Whisker-Reinforced Repairing Mortar for High-Speed Railway Concrete

-

摘要:

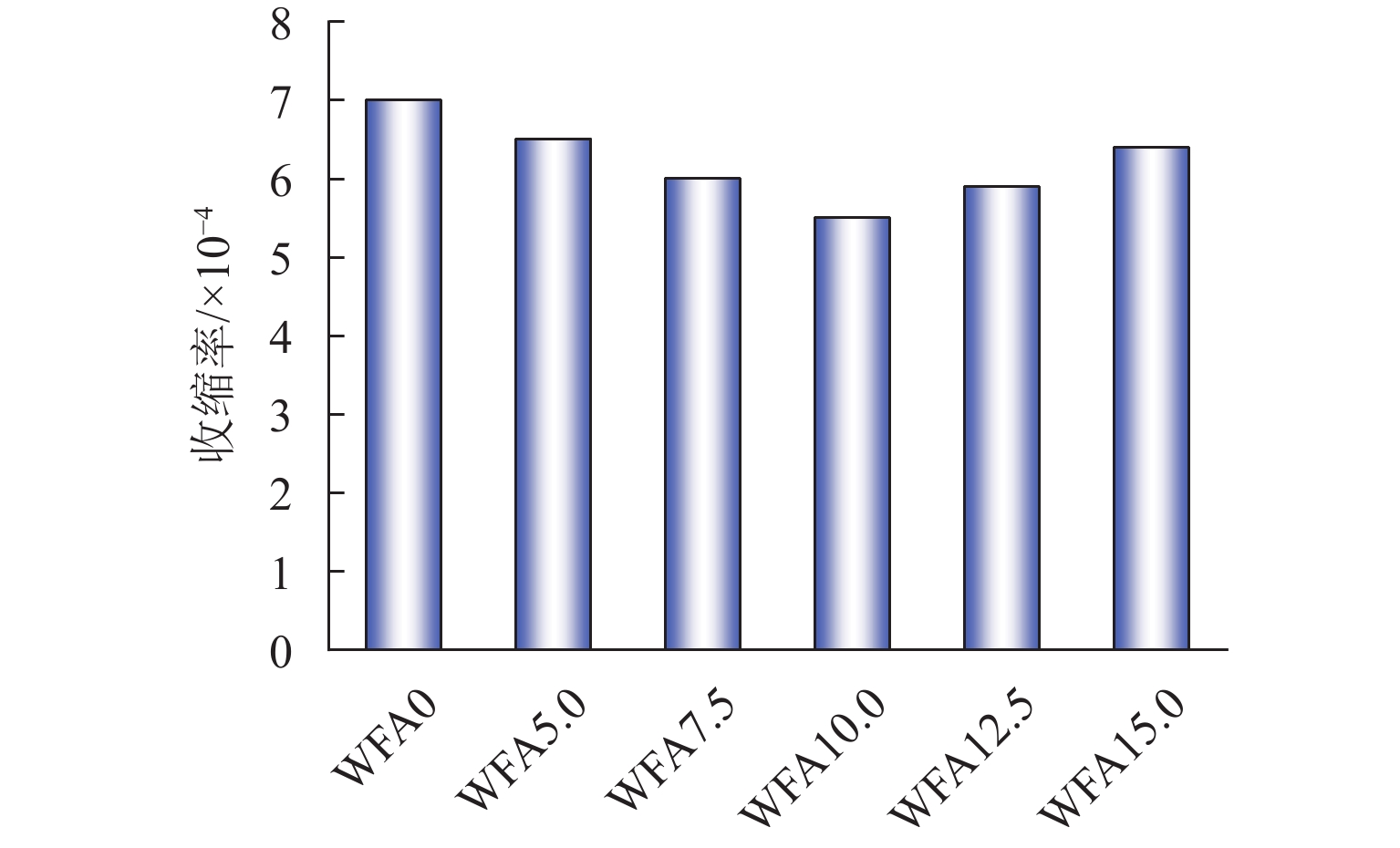

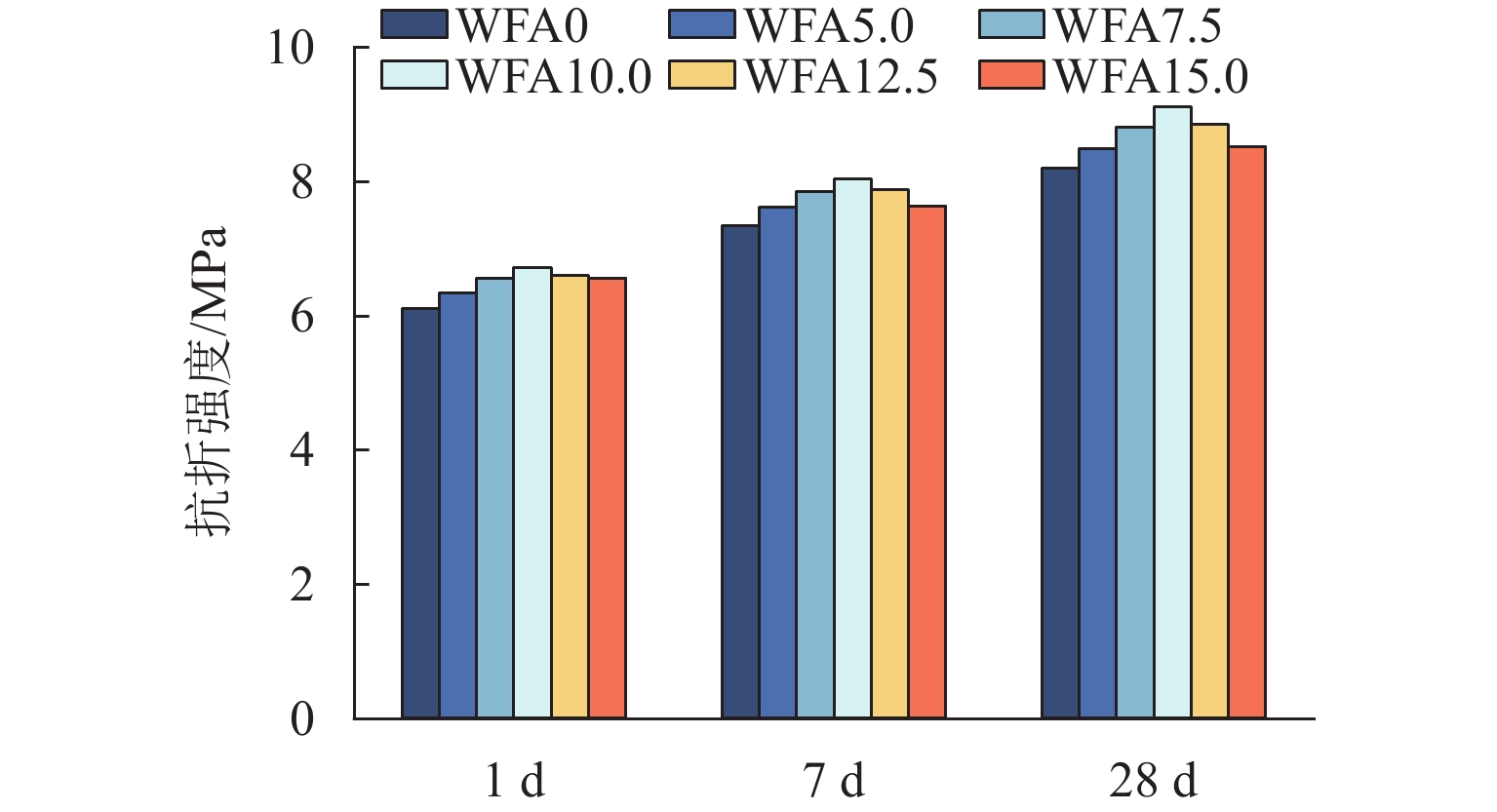

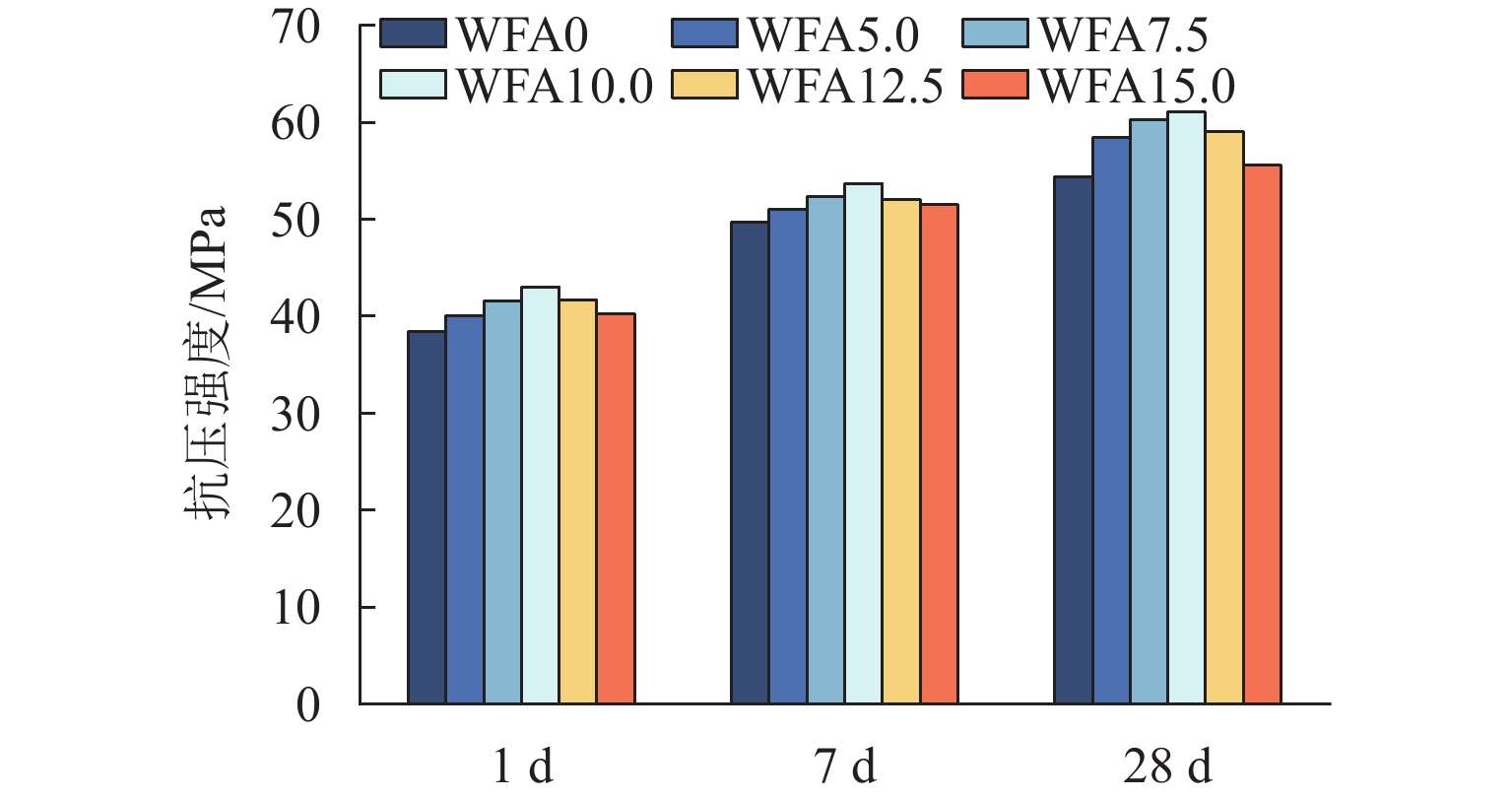

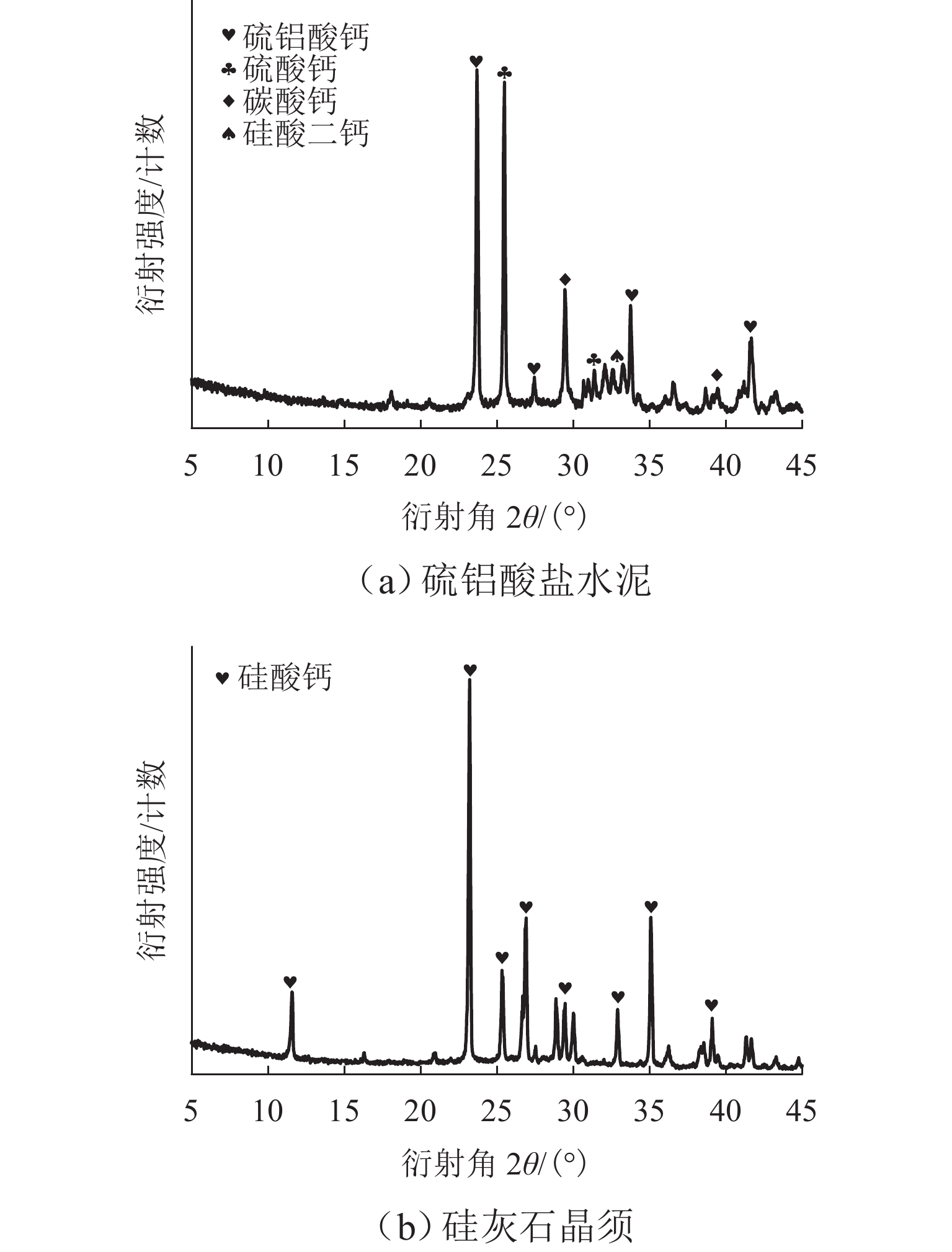

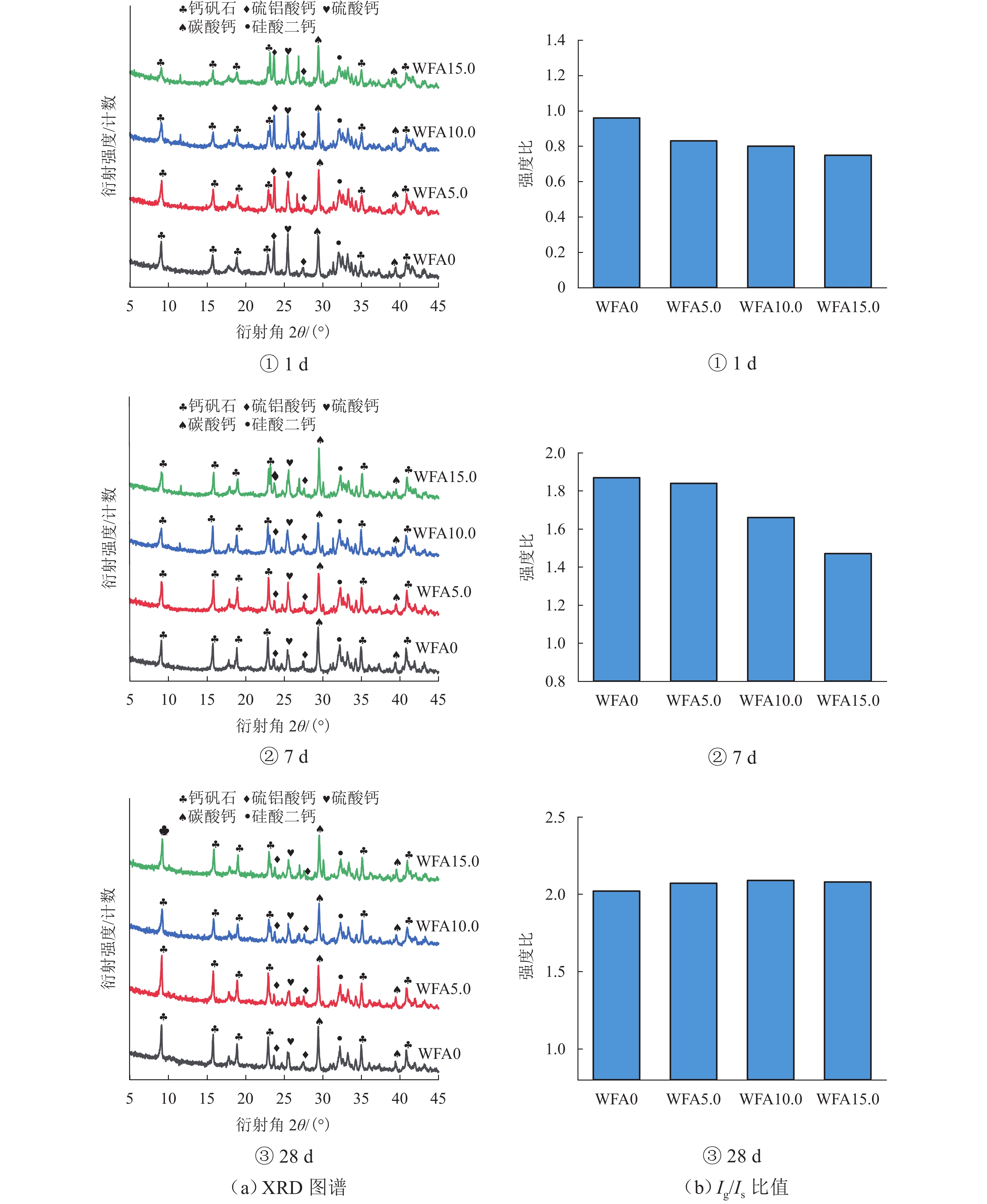

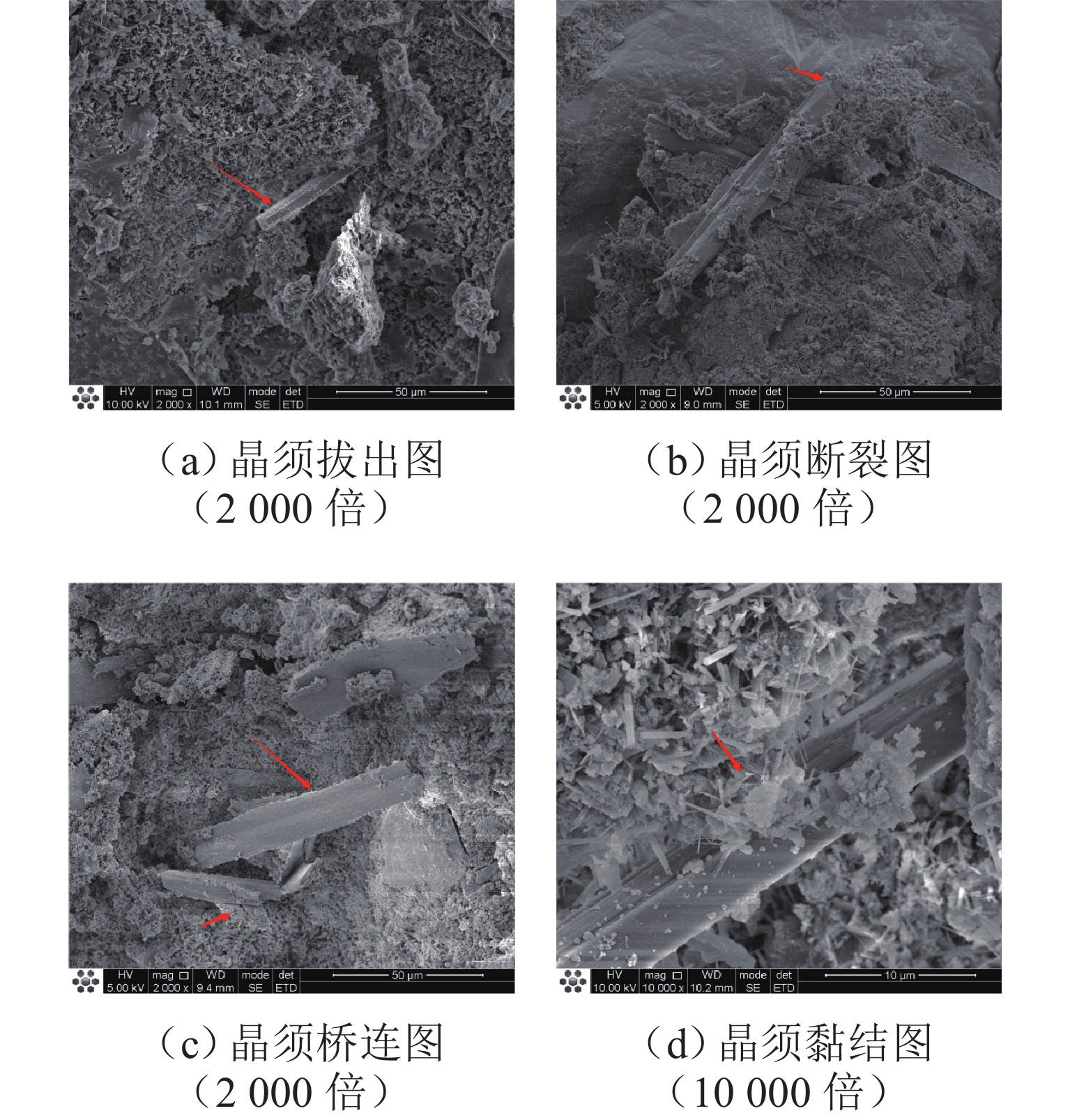

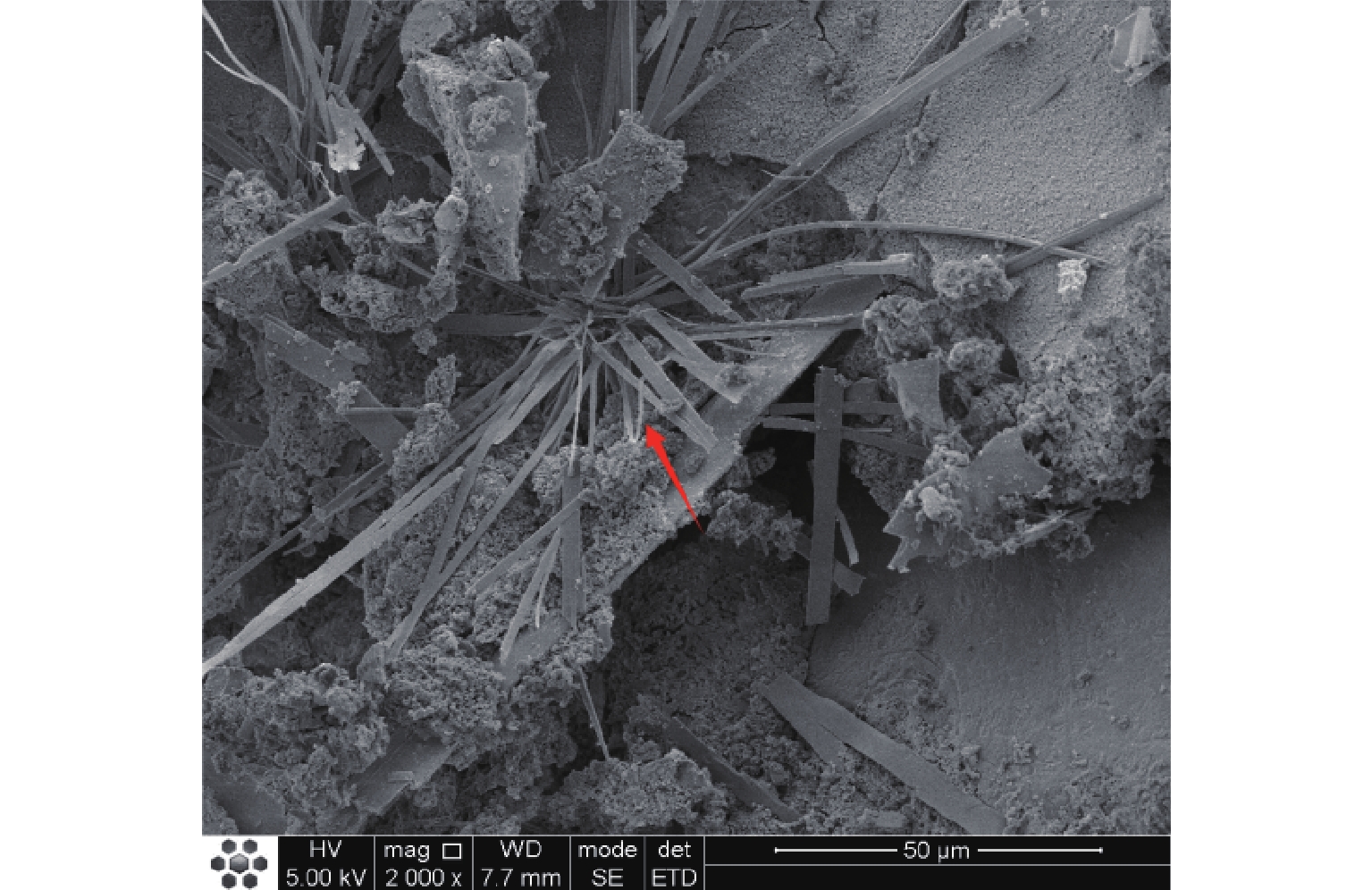

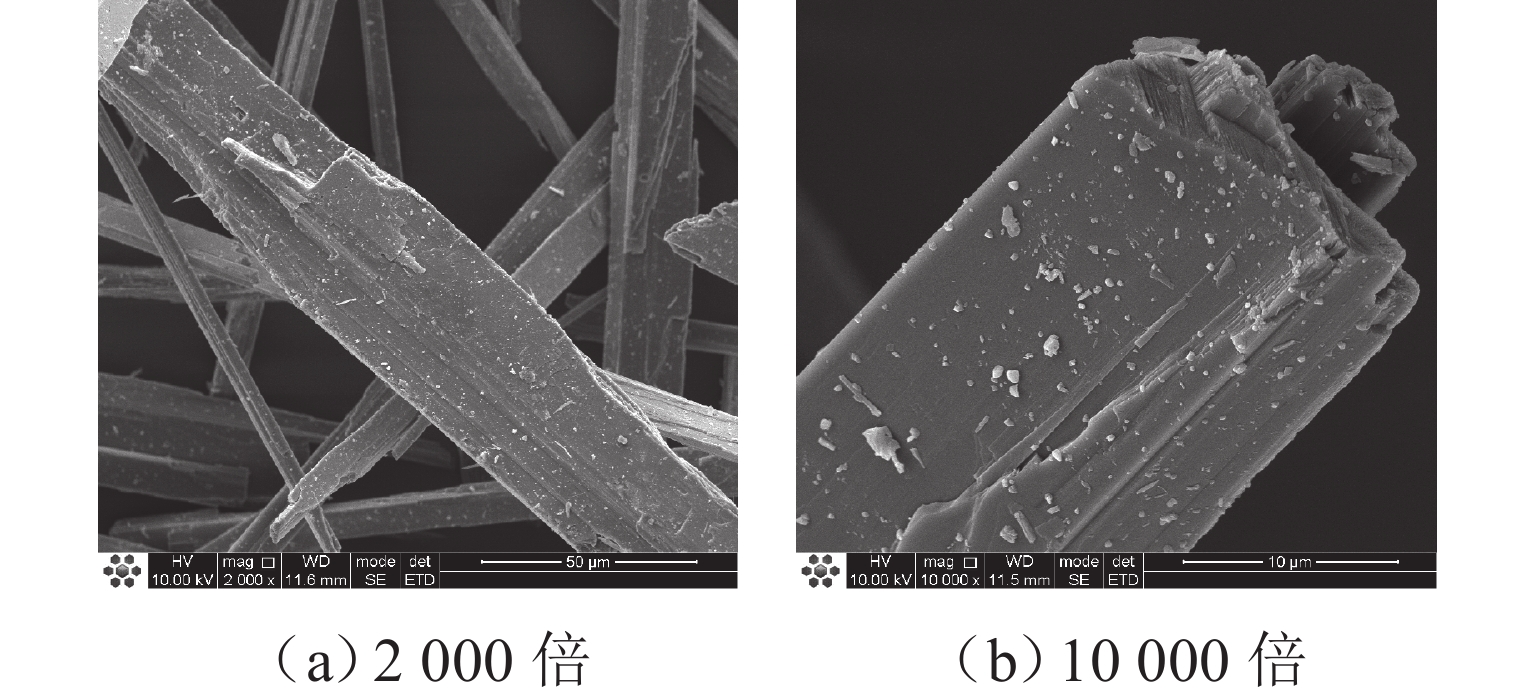

为满足高铁混凝土修补砂浆性能需求,制备不同掺量硅灰石晶须硫铝酸盐水泥砂浆,测试其抗折强度、抗压强度和收缩率,并采用X-射线衍射仪(XRD)、扫描电子显微镜(SEM)进行表征观察. 研究结果表明:砂浆强度随硅灰石晶须掺量增加先增大后减小,在掺量为10.0%时,抗折强度、抗压强度均达到最大值,收缩率最小;掺量不大于10.0%时,砂浆强度提高,收缩率减小,主要归因于晶须拔出、断裂、桥接作用和晶须-水泥共同拔出,而受晶须对水泥水化反应影响较小;掺量过大,晶须发生团聚增大砂浆孔隙,反而导致强度降低;硫铝酸盐水泥砂浆掺入适量晶须,可改善修补砂浆多方面性能,具有用作高铁混凝土修补材料的潜质.

Abstract:To meet the performance requirements of repairing mortar for high-speed railway concrete, sulfoaluminate cement mortars with different contents of wollastonite whisker were prepared. Their flexural strength, compressive strength, and shrinkage were tested, and they were characterized by X-ray diffraction (XRD) and scanning electron microscopy (SEM). The results show that the mortar strength increases initially and then decreases with the increase in the wollastonite whisker content. At a content of 10.0%, mortar exhibits the maximum flexural strength and compressive strength and the minimal shrinkage. When the content is not greater than 10.0%, the improvement in strength and reduction in shrinkage are mainly attributed to the pullout, fracture, and bridging effects of the whiskers, as well as the cooperative pullout of whiskers and cements. The influence of whiskers on the cement hydration reaction is minimal. When the content is too high, the whiskers can aggregate to amplify the pore size of the mortar, resulting in a decrease in strength. In summary, the addition of an appropriate amount of whiskers can improve the multi-faceted performance of repairing mortar, showing potential for application in high-speed railway concrete repair.

-

Key words:

- whisker /

- sulfoaluminate cement /

- repairing mortar /

- high-speed railway /

- flexural strength

-

表 1 硫铝酸盐水泥基本性能

Table 1. Basic properties of sulphoaluminate cement

安定性 凝结时间/min 抗折强度/MPa 抗压强度/MPa 初凝 终凝 1 d 7 d 28 d 1 d 7 d 28 d 良好 24 30 6.03 7.28 8.12 38.89 42.11 57.57 表 2 标准砂粒径分布

Table 2. Particle size distribution of standard sand

筛孔边长/mm 2.00 1.60 1.00 0.50 0.16 0.08 累计筛余/% 0 7±5 33±5 67±5 87±5 99±1 表 3 硅灰石晶须基本性能指标

Table 3. Basic performance indicators of wollastonite whiskers

密度/(g·cm−3) 长度/μm 宽度/μm 水溶/

(g·100 mL−1)膨胀系数 0.34 480.8 24.2 0.0095 6.5 × 10−6 表 4 不同硅灰石晶须掺量的硫铝酸盐水泥砂浆配合比

Table 4. Mixing proportions of sulphoaluminate cement mortars with different amounts of wollastonite whiskers

g 试样编号 水 水泥 标准砂 硅灰石晶须 WFA0 211.5 450 1350.00 0 WFA5.0 211.5 450 1327.50 22.50 WFA7.5 211.5 450 1316.25 33.75 WFA10.0 211.5 450 1305.00 45.00 WFA12.5 211.5 450 1293.75 56.25 WFA15.0 211.5 450 1282.50 67.50 -

[1] 景璞, 李飞. CRTSⅡ型板式无砟轨道病害修补方案研究[J]. 铁道技术监督, 2017, 45(11): 22-29. doi: 10.3969/j.issn.1006-9178.2017.11.008JING Pu, LI Fei. Study on repair scheme of CRTSⅡ slab ballastless track disease[J]. Railway Quality Control, 2017, 45(11): 22-29. doi: 10.3969/j.issn.1006-9178.2017.11.008 [2] 田卫东. 高速铁路CRTS Ⅱ型板式无砟轨道维修技术探索[J]. 铁道勘察, 2013, 39(3): 79-81. doi: 10.3969/j.issn.1672-7479.2013.03.026TIAN Weidong. Technological exploration of CRTS Ⅱ plate-type ballastless track maintenance in high speed railway[J]. Railway Investigation and Surveying, 2013, 39(3): 79-81. doi: 10.3969/j.issn.1672-7479.2013.03.026 [3] 姜子清, 杜香刚, 刘伟斌, 等. 高速铁路无砟轨道挡肩及承轨槽伤损维修技术[J]. 铁道建筑, 2018, 58(9): 94-97. doi: 10.3969/j.issn.1003-1995.2018.09.24JIANG Ziqing, DU Xianggang, LIU Weibin, et al. Maintenance and repair technique for damages in shoulders and track bearing slots of high speed railway ballastless track[J]. Railway Engineering, 2018, 58(9): 94-97. doi: 10.3969/j.issn.1003-1995.2018.09.24 [4] 胡华洁. 用于高铁无砟轨道损伤快速修复磷酸镁水泥研究[D]. 上海: 上海交通大学, 2015. [5] 张忠. 无砟轨道Ⅲ型板挡肩裂缝修复技术研究与应用[J]. 铁道建筑技术, 2014(6): 124-126. doi: 10.3969/j.issn.1009-4539.2014.06.032ZHANG Zhong. Research and application of crack patching technology for retaining shoulder of type HI ballastless track slab[J]. Railway Construction Technology, 2014(6): 124-126. doi: 10.3969/j.issn.1009-4539.2014.06.032 [6] 沈燕, 张伟, 陈玺, 等. 硫铝酸盐水泥改性的研究进展[J]. 硅酸盐通报, 2019, 38(3): 683-687.SHEN Yan, ZHANG Wei, CHEN Xi, et al. Research progress of sulfoaluminate cement modification[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(3): 683-687. [7] 张广兴. 轨道修补用高性能硫铝酸盐基快速修补材料研究[J]. 中国测试, 2021, 47(5): 145-150, 161. doi: 10.11857/j.issn.1674-5124.2020120053ZHANG Guangxing. Research on high performance sulfoaluminate based rapid repair material for track repair[J]. China Measurement & Test, 2021, 47(5): 145-150, 161. doi: 10.11857/j.issn.1674-5124.2020120053 [8] 中国国家铁路集团有限公司. 高速铁路混凝土结构用修补砂浆: Q-CR 659—2018[S]. 北京: 中国铁道出版社, 2018. [9] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 硫铝酸盐水泥: GB 20472—2006 [S]. 北京: 中国标准出版社, 2006. [10] WYDRA M, DOLNY P, SADOWSKI G, et al. Flexural behaviour of cementitious mortars with the addition of basalt fibres[J]. Materials, 2021, 14(6): 133.4-135.1. doi: 10.3390/ma14061334 [11] 颜祥程, 翁兴中, 寇雅楠, 等. 纤维格栅增强水泥混凝土的弯曲力学特性[J]. 西南交通大学学报, 2012, 47(3): 394-399. doi: 10.3969/j.issn.0258-2724.2012.03.007YAN Xiangcheng, WENG Xingzhong, KOU Yanan, et al. Bending mechanical properties of cement concrete with fiber grid reinforcement[J]. Journal of Southwest Jiaotong University, 2012, 47(3): 394-399. doi: 10.3969/j.issn.0258-2724.2012.03.007 [12] LIU Q, LIU R J, WANG Q, et al. Cement mortar with enhanced flexural strength and durability-related properties using in situ polymerized interpenetration network[J]. Frontiers of Structural and Civil Engineering, 2021, 15(1): 99-108. doi: 10.1007/s11709-021-0721-0 [13] 魏小凡, 何牟, 段后红, 等. 矿物掺合料对硫铝酸盐水泥混凝土性能的影响[J]. 四川水泥, 2023(5): 8-10, 7. [14] MARTIN L H J, WINNEFELD F, TSCHOPP E, et al. Influence of fly ash on the hydration of calcium sulfoaluminate cement[J]. Cement and Concrete Research, 2017, 95: 152-163. doi: 10.1016/j.cemconres.2017.02.030 [15] 王海龙, 罗月静, 彭光宇, 等. 掺合料对纤维增强水泥基材料拉伸性能的影响[J]. 西南交通大学学报, 2017, 52(1): 61-68. doi: 10.3969/j.issn.0258-2724.2017.01.009WANG Hailong, LUO Yuejing, PENG Guangyu, et al. Effect of admixtures on tensile behavior of fiber reinforced cementitious composites[J]. Journal of Southwest Jiaotong University, 2017, 52(1): 61-68. doi: 10.3969/j.issn.0258-2724.2017.01.009 [16] 马保国, 梅军鹏, 李海南, 等. 纳米SiO2对硫铝酸盐水泥水化硬化的影响[J]. 功能材料, 2016, 47(2): 2010-2014. doi: 10.3969/j.issn.1001-9731.2016.02.003MA Baoguo, MEI Junpeng, LI Hainan, et al. Effect of nano-SiO2 on hydration and hardening of sulphoaluminate cement[J]. Journal of Functional Materials, 2016, 47(2): 2010-2014. doi: 10.3969/j.issn.1001-9731.2016.02.003 [17] 高为民. 硫铝酸盐水泥基修补砂浆制备与性能研究[D]. 济南: 济南大学, 2018. [18] SHI C, WANG P, MA C Y, et al. Effects of SAE and SBR on properties of rapid hardening repair mortar[J]. Journal of Building Engineering, 2021, 35: 102000. doi: 10.1016/j.jobe.2020.102000 [19] LIAO Y S, JIANG G X, WANG K J, et al. Effect of steel slag on the hydration and strength development of calcium sulfoaluminate cement[J]. Construction and Building Materials, 2020, 265: 12030.1-12030.11. doi: 10.1016/j.conbuildmat.2020.120301 [20] ZOU S, DANG L, LI Y W, et al. Inorganic-organic dual modification of magnesium borate whisker by magnesium hydrate and dodecyl dihydrogen phosphate and its effect on the fire safety and mechanical properties of epoxy resin[J]. Applied Surface Science, 2022, 589: 1530.64-1530.74. doi: 10.1016/j.apsusc.2022.153064 [21] ZHANG B J, PENG Z G, ZOU C J, et al. Study on surface modification of CaSO4 whisker and mechanism of enhancing mechanical properties of oil-well cement[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2021, 618: 1264.08-1264.19. doi: 10.1016/j.colsurfa.2021.126408 [22] DE AZEVEDO N H, DE MATOS P R, GLEIZE P J P, et al. Effect of thermal treatment of SiC nanowhiskers on rheological, hydration, mechanical and microstructure properties of Portland cement pastes[J]. Cement and Concrete Composites, 2021, 117: 1039.03-1039.14. doi: 10.1016/j.cemconcomp.2020.103903 [23] XIE C P, CAO M L, SI W, et al. Experimental evaluation on fiber distribution characteristics and mechanical properties of calcium carbonate whisker modified hybrid fibers reinforced cementitious composites[J]. Construction and Building Materials, 2020, 265: 120.292-120.312. doi: 10.1016/j.conbuildmat.2020.120292 [24] CAO K, LIU G G, LI H, et al. Mechanical properties and microstructure of calcium sulfate whisker-reinforced cement-based composites[J]. Materials, 2022, 15(3): 9.47-9.57. doi: 10.3390/ma15030947 [25] 温浩宇, 吴波, 高灵强, 等. 晶须增强PET复合材料的增韧改性研究[J]. 橡塑技术与装备, 2023, 49(7): 18-21.WEN Haoyu, WU Bo, GAO Lingqiang, et al. Study on toughening modification of whisker reinforced PET composite materials[J]. China Rubber/Plastics Technology and Equipment, 2023, 49(7): 18-21. [26] LI M, YANG Y J, LIU M, et al. Hybrid effect of calcium carbonate whisker and carbon fiber on the mechanical properties and microstructure of oil well cement[J]. Construction and Building Materials, 2015, 93: 995-1002. doi: 10.1016/j.conbuildmat.2015.05.056 [27] 中国建筑材料科学研究总院有限公司, 厦门艾思欧标准砂有限公司, 安徽海螺水泥股份有限公司, 等. 水泥胶砂强度检验方法(ISO法): GB/T 17671—2021[S]. 北京: 中国出版社, 2021. [28] 陕西省建筑科学研究院, 山河建设集团有限公司, 福建省建筑科学研究院, 等. 建筑砂浆基本性能试验方法标准: JGJ/70—2009[S]. 北京: 中国建筑工业出版社, 2009. [29] 张绍康, 王茹, 徐玲琳, 等. 羟乙基甲基纤维素改性水泥砂浆的物理力学性能和孔隙率[J]. 材料导报, 2020, 34(增2): 1607-1611.ZHANG Shaokang, WANG Rui, XU Linglin, et al. Physical and mechanical properties and porosity of cement mortar modified by hydroxyethyl methyl cellulose[J]. Materials Reports, 2020, 34(S2): 1607-1611. [30] ZHANG S K, WANG R, XU L L, et al. Physical and mechanical properties and porosity of cement mortar modified by hydroxyethyl methyl cellulose[J]. Materials Reports, 2020, 34(S2): 1607-1611. [31] CAO M L, ZHANG C, LV H F, et al. Characterization of mechanical behavior and mechanism of calcium carbonate whisker-reinforced cement mortar[J]. Construction and Building Materials, 2014, 66: 89-97. doi: 10.1016/j.conbuildmat.2014.05.059 [32] CAO M L, XU L, ZHANG C. Rheology, fiber distribution and mechanical properties of calcium carbonate (CaCO3) whisker reinforced cement mortar[J]. Composites Part A: Applied Science and Manufacturing, 2016, 90: 662-669. doi: 10.1016/j.compositesa.2016.08.033 [33] 宋建建, 许明标, 周俊, 等. 针状硅灰石微粉改善固井水泥浆性能研究[J]. 硅酸盐通报, 2018, 37(8): 2656-2661.SONG Jianjian, XU Mingbiao, ZHOU Jun, et al. Needle-shape wollastonite powder improved the performance of cement slurry[J]. Bulletin of the Chinese Ceramic Society, 2018, 37(8): 26.56-26.61. [34] ZYMAN Z, EPPLE M, GONCHARENKO A, et al. Favorable features of a calcium phosphate cement based on a metastable α-tricalcium phosphate and reinforced by hydroxyapatite whiskers[J]. Physica Scripta, 2023, 98(12): 125905-125915. doi: 10.1088/1402-4896/ad0696 [35] HU Y Y, LI W F, MA S H, et al. Influence of borax and citric acid on the hydration of calcium sulfoaluminate cement[J]. Chemical Papers, 2017, 71(10): 1909-1919. doi: 10.1007/s11696-017-0185-9 [36] LI M H, HONG Y X, YU H, et al. A novel high solar reflective coating based on potassium silicate for track slab in high-speed railway[J]. Construction and Building Materials, 2019, 225: 900-908. doi: 10.1016/j.conbuildmat.2019.07.223 [37] CAO M L, ZHANG C, WEI J Q. Microscopic reinforcement for cement based composite materials[J]. Construction and Building Materials, 2013, 40: 14-25. doi: 10.1016/j.conbuildmat.2012.10.012 -

下载:

下载: