩作用,其切削力较邻刀高约30%,故滚刀切削力的均值与标准差随安装半径增大呈两端高、中间低的“W”形分布;2种刃形滚刀法向力的均值与标准差均呈正相关,但在相同法向推力水平下,平顶滚刀的法向力标准差较圆顶滚刀低37%~50%,表明圆顶滚刀可能引起更为剧烈的振动;此外,随刀盘转速的提高,2种滚刀的切削力均相应增大,其中平顶滚刀对转速变化更为敏感.

Abstract:To ensure the safe and efficient operation of full-face tunnel boring machines (TBMs) in complex terrains, it is essential to clarify the load characteristics of cutters in the multi-cutter collaborative rock-breaking condition and to analyze the performance of cutter profiles in different geological strata. Therefore, a numerical discrete element model based on the particle-flow method for the multi-cutter collaborative rock-breaking condition was established. The load characteristics of flat-tipped and circle-tipped cutters under varying rock strength and rotational speeds of cutterheads were investigated. Additionally, multi-cutter rock-breaking experiments were conducted to verify the accuracy of the numerical analysis results. The findings indicate that under a given penetration depth, the circle-tipped cutter exhibits a normal total thrust that is 23%−50% lower than that of the flat-tipped cutter, along with a reduction in rock-breaking volume and specific energy by 10%−20%. The load of cutters at different installation radii varies. The innermost and outermost cutters only collaborate in rock breaking with adjacent single-sided cutters, so the cutting force is approximately 30% higher than that of the adjacent cutter. Consequently, the mean and the standard deviation of cutting forces show a “W”-shaped distribution, with higher values at both ends and lower values in the middle as the installation radius increases. The mean and standard deviation of the normal forces for both cutter profiles are positively correlated. However, at the same level of normal thrust, the flat-tipped cutter exhibits a 37%−50% lower standard deviation of normal force, which means the circle-tipped cutter may lead to more severe vibrations. Additionally, the cutting forces for both types of cutters increase with an elevation in the rotational speed of the cutterhead. The flat-tipped cutter exhibits greater sensitivity to variations in the rotational speed.

-

Key words:

- tunnel boring machine /

- cutter /

- cutter profile /

- cutting force /

- discrete element

-

表 1 模拟与试验结果的对比

Table 1. Comparison between simulation and experiment results

岩石 项目 单轴抗压强度/MPa 单轴抗拉强度/MPa 杨氏模量/GPa 泊松比 大理岩 实验 69.8 69.8 129.6 130.0 仿真 6.95 8.1 7.9 19.2 花岗岩 实验 42.0 42.2 57.6 57.1 仿真 0.168 0.165 0.263 0.256 表 2 离散元模型细观参数

Table 2. Microscopic parameters of discrete element model

项目 细观参数 大理岩 花岗岩 颗粒属性 最小颗粒直径/mm 3.5 3.5 最大颗粒直径/mm 5.6 5.6 表观密度/(kg•m−3) 2654 2565 局部阻尼系数 0.7 0.7 线性组 有效模量/GPa 19.2 34.0 摩擦系数 0.4 0.5 刚度比 1.8 5.2 平行黏结组 黏结激活间隙/mm 0.35 0.35 半径乘子 1.0 1.0 有效模量/GPa 19.2 34.0 刚度比 1.8 5.2 弯矩贡献系数 1.0 1.0 抗拉强度均值/MPa 8.2 31.9 抗拉强度标准差/MPa 0.82 3.19 内聚力均值/MPa 41.0 159.5 内聚力标准差/MPa 4.1 16.0 -

[1] REN D J, SHEN S L, ARULRAJAH A, et al. Prediction model of TBM disc cutter wear during tunnelling in heterogeneous ground[J]. Rock Mechanics and Rock Engineering, 2018, 51(11): 3599-3611. doi: 10.1007/s00603-018-1549-3 [2] 刘泉声, 黄兴, 刘建平, 等. 深部复合地层围岩与TBM的相互作用及安全控制[J]. 煤炭学报, 2015, 40(6): 1213-1224. doi: 10.13225/j.cnki.jccs.2014.3041LIU Quansheng, HUANG Xing, LIU Jianping, et al. Interaction and safety control between TBM and deep mixed ground[J]. Journal of China Coal Society, 2015, 40(6): 1213-1224. doi: 10.13225/j.cnki.jccs.2014.3041 [3] LAWN B, WILSHAW R. Indentation fracture: principles and applications[J]. Journal of Materials Science, 1975, 10(6): 1049-1081. doi: 10.1007/BF00823224 [4] ALEHOSSEIN H, DETOURNAY E, HUANG H. An analytical model for the indentation of rocks by blunt tools[J]. Rock Mechanics and Rock Engineering, 2000, 33(4): 267-284. doi: 10.1007/s006030070003 [5] ROSTAMI J. Design optimization, performance prediction and economic analysis of tunnel boring machines for the construction of the proposed Yucca Mountain nuclear waste repository[D]. Golden: Colorado School of Mines , 1992. [6] ROSTAMI J. Development of a force estimation model for rock fragmentation with disc cutters through theoretical modeling and physical measurement of crushed zone pressure[D]. Golden: Colorado School of Mines , 1997. [7] 姚敏, 李旭, 原继东, 等. 基于TBM破岩数据的岩体条件深度学习表征方法[J]. 地球科学, 2023, 48(5): 1908-1922.YAO Min, LI Xu, YUAN Jidong, et al. Deep learning characterization method of rock mass conditions based on TBM rock breaking data[J]. Earth Science, 2023, 48(5): 1908-1922. [8] 侯少康, 刘耀儒, 张凯. 基于IPSO-BP混合模型的TBM掘进参数预测[J]. 岩石力学与工程学报, 2020, 39(8): 1648-1657. doi: 10.13722/j.cnki.jrme.2019.1084HOU Shaokang, LIU Yaoru, ZHANG Kai. Prediction of TBM tunnelling parameters based on IPSO‐BP hybrid model[J]. Chinese Journal of Rock Mechanics and Engineering, 2020, 39(8): 1648-1657. doi: 10.13722/j.cnki.jrme.2019.1084 [9] CHEN Z Y, ZHANG Y P, LI J B, et al. Diagnosing tunnel collapse sections based on TBM tunneling big data and deep learning: a case study on the Yinsong Project, China[J]. Tunnelling and Underground Space Technology, 2021, 108: 103700. doi: 10.1016/j.tust.2020.103700 [10] LIN L K. Rock-breaking characteristics of TBM gage disc cutters and sensitivity analysis of their influencing factors[J]. Journal of Mechanical Engineering, 2018, 54(1): 18-26. doi: 10.3901/JME.2018.01.018 [11] DENG L C, ZHANG F B, LI X Z, et al. Experimental and numerical investigations on rock breaking of TBM disc cutter based on a novel platform with rotational cutting[J]. Rock Mechanics and Rock Engineering, 2023, 56(2): 1415-1436. doi: 10.1007/s00603-022-03147-5 [12] 黄鸿颖, 管会生, 母国旺, 等. 竖井全断面掘进机异型刀盘的滚刀布局[J]. 西南交通大学学报, 2025, 60(3): 704-713, 730.HUANG Hongying, GUAN Huisheng, MU Guowang, et al. Cutter layout on special-shaped cutterhead for shaft boring machine[J]. Journal of Southwest Jiaotong University, 2025, 60(3): 704-713,730. [13] ZHANG X H, XIA Y M, ZENG G Y, et al. Numerical and experimental investigation of rock breaking method under free surface by TBM disc cutter[J]. Journal of Central South University, 2018, 25(9): 2107-2118. doi: 10.1007/s11771-018-3900-y [14] ZHANG X H, HU D B, LI J M, et al. Investigation of rock breaking mechanism with TBM hob under traditional and free-face condition[J]. Engineering Fracture Mechanics, 2021, 242: 107432. doi: 10.1016/j.engfracmech.2020.107432 [15] 蒋明镜, 傅程, 王华宁, 等. 简单复合岩体中TBM多滚刀破岩机理离散元分析[J]. 土木工程学报, 2019, 52(增1): 120-126.JIANG Mingjing, FU Cheng, WANG Huaning, et al. Distinct element analysis of mechanism of rock fragmentation induced by TBM cutting in simply composite rock mass with multiple cutters[J]. China Civil Engineering Jjournal, 2019, 52(S1): 120-126. [16] 温森, 周书宇, 盛桂琳. 复合岩层中滚刀旋转切割破岩效率试验研究[J]. 岩土力学, 2019, 40(7): 2628-2636. doi: 10.16285/j.rsm.2018.1321WEN Sen, ZHOU Shuyu, SHENG Guilin. Experiments on the efficiency of rock fragmentation by rotary cutting in composite rock strata[J]. Rock and Soil Mechanics, 2019, 40(7): 2628-2636. doi: 10.16285/j.rsm.2018.1321 [17] LI T, ZHANG Z Y, JIA C T, et al. Investigating the cutting force of disc cutter in multi-cutter rotary cutting of sandstone: Simulations and experiments[J]. International Journal of Rock Mechanics and Mining Sciences, 2022, 152: 105069. doi: 10.1016/j.ijrmms.2022.105069 [18] GOU B, ZHANG M Q. Effects of surface grooves on rock cutting performance and contact behavior of a TBM disc cutter[J]. Engineering Fracture Mechanics, 2022, 267: 108466. doi: 10.1016/j.engfracmech.2022.108466 [19] 袁聚云, 蒋明镜, 廖优斌, 等. 全断面隧道掘进机滚刀破岩尺寸效应离散元分析[J]. 同济大学学报(自然科学版), 2017, 45(10): 1437-1445.YUAN Juyun, JIANG Mingjing, LIAO Youbin, et al. Discrete element method analysis of rock failure mechanism considering scale effects of tunnel boring machine cutter[J]. Journal of Tongji University (Natural Science), 2017, 45(10): 1437-1445. [20] 中华人民共和国住房和城乡建设部. 工程岩体试验方法标准: GBT 50266-2013[S]. 北京: 中国计划版社, 2013. [21] YOON J. Application of experimental design and optimization to PFC model calibration in uniaxial compression simulation[J]. International Journal of Rock Mechanics and Mining Sciences, 2007, 44(6): 871-889. doi: 10.1016/j.ijrmms.2007.01.004 [22] WANG Y N, TONON F. Modeling Lac du Bonnet granite using a discrete element model[J]. International Journal of Rock Mechanics and Mining Sciences, 2009, 46(7): 1124-1135. doi: 10.1016/j.ijrmms.2009.05.008 [23] YANG B D, JIAO Y, LEI S T. A study on the effects of microparameters on macroproperties for specimens created by bonded particles[J]. Engineering Computations, 2006, 23(6): 607-631. doi: 10.1108/02644400610680333 -

下载:

下载: