Shear and Pull-Out Performance of Ribbed Straight-Hooked Rebar Shear Connector

-

摘要:

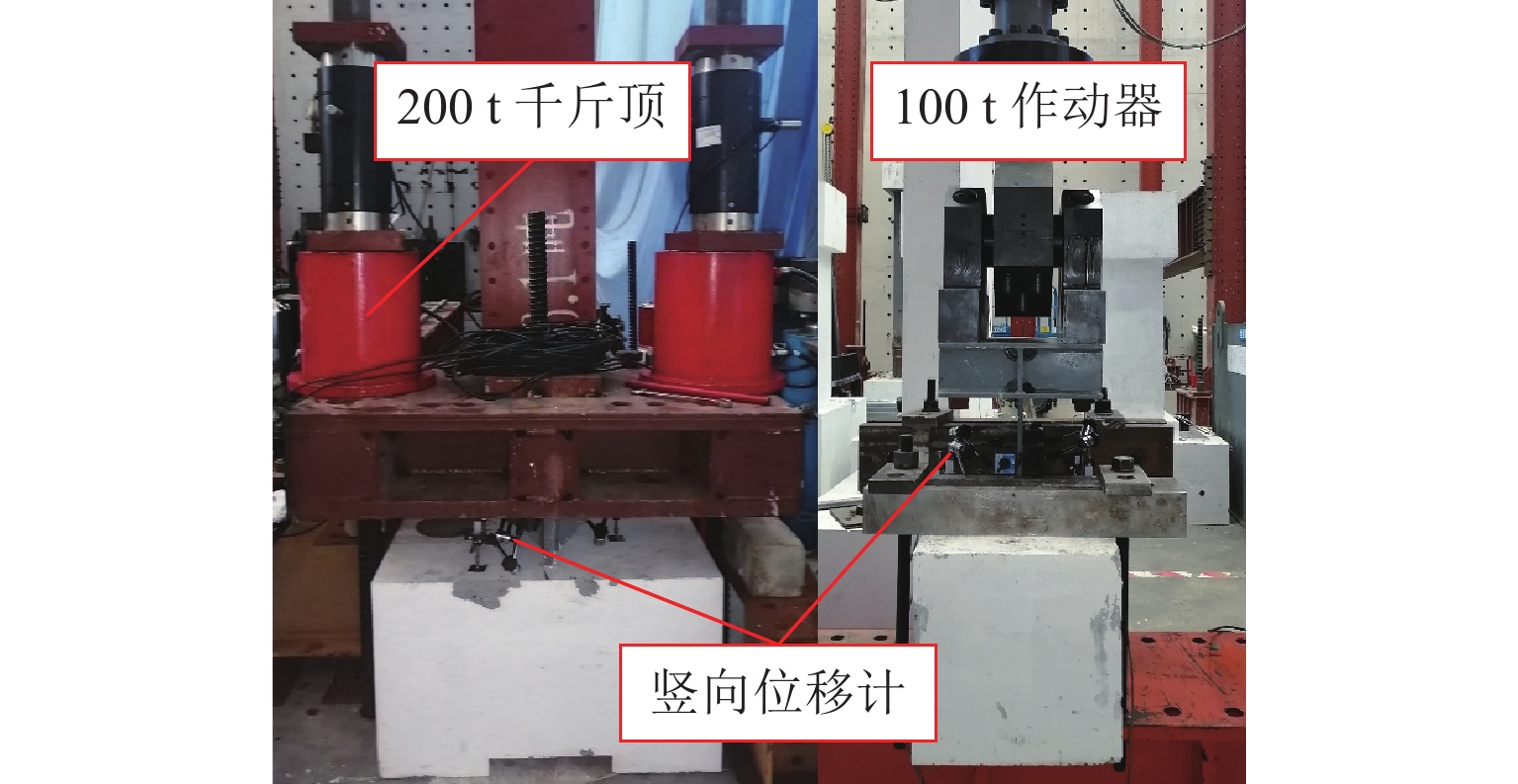

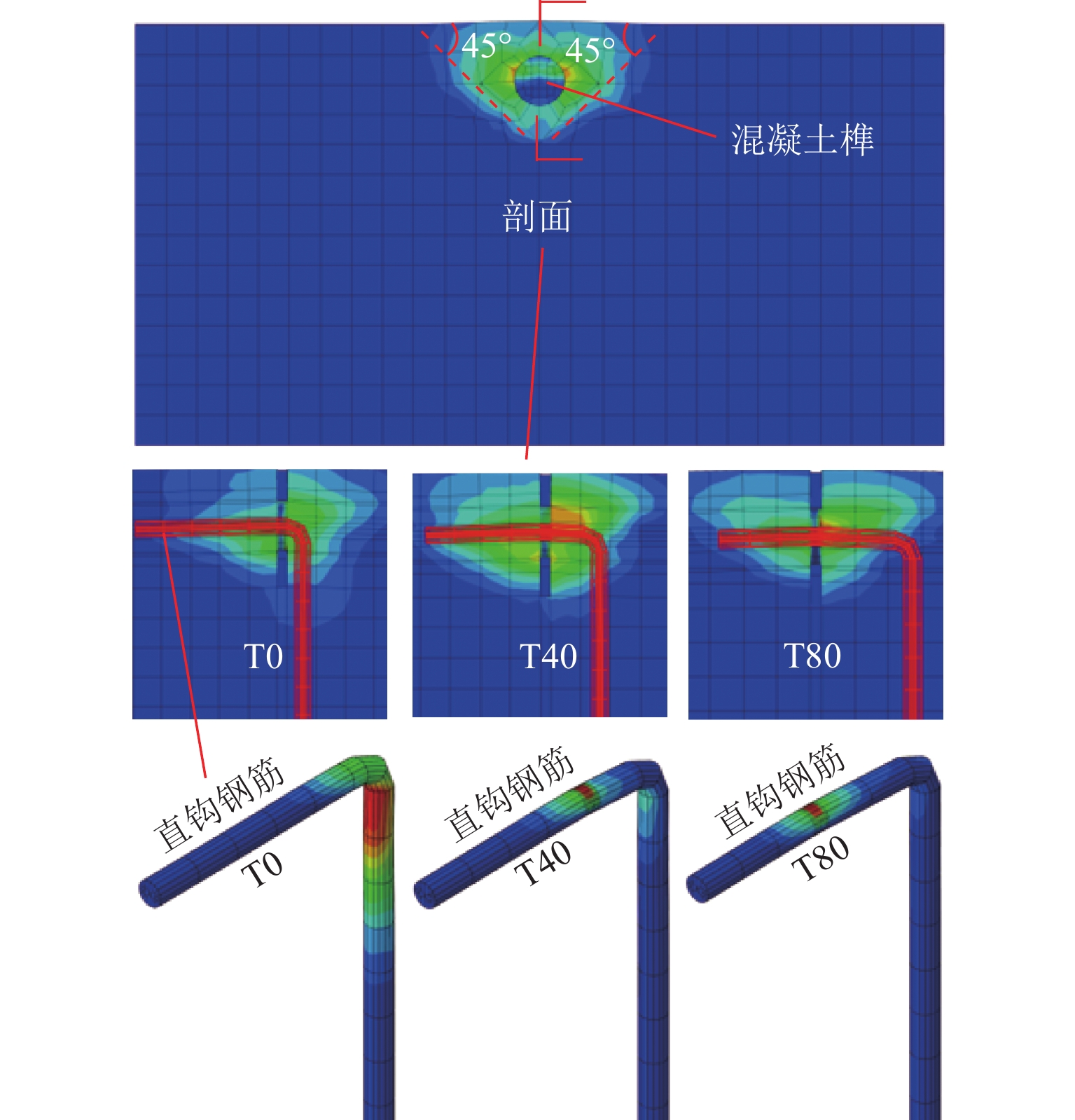

为简化钢壳-混凝土组合索塔结构构造并提升建造效率,对新型的带肋直钩钢筋剪力键进行研究. 首先,对该新型剪力键设计推出与拔出荷载试验,得到各试件的剪切承载力、拔出承载力及相应破坏特征;其次,结合有限元软件进行分析,建立试件破坏模式与承载力之间的对应关系;最后,在分析模型基础上,进一步探讨埋深对剪力键性能的影响,并提出直钩钢筋剪力键的剪切与拔出承载力计算式. 研究结果表明:直钩钢筋剪力键在剪切荷载下表现为加劲肋屈服,在拔出荷载下表现为混凝土冲切破坏,并伴随着直钩钢筋屈服,破坏模式的不同使剪力键的承载力差距最大可达5倍;推出荷载下钢混黏结力占总承载力的30%;直钩钢筋的位置决定了其在拔出荷载下的受力特点及失效模式;减小直钩钢筋与加劲肋间距后,剪力键的拔出承载力提升了35%,增大1倍剪力键埋深后,拔出承载力提升了1倍.

Abstract:To simplify the steel shell–concrete composite pylon structure and improve construction efficiency, a novel ribbed straight-hooked rebar (RSHR) shear connector was studied. Firstly, the push-out and pull-out tests of the shear connector were designed. The shear bearing capacity, pull-out bearing capacity, and failure characteristics of each specimen were obtained. Secondly, the corresponding relationship between the failure mode and the bearing capacity of the specimen was obtained by using finite element analysis software. Finally, based on model analysis, the influence of the burial depth on the shear connector performance was further discussed, and the formula for calculating the shear and pull-out bearing capacity of the RSHR shear connector was proposed. The results show that under shear loading, the RSHR shear connector undergoes yielding of its stiffening ribs, while under pull-out loading, concrete punching failure occurs. Along with the yielding of the straight-hooked rebar, the difference in failure modes can cause the shear connector’s bearing capacity to vary by up to five times. Under push-out loading, the steel–concrete bonding force accounts for 30% of the total bearing capacity. The position of the straight-hooked rebar determines its stress characteristics and failure modes under pull-out loading. Reducing the spacing between the straight-hooked rebar and stiffening ribs increases the pull-out bearing capacity of the shear connector by 35%, while doubling the burial depth of the shear connector makes the pull-out bearing capacity increase by one time.

-

Key words:

- composite structure /

- connector /

- shear loading /

- pull-out test /

- bearing capacity

-

表 1 试件参数

Table 1. Specimen parameters cm

荷载类型 编号 D 推出 S0 0 S40 40 S80 80 拔出 T0 0 T40 40 T80 80 表 2 承载力公式结果与试验结果对比

Table 2. Comparison between bearing capacity calculated by formula and obtained from test

kN 试件名 试验值 公式 S0 932 797 S40 871 797 S80 771 797 T0 191 193 T40 198 182 T80 142 171 -

[1] 樊健生,朱尧于,崔冰,等. 钢板-混凝土组合结构桥塔研究及应用综述[J]. 土木工程学报,2023,56(4): 61-71.FAN Jiansheng, ZHU Yaoyu, CUI Bing, et al. A review on research and applications of concrete-filled steel-plate composite bridge tower[J]. China Civil Engineering Journal, 2023, 56(4): 61-71. [2] CUI B, WU H L, ZHAO C H, et al. Steel-concrete composite cable-stayed bridge—main bridge of the Jiangxinzhou Yangtze River bridge at Nanjing[J]. Structural Engineering International, 2023, 33(1): 107-114. doi: 10.1080/10168664.2021.1999191 [3] 刘益铭,张清华,卜一之. ECC桥面板中栓钉抗剪性能试验研究与数值分析[J]. 西南交通大学学报,2025,60(1): 35-44.LIU Yiming, ZHANG Qinghua, PU Yizhi. Experimental study and numerical analysis of shear behavior of studs embedded in engineered cementitious composite bridge decks[J]. Journal of Southwest Jiaotong University, 2025, 60(1): 35-44. [4] 聂建国,陶慕轩,吴丽丽,等. 钢-混凝土组合结构桥梁研究新进展[J]. 土木工程学报,2012,45(6): 110-122.NIE Jianguo, TAO Muxuan, WU Lili, et al. Advances of research on steel-concrete composite bridges[J]. China Civil Engineering Journal, 2012, 45(6): 110-122. [5] 张清华,李乔,唐亮. 桥塔钢-混凝土结合段剪力键破坏机理及极限承载力[J]. 中国公路学报,2007,20(1): 85-90. doi: 10.3321/j.issn:1001-7372.2007.01.016ZHANG Qinghua, LI Qiao, TANG Liang. Fracture mechanism and ultimate carrying capacity of shear connectors applied for steel-concrete joint segment of bridge pylon[J]. China Journal of Highway and Transport, 2007, 20(1): 85-90. doi: 10.3321/j.issn:1001-7372.2007.01.016 [6] ZHU Bing, WANG Xuewei. Experimental study on PBL shear connectors of steel-concrete composite bridge considering transverse prestressing[J]. Journal of Southwest Jiaotong University, 2016, 51(4): 621-631. [7] 肖林,刘丽芳,卫星,等. 钢-混组合索塔锚固结构的力学行为及结构优化[J]. 西南交通大学学报,2019,54(5): 923-930,944. doi: 10.3969/j.issn.0258-2724.20170320XIAO Lin, LIU Lifang, WEI Xing, et al. Mechanical behavior and structural optimization of steel-concrete composite cable-pylon anchor[J]. Journal of Southwest Jiaotong University, 2019, 54(5): 923-930,944. doi: 10.3969/j.issn.0258-2724.20170320 [8] AHN J H, LEE C G, WON J H, et al. Shear resistance of the perfobond-rib shear connector depending on concrete strength and rib arrangement[J]. Journal of Constructional Steel Research, 2010, 66(10): 1295-1307. doi: 10.1016/j.jcsr.2010.04.008 [9] 肖林,强士中,李小珍,等. 考虑开孔钢板厚度的PBL剪力键力学性能研究[J]. 工程力学,2012,29(8): 282-288,296. doi: 10.6052/j.issn.1000-4750.2011.06.0343XIAO Lin, QIANG Shizhong, LI Xiaozhen, et al. Research on mechanical performance of pbl shear connectors considering the perforated plate’s thickness[J]. Engineering Mechanics, 2012, 29(8): 282-288,296. doi: 10.6052/j.issn.1000-4750.2011.06.0343 [10] SU Q T, WANG W, LUAN H W, et al. Experimental research on bearing mechanism of perfobond rib shear connectors[J]. Journal of Constructional Steel Research, 2014, 95: 22-31. doi: 10.1016/j.jcsr.2013.11.020 [11] 王振海,赵灿晖,李乔. PBL剪力键荷载•滑移关系试验研究[J]. 西南交通大学学报,2011,46(4): 547-552. doi: 10.3969/j.issn.0258-2724.2011.04.004WANG Zhenhai, ZHAO Canhui, LI Qiao. Experimental investigation on load-slip relationship of perfobond rib shear connectors[J]. Journal of Southwest Jiaotong University, 2011, 46(4): 547-552. doi: 10.3969/j.issn.0258-2724.2011.04.004 [12] 朱尧于,聂鑫,樊健生,等. 薄开孔板连接件抗拔性能试验及理论研究[J]. 中国公路学报,2018,31(9): 65-74. doi: 10.3969/j.issn.1001-7372.2018.09.008ZHU Yaoyu, NIE Xin, FAN Jiansheng, et al. Experimental and theoretical study on pullout resistance of single-hole thin-rib perfobond connectors[J]. China Journal of Highway and Transport, 2018, 31(9): 65-74. doi: 10.3969/j.issn.1001-7372.2018.09.008 [13] 汪维安. 混合结构中PBL剪力键群的力学特性研究[D]. 成都:西南交通大学,2015. [14] 张清华,李乔,卜一之. PBL剪力连接件群传力机理研究(Ⅰ)——理论模型[J]. 土木工程学报,2011,44(4): 71-77.ZHANG Qinghua, LI Qiao, BU Yizhi. Load transmission mechanism of PBL shear connector group(Ⅰ)—theoretical model[J]. China Civil Engineering Journal, 2011, 44(4): 71-77. [15] 张清华,李乔,卜一之. PBL剪力连接件群传力机理研究Ⅱ——极限承载力[J]. 土木工程学报,2011,44(5): 101-108.ZHANG Qinghua, LI Qiao, BU Yizhi. Load transmission mechanism of PBL shear connector groups Ⅱ: load capacity[J]. China Civil Engineering Journal, 2011, 44(5): 101-108. [16] LI Z X, WU B, LIAO M, et al. Experimental investigation on the cyclic performance of perfobond rib shear connectors[J]. Advances in Structural Engineering, 2020, 23(16): 3509-3524. doi: 10.1177/1369433220939211 [17] 宋瑞年,占玉林,赵人达,等. 嵌入式波形钢板剪力键推出试验及数值分析[J]. 中国公路学报,2019,32(5): 88-99.SONG Ruinian, ZHAN Yulin, ZHAO Renda, et al. Push-out test and numerical analysis of embedded shear connectors with corrugated steel plates[J]. China Journal of Highway and Transport, 2019, 32(5): 88-99. [18] KIM S H, CHOI K T, PARK S J, et al. Experimental shear resistance evaluation of Y-type perfobond rib shear connector[J]. Journal of Constructional Steel Research, 2013, 82: 1-18. doi: 10.1016/j.jcsr.2012.12.001 [19] DA C VIANNA J, COSTA-NEVES L F, DA S VELLASCO P C G, et al. Structural behaviour of T-Perfobond shear connectors in composite girders: an experimental approach[J]. Engineering Structures, 2008, 30(9): 2381-2391. doi: 10.1016/j.engstruct.2008.01.015 [20] 宋随弟,黄博,祝兵,等. 预应力PBL剪力键的承载能力试验研究[J]. 西南交通大学学报,2017,52(4): 647-654. doi: 10.3969/j.issn.0258-2724.2017.04.001SONG Suidi, HUANG Bo, ZHU Bing, et al. Analysis of the bearing capacity of PBL shear connector[J]. Journal of Southwest Jiaotong University, 2017, 52(4): 647-654. doi: 10.3969/j.issn.0258-2724.2017.04.001 [21] 占玉林,李贵峰,赵人达,等. 有机聚合物剪力键的破坏机理及承载能力研究[J]. 西南交通大学学报,2017,52(3): 524-531.ZHAN Yulin, LI Guifeng, ZHAO Renda, et al. Failure mechanism and shear capacity of organic polymer shear connectors[J]. Journal of Southwest Jiaotong University, 2017, 52(3): 524-531. [22] 肖林,廖轩,卫星,等. UHPC中PBL剪力键力学性能试验研究[J]. 铁道学报,2022,44(12): 157-164.XIAO Lin, LIAO Xuan, WEI Xing, et al. Experimental study on mechanical properties of PBL shear connectors in UHPC[J]. Journal of the China Railway Society, 2022, 44(12): 157-164. [23] 阳先全,李艳. PBL剪力键承载能力试验研究[J]. 桥梁建设,2015,45(1): 85-90.YANG Xianquan, LI Yan. Test study of bearing capacity of PBL shear connectors[J]. Bridge Construction, 2015, 45(1): 85-90. [24] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范:GB 50010—2010 [S]. 北京:中国建筑工业出版社,2010. [25] 中华人民共和国交通运输部. 公路钢结构桥梁设计规范:JTG D64—2015[S]. 北京:人民交通出版社,2015. -

下载:

下载: