Conveying Efficiency Analysis of Vacuum Pneumatic Slagging of Shaft Boring Machine

-

摘要:

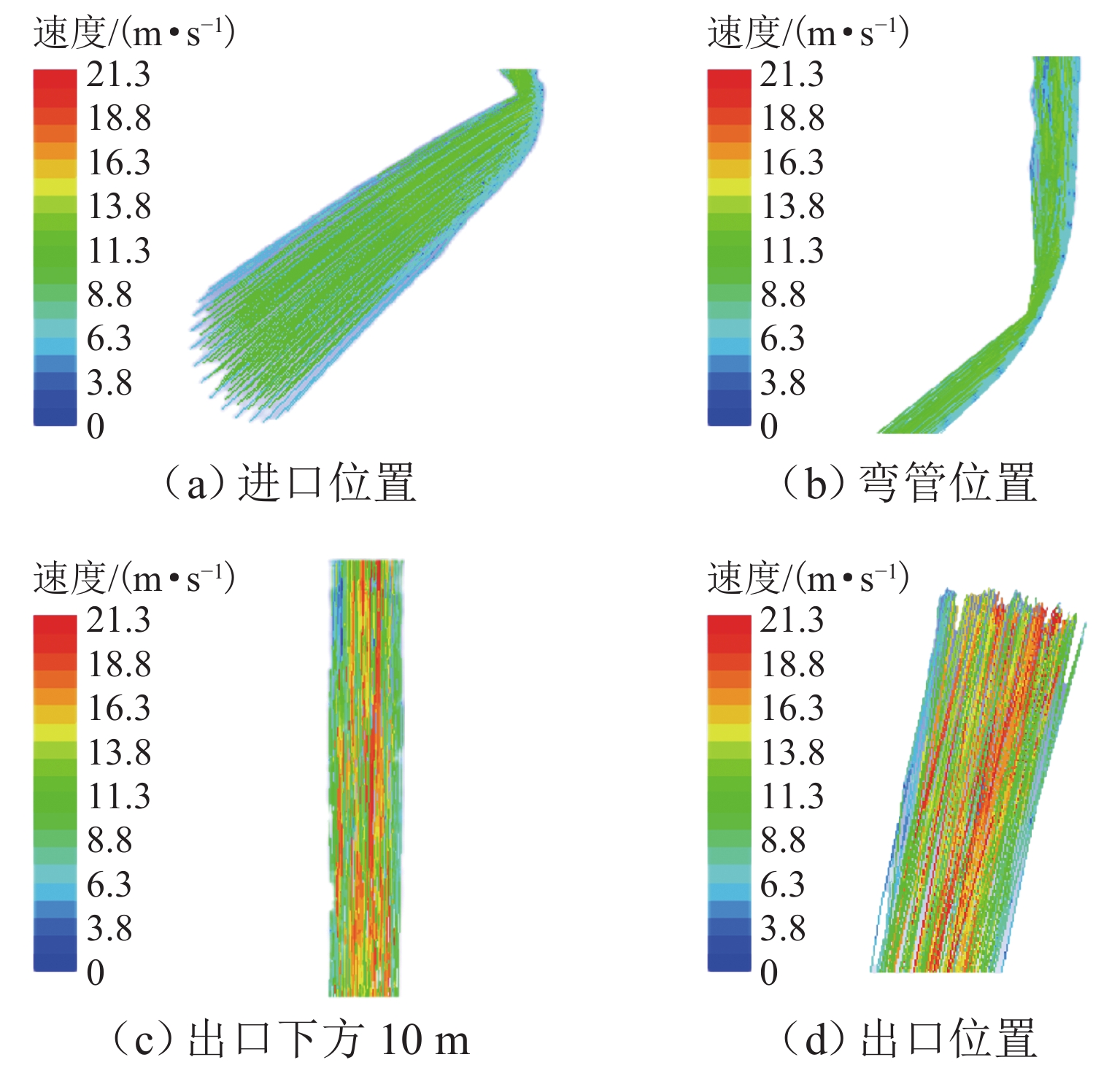

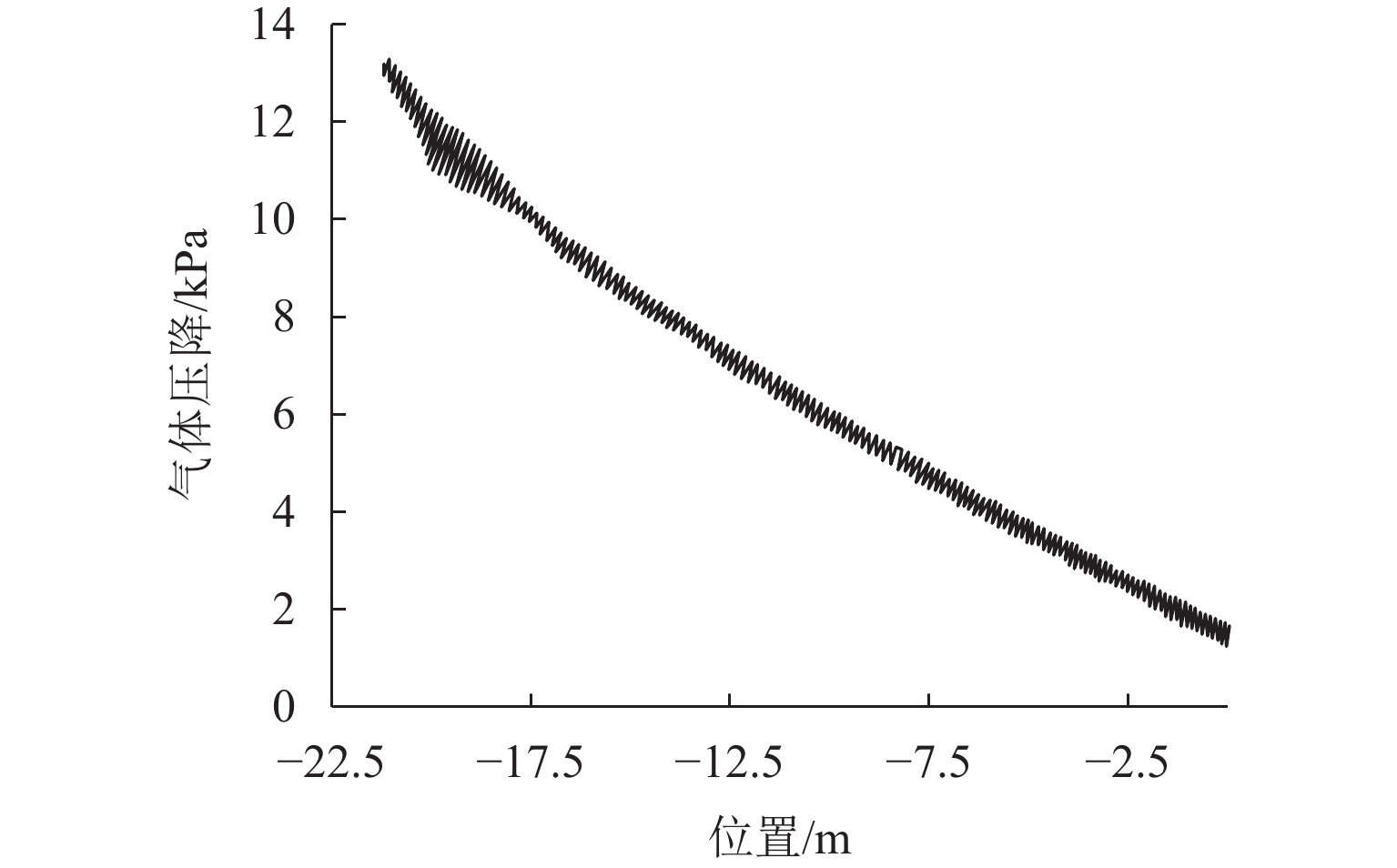

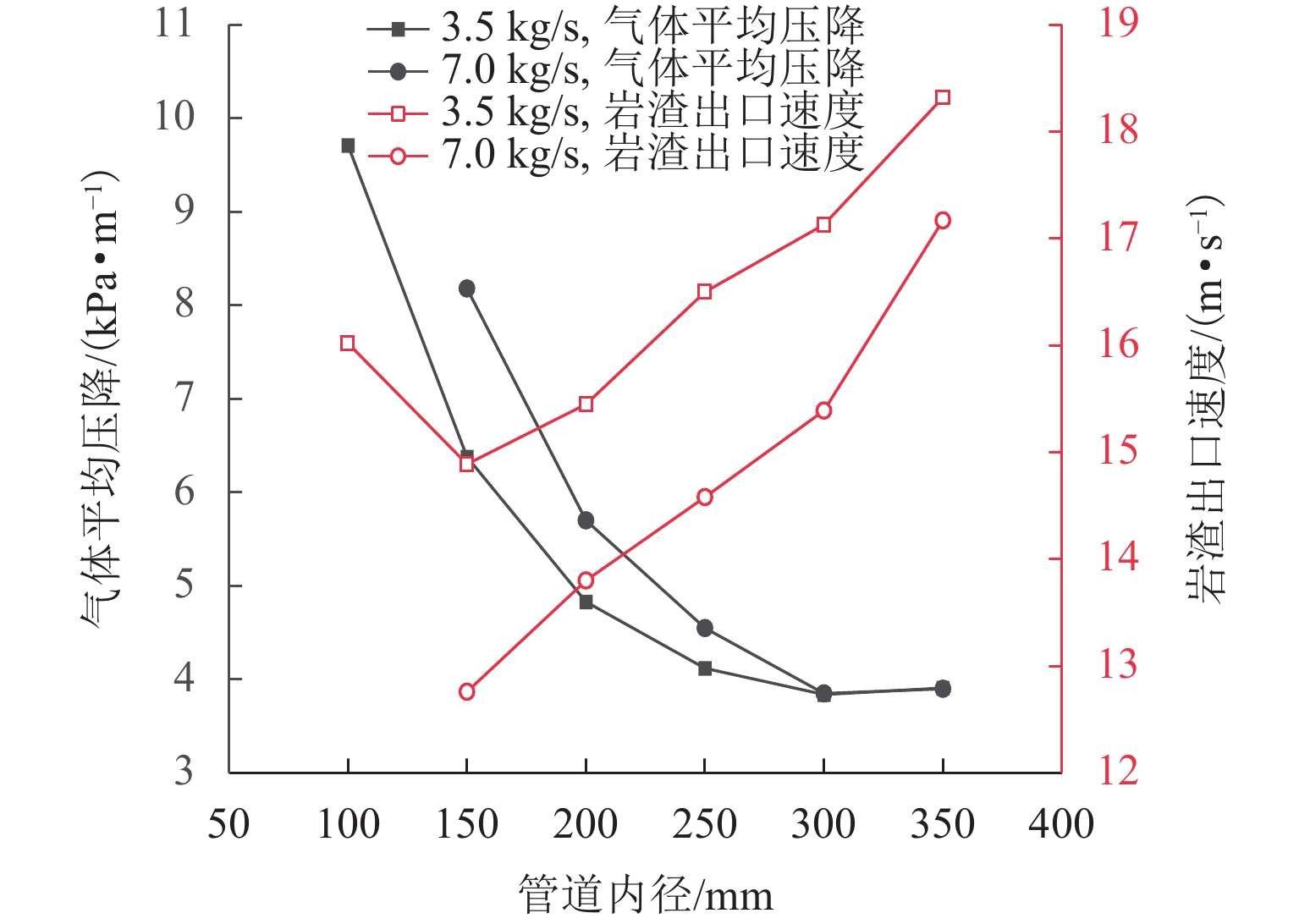

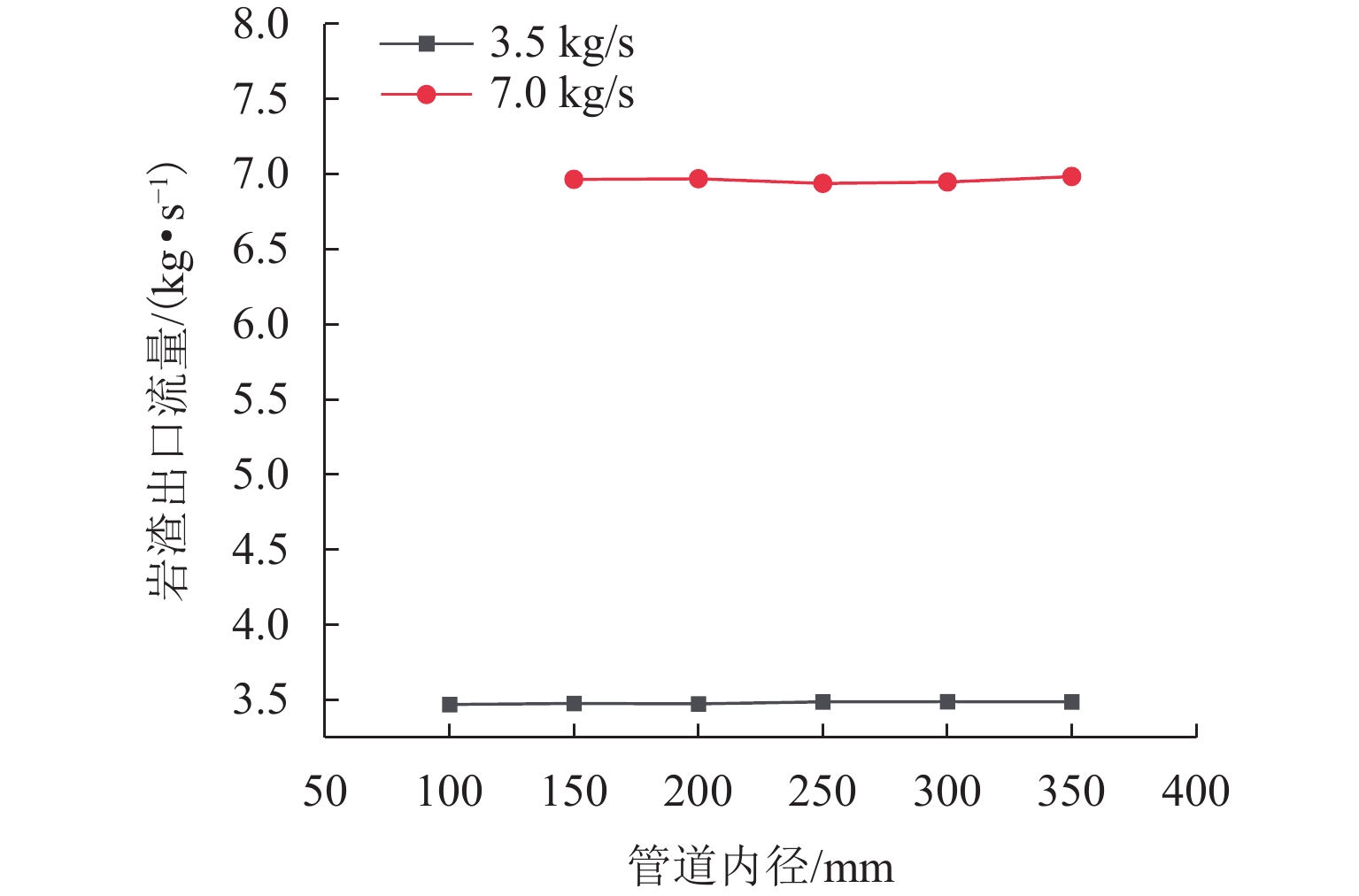

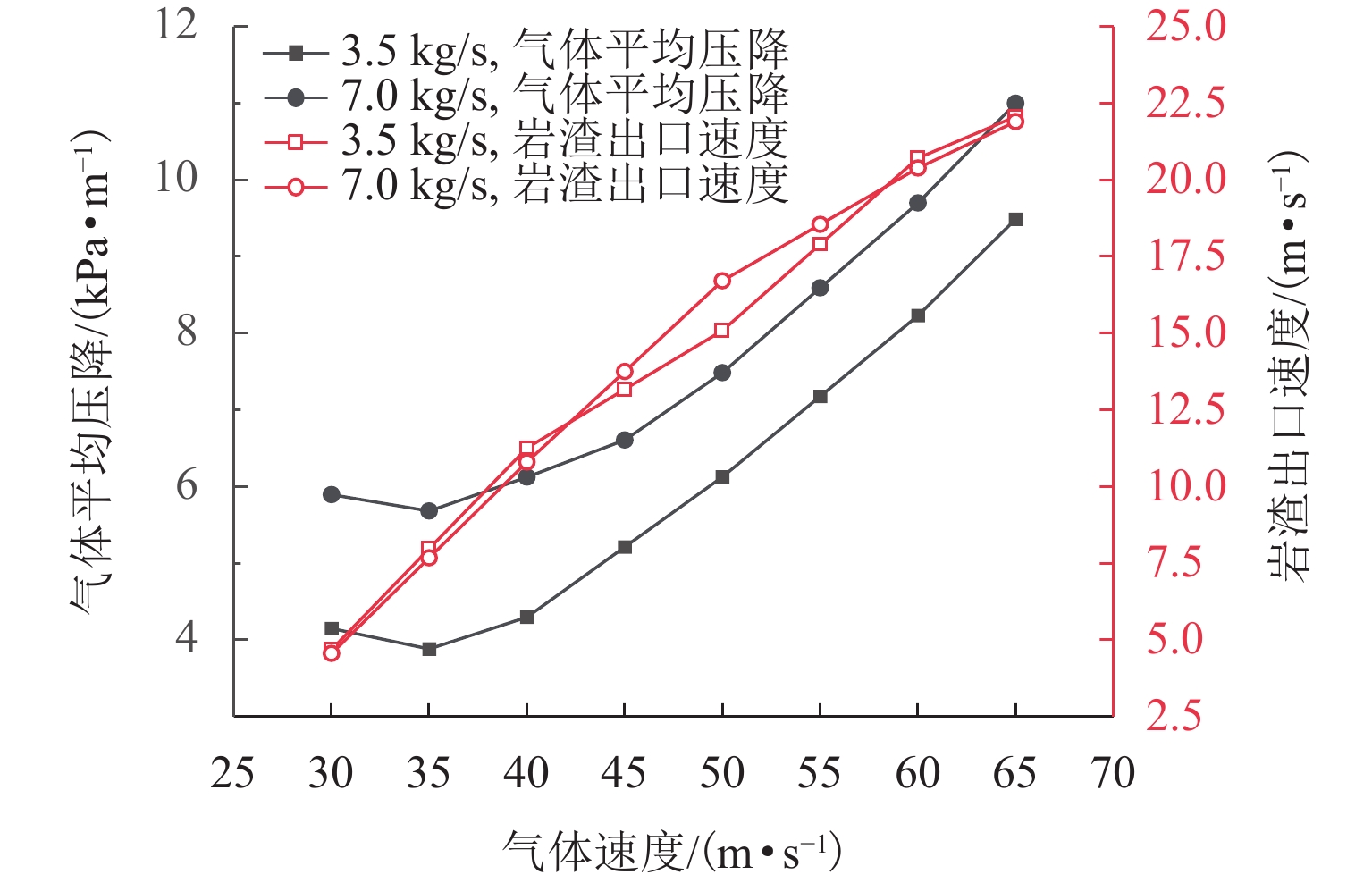

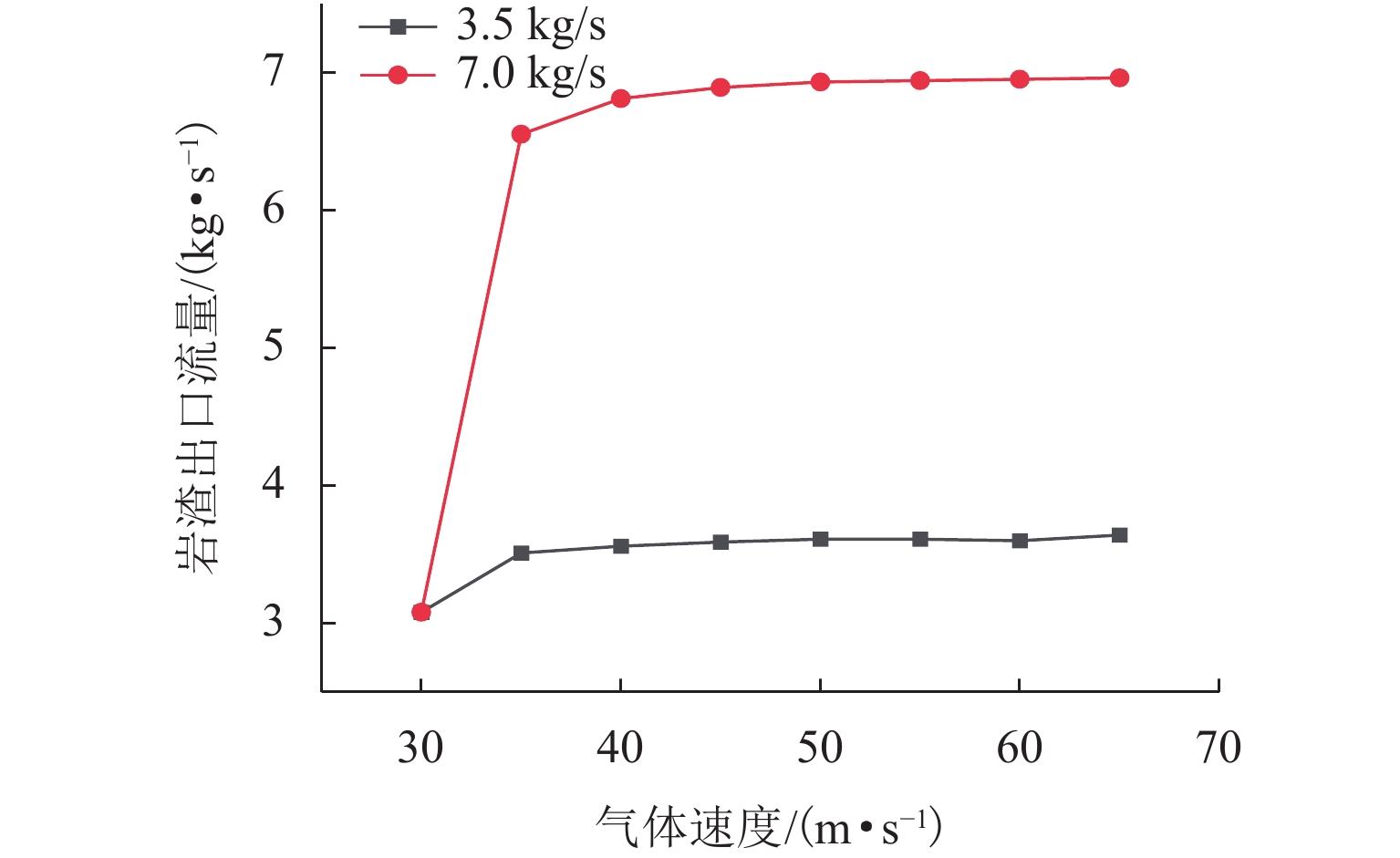

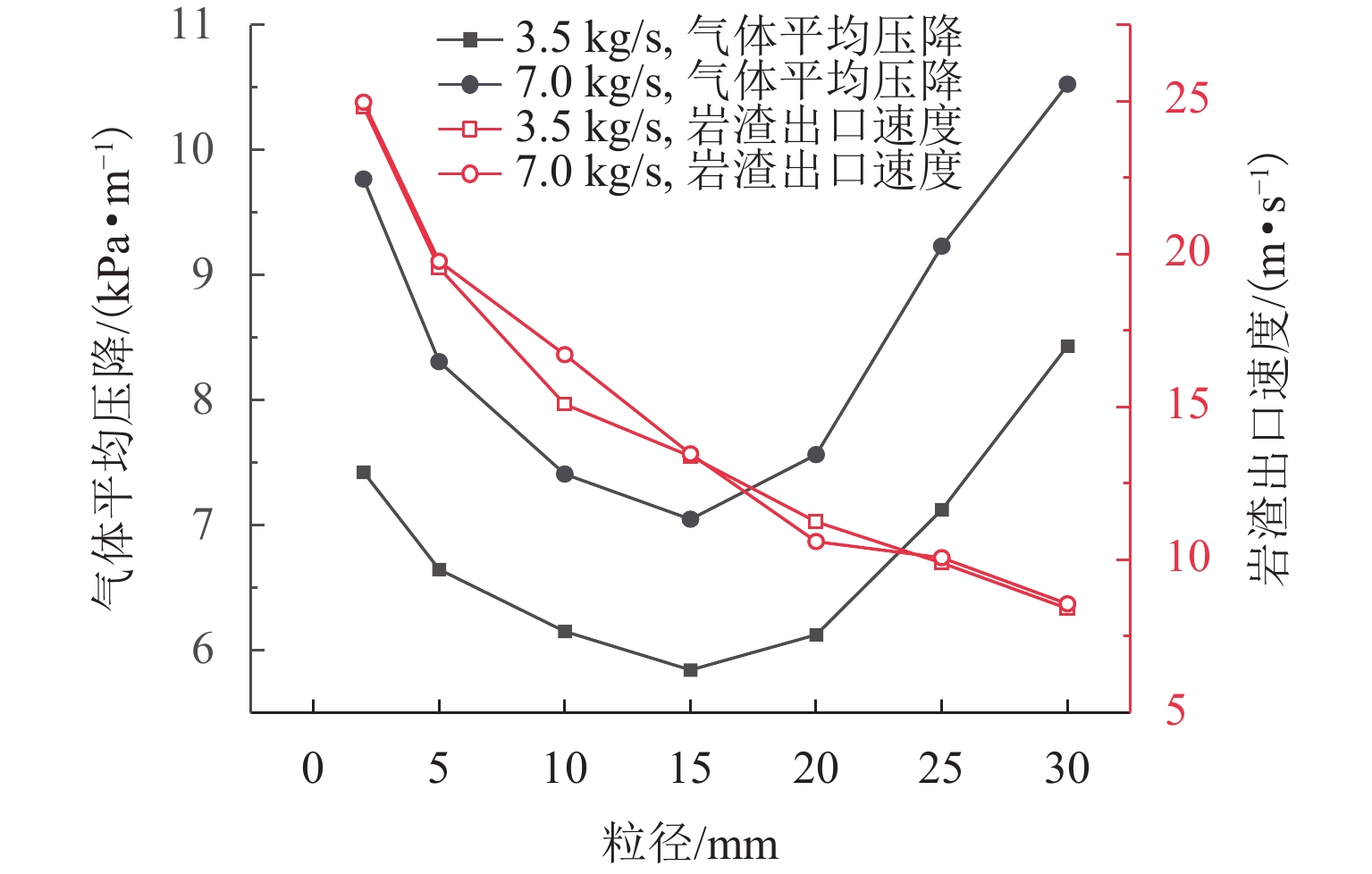

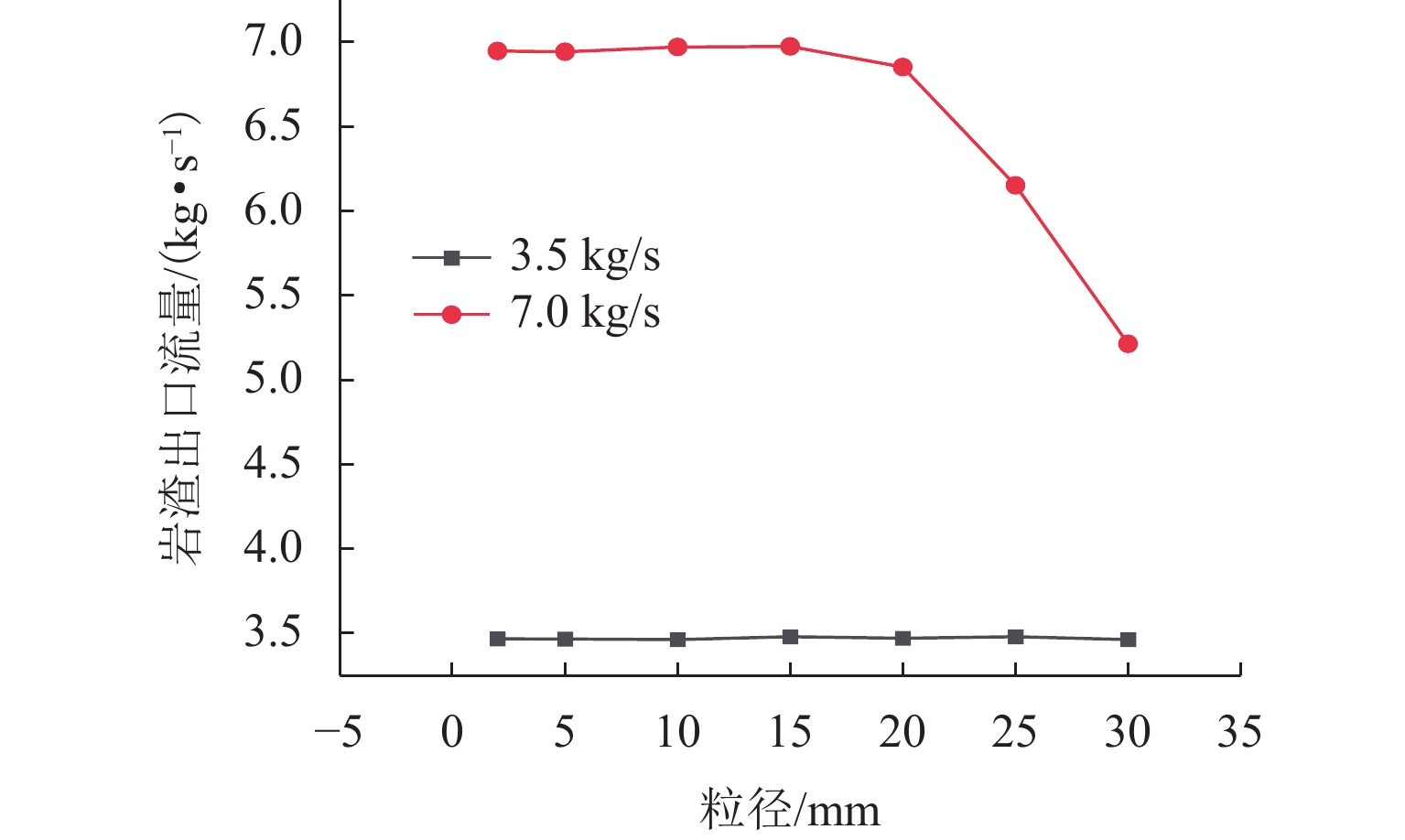

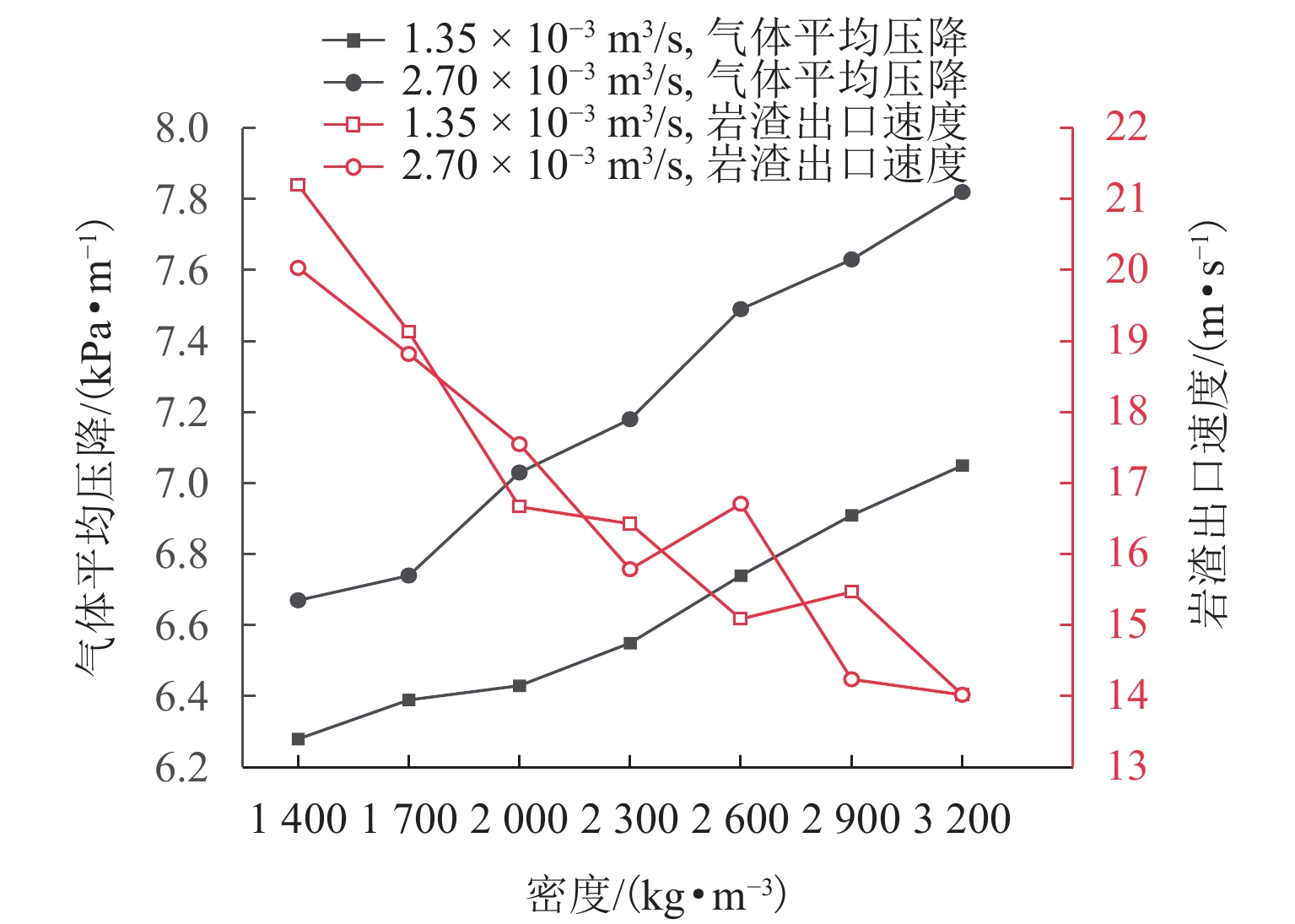

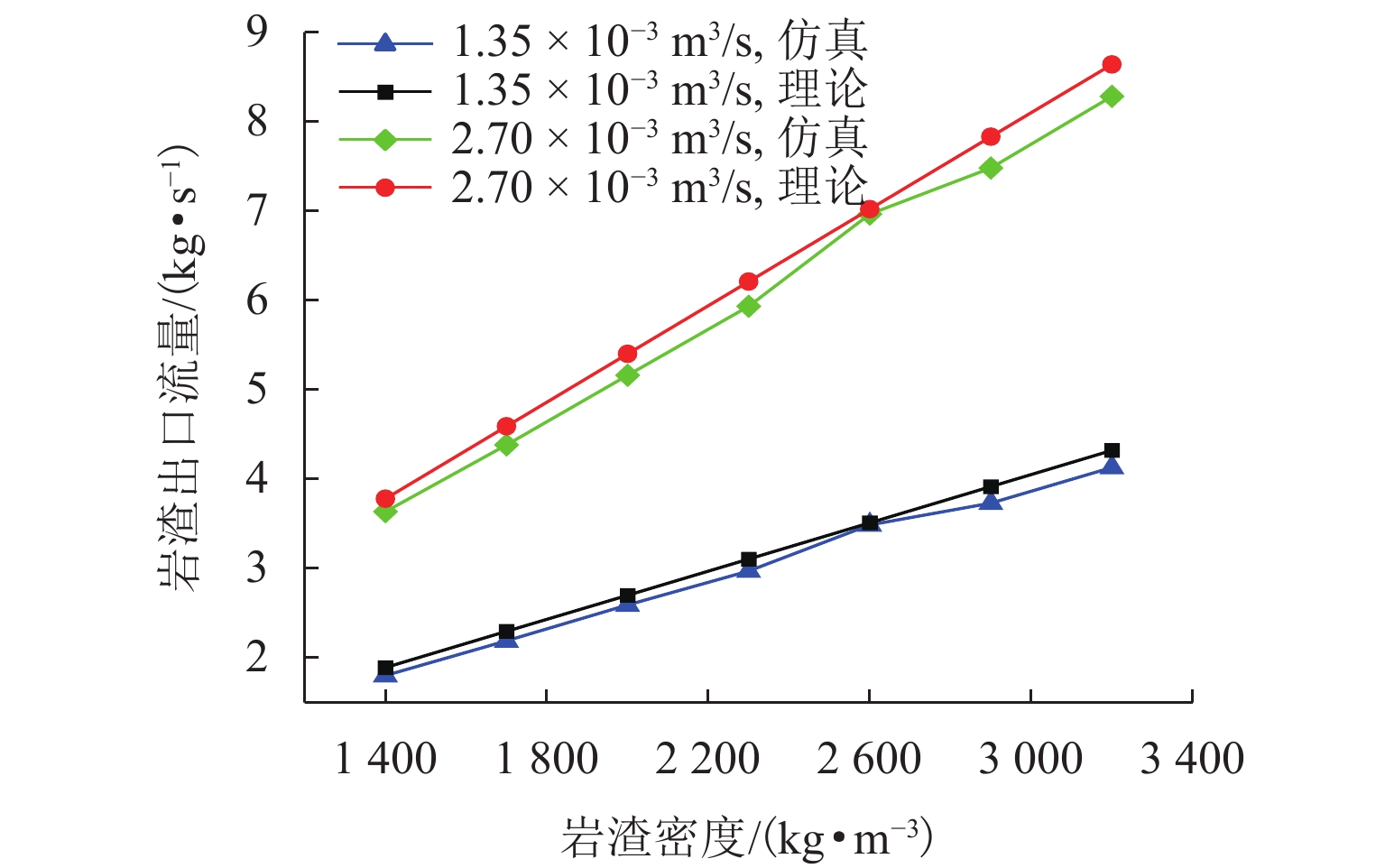

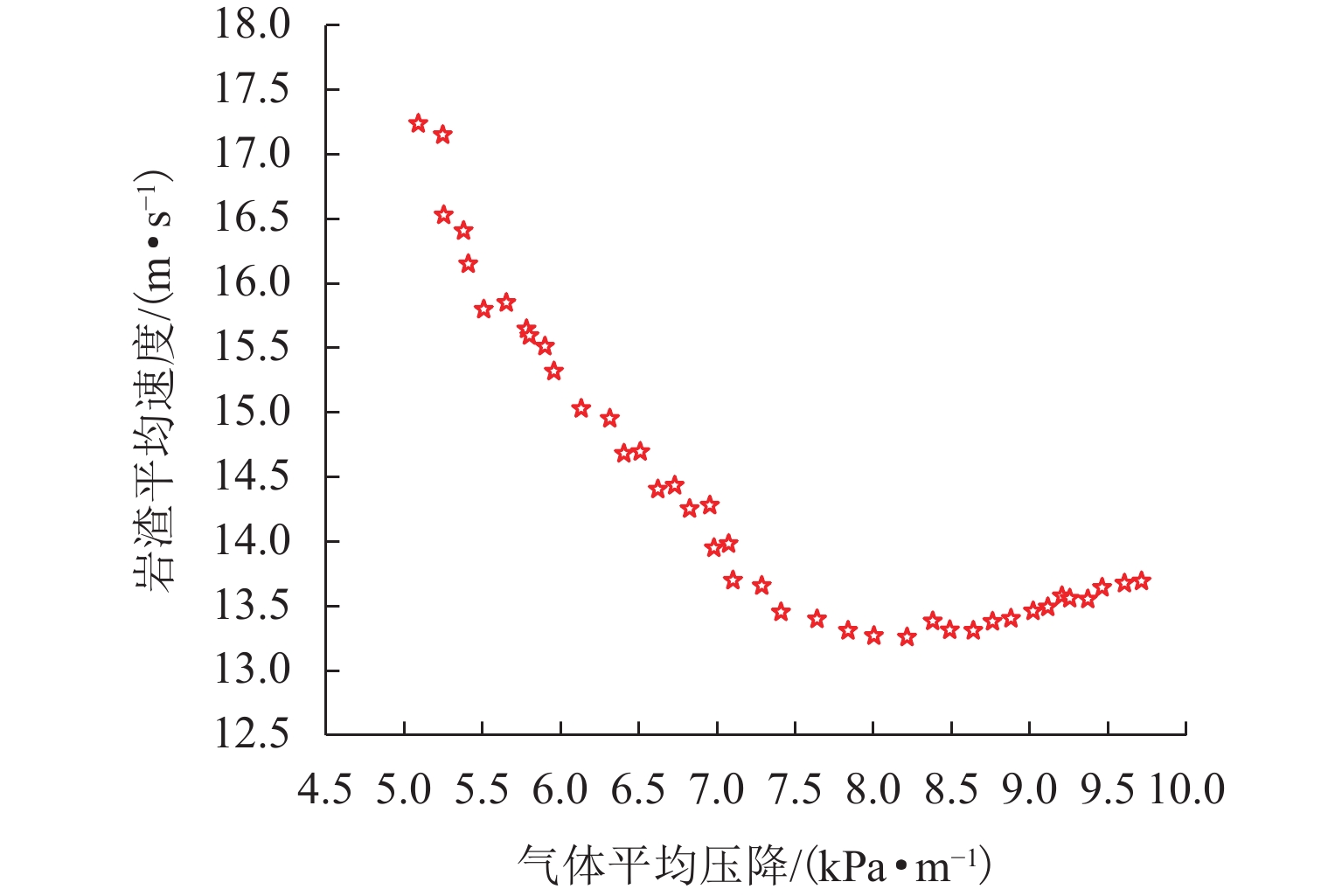

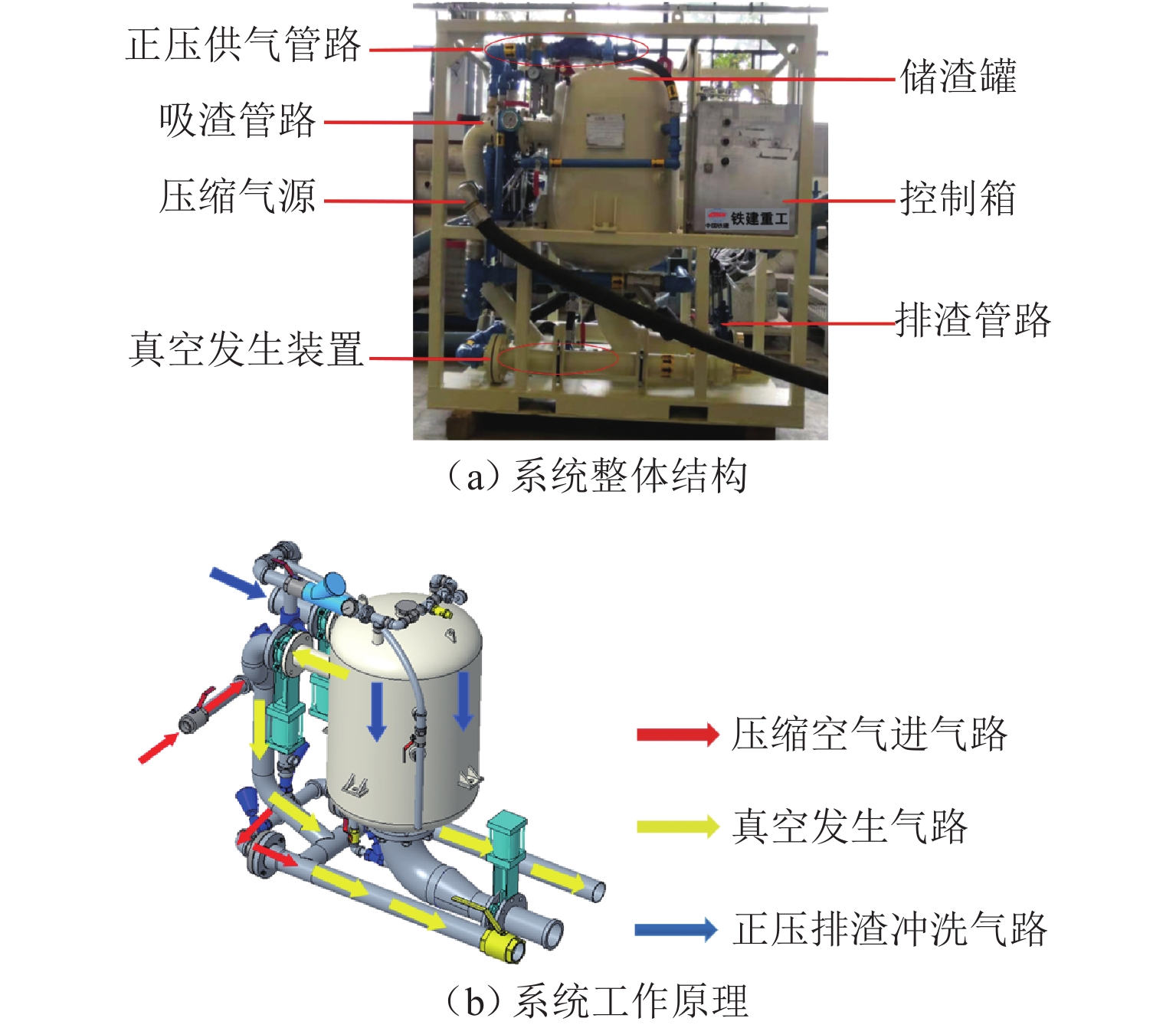

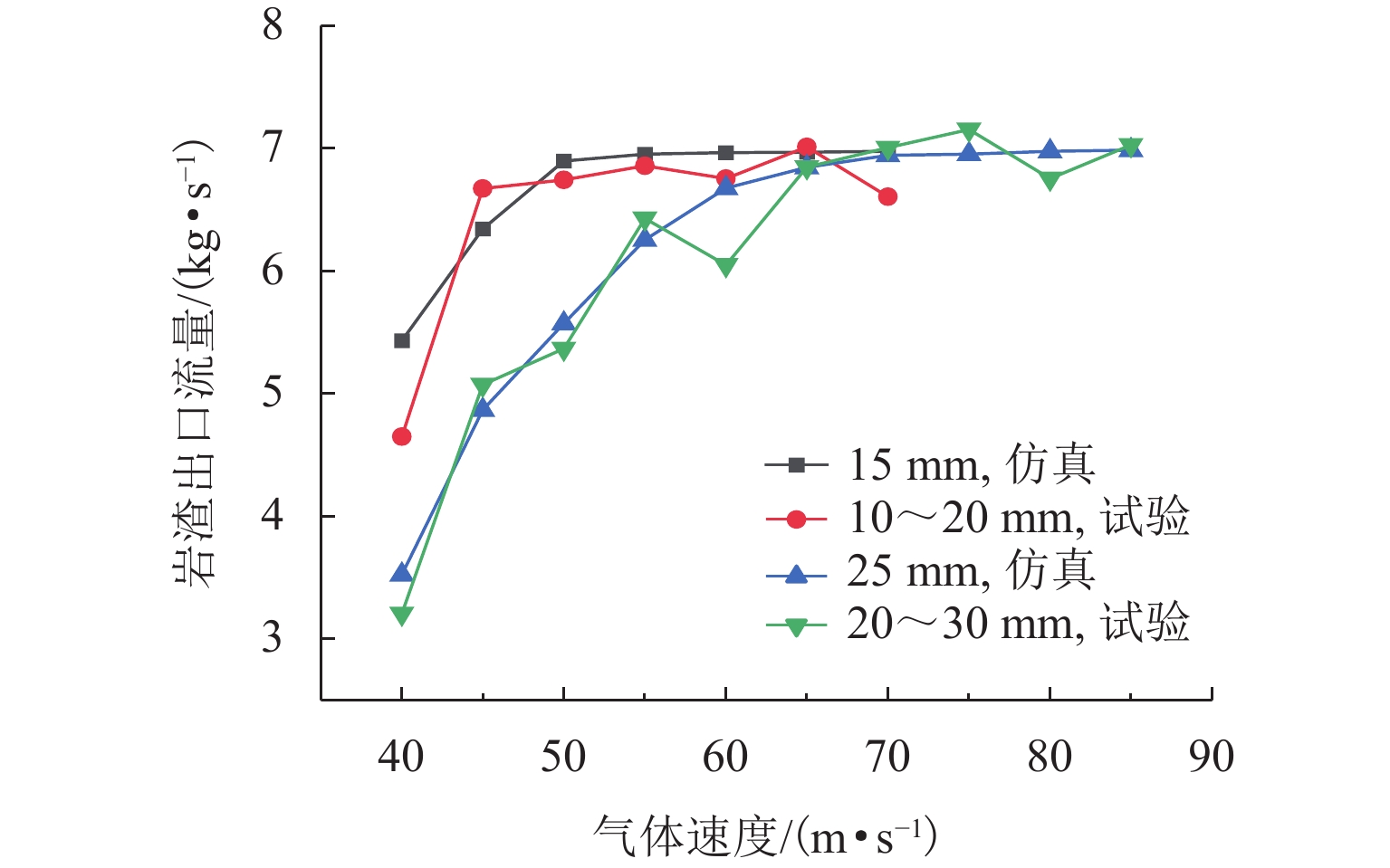

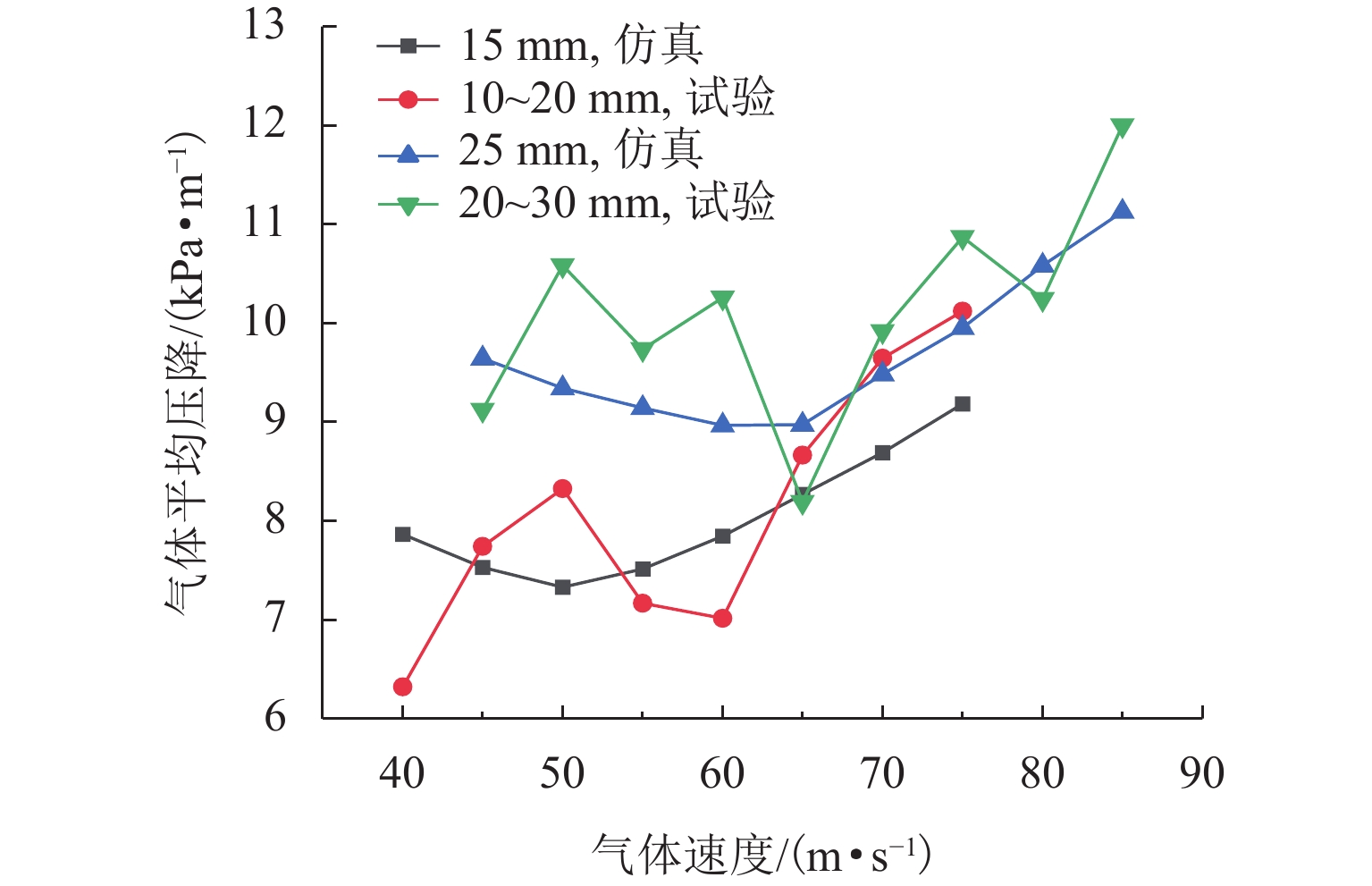

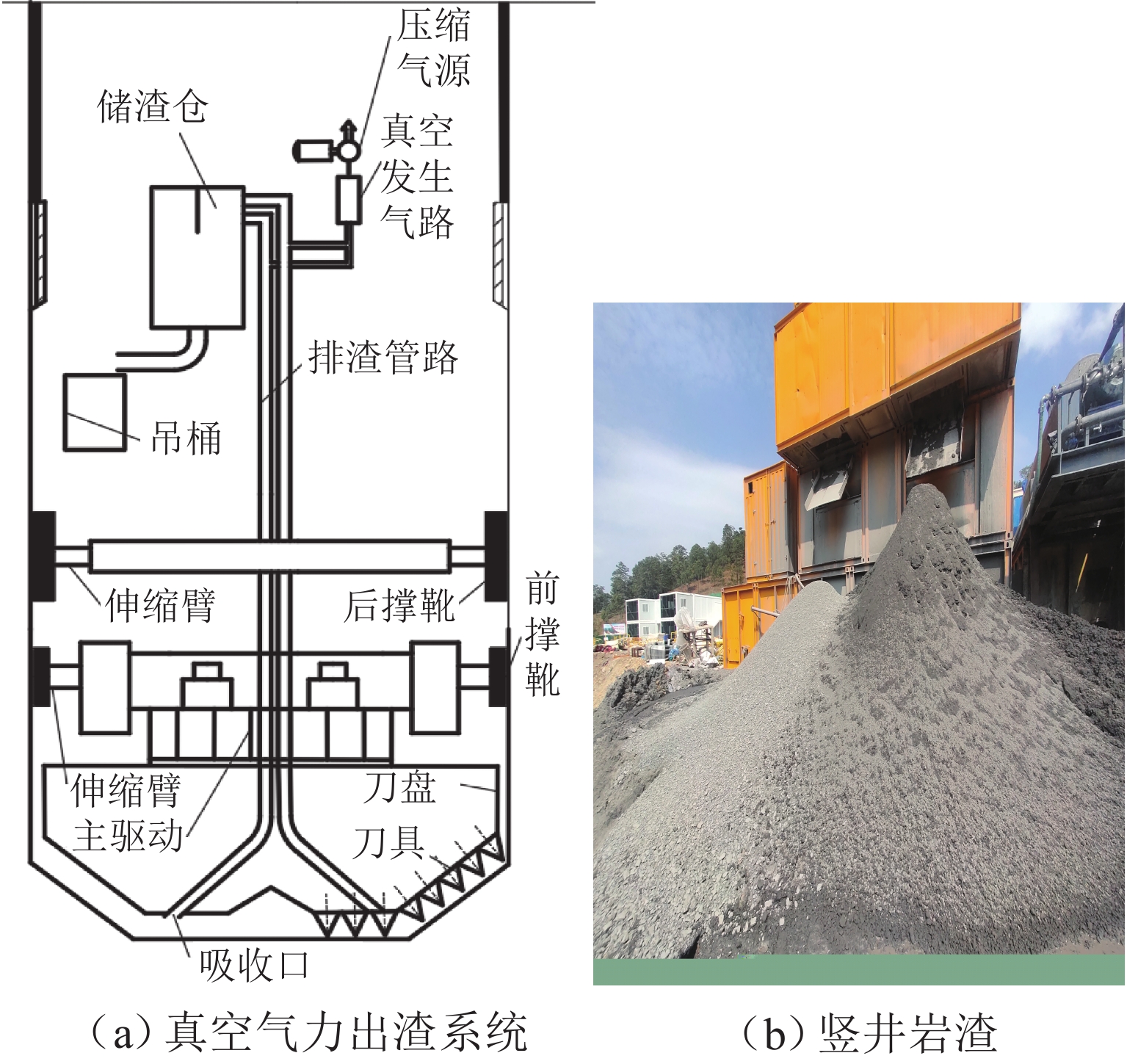

为提高竖井掘进机真空气力出渣系统的输送效率,解决出渣系统参数与岩渣参数不匹配导致的输送效率低下的问题,基于单因素分析法和正交试验法研究输送系统参数对出渣效率的影响. 首先,基于流体力学原理,建立真空气力出渣系统参数与压力损失的计算模型,确定系统关键参数;利用Fluent软件模拟真空气力出渣过程,并以岩渣出口速度和气体平均压降作为出渣效率的考量指标;采用单因素分析法,研究管道内径、气体流速、岩渣粒径和岩渣密度4个因素对输送效率的影响规律;进一步,运用正交试验法开展多因素分析,并应用非支配排序遗传算法获得帕累托前沿解集;最后,开展真空气力出渣系统的输送效率试验. 研究结果表明:气体流速和岩渣粒径对岩渣出口速度的影响最显著,管道内径和气体流速对气体平均压降的影响最显著;气体平均压降与岩渣出口速度难以同时达到最优,岩渣出口速度的最小值对应最佳经济输送点,得到的输送参数优化组合为岩渣粒径10 mm、管道内径150 mm、气体流速40 m/s. 研究成果可为竖井掘进机真空气力出渣系统的施工应用提供参考.

Abstract:For the purpose of improving the conveying efficiency of the vacuum pneumatic slagging system of the shaft boring machine (SBM) and addressing low conveying efficiency caused by the mismatch between the parameters of the slagging system and the rock slag, the effect of conveying system parameters on slagging efficiency was investigated based on single factor analysis method and orthogonal test method. Firstly, a parameter and pressure loss calculation model for the vacuum pneumatic slagging system was constructed based on fluid mechanics to determine the key parameters of the system. Then, the Fluent software was used to simulate the process of vacuum pneumatic slagging, and the outlet velocity of rock slag and the average gas pressure drop were taken as the consideration index of slag conveying efficiency. The single factor analysis method was used to study the influence of four factors, including inner diameter of pipe, gas velocity, rock slag particle size, and rock slag density, on the conveying efficiency. The multi-factor analysis was carried out based on the orthogonal test method, and the non-dominated sorting genetic algorithm was applied to obtain the Pareto frontier solution set. Finally, the slag conveying efficiency test of the vacuum pneumatic slagging system was carried out. The results show that the influence of gas velocity and rock slag particle size on the outlet velocity of rock slag is the most significant, and the influence of inner diameter of pipe and gas velocity on the average gas pressure drop is the most significant. In addition, the average gas pressure drop and the outlet velocity of rock slag cannot reach the optimum simultaneously. When the minimum value of the outlet velocity of rock slag is selected as the best economic conveying point, the optimal combination of conveying parameters is as follows: rock slag particle size of 10 mm, inner diameter of pipe of 150 mm, gas velocity of 40 m/s. The research results can provide a reference for the construction application of the vacuum pneumatic slagging system of SBM.

-

Key words:

- boring machine /

- vacuum /

- fluid mechanics /

- conveying efficiency /

- orthogonal test

-

表 1 竖井工程的初始参数

Table 1. Initial parameters of shaft project

参数 取值 竖井直径/m 6 平均掘进速度/(m•h−1) 0.33 岩渣粒径/mm 10 岩渣密度/(kg•m−3) 2600 空气密度/(kg•m−3) 1.29 管道输送高度/m 20 表 2 出渣系统关键参数及压力损失

Table 2. Key parameters and pressure loss of slagging system

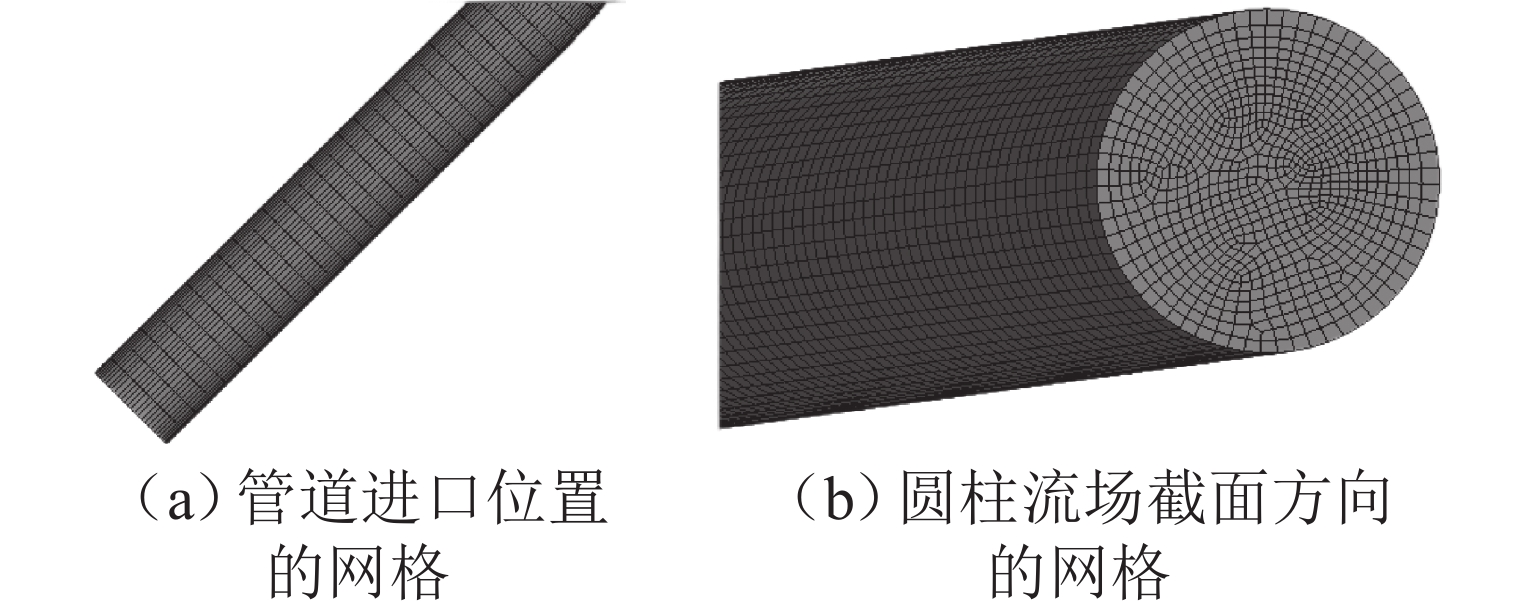

参数 取值 单位时间输送量/(kg•s−1) 6.74 固气混合比 5 输送气速/(m•s−1) 50 管道内径/mm 160 压力损失/Pa 179748.60 真空泵风量/(m³•h−1) 4500 真空泵风压/Pa 800000 表 3 仿真模型的网格无关性验证

Table 3. Grid independence verification of simulation model

网格尺寸/

mm网格节点数/

个总单元数/

个气体平均压降/

(kPa•m−1)5 4008462 1609208 6.380 10 3497094 840868 6.383 15 1969533 468280 6.379 20 1046886 242284 6.293 25 688146 101800 5.924 30 497363 61080 5.871 35 326077 54792 5.963 45 102962 38684 5.641 表 4 四因素四水平正交试验方案

Table 4. Four-factor and four-level orthogonal test scheme

试验号 因素 A/mm B/(m•s−1) C/mm D/(kg•m−3) 1 150 40 10 1400 2 150 45 15 2000 3 150 50 20 2600 4 150 55 25 3200 5 200 40 15 2600 6 200 45 10 3200 7 200 50 25 1400 8 200 55 20 2000 9 250 40 20 3200 10 250 45 25 2600 11 250 50 10 2000 12 250 55 15 1400 13 300 40 25 2000 14 300 45 20 1400 15 300 50 15 3200 16 300 55 10 2600 表 5 正交试验结果

Table 5. Orthogonal test results

试验号 岩渣出口速度/

(m•s−1)气体平均压降/

(kPa•m−1)岩渣出口流量/

(kg•s−1)1 18.36 9.98 6.90 2 13.67 9.18 6.90 3 14.06 7.45 6.89 4 10.35 6.52 6.12 5 16.32 6.53 6.91 6 15.32 6.80 6.91 7 10.35 7.28 6.24 8 16.24 6.28 6.96 9 15.12 6.96 6.94 10 13.40 7.98 6.37 11 15.16 6.53 6.93 12 17.23 5.78 6.92 13 11.23 8.63 6.48 14 14.81 5.88 6.86 15 15.13 5.08 6.92 16 18.33 5.08 6.94 表 6 岩渣出口速度极差分析结果

Table 6. Range analysis results of rock slag outlet velocity

水平号 因素 A/mm B/(m•s−1) C/mm D/(kg•m−3) K1 56.45 61.04 67.17 60.76 K2 58.24 57.20 62.35 56.31 K3 60.92 54.71 60.24 62.11 K4 59.50 62.15 45.34 55.93 k1 14.11 15.26 16.79 15.19 k2 14.56 14.30 15.59 14.08 k3 15.23 13.68 15.06 15.53 k4 14.88 15.54 11.34 13.98 极差 R 1.12 1.86 5.46 1.54 表 7 气体平均压降极差分析结果

Table 7. Range analysis results of average gas pressure drop

水平号 因素 A/mm B/(m•s−1) C/mm D/(kg•m−3) K1 33.12 32.09 28.38 28.92 K2 26.88 29.82 26.56 30.61 K3 27.24 26.33 26.56 27.03 K4 24.66 23.66 30.40 25.35 k1 8.28 8.02 7.10 7.23 k2 6.72 7.46 6.64 7.65 k3 6.81 6.58 6.64 6.76 k4 6.16 5.91 7.60 6.34 极差 R 2.12 2.11 0.96 1.32 -

[1] 刘志强. 竖井掘进机[M]. 北京: 煤炭工业出版社, 2019. [2] 黄鸿颖, 管会生, 母国旺, 等. 竖井全断面掘进机异型刀盘的滚刀布局[J]. 西南交通大学学报, 2025, 60(3): 704-713, 730.HUANG Hongying, GUAN Huisheng, MU Guowang, et al. Cutter layout on special-shaped cutterhead for shaft boring machine[J]. Journal of Southwest Jiaotong University, 2025, 60(3): 704-713, 730. [3] 贾连辉, 吕旦, 郑康泰, 等. 全断面竖井掘进机上排渣关键技术研究与试验[J]. 隧道建设(中英文), 2020, 40(11): 1657-1663.JIA Lianhui, LYU Dan, ZHENG Kangtai, et al. Research and test on vertical discharge of full-face shaft boring machine[J]. Tunnel Construction, 2020, 40(11): 1657-1663. [4] 周云, 陈晓平, 梁财, 等. 不同平均粒径煤粉的高压密相气力输送[J]. 动力工程, 2009, 29(3): 218-222.ZHOU Yun, CHEN Xiaoping, LIANG Cai, et al. Dense-phase pneumatic conveying for pulverized coal with different mean particle size under high pressure[J]. Journal of Power Engineering, 2009, 29(3): 218-222. [5] ZHOU H J, XIONG Y Q, PEI Y. Effect of moisture content on dense-phase pneumatic conveying of pulverized lignite under high pressure[J]. Powder Technology, 2016, 287: 355-363. doi: 10.1016/j.powtec.2015.10.026 [6] GUAN Q L, LIU Z, FANG X H, et al. Experimental study on dense-phase pneumatic conveying of coal powder at high pressures[J]. Clean Energy, 2017, 1(1): 50-67. doi: 10.1093/ce/zkx007 [7] SANTO N, PORTNIKOV D, TRIPATHI N M, et al. Experimental study on the particle velocity development profile and acceleration length in horizontal dilute phase pneumatic conveying systems[J]. Powder Technology, 2018, 339: 368-376. doi: 10.1016/j.powtec.2018.07.074 [8] SANTO N, PORTNIKOV D, ESHEL I, et al. Experimental study on particle steady state velocity distribution in horizontal dilute phase pneumatic conveying[J]. Chemical Engineering Science, 2018, 187: 354-366. doi: 10.1016/j.ces.2018.04.058 [9] ZHOU J W, SHANGGUAN L J, GAO K D, et al. Numerical study of slug characteristics for coarse particle dense phase pneumatic conveying[J]. Powder Technology, 2021, 392: 438-447. doi: 10.1016/j.powtec.2021.07.024 [10] 周甲伟, 上官林建, 许兰贵, 等. 粗重颗粒轻介共流气力输送机理及特性[J]. 机械工程学报, 2022, 58(14): 308-319. doi: 10.3901/JME.2022.14.308ZHOU Jiawei, SHANGGUAN Linjian, XU Langui, et al. Mechanism and characteristics of light medium mixed flow pneumatic conveying for coarse particle[J]. Journal of Mechanical Engineering, 2022, 58(14): 308-319. doi: 10.3901/JME.2022.14.308 [11] 周锋. 煤炭大颗粒气力输送关键技术研究[D]. 徐州: 中国矿业大学, 2022. [12] 蔡海峰, 熊源泉, 周海军. 水平弯管高压密相气力输送数值模拟[J]. 东南大学学报(自然科学版), 2019, 49(1): 154-163.CAI Haifeng, XIONG Yuanquan, ZHOU Haijun. Numerical simulation on dense phase pneumatic conveying under high pressure in horizontal bend[J]. Journal of Southeast University (Natural Science Edition), 2019, 49(1): 154-163. [13] 杨辉. 气力输送计算机设计计算系统的研制与开发[D]. 杭州: 浙江大学, 2004. [14] 王云强. 烟草行业负压吸送式气力输送装置(系统)的设计计算[J]. 机械工程师, 2018(1): 77-79, 83.WANG Yunqiang. Design and calculation of negative-pressure pneumatic transporting device (system) for tobacco industry[J]. Mechanical Engineer, 2018(1): 77-79,83. [15] 杨伦, 谢一华. 气力输送工程[M]. 北京: 机械工业出版社, 2006. [16] 姜棚仁. 散粮管道气力输送多相流场特性研究[D]. 郑州: 河南工业大学, 2023. [17] 吴建章, 李东森. 通风除尘与气力输送[M]. 北京: 中国轻工业出版社, 2009. [18] 程克勤, 陈宏勋. 气力输送装置[M]. 北京: 机械工业出版社, 1993. [19] 李朝弟, 周磊, 周树光, 等. 弃料煤样真空气力输送系统的设计及应用[J]. 煤质技术, 2019, 34(6): 39-43, 51.LI Zhaodi, ZHOU Lei, ZHOU Shuguang, et al. Design and application of vacuum pneumatic conveying system for discarded coal samples[J]. Coal Quality Technology, 2019, 34(6): 39-43, 51. [20] 张则强, 汪开普, 朱立夏, 等. 多目标U型拆卸线平衡问题的Pareto蚁群遗传算法[J]. 西南交通大学学报, 2018, 53(3): 628-637, 660.ZHANG Zeqiang, WANG Kaipu, ZHU Lixia, et al. Pareto hybrid ant colony and genetic algorithm for multi-objective U-shaped disassembly line balancing problem[J]. Journal of Southwest Jiaotong University, 2018, 53(3): 628-637, 660. [21] 谢灼利, 黎明, 张政. 水平管气力输送的数值模拟研究[J]. 高校化学工程学报, 2006, 20(3): 331-337.XIE Zhuoli, LI Ming, ZHANG Zheng. Numerical simulation of horizontal pneumatic conveying[J]. Journal of Chemical Engineering of Chinese Universities, 2006, 20(3): 331-337. -

下载:

下载: