Mechanism and Control Method of Rail Corrugation-Induced Clip Fracture in Sections with Double-Layer Nonlinear Vibration Damping Fastener

-

摘要:

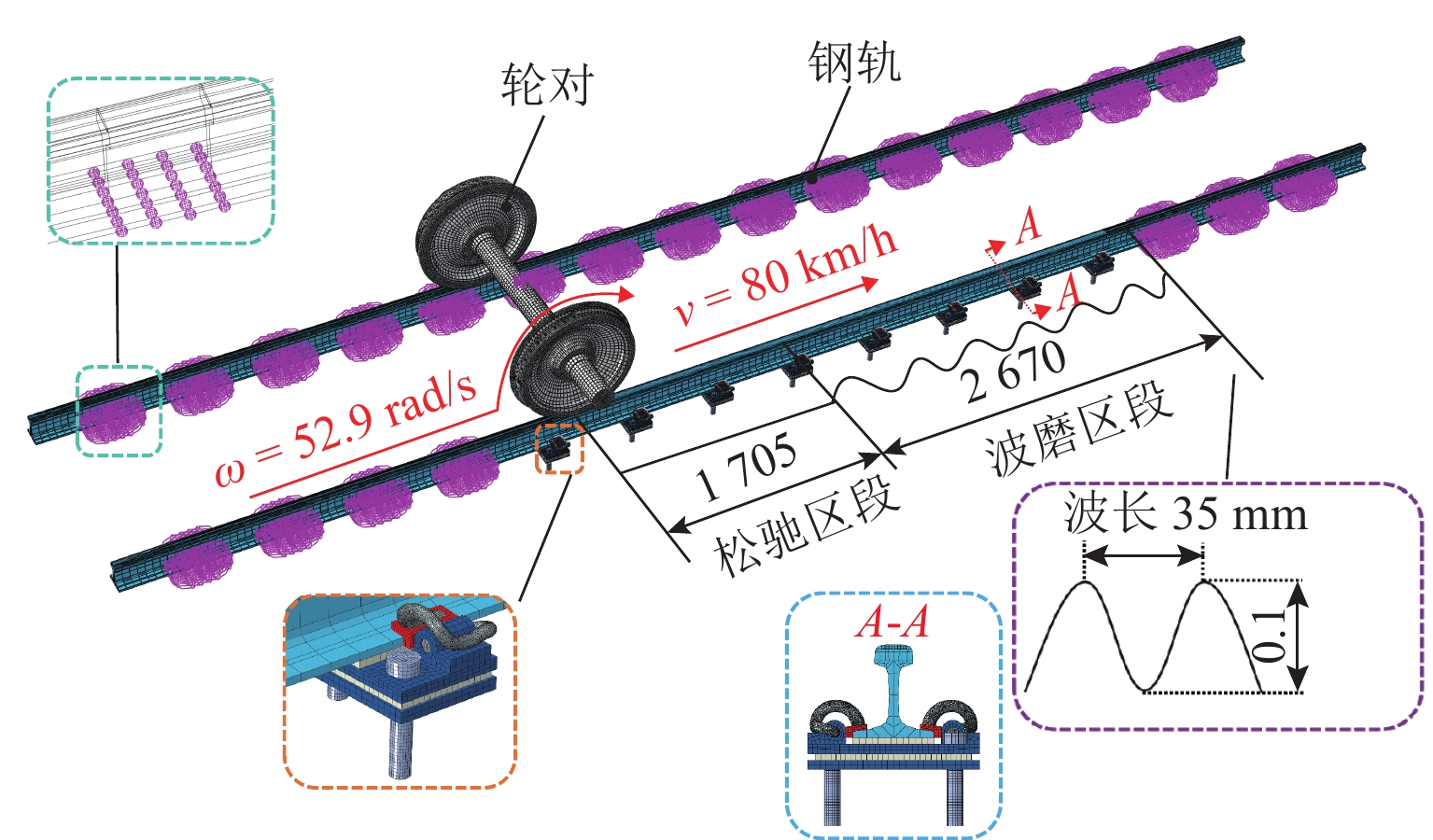

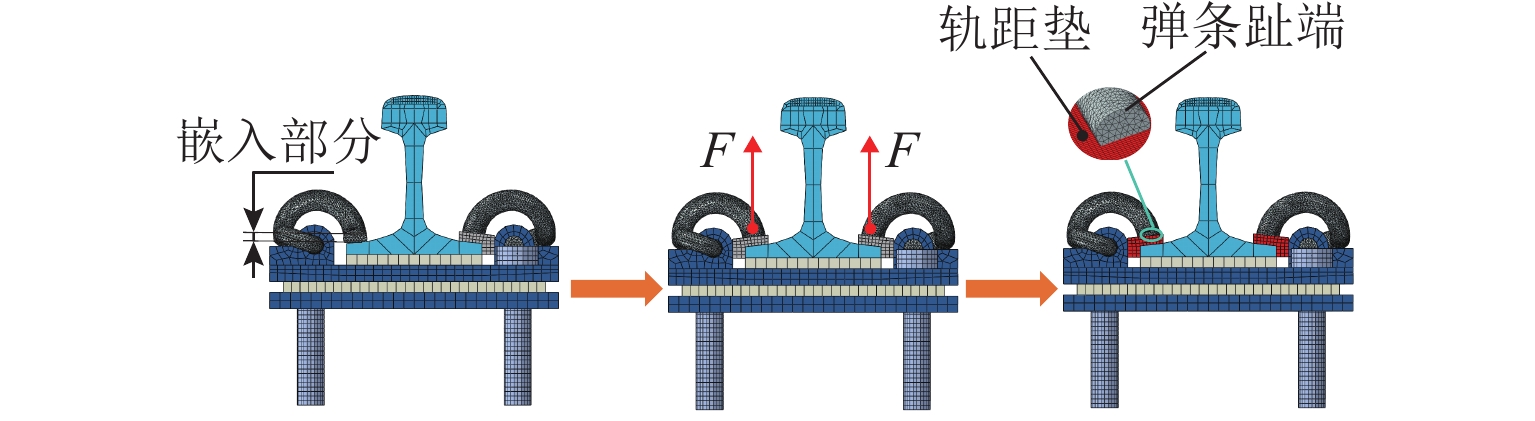

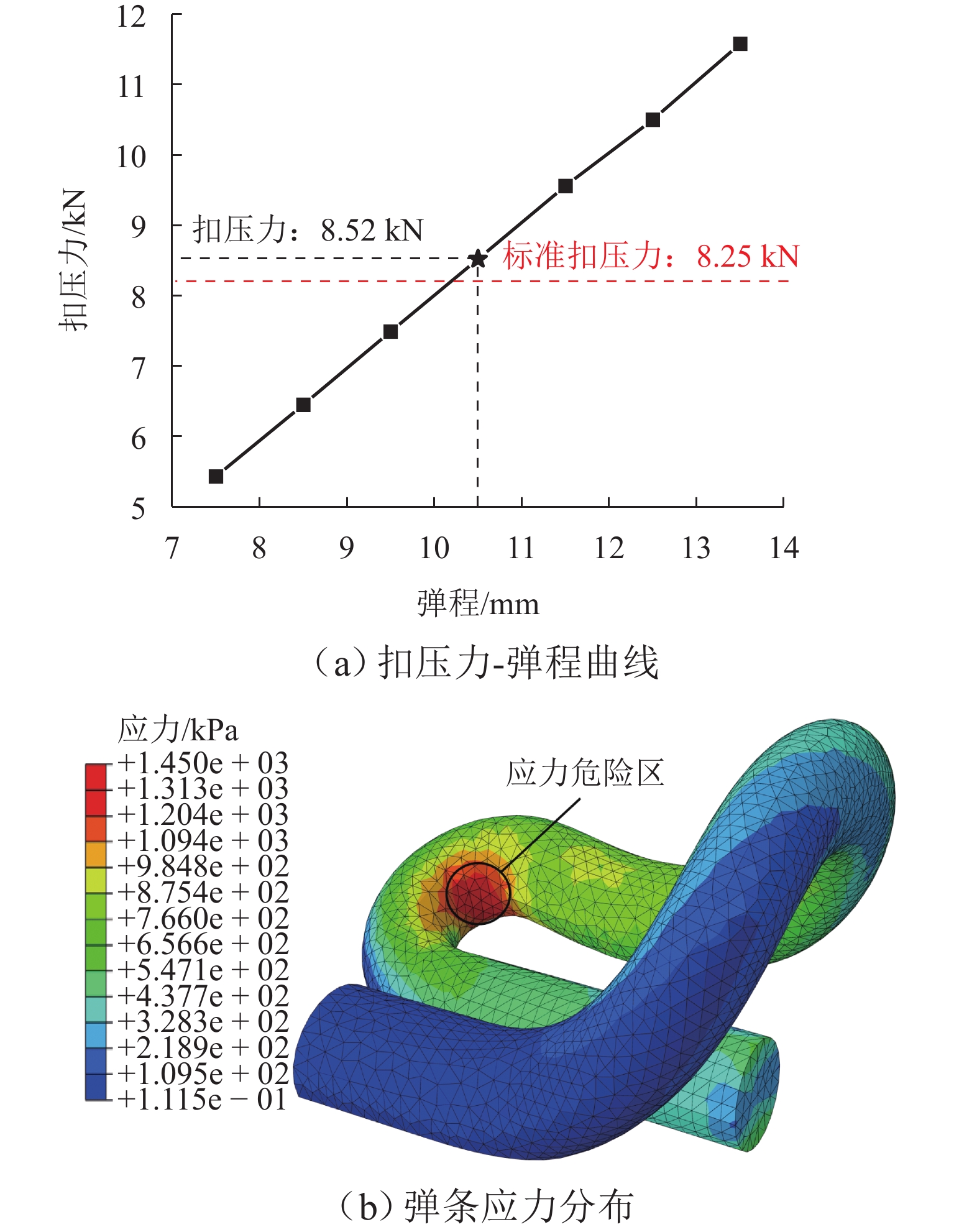

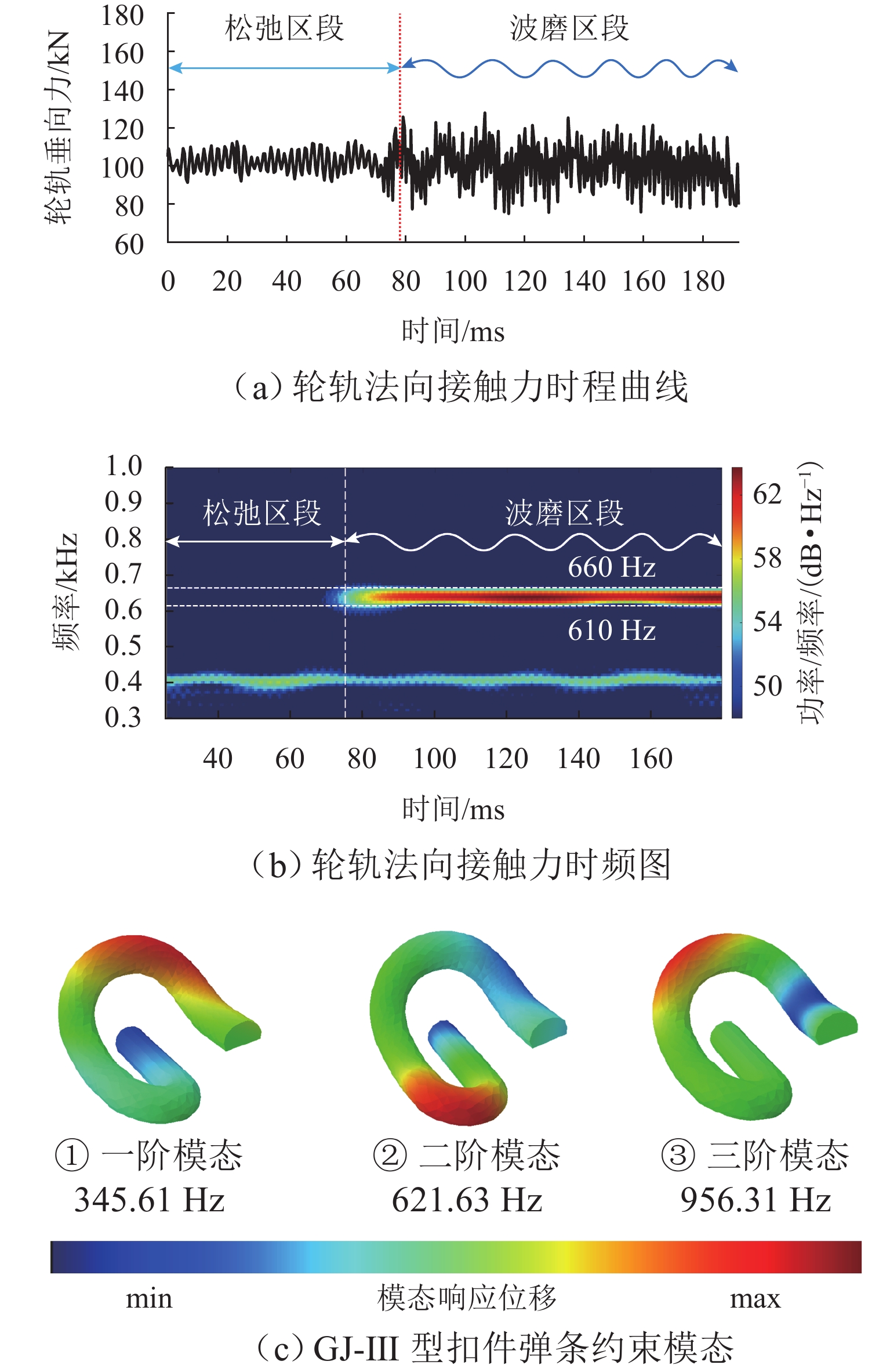

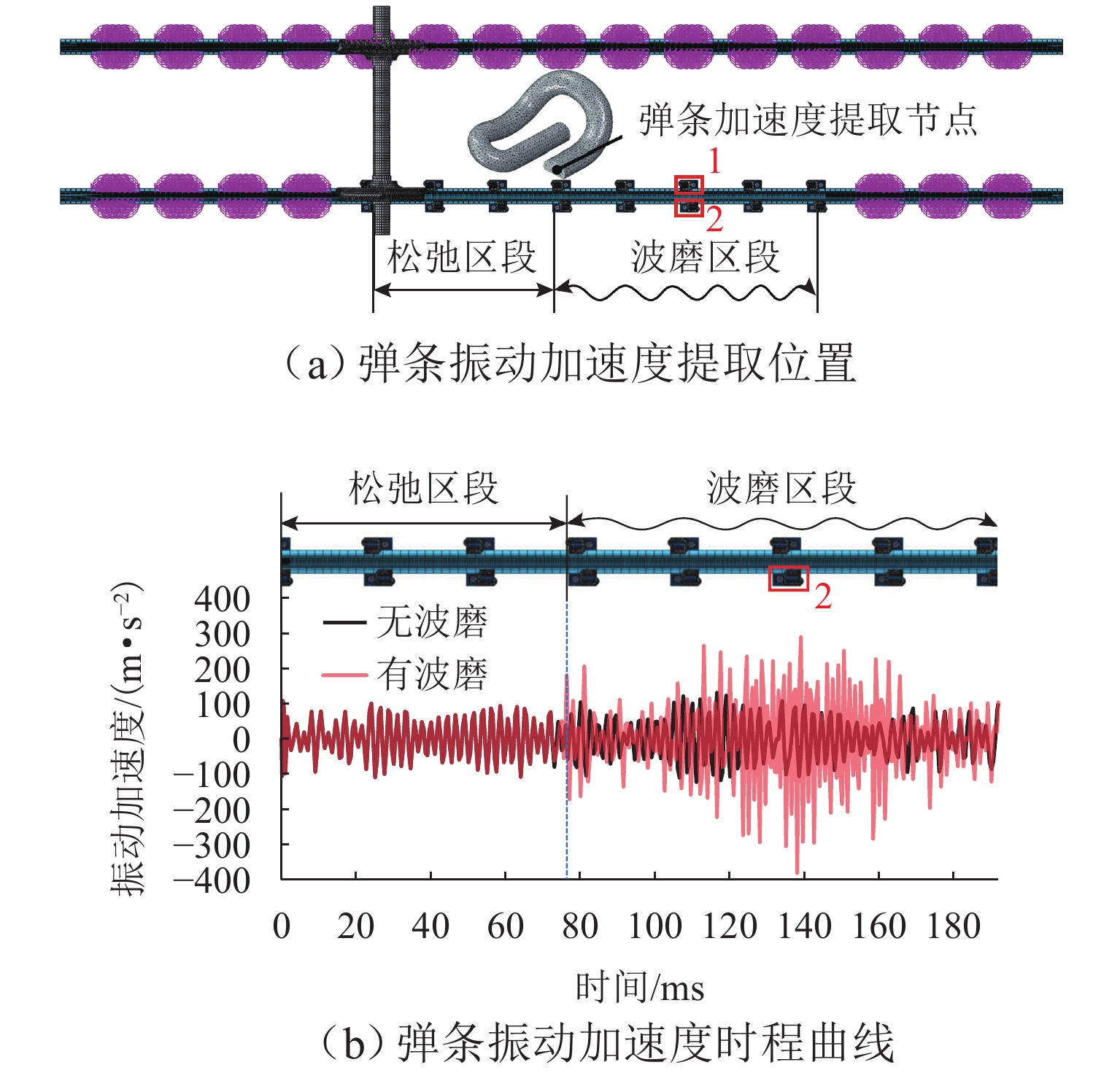

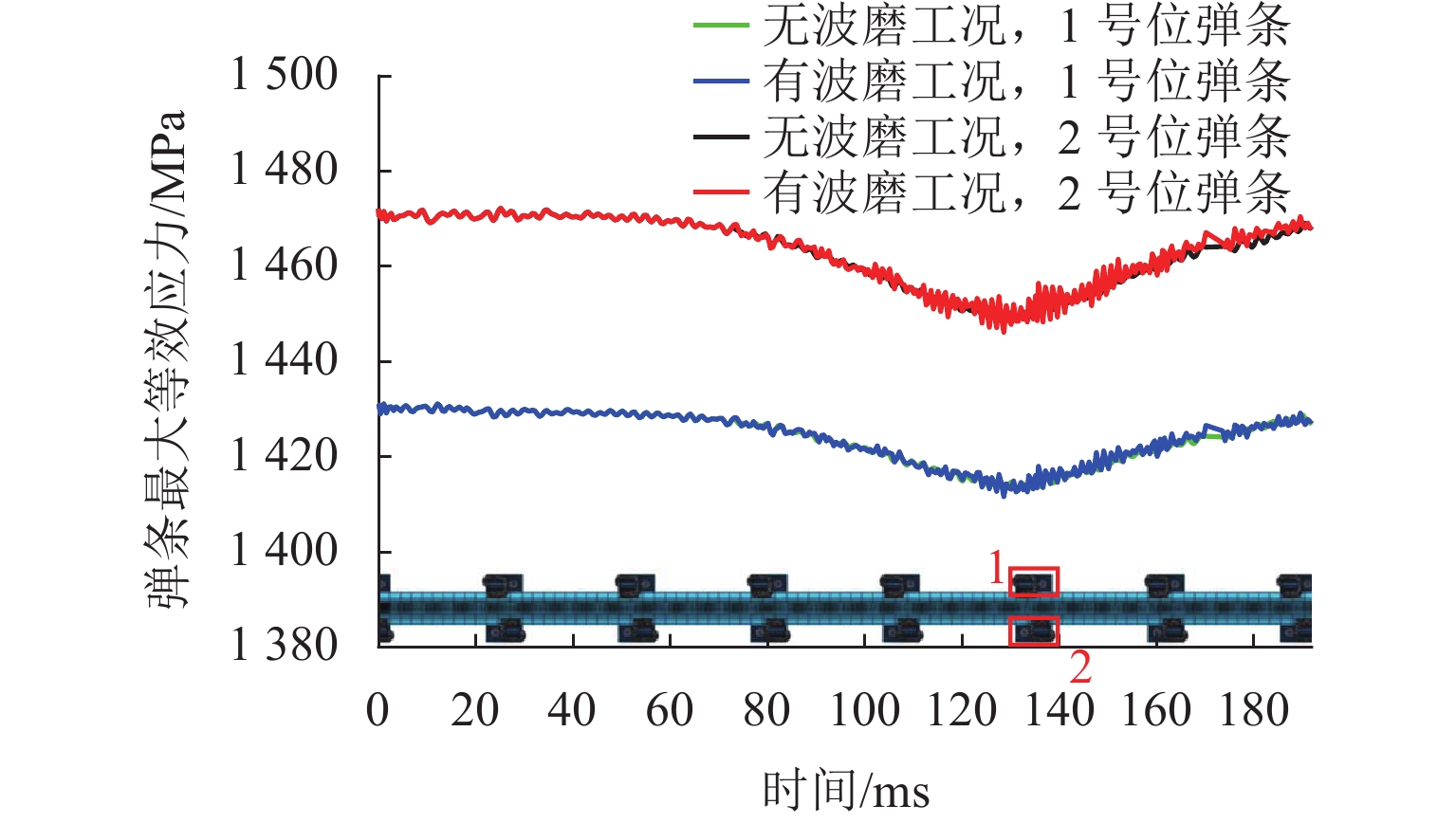

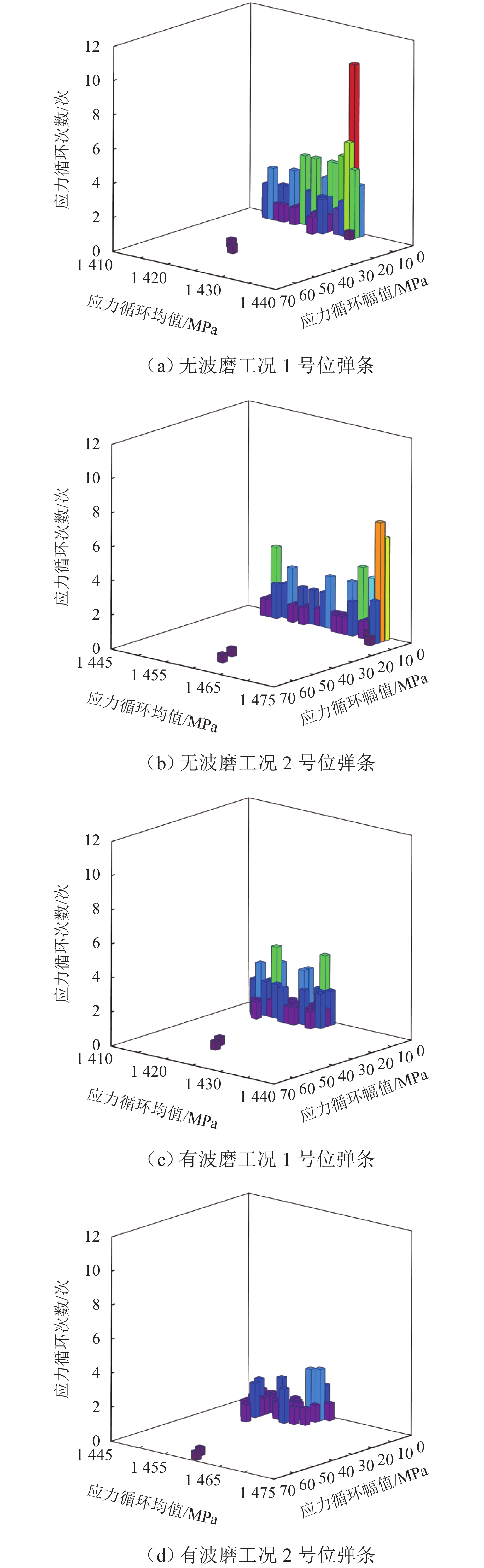

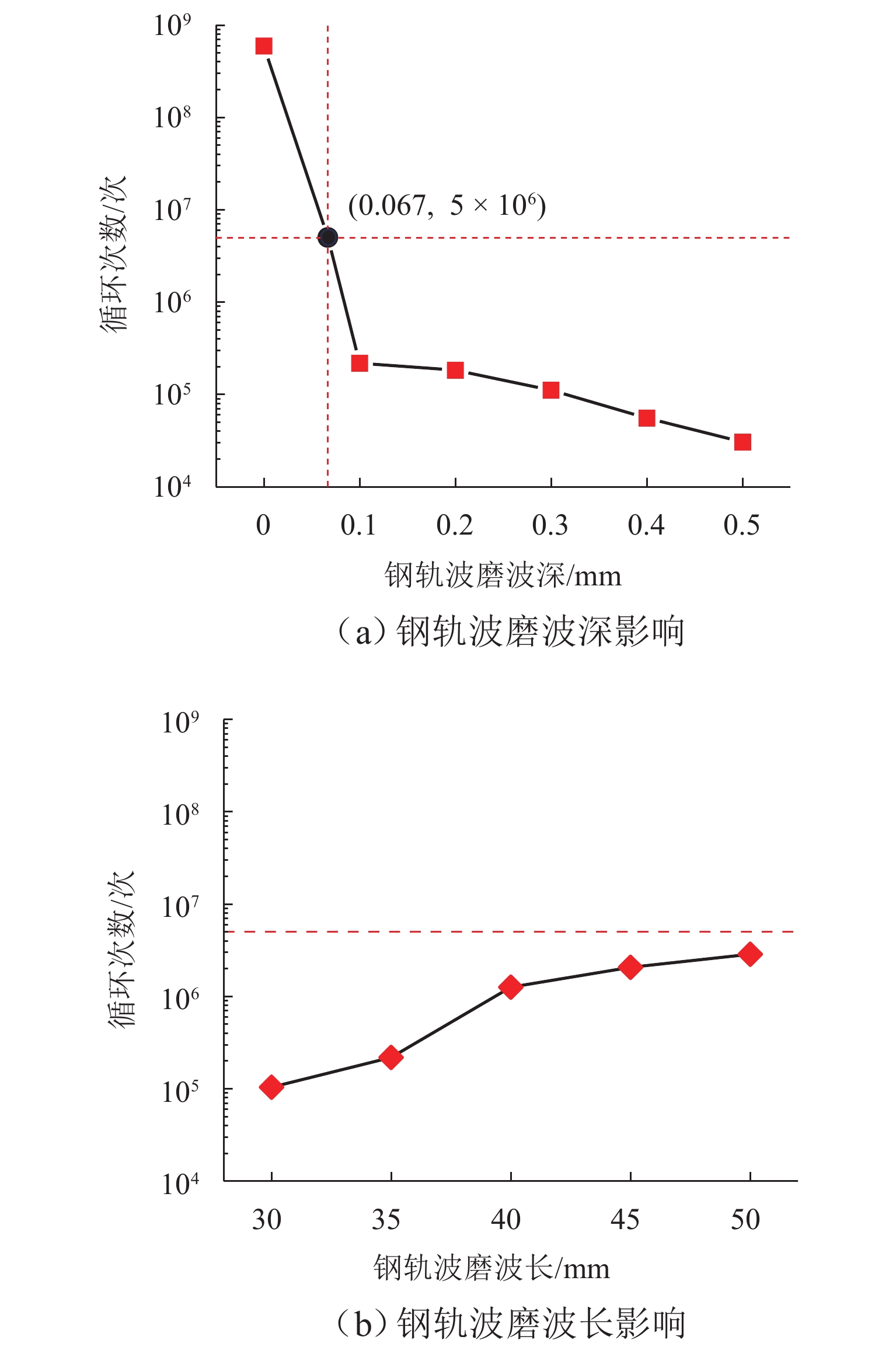

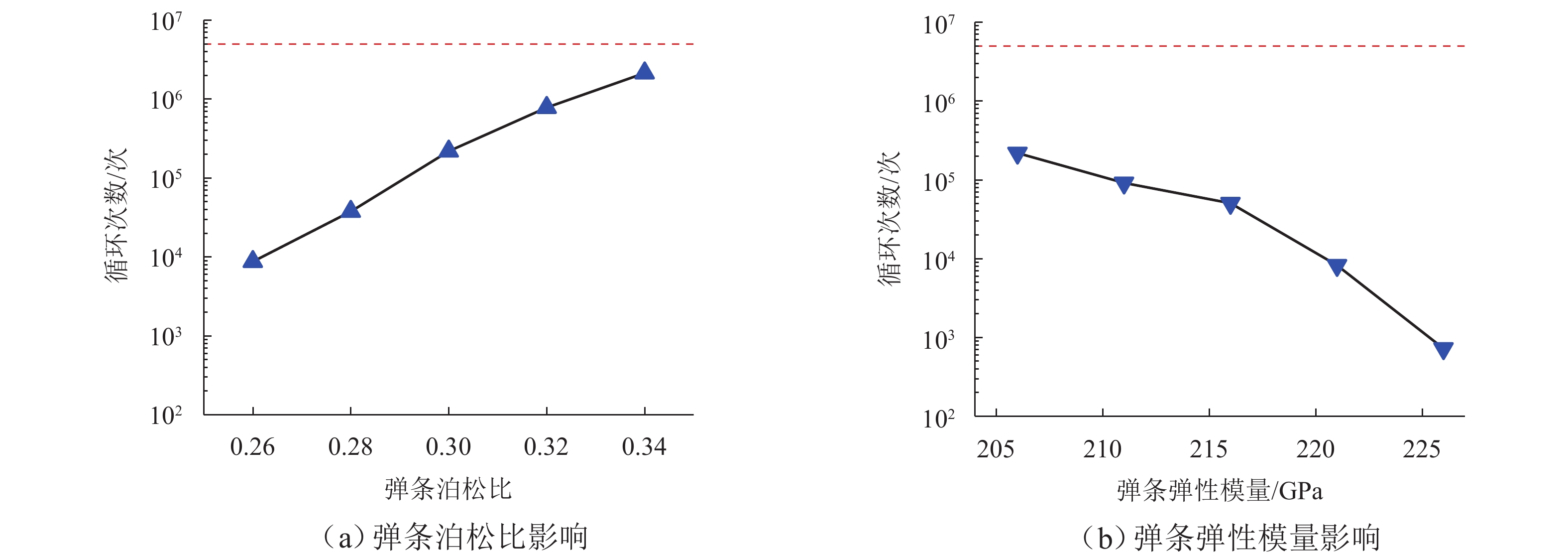

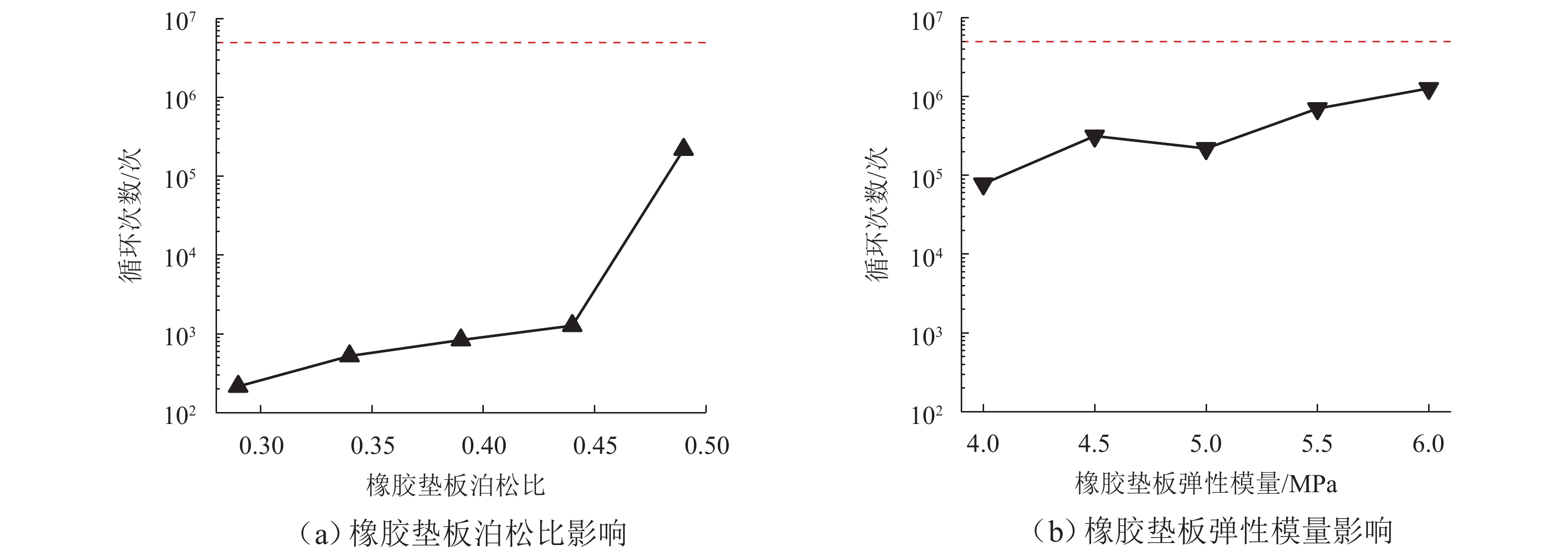

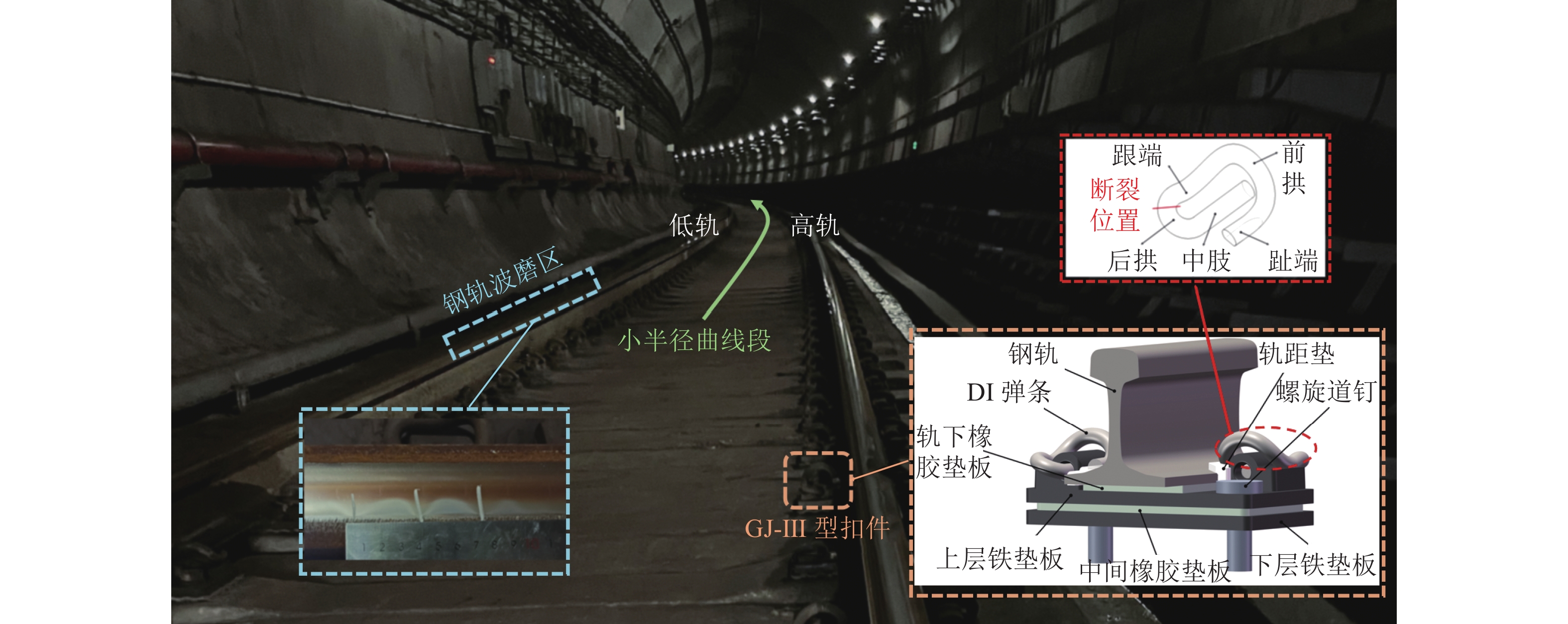

为研究地铁双层非线性减振扣件区段由钢轨波磨诱导的弹条断裂问题,以典型的GJ-Ⅲ型双层非线性减振扣件为研究对象,结合现场调研和数值仿真对该区段扣件弹条的断裂诱因及其影响因素进行分析. 首先,构建了含有钢轨波磨的轮对-钢轨-扣件系统有限元模型;然后,采用瞬时动态分析方法从共振响应角度探究了钢轨波磨区段扣件弹条的断裂诱因;接着,通过疲劳累计损伤理论从疲劳特性角度对比研究了低轨两侧弹条在有无波磨情况下的疲劳寿命;最后,进行参数化分析,探究了钢轨波磨外在激励和扣件部件内在特性对弹条疲劳寿命的影响规律. 结果表明:钢轨波磨诱导的高频激励导致了GJ-Ⅲ型扣件弹条共振,是弹条断裂的主要诱因;钢轨波磨加剧了轮轨系统的振动响应,降低了弹条的使用寿命且对低轨外侧弹条影响更为严重,使其疲劳寿命降低至2.18 × 105次,仅为弹条设计寿命的4.36%;钢轨波磨外在激励方面,波磨波深减小和波磨波长增大会使弹条疲劳寿命有所增加,且当波磨波长在40 mm以上时,其疲劳寿命提升较大;扣件部件内在特性方面,减小弹条弹性模量,增加弹条泊松比、橡胶垫板泊松比及其弹性模量,能一定程度上减少弹条的疲劳损伤,进而缓解钢轨波磨区段扣件弹条的断裂.

Abstract:To study the problem of rail corrugation-induced clip fracture in metro sections with double-layer nonlinear vibration damping fasteners, by taking the typical GJ-Ⅲ type fastener as the research object, field investigation and numerical simulation were combined to analyze the causes and influencing factors of fastener clip fracture in this section. Firstly, a finite element model of the wheel–rail–fastener system incorporating rail corrugation was constructed. Subsequently, the instantaneous dynamic analysis method was employed to investigate the causes of fastener clip failure in the rail corrugation section from the perspective of resonance response. Then, based on cumulative fatigue damage theory, the fatigue life of the fastener clips on both sides of the low rail was compared under conditions with and without rail corrugation from the perspective of fatigue characteristics. Finally, a parametric analysis was conducted to explore the influence of external rail corrugation excitation and internal characteristics of fastening components on the fatigue life of the fastener clip. The results show that the high-frequency excitation induced by rail corrugation leads to the resonance in the GJ-III type fastener clip, which is the main cause of the clip fracture. Rail corrugation aggravates the vibration responses of the wheel–rail system, reduces the clip’s service life, and has a more serious impact on the outer clip of the low rail. It cuts the fatigue life to 2.18 × 105 cycles, which is only 4.36% of the design life. In terms of external excitation from rail corrugation, reducing the corrugation depth and increasing the corrugation wavelength can extend the fatigue life of the clip; moreover, when the corrugation wavelength exceeds 40 mm, the fatigue life improves significantly. In terms of the internal characteristics of fastener components, reducing the elastic modulus of the clip, increasing the Poisson’s ratio of both the clip and the rubber pad, and increasing the rubber pad’s elastic modulus can reduce the fatigue damage of the clip to some extent, thereby mitigating clip fracture in the rail corrugation section.

-

Key words:

- rail corrugation /

- clip fracture /

- GJ-Ⅲ fastener /

- resonance response /

- fatigue failure

-

表 1 轮对-钢轨-扣件系统有限元模型材料属性[17-19]

Table 1. Material properties of finite element model of wheelset–rail–fastener system [17–19]

部件 弹性模量/

MPa泊松比 密度/

(kg·m−3)轮对 210000 0.30 7800 钢轨 206000 0.30 7800 DI 弹条 206000 0.30 7800 螺旋道钉 206000 0.30 7800 轨距垫 6200 0.35 1400 轨下橡胶垫板 5 0.49 1200 中间橡胶垫板 5 0.49 1200 上、下层铁垫板 174000 0.28 7200 扣件 纵向 垂向 横向 扣件刚度/(MN·m−1) 10 16 22 扣件阻尼/(kN·s·m−1) 2 20 2 -

[1] 潘健英, 李英奇, 梁旭, 等. 城轨小半径曲线钢轨波磨的成因与整治研究综述[J]. 铁道运输与经济, 2023, 45(7): 76-82.PAN Jianying, LI Yingqi, LIANG Xu, et al. Review of causes and remediation of rail corrugation with small-radius curves in urban rail transit[J]. Railway Transport and Economy, 2023, 45(7): 76-82. [2] 朱海燕, 袁遥, 肖乾, 等. 钢轨波磨研究进展[J]. 交通运输工程学报, 2021, 21(3): 110-133.ZHU Haiyan, YUAN Yao, XIAO Qian, et al. Research progress on rail corrugation[J]. Journal of Traffic and Transportation Engineering, 2021, 21(3): 110-133. [3] GRASSIE S L. Rail corrugation: characteristics, causes, and treatments[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2009, 223(6): 581-596. doi: 10.1243/09544097JRRT264 [4] TANAKA H, MIWA M. Modeling the development of rail corrugation to schedule a more economical rail grinding[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2020, 234(4): 370-380. doi: 10.1177/0954409719894833 [5] 王阳, 肖宏, 张智海, 等. 地铁钢轨波磨对车辆-轨道振动及噪声特性的影响[J]. 铁道标准设计, 2024, 68(10): 61-68.WANG Yang, XIAO Hong, ZHANG Zhihai, et al. Influence of metro rail corrugation on vehicle-track vibration and noise characteristics[J]. Railway Standard Design, 2024, 68(10): 61-68. [6] 张鹏飞, 姚典, 冯青松, 等. 地铁波磨对轮轨动力特性影响及其安全阈值分析[J]. 振动与冲击, 2022, 41(5): 123-130, 150.ZHANG Pengfei, YAO Dian, FENG Qingsong, et al. Effects of metro rail corrugation on wheel-track system dynamic characteristics and its wave depth safety threshold[J]. Journal of Vibration and Shock, 2022, 41(5): 123-130, 150. [7] MORALES-IVORRA S, REAL J I, HERNÁNDEZ C, et al. Derailment risk and dynamics of railway vehicles in curved tracks: analysis of the effect of failed fasteners[J]. Journal of Modern Transportation, 2016, 24(1): 38-47. doi: 10.1007/s40534-015-0093-z [8] 崔晓璐, 彭双千, 徐佳, 等. 钢轨波磨区段科隆蛋扣件弹条断裂机理[J]. 西南交通大学学报, 2025, 60(1): 205-213.CUI Xiaolu, PENG Shuangqian, XU Jia, et al. Fracture mechanism of cologne-egg fastener clips in rail corrugation sections[J]. Journal of Southwest Jiaotong University, 2025, 60(1): 205-213. [9] XIAO H, WANG J B, ZHANG Y R. The fractures of e-type fastening clips used in the subway: theory and experiment[J]. Engineering Failure Analysis, 2017, 81: 57-68. doi: 10.1016/j.engfailanal.2017.07.006 [10] LING L, LI W, SHANG H X, et al. Experimental and numerical investigation of the effect of rail corrugation on the behaviour of rail fastenings[J]. Vehicle System Dynamics, 2014, 52(9): 1211-1231. doi: 10.1080/00423114.2014.934844 [11] 肖宏, 马春生, 郭骁, 等. e型扣件弹条断裂原因频谱分析[J]. 同济大学学报(自然科学版), 2017, 45(7): 1000-1008.XIAO Hong, MA Chunsheng, GUO Xiao, et al. Fractures of e-type fastening clip by spectral analysis method[J]. Journal of Tongji University (Natural Science), 2017, 45(7): 1000-1008. [12] MOHAMMADZADEH S, AHADI S, NOURI M. Stress-based fatigue reliability analysis ofthe rail fastening spring clipunder traffic loads[J]. Latin American Journal of Solids and Structures, 2014, 11(6): 993-1011. doi: 10.1590/S1679-78252014000600006 [13] HASAP A, PAITEKUL P, NORAPHAIPHIPAKSA N, et al. Analysis of the fatigue performance of elastic rail clip[J]. Engineering Failure Analysis, 2018, 92: 195-204. doi: 10.1016/j.engfailanal.2018.05.013 [14] 郁宗飞, 顾晓菡, 王灵水, 等. 铁路钢轨扣件e形弹条动态性能研究及结构改进[J]. 噪声与振动控制, 2023, 43(4): 187-193.YU Zongfei, GU Xiaohan, WANG Lingshui, et al. Study on dynamic performance and structure improvement of e-type rail fastening clips[J]. Noise and Vibration Control, 2023, 43(4): 187-193. [15] 刘玉涛. 钢轨波磨下扣件弹条疲劳断裂机理研究[D]. 成都: 西南交通大学, 2017. [16] 尹华拓, 袁宇, 曾志平, 等. 地铁线路中等减振扣件振动测试与减振效果研究[J]. 噪声与振动控制, 2022, 42(2): 161-166, 246.YIN Huatuo, YUAN Yu, ZENG Zhiping, et al. Study on vibration test and vibration damping effect of medium damping fasteners in metro lines[J]. Noise and Vibration Control, 2022, 42(2): 161-166, 246. [17] 宋子洋, 卢俊, 胡世斌, 等. DT-Ⅲ型扣件系统弹条疲劳特性及优化研究[J]. 中南大学学报(自然科学版), 2021, 52(10): 3623-3635.SONG Ziyang, LU Jun, HU Shibin, et al. Study on fatigue characteristics and optimization of fastener clips of DT-Ⅲ fastener system[J]. Journal of Central South University (Science and Technology), 2021, 52(10): 3623-3635. [18] 钱彦行. 地铁减振扣件轨道钢轨波磨形成机理的动力学分析[D]. 成都: 西南交通大学, 2022. [19] 周志军, 李伟, 温泽峰, 等. 采用GJ-Ⅲ型扣件地铁轨道的钢轨波磨形成机理[J]. 中国铁道科学, 2022, 43(3): 37-49.ZHOU Zhijun, LI Wei, WEN Zefeng, et al. Formation mechanism of rail corrugation on metro track with GJ-Ⅲ fastener[J]. China Railway Science, 2022, 43(3): 37-49. [20] CUI X L, BAO P Y, LI T, et al. Research on the failure mechanism of elastic strip fracture in corrugated sections of metros[J]. Engineering Failure Analysis, 2023, 143: 106837. doi: 10.1016/j.engfailanal.2022.106837 [21] 金学松, 李霞, 李伟, 等. 铁路钢轨波浪形磨损研究进展[J]. 西南交通大学学报, 2016, 51(2): 264-273. doi: 10.3969/j.issn.0258-2724.2016.02.006JIN Xuesong, LI Xia, LI Wei, et al. Review of rail corrugation progress[J]. Journal of Southwest Jiaotong University, 2016, 51(2): 264-273. doi: 10.3969/j.issn.0258-2724.2016.02.006 [22] CHEN G X, ZHANG S, WU B W, et al. Field measurement and model prediction of rail corrugation[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2020, 234(4): 381-392. doi: 10.1177/0954409719877318 [23] 张松琦, 张远庆, 汝继来, 等. 扣件DI弹条非正常部位断裂原因分析及结构优化[J]. 铁道建筑, 2020, 60(3): 137-140. [24] 陈明明, 卢俊, 余鸿, 等. 地铁扣件DI弹条安装受力分析及工艺优化改进研究[J]. 铁道标准设计, 2019, 63(4): 52-57. [25] 汤雪扬, 蔡小培, 彭华, 等. 基于轮轨系统耦合振动的地铁钢轨波磨研究[J]. 中南大学学报(自然科学版), 2022, 53(8): 3232-3244. doi: 10.11817/j.issn.1672-7207.2022.08.038TANG Xueyang, CAI Xiaopei, PENG Hua, et al. Study on rail corrugation of metro rail based on coupling vibration of wheel-rail system[J]. Journal of Central South University (Science and Technology), 2022, 53(8): 3232-3244. doi: 10.11817/j.issn.1672-7207.2022.08.038 [26] 周佐斌, 吴兴文, 池茂儒. 地铁车辆轮轨耦合振动特性研究[J]. 机车电传动, 2022(2): 163-170.ZHOU Zuobin, WU Xingwen, CHI Maoru. Research on wheel/rail coupled vibration of metro cars[J]. Electric Drive for Locomotives, 2022(2): 163-170. [27] 吴浩, 韦凯, 王显, 等. 地铁曲线波磨段e型弹条大圆弧共振断裂因素研究[J]. 铁道科学与工程学报, 2022, 19(7): 1862-1871.WU Hao, WEI Kai, WANG Xian, et al. Large arc resonance fracture factors of e-type clip in metro curve wave corrugation section[J]. Journal of Railway Science and Engineering, 2022, 19(7): 1862-1871. [28] 王安斌, 高晓刚, 肖俊恒, 等. 轨道弹条高频疲劳断裂机理研究及优化[J]. 铁道学报, 2021, 43(9): 93-99.WANG Anbin, GAO Xiaogang, XIAO Junheng, et al. Study and optimization of mechanism of high frequency fatigue fracture of rail clip[J]. Journal of the China Railway Society, 2021, 43(9): 93-99. [29] 杨程亮, 李承亮. Ⅲ型弹条断裂原因分析[J]. 铁道建筑, 2019, 59(4): 135-138. doi: 10.3969/j.issn.1003-1995.2019.04.30YANG Chengliang, LI Chengliang. Cause analysis of fracture of Ⅲ-type elastic rod[J]. Railway Engineering, 2019, 59(4): 135-138. doi: 10.3969/j.issn.1003-1995.2019.04.30 [30] 陈金明, 钟盛华, 刘逸平, 等. 地铁扣件Ⅲ型弹条的静力学模型与参数优化分析[J]. 科学技术与工程, 2023, 23(22): 9650-9658.CHEN Jinming, ZHONG Shenghua, LIU Yiping, et al. Static model and parameter optimization analysis of type Ⅲ clip in metro fastener[J]. Science Technology and Engineering, 2023, 23(22): 9650-9658. -

下载:

下载: