Fatigue Reliability of Welded Frame-Type Bogie Frames

-

摘要:

焊接构架式转向架是近年开发的新产品,其运行的安全性与可靠性至关重要,本文针对该型转向架焊接构架进行了疲劳可靠性评估. 基于等效结构应力(ESS)方法和主

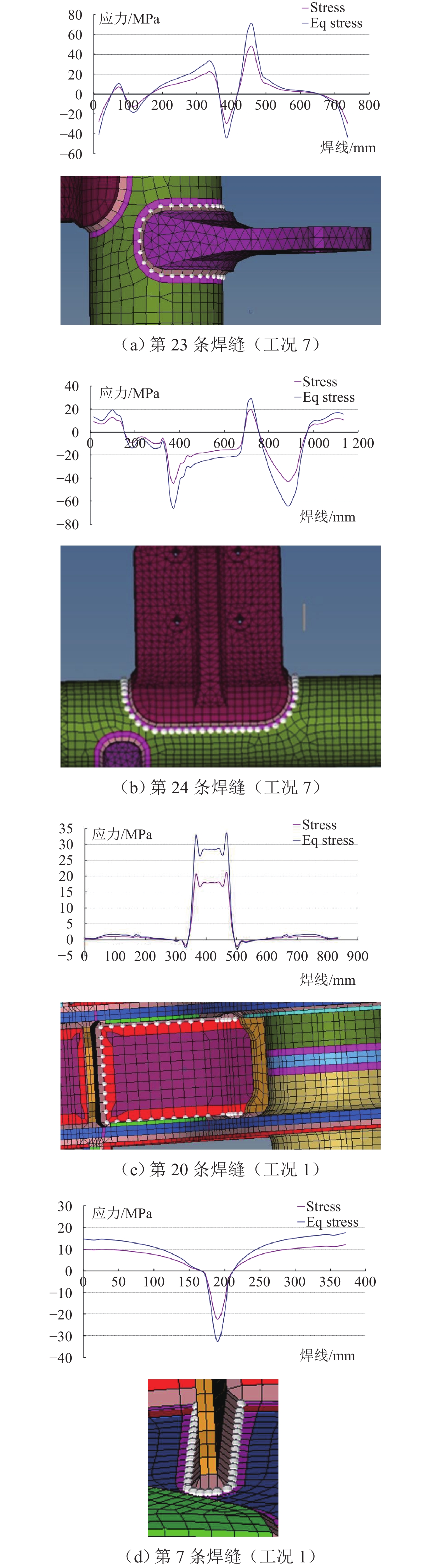

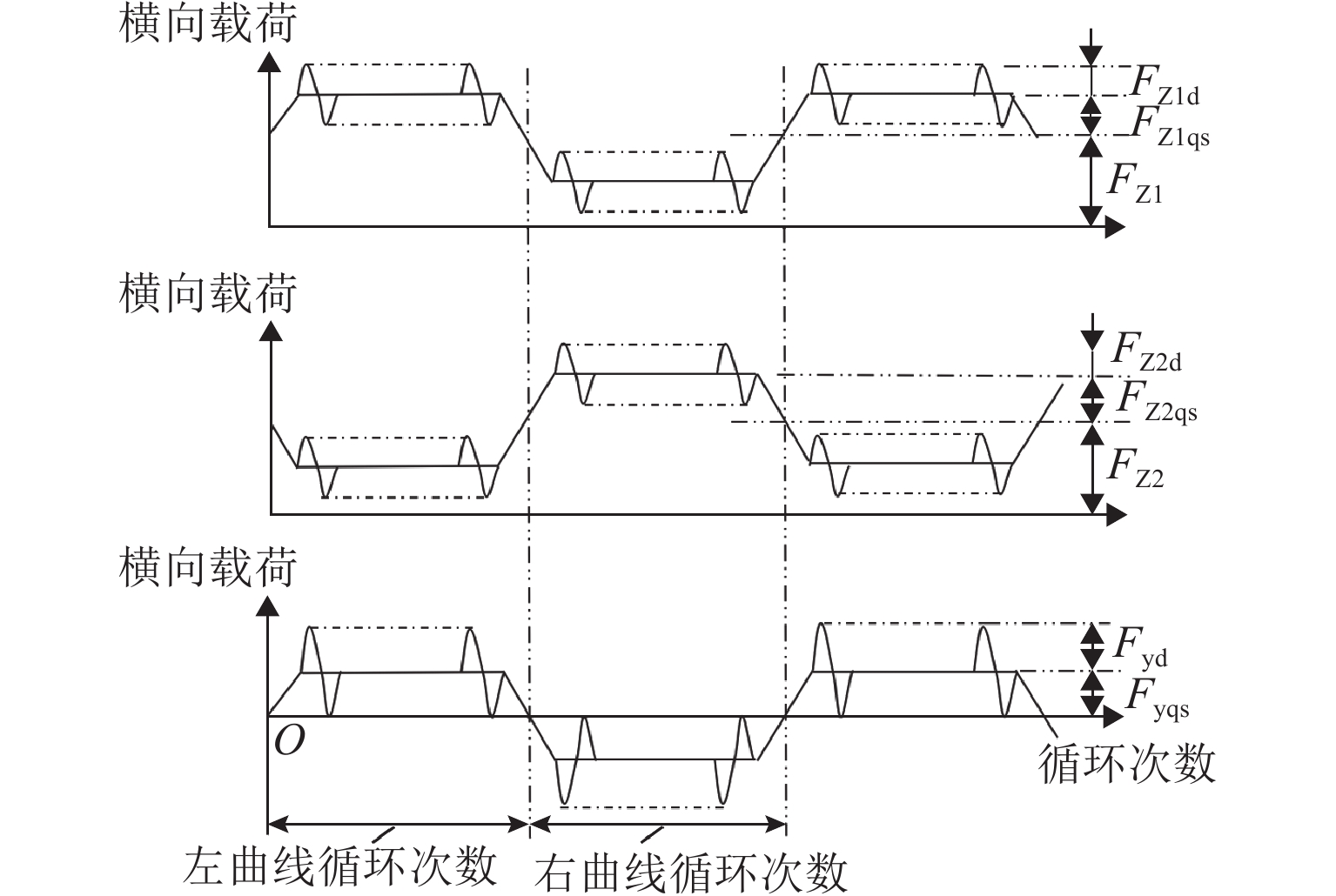

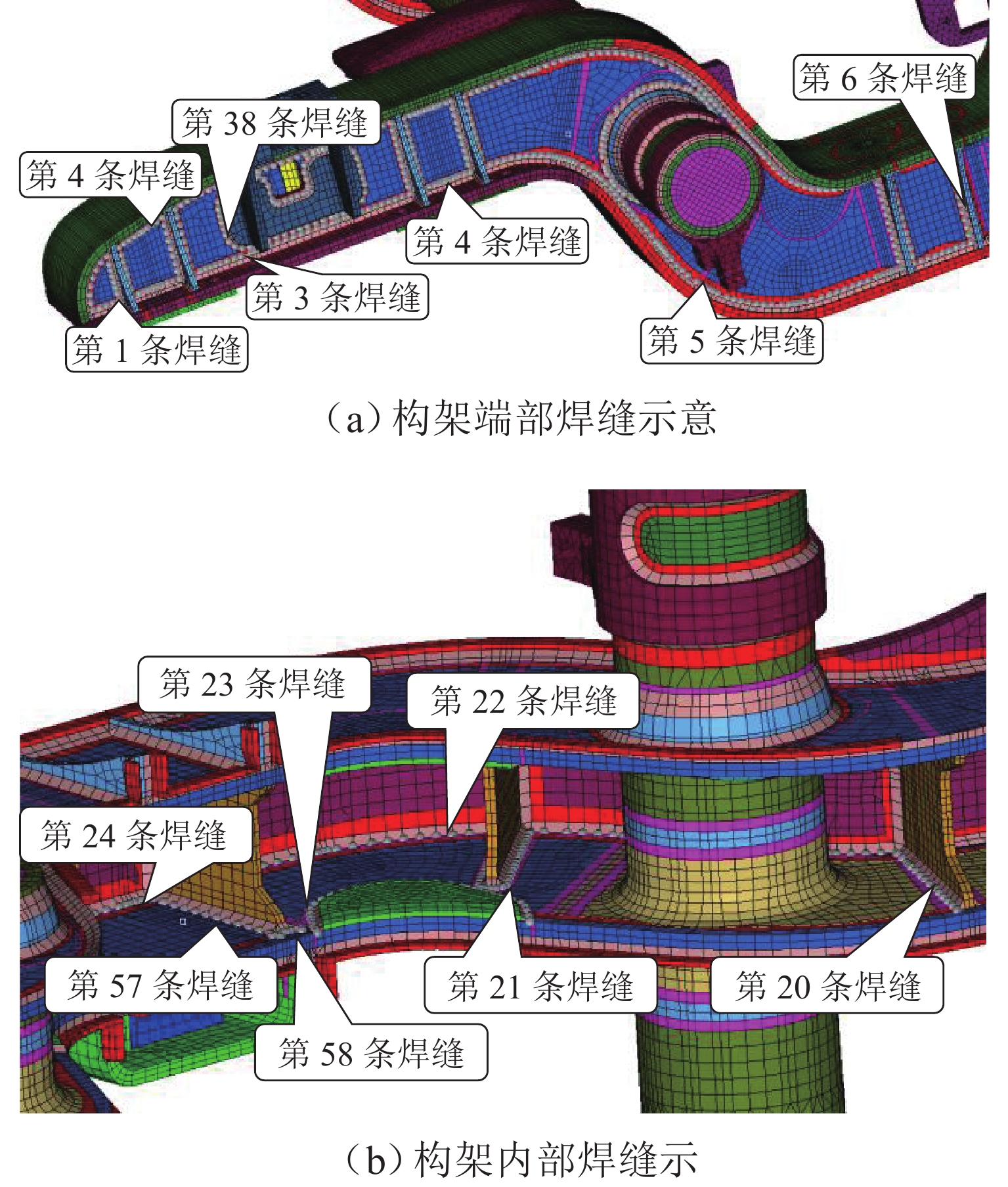

S -N 曲线模型提出焊接结构疲劳寿命评估流程,进一步推导多载荷作用下的焊接结构应力状态确定公式;依据BS EN15085-3:2007标准中铁路车辆焊接结构设计要求,结合有限元模型仿真与疲劳试验数据,全面分析转向架构架焊接接头的应力状态和疲劳寿命;通过建立含焊缝细节的有限元模型模拟实际运行条件下的受力状态,使用疲劳试验大纲提供的载荷谱进行疲劳寿命仿真计算,并根据标准确定焊接接头的应力状态等级,以此评估焊缝的质量等级和检查等级;依据EN13749:2011标准进行了转向架构架的疲劳试验. 结果表明:ESS方法结合BS EN15085标准能够精确预测焊接接头的疲劳寿命,转向架构架关键焊缝的总损伤均小于1,满足疲劳寿命设计要求;转向架构架疲劳试验结束后,进行磁粉探伤均未发现裂纹,满足疲劳强度试验要求;基于等效结构应力计算构架焊缝的应力因数最大值为0.939,根据每个关键焊缝的应力因数值明确了构架焊缝应力状态等级,为焊缝质量和检查等级的优化提供了依据.Abstract:The welded frame-type bogie is a newly developed product in recent years, and its operational safety and reliability are crucial. A fatigue reliability assessment of the welded frame-type bogie frames was carried out. A fatigue life assessment procedure for welded structures was proposed based on the equivalent structural stress (ESS) method and the main S-N curve model, and a formula for determining the stress state of welded structures under multiple loads was derived. According to the BS EN15085-3:2007 standard for the design of welded structures in railway vehicles, combined with finite element model simulations and fatigue test data, the stress state and fatigue life of the bogie frame weld joints were comprehensively analyzed. A finite element model including weld details was established to simulate the stress state under actual operating conditions. Fatigue life simulations were performed using the load spectrum provided by the fatigue test outline, and the stress state level of the weld joints was determined according to the standards to assess the quality grade and inspection grade of the welds. Fatigue tests of the bogie frames were conducted according to the EN13749:2011 standard. The results show that the ESS method, combined with the BS EN15085 standard, can accurately predict the fatigue life of weld joints. The total damage of key welds in the bogie frames is less than 1, meeting the design requirements for fatigue life. After fatigue tests, no cracks are detected by magnetic particle inspection, meeting the fatigue strength requirements. The maximum stress factor of the frame welds calculated by ESS is 0.939. The stress state level of each key weld is clarified based on the stress factor values, providing a basis for optimizing the quality and inspection grade of the welds.

-

Key words:

- welded frame /

- structural stress /

- fatigue strength /

- stress factor /

- stress state

-

表 1 构架载荷类型

Table 1. Types of frame loads

载荷类型 描述 值/kN 垂向载荷 静态部分 Fz1=Fz2= Fz/2 162.2 准静态部分 Fz1qs= Fz2qs=±ɑFz/2 ±16.2 动态部分 Fz1d=Fz2d= ±βFz/2 ±32.4 横向载荷 准静态部分 Fy1qs= Fy2qs=±0.063(Fz + mg) ±24.5 动态部分 Fy1d=Fy2d= ±0.063(Fz + mg) ±24.5 其它载荷 拉杆座纵向载荷 Fxmax=0.1(Fz + mg) 38.8 制动载荷 Fb=1.1 × 2Fpμ 31 减振器载荷 ±10 表 2 疲劳载荷工况

Table 2. Fatigue load conditions

工况 载荷描述 载荷大小/ kN 位移约束 疲劳载荷循环次数和系数 1 垂直载荷(每侧侧梁对称中心) 32.4 垂向、纵向和横向 600 万次(系数1.0)、200 万次(系数1.2)、200 万次(系数1.4) 2、3 垂直载荷(一侧侧梁对称中心处) 16.2 垂向、纵向和横向 15 万次(系数1.0)、5 万次(系数1.2)、5 万次(系数1.4) 4、5 横向载荷(构架一侧横向止挡处) 24.5 垂向、纵向和横向 315 万次(系数1.0)、105 万次(系数1.2)、105 万次(系数1.4) 6 纵向载荷(牵引拉杆座处) 38.8 垂向、纵向和横向 200 万次 7 制动载荷 31.0 垂向、纵向和横向 200 万次 8 扭转载荷(垂向强位移) 11.5 mm位移 垂向、纵向和横向(除施加载荷端) 60 万次(系数1.0)、20 万次(系数1.2)、20 万次(系数1.4) 9 减振器载荷(横向减振器对角侧和垂向减振器) 10 垂向、纵向和横向 200 万次 表 3 构架重点评估的焊缝位置说明

Table 3. Description of weld joint locations for frame assessment

编号 位置说明 1~4 侧梁外侧筋板(或减振器)与腹板间焊缝 5~6 侧梁腹板与内补强板间焊缝 7~11 侧梁隔板与腹板间焊缝 12~13 横梁处侧梁腹板与内加强环间 14~15 横梁接头与腹板间焊缝 16~17 上盖板与腹板(或筋板)间焊缝 18~9 横向止挡(或减振器)与上盖板间焊缝 20~22 侧梁隔板与下盖板间焊缝 23~24 横梁接头与横梁间焊缝 25~26 横档与筋板(或腹板)间焊缝 27~28 侧梁中间隔板与腹板间焊缝 29 中间弹簧座与下盖板(或腹板)间焊缝 30 横梁端部补强环与腹板间焊缝 表 4 构架评估焊缝的总损伤及应力状态等级

Table 4. Overall damage and stress state grades of welds in frame assessment

焊缝编号 节点号 各工况损伤 总损伤 应力因数 应力状态 工况 1 工况 2 工况 3 工况 4 工况 5 工况 6 工况 7 工况 8 工况 9 1 266878 2.64×10−1 6.95×10−4 7.93×10−9 7.03×10−3 8.34×10−4 7.96×10−4 5.84×10−7 6.12×10−6 4.82×10−4 2.74×10−1 0.661 低 2 266890 3.84×10−1 1.04×10−3 3.35×10−9 6.40×10−3 2.23×10−3 1.17×10−3 1.19×10−5 1.84×10−9 5.88×10−4 3.95×10−1 0.743 低 3 308702 2.98×10−1 6.93×10−4 2.37×10−7 1.71×10−3 3.28×10−8 3.26×10−7 6.44×10−4 3.26×10−5 2.43×10−6 3.01×10−1 0.681 低 4 308740 5.33×10−1 1.23×10−3 3.09×10−7 2.13×10−3 6.33×10−6 5.19×10−8 9.40×10−4 5.92×10−6 2.89×10−5 5.37×10−1 0.820 低 5 288997 3.57×10−1 8.74×10−4 7.56×10−8 5.56×10−3 5.69×10−4 1.55×10−4 1.67×10−3 6.50×10−4 9.44×10−5 3.67×10−1 0.725 低 6 308816 4.08×10−1 9.59×10−4 2.14×10−5 1.75×10−7 1.48×10−5 9.07×10−5 1.84×10−3 2.14×10−5 1.27×10−7 4.12×10−1 0.753 中 7 289225 7.98×10−1 2.29×10−3 2.76×10−11 3.05×10−2 1.55×10−2 1.85×10−3 1.54×10−4 1.00×10−4 4.83×10−3 8.53×10−1 0.850 中 8 264498 9.61×10−2 2.71×10−4 3.31×10−12 5.77×10−6 2.27×10−3 2.14×10−3 6.45×10−3 1.11×10−4 1.96×10−4 1.08×10−1 0.490 低 9 291921 7.93×10−1 1.54×10−3 2.70×10−6 1.06×10−2 1.75×10−3 3.01×10−5 5.53×10−3 3.36×10−5 1.48×10−3 8.14×10−1 0.936 高 10 308718 3.13×10−1 8.07×10−4 1.85×10−8 1.78×10−3 6.22×10−4 4.31×10−5 1.01×10−6 1.18×10−6 1.20×10−4 3.16×10−1 0.692 低 11 267421 3.38×10−1 9.05×10−4 5.02×10−9 2.52×10−3 2.19×10−3 9.69×10−4 6.65×10−6 2.50×10−5 6.56×10−4 3.45×10−1 0.712 低 12 286937 1.32×10−2 3.54×10−5 1.62×10−10 2.22×10−3 1.20×10−2 1.82×10−2 2.24×10−3 3.52×10−5 2.50×10−3 5.05×10−2 0.385 低 13 286588 1.90×10−3 5.30×10−6 1.80×10−9 7.63×10−4 4.43×10−5 4.05×10−2 7.81×10−7 1.19×10−5 3.35×10−4 4.36×10−2 0.367 低 14 292299 5.81×10−2 9.94×10−5 4.44×10−7 1.28×10−4 1.79×10−4 7.60×10−5 1.61×10−3 6.87×10−7 2.36×10−4 6.04×10−2 0.407 低 15 291900 5.20×10−2 4.31×10−5 3.21×10−7 1.61×10−5 4.89×10−5 1.69×10−5 2.40×10−3 1.67×10−5 8.21×10−5 5.46×10−2 0.394 低 16 268275 5.30×10−1 1.38×10−3 2.16×10−8 1.09×10−2 2.77×10−3 1.01×10−3 1.19×10−4 2.20×10−5 7.02×10−4 5.46×10−1 0.824 中 17 268561 4.60×10−1 1.21×10−3 3.84×10−9 1.24×10−2 3.82×10−3 1.60×10−3 4.35×10−6 1.05×10−7 1.05×10−3 4.80×10−1 0.791 中 18 308855 6.20×10−1 1.16×10−3 2.69×10−6 9.36×10−2 1.37×10−3 2.90×10−7 5.21×10−2 2.52×10−3 1.57×10−3 7.72×10−1 0.921 中 19 294382 1.38×10−1 2.89×10−4 2.37×10−7 3.26×10−4 1.67×10−5 1.95×10−6 8.62×10−4 1.97×10−6 4.23×10−5 1.39×10−1 0.532 低 20 281187 8.17×10−1 2.08×10−3 7.17×10−8 1.11×10−3 9.70×10−4 7.11×10−5 1.77×10−5 1.43×10−6 1.63×10−4 8.21×10−1 0.939 高 21 291059 1.74×10−1 4.09×10−4 7.77×10−8 1.02×10−7 3.81×10−5 1.97×10−9 1.60×10−7 3.95×10−10 1.51×10−6 1.75×10−1 0.572 低 22 281207 5.87×10−1 1.50×10−3 4.62×10−8 3.39×10−3 8.78×10−4 8.14×10−5 5.83×10−4 2.45×10−8 1.28×10−4 5.93×10−1 0.846 中 23 305943 1.82×10−8 3.74×10−8 5.36×10−8 2.27×10−2 1.11×10−4 9.96×10−5 1.02×10−3 1.23×10−4 2.49×10−1 2.73×10−1 0.660 低 24 291754 5.10×10−12 1.27×10−7 1.29×10−7 7.15×10−3 7.44×10−3 4.24×10−10 9.87×10−2 1.59×10−7 8.33×10−3 1.22×10−1 0.510 低 25 287803 7.10×10−3 1.86×10−5 2.69×10−10 8.90×10−2 1.06×10−7 8.04×10−7 1.79×10−6 4.95×10−8 2.91×10−7 9.61×10−2 0.473 低 26 287863 4.49×10−4 1.12×10−6 5.17×10−11 7.73×10−2 3.56×10−8 1.54×10−8 3.33×10−6 6.26×10−7 3.50×10−9 7.77×10−2 0.442 低 27 267672 4.16×10−1 9.18×10−4 4.18×10−7 3.45×10−3 9.48×10−5 4.63×10−5 2.46×10−5 1.22×10−7 8.84×10−5 4.20×10−1 0.758 中 28 272122 2.49×10−1 7.03×10−4 9.16×10−12 3.42×10−4 1.13×10−5 5.87×10−8 9.91×10−6 6.43×10−6 3.39×10−6 2.50×10−1 0.642 低 29 124686 6.15×10−3 1.77×10−5 2.52E-16 4.94×10−5 1.84×10−4 1.18×10−8 3.02×10−4 5.00×10−7 7.57×10−6 6.71×10−3 0.202 低 30 285761 4.44×10−2 1.32×10−4 6.17×10−3 4.19×10−3 5.89×10−2 3.04×10−2 8.51×10−3 1.55×10−4 6.17×10−3 1.53×10−1 0.548 低 -

[1] 谢素明, 范文杰, 牛春亮, 等. 轨道车辆复杂承载焊接结构的抗疲劳设计[J]. 大连交通大学学报, 2023, 44(5): 29-34, 78.XIE Suming, FAN Wenjie, NIU Chunliang, et al. Anti-fatigue design of complex load-bearing welded structure of rail vehicles[J]. Journal of Dalian Jiaotong University, 2023, 44(5): 29-34, 78. [2] 杜文. 基于载荷反演的地铁车辆焊接构架服役安全性评估[D]. 兰州: 兰州交通大学, 2023. [3] 张继旺, 张浩楠, 杨冰, 等. 超声滚压EA4T车轴钢疲劳性能及寿命预测[J]. 西南交通大学学报, 2024, 59(6): 1305-1313. doi: 10.3969/j.issn.0258-2724.20220257ZHANG Jiwang, ZHANG Haonan, YANG Bing, et al. Fatigue properties and life prediction of ultrasonic rolling EA4T axle steel[J]. Journal of Southwest Jiaotong University, 2024, 59(6): 1305-1313. doi: 10.3969/j.issn.0258-2724.20220257 [4] 高天, 吉伯海, 袁周致远, 等. 基于焊缝辅助配准的钢箱梁疲劳裂纹视觉定位方法研究[J/OL]. 西南交通大学学报, 2024: 1-12. (2024-10-30). https://kns.cnki.net/KCMS/detail/detail.aspx?filename=XNJT20241030009&dbname=CJFD&dbcode=CJFQ.GAO Tian, JI Bohai, YUAN Zhouzhiyuan, et al. Visual localization method of fatigue crack in steel box girder based on weld auxiliary registration[J/OL]. Journal of Southwest Jiaotong University, 2024: 1-12. (2024-10-30). https://kns.cnki.net/KCMS/detail/detail.aspx?filename=XNJT20241030009&dbname=CJFD&dbcode=CJFQ. [5] 李新康, 王苏秦, 刘潮涛, 等. 基于子模型方法的地铁车体疲劳寿命评估[J]. 西南交通大学学报, 2022, 57(2): 295-300, 330. doi: 10.3969/j.issn.0258-2724.20200301LI Xinkang, WANG Suqin, LIU Chaotao, et al. Fatigue life assessment of metro carbody based on submodel method[J]. Journal of Southwest Jiaotong University, 2022, 57(2): 295-300,330. doi: 10.3969/j.issn.0258-2724.20200301 [6] 唐枫. CRH3型高速动车组转向架构架结构的可靠性分析与优化[D]. 兰州: 兰州交通大学, 2023. [7] 英国标准学会. 铁路上应用-铁路车辆及其部件的焊接: BS EN15085. [S]. 伦敦: 出版者不详, 2007. [8] 李向伟. 基于ESS法的重载货车焊缝疲劳仿真[J]. 大连交通大学学报, 2013, 34(5): 85-88. doi: 10.3969/j.issn.1673-9590.2013.05.020LI Xiangwei. ESS principle and simulation of heavy wagon weld fatigue[J]. Journal of Dalian Jiaotong University, 2013, 34(5): 85-88. doi: 10.3969/j.issn.1673-9590.2013.05.020 [9] 兆文忠, 李向伟, 董平沙. 焊接结构抗疲劳设计理论与方法[M]. 北京: 机械工业出版社, 2017. [10] 高杰, 鞠晓臣, 左照坤, 等. 基于等效结构应力法的高强钢焊接结构低温主S-N曲线[J]. 船舶力学, 2024, 28(4): 571-581. doi: 10.3969/j.issn.1007-7294.2024.04.009GAO Jie, JU Xiaochen, ZUO Zhaokun, et al. Low temperature master S-N curve of high strength steel welded structure based on equivalent structural stress method[J]. Journal of Ship Mechanics, 2024, 28(4): 571-581. doi: 10.3969/j.issn.1007-7294.2024.04.009 [11] HONG T K, DONG P, HONG J K. Fatigue analysis of spot welds using a mesh-insensitive structural stress approach[J]. International Journal of Fatigue, 2007, 29(8): 1546-1553. doi: 10.1016/j.ijfatigue.2006.10.025 [12] British Standard Institute. Fatigue design and assessment of steel structures: BS7608: 2014 + A1: 2015 [S]. British: BSI, 2015. [13] ASME Boiler and Pressure Vessel Code. ASME BPVC VIII-2-2015 [S]. New York: The American society of mechanical engineers, 2015. [14] DONG P, HONG J K, OSAGE D A, et al. The master S-N curve method: an implementation for fatigue evaluation of welded components in the ASME B&PV code, section VIII, division 2 and API 579-1/ASME FFS-1[M]. New York: Welding Research Council, 2010 [15] 杨思源, 宋绪丁, 万一品. 基于主S-N曲线的装载机工作装置疲劳寿命评估[J]. 机械设计, 2023, 40(12): 15-22.YANG Siyuan, SONG Xuding, WAN Yipin. Fatigue-life assessment of loader’s working device based on master S-N curve[J]. Journal of Machine Design, 2023, 40(12): 15-22. [16] 谢素明, 莫浩, 牛春亮, 等. 基于结构应力法的焊接构架应力状态研究[J]. 大连交通大学学报, 2019, 40(1): 36-39.XIE Suming, MO Hao, NIU Chunliang, et al. Research on stress state of welded frame based on structural stress method[J]. Journal of Dalian Jiaotong University, 2019, 40(1): 36-39. [17] British Standards Institution. Railway applications—Welding of railway vehicles and components—part 3: design requirements: BS EN 15085-3: 2007 [S]. London: British Standards Institution, 2007. [18] 欧洲标准化委员会. 铁路应用-轮对和转向架构架结构要求的确定方法: EN13749 [S]. 伦敦: 出版者不详, 2011. [19] 周韶泽, 郭硕, 陈秉智, 等. 焊接结构超高周疲劳主S-N曲线拟合及寿命预测方法[J]. 焊接学报, 2022, 43(5): 76-82, 118. doi: 10.12073/j.hjxb.20211116002ZHOU Shaoze, GUO Shuo, CHEN Bingzhi, et al. Master S-N curve fitting and life prediction method for very high cycle fatigue of welded structures[J]. Transactions of the China Welding Institution, 2022, 43(5): 76-82, 118. doi: 10.12073/j.hjxb.20211116002 [20] 周张义, 黄运华, 杨阳, 等. 基于结构应力的转向架构架焊缝疲劳强度研究[J]. 西南交通大学学报, 2018, 53(5): 937-944. doi: 10.3969/j.issn.0258-2724.2018.05.009ZHOU Zhangyi, HUANG Yunhua, YANG Yang, et al. Study on Fatigue Strength of Welds in Bogie Frame Based on Structural Stresse[J]. Transactions of the China Welding Institution, 2018, 53(5): 937-944. doi: 10.3969/j.issn.0258-2724.2018.05.009 [21] ALENCAR G, HONG J K, DE JESUS A, et al. The Master S-N curve approach for fatigue assessment of welded bridge structural details[J]. International Journal of Fatigue, 2021, 152: 106432. doi: 10.1016/j.ijfatigue.2021.106432 [22] HAVIA J, AHOLA A, BJÖRK T. Fatigue strength of welded aluminum structures–A re-evaluation of fatigue data of welded aluminum joints with nominal stress approach[J]. Materials & Design, 2025, 254: 114050. [23] ZHANG Z, HE Z, YANG B, et al. An improved Goodman–Smith fatigue limit diagram for railway vehicle base metals and welded structures[J]. International Journal of Fatigue, 2024, 182: 108160. doi: 10.1016/j.ijfatigue.2024.108160 [24] ZHANG Z, YANG B, WANG Y, et al. A hybrid distribution characteristics of equivalent structural stress method for fatigue evaluation of welded structures[J]. International Journal of Fatigue, 2024, 179: 108057. doi: 10.1016/j.ijfatigue.2023.108057 -

下载:

下载: