Empirical Fourier Decomposition Algorithm Based on Spectrum Reconstruction and Its Application in Bearing Fault Diagnosis

-

摘要:

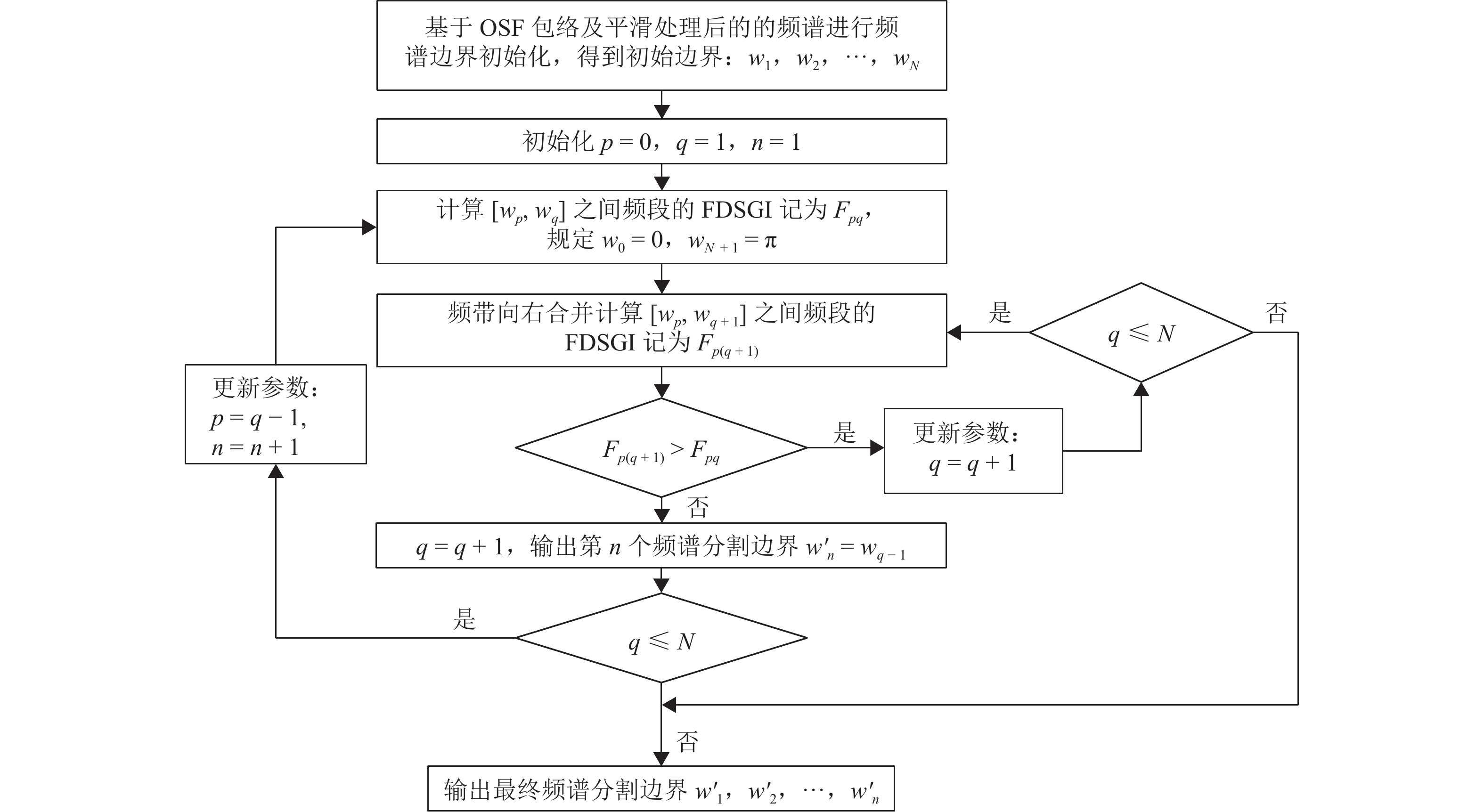

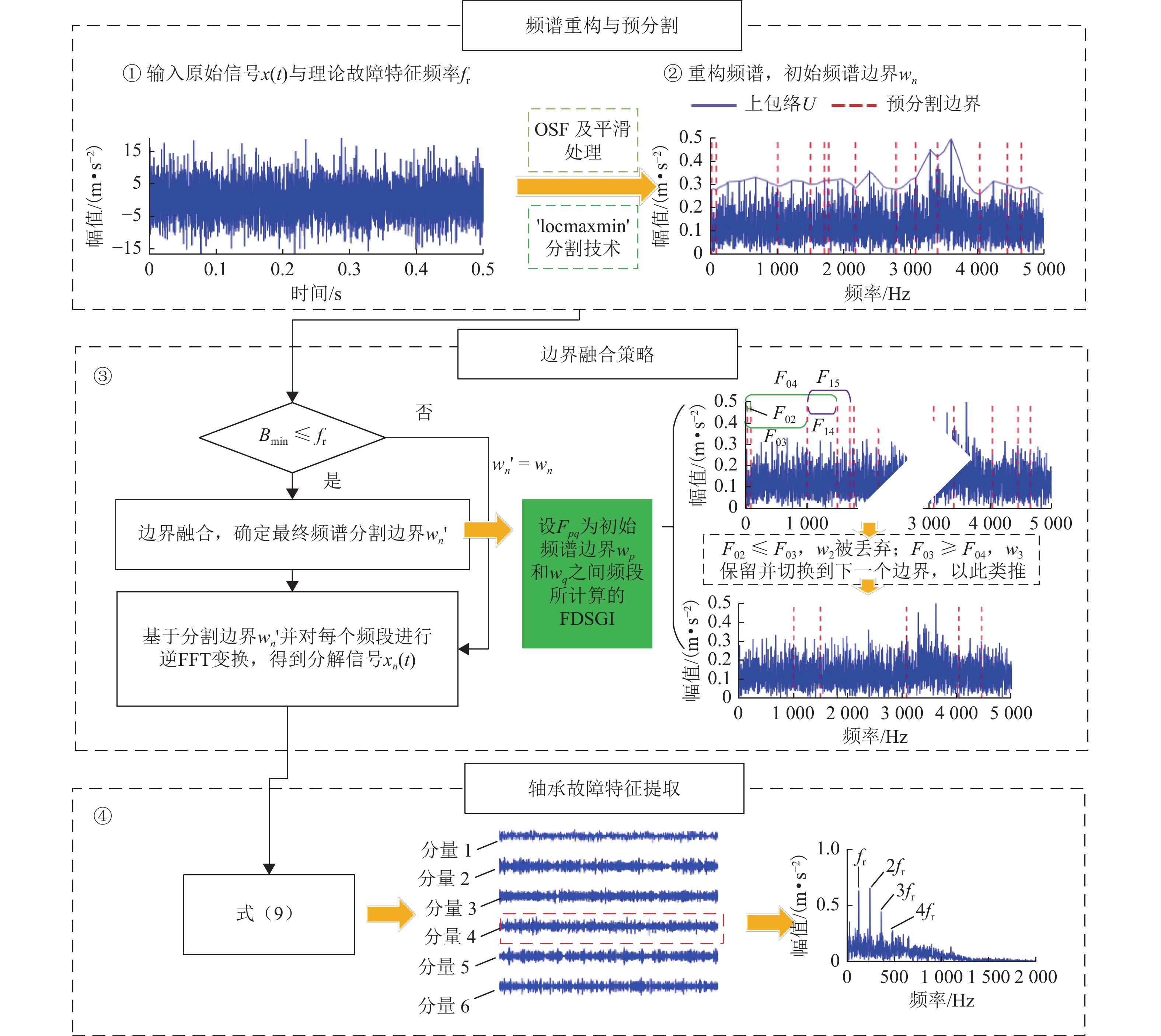

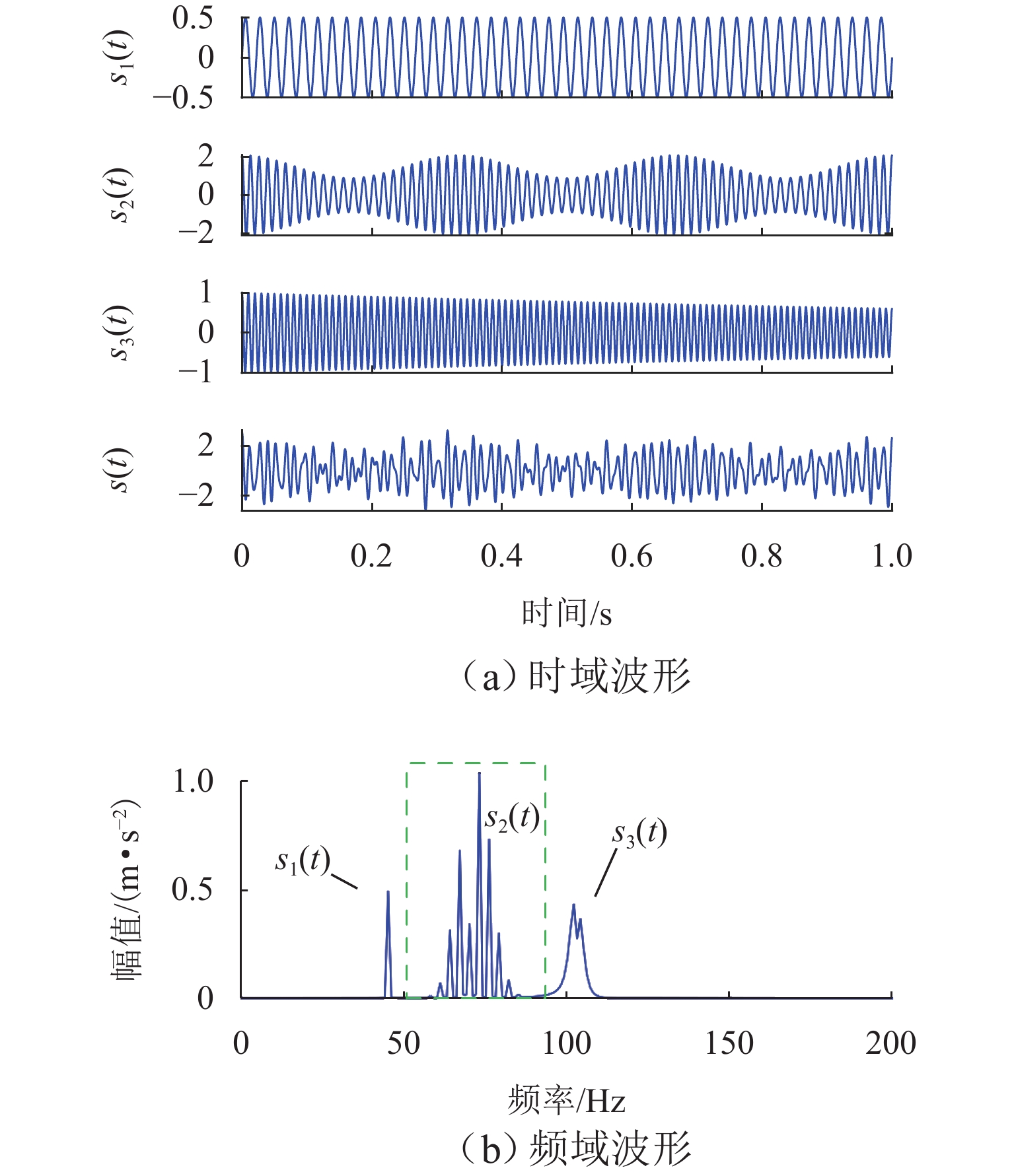

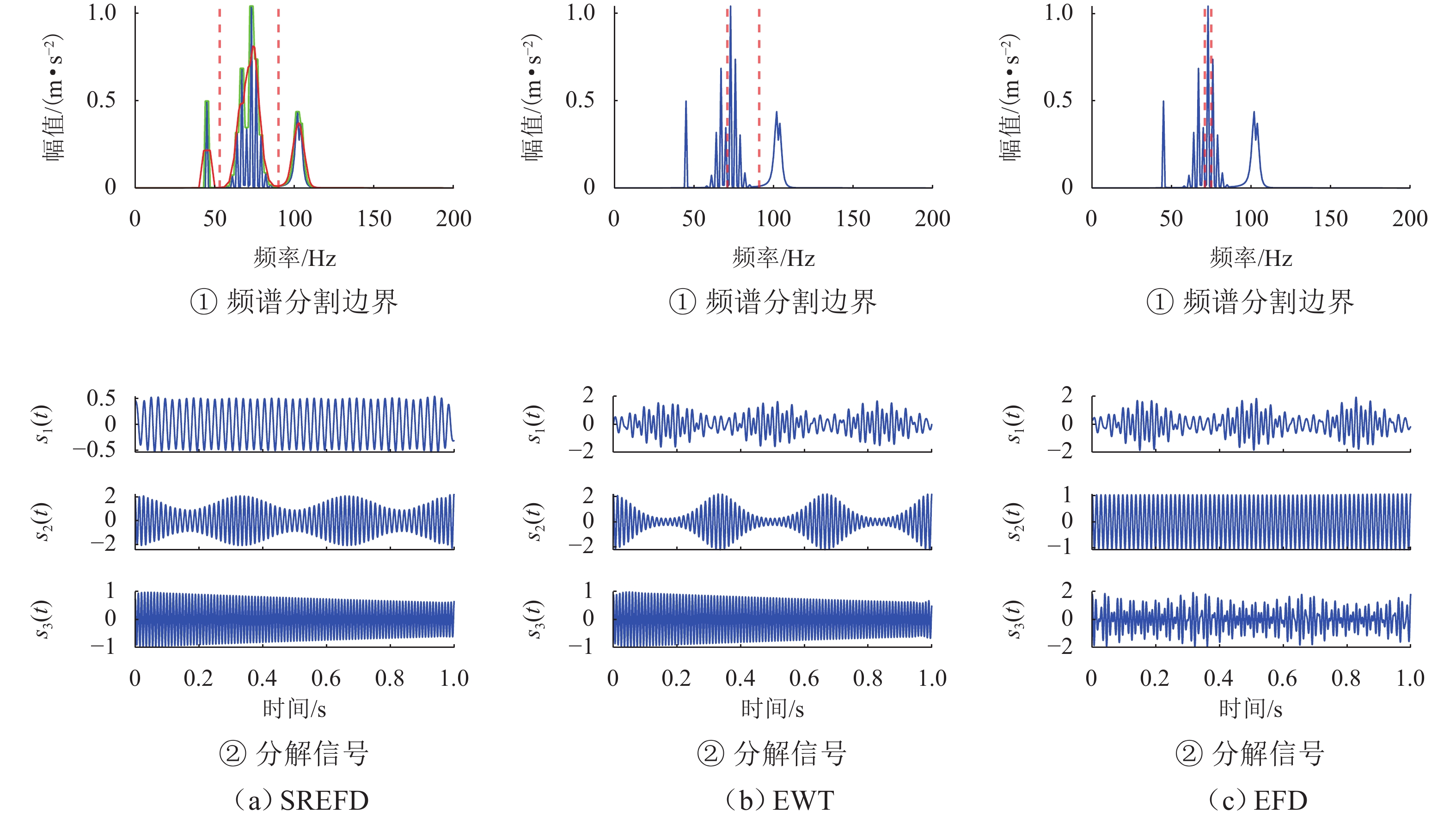

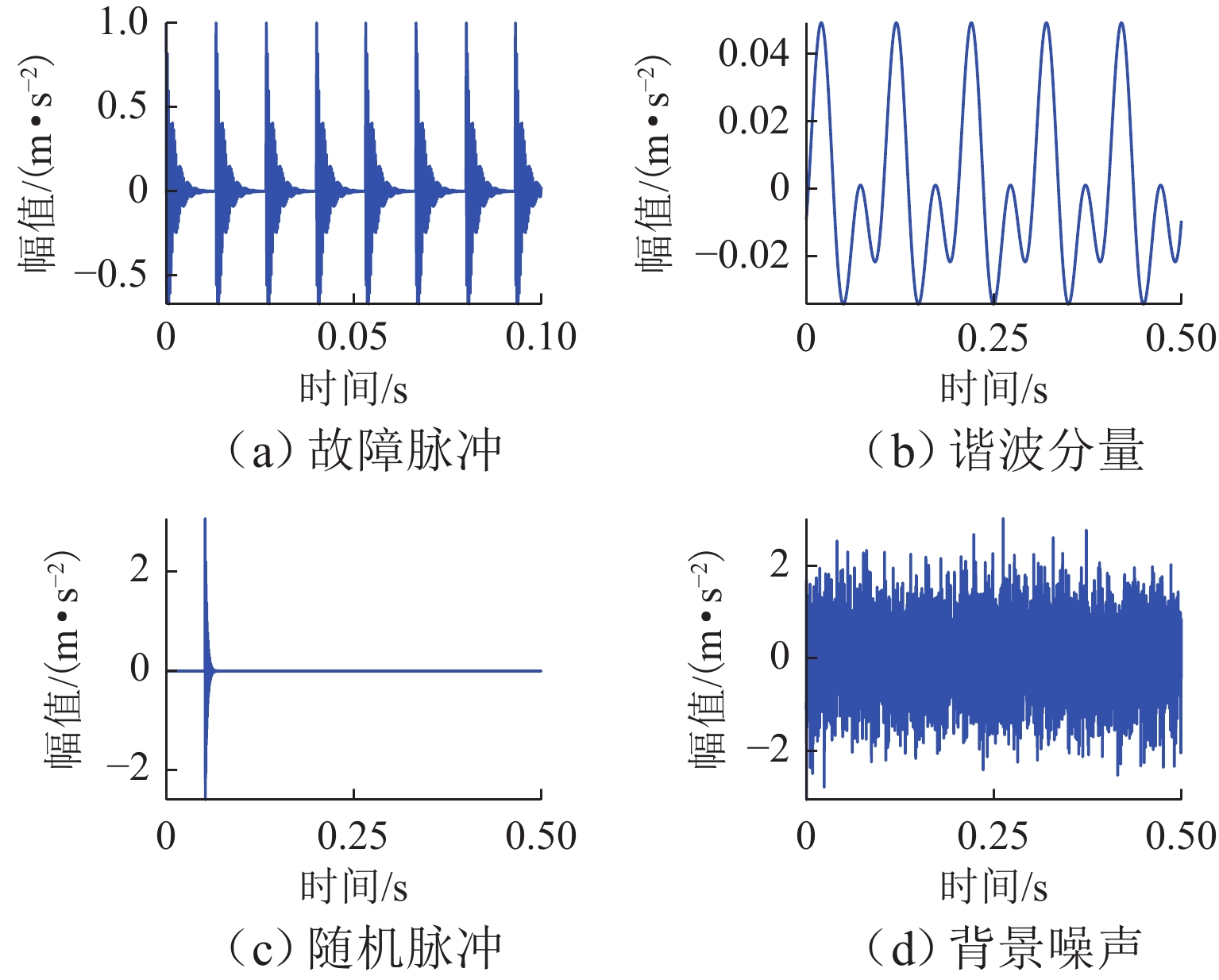

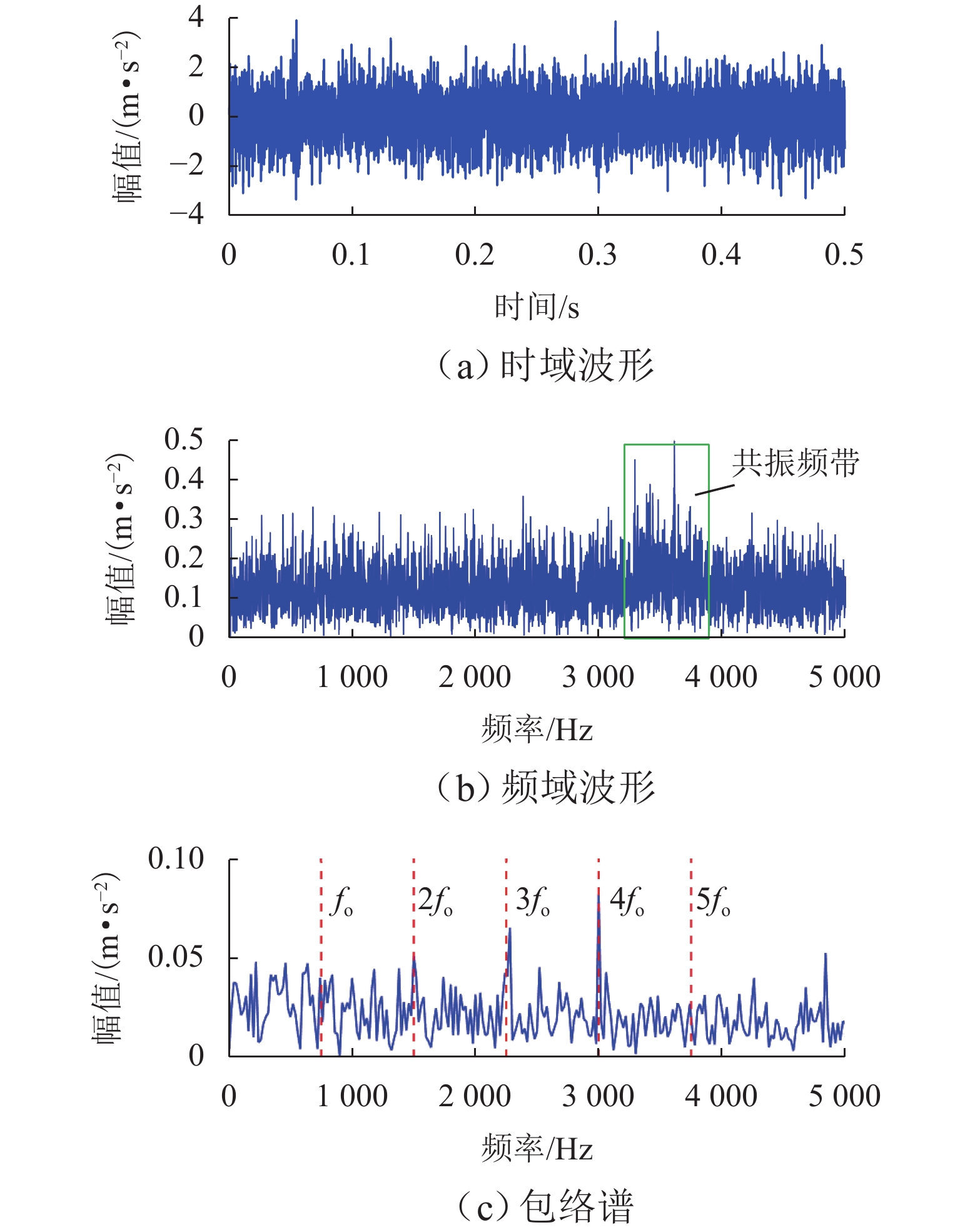

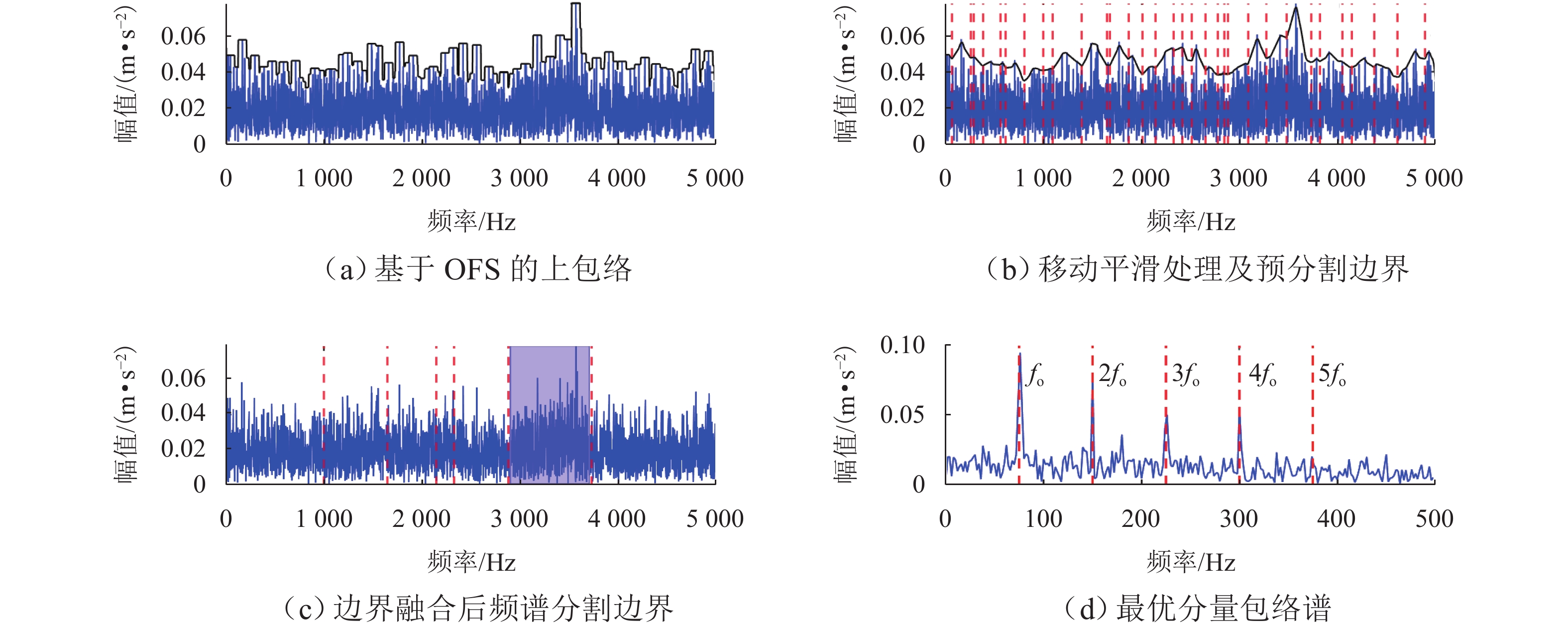

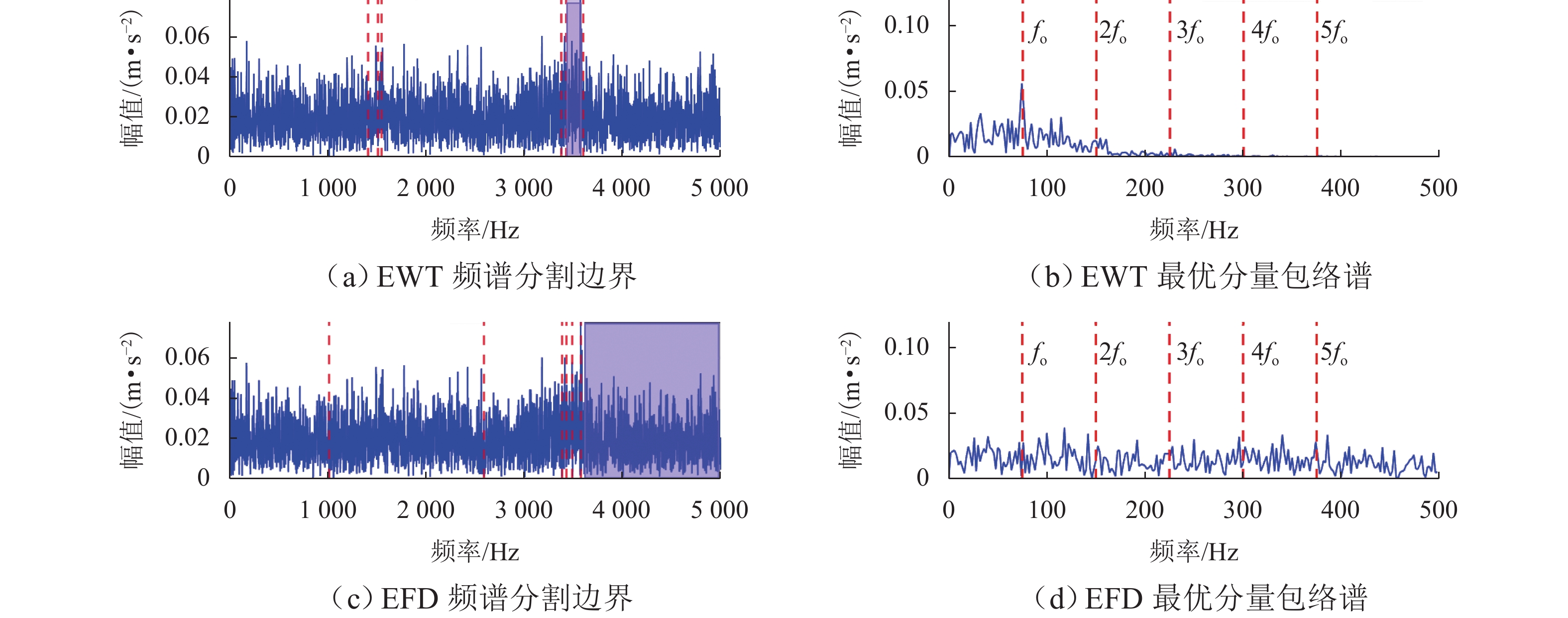

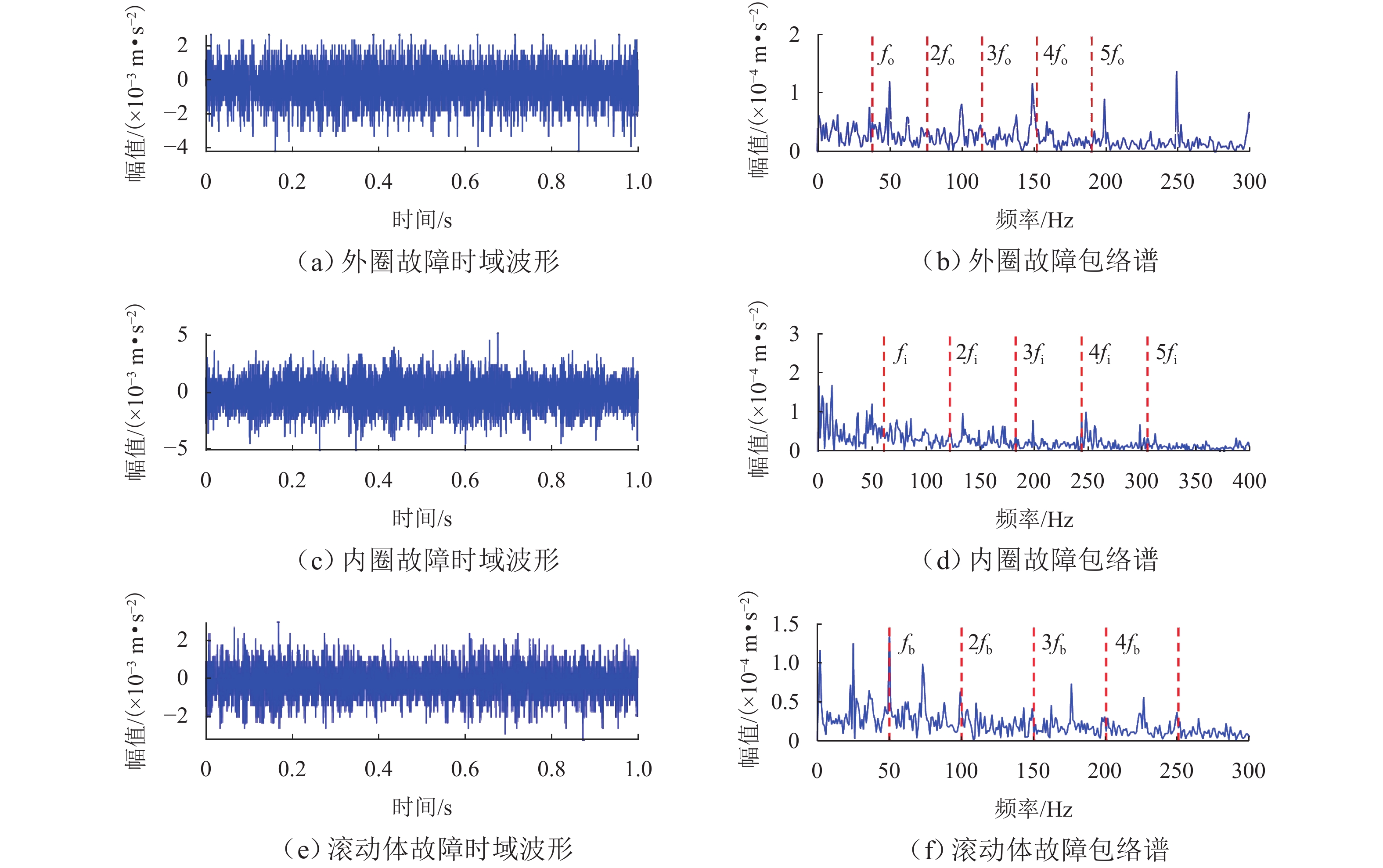

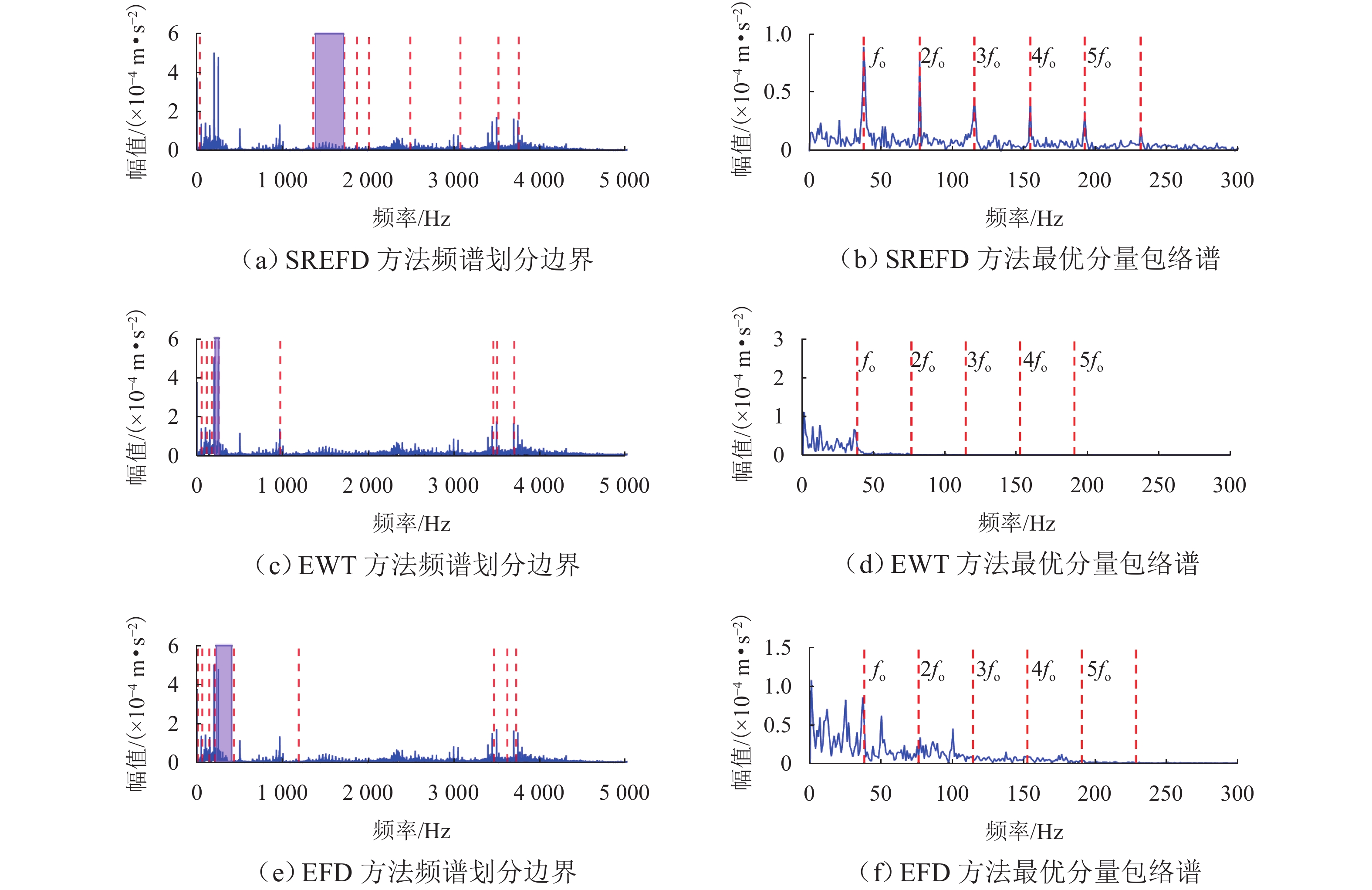

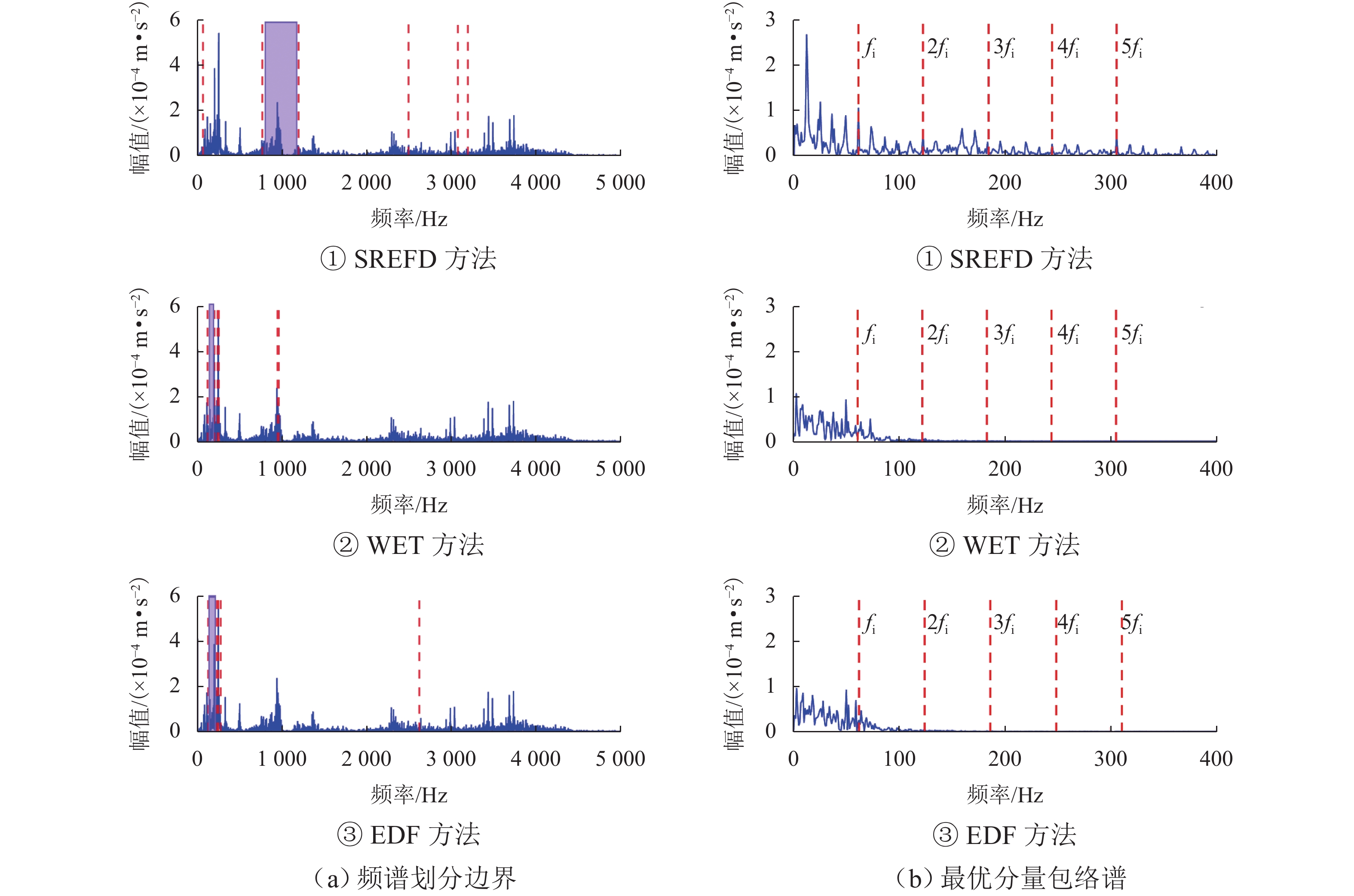

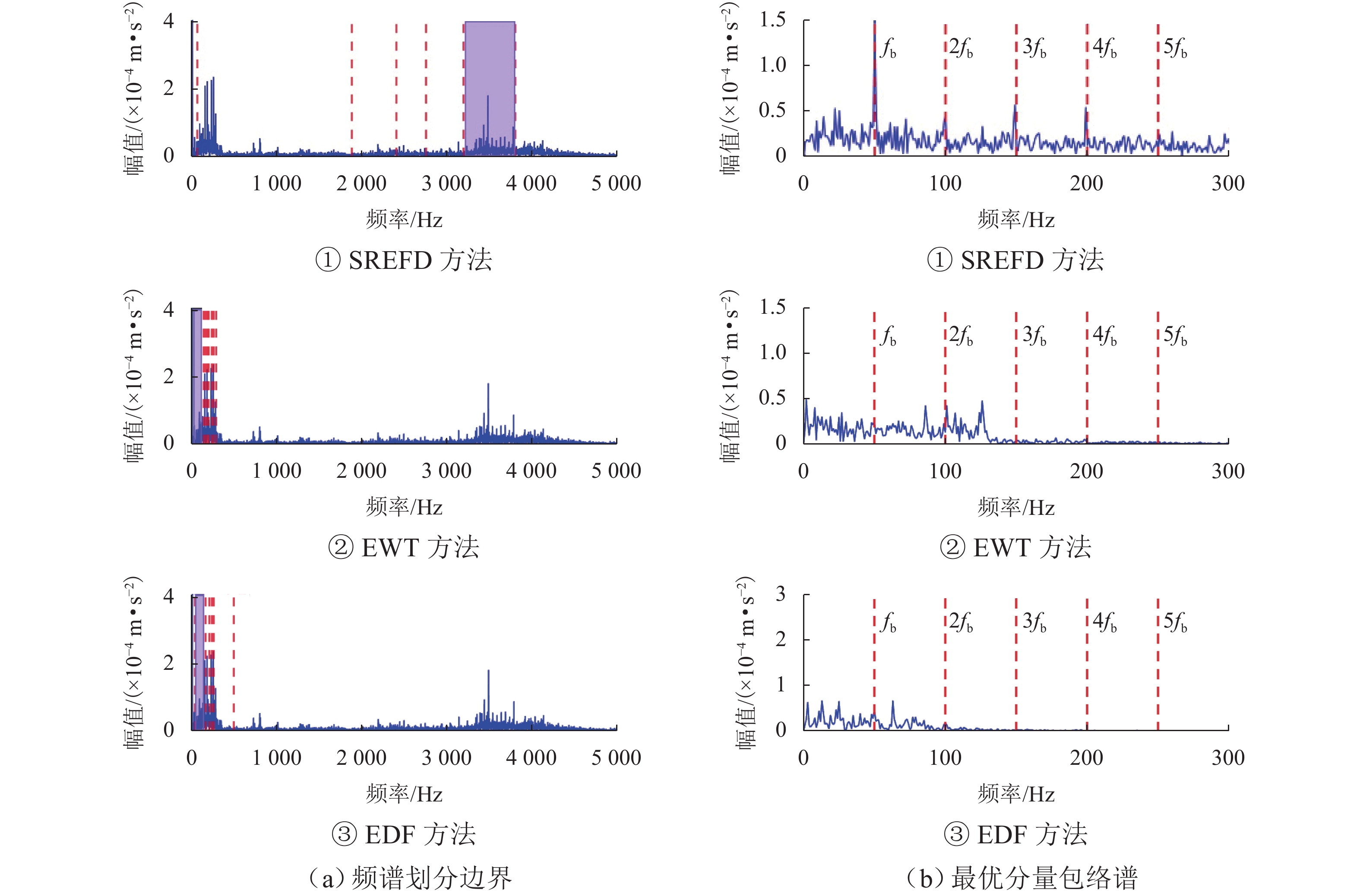

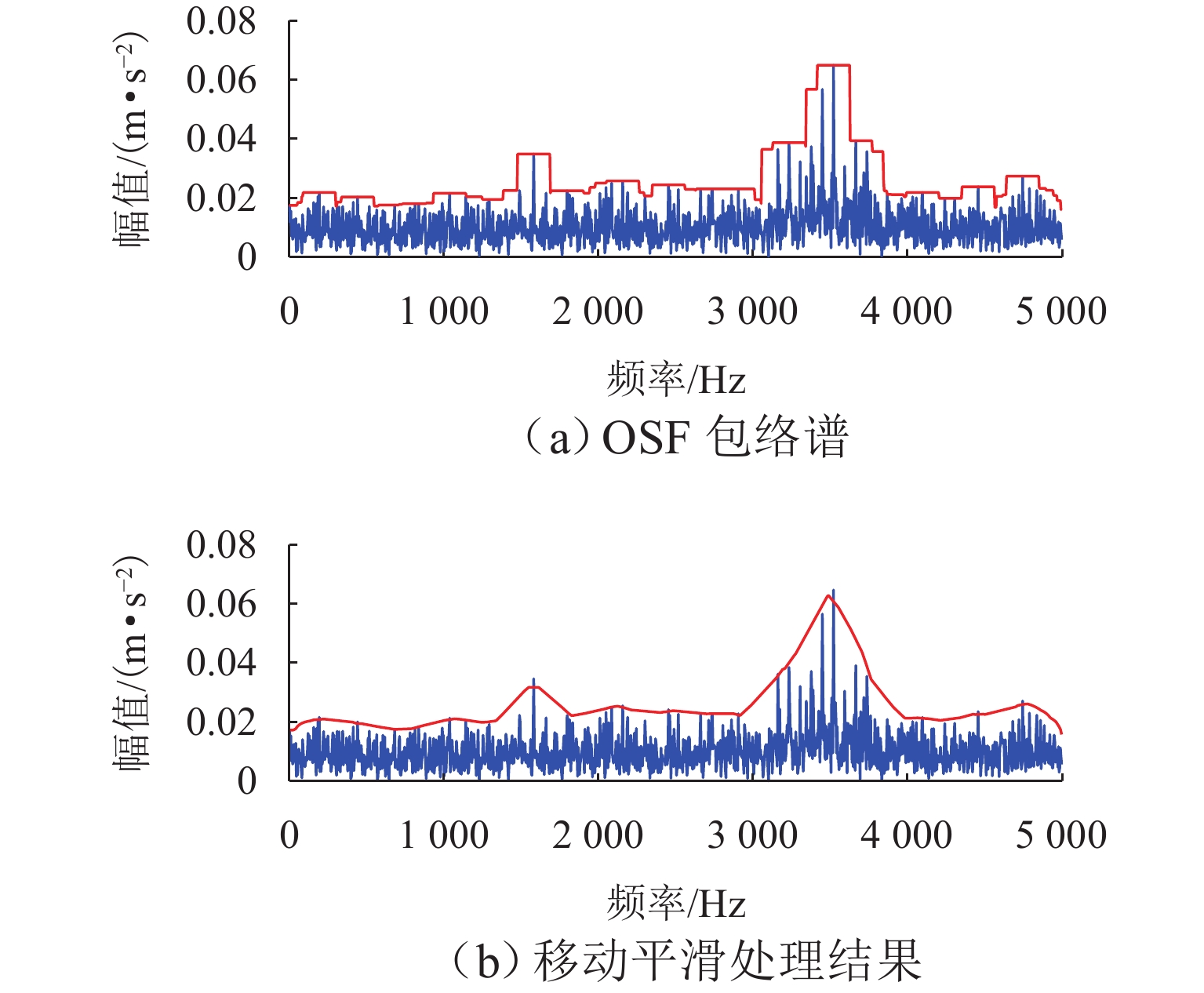

为解决经验傅里叶分解(EFD)方法处理轴承故障信号时易于发生频谱分割边界集中在局部窄带的问题,通过统计排序滤波器(OSF)简化采集的轴承振动信号的频谱,进行平均滑移处理和预分割;针对可能存在的过度分解问题,提出根据频域平方基尼指数(FDSGI)的边界融合算法,实现自适应地确定分割边界和分解模式数;并利用包络谱谐波显著度(ESHS)指标选择最佳分量,进而通过对最佳分量进行包络谱分析,达到轴承故障诊断目标. 轴承故障仿真信号和试验信号的对比试验证明了SREFD在频谱分割精确度方面优于EFD和经验小波变换(EWT),处理后的信号中能够更清晰地观察到轴承故障特征频率及其倍频,证明了所提方法的有效性和鲁棒性.

-

关键词:

- 频谱重构 /

- 经验傅里叶分解 /

- 频谱重构经验傅里叶分解 /

- 边界融合 /

- 轴承故障诊断

Abstract:To address the tendency of spectral segmentation boundaries concentrating on local narrow bands when the empirical Fourier decomposition (EFD) method was applied to bearing fault signals, an order statistics filter (OSF) was used to simplify the frequency spectrum of the acquired bearing vibration signal, and then averaging and sliding processing and pre-segmentation were performed. To address the potential problem of excessive decomposition, a boundary fusion algorithm based on the frequency-domain squared Gini index (FDSGI) was proposed to adaptively determine segmentation boundaries and decomposition modes. The envelope spectrum harmonic significance (ESHS) indicator was used to select the optimal components. Further, bearing fault diagnosis was enabled through envelope spectrum analysis of the optimal components. The comparative test of bearing fault simulation signals and experimental signals demonstrates that empirical Fourier decomposition based on spectrum reconstruction (SREFD) outperforms EFD and empirical wavelet transform (EWT) in terms of spectral segmentation accuracy. The processed signals allow for clearer observation of bearing fault characteristic frequencies and their harmonics, which validates the effectiveness and robustness of the proposed method.

-

表 1 轴承外圈故障信号仿真参数

Table 1. Simulation parameters of bearing outer ring fault signal

参数 取值 参数 取值 参数 取值 ${M_1}$ 50 ${M_2}$ 1 ${M_3}$ 2 ${T_{\mathrm{a}}}$ 1/75 ${T_{{s}}}$ $ \begin{array}{*{20}{c}} {U(1\;000,} \\ {9\;000)} \end{array} $ $ {C_1} $ 0.025 $ A(t) $ 1 ${B_s}$ $ N(3.5,1) $ $ {C_2} $ 0.025 $ {f_{\mathrm{a}}} $ 3500 ${f_{\mathrm{d}}}$ 1500 ${f_1}$ 10 $ {\varphi _{\mathrm{a}}} $ 0 ${\varphi _{\mathrm{d}}}$ 0 $ {f_2} $ 20 $ {\xi _{\mathrm{a}}} $ 600 ${\xi _{\mathrm{d}}}$ 400 $ {\theta _1} $ $ {\text{π}} /6 $ ${\delta _{\mathrm{l}}}$ $ \begin{array}{*{20}{c}} {U( - 0.02{T_{\text{a}} },} \\ {0.02{T_{\text{a}} })} \end{array} $ $ {\theta _2} $ $ - {\text{π}} /3 $ 表 2 SREFD、EWT和EDF的各分解分量所对应的ESHS值

Table 2. ESHS values corresponding to each decomposition component of SREFD, EWT, and EDF

分量 SREFD EWT EDF 1 0.0072 0.0049 0.0077 2 0.0117 0.0018 0.0049 3 0.0087 0.0007 0.0083 4 0.0148 0.0034 0.0012 5 0.0122 0.0009 0.0024 6 0.0156 0.0098 0.0019 7 0.0030 0.0063 0.0110 -

[1] LIU R N, YANG B Y, ZIO E, et al. Artificial intelligence for fault diagnosis of rotating machinery: a review[J]. Mechanical Systems and Signal Processing, 2018, 108: 33-47. doi: 10.1016/j.ymssp.2018.02.016 [2] ZHAO Y J, QIN B F, ZHOU Y H, et al. Bearing fault diagnosis based on inverted mel-scale frequency cepstral coefficients and deformable convolution networks[J]. Measurement Science and Technology, 2023, 34(5): 055404. doi: 10.1088/1361-6501/acb0ea [3] ZHANG R X, GU Y. A transfer learning framework with a one-dimensional deep subdomain adaptation network for bearing fault diagnosis under different working conditions[J]. Sensors, 2022, 22(4): 1624. doi: 10.3390/s22041624 [4] 杨岗, 徐五一, 邓琴, 等. 基于复合基尼指数和最大相关峭度特征模态分解的轴承故障诊断算法[J]. 机车电传动, 2023(4): 9-17.YANG Gang, XU Wuyi, DENG Qin, et al. Bearing fault diagnosis algorithm based on maximum correlated kurtosis feature mode decomposition and compound Gini index[J]. Electric Drive for Locomotives, 2023(4): 9-17. [5] HU Y, LI F C, LI H G, et al. An enhanced empirical wavelet transform for noisy and non-stationary signal processing[J]. Digital Signal Processing, 2017, 60: 220-229. doi: 10.1016/j.dsp.2016.09.012 [6] 程尧, 陈丙炎, 张卫华, 等. 基于加权联合提升包络谱的轴箱轴承故障诊断[J]. 西南交通大学学报, 2024, 59(1): 142-150.CHENG Yao, CHEN Bingyan, ZHANG Weihua, et al. Fault diagnosis of axle-box bearing based on weighted combined improved envelope spectrum[J]. Journal of Southwest Jiaotong University, 2024, 59(1): 142-150. [7] 易彩, 林建辉, 汪浩, 等. VMD引导的轮对与轴承复合故障诊断方法[J]. 西南交通大学学报, 2024, 59(1): 151-159.YI Cai, LIN Jianhui, WANG Hao, et al. Compound fault diagnosis method guided by variational mode decomposition for wheelsets and bearings[J]. Journal of Southwest Jiaotong University, 2024, 59(1): 151-159. [8] 陈丙炎, 谷丰收, 张卫华, 等. 基于多带加权包络谱的轴箱轴承故障诊断[J]. 西南交通大学学报, 2024, 59(1): 201-210.CHEN Bingyan, GU Fengshou, ZHANG Weihua, et al. Axle-box bearing fault diagnosis based on multiband weighted envelope spectrum[J]. Journal of Southwest Jiaotong University, 2024, 59(1): 201-210. [9] QIN L M, YANG G, LV K, et al. An adaptive generalized logarithm sparse regularization method and its application in rolling bearing fault diagnosis[J]. Measurement Science and Technology, 2023, 34(3): 035118. doi: 10.1088/1361-6501/acaa4c [10] WANG B X, LIAO Y H, DING C C, et al. Periodical sparse low-rank matrix estimation algorithm for fault detection of rolling bearings[J]. ISA Transactions, 2020, 101: 366-378. doi: 10.1016/j.isatra.2020.01.037 [11] QIN L M, YANG G, SUN Q. Maximum correlation Pearson correlation coefficient deconvolution and its application in fault diagnosis of rolling bearings[J]. Measurement, 2022, 205: 112162. doi: 10.1016/j.measurement.2022.112162 [12] CHEN B Y, ZHANG W H, SONG D L, et al. Blind deconvolution assisted with periodicity detection techniques and its application to bearing fault feature enhancement[J]. Measurement, 2020, 159: 107804. doi: 10.1016/j.measurement.2020.107804 [13] CHEN Z Y, LI Z R, WU J, et al. Deep residual shrinkage relation network for anomaly detection of rotating machines[J]. Journal of Manufacturing Systems, 2022, 65: 579-590. doi: 10.1016/j.jmsy.2022.10.014 [14] CHEN Z Y, WU J, DENG C, et al. Deep attention relation network: a zero-shot learning method for bearing fault diagnosis under unknown domains[J]. IEEE Transactions on Reliability, 2023, 72(1): 79-89. doi: 10.1109/TR.2022.3177930 [15] CHEN Z Y, WANG X Q, WU J, et al. Relational conduction graph network for intelligent fault diagnosis of rotating machines under small fault samples[J]. IEEE Transactions on Instrumentation and Measurement, 2023, 72: 3514511. [16] JIN Z Z, XIAO Y L, HE D Q, et al. Fault diagnosis of bearing based on refined piecewise composite multivariate multiscale fuzzy entropy[J]. Digital Signal Processing, 2023, 133: 103884. doi: 10.1016/j.dsp.2022.103884 [17] ANTONI J. Fast computation of the kurtogram for the detection of transient faults[J]. Mechanical Systems and Signal Processing, 2007, 21(1): 108-124. doi: 10.1016/j.ymssp.2005.12.002 [18] GILLES J. Empirical wavelet transform[J]. IEEE Transactions on Signal Processing, 2013, 61(16): 3999-4010. doi: 10.1109/TSP.2013.2265222 [19] 冯博, 李辉, 郑海起. 基于经验小波变换的轴承故障诊断研究[J]. 轴承, 2015(12): 53-58.FENG Bo, LI Hui, ZHENG Haiqi. Study on fault diagnosis for bearings based on empirical wavelet transform[J]. Bearing, 2015(12): 53-58. [20] 盛嘉玖, 陈果, 康玉祥, 等. 一种用于滚动轴承故障诊断的改进EWT方法[J]. 航空动力学报, 2024, 39(9): 371-383.SHENG Jiajiu, CHEN Guo, KANG Yuxiang, et al. An improved EWT method for fault diagnosis of rolling bearings[J]. Journal of Aerospace Power, 2024, 39(9): 371-383. [21] GILLES J, TRAN G, OSHER S. 2D empirical transforms. wavelets, ridgelets, and curvelets revisited[J]. SIAM Journal on Imaging Sciences, 2014, 7(1): 157-186. doi: 10.1137/130923774 [22] SINGH P, JOSHI S D, PATNEY R K, et al. The Fourier decomposition method for nonlinear and non-stationary time series analysis[J]. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences, 2017, 473(2199): 20160871. [23] 黄斯琪, 郑近德, 潘海洋, 等. 最大相关峭度反褶积与傅里叶分解方法相结合的滚动轴承故障诊断[J]. 机械科学与技术, 2020, 39(8): 1163-1170.HUANG Siqi, ZHENG Kinde, PAN Ocean et al. Rolling bearing fault diagnosis of maximum correlation kurtosis deconvolution combining with fourier decomposition method[J]. Mechanical Science and Technology for Aerospace Engineering, 2020, 39(8): 1163-1170. [24] 张辉, 张超, 辛阔, 等. 基于FDM和TEO的滚动轴承故障诊断研究[J]. 机电工程, 2021, 38(7): 850-856.ZHANG Hui, ZHANG Chao, XIN Kuo, et al. Fault diagnosis of rolling bearing based on FDM and TEO[J]. Journal of Mechanical & Electrical Engineering, 2021, 38(7): 850-856. [25] ZHOU W, FENG Z R, XU Y F, et al. Empirical Fourier decomposition: an accurate signal decomposition method for nonlinear and non-stationary time series analysis[J]. Mechanical Systems and Signal Processing, 2022, 163: 108155. doi: 10.1016/j.ymssp.2021.108155 [26] MO Z L, WANG J Y, ZHANG H, et al. Weighted cyclic harmonic-to-noise ratio for rolling element bearing fault diagnosis[J]. IEEE Transactions on Instrumentation and Measurement, 2019, 69(2): 432-442. -

下载:

下载: