Experimental Study on Temperature Distribution of Wheel Tread under Continuous Braking on Super-Long Large Ramp

-

摘要:

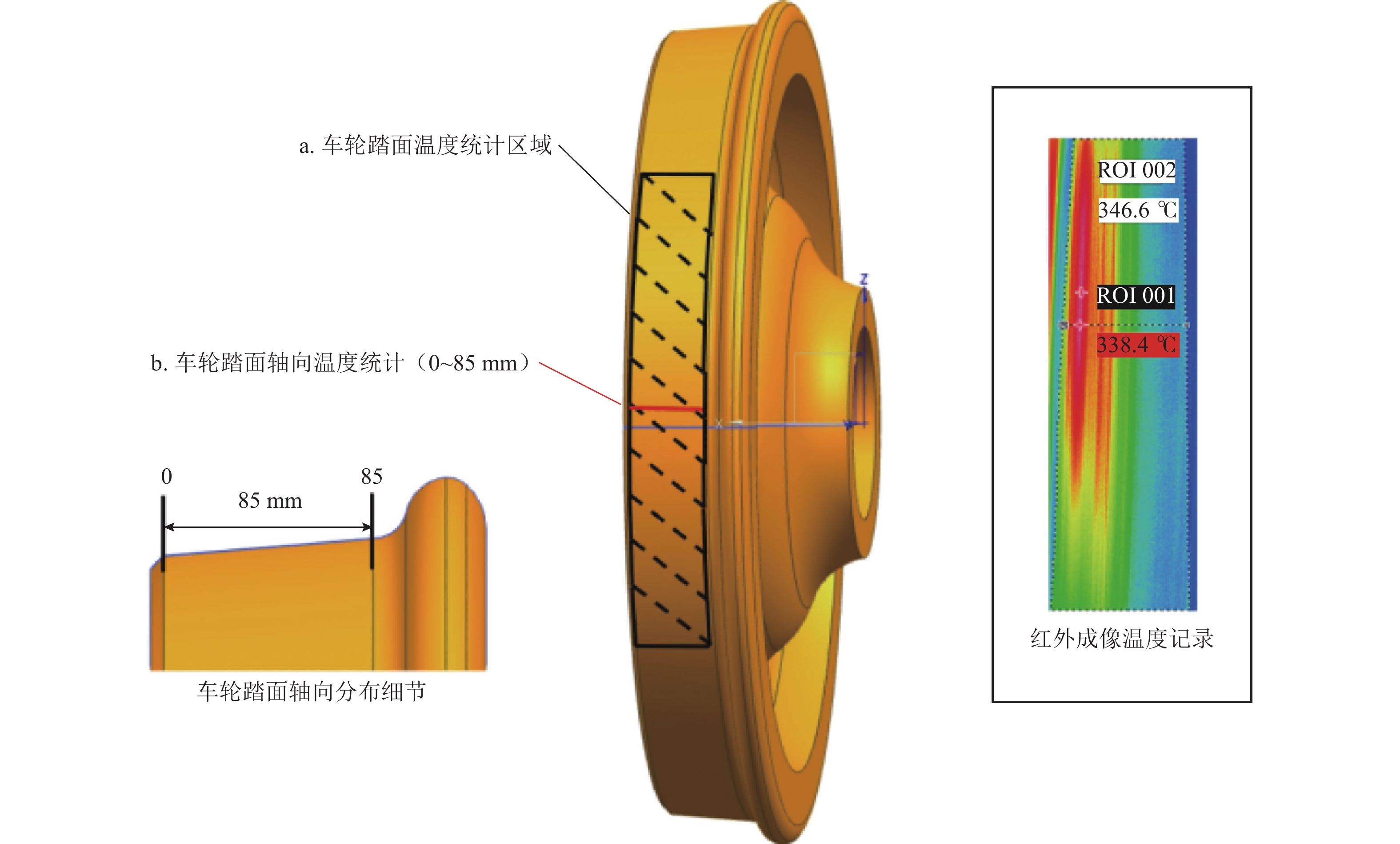

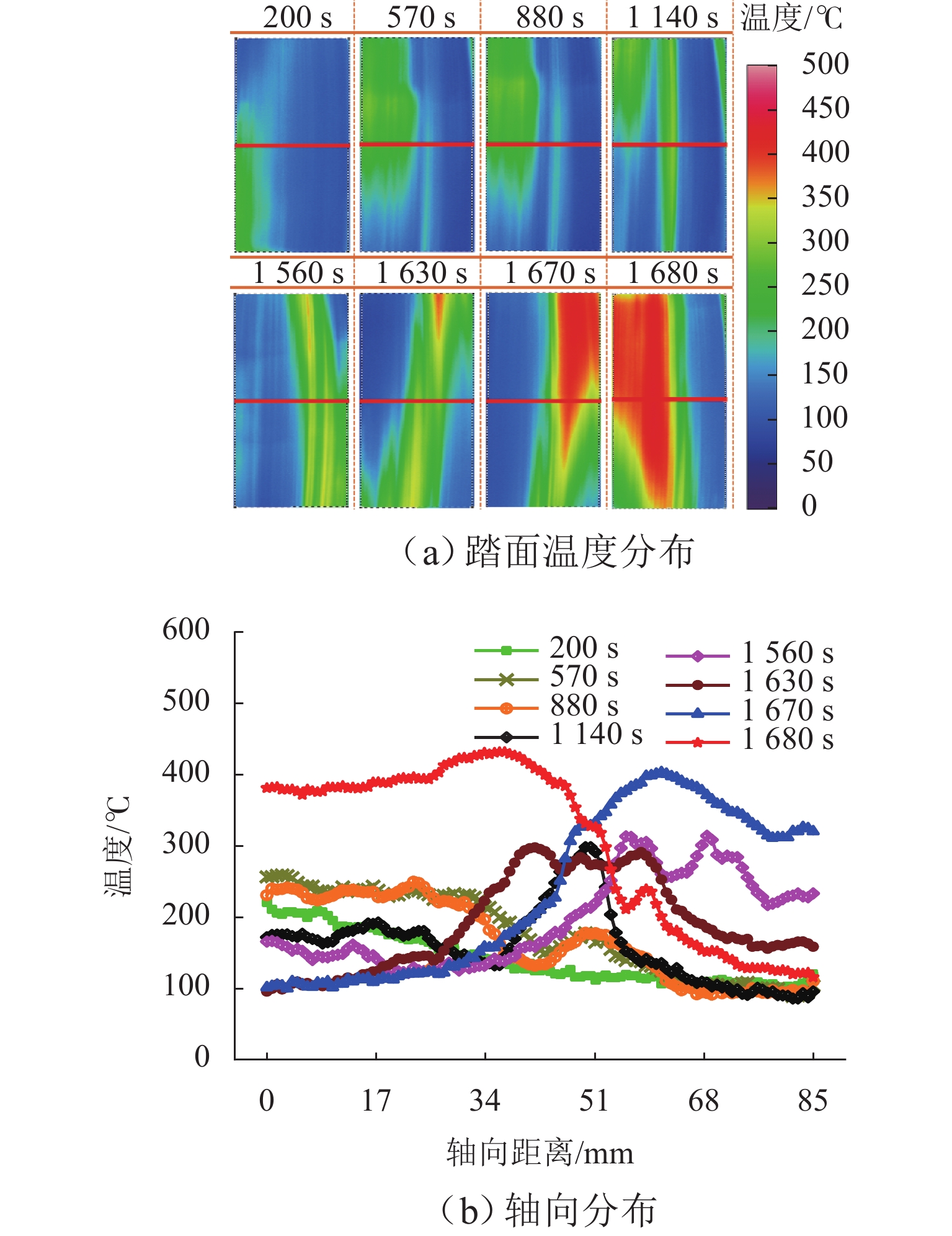

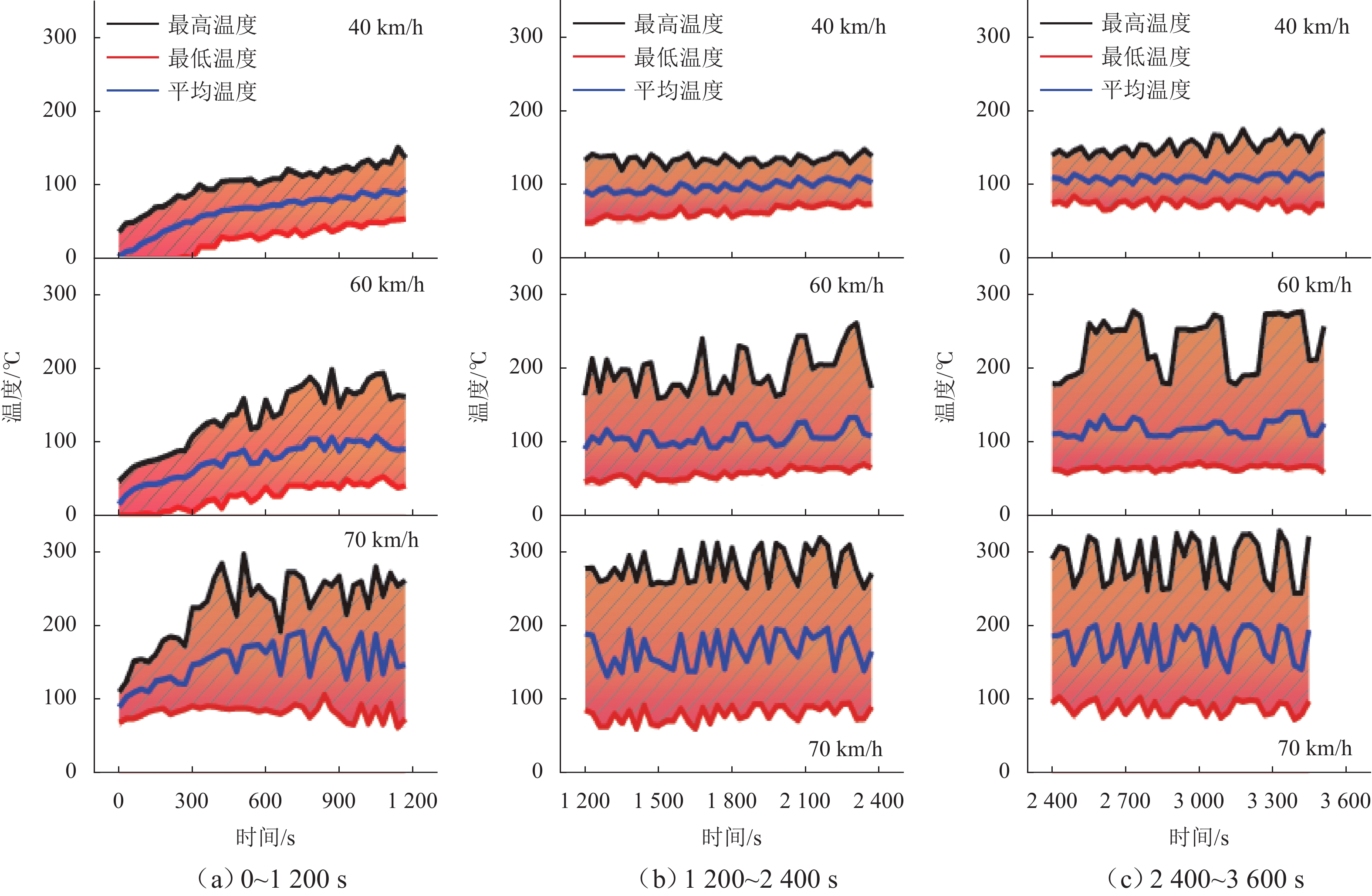

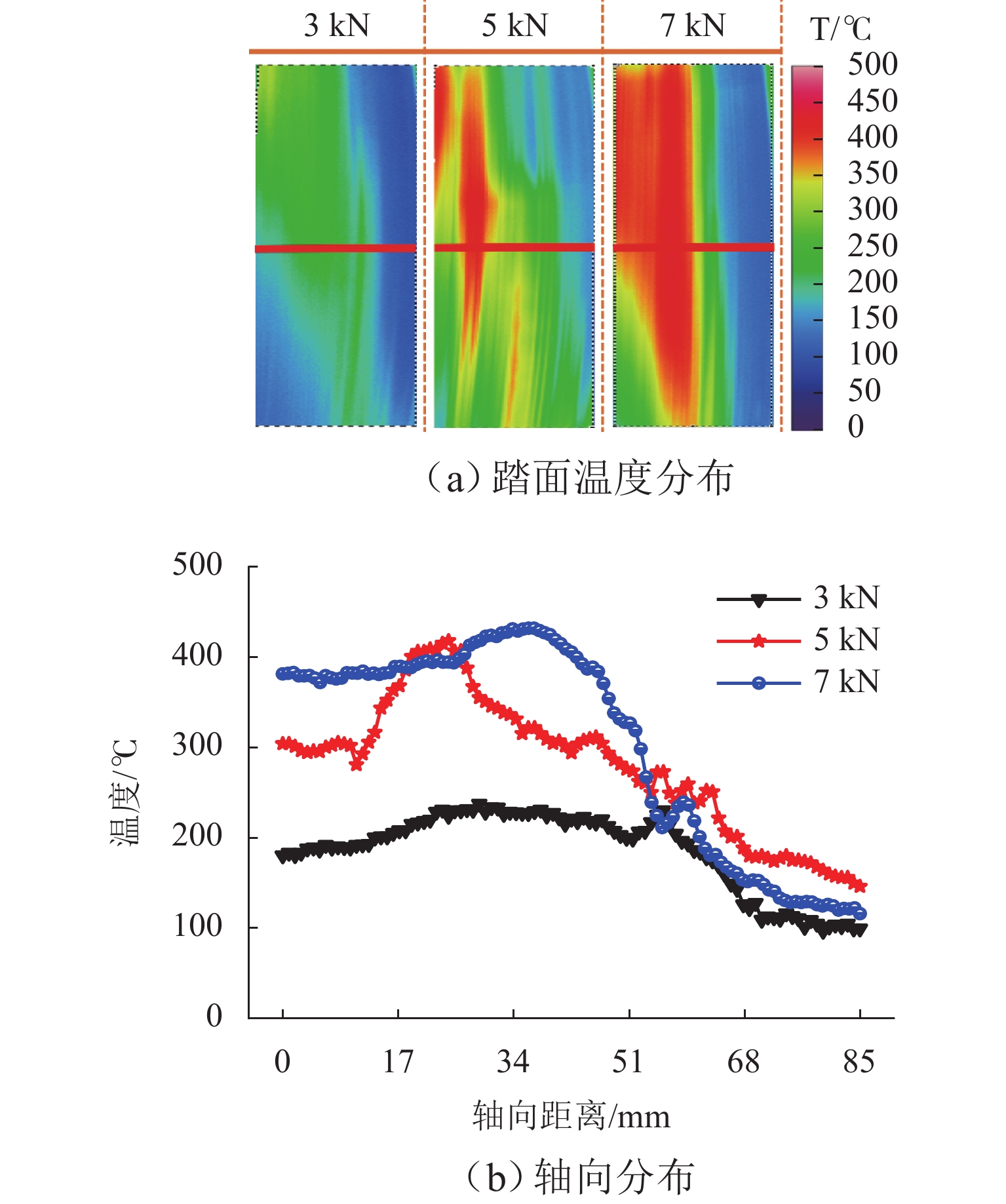

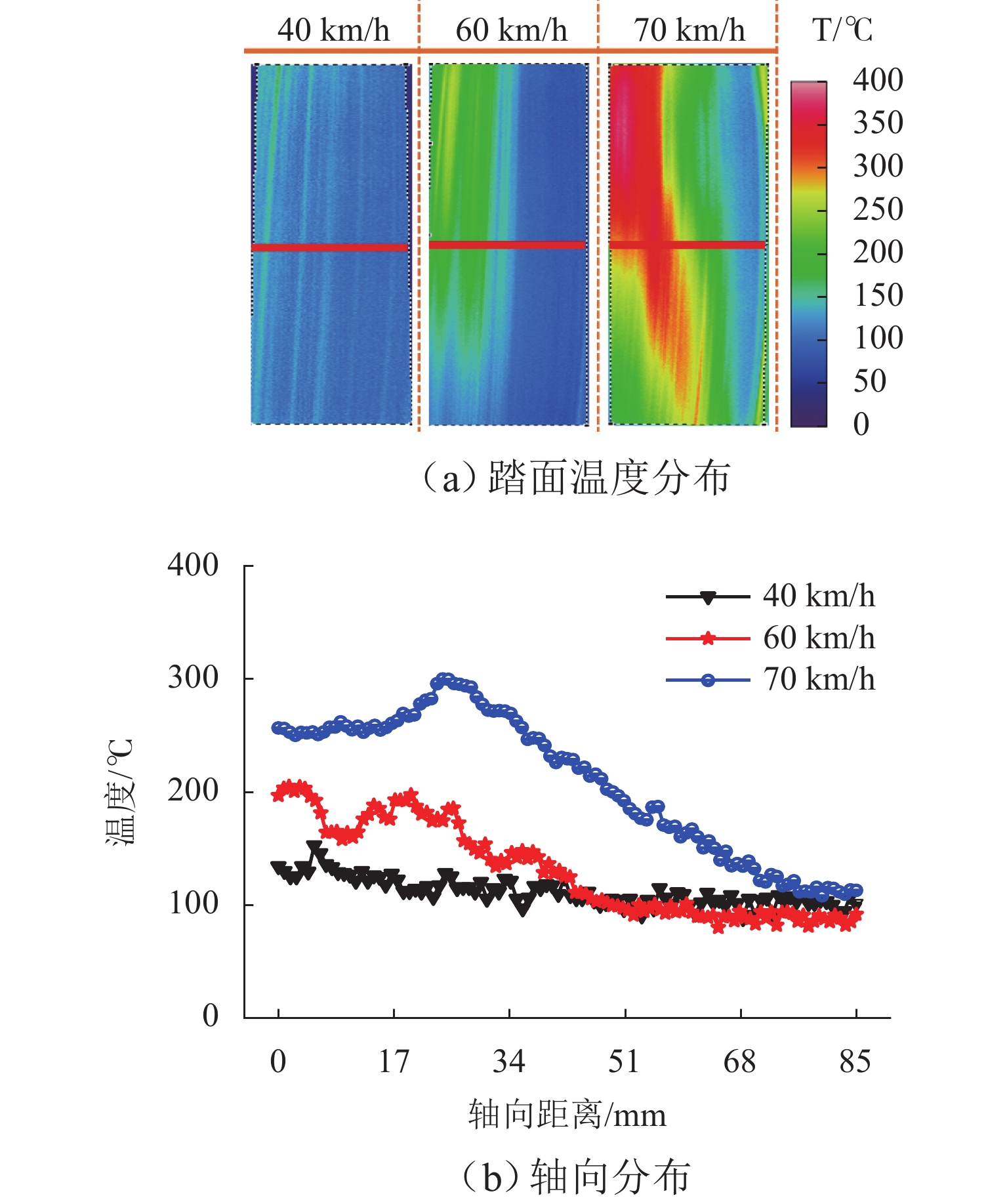

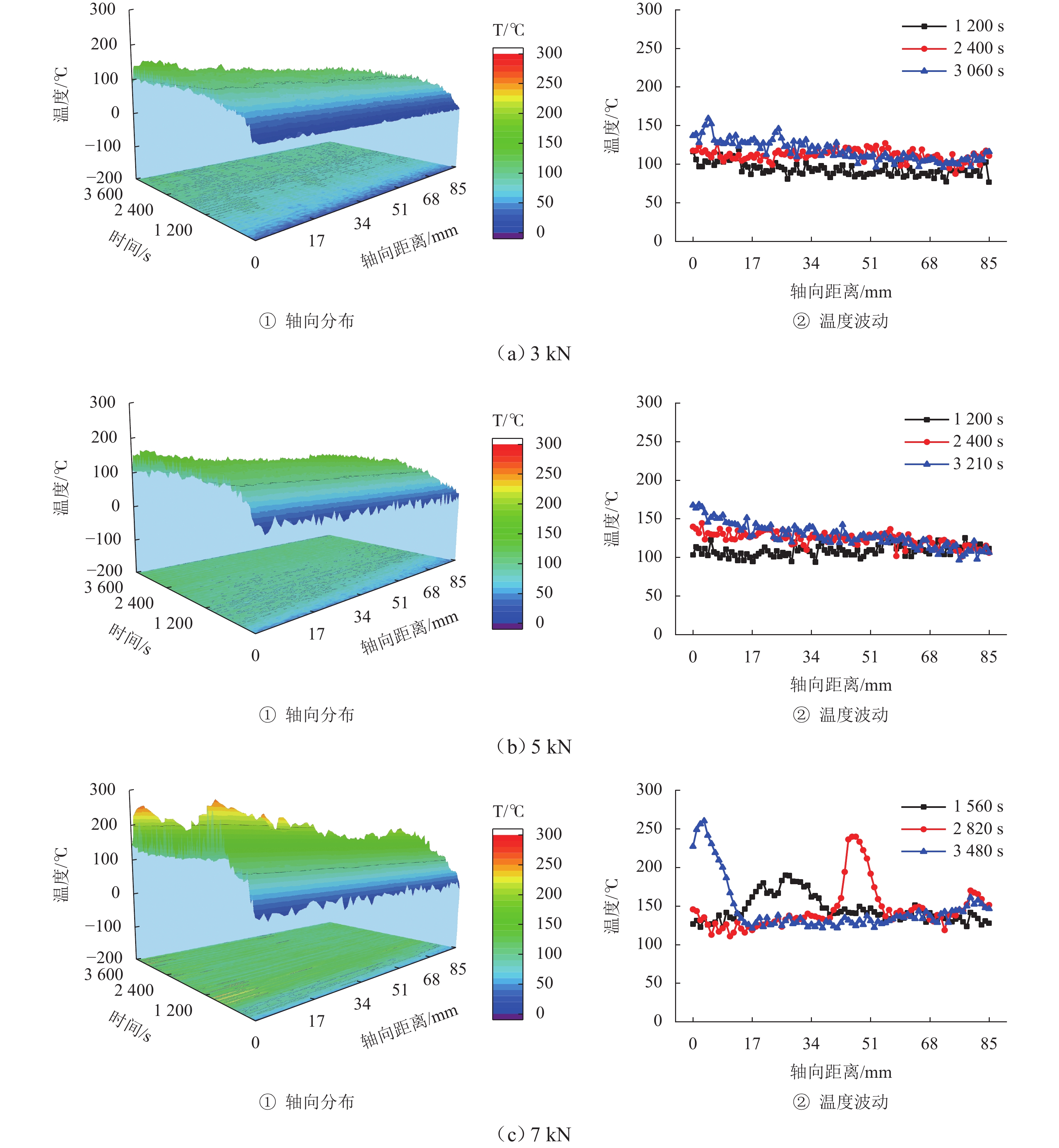

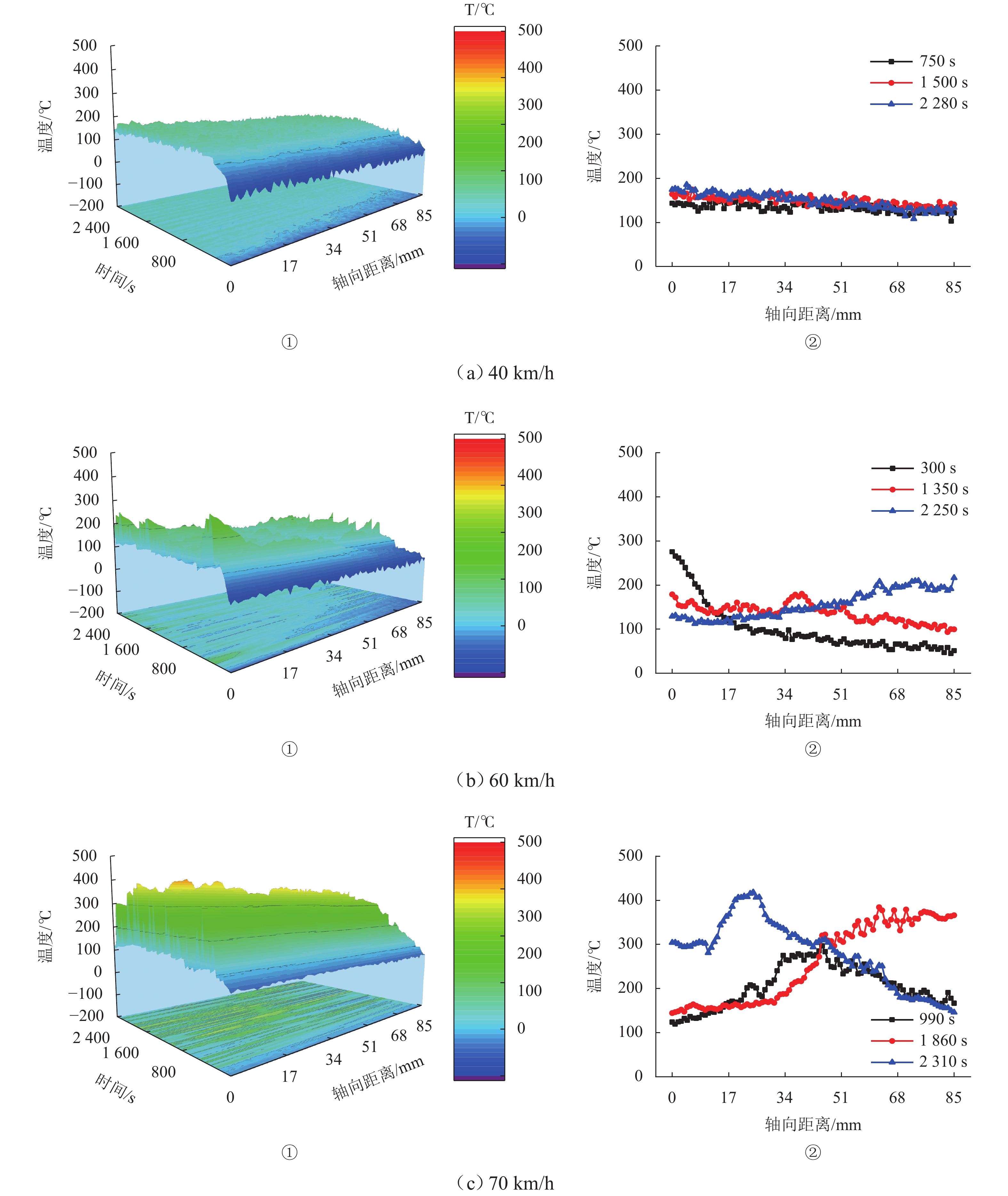

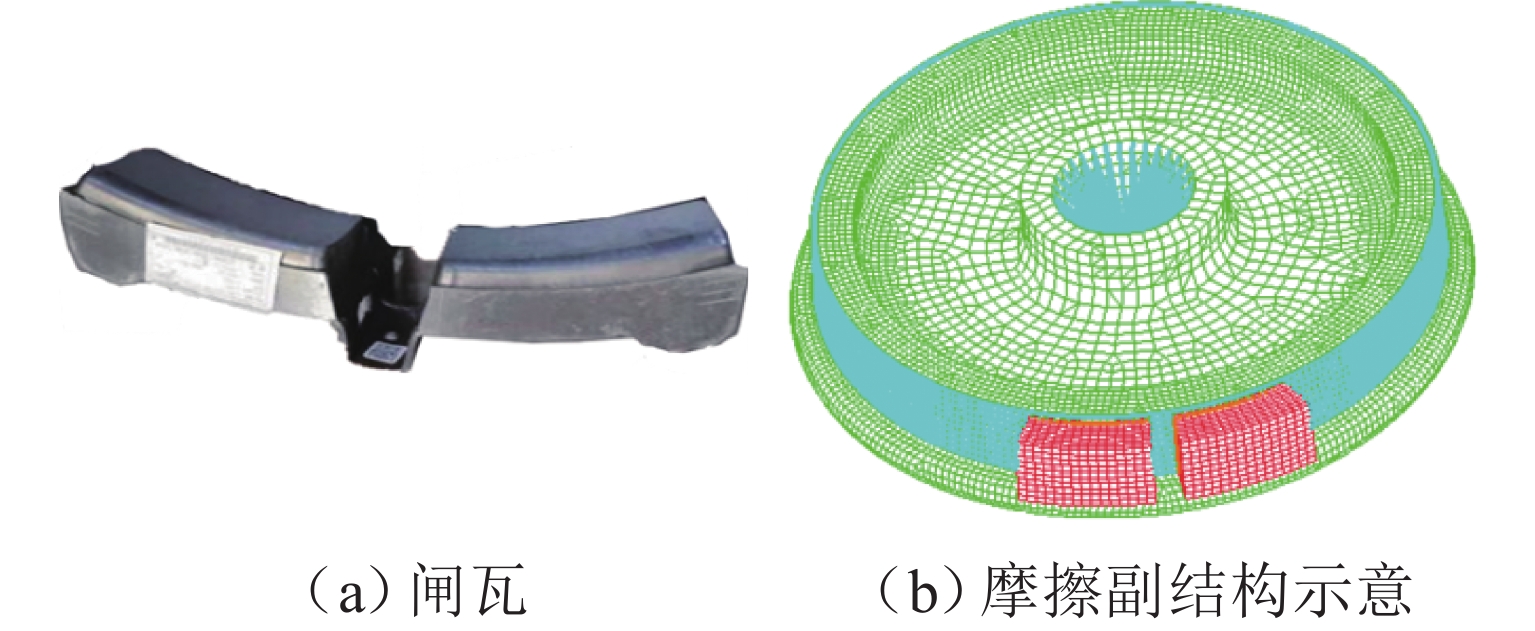

为探究持续制动条件对车轮踏面最大温度及温差的影响,明确车轮热负荷特性,以闸瓦-车轮踏面摩擦副为研究对象,基于1∶1 制动试验台开展超长大坡道持续制动试验;通过改变制动压力、制动速度及制动持续时间3个关键参数,分析制动过程中踏面温度的分布规律. 结果表明:制动速度由40 km/h增至70 km/h时,在制动0~

1200 、1200 ~2400 、2400 ~3600 s 3个阶段,各阶段的最高温度分别升高97%、118%和86%,最大温差分别增大113%、150%和128%,增加制动速度对前2个阶段的温差增幅影响大,制动初始摩擦面温度较低,闸瓦接触区域耐磨而不容易增加接触面积;在制动速度70 km/h条件下,制动压力由3 kN增至7 kN时,踏面最高温度由321 ℃增至436 ℃,增幅为36%,增加制动压力提高了摩擦功率,放大了局部接触状态对摩擦温度的影响,进而加剧踏面温度分布不均;在制动压力3 kN条件下,速度由40 km/h增至70 km/h,踏面最高温度由176 ℃增至328 ℃,增幅为86%,增加制动速度在提升制动能量的同时增大了制动功率,导致高温区域大幅扩展. 本文所研究内容对于机车车辆在超长大下坡道踏面制动性能的分析及运行方案的研究具有一定借鉴意义.Abstract:To investigate the effects of continuous braking conditions on the maximum temperature and temperature difference of wheel tread and clarify thermal load characteristics of the wheel, continuous braking tests on the super-long large ramp were conducted on a 1∶1 brake test bench, with the friction pair of brake shoe and wheel tread taken as the research object. The distribution pattern of tread temperature during braking was analyzed by changing three key parameters: braking pressure, speed, and duration. Results demonstrate that when the braking speed increases from 40 km/h to 70 km/h, the maximum temperature during the three braking phases (0–1 200 s, 1 200–2 400 s, and 2 400–3 600 s) increases by 97%, 118%, and 86%, respectively, and the maximum temperature difference rises by 113%, 150%, and 128%, respectively. The increase in braking speed exerts a greater influence on temperature difference during the first two stages, which is attributable to the lower temperature of the initial friction surface and the wear-resistant properties of brake shoe contact areas that constrain expansion of contact areas. At a braking speed of 70 km/h, when the braking pressure increases from 3 kN to 7 kN, the maximum tread temperature increases from 321 ℃ to 436 ℃, representing a 36% increase. The increase in the braking pressure enhances the friction power and amplifies the effect of local contact on the friction temperature, which further exacerbates the uneven distribution of tread temperature. Under the braking pressure of 3 kN, augmentation of speed from 40 km/h to 70 km/h increases the maximum tread temperature from 176 ℃ to 328 ℃, representing an 86% increase. Increasing the braking speed can boost braking energy and increase braking power, which significantly expands the high-temperature regions. This study can provide a reference for analyzing the tread braking performance and developing operational strategies of rolling stock under super-long large ramps.

-

Key words:

- braking /

- thermal load /

- temperature distribution /

- friction /

- abrasion

-

图 8 不同制动速度下,踏面温度轴向分布的变化情况(5 kN,40 min) 不同制动阶段踏面温度的波动情况 (d) 3 kN;(e) 5 kN; (f) 7 kN

Figure 8. Evolution of tread temperature in axial direction under different braking speeds (5 kN, 40 min; (a) 40 km/h; (b) 60 km/h; (c) 70 km/h) and fluctuation of tread temperature at different braking stages (d) 3 kN; (e) 5 kN; (f) 7 kN)

-

[1] 马思群, 李吉, 王成强, 等. 城轨车车轮轮对热容量有限元分析[J]. 大连交通大学学报, 2016, 37(3): 19-22. doi: 10.3969/j.issn.1673-9590.2016.03.005MA Siqun, LI Ji, WANG Chengqiang, et al. Finite element analysis of urban rail vehicle wheel thermal capacity[J]. Journal of Dalian Jiaotong University, 2016, 37(3): 19-22. doi: 10.3969/j.issn.1673-9590.2016.03.005 [2] 庞淑娟, 马璐, 曹云丽. 一种制动盘热容量近似计算方法的探讨[J]. 铁道车辆, 2024, 62(2): 76-78, 112.PANG Shujuan, MA Lu, CAO Yunli, Exploration of an approximate calculation method of brake disc thermal capacity[J]. Rolling Stock, 2024, 62(2): 76-78, 112. [3] 刘雄强, 卢纯, 孙田龙, 等. 多次制动工况下列车制动闸片摩擦块磨损行为的演变规律分析[J]. 摩擦学学报, 2025, 45(8): 1128-1139.LIU Xiongqiang, LU Chun, SUN Tianlong, et al. Evolution analysis of wear behavior of brake pad friction block under multiple braking conditions[J]. Tribology, 2025, 45(8): 1128-1139. [4] 张金煜, 虞大联, 林鹏. 基于旋转热源法和均布热源法的列车踏面制动温度场分析[J]. 机械工程学报, 2018, 54(6): 93-101. doi: 10.3901/JME.2018.06.093ZHANG Jinyu, YU Dalian, LIN Peng. Analysis of temperature field of train tread braking based on rotating heat source method and uniformly distributed heat source method[J]. Journal of Mechanical Engineering, 2018, 54(6): 93-101. doi: 10.3901/JME.2018.06.093 [5] 陈帅, 吴磊, 付青云, 等. 基于间隙热源法的车轮踏面制动摩擦温升研究[J]. 润滑与密封, 2017, 42(5): 30-35. doi: 10.3969/j.issn.0254-0150.2017.05.006CHEN Shuai, WU Lei, FU Qingyun, et al. Research on wheel temperature rising due to tread braking based on intermittent heat source method[J]. Lubrication Engineering, 2017, 42(5): 30-35. doi: 10.3969/j.issn.0254-0150.2017.05.006 [6] 张野, 马晓杰, 朱绘丽. 基于ANSYS的车轮踏面紧急制动热分析[J]. 铁道机车车辆, 2020, 40(3): 122-126, 130. doi: 10.3969/j.issn.1008-7842.2020.03.25ZHANG Ye, MA Xiaojie, ZHU Huili. Thermal analysis of emergency braking of wheel tread based on ANSYS[J]. Railway Locomotive & Car, 2020, 40(3): 122-126,130. doi: 10.3969/j.issn.1008-7842.2020.03.25 [7] 周翠, 高卿. 地铁车轮踏面紧急制动热应力分析[J]. 山东农业大学学报(自然科学版), 2019, 50(1): 57-61. doi: 10.3969/j.issn.1000-2324.2019.01.012ZHOU Cui, GAO Qing. Analysis on thermal stress from metro wheel tread emergency braking[J]. Journal of Shandong Agricultural University(Natural Science Edition), 2019, 50(1): 57-61. doi: 10.3969/j.issn.1000-2324.2019.01.012 [8] 应何蓉, 颜晓雨, 丁宁, 等. 地铁紧急制动踏面热应力分析研究[J]. 实验室研究与探索, 2021, 40(7): 96-99, 105. doi: 10.19927/j.cnki.syyt.2021.07.021YING Herong, YAN Xiaoyu, DING Ning, et al. Analyis of thermal stress of metro wheel tread under emergency braking condition[J]. Research and Exploration in Laboratory, 2021, 40(7): 96-99,105. doi: 10.19927/j.cnki.syyt.2021.07.021 [9] 董永刚, 仪帅, 黄鑫磊, 等. 重载列车紧急制动过程车轮踏面疲劳裂纹萌生寿命预测[J]. 中国铁道科学, 2021, 42(5): 123-131. doi: 10.3969/j.issn.1001-4632.2021.05.14DONG Yonggang, YI Shuai, HUANG Xinlei, et al. Prediction of fatigue crack initiation life of wheel tread during emergency braking of heavy haul train[J]. China Railway Science, 2021, 42(5): 123-131. doi: 10.3969/j.issn.1001-4632.2021.05.14 [10] TEIMOURIMANESH S, VERNERSSON T, LUNDÉN R, et al. Tread braking of railway wheels–temperatures generated by a metro train[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2014, 228(2): 210-221. doi: 10.1177/0954409712470608 [11] FACCOLI M, GHIDINI A, MAZZÙ A. Experimental and numerical investigation of the thermal effects on railway wheels for shoe-braked high-speed train applications[J]. Metallurgical and Materials Transactions A, 2018, 49(10): 4544-4554. doi: 10.1007/s11661-018-4749-2 [12] 李兰, 蔡园武, 郭刚. 轮轨滚动接触和制动热负荷耦合作用对重载车轮踏面裂纹萌生寿命的影响[J]. 中国铁道科学, 2019, 40(3): 89-96. doi: 10.3969/j.issn.1001-4632.2019.03.13LI Lan, CAI Yuanwu, GUO Gang. Coupling effect of wheel-rail rolling contact and braking thermal load on crack initiation life of heavy haul wheel tread[J]. China Railway Science, 2019, 40(3): 89-96. doi: 10.3969/j.issn.1001-4632.2019.03.13 [13] 应之丁, 李小宁, 林建平, 等. 列车车轮踏面制动温度循环试验与温度场仿真分析[J]. 中国铁道科学, 2010, 31(3): 70-75.YING Zhiding, LI Xiaoning, LIN Jianping, et al. The temperature cycle test of wheel tread braking for freight trains and the simulation analysis of the temperature field[J]. China Railway Science, 2010, 31(3): 70-75. [14] 常崇义, 蔡园武, 李兰, 等. 高速轮轨黏着机理的研究进展及其应用[J]. 中国铁路, 2017(11): 24-32. doi: 10.19549/j.issn.1001-683x.2017.11.024CHANG Chongyi, CAI Yuanwu, LI Lan, et al. Research progress and application of the mechanism of high-speed wheel-rail adhesion[J]. Chinese Railways, 2017(11): 24-32. doi: 10.19549/j.issn.1001-683x.2017.11.024 [15] 董永刚, 仪帅, 黄鑫磊, 等. 重载列车紧急制动过程车轮踏面疲劳裂纹萌生寿命预测[J]. 中国铁道科学, 2021, 42(5): 123-131.DONG Yonggang, YI Shuai, HUANG Xinlei, et al. Prediction of fatigue crack initiation life of wheel tread during emergency braking of heavy haul train[J]. China Railway Science, 2021, 42(5): 123-131. [16] 吴涛, 李林波, 孙智, 等. 紧急制动时闸瓦性能对地铁车轮踏面热应力的影响[J]. 现代城市轨道交通, 2019(7): 57-61.WU Tao, LI Linbo, SUN Zhi, et al. Effect of brake shoe performance on thermal stress of metro wheel tread during emergency brake[J]. Modern Urban Transit, 2019(7): 57-61. [17] 仪帅. 重载列车踏面制动过程车轮热摩擦损伤及热疲劳寿命研究[D]. 秦皇岛: 燕山大学, 2021. [18] 董永刚, 仪帅, 黄鑫磊, 等. 列车紧急制动过程中踏面温度分布及磨耗预测[J]. 中国机械工程, 2021, 32(4): 431-438, 445. doi: 10.3969/j.issn.1004-132X.2021.04.007DONG Yonggang, YI Shuai, HUANG Xinlei, et al. Temperature distribution of treads and wear prediction during train emergency braking[J]. China Mechanical Engineering, 2021, 32(4): 431-438,445. doi: 10.3969/j.issn.1004-132X.2021.04.007 [19] 王钰博. 高速重载列车踏面制动过程仿真及踏面疲劳寿命预测[D]. 秦皇岛: 燕山大学, 2021. [20] HANDA K, IKEUCHI K, MORIMOTO F. Temperature-dependent wear of tread-braked railway wheels[J]. Wear, 2020, 452/453: 203265. [21] WALIA M S, ESMAEILI A, VERNERSSON T, et al. Thermomechanical capacity of wheel treads at stop braking: a parametric study[J]. International Journal of Fatigue, 2018, 113: 407-415. doi: 10.1016/j.ijfatigue.2018.04.031 [22] 宋剑锋, 黄鑫磊, 仪帅, 等. 列车制动过程踏面温度场及应力-应变分布特性[J]. 吉林大学学报(工学版), 2023, 53(10): 2773-2784. doi: 10.13229/j.cnki.jdxbgxb.20211324SONG Jianfeng, HUANG Xinlei, YI Shuai, et al. Temperature field and stress-strain distribution of tread during train braking[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(10): 2773-2784. doi: 10.13229/j.cnki.jdxbgxb.20211324 [23] 王思然. 列车长大下坡制动过程车轮踏面磨耗与疲劳分析及耦合竞争关系研究[D]. 秦皇岛: 燕山大学, 2024. -

下载:

下载: