Experimental Study on Friction and Sliding Performance of Laminated-Rubber Bearings Based on Shear Aging Resistance

-

摘要:

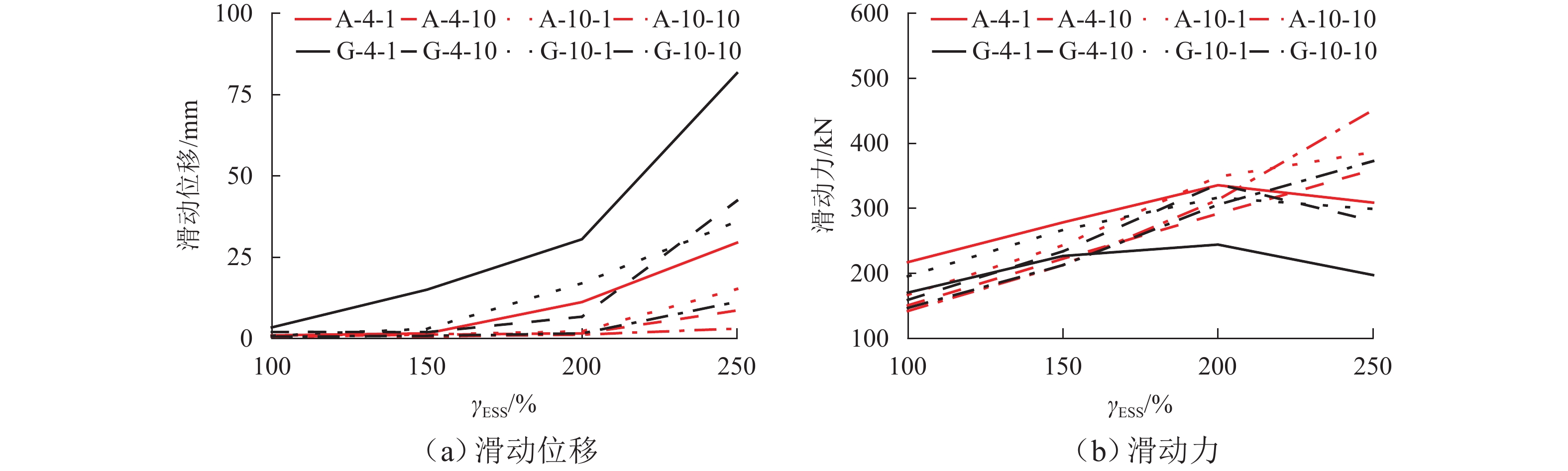

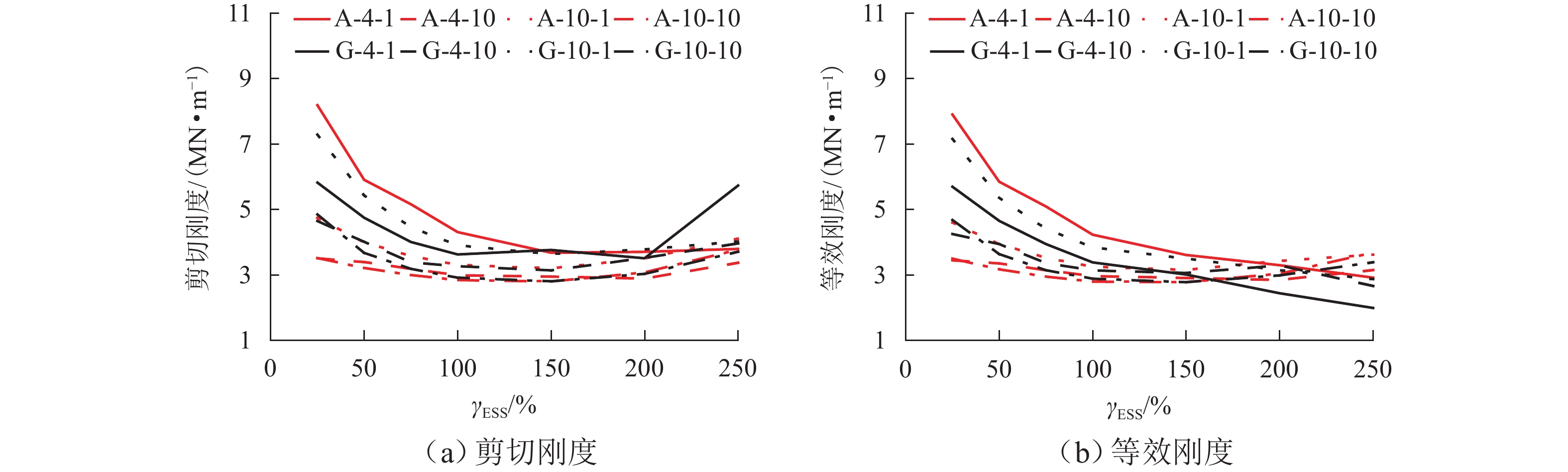

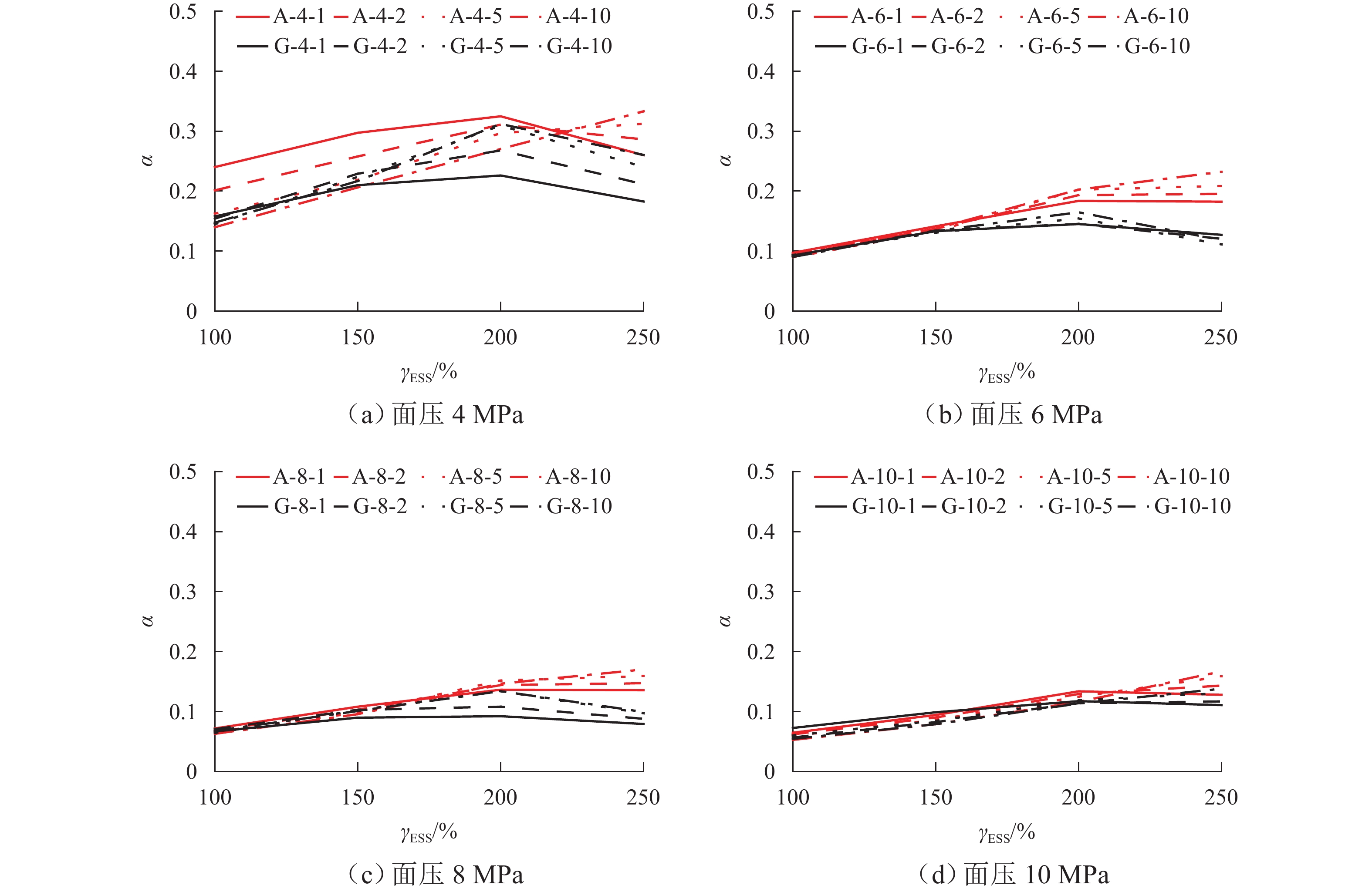

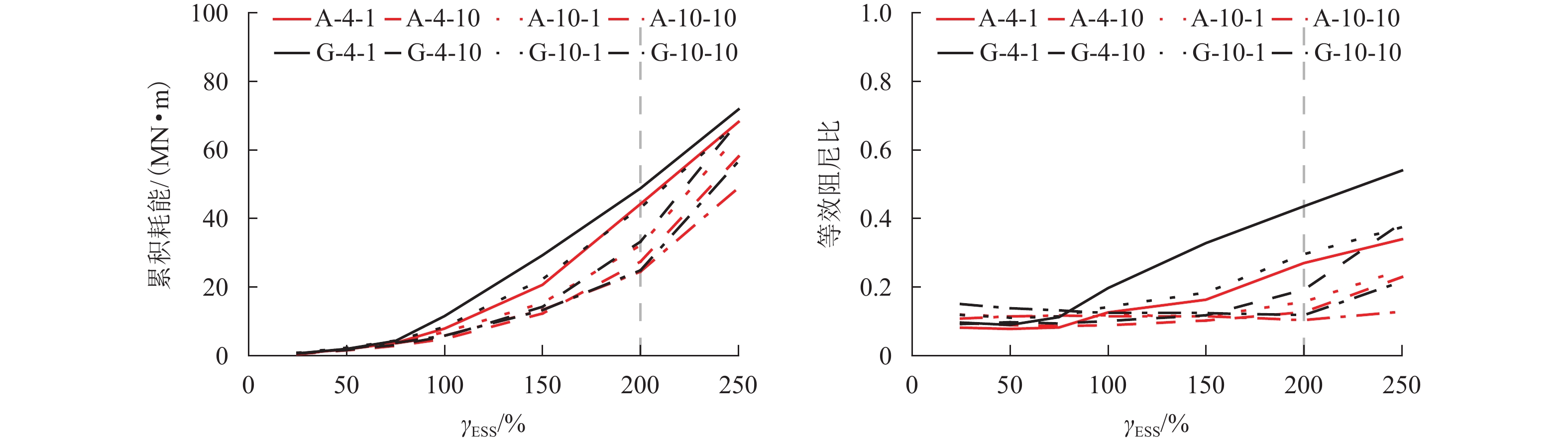

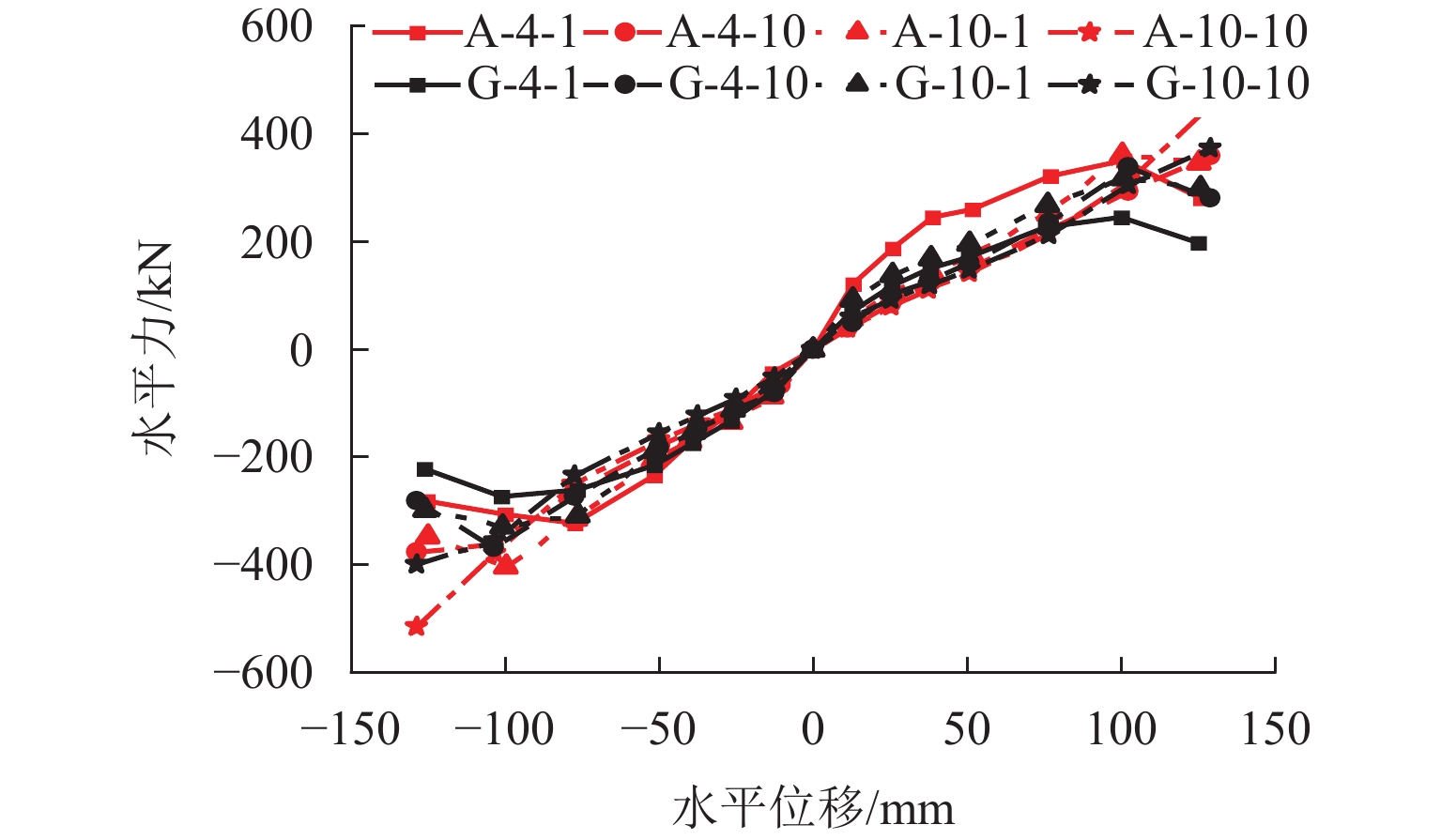

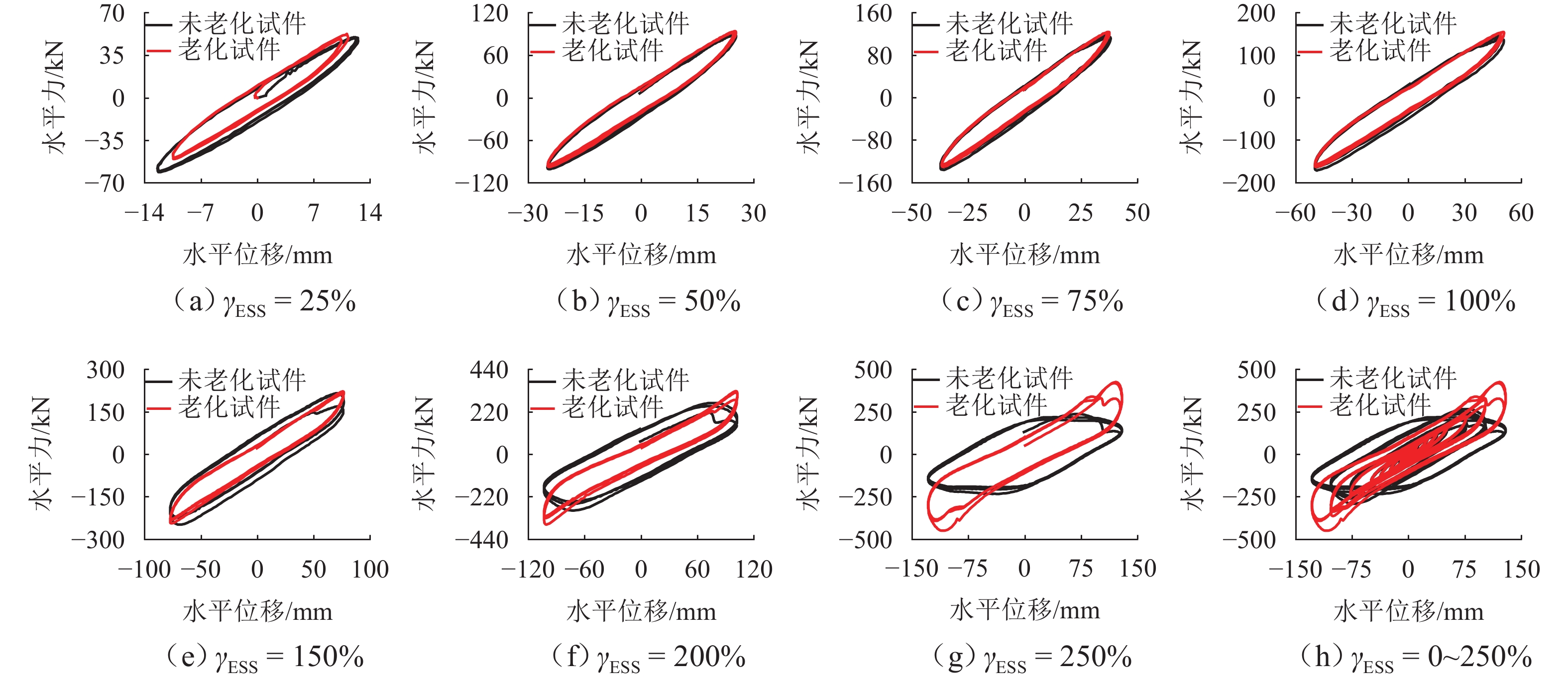

为探明板式橡胶支座在老化情况下的摩擦滑动性能,基于支座规范中抗剪老化的有关规定,对支座开展热老化试验及拟静力试验. 首先,构造桥梁工程中真实的支座工作状态;其次,通过老化箱对支座样本进行热空气加速老化处理,并通过压剪机对支座进行水平循环拟静力加载;最后,对比分析支座试件在不同加载条件下的变形状态、滞回行为及相关力学响应. 研究结果表明:在加载过程中老化试件的剪切变形程度较大,滑动程度较小,滞回环较狭长;支座的滑动位移与面压、加载速率呈负相关;支座剪切刚度随等效剪切应变先减后增,老化试件的剪切刚度降低,等效刚度增大;在支座使用阶段平均面压10 MPa下,2类试件的摩擦系数差异不大,均低于规范建议值0.20;老化试件的摩擦系数普遍大于未老化试件,而耗能不充分;未老化试件存在性能变化点,整体力学行为为三折线趋势,而老化试件的摩擦滑动行为稳定,在0~250%等效剪切应变过程中未出现突变点.

Abstract:To investigate the friction and sliding performance of laminated-rubber bearings under aging conditions, heat aging tests and quasi-static tests were conducted based on the related provisions of shear aging resistance in the bearing specification. Firstly, the actual working state of the bearing in bridge engineering was simulated. Then, the bearing samples were subjected to hot air accelerated aging treatment through an aging chamber and then to horizontal cyclic quasi-static loading through a compression-shear machine. Finally, comparative analyses were conducted on the deformation state, hysteresis behavior, and related mechanical responses of the bearing specimens under different loading conditions. The results show that the shear deformation degree of the aged specimens is large during loading; the sliding degree is small, and the hysteresis loop is narrow and long. The sliding displacement of the bearings is negatively correlated with surface pressure and loading rate. The shear stiffness of the bearings first decreases and then increases as equivalent shear strain rises, and the shear stiffness of aged specimens decreases; the equivalent stiffness increases. At the average surface pressure of 10 MPa during the use of the bearings, there is less difference in the friction coefficient between the two types of specimens, both of which are lower than the recommended value of 0.20 in the specifications. The friction coefficient of the aged specimens is generally greater than that of unaged specimens, and insufficient energy dissipation is observed. There is a performance change point in the unaged specimens, and the overall mechanical behavior shows a three-fold trend. However, the friction and sliding behaviors of the aged specimens are stable, and there is no sudden change as the equivalent shear strain increases from 0 to 250%.

-

表 1 老化箱设备性能及技术参数

Table 1. Performance and technical parameters of aging chamber

温度范围/℃ 温度均匀度/℃ 温度偏差/℃ 气体流量/

(L·min−1−55~160 [−2,2] [−2,2] 20~60 表 2 压剪机设备性能及技术参数

Table 2. Performance and technical parameters of compression-shear machine

竖向最大静

态荷载/GN横向最大动

态荷载/GN横向动态频

率范围/Hz横向最大

位移/mm20 2 1 ±600 表 3 试验工况

Table 3. Test conditions

工况系列 工况编号 支座试件 面压 σ/MPa 加载速率v/(mm·s−1) G G-σ-v 未老化 4、6、8、10 1、2、5、10 A A-σ-v 老化 4、6、8、10 1、2、5、10 表 4 支座试件变形阶段及变形状态

Table 4. Deformation stage and deformation status of bearing specimens

工况系列 支座试件 纯剪切变形 初始滑动 显著滑动 稳定滑动 G 未老化

(0<γESS≤50%) (50%<γESS≤100%) (100%<γESS≤200%) (200%<γESS≤250%) A 老化

(0<γESS≤75%) (75%<γESS≤150%) (150%<γESS≤200%) (200%<γESS≤250%) 表 5 支座试件各变形阶段的位移响应

Table 5. Displacement response of bearing specimens at each deformation stage

mm 变形阶段 剪切变形量 摩擦滑动位移 未老化试件 老化试件 未老化试件 老化试件 纯剪切变形 25 38 0 0 初始滑动 45 73 5 2 显著滑动 78 89 22 11 稳定滑动 84 110 26 15 表 6 两类支座试件的摩擦条件α

Table 6. Friction condition α of two types of bearing specimens

工况 老化试件 未老化试件 γESS=100% γESS=150% γESS=200% γESS=250% γESS=100% γESS=150% γESS=200% γESS=250% A-4-1 0.240 0.297 0.325 0.260 0.158 0.210 0.226 0.183 A-4-2 0.201 0.258 0.311 0.286 0.154 0.229 0.268 0.211 A-4-5 0.162 0.218 0.297 0.312 0.145 0.224 0.309 0.240 A-4-10 0.140 0.206 0.270 0.333 0.147 0.217 0.312 0.260 A-6-1 0.097 0.141 0.184 0.182 0.093 0.133 0.145 0.127 A-6-2 0.093 0.137 0.193 0.195 0.092 0.134 0.145 0.120 A-6-5 0.090 0.133 0.202 0.208 0.093 0.131 0.154 0.111 A-6-10 0.095 0.137 0.202 0.232 0.090 0.134 0.165 0.118 A-8-1 0.072 0.108 0.136 0.135 0.067 0.090 0.092 0.079 A-8-2 0.069 0.103 0.144 0.147 0.071 0.103 0.108 0.088 A-8-5 0.066 0.098 0.152 0.159 0.064 0.102 0.134 0.097 A-8-10 0.063 0.096 0.146 0.170 0.068 0.101 0.134 0.099 A-10-1 0.064 0.094 0.134 0.128 0.072 0.099 0.117 0.111 A-10-2 0.062 0.090 0.129 0.143 0.057 0.082 0.114 0.117 A-10-5 0.059 0.086 0.125 0.158 0.060 0.084 0.119 0.130 A-10-10 0.053 0.079 0.116 0.167 0.054 0.079 0.113 0.138 -

[1] 徐略勤,王龙,李建中,等. 在役桥梁挡块基于保险丝理念的改造方法[J]. 西南交通大学学报,2020,55(1): 118-125,143. doi: 10.3969/j.issn.0258-2724.20180425XU Lueqin, WANG Long, LI Jianzhong, et al. Reconstruction method of shear keys on existing bridges based on structural fuse concept[J]. Journal of Southwest Jiaotong University, 2020, 55(1): 118-125,143. doi: 10.3969/j.issn.0258-2724.20180425 [2] XIANG N L, LI J Z. Seismic performance of highway bridges with different transverse unseating-prevention devices[J]. Journal of Bridge Engineering, 2016, 21(9): 04016045.1-04016045.16. [3] 庄卫林,刘振宇,蒋劲松. 汶川大地震公路桥梁震害分析及对策[J]. 岩石力学与工程学报,2009,28(7):1377-1387.ZHUANG Weilin,LIU Zhenyu,JIANG Jinsong. Earthquake-induced damage analysis of highway bridges in Wenchuan earthquake and countermeasures[J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(7):1377-1387. [4] 李建中,汤虎. 中小跨径板式橡胶支座梁桥横向抗震设计研究[J]. 土木工程学报,2016,49(11): 69-78.LI Jianzhong, TANG Hu. Study on transverse seismic design of small and medium span bridges with elastomeric bearing pads[J]. China Civil Engineering Journal, 2016, 49(11): 69-78. [5] 王克海,韦韩,李茜,等. 中小跨径公路桥梁抗震设计理念[J]. 土木工程学报,2012,45(9): 115-121.WANG Kehai, WEI Han, LI Qian, et al. Philosophies on seismic design of highway bridges of small or medium spans[J]. China Civil Engineering Journal, 2012, 45(9): 115-121. [6] 陈力波,黄才贵,黄勇冰,等. 公路规则梁桥地震易损性模型及简化计算方法[J]. 西南交通大学学报,2018,53(1): 146-155. doi: 10.3969/j.issn.0258-2724.2018.01.018CHEN Libo, HUANG Caigui, HUANG Yongbing, et al. Seismic vulnerabilitu models and simplified calculation method for regular highway girder bridges[J]. Journal of Southwest Jiaotong University, 2018, 53(1): 146-155. doi: 10.3969/j.issn.0258-2724.2018.01.018 [7] 中华人民共和国交通运输部. 公路桥梁抗震设计规范:JTG/T 2231-01—2020[S]. 北京:人民交通出版社,2020. [8] 中华人民共和国交通运输部. 公路桥梁板式橡胶支座:JT/T 4—2019[S]. 北京:人民交通出版社,2019. [9] XIANG N L, LI J Z. Experimental and numerical study on seismic sliding mechanism of laminated-rubber bearings[J]. Engineering Structures, 2017, 141: 159-174. doi: 10.1016/j.engstruct.2017.03.032 [10] 李冲,王克海,惠迎新,等. 考虑摩擦滑移的板式橡胶支座连续梁桥地震反应分析[J]. 中国公路学报,2016,29(3): 73-81. doi: 10.3969/j.issn.1001-7372.2016.03.010LI Chong, WANG Kehai, HUI Yingxin, et al. Seismic response of continuous girder bridge with laminated rubber bearing considering friction sliding[J]. China Journal of Highway and Transport, 2016, 29(3): 73-81. doi: 10.3969/j.issn.1001-7372.2016.03.010 [11] LI Y, WU Q Q. Experimental study on friction sliding performance of rubber bearings in bridges[J]. Advances in Materials Science and Engineering, 2017, 2017:5845149.1-5845149.8. [12] LIU K, CHANG K, LU C, et al. Seismic performance of skew bridge with friction type rubber bearings[C]// 14th World Conference on Earthquake Engineering. Beijing: WCEE, 2008: 1-8. [13] 王克海,吴刚,张盼盼. 板式橡胶支座摩擦滑移性能试验研究[J]. 振动与冲击,2020,39(19): 1-6.WANG Kehai, WU Gang, ZHANG Panpan. Tests for friction sliding performance of plate rubber bearing[J]. Journal of Vibration and Shock, 2020, 39(19): 1-6. [14] WU G, WANG K H, ZHANG P P, et al. Effect of mechanical degradation of laminated elastomeric bearings and shear keys upon seismic behaviors of small-to-medium-span highway bridges in transverse direction[J]. Earthquake Engineering and Engineering Vibration, 2018, 17(1): 205-220. doi: 10.1007/s11803-018-0435-z [15] WU G, WANG K H, LU G Y, et al. An experimental investigation of unbonded laminated elastomeric bearings and the seismic evaluations of highway bridges with tested bearing components[J]. Shock and Vibration, 2018, 2018(1): 8439321.1-8439321.18. [16] MA Y H, LI Y M, ZHAO G F, et al. Experimental research on the time-varying law of performance for natural rubber laminated bearings subjected to seawater dry-wet cycles[J]. Engineering Structures, 2019, 195: 159-171. doi: 10.1016/j.engstruct.2019.05.101 [17] RUSSO G, PAULETTA M. Sliding instability of fiber-reinforced elastomeric isolators in unbonded applications[J]. Engineering Structures, 2013, 48: 70-80. doi: 10.1016/j.engstruct.2012.08.031 [18] LI Y M, MA Y H, ZHAO G F, et al. Experimental study on the effect of alternating ageing and sea corrosion on laminated natural rubber bearing’s tension-shear property[J]. Journal of Rubber Research, 2020, 23(3): 151-161. doi: 10.1007/s42464-020-00045-9 [19] 黄海新,李炫钢,李帆,等. 老化与偏心受压下板式橡胶支座抗震性能拟静力试验研究[J]. 土木与环境工程学报(中英文),2021,43(3): 51-58. doi: 10.11835/j.issn.2096-6717.2020.069HUANG Haixin, LI Xuangang, LI Fan, et al. Pseudo static test of seismic performance of rubber bearing plate under aging and eccentric compression[J]. Journal of Civil and Environmental Engineering, 2021, 43(3): 51-58. doi: 10.11835/j.issn.2096-6717.2020.069 [20] 关宏摘. 板式橡胶支座力学性能退化模型及损伤识别[D]. 开封:河南大学,2022. [21] FUKAHORI Y, GABRIEL P, LIANG H, et al. A new generalized philosophy and theory for rubber friction and wear[J]. Wear, 2020, 446/447: 203166.1-203166.18. -

下载:

下载: