Fabrication of Reflective Insulation Coating with Medium Brightness for Controlling Track Slab Temperature

-

摘要:

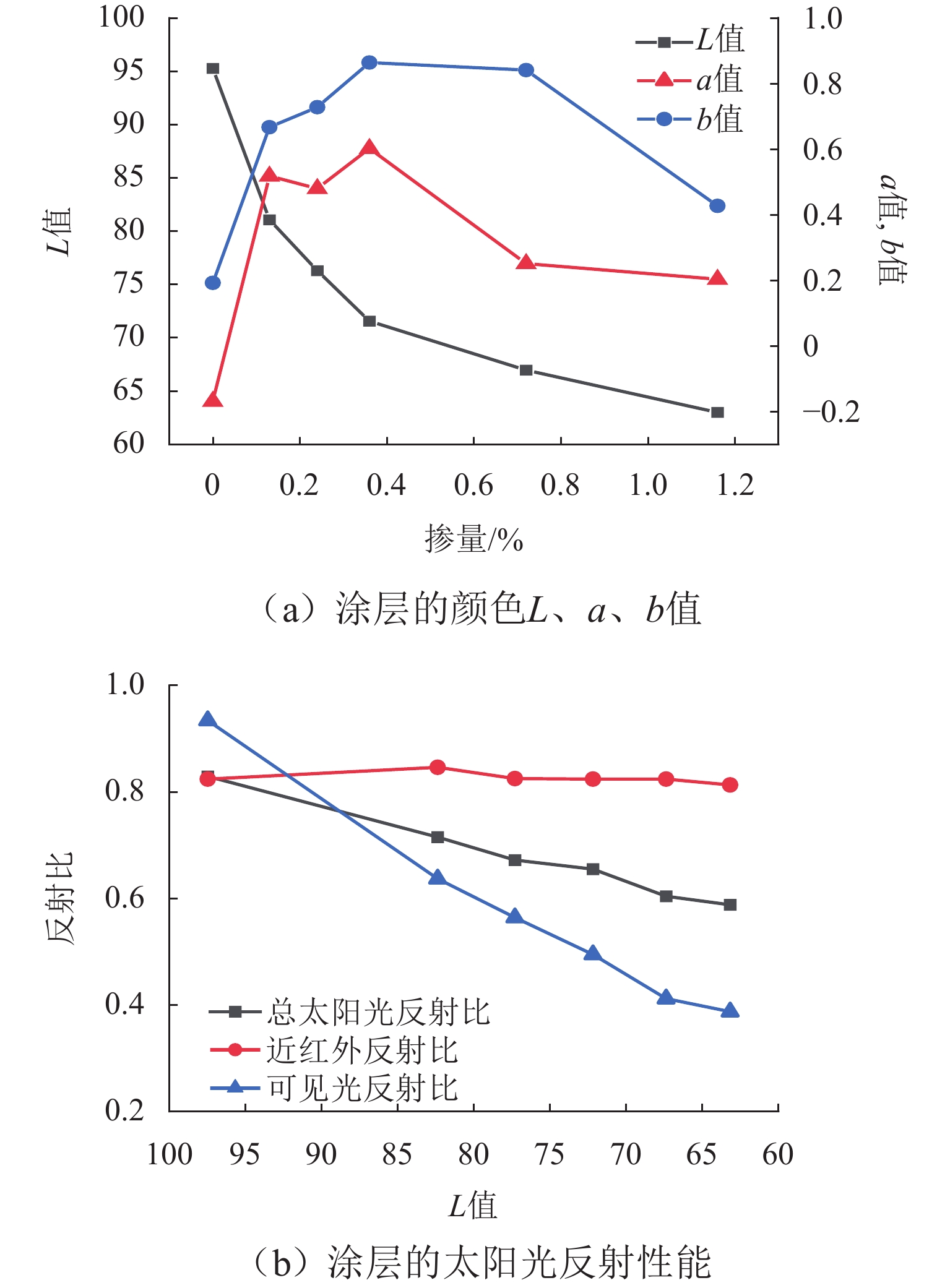

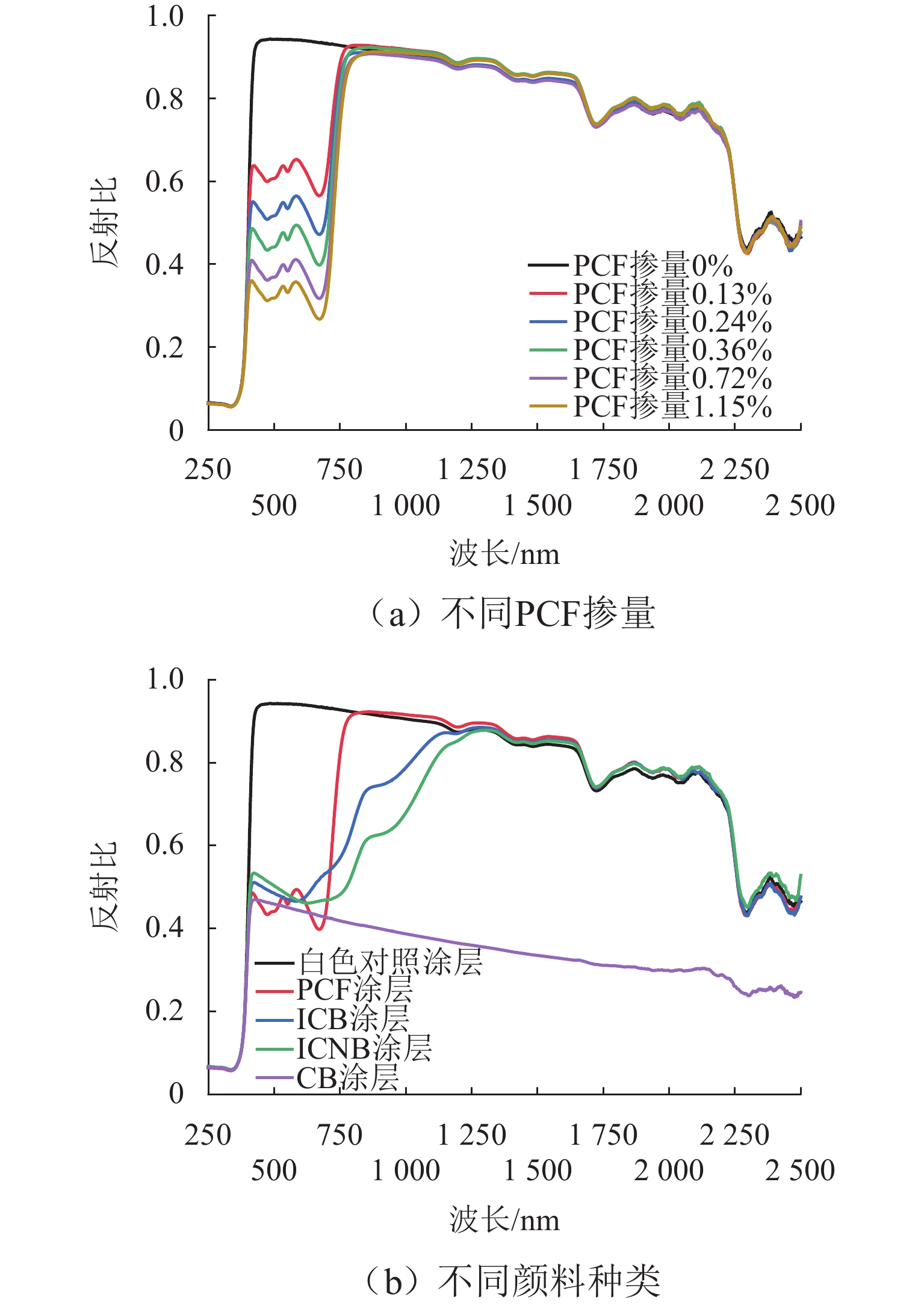

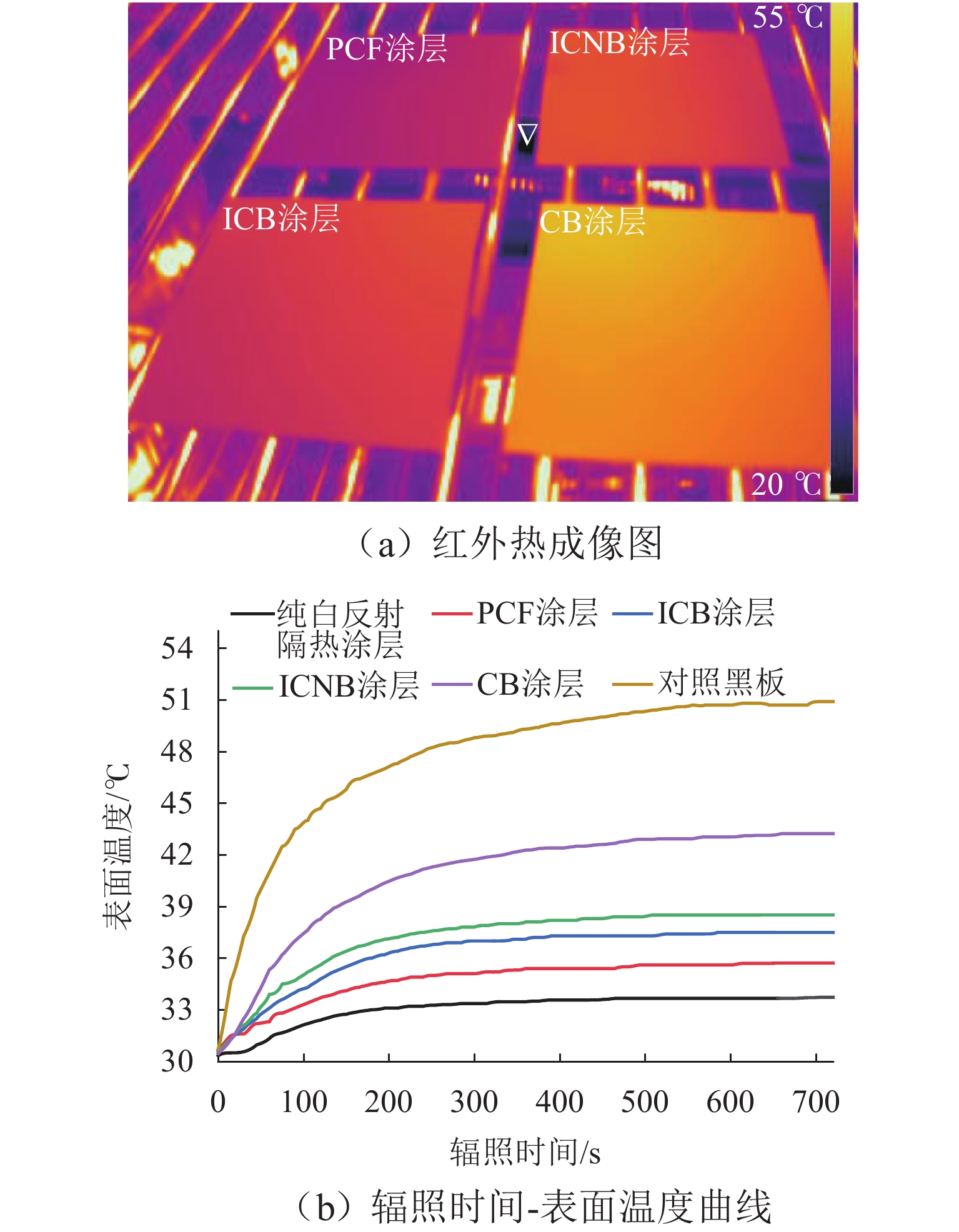

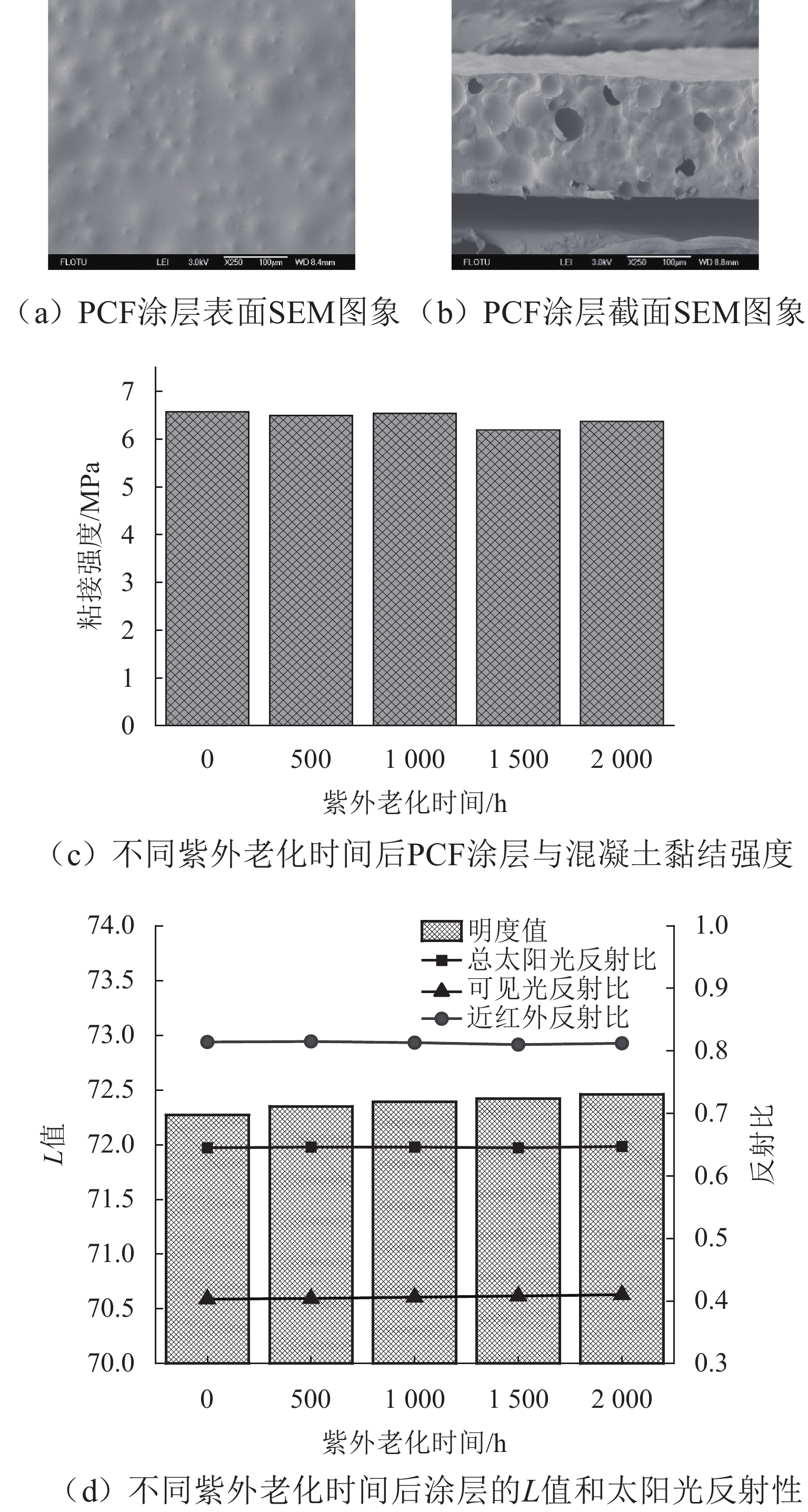

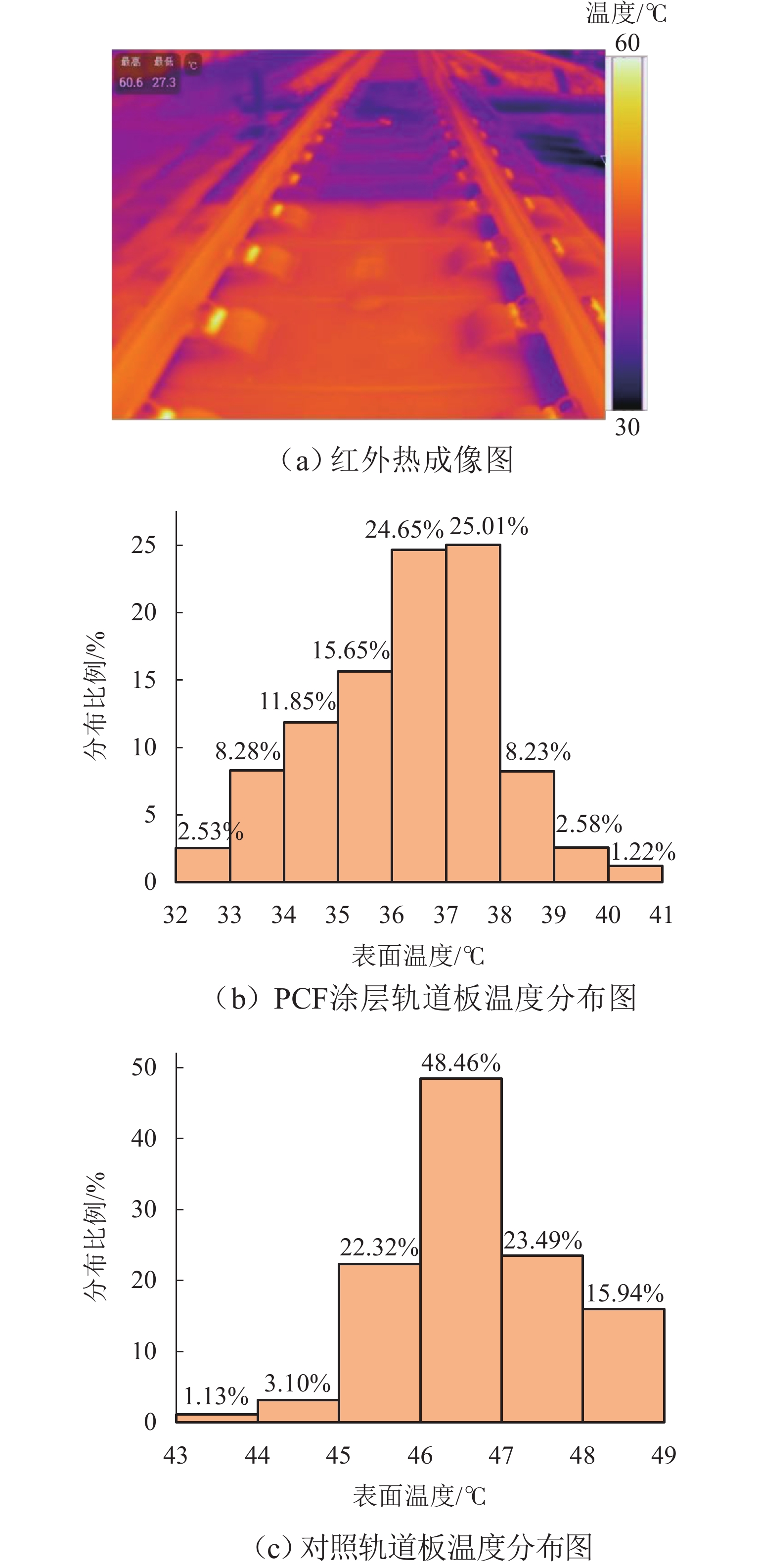

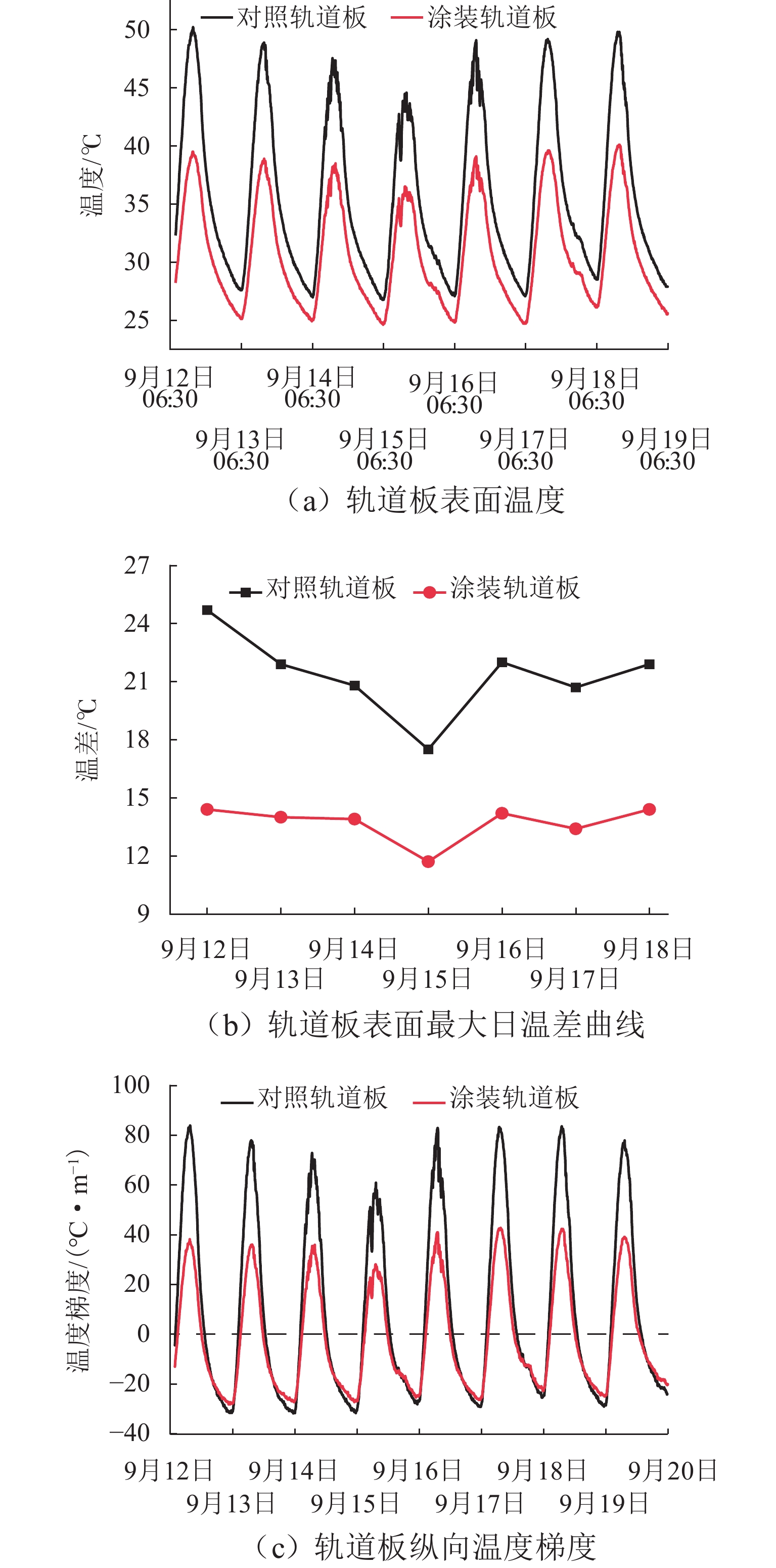

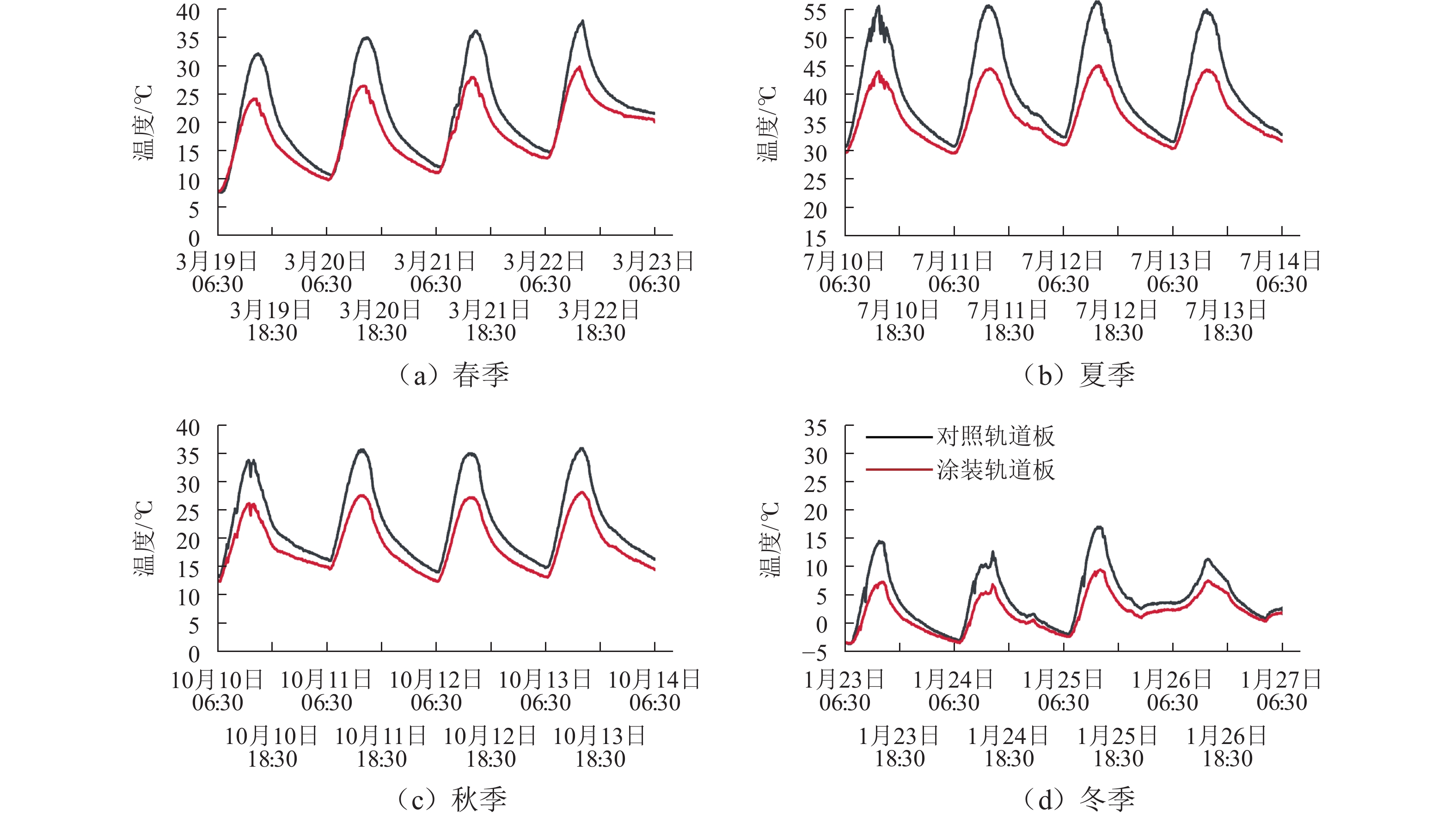

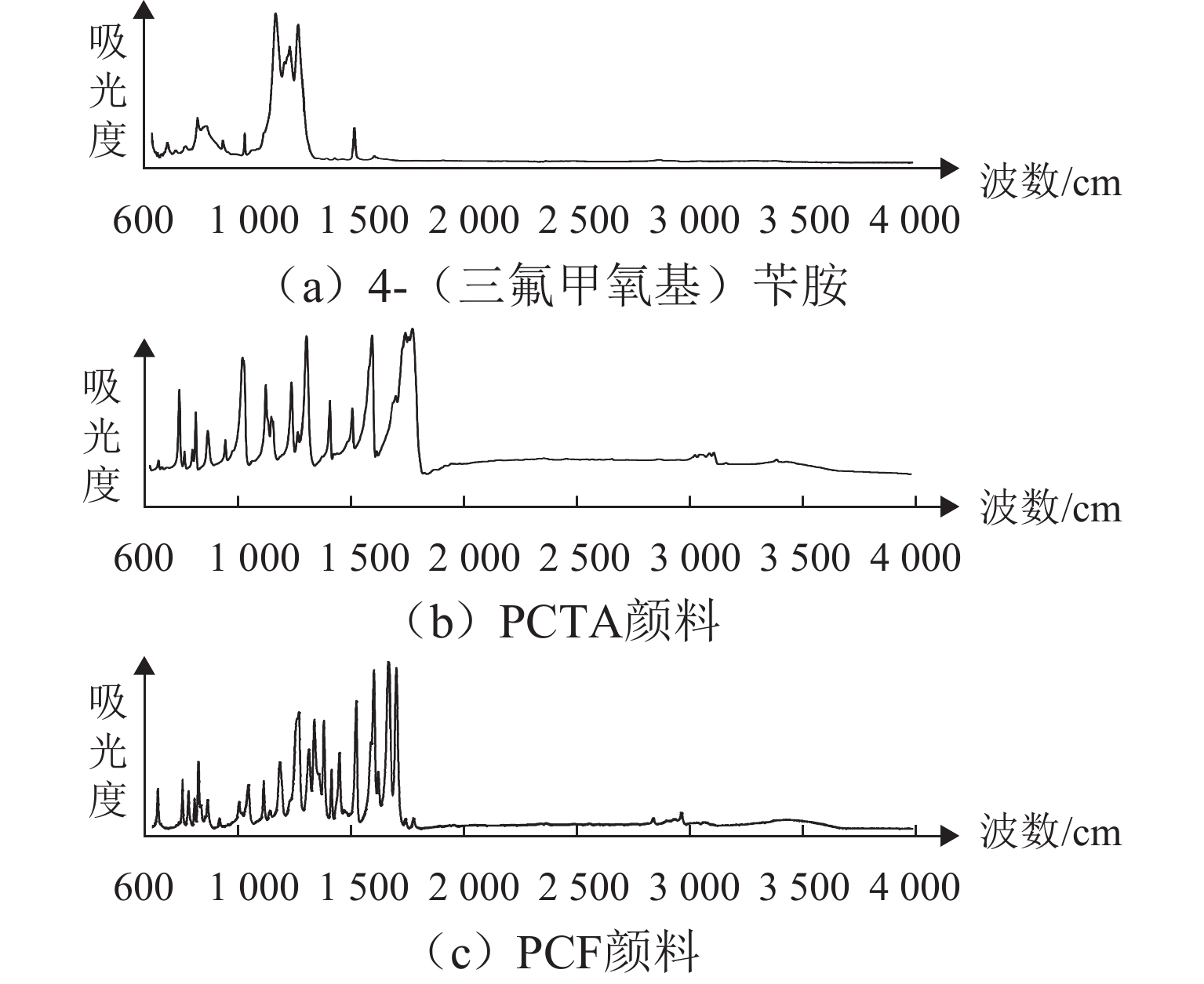

为缓解高速铁路纵连结构型无砟轨道结构在高温环境下易出现的形变上拱病害,使用自制氟改性黑色颜料,配制一种兼具中明度值和高反射性能的反射隔热涂料. 该涂料在实现高效控温的同时,可避免常规高明度白色反射涂料对目视人员造成的视觉损伤. 采用红外光谱对自制氟改性黑色颜料的分子结构进行表征,并利用紫外-可见-近红外分光光度计揭示其高太阳光反射性能作用机制,同时与常规冷颜料进行对比分析;在此基础上,配制相应的中明度反射隔热涂料,对成膜后涂层的控温、黏结、耐久等性能进行测试;进一步在自然暴露环境下的实尺轨道板结构进行表面涂装,通过长期温度监测评估其现场控温效果. 试验结果表明:自制氟改性黑色颜料凭借其近红外波段的透明特性,提升了中明度反射隔热涂层的太阳光反射性能;与常规颜料中明度涂层相比,自制涂层的太阳光反射率提升7.2%以上,在模拟太阳辐射下隔热温差可提升3.0 ℃以上,并具有较好的匀质性、黏结力和耐紫外老化性能;在典型晴朗天气条件下,自制涂层可将实尺轨道板结构表面峰值温度降低10.0 ℃以上,表面日温差减小5.0~10.0 ℃,并将轨道板纵向正温度梯度降低约50%.

Abstract:To mitigate the deformation and upward arching defects prone to occur in the longitudinally continuous ballastless track structures of high-speed railway under high-temperature conditions, a reflective insulation coating with medium brightness and high reflective properties was formulated by using self-made fluorine-modified black pigments. This coating can effectively control the temperature while avoiding the visual damage caused by conventional white reflective coating with high brightness to people seeing it. The molecular structure of the self-made fluorine-modified black pigment was characterized by infrared spectroscopy. The mechanism underlying the high solar reflectance performance of the self-made black pigment was elucidated by using a UV-VIS-NIR spectrophotometer, with a comparison made against conventional cool pigments. Based on this, a reflective thermal insulation coating with medium brightness was developed, and the properties of the film-formed coating, including temperature control, adhesion, and durability, were tested. Furthermore, the full-scale track slab structures under natural exposure conditions were coated, and long-term temperature monitoring and analysis were conducted to evaluate the actual temperature control effect of the coating. The results show that the self-made fluorine-modified black pigment can effectively improve the solar reflectance performance of the reflective thermal insulation coating with medium brightness through the transparency characteristics of its near-infrared band. The solar reflectivity of the self-made coating can be increased by more than 7.2% compared to the coating with medium brightness by using conventional pigments. The insulation temperature difference under simulated solar radiation can be increased by more than 3 ℃. The coating possesses good uniformity, adhesion, and resistance to ultraviolet-induced aging. Under typical sunny conditions, it can reduce the surface peak temperature of a full-scale track slab structure by more than 10 ℃, the daily temperature difference on the surface by 5–10 ℃, and the longitudinal positive temperature gradient of the track slab by about 50%.

-

Key words:

- reflective insulation coating /

- pigment /

- brightness /

- temperature /

- solar radiation

-

表 1 反射隔热涂料基础配方

Table 1. Basic formula of reflective insulation coating

序号 种类 牌号 用量/份 1 氟碳树脂 GK570 60 2 钛白粉 R930 13 3 玻璃微珠 H26 13 4 醋酸丁酯 10 5 流平剂 B354 1 6 消泡剂 B066 0.5 7 分散剂 B110 1.5 8 触变剂 R974 1 表 2 不同颜料制备涂层及混凝土试样的颜色与太阳光反射性能

Table 2. Colors and solar reflectance performance of coatings and concrete specimens fabricated by different pigments

材料 掺量/% L值 a值 b值 TSR NIR VLR PCF 0.36 72.17 0.602 0.864 0.655 0.824 0.463 ICB 0.95% 71.88 1.228 −3.163 0.583 0.717 0.450 ICNB 1.96% 72.34 −0.474 −4.556 0.543 0.656 0.437 CB 0.20% 72.22 −0.294 −2.065 0.347 0.303 0.401 混凝土 / 65.21 0.520 4.790 0.248 0.224 0.268 -

[1] 何元庆. 温度梯度荷载作用下CRTS Ⅱ型无砟轨道层间离缝分析[J]. 铁道建筑, 2017, 57(4): 102-105. doi: 10.3969/j.issn.1003-1995.2017.04.26HE Yuanqing. Analysis on interface seam of CRTS Ⅱ slab ballastless track under temperature gradient load[J]. Railway Engineering, 2017, 57(4): 102-105. doi: 10.3969/j.issn.1003-1995.2017.04.26 [2] 赵国堂, 高亮, 赵磊, 等. CRTSⅡ型板式无砟轨道板下离缝动力影响分析及运营评估[J]. 铁道学报, 2017, 39(1): 1-10. doi: 10.3969/j.issn.1001-8360.2017.01.001ZHAO Guotang, GAO Liang, ZHAO Lei, et al. Analysis of dynamic effect of gap under CRTSⅡ track slab and operation evaluation[J]. Journal of the China Railway Society, 2017, 39(1): 1-10. doi: 10.3969/j.issn.1001-8360.2017.01.001 [3] KRAYENHOFF E S, BROADBENT A M, ZHAO L, et al. Cooling hot cities: a systematic and critical review of the numerical modelling literature[J]. Environmental Research Letters, 2021, 16(5): 053007.1-053007.30. doi: 10.1088/1748-9326/abdcf1 [4] 李永乐, 黄旭, 朱金, 等. 极端天气下桥塔温致效应及抗裂性能优化[J]. 西南交通大学学报, 2023, 58(5): 975-984, 1036.LI Yongle, HUANG Xu, ZHU Jin, et al. Thermal effects and anti-crack performance optimization of bridge pylons under extreme weather conditions[J]. Journal of Southwest Jiaotong University, 2023, 58(5): 975-984,1036. [5] 冀磊, 王鑫, 周燚杭, 等. 反射隔热涂料对轨道板温度及应力的影响[J]. 西南交通大学学报, 2021, 56(5): 960-966.JI Lei, WANG Xin, ZHOU Yihang, et al. Effect of reflective thermal insulation coatings on temperature and stress of track slab[J]. Journal of Southwest Jiaotong University, 2021, 56(5): 960-966. [6] SU R, LV Y, SU Q, et al. Development of composite-phase change microcapsule coating and numerical investigation on its effect in ballastless track slabs[J]. Construction and Building Materials, 2023, 375: 130974. doi: 10.1016/j.conbuildmat.2023.130974 [7] ZHANG Z T, WANG K T, MO B H, et al. Preparation and characterization of a reflective and heat insulative coating based on geopolymers[J]. Energy and Buildings, 2015, 87: 220-225. doi: 10.1016/j.enbuild.2014.11.028 [8] SHA A M, LIU Z Z, TANG K, et al. Solar heating reflective coating layer (SHRCL) to cool the asphalt pavement surface[J]. Construction and Building Materials, 2017, 139: 355-364. doi: 10.1016/j.conbuildmat.2017.02.087 [9] CHEN Y Z, LI Z X, DING S Q, et al. Research on heat reflective coating technology of asphalt pavement[J]. International Journal of Pavement Engineering, 2022, 23(13): 4455-4464. doi: 10.1080/10298436.2021.1952410 [10] MIAO C C, LI Z H, LI K, et al. A super-cooling solar reflective coating with waterborne polyurethane for asphalt pavement[J]. Progress in Organic Coatings, 2022, 165: 106741.1-106741.9. doi: 10.1016/j.porgcoat.2022.106741 [11] SYNNEFA A, SANTAMOURIS M, LIVADA I. A study of the thermal performance of reflective coatings for the urban environment[J]. Solar Energy, 2006, 80(8): 968-981. doi: 10.1016/j.solener.2005.08.005 [12] BECHERINI F, LUCCHI E, GANDINI A, et al. Characterization and thermal performance evaluation of infrared reflective coatings compatible with historic buildings[J]. Building and Environment, 2018, 134: 35-46. doi: 10.1016/j.buildenv.2018.02.034 [13] MORINI E, CASTELLANI B, NICOLINI A, et al. Effects of aging on retro-reflective materials for building applications[J]. Energy and Buildings, 2018, 179: 121-132. doi: 10.1016/j.enbuild.2018.09.013 [14] ZHANG W D, SONG Z N, SONG J R, et al. A systematic laboratory study on an anticorrosive cool coating of oil storage tanks for evaporation loss control and energy conservation[J]. Energy, 2013, 58: 617-627. doi: 10.1016/j.energy.2013.06.044 [15] LEVINSON R, AKBARI H, REILLY J C. Cooler tile-roofed buildings with near-infrared-reflective non-white coatings[J]. Building and Environment, 2007, 42(7): 2591-2605. doi: 10.1016/j.buildenv.2006.06.005 [16] 程冠之, 刘竞, 郑新国, 等. 功能填料对中明度反射隔热氟碳涂层性能的影响[J]. 铁道建筑, 2018, 58(1): 86-89. doi: 10.3969/j.issn.1003-1995.2018.01.21CHENG Guanzhi, LIU Jing, ZHENG Xinguo, et al. Inf luence of functional fillers on performance of ref lective thermal-insulation fluorocarbon coating with medium brightness[J]. Railway Engineering, 2018, 58(1): 86-89. doi: 10.3969/j.issn.1003-1995.2018.01.21 [17] WANG X X, KENDRICK C, OGDEN R, et al. Dynamic thermal simulation of a retail shed with solar reflective coatings[J]. Applied Thermal Engineering, 2008, 28(8/9): 1066-1073. doi: 10.1016/j.applthermaleng.2007.06.011 [18] CAI L G, WU X M, GAO Q, et al. Effect of morphology on the near infrared shielding property and thermal performance of K0.3WO3 blue pigments for smart window applications[J]. Dyes and Pigments, 2018, 156: 33-38. doi: 10.1016/j.dyepig.2018.03.074 [19] ELAKKIYA V, SUMATHI S. Effect of preparation methodology on the colour and the NIR reflectance of nickel doped manganese pyrophosphate[J]. Journal of Alloys and Compounds, 2018, 768: 535-544. doi: 10.1016/j.jallcom.2018.07.236 [20] 国家质量监督检验检疫总局国家标准化管理委员会. 色漆和清漆拉开法附着力试验: GB/T 5210—2006[S]. 北京: 中国标准出版社, 2007. [21] 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 机械工业产品用塑料、涂料、橡胶材料人工气候老化试验方法 荧光紫外灯: GB/T 14522—2008[S]. 北京: 中国标准出版社, 2009. [22] 徐永祥, 李运德, 师华, 等. 太阳热反射隔热涂料研究进展[J]. 涂料工业, 2010, 40(1): 70-74. doi: 10.3969/j.issn.0253-4312.2010.01.019XU Yongxiang, LI Yunde, SHI Hua, et al. Present situation and progress of solar heat reflective thermal insulating coatings[J]. Paint & Coatings Industry, 2010, 40(1): 70-74. doi: 10.3969/j.issn.0253-4312.2010.01.019 [23] ZHOU A, YU Z C, CHOW C L, et al. Enhanced solar spectral reflectance of thermal coatings through inorganic additives[J]. Energy and Buildings, 2017, 138: 641-647. doi: 10.1016/j.enbuild.2016.12.027 [24] SARFARAZI V, HAERI H, EBNEABBASI P, et al. Determination of tensile strength of concrete using a novel apparatus[J]. Construction and Building Materials, 2018, 166: 817-832. doi: 10.1016/j.conbuildmat.2018.01.157 [25] 黄良美, 黄海霞, 项东云, 等. 南京市四种下垫面气温日变化规律及城市热岛效应[J]. 生态环境, 2007, 16(5): 1411-1420. doi: 10.3969/j.issn.1674-5906.2007.05.017HUANG Liangmei, HUANG Haixia, XIANG Dongyun, et al. The diurnal change of air temperature in four types of land cover and urban heat island effect in Nanjing, China[J]. Ecology and Environment, 2007, 16(5): 1411-1420. doi: 10.3969/j.issn.1674-5906.2007.05.017 [26] 王树和, 水中和, 玄东兴. 大温差环境条件下混凝土表面裂缝损伤[J]. 东南大学学报(自然科学版), 2006, 36(增2): 122-125.WANG Shuhe, SHUI Zhonghe, XUAN Dongxing. Investigation on surface cracking damage of concrete under big temperature difference[J]. Journal of Southeast University (Natural Science Edition), 2006, 36(S2): 122-125. [27] 刘鹏, 余志武, 陈令坤, 等. 自然环境温度作用下一维混凝土内温度响应模型[J]. 铁道学报, 2014, 36(8): 103-109. doi: 10.3969/j.issn.1001-8360.2014.08.017LIU Peng, YU Zhiwu, CHEN Lingkun, et al. Interior temperature response model of one-dimension concrete under the action of temperatures in the natural environment[J]. Journal of the China Railway Society, 2014, 36(8): 103-109. doi: 10.3969/j.issn.1001-8360.2014.08.017 [28] 国家铁路局. 高速铁路设计规范: TB 10621—2014[S]. 北京: 中国铁道出版社, 2015. [29] 朱晓嘉. CRTS II型轨道板温度效应及其对列车运行安全性的影响分析[D]. 成都: 西南交通大学, 2012. -

下载:

下载: