Axle-Box Bearing Fault Diagnosis of Railway Vehicle Based on Enhanced Time-Varying Morphological Filtering

-

摘要:

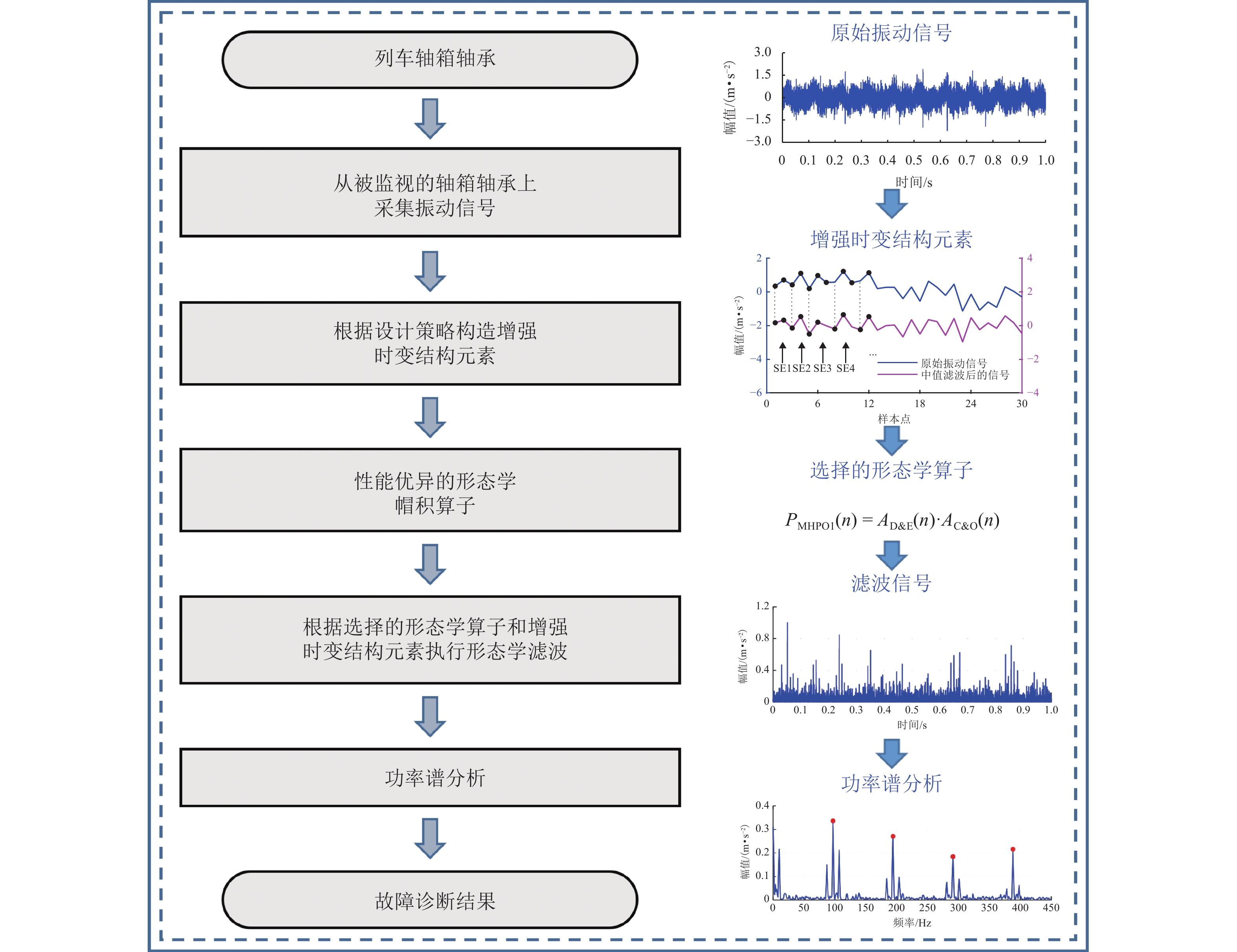

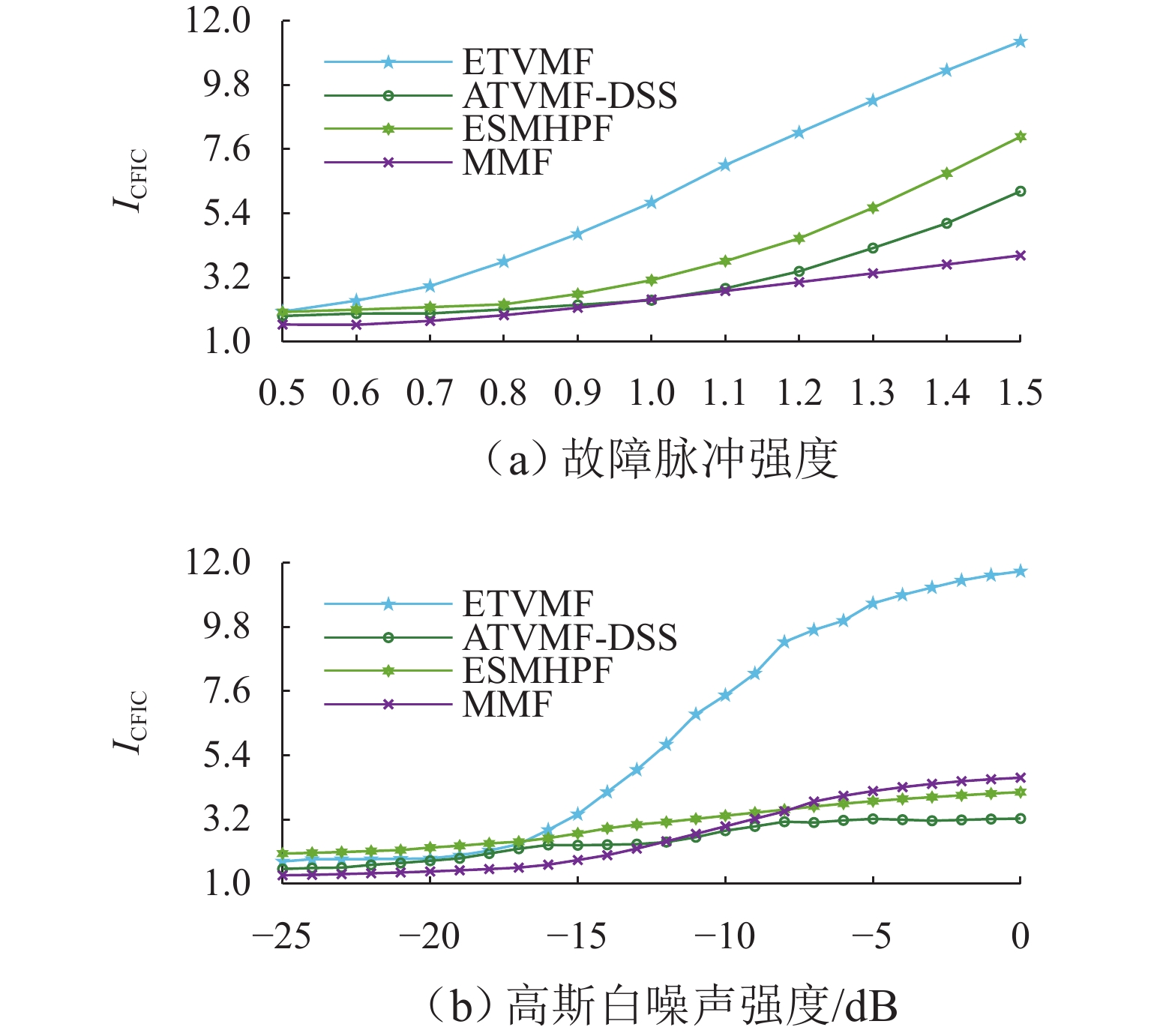

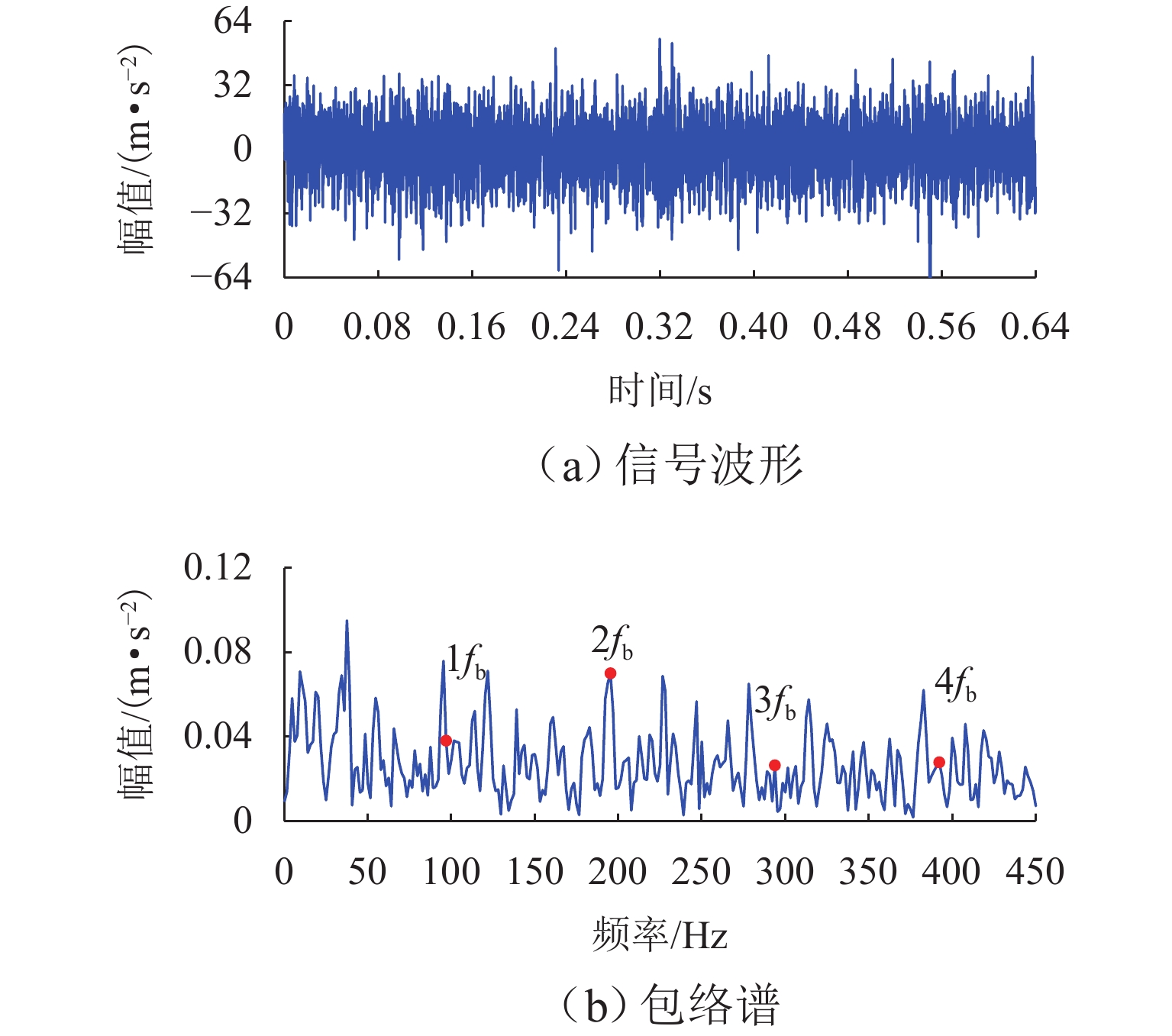

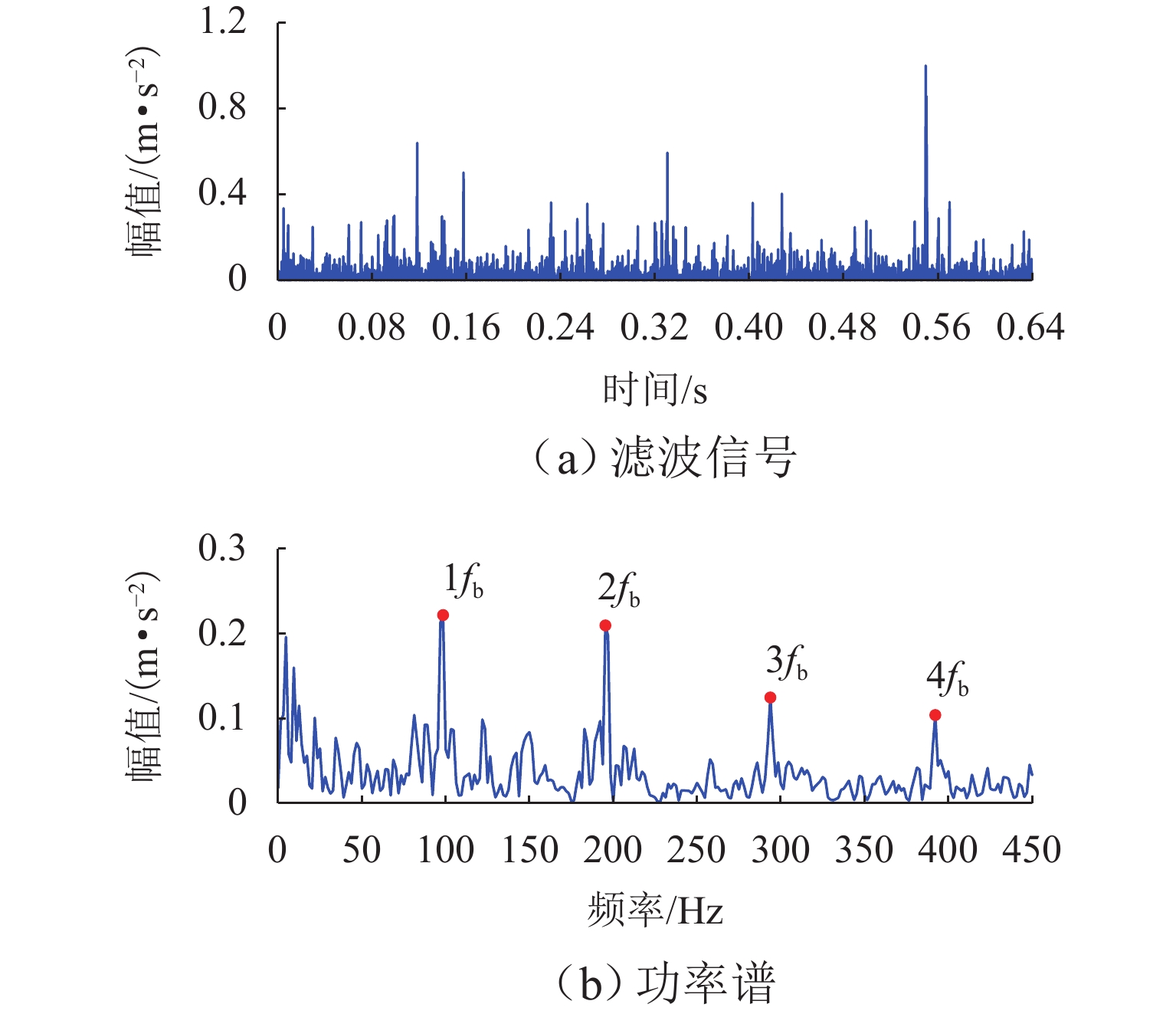

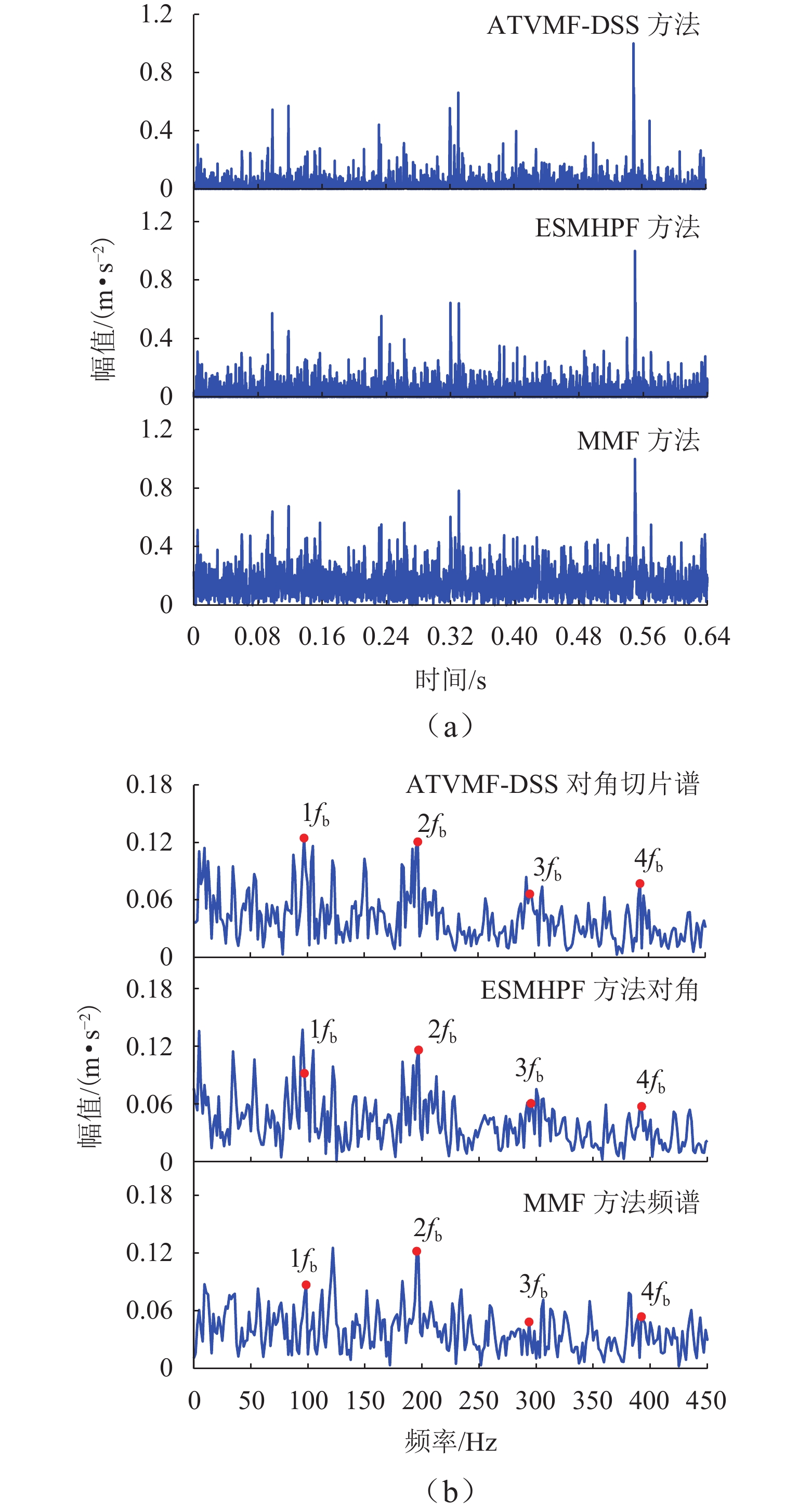

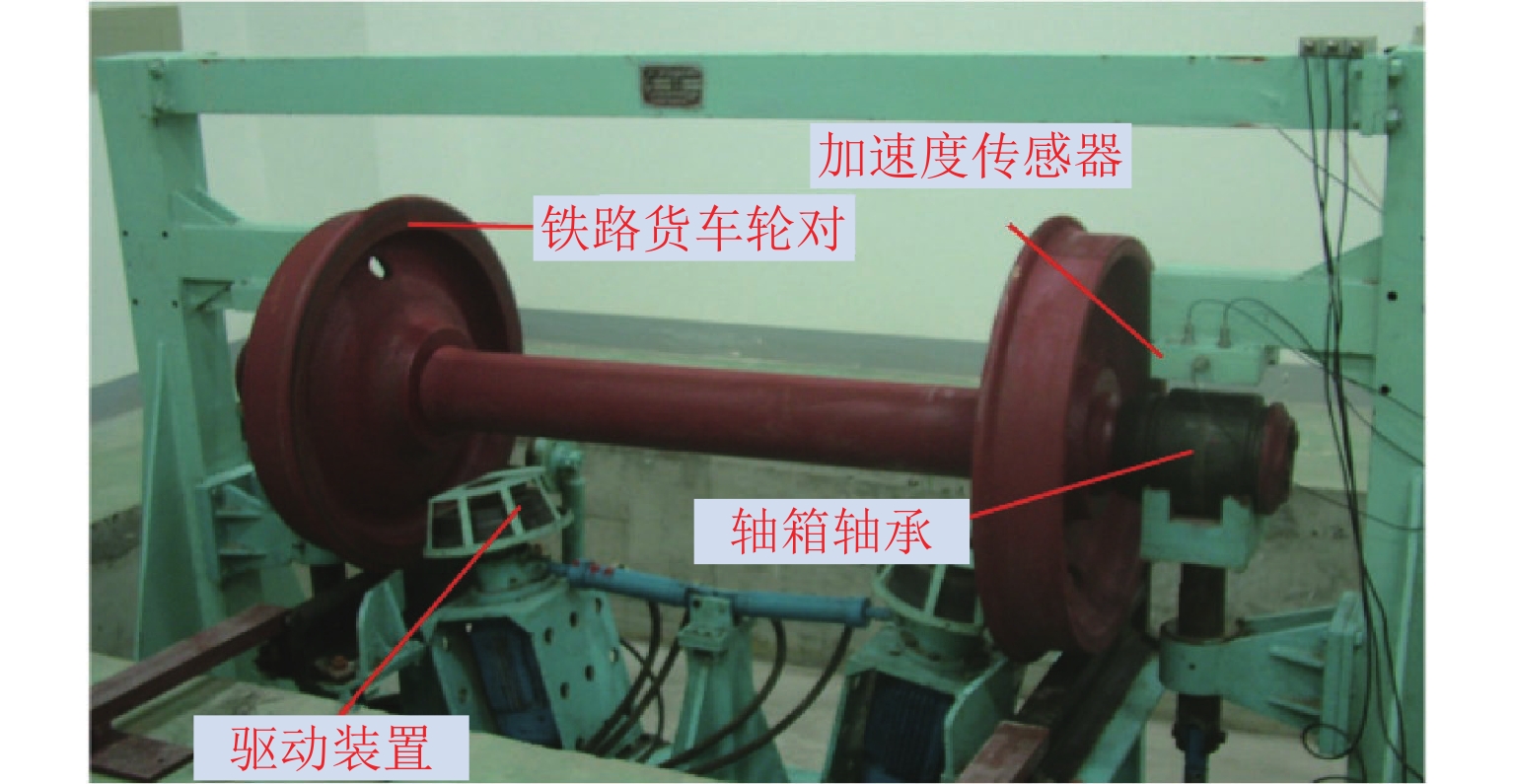

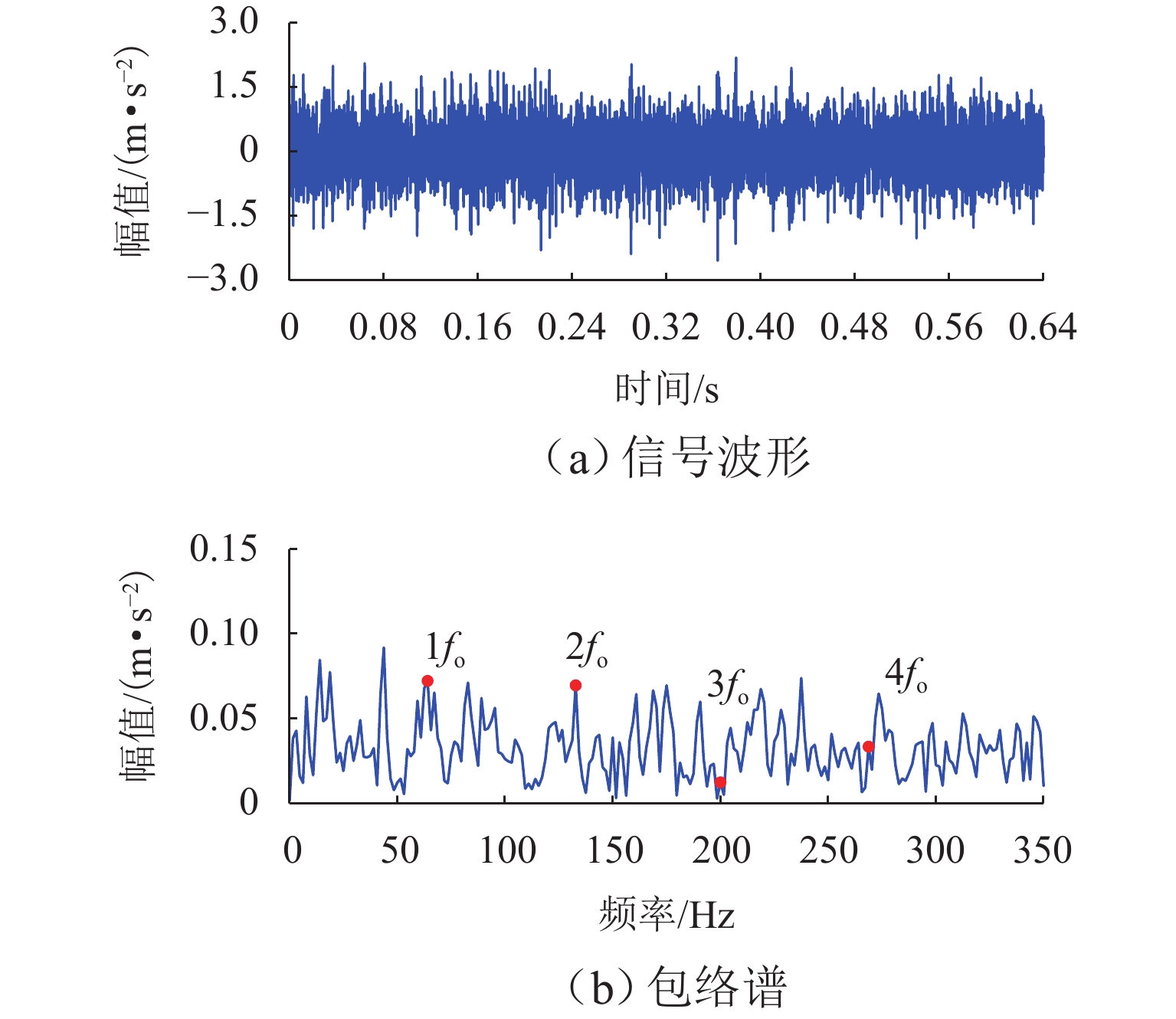

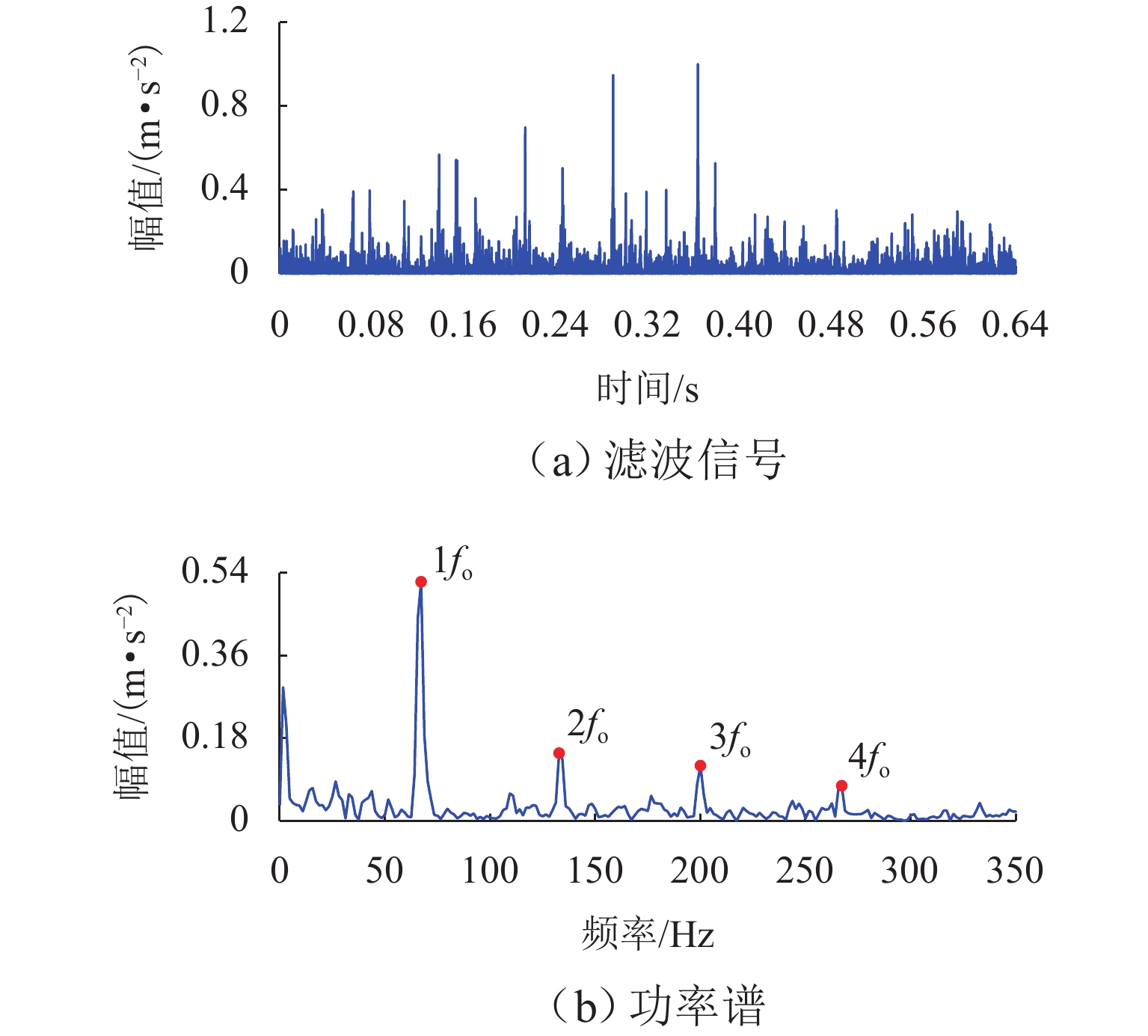

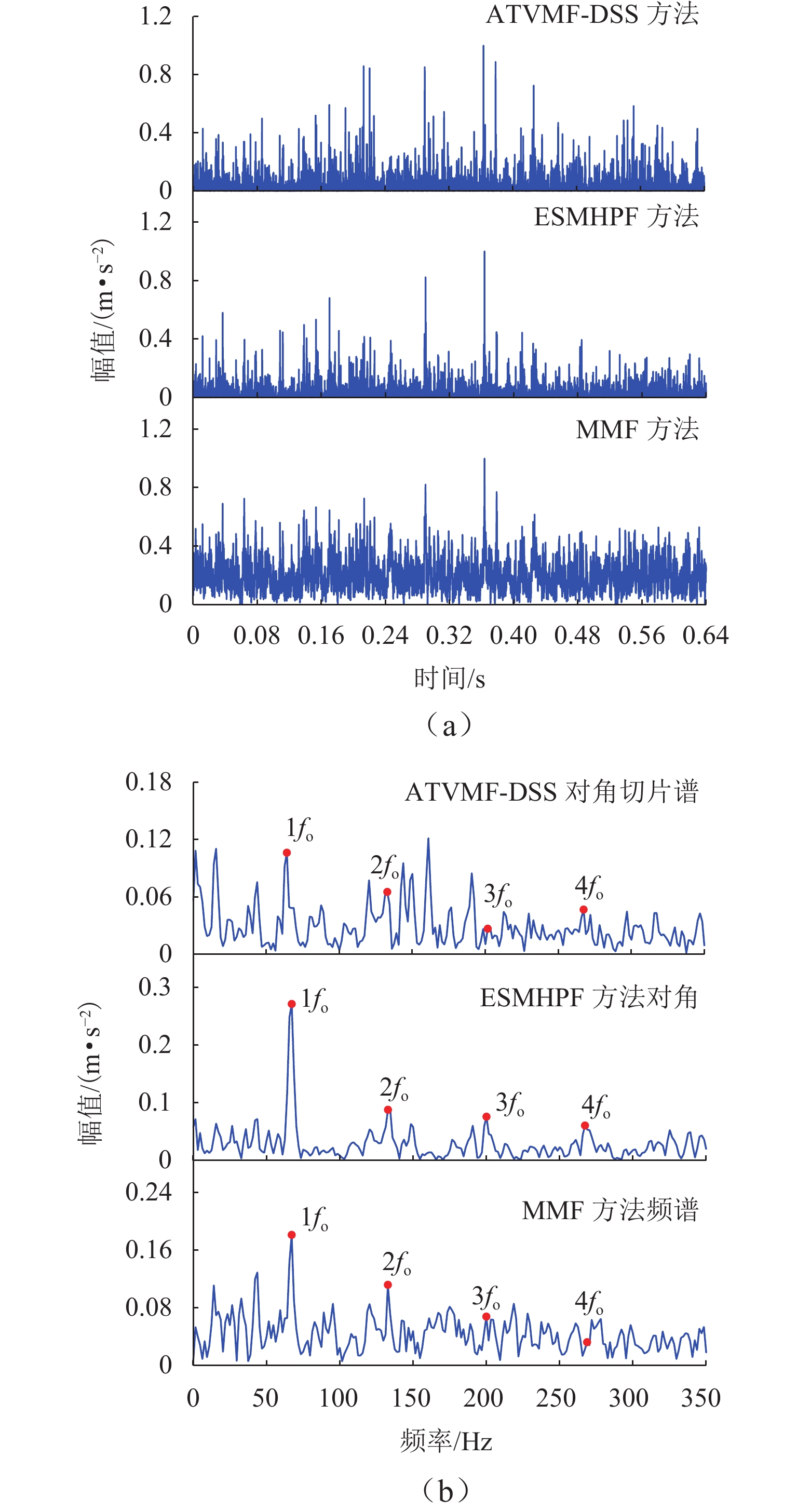

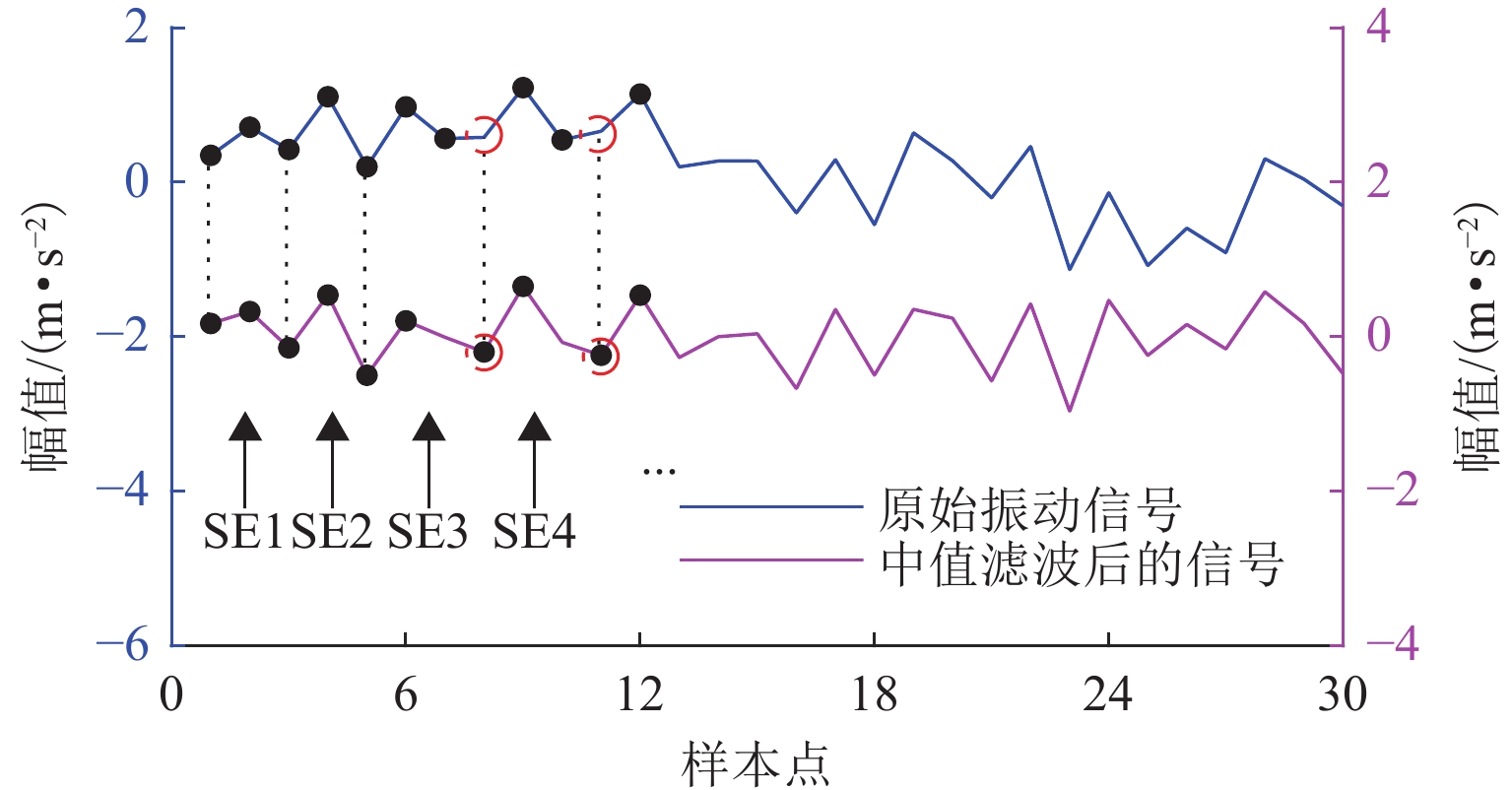

形态学滤波是一种用于轴承故障诊断的有效方法,能够从嘈杂的振动信号中恢复瞬态脉冲特征,其中结构元素形状和长度的选择对形态学滤波性能有着至关重要的影响. 为解决这个问题,提出一种基于中值滤波的增强时变结构元素,以更准确地匹配和提取隐藏在嘈杂信号中的周期性瞬态特征;此外,将功率谱(即自相关信号的频谱)应用于滤波信号,以进一步增强故障相关分量并消除宽带噪声污染;最后,提出一种结合增强时变结构元素和功率谱的轴承故障诊断方法——增强时变形态学滤波. 对仿真数据和2个铁路轴箱轴承试验台测量数据的分析结果表明:相较于对比方法,增强时变形态学滤波具有优异的故障特征提取性能,能够在复杂噪声干扰下准确识别轴承的内圈、外圈和滚动体故障,并取得更高的性能量化指标和更少的计算消耗.

Abstract:Morphological filtering (MF) is an effective method for bearing fault diagnosis with the capacity of recovering transient impulse features from noisy vibration signals, in which the choice of shape and length of structural element has an important impact on MF performance. To solve this problem, an enhanced time-varying structural element (ETVSE) based on median filtering was proposed to more accurately match and extract periodic transient features hidden in noisy signals. Moreover, the power spectrum (i.e., the frequency spectrum of autocorrelation signal) was applied to the filtered signal to further enhance fault-related components and eliminate broadband noise pollution. Finally, a bearing fault diagnosis method called enhanced time-varying morphological filtering (ETVMF) was developed, which combined the advantages of ETVSE and power spectrum. The analysis results of simulated data and measured data of two railway axle-box bearing test rigs show that, compared with the compared method, ETVMF demonstrates superior fault feature extraction performance and can accurately identify bearing inner race, outer race, and rolling element faults under complex noise interference, while obtaining higher performance quantification index and lower calculation cost.

-

表 1 基本形态学算子

Table 1. Basic morphological operators

算子 定义 膨胀 $ (f \oplus g)(n) = \mathop {\max }\limits_{0 \leqslant m \leqslant M - 1} [f(n - m) + g(m)] $ 腐蚀 $ (f\Theta g)(n) = \mathop {\min }\limits_{0 \leqslant m \leqslant M - 1} [f(n + m) - g(m)] $ 开 $ (f \circ g)(n) = (f\Theta g \oplus g)(n) $ 闭 $ (f \cdot g)(n)=(f\oplus g\Theta g)(n) $ 开-闭 $ {F}_{\text{OC}}(n)=(f\circ g \cdot g)(n) $ 闭-开 $ {F}_{\text{CO}}(n)=(f \cdot g\circ g)(n) $ 表 2 不同方法的CFIC比较

Table 2. Comparison of CFICs of different methods

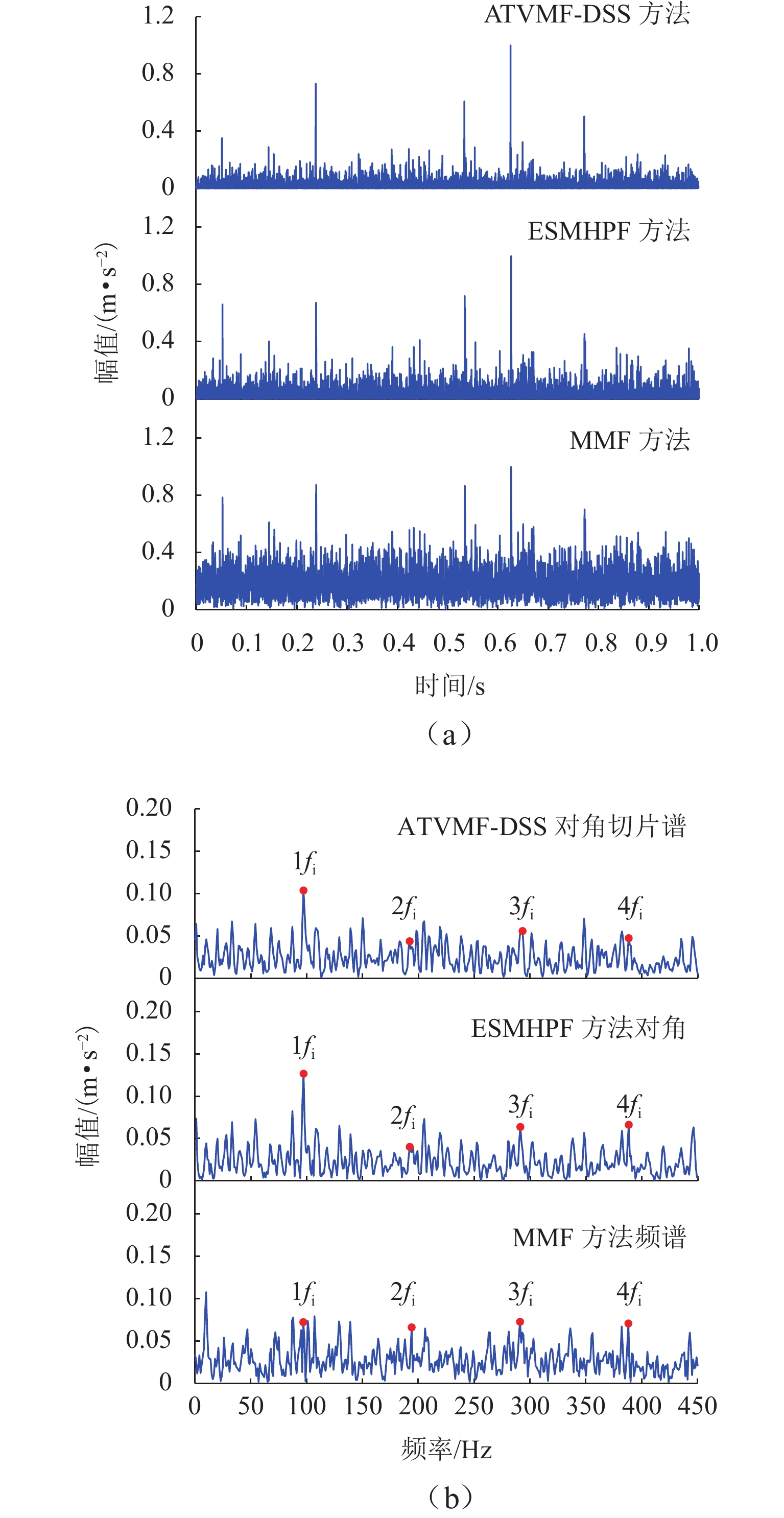

故障类型 ETVMF ATVMF-DSS MSMHPF MMF 内圈故障 5.776 2.429 3.116 2.455 滚动体故障 4.425 2.297 1.937 1.929 外圈故障 6.551 1.544 4.318 2.148 表 3 不同方法的Hoyer测度比较

Table 3. Comparison of Hoyer measure of different methods

故障类型 ETVMF ATVMF-DSS MSMHPF MMF 内圈故障 0.977 0.620 0.663 0.689 滚动体故障 0.875 0.763 0.762 0.723 外圈故障 0.971 0.662 0.864 0.773 表 4 不同方法的频域信噪比比较

Table 4. Comparison of frequency-domain signal-to-noise ratios of different methods

故障类型 ETVMF ATVMF-DSS MSMHPF MMF 内圈故障 1.458 0.549 0.511 0.335 滚动体故障 0.952 0.667 0.564 0.354 外圈故障 2.049 0.148 0.779 0.402 表 5 不同方法的计算效率比较

Table 5. Comparison of computational efficiencies of different methods

s 故障类型 ETVMF ATVMF-DSS MSMHPF MMF 内圈故障 0.363 1.978 269.142 0.012 滚动体故障 0.257 0.730 98.700 0.011 外圈故障 0.218 0.795 162.544 0.008 -

[1] 惠昌武, 许得杰, 巩亮, 等. 基于主成分分析法的城轨运营安全评价指标体系研究[J]. 都市快轨交通, 2024, 37(2): 131-138.HUI Changwu, XU Dejie, GONG Liang, et al. Urban rail operation safety evaluation index system based on principal component analysis method[J]. Urban rapid rail transit, 2024, 37(2): 131-138. [2] 赵晗, 尹恩华, 李伯男. 城市轨道交通站台门智能运维系统研究[J]. 都市快轨交通, 2023, 36(2): 156-161.ZHAO Han, YIN Enhua, LI Bonan. Intelligent operation and maintenance system for the urban rail transit platform gate[J]. Urban rapid rail transit, 2023, 36(2): 156-161. [3] 刘志亮, 潘登, 左明健, 等. 轨道车辆故障诊断研究进展[J]. 机械工程学报, 2016, 52(14): 134-146. doi: 10.3901/JME.2016.14.134LIU Zhiliang, PAN Deng, ZUO Mingjian, et al. A review on fault diagnosis for rail vehicles[J]. Journal of Mechanical Engineering, 2016, 52(14): 134-146. doi: 10.3901/JME.2016.14.134 [4] CHENG Y, WANG S B, CHEN B Y, et al. An improved envelope spectrum via candidate fault frequency optimization-gram for bearing fault diagnosis[J]. Journal of Sound and Vibration, 2022, 523: 116746. doi: 10.1016/j.jsv.2022.116746 [5] 易彩, 林建辉, 汪浩, 等. VMD引导的轮对与轴承复合故障诊断方法[J]. 西南交通大学学报, 2024, 59(1): 151-159.YI Cai, LIN Jianhui, WANG Hao, et al. Compound fault diagnosis method guided by variational mode decomposition for wheelsets and bearings[J]. Journal of Southwest Jiaotong University, 2024, 59(1): 151-159. [6] 刘志强, 龚廷恺, 陈萍, 等. 多尺度形态滤波在行星轮轴承故障诊断的应用[J]. 振动与冲击, 2023, 42(10): 103-111, 187.LIU Zhiqiang, GONG Tingkai, CHEN Ping, et al. Application of multiscale morphological filter in fault diagnosis of planetary bearing[J]. Journal of Vibration and Shock, 2023, 42(10): 103-111, 187. [7] 韩笑乐, 胡天中, 余建波. 基于自适应加权多尺度组合形态滤波的轴承故障特征提取研究[J]. 振动与冲击, 2020, 39(1): 245-252.HAN Xiaole, HU Tianzhong, YU Jianbo. Feature extraction of bearing faults based on adaptive weighted multi-scale combination morphological filtering[J]. Journal of Vibration and Shock, 2020, 39(1): 245-252. [8] CHEN B Y, SONG D L, ZHANG W H, et al. A performance enhanced time-varying morphological filtering method for bearing fault diagnosis[J]. Measurement, 2021, 176: 109163. doi: 10.1016/j.measurement.2021.109163 [9] ZHANG L J, XU J W, YANG J H, et al. Multiscale morphology analysis and its application to fault diagnosis[J]. Mechanical Systems and Signal Processing, 2008, 22(3): 597-610. doi: 10.1016/j.ymssp.2007.09.010 [10] LI Y F, LIANG X H, ZUO M J. A new strategy of using a time-varying structure element for mathematical morphological filtering[J]. Measurement, 2017, 106: 53-65. doi: 10.1016/j.measurement.2017.04.032 [11] LI Y F, LIANG X H, ZUO M J. Diagonal slice spectrum assisted optimal scale morphological filter for rolling element bearing fault diagnosis[J]. Mechanical Systems and Signal Processing, 2017, 85: 146-161. doi: 10.1016/j.ymssp.2016.08.019 [12] ZHAO S Y, CHEN C Z, LUO Y Q. Probabilistic principal component analysis assisted new optimal scale morphological top-hat filter for the fault diagnosis of rolling bearing[J]. IEEE Access, 2020, 8: 156774-156791. doi: 10.1109/ACCESS.2020.3019638 [13] DENG F Y, YANG S P, TANG G J, et al. Self adaptive multi-scale morphology AVG-Hat filter and its application to fault feature extraction for wheel bearing[J]. Measurement Science and Technology, 2017, 28(4): 045011. doi: 10.1088/1361-6501/aa5c2a [14] YAN X A, JIA M P, ZHANG W, et al. Fault diagnosis of rolling element bearing using a new optimal scale morphology analysis method[J]. ISA Transactions, 2018, 73: 165-180. doi: 10.1016/j.isatra.2018.01.004 [15] LI Y F, ZUO M J, CHEN Y J, et al. An enhanced morphology gradient product filter for bearing fault detection[J]. Mechanical Systems and Signal Processing, 2018, 109: 166-184. doi: 10.1016/j.ymssp.2018.03.002 [16] CHEN B Y, CHENG Y, ZHANG W H, et al. Investigation on enhanced mathematical morphological operators for bearing fault feature extraction[J]. ISA Transactions, 2022, 126: 440-459. doi: 10.1016/j.isatra.2021.07.027 [17] 赵思雨, 陈长征, 罗园庆, 等. 基于增强组合差分形态滤波器的大型风力机轴承故障诊断[J]. 太阳能学报, 2021, 42(7): 424-430.ZHAO Siyu, CHEN Changzheng, LUO Yuanqing, et al. Fault diagnosis of large-scale wind turbine bearing based on enhanced combination gradient morphological filter[J]. Acta Energiae Solaris Sinica, 2021, 42(7): 424-430. [18] 徐先峰, 赵卫峰, 邹浩泉, 等. 增强组合差分乘积形态学滤波的轴承故障特征提取方法[J]. 重庆大学学报, 2024, 47(3): 96-106.XU Xianfeng, ZHAO Weifeng, ZOU Haoquan, et al. Bearing fault feature extraction method based on enhanced combination difference multiply morphological filter[J]. Journal of Chongqing University, 2024, 47(3): 96-106. [19] HU A J, XIANG L. Selection principle of mathematical morphological operators in vibration signal processing[J]. Journal of Vibration and Control, 2016, 22(14): 3157-3168. doi: 10.1177/1077546314560783 [20] ZHAO M, LIN J, MIAO Y H, et al. Detection and recovery of fault impulses via improved harmonic product spectrum and its application in defect size estimation of train bearings[J]. Measurement, 2016, 91: 421-439. doi: 10.1016/j.measurement.2016.05.068 [21] YAN X A, LIU Y, JIA M P. Research on an enhanced scale morphological-hat product filtering in incipient fault detection of rolling element bearings[J]. Measurement, 2019, 147: 106856. doi: 10.1016/j.measurement.2019.106856 [22] DENG F Y, QIANG Y W, YANG S P, et al. Sparse representation of parametric dictionary based on fault impact matching for wheelset bearing fault diagnosis[J]. ISA Transactions, 2021, 110: 368-378. doi: 10.1016/j.isatra.2020.10.034 [23] 陈丙炎, 谷丰收, 张卫华, 等. 基于多带加权包络谱的轴箱轴承故障诊断[J]. 西南交通大学学报, 2024, 59(1): 201-210.CHEN Bingyan, GU Fengshou, ZHANG Weihua, et al. Axle-box bearing fault diagnosis based on multiband weighted envelope spectrum[J]. Journal of Southwest Jiaotong University, 2024, 59(1): 201-210. [24] CHEN B Y, CHENG Y, ZHANG W H, et al. Optimal frequency band selection using blind and targeted features for spectral coherence-based bearing diagnostics: A comparative study[J]. ISA transactions, 2021, 127: 395-414. [25] HOU B C, WANG D, YAN T T, et al. A comparison of machine health indicators based on the impulsiveness of vibration signals[J]. Acoustics Australia, 2021, 49(2): 199-206. doi: 10.1007/s40857-021-00224-7 -

下载:

下载: