Load Analysis of Statically Indeterminate Support Systems for Reaction Vessel Wheels

-

摘要:

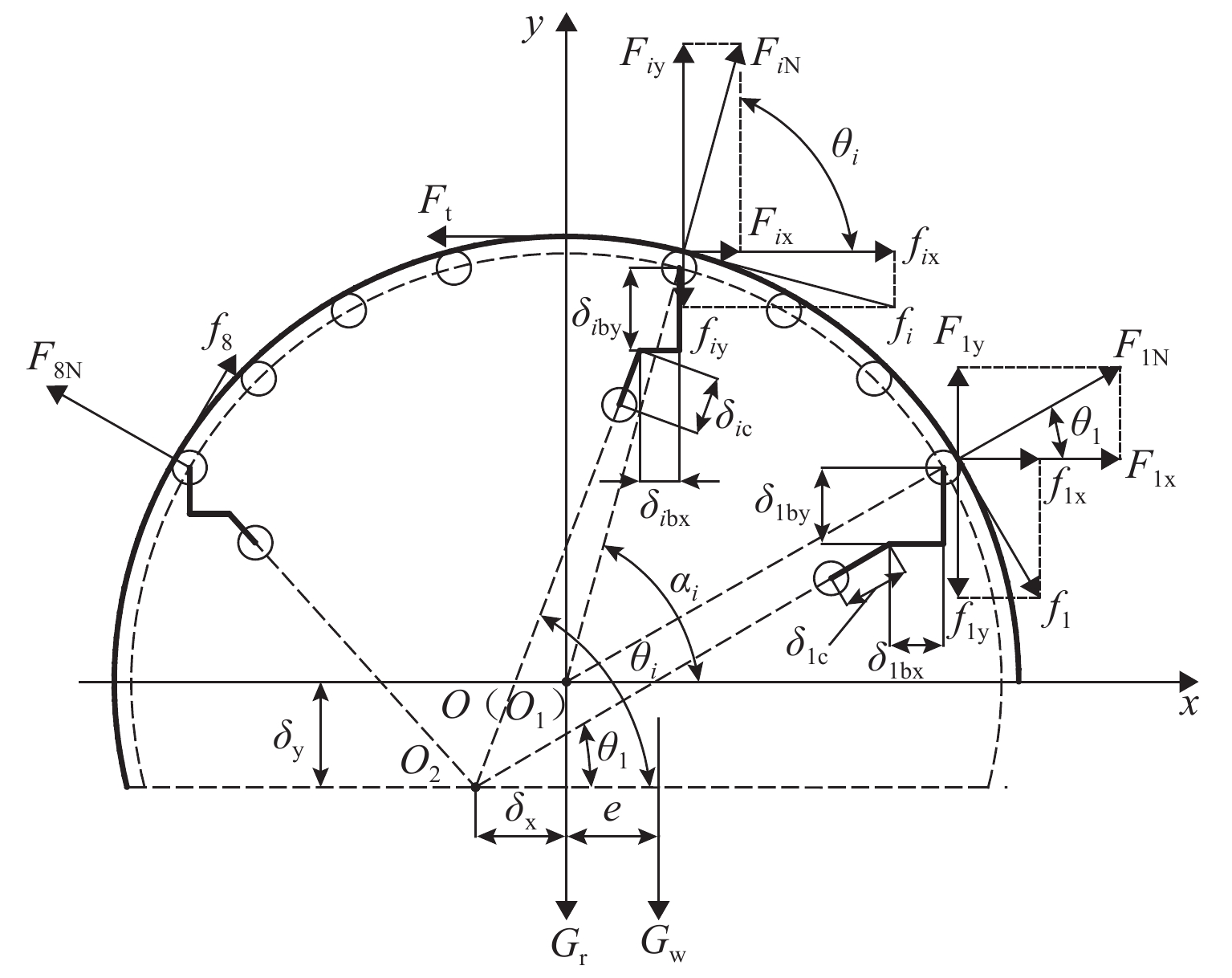

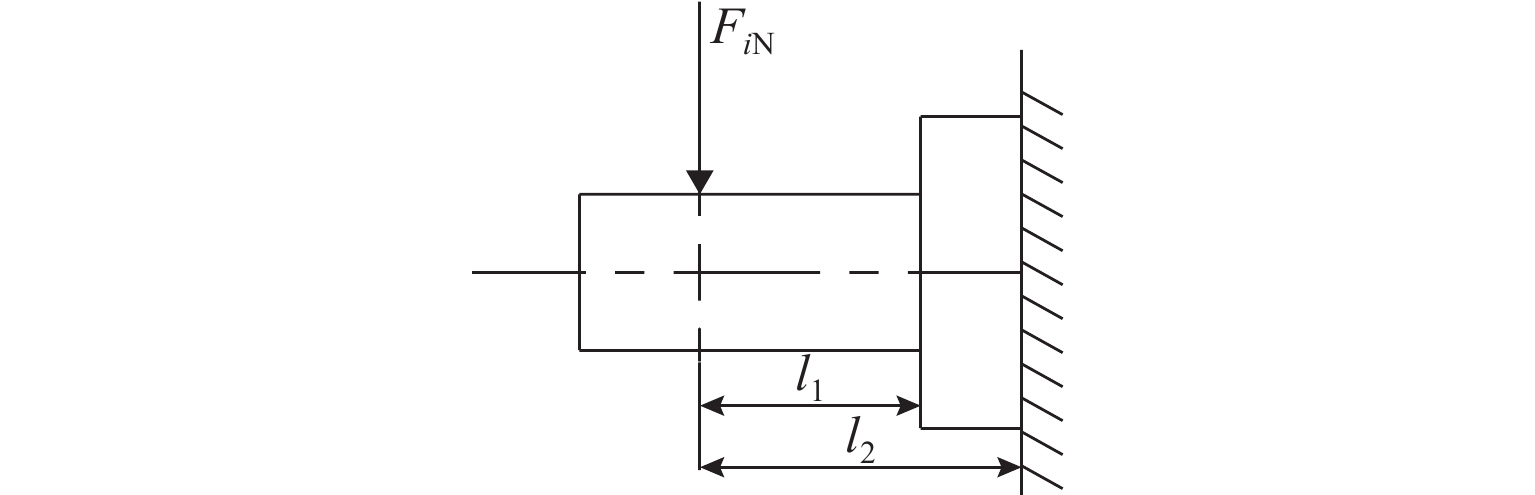

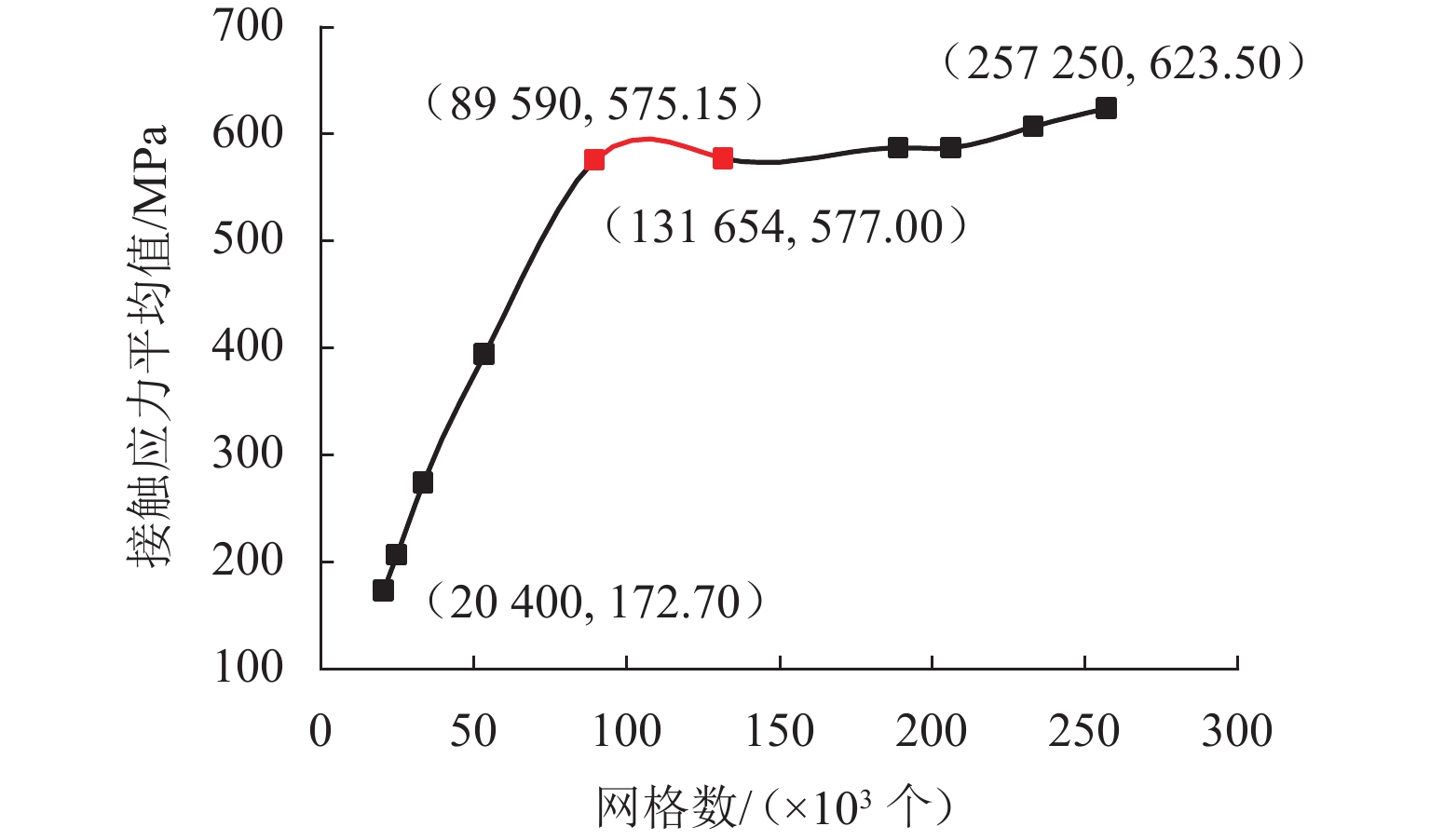

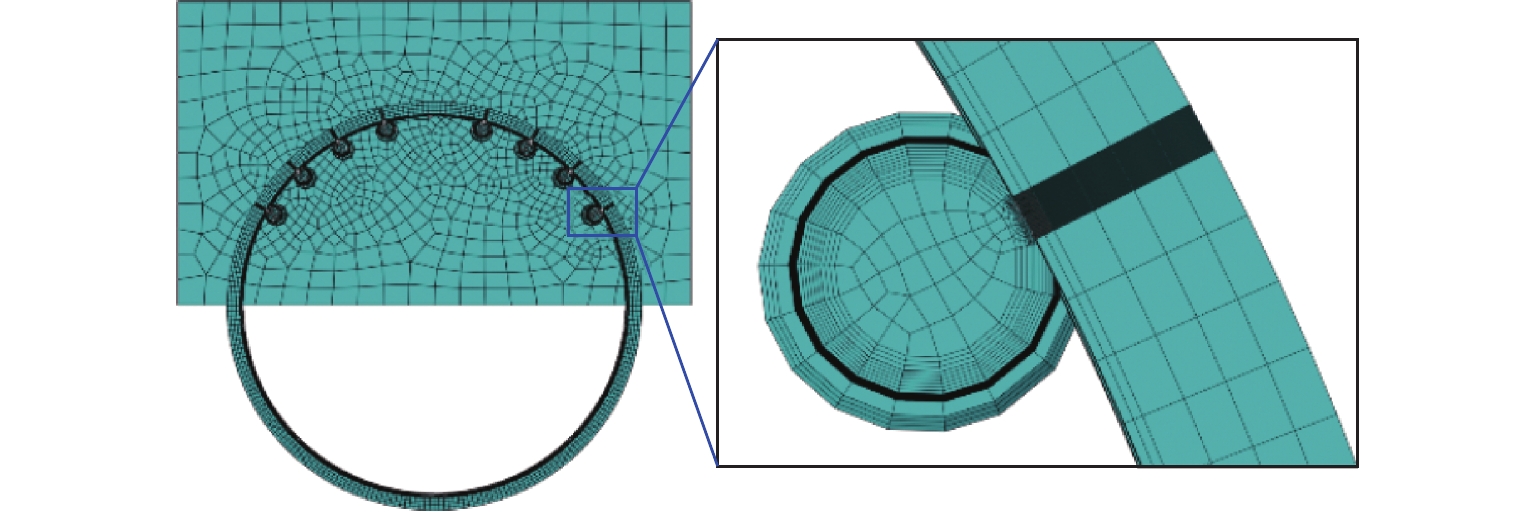

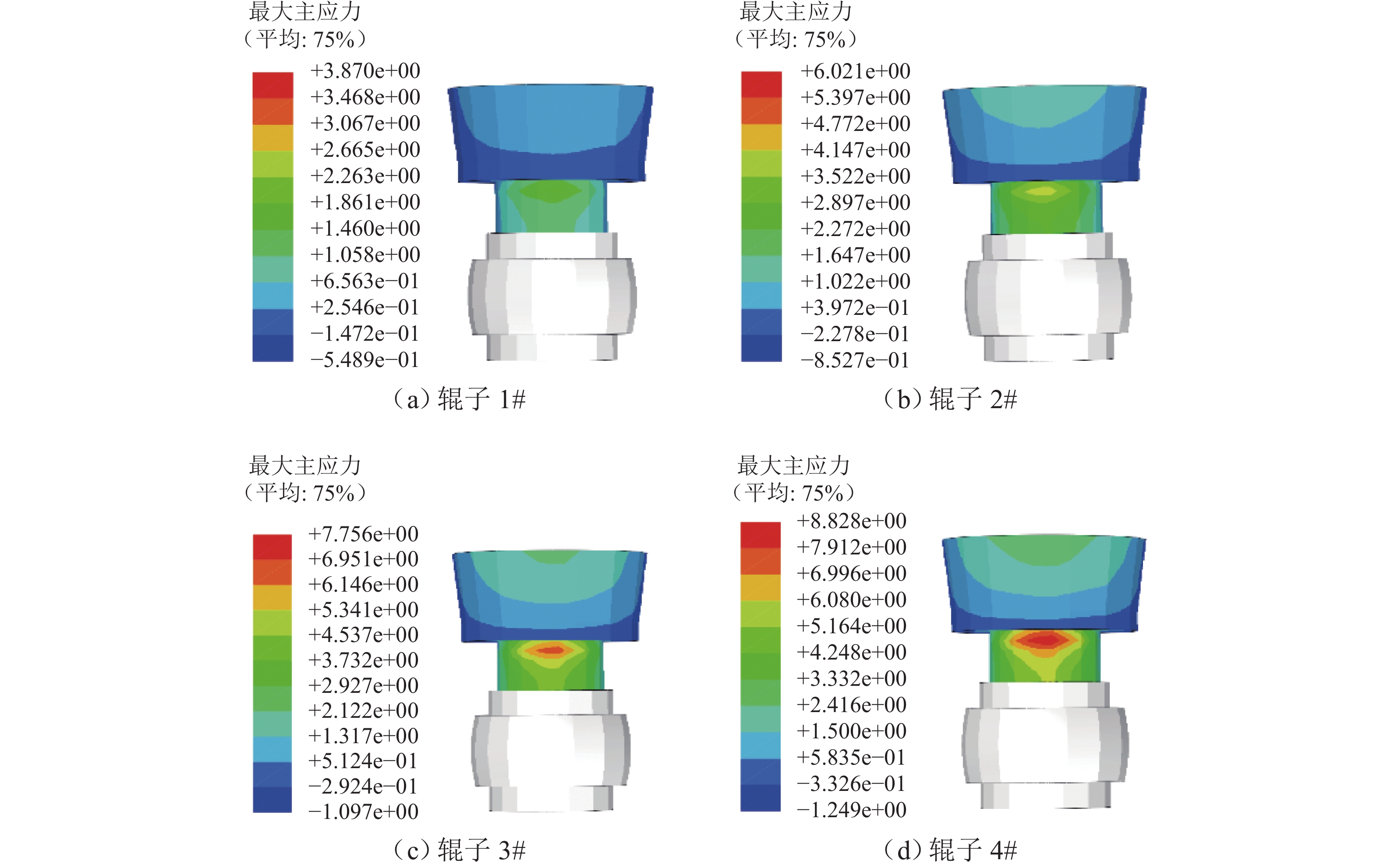

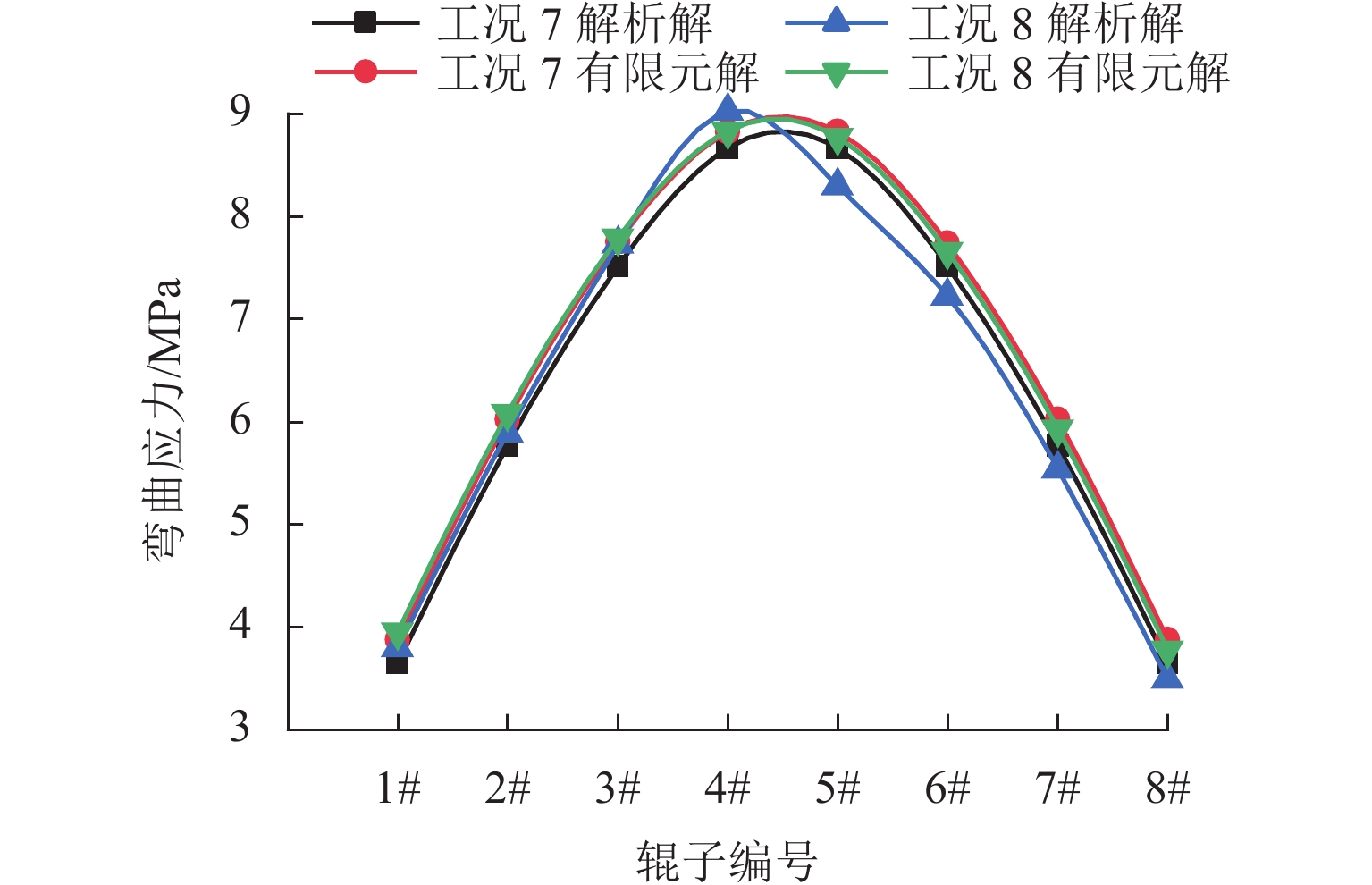

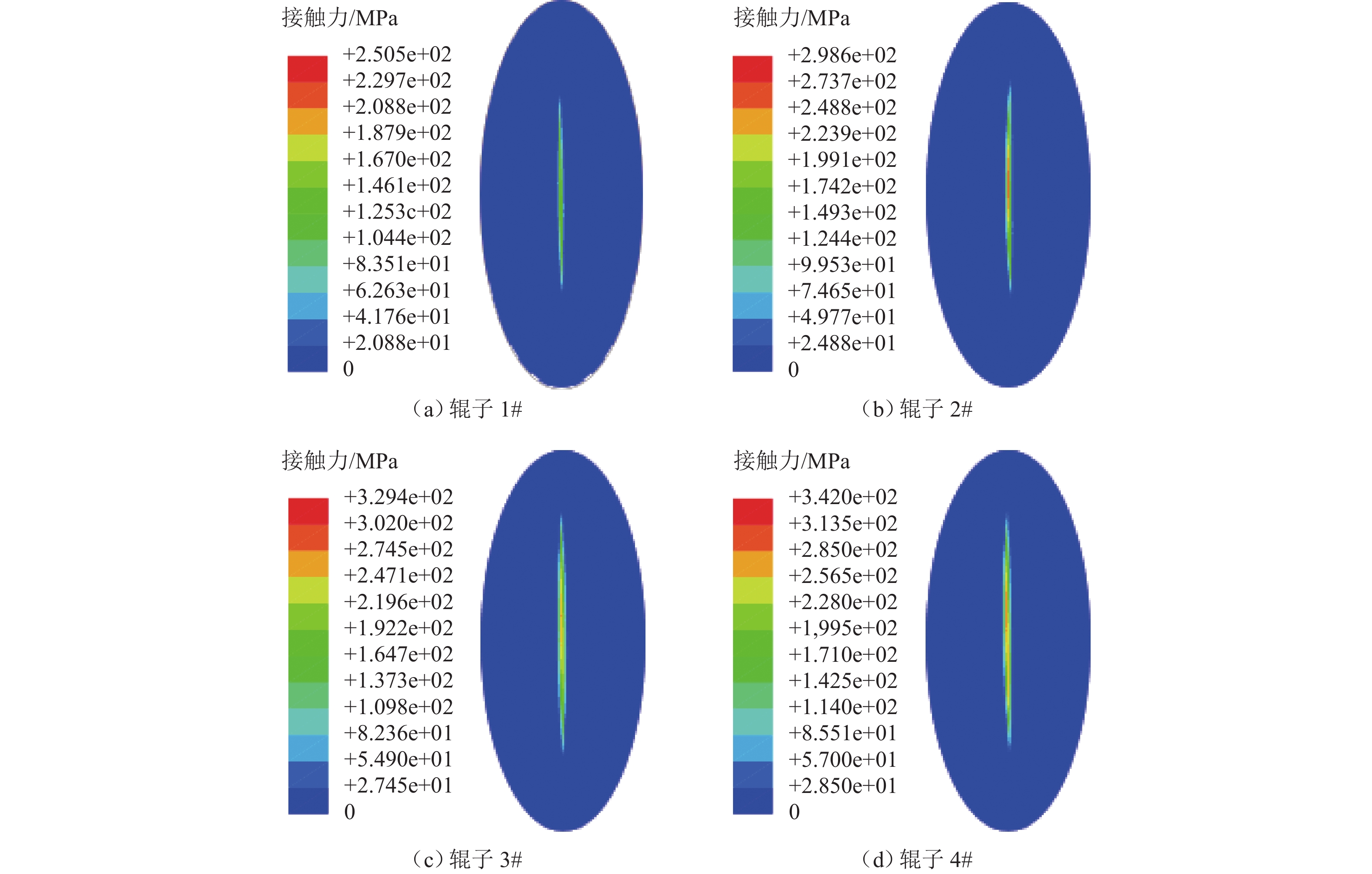

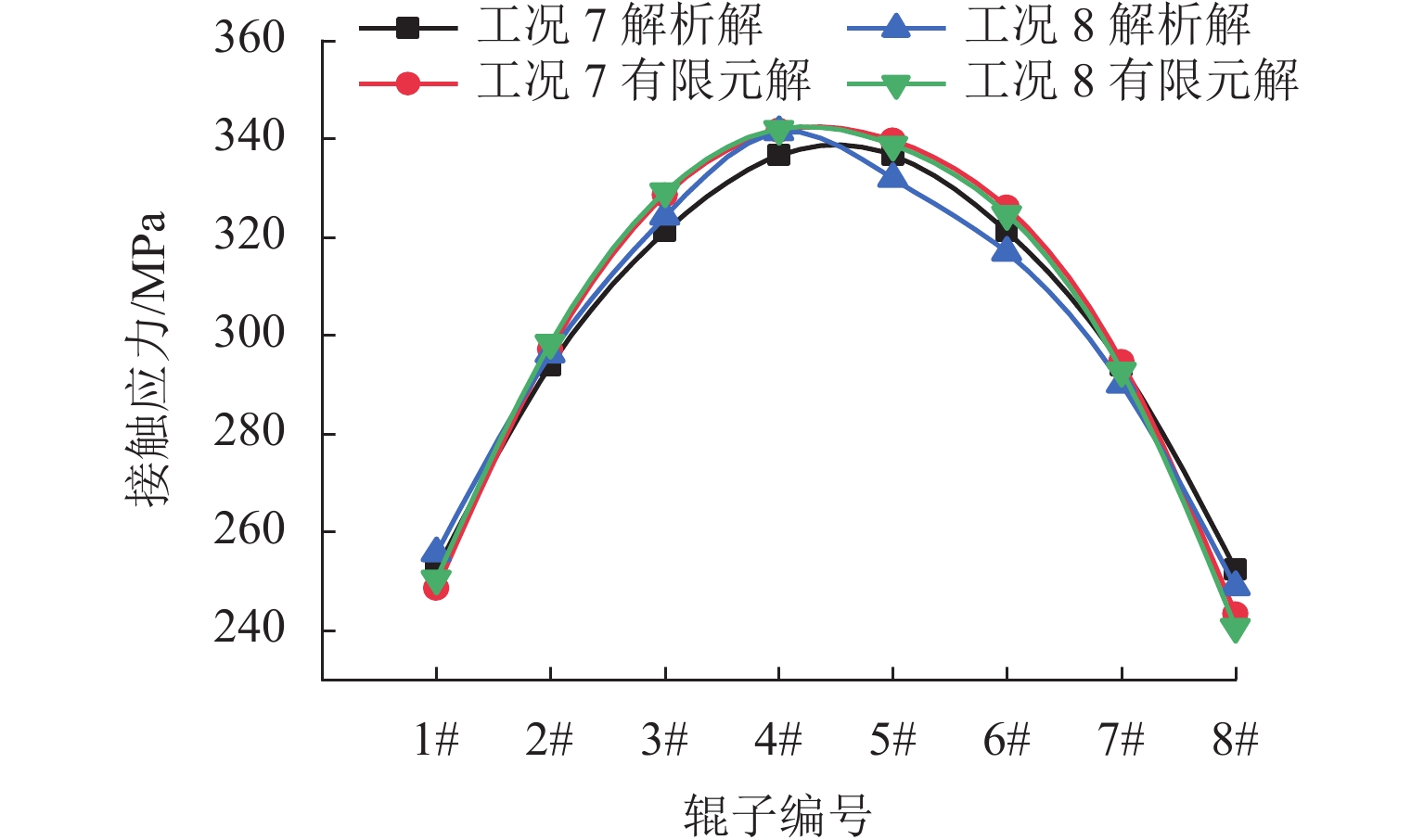

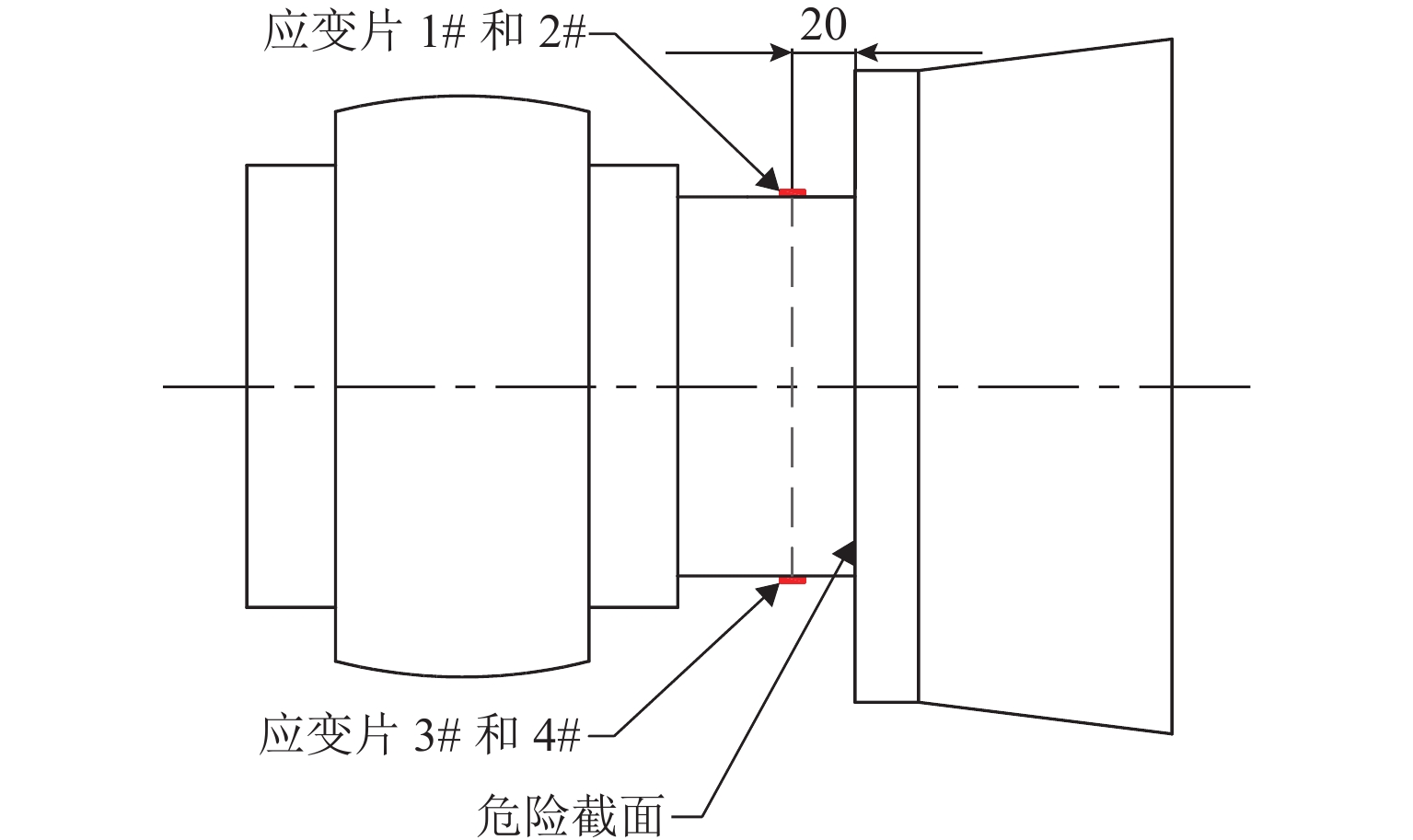

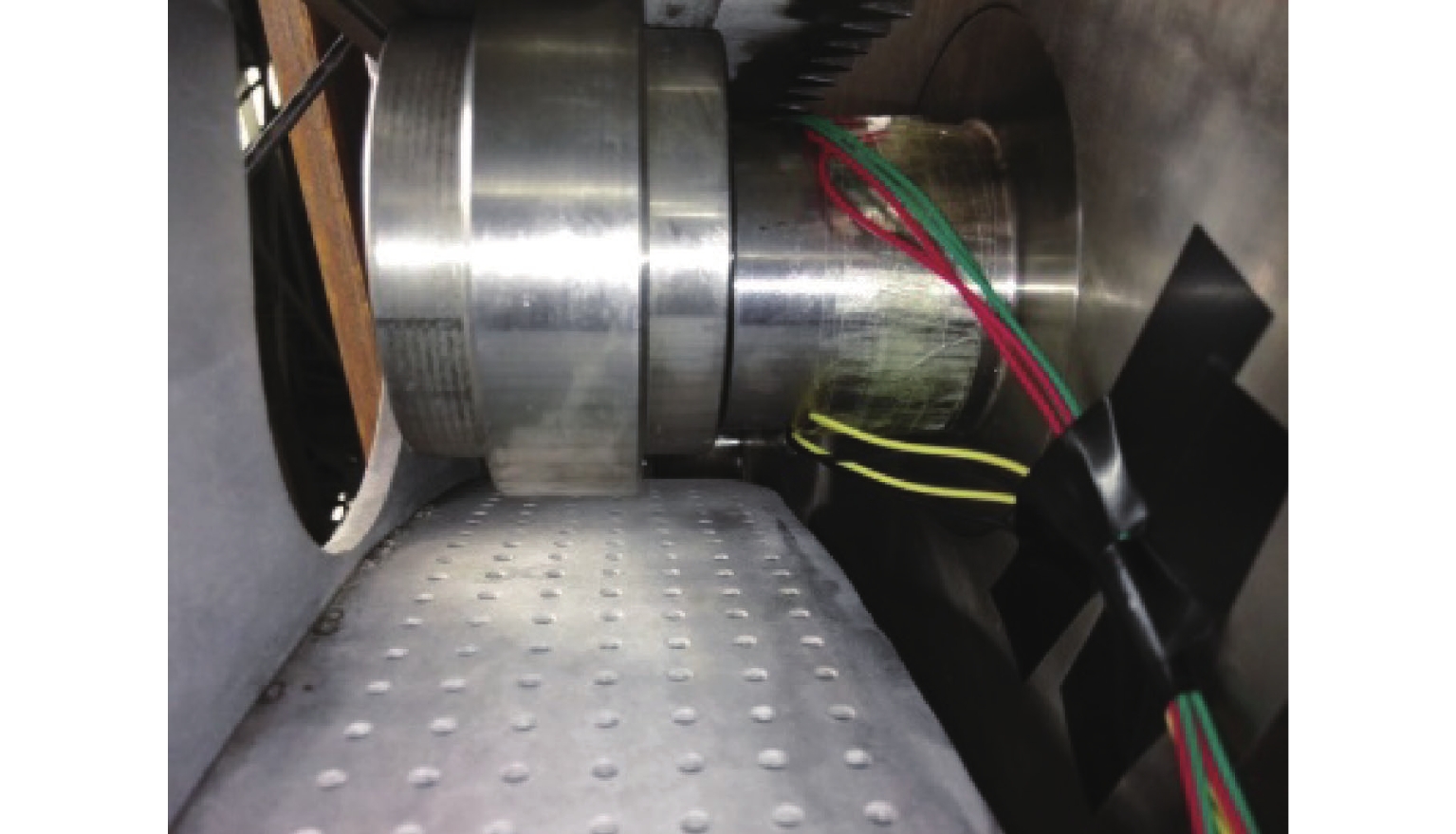

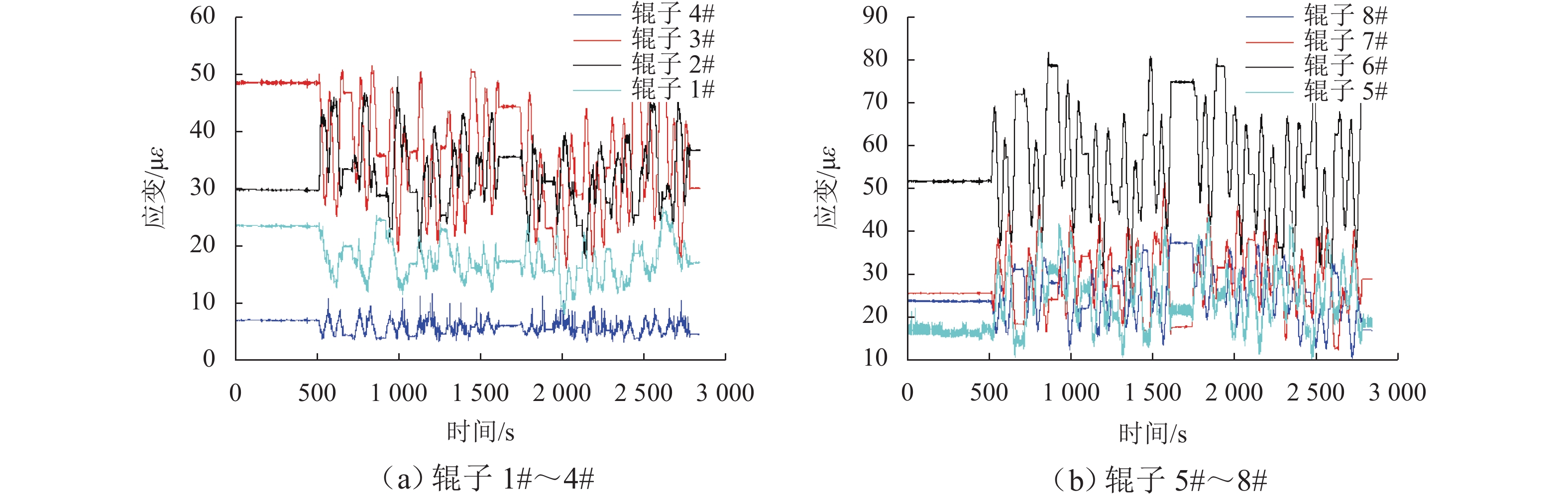

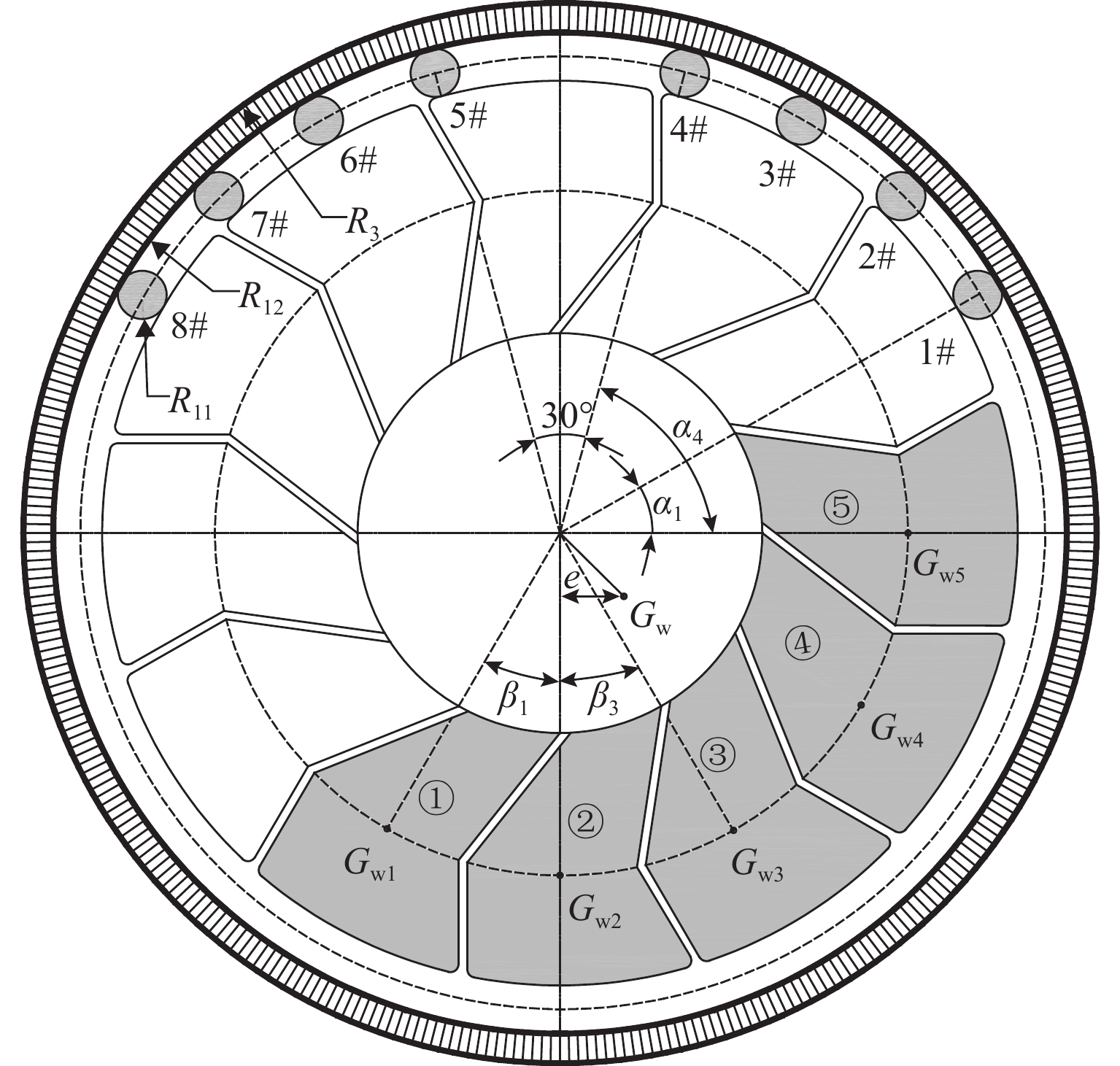

转轮支撑结构是后处理反应容器的重要组成部分,为提高反应容器的安全强度,该支撑系统采用超静定结构,针对支撑辊子的强度和系统的均载性问题,本文基于能量法,引入拉格朗日乘数,结合能量守恒定律解算各辊子上的法向力,进而求解出弯曲应力和接触应力;建立简易三维模型,使用有限元软件分析各辊子的应力分布和变化规律,并通过实验对结果进行验证;定义载荷分配系数,通过SPSSAU分析得出各制造误差对载荷分配系数的影响规律. 结果表明:辊子的最大弯曲应力为42 MPa,远小于材料屈服强度;有限元结果与理论结果的最大误差约为8%,并通过辊子的应变实验验证该方法的准确性;载荷分配系数与辊子弧面曲率半径呈负相关,与转轮弧面曲率半径呈正相关.

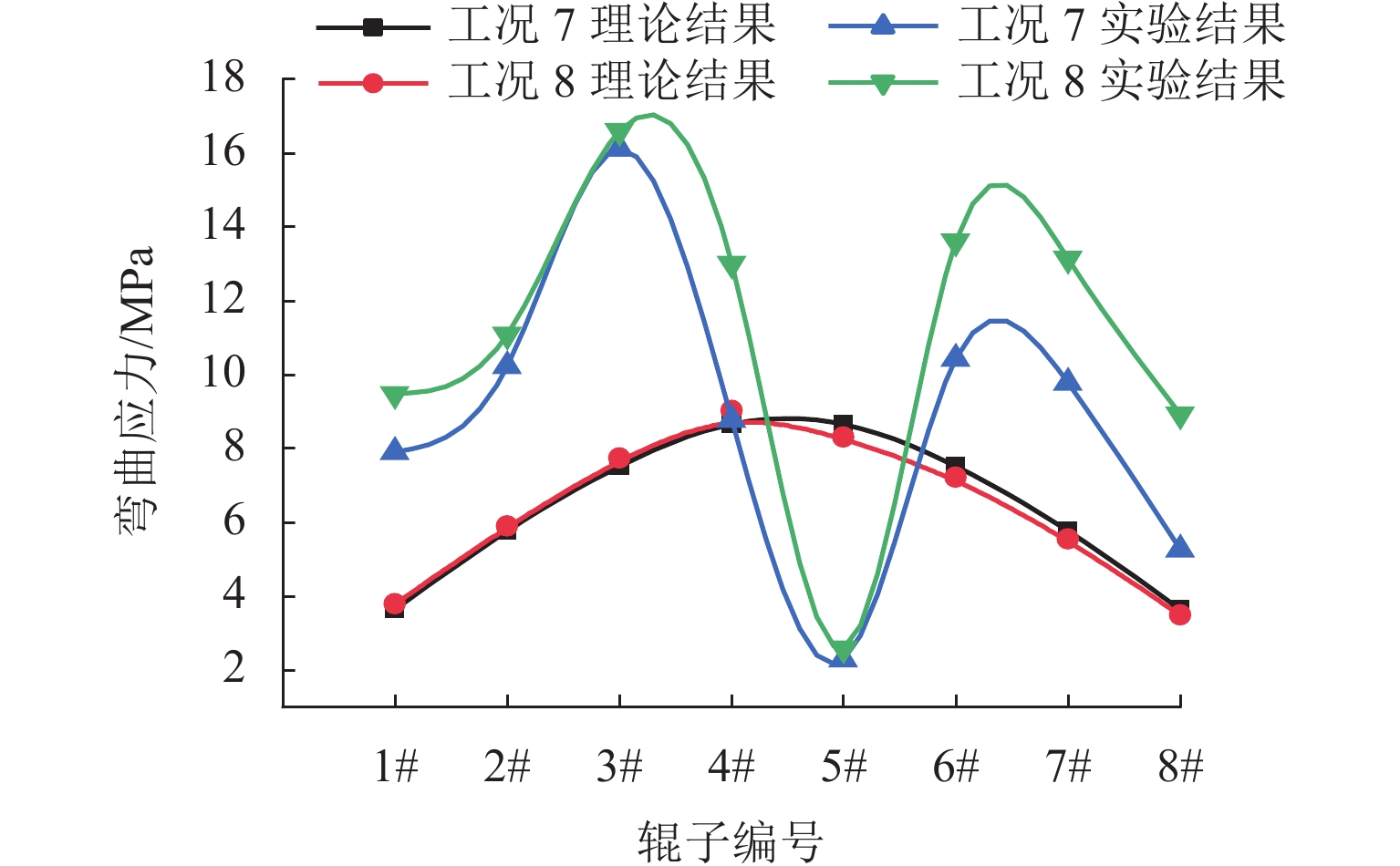

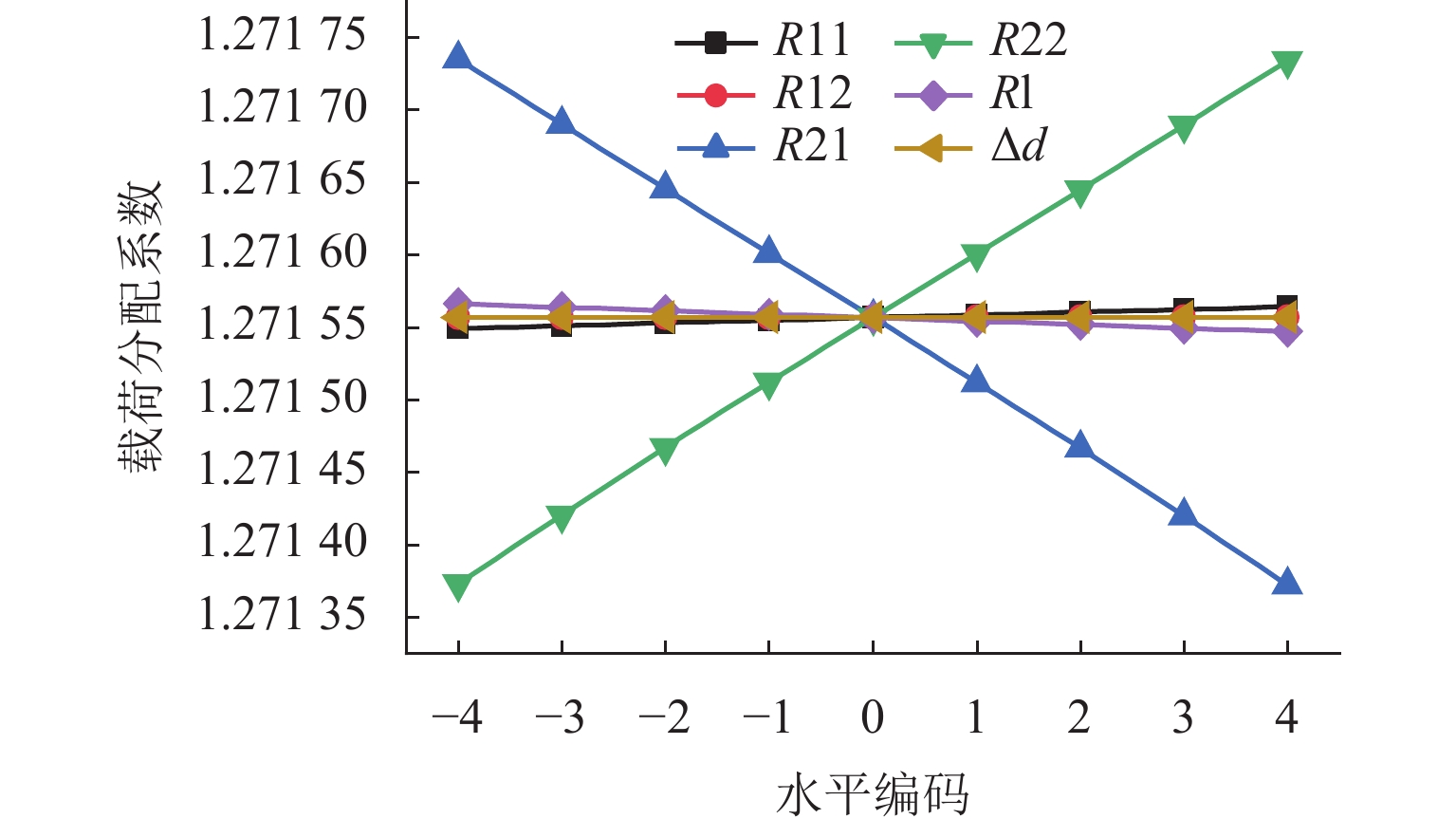

Abstract:The support structure of wheels is an important component of post-treatment reaction vessels. To improve the safety strength of the reaction vessels, the support system adopts a statically indeterminate structure. In view of the strength of supporting rollers and load-bearing characteristics of the system, based on the energy method, Lagrange multipliers were introduced and the law of energy conservation was combined to calculate the normal forces on each roller, thus solving the bending stress and contact stress. A simple 3D model was built, and by adopting finite element software, the stress distribution and variation laws of each roller were analyzed, with the results verified via experiments. The load distribution factor was defined, and the influence laws of manufacturing errors on the load distribution factor were analyzed by utilizing SPSSAU. The results show that the maximum bending stress of the roller is 42 MPa, which is much smaller than the yield strength of the material. The maximum error between the finite element simulation results and theoretical results is about 8%, and the accuracy of the proposed method was verified by strain experiments on rollers. The load distribution factor negatively correlates with the curvature radius of the roller surface, and positively correlates with the curvature radius of the wheel surface.

-

Key words:

- statically indeterminate structure /

- energy method /

- Lagrange multiplier /

- stress /

- finite element /

- load distribution

-

表 1 加载的物料重量

Table 1. Weight of loaded materials

编号 Gw1 Gw2 Gw3 Gw4 Gw5 物料重量/kg 240 200 160 120 80 表 2 转轮与辊子的尺寸参数

Table 2. Size parameters of wheel and roller

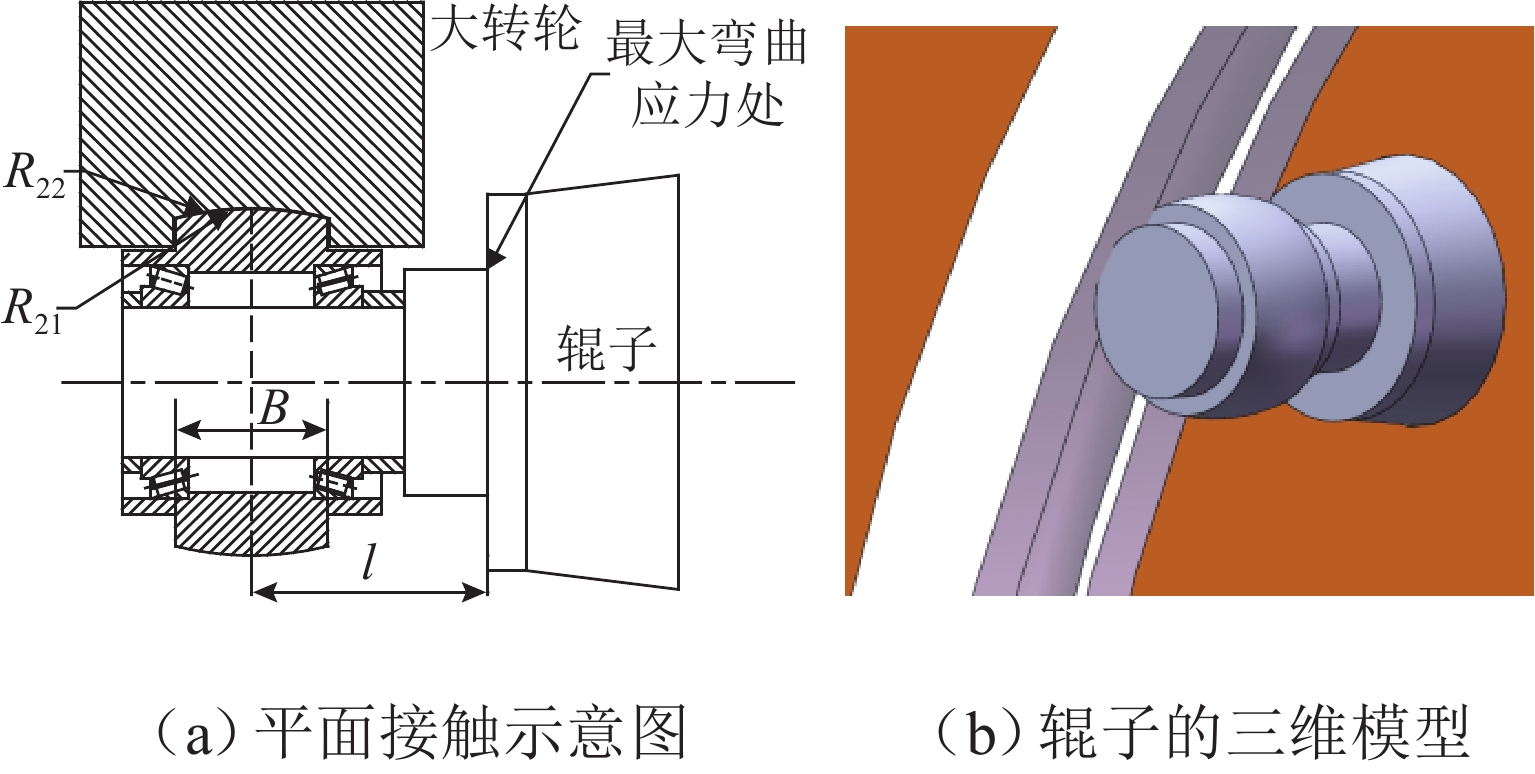

参数 数值 辊子接触截面半径 R11/mm 90 转轮内径 R12/mm 1865 辊子弧面曲率半径 R21/mm 162.5 转轮弧面曲率半径 R22/mm 162.9 转轮重力 Gr/N 49000 物料总重力 Gw/N 7840 辊子最大弯曲应力力臂 l/mm 124 辊子最大弯曲应力处截面直径 d/mm 120 接触长度 B/mm 80 转轮与辊子弹性模量 E/MPa 210000 摩擦系数 μ 0.003 泊松比 ν 0.3 转轮外径 R3/mm 1975 转轮偏心圆半径 Rh/mm 1275 表 3 静止工况下各辊子受力

Table 3. Forces on each roller in static working conditions

辊子编号 1# 8# 2# 7# 3# 6# 4# 5# 支反力/N 4985 4985 7885 7885 10282 10282 11851 11851 表 4 运转工况下各辊子受力

Table 4. Forces on each roller in operating conditions

辊子编号 1# 2# 3# 4# 支反力/N 5192 8061 10578 12352 辊子编号 5# 6# 7# 8# 支反力/N 11351 9883 7580 4780 表 5 工况列表

Table 5. Working conditions

工况编号 支撑状态 加载状况 1 1#、8#辊子承载 静止工况 2 运转工况 3 4#、5#辊子承载 静止工况 4 运转工况 5 4#、8#辊子承载 静止工况 6 运转工况 7 1#~8#辊子承载 静止工况 8 运转工况 表 6 解析解和有限元解的应力对比

Table 6. Stress comparison between analytical and finite element solutions

工况编号 辊子编号 弯曲应力/MPa 接触应力/MPa 解析解 有限元解 解析解 有限元解 1 1# 41.546 42.220 567.9 577.3 8# 41.546 42.240 567.9 576.7 2 1# 41.722 42.220 568.7 577.6 8# 41.372 41.760 567.1 573.6 3 4# 21.506 22.800 456.0 457.3 5# 21.506 22.900 456.0 456.1 4 4# 21.868 22.500 458.6 461.7 5# 21.145 21.360 453.4 451.5 5 4# 37.249 36.86 547.6 545.0 8# 11.132 16.99 366.1 379.7 6 4# 37.355 37.79 548.2 552.1 8# 10.930 11.37 363.9 361.4 表 7 部分支撑情况下实验与理论结果对比

Table 7. Comparison of experimental and theoretical results under partial support

工况编号 辊子编号 弯曲应力/MPa 辊子编号 弯曲应力/MPa 1(理论结果) 1# 41.55 8# 41.55 1(实验结果) 41.98 30.12 2(理论结果) 1# 41.72 8# 41.37 2(实验结果) 3(理论结果) 4# 21.51 5# 21.51 3(实验结果) 28.39 20.97 4(理论结果) 4# 21.87 5# 21.15 4(实验结果) 31.91 29.95 5(理论结果) 4# 37.25 8# 11.13 5(实验结果) 26.13 14.04 6(理论结果) 4# 37.36 8# 10.93 6(实验结果) 35.31 14.72 表 8 制造误差因素水平表

Table 8. Factors and levels of manufacturing errors

水平编码 R11/mm R12/mm R21/mm R22/mm ∆l/mm ∆d/mm −4 −0.046 −0.260 −0.057 −0.057 −0.040 −0.040 4 0.046 0.260 0.057 0.057 0.040 0.040 间隔 0.01150 0.06500 0.01425 0.01425 0.01000 0.01000 表 9 多元线性回归分析结果

Table 9. Multiple linear regression analysis results

参数 未标准化系数 B 标准化系数 β B的95%置信区间 t p VIF 取值 标准错误 下限 上限 常数项 1.274 0.006 1.261 1.287 207.242 <0.001 x1 −0.006 0 −0.709 −0.006 −0.006 −237.045 <0.001 1.000 x2 0.006 0 0.705 0.006 0.006 235.855 <0.001 1.000 -

[1] 李腾, 周小毛, 王玲钰, 等. 乏燃料处置的必要性及其处置库环境化学行为[J]. 核化学与放射化学, 2020, 42(6): 513-523. doi: 10.7538/hhx.2020.YX.2020098LI Teng, ZHOU Xiaomao, WANG Lingyu, et al. Spent fuel disposal and chemical behaviors at repository environment[J]. Journal of Nuclear and Radiochemistry, 2020, 42(6): 513-523. doi: 10.7538/hhx.2020.YX.2020098 [2] 刘继连, 卢涛, 陈勇. 转轮式连续溶解器的相关信息[C]//中国核学会核化工分会成立三十周年庆祝大会暨全国核化工学术交流年会会议论文集. 北京: [出版者不祥], 2010: 86-91. [3] 乔朋, 谭晶晶. 带弹簧支撑超静定结构位移的简化计算方法[J]. 力学与实践, 2011, 33(6): 85-87.QIAO Peng, TAN Jingjing. Simplified calculation method of displacement of statically indeterminate structure with spring support[J]. Mechanics in Engineering, 2011, 33(6): 85-87. [4] 汪大洋, 孙静, 梁颖晶, 等. 基于力等价结构的复杂超静定结构求解新方法研究[J]. 力学与实践, 2023, 45(4): 899-908.WANG Dayang, SUN Jing, LIANG Yingjing, et al. A new method for solving complex statically indeterminate structures based on force equivalent idea[J]. Mechanics in Engineering, 2023, 45(4): 899-908. [5] ILLOULI S, SADAOUI A, KHENNANE A. Application of the theory statically indeterminate structures of infinite degree to a cable-truss footbridge under lateral forces[J]. Engineering Structures, 2019, 188: 665-676. doi: 10.1016/j.engstruct.2019.03.063 [6] 何峰, 杨松, 任天娇, 等. 均布载荷作用下单跨三次超静定等截面梁Maple求解研究[J]. 科技创新与应用, 2021, 11(15): 28-31.HE Feng, YANG Song, REN Tianjiao, et al. Maple solution of cubic statically indeterminate equal cross-section beam of single span under uniform load[J]. Technology Innovation and Application, 2021, 11(15): 28-31. [7] RȨBIELAK J. Two-stage method applied for approximate calculations of selected types of statically indeterminate trusses[J]. International Journal of Computational Methods, 2021, 18(3): 2041004. doi: 10.1142/S0219876220410042 [8] RȨBIELAK J. Examples of applications of two-stage method in calculations of statically indeterminate trusses[J]. International Journal of Computational Methods, 2020, 17(1): 1844009. doi: 10.1142/S0219876218440097 [9] 李银山, 丁千, 李子瑞, 等. 超静定梁-柱的解析解研究[J]. 力学学报, 2022, 54(11): 3068-3079.LI Yinshan, DING Qian, LI Zirui, et al. Analytical solution of statically indeterminate beam-column[J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(11): 3068-3079. [10] 吴晓. 求解工程中静不定结构内力的通用方法[J]. 中南大学学报(自然科学版), 2016, 47(1): 262-272. doi: 10.11817/j.issn.1672-7207.2016.01.036WU Xiao. A general method of solutions for engineering statically indeterminate structure force[J]. Journal of Central South University (Science and Technology), 2016, 47(1): 262-272. doi: 10.11817/j.issn.1672-7207.2016.01.036 [11] 杨咸启. 接触力学理论与滚动轴承设计分析[M]. 武汉: 华中科技大学出版社, 2018. [12] 王学理. 用叠加法求阶梯轴的变形[J]. 力学学报, 1976, 8(4): 244-246.WANG Xueli. Solving the deformation of stepped shaft by superposition method[J]. Chinese Journal of Theoretical and Applied Mechanics, 1976, 8(4): 244-246. [13] 徐香新, 吴勇刚. 叠加法在变截面梁的变形上的应用[J]. 科技传播, 2011, 3(5): 168, 171.XU Xiangxin, WU Yonggang. Application of superposition method in deformation of variable cross-section beam[J]. Public Communication of Science & Technology, 2011, 3(5): 168, 171. [14] 吴佳奇. 多体组合航天器协同姿态控制研究[D]. 南京: 南京航空航天大学, 2020. [15] 李炜明, 蔡利. 同一超静定结构计算多种解题方法的教学思考[J]. 武汉轻工大学学报, 2018, 37(5): 113-118. doi: 10.3969/j.issn.2095-7386.2018.05.021LI Weiming, CAI Li. Teaching exploration on a topic with multi-solution method for statically indeterminate structure[J]. Journal of Wuhan Polytechnic University, 2018, 37(5): 113-118. doi: 10.3969/j.issn.2095-7386.2018.05.021 [16] 李永和. 非线性超静定结构的拉格朗日乘子法及其应用[J]. 西安建筑科技大学学报, 1995, 27(4): 461-465. doi: 10.15986/j.1006-7930.1995.04.023LI Yonghe. Lagrange method and its application to inelastic structure[J]. Journal of Xi’an University of Architecture & Technology (Natural Science Edition), 1995, 27(4): 461-465. doi: 10.15986/j.1006-7930.1995.04.023 [17] 苏昂, 封坤, 何川, 等. 高水压大直径盾构隧道管片结构力学特性研究[J/OL]. 西南交通大学学报, 1-14[2025-11-25]. https://link.cnki.net/urlid/51.1277.U.20241204.1745.007. [18] 莫忧, 杨保杉, 包忠辉, 等. 钢筋骨架系统约束藏羌民居片石墙抗震性能[J]. 西南交通大学学报, 2025, 60(03): 569-579 , 598. doi: 10.3969/j.issn.0258-2724.20230235MO You, YANG Baobing, XU Zili, et al. Restraints on seismic performance of slab stone walls of Tibetan and Qiang residential buildings by reinforcement skeleton system[J]. Journal of Southwest Jiaotong University, 2025, 60(03): 569-579 , 598. doi: 10.3969/j.issn.0258-2724.20230235 [19] 吴锦涛, 王珺, 徐自力, 等. 高转速部分进气涡轮盘气流力及叶片振动响应研究[J]. 西安交通大学学报, 2022, 56(7): 108-117. doi: 10.7652/xjtuxb202207012WU Jintao, WANG Jun, XU Zili, et al. Airflow force and vibration response for high speed partial-admission turbine disk[J]. Journal of Xi’an Jiaotong University, 2022, 56(7): 108-117. doi: 10.7652/xjtuxb202207012 [20] SADIQUE M R, ZAID M, ALAM M M. Rock tunnel performance under blast loading through finite element analysis[J]. Geotechnical and Geological Engineering, 2022, 40(1): 35-56. doi: 10.1007/s10706-021-01879-9 [21] 纪佳馨, 彭程, 项冲, 等. 考虑变速条件的斯特封磨损寿命预测方法[J]. 机械工程学报, 2024, 60(3): 191-202. doi: 10.3901/JME.2024.03.191JI Jiaxin, PENG Cheng, XIANG Chong, et al. A method for predicting the wear life of the step seal considering variable speed conditions[J]. Journal of Mechanical Engineering, 2024, 60(3): 191-202. doi: 10.3901/JME.2024.03.191 [22] 贾超, 程洪业, 李国炬, 等. 新型内啮合S型齿轮设计及啮合特性分析[J]. 华中科技大学学报(自然科学版), 2023, 51(12): 60-65. doi: 10.13245/j.hust.230778JIA Chao, CHENG Hongye, LI Guoju, et al. Design and meshing characteristics analysis of new internal S-gear[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2023, 51(12): 60-65. doi: 10.13245/j.hust.230778 [23] 覃艳明, 赵静一, 王向南, 等. 刚性悬挂四轮车辆静力学解算与均载性分析[J]. 中国机械工程, 2020, 31(4): 384-389.QIN Yanming, ZHAO Jingyi, WANG Xiangnan, et al. Static calculation and load sharing characteristics analysis of four-wheeled vehicles with rigid suspension[J]. China Mechanical Engineering, 2020, 31(4): 384-389. [24] 雷新沛, 冯利博, 张航, 等. 磁气负载比对箔片-磁力混合轴承支承特性及转子动力学特性的影响[J]. 中国机械工程, 2023, 34(11): 1287-1295, 1305.LEI Xinpei, FENG Libo, ZHANG Hang, et al. Influences of magnetic-gas load ratio on supporting characteristics and rotor dynamics characteristics of foil-magnetic hybrid bearings[J]. China Mechanical Engineering, 2023, 34(11): 1287-1295, 1305. [25] 张明, 卫夕阳, 杨子民, 等. 六轮小车式起落架地面载荷分析研究[J]. 西北工业大学学报, 2022, 40(5): 1090-1099. doi: 10.1051/jnwpu/20224051090ZHANG Ming, WEI Xiyang, YANG Zimin, et al. Six-wheel trolley type landing gear ground load analysis study[J]. Journal of Northwestern Polytechnical University, 2022, 40(5): 1090-1099. doi: 10.1051/jnwpu/20224051090 [26] CHAARI F, FAKHFAKH T, HBAIEB R, et al. Influence of manufacturing errors on the dynamic behavior of planetary gears[J]. The International Journal of Advanced Manufacturing Technology, 2006, 27(7): 738-746. [27] 陈茜. 制造装配误差对双圆弧谐波传动啮合特性与柔轮应力分布影响规律分析[D]. 重庆: 重庆大学, 2020. [28] 胡涛, 万志辉, 戴国亮, 等. 饱和土中后注浆灌注桩的注浆压力回归分析及优化[J]. 东南大学学报(自然科学版), 2022, 52(5): 875-882.HU Tao, WAN Zhihui, DAI Guoliang, et al. Regression analysis and optimization for grouting pressure of post-grouting pile in saturated soil[J]. Journal of Southeast University (Natural Science Edition), 2022, 52(5): 875-882. -

下载:

下载: