Characteristics Analysis of Lithium Metal Batteries with Ultra-High Energy Density Under Pressure Conditions

-

摘要:

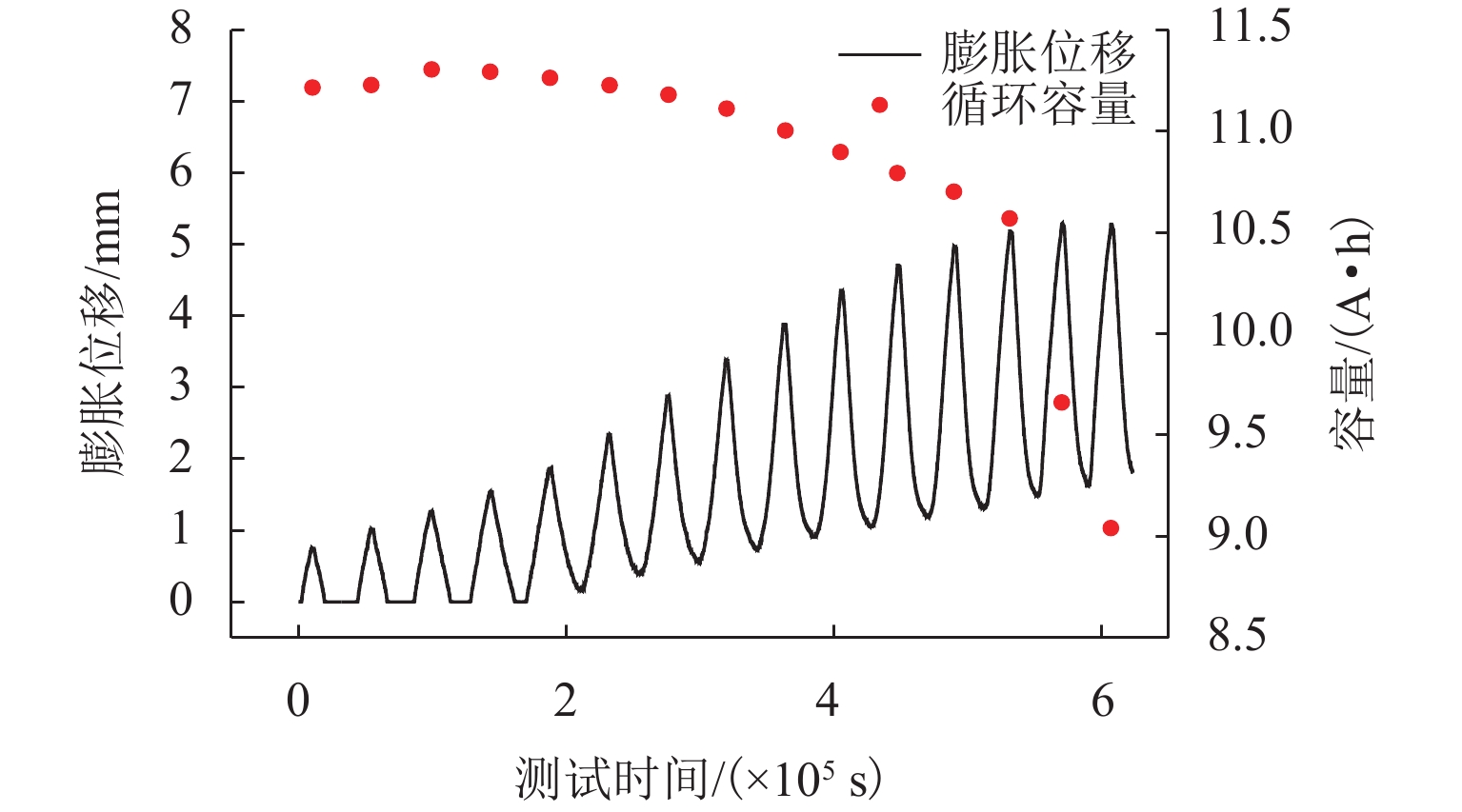

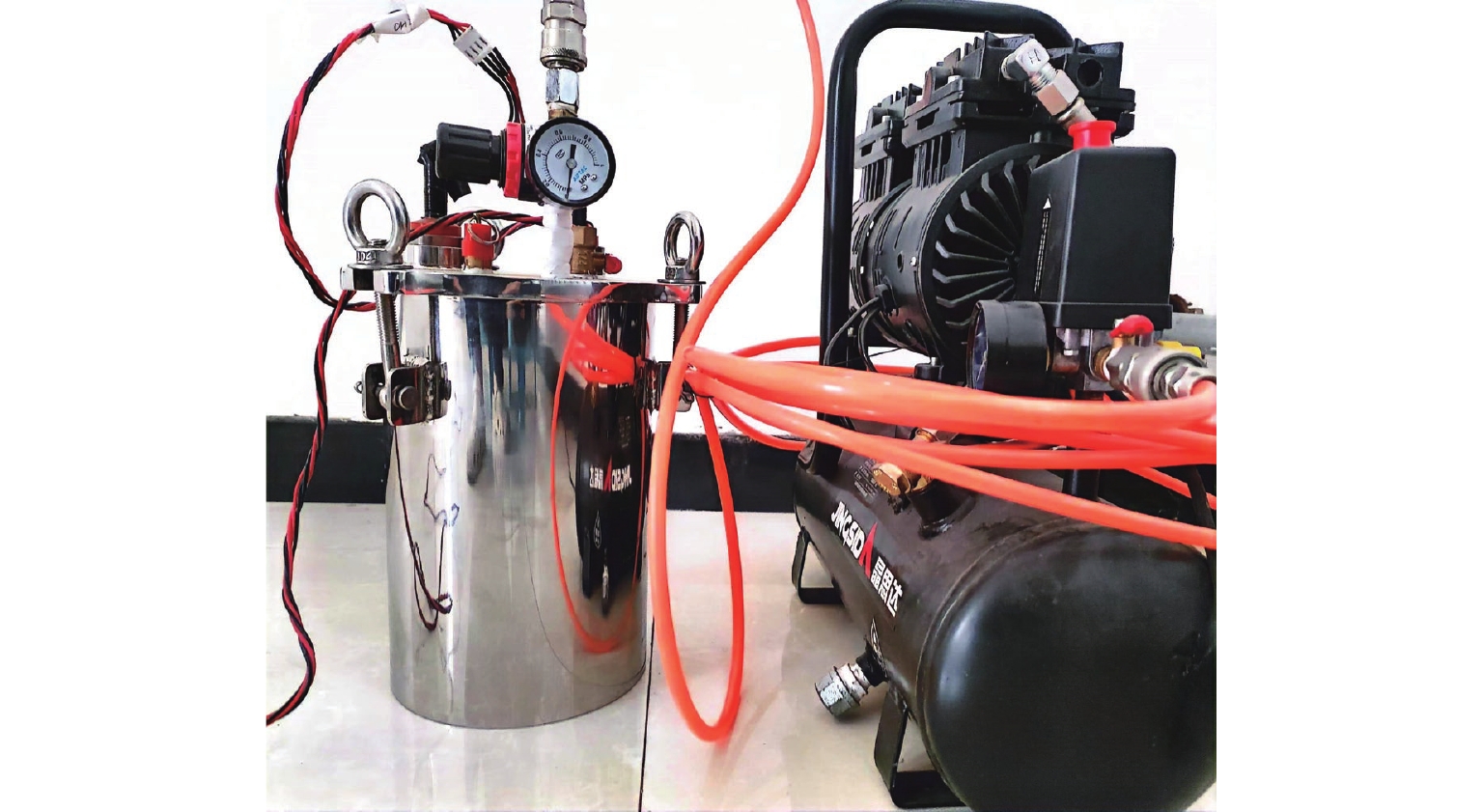

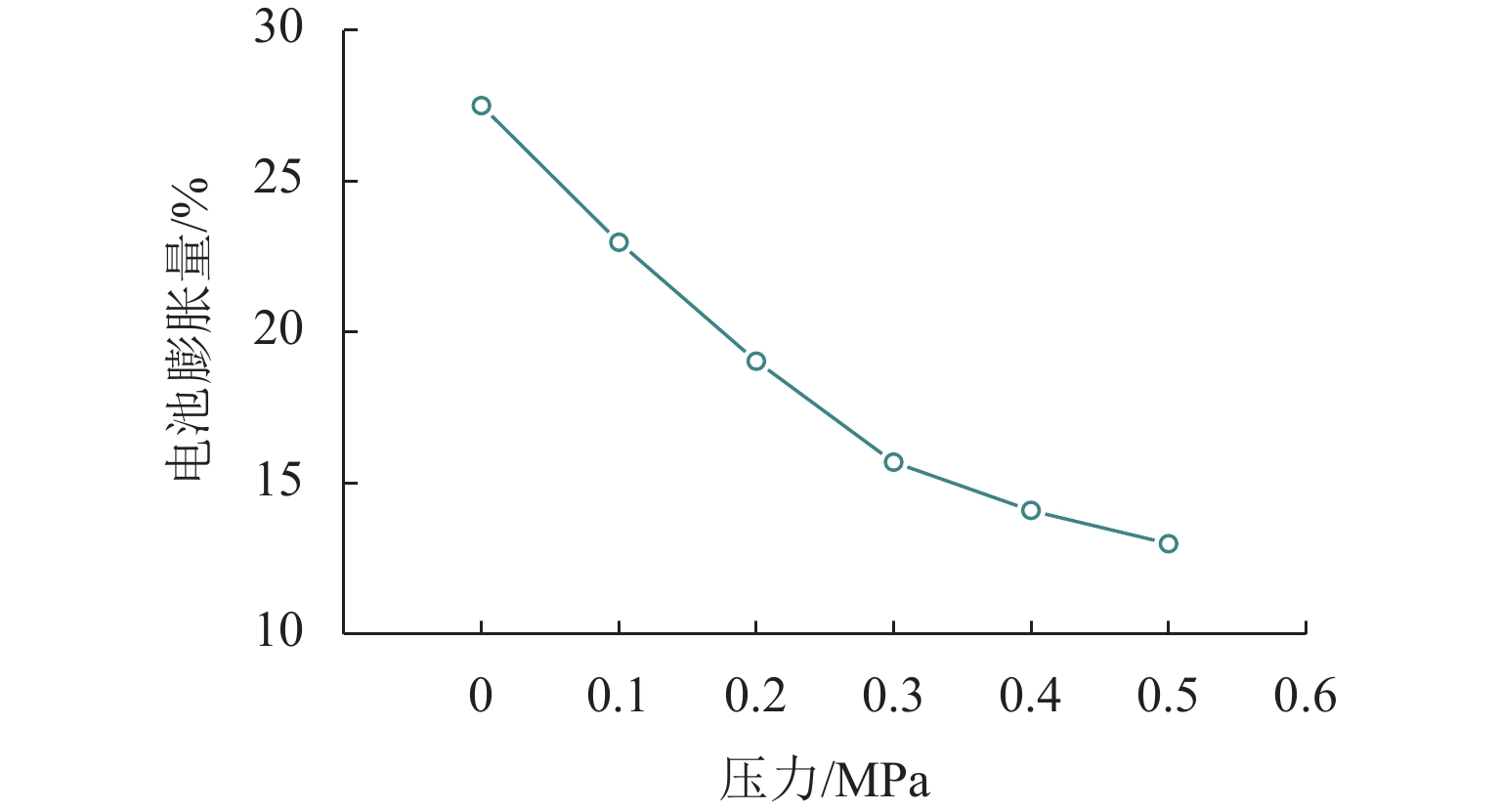

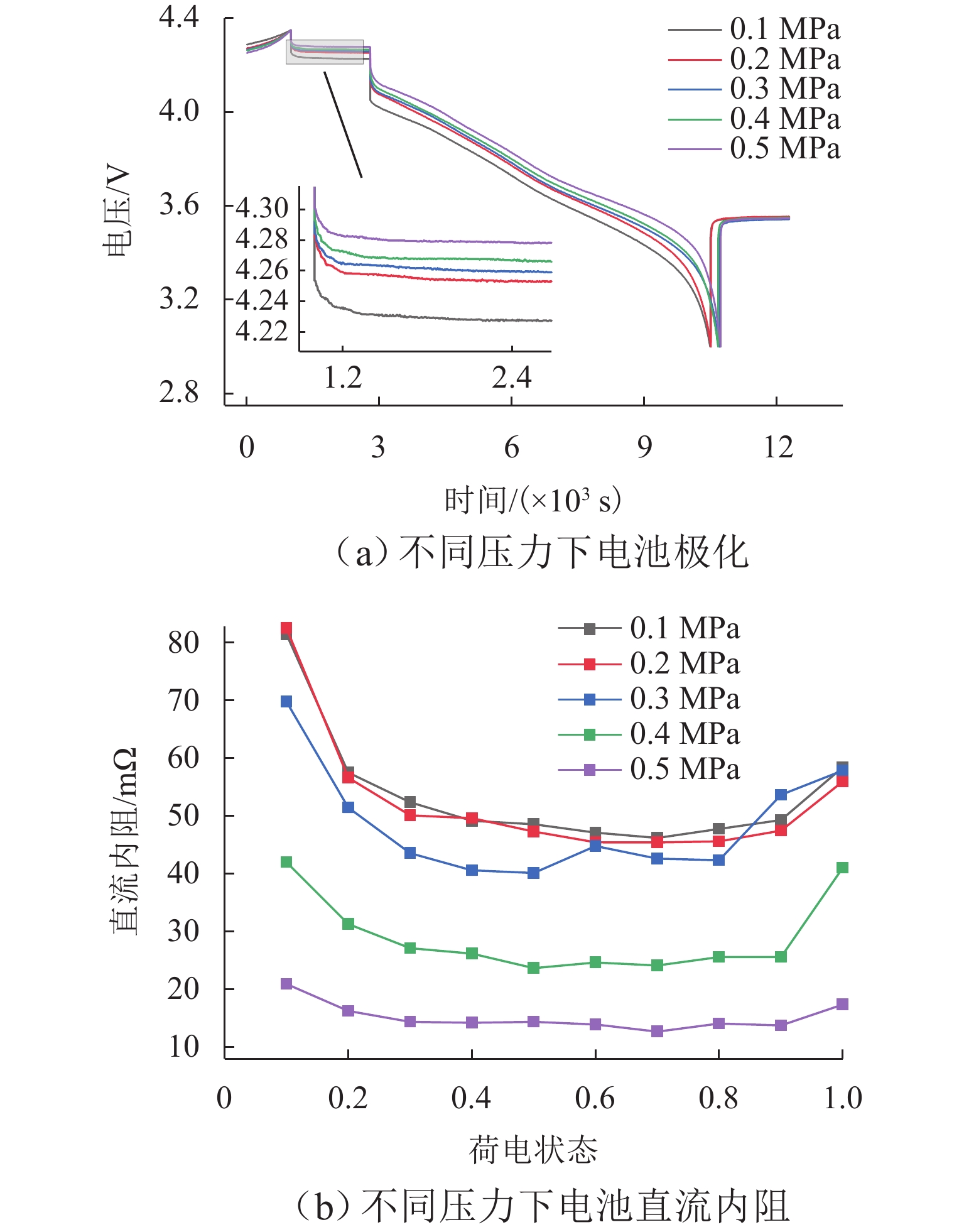

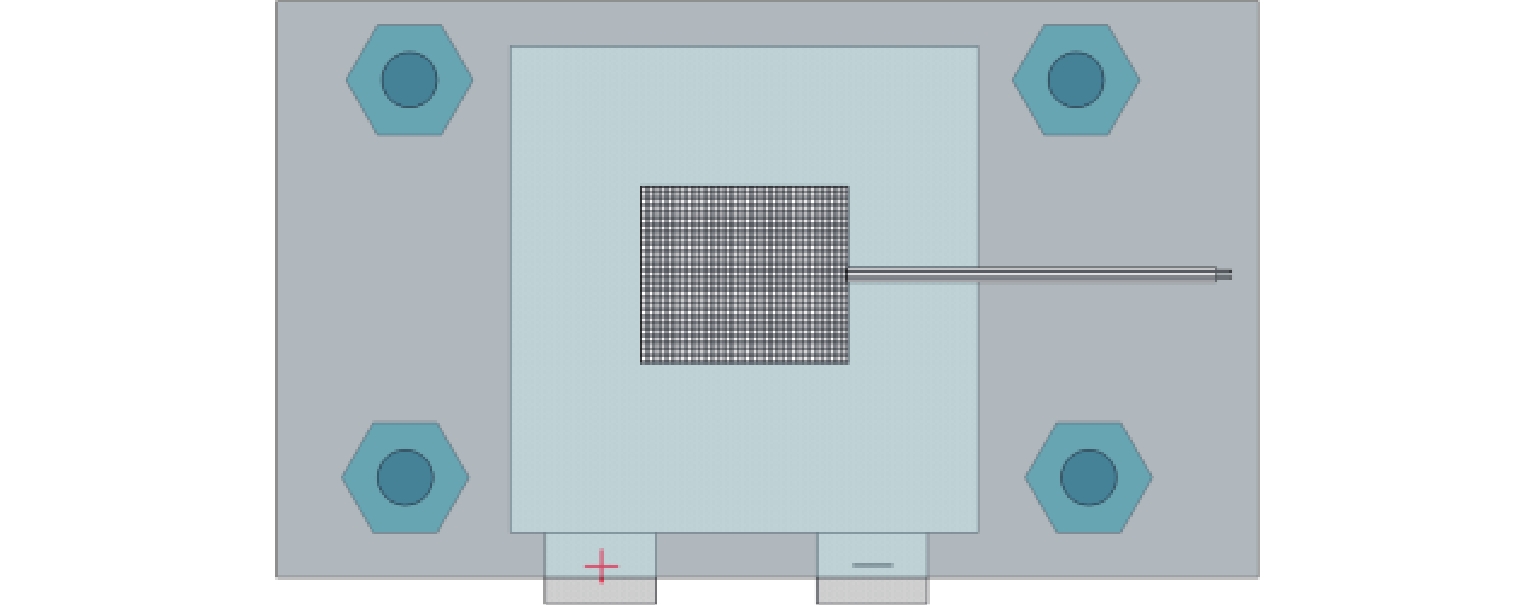

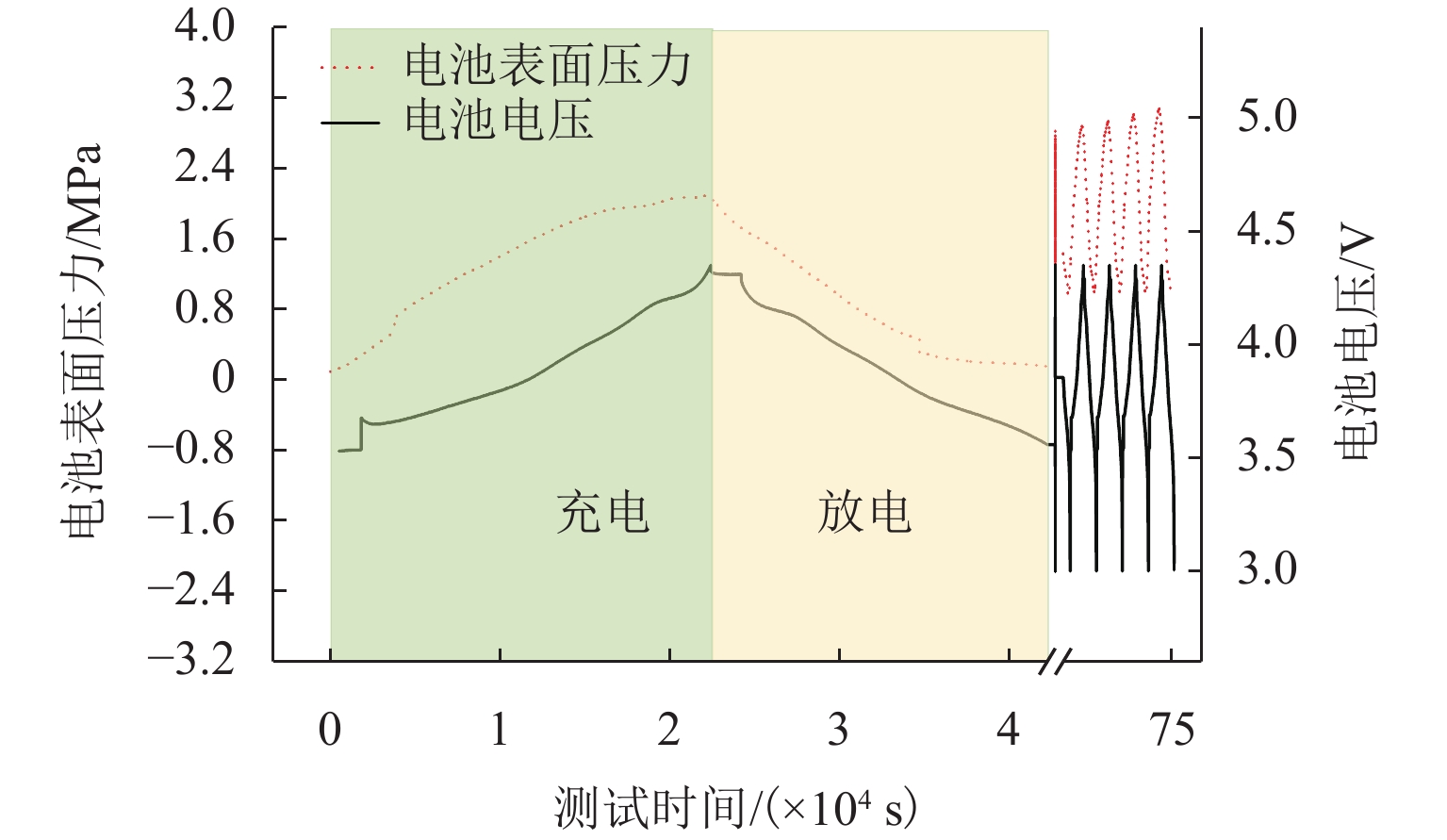

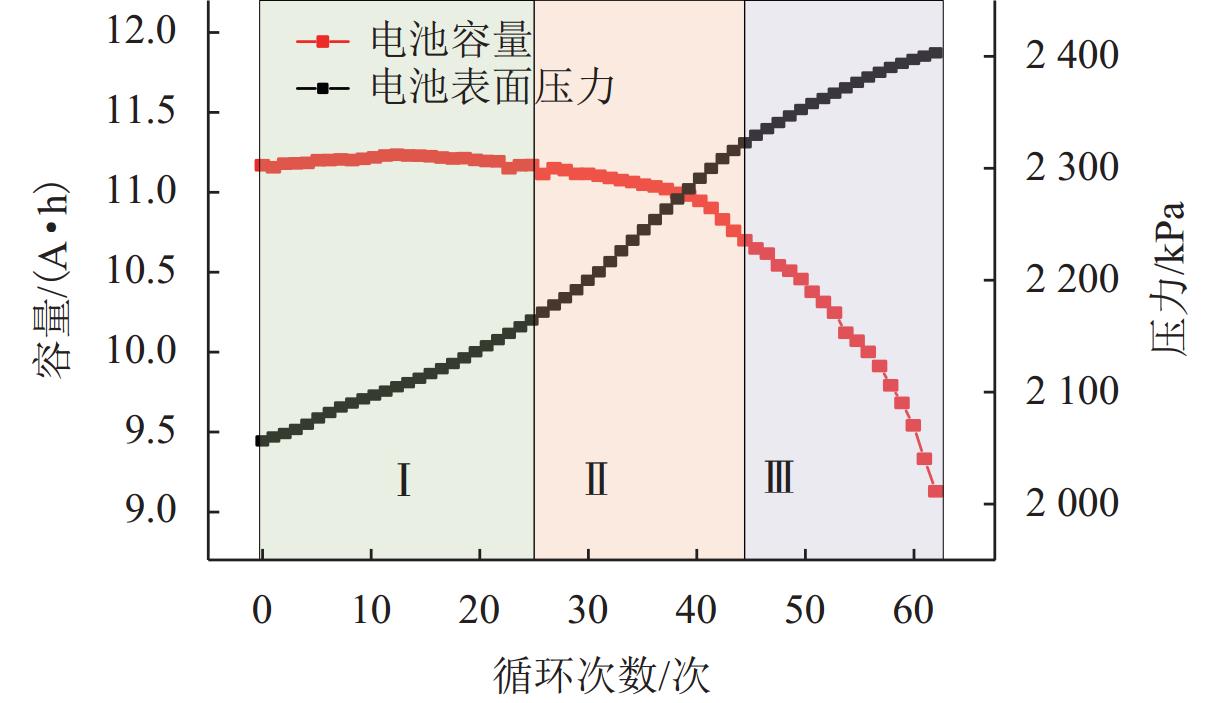

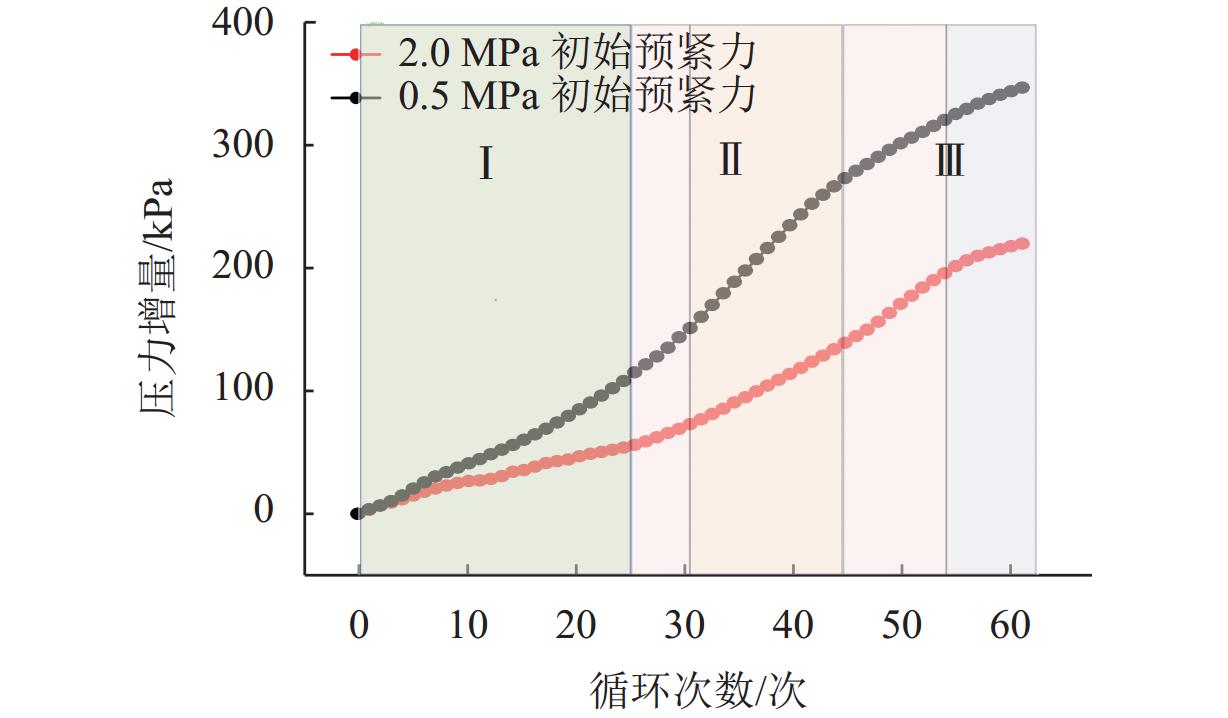

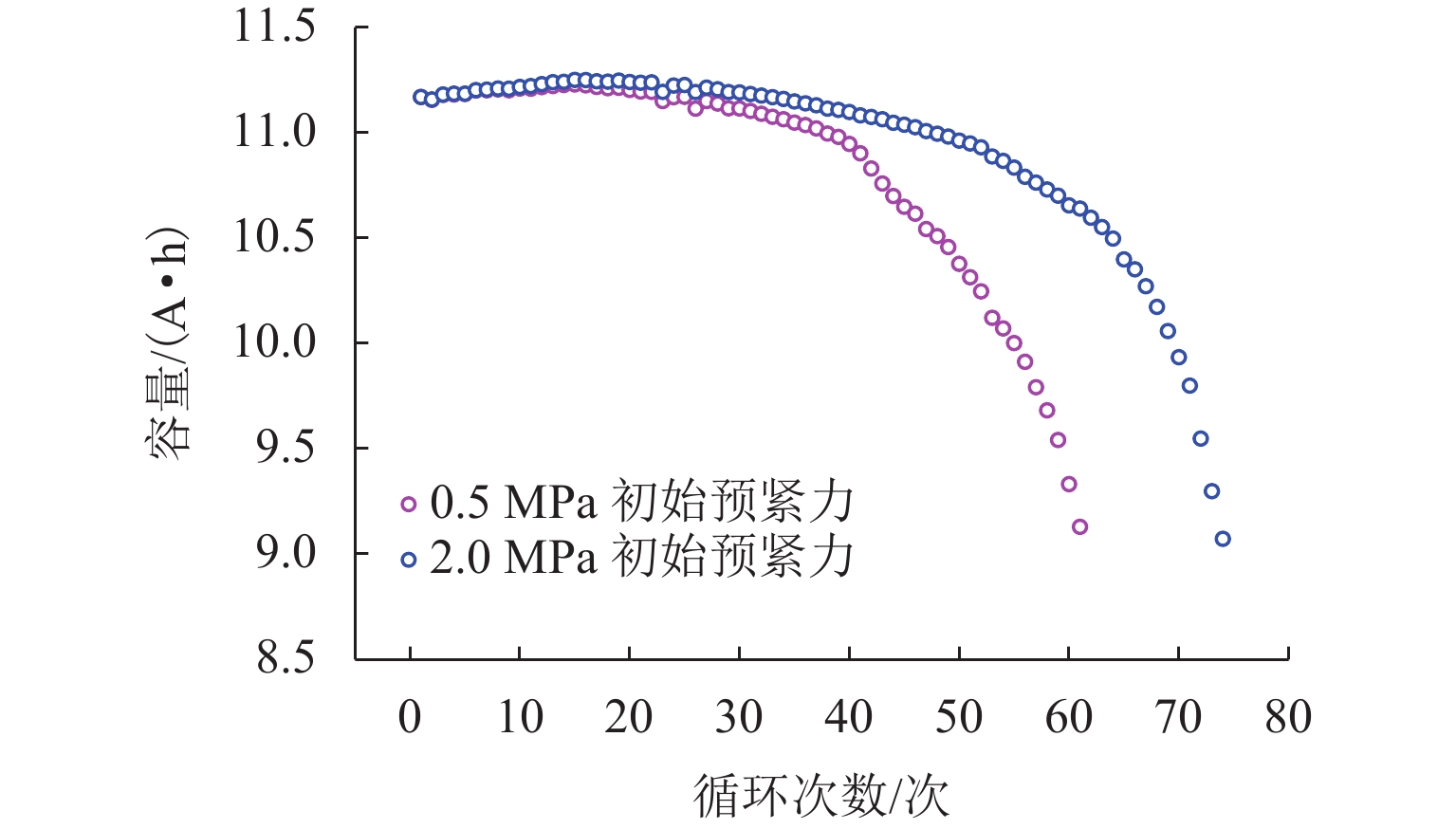

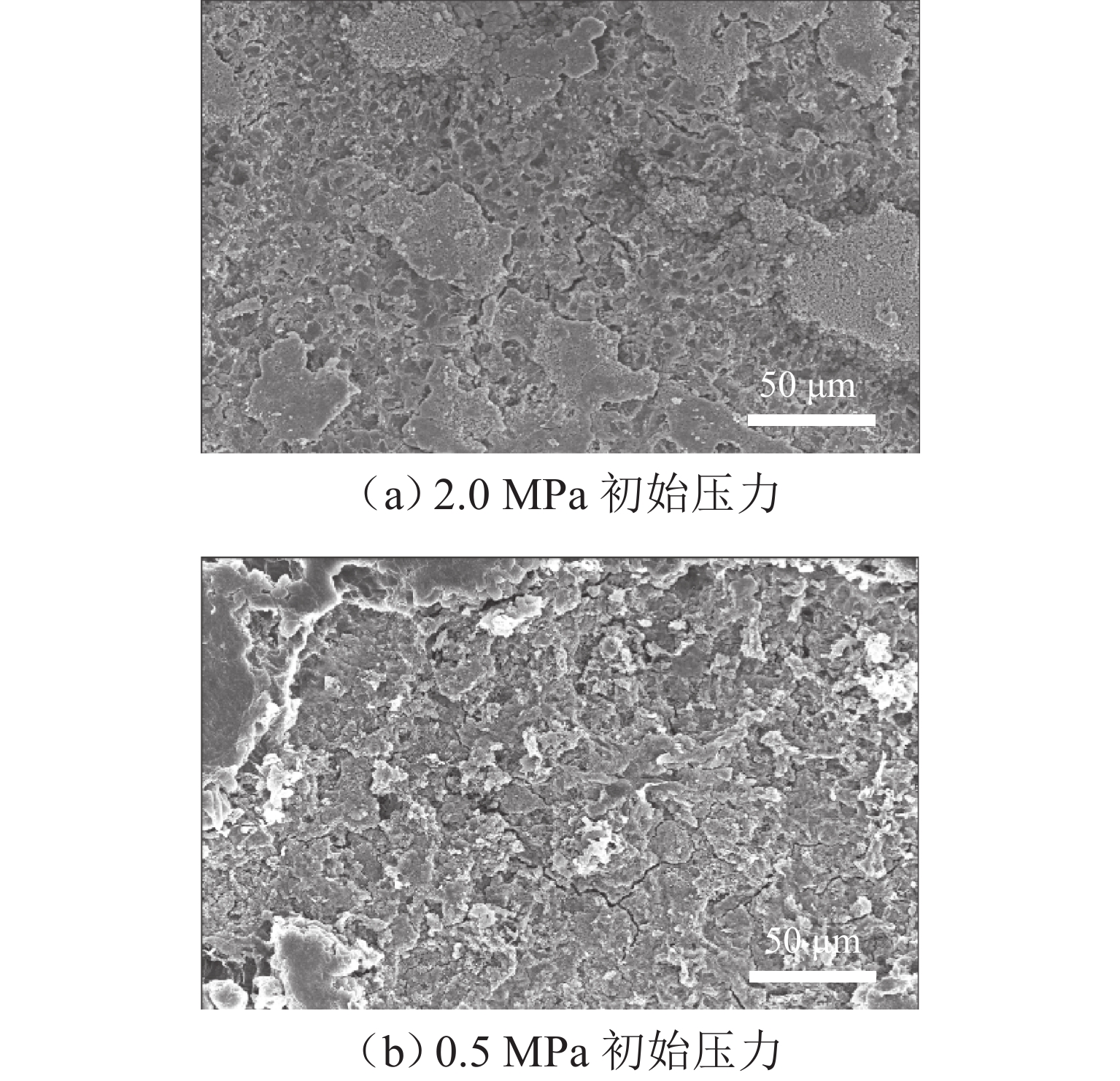

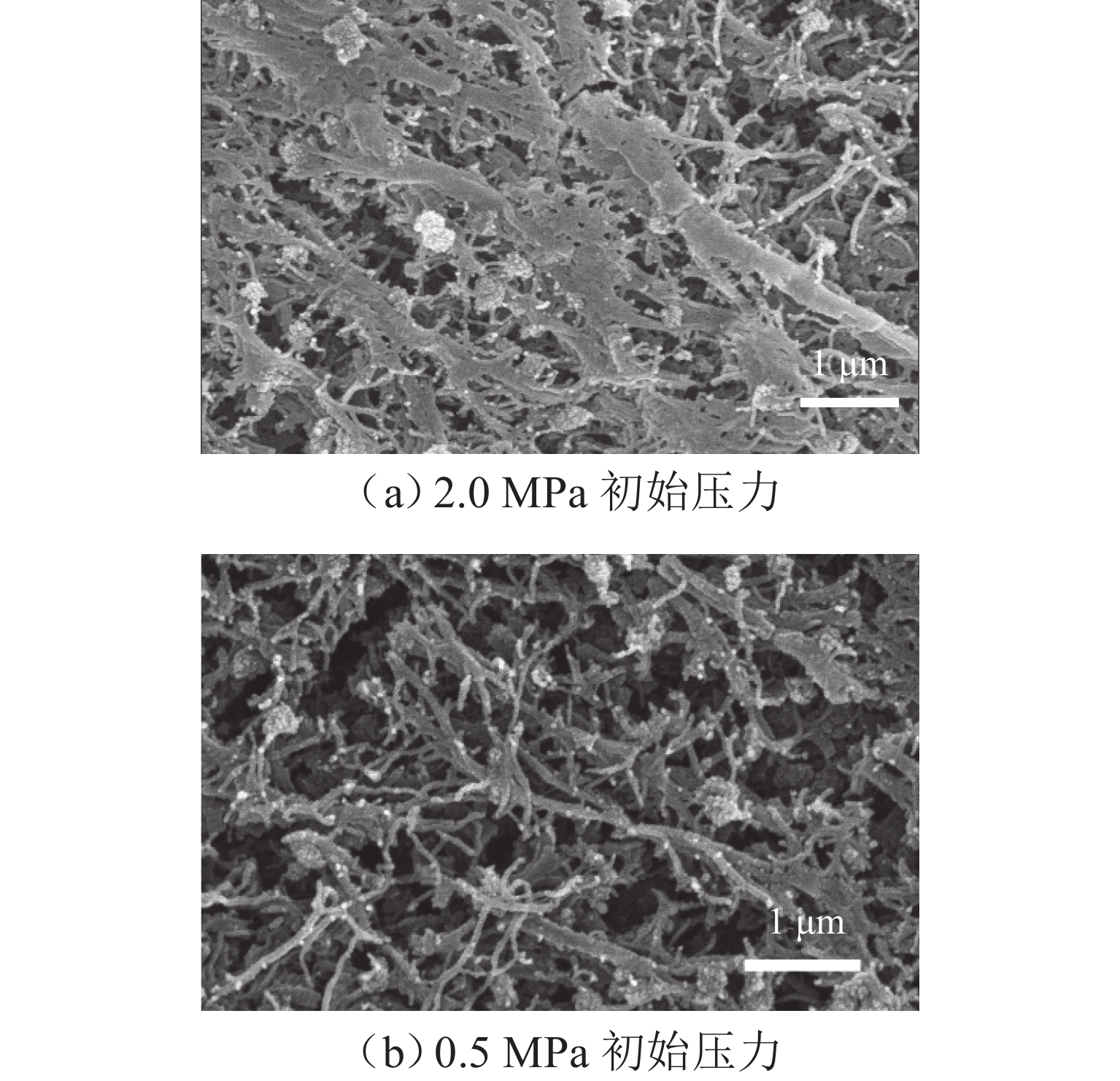

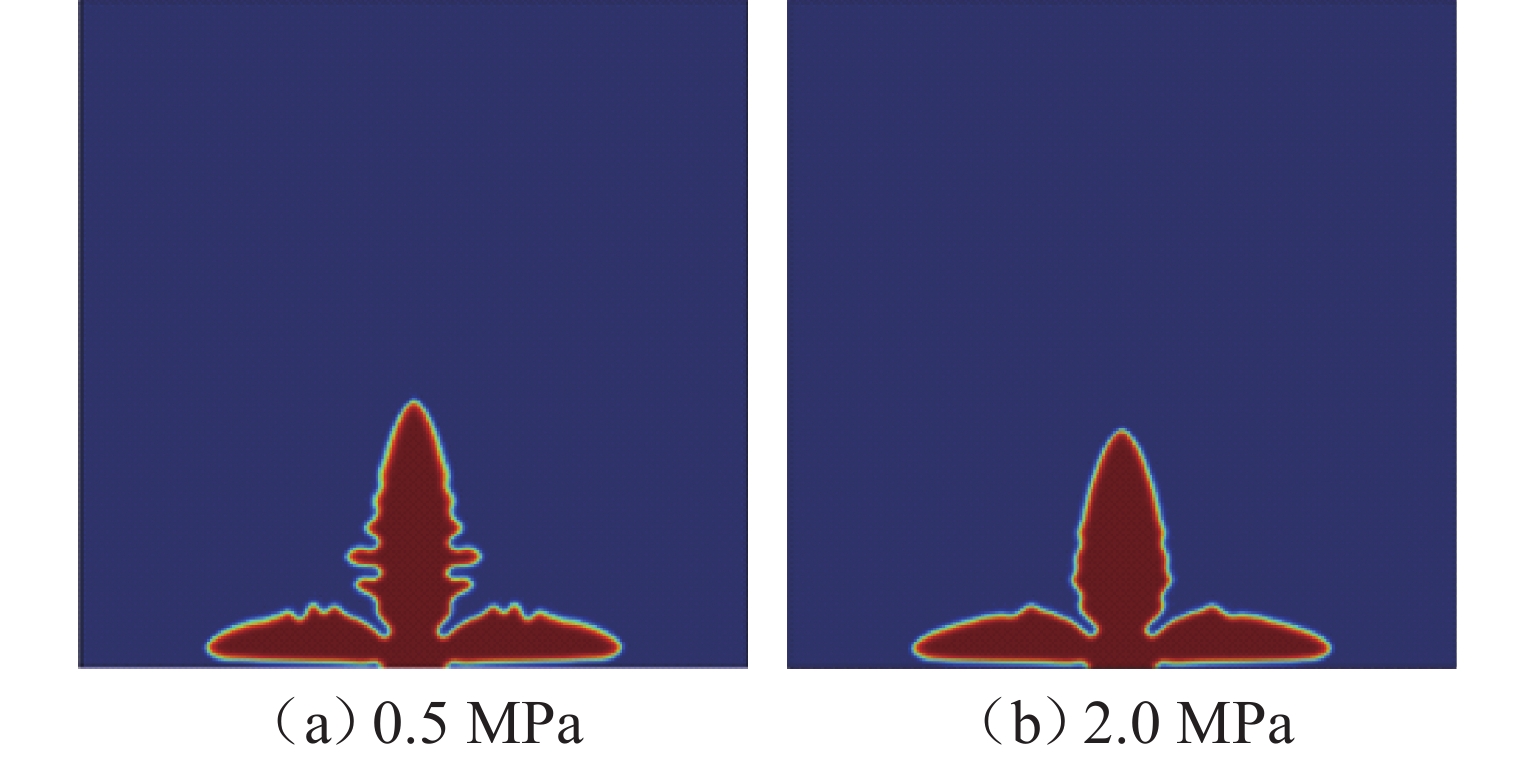

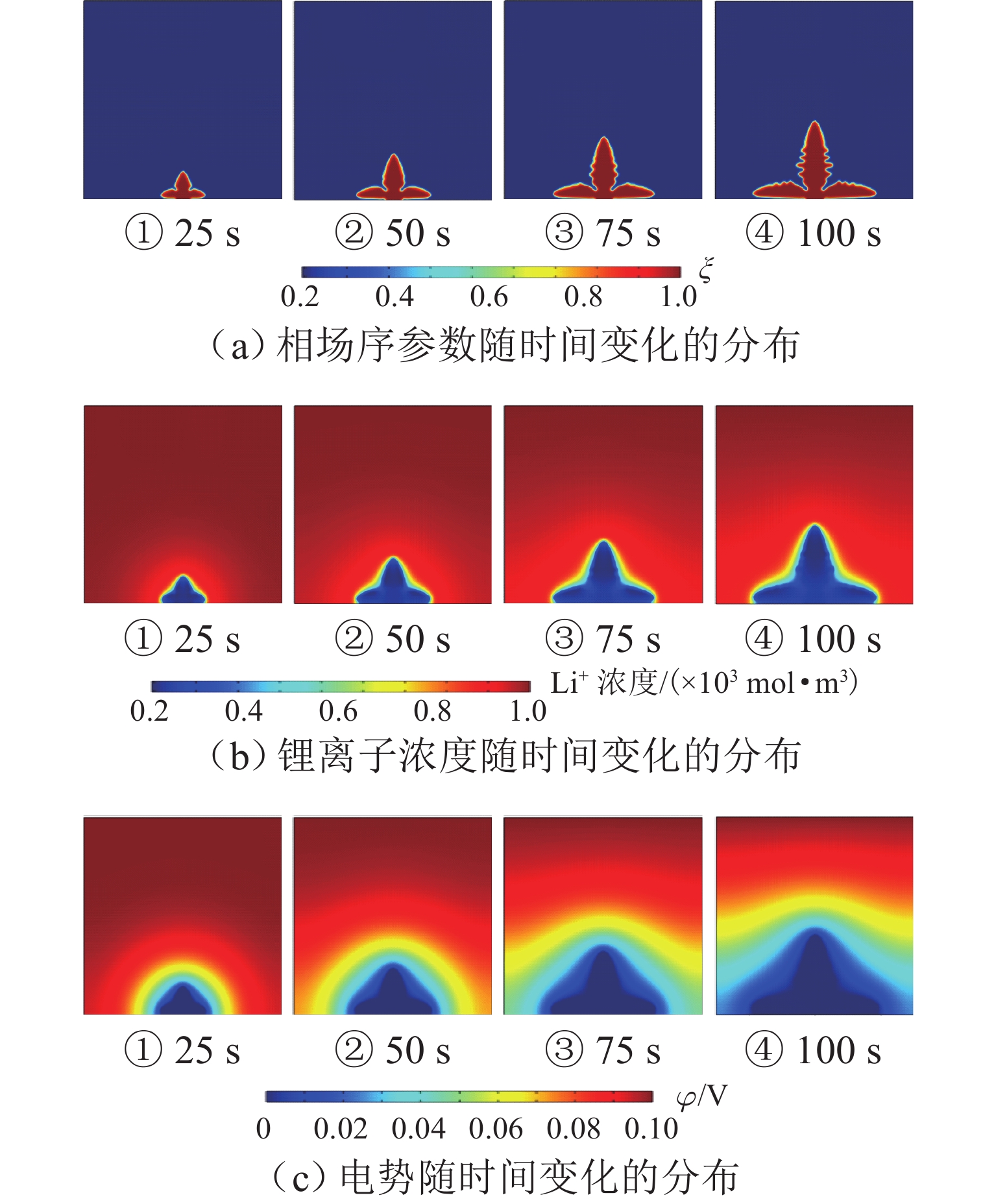

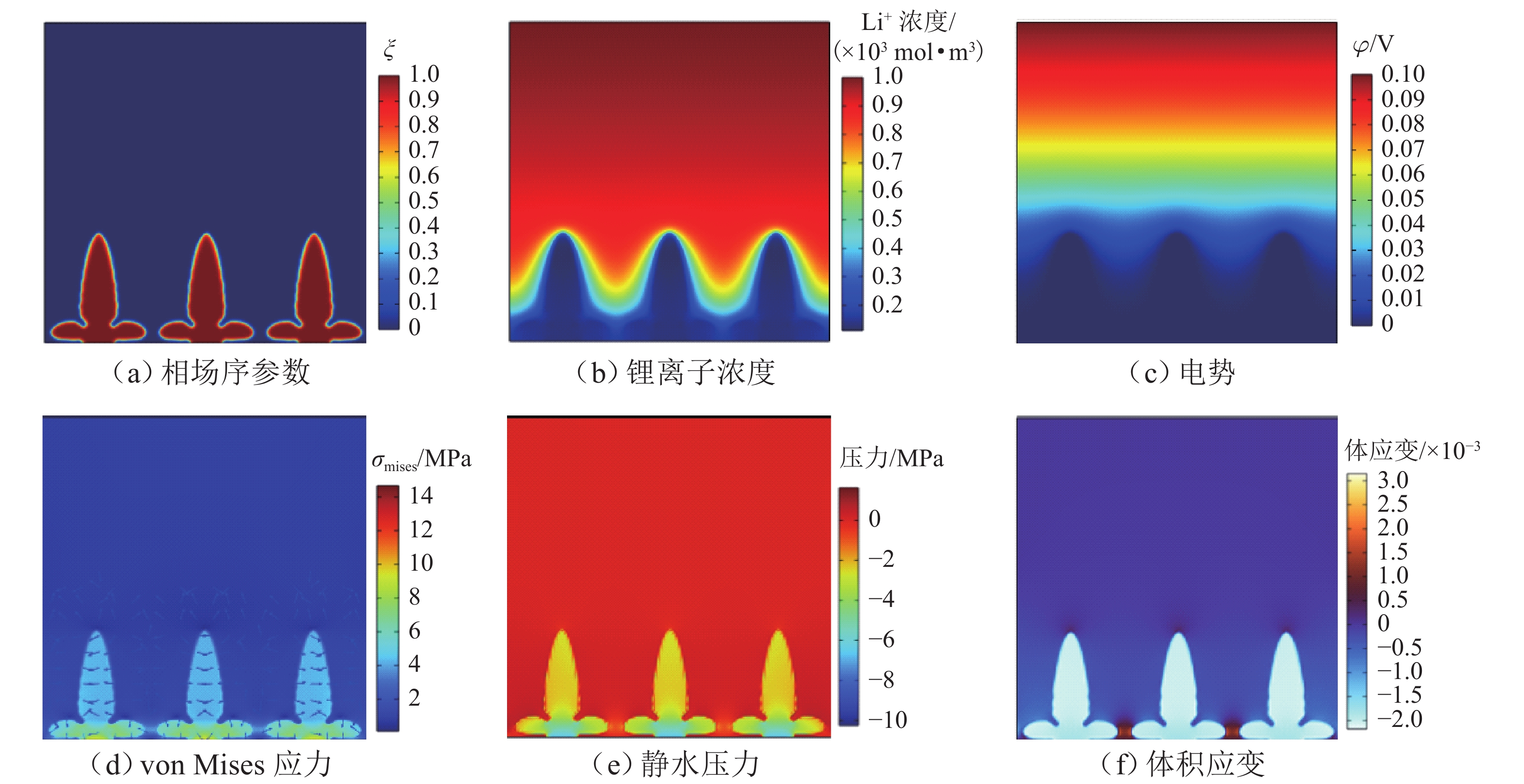

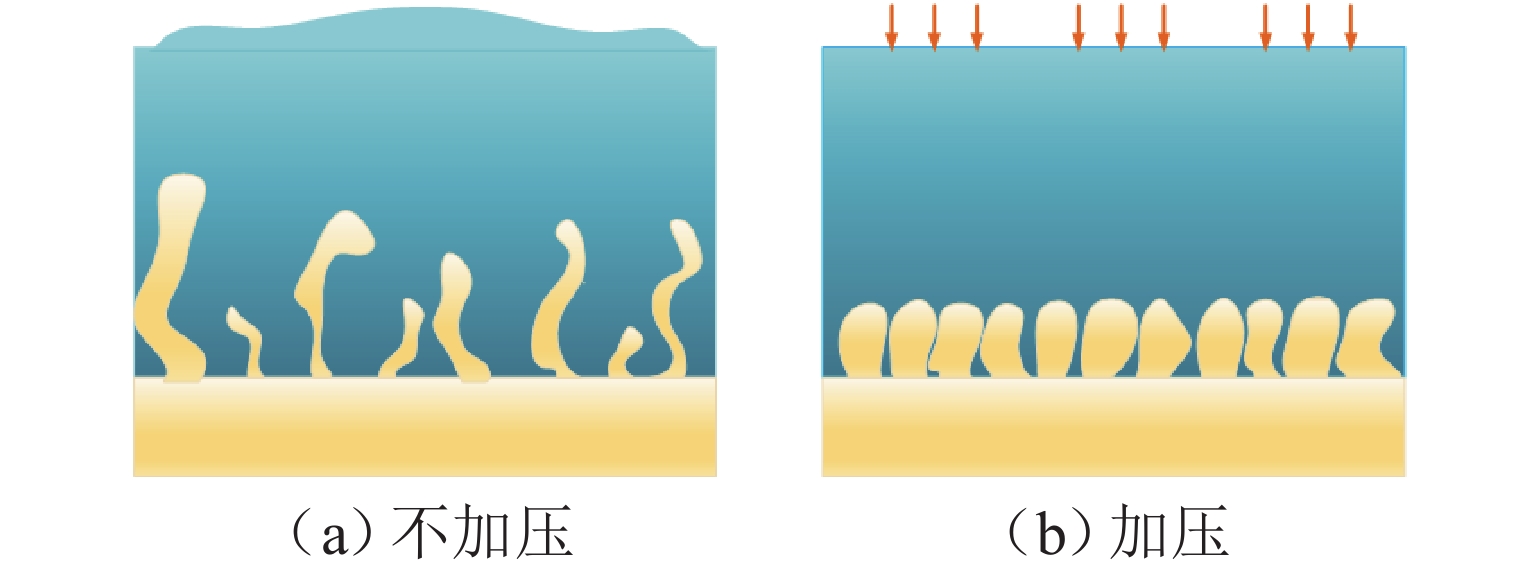

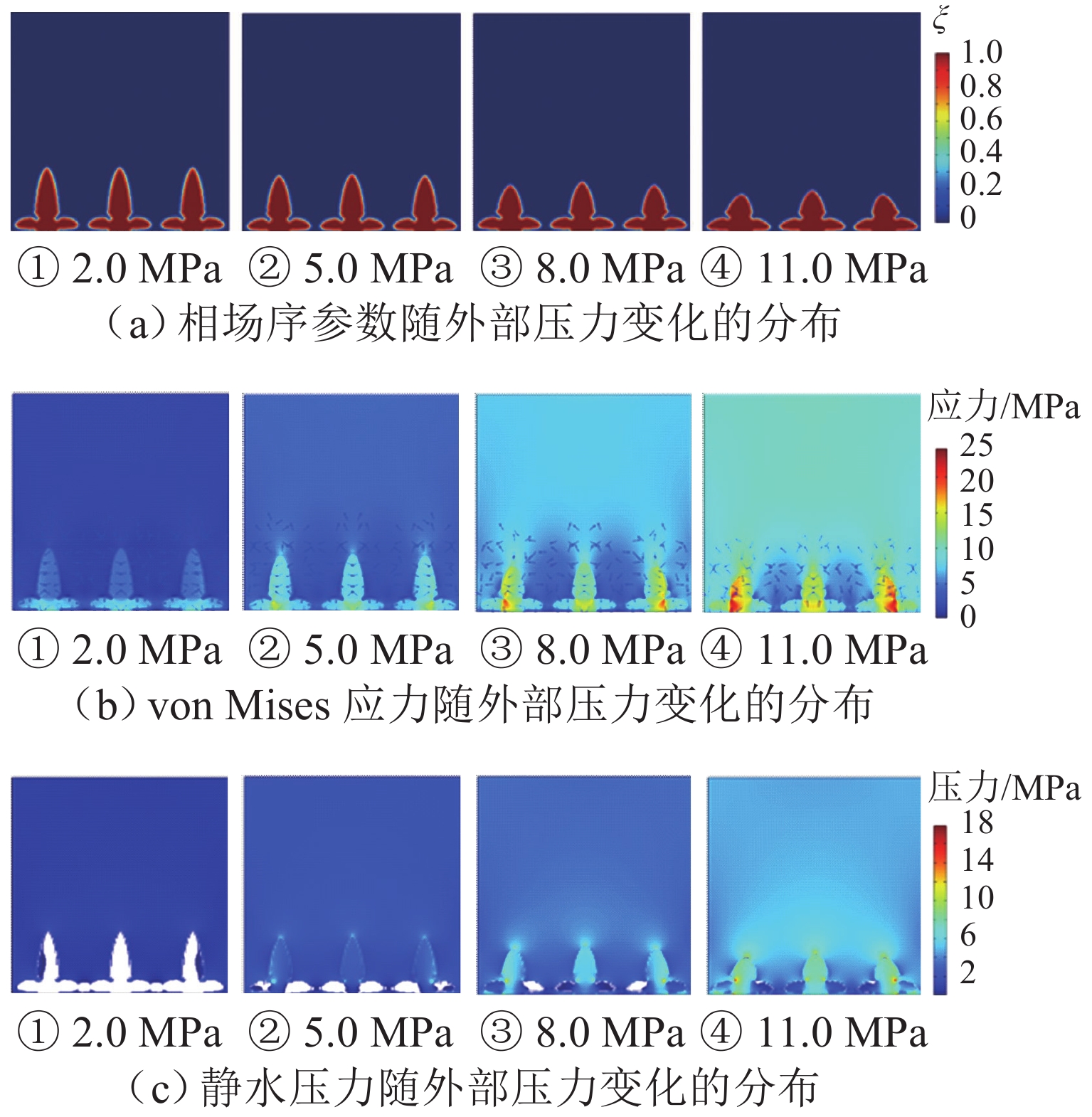

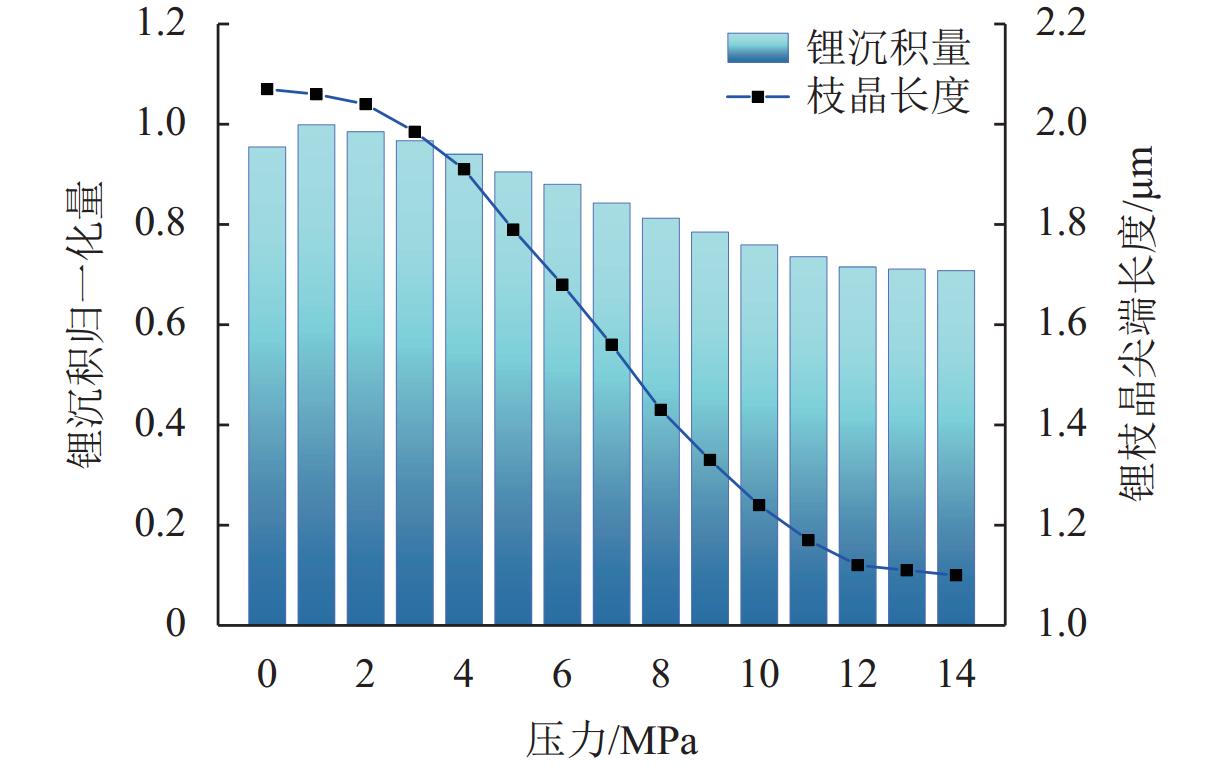

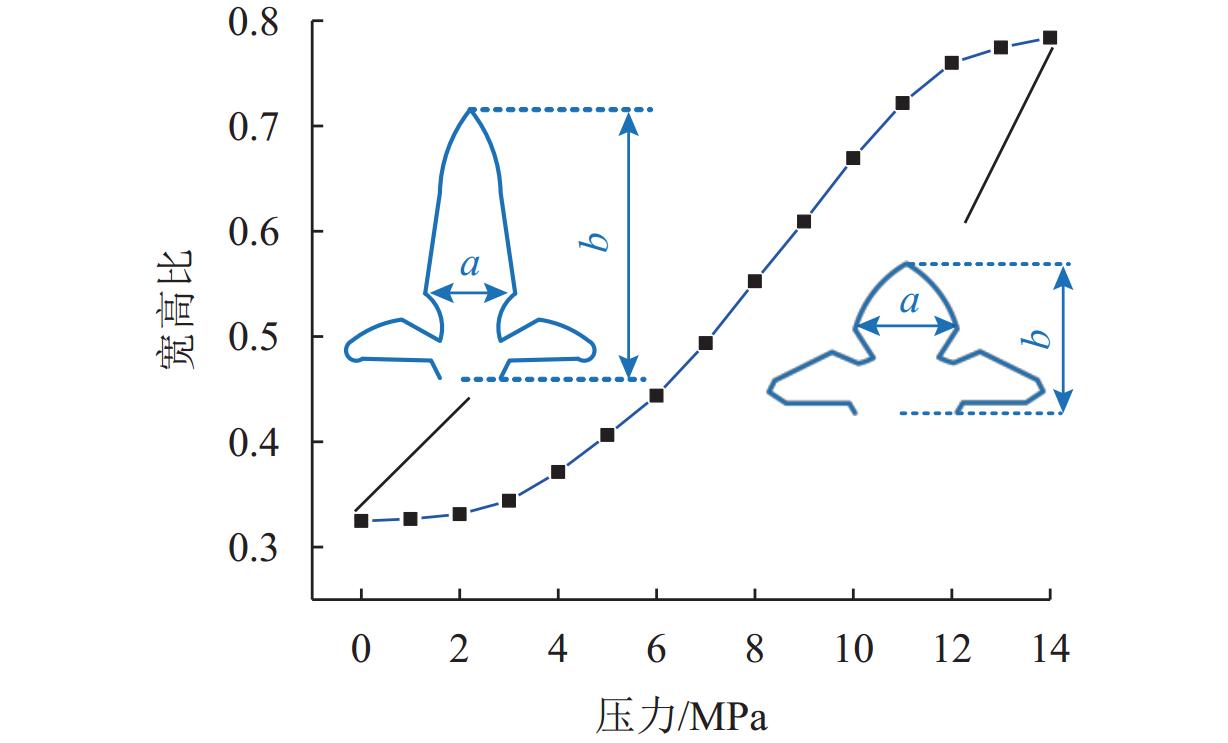

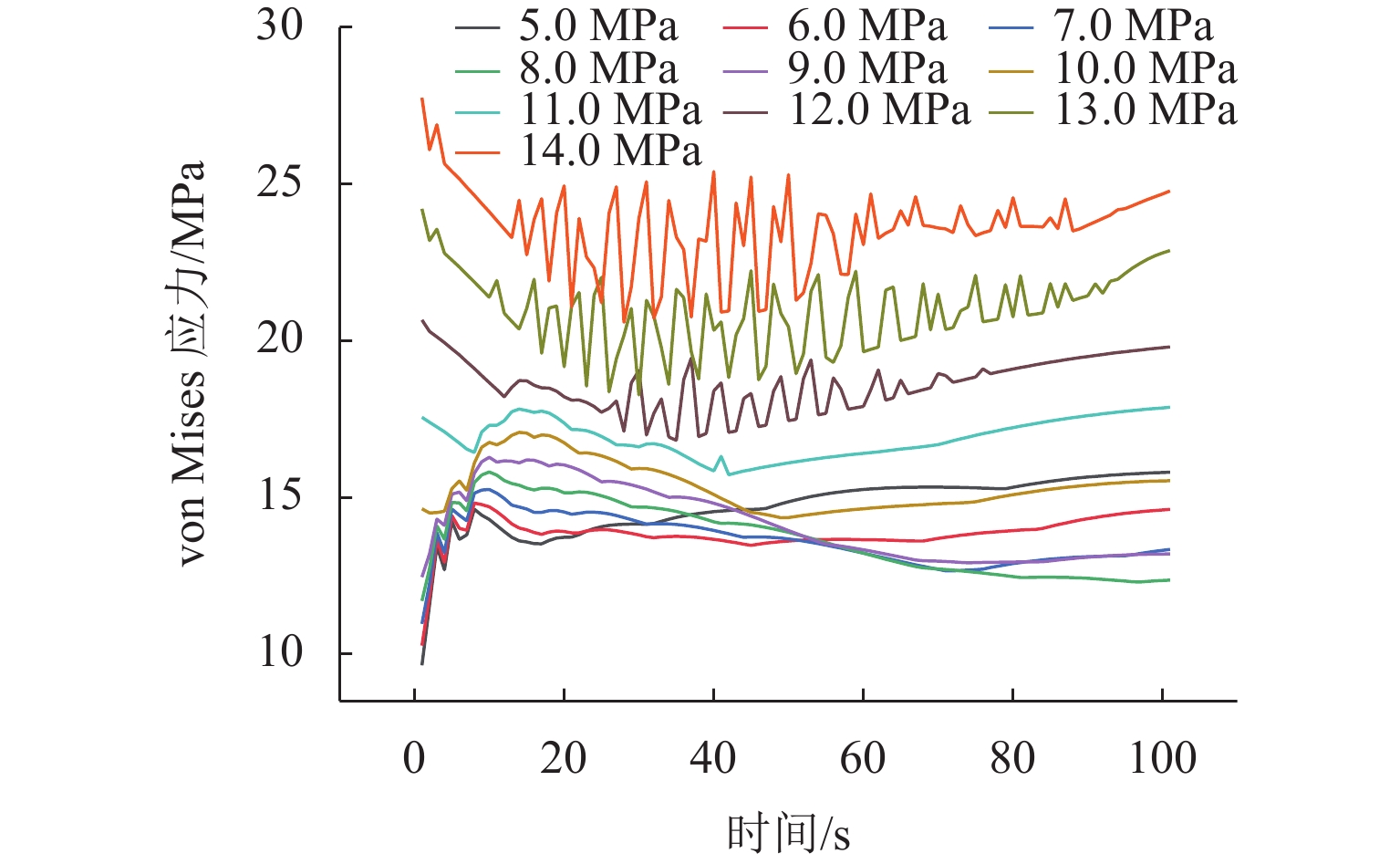

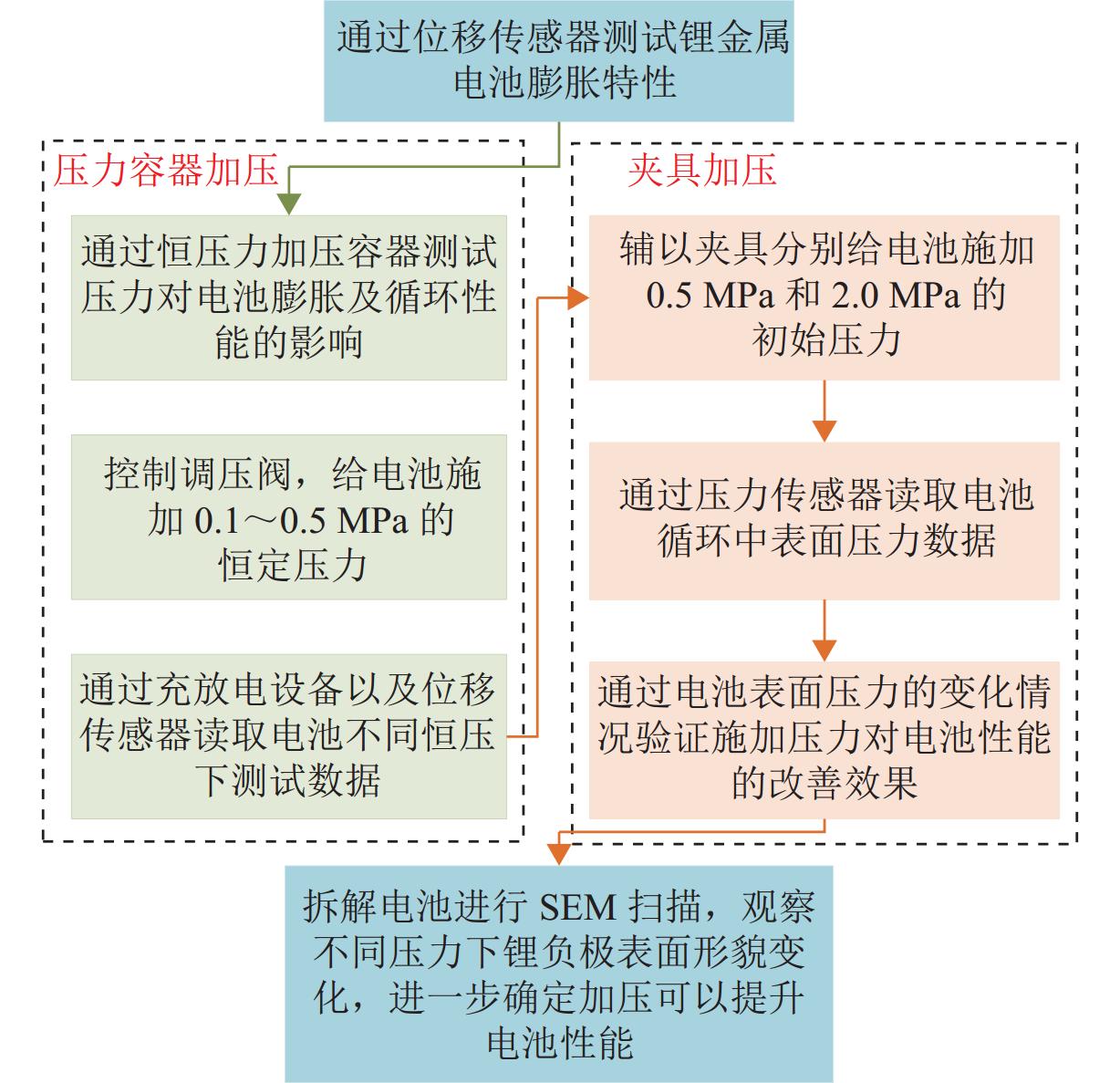

外部压力对锂金属电池的性能起着至关重要的作用. 为研究锂金属电池在不同压力条件下宏观电池性能表现和微观锂沉积特性,首先通过加压试验及电子显微镜扫描验证施加外部压力有助于改善锂金属负极表面形貌,为揭示其作用机理,并将非线性相场模型与力模型耦合,分析微观不同压力条件对锂的沉积形貌及内部应力分布的影响. 研究结果表明:在没有外部压力作用时,锂金属电池对外膨胀加速了锂枝晶的持续生长,导致容量快速衰退;模拟数据显示,随着外部压力的逐渐增大,锂枝晶的主轴长度由2.04 μm降低到1.10 μm,宽高比由0.32提升至0.79,这种光滑粗壮的形貌演变显著降低锂枝晶的比表面积,但同时也增加了力学不稳定性. 本文所提供的在不同外部压力下锂枝晶的相图,为锂金属电池压力管理设计提供理论支持.

Abstract:External pressure plays a crucial role in the performance of lithium metal batteries. In order to study the macroscopic performance and the microscopic lithium deposition characteristics of lithium metal batteries under different pressure conditions, the pressure test and scanning electron microscope (SEM) verification were conducted to verify that applying external pressure can improve the surface morphology of negative electrodes of lithium metal batteries. The nonlinear phase field model and the force model were coupled to reveal relevant mechanisms. The influence of non-pressure conditions on the deposition morphology and internal stress distribution of lithium was analyzed from the microscopic perspective. The results show that in the absence of external pressure, the external expansion of lithium metal batteries accelerates the continuous growth of lithium dendrites, which results in rapid capacity fading. According to the simulation data, as external pressure rises, the principal axis length of lithium dendrites decreases from 2.04 μm to 1.10 μm, and the aspect ratio increases from 0.32 to 0.79. The smooth and robust morphology evolution can significantly reduce the specific surface area of lithium dendrites, but at the same time, it increases the mechanical instability. The phases of lithium dendrites under different external pressures are displayed, which provides theoretical support for the pressure management and design of lithium metal batteries.

-

表 1 耦合模型参数值

Table 1. Coupling model parameter values

参数 符号 数值 参考文献 界面迁移速率/(m3•(J•s)−1) $ {L_\sigma } $ 1.0 × 10−6 [17-18] 反应速率常数/s−1 $ {L_\eta } $ 0.5 [17-18] 能量梯度系数/(J•m−1) $ {k_0} $ 1.5 × 10−6 [17-18] 势垒高度/(J•m−3) $ w $ 3.5 × 105 [17-18] 各向异性强度 $ \delta $ 0.03 [17-18] 各向异性模数 $ \omega $ 4 [17-18] 对称因子 $ \alpha $ 0.5 [17-18] 初始电解质浓度/(mol•m3) $ {c_0} $ 1.00 × 103 [17-18] 金属锂中初始锂原

子浓度/(mol•m3)$ {c_{\mathrm{s}}} $ 7.69 × 104 [17-18] 电极扩散系数/(m2•s−1) $ {D_{\mathrm{e}}} $ 2 × 10−15 [24] 电解质扩散系数/(m2•s−1) $ {D_{\mathrm{s}}} $ 2 × 10−15 [24] 电极电导率/(S•m−1) $ {\sigma _{\mathrm{e}}} $ 1.0 × 107 [24] 电解质电导率/(S•m−1) $ {\sigma _{\mathrm{s}}} $ 0.1 [24] 电极杨氏模量/GPa $ {E_{\mathrm{e}}} $ 7.8 [24-25] 电解质杨氏模量/GPa $ {E_{\mathrm{s}}} $ 1.0 [24-25] 电极泊松比 $ {v_{\mathrm{e}}} $ 0.42 [24-25] 电解质泊松比 $ {v_{\mathrm{s}}} $ 0.30 [24-25] Vegard 应变系数 $ {\lambda _{\mathrm{i}}} $ −8.66 × 10−4,

−7.73 × 10−4,

−5.29 × 10−4[24-25] -

[1] 秦潜聪, 吴冠霖, 高原, 等. 面向战场条件的无人机集群分布式存储方法[J]. 西南交通大学学报, 2024, 59(4): 942-958. doi: 10.3969/j.issn.0258-2724.20230521QIN Qiancong, WU Guanlin, GAO Yuan, et al. Distributed storage methods for unmanned aerial vehicle clusters in battlefield[J]. Journal of Southwest Jiaotong University, 2024, 59(4): 942-958. doi: 10.3969/j.issn.0258-2724.20230521 [2] 郭林, 刘飞, 李佳钰, 等. 基于能量管理策略的太阳能无人机航迹跟踪控制[J]. 西北工业大学学报, 2023, 41(2): 409-418. doi: 10.3969/j.issn.1000-2758.2023.02.019GUO Lin, LIU Fei, LI Jiayu, et al. Path tracking control of solar-powered UAV based on energy management strategy[J]. Journal of Northwestern Polytechnical University, 2023, 41(2): 409-418. doi: 10.3969/j.issn.1000-2758.2023.02.019 [3] KRAUSKOPF T, RICHTER F H, ZEIER W G, et al. Physicochemical concepts of the lithium metal anode in solid-state batteries[J]. Chemical Reviews, 2020, 120(15): 7745-7794. doi: 10.1021/acs.chemrev.0c00431 [4] 金礼芬, 蒲建, 杨文斌, 等. 太阳能无人机的能源系统技术与发展趋势[J]. 信息记录材料, 2022, 23(6): 13-16. doi: 10.3969/j.issn.1009-5624.2022.6.xxjlcl202206003JIN Lifen, PU Jian, YANG Wenbin, et al. Overview of solar powered UAV development[J]. Information Recording Materials, 2022, 23(6): 13-16. doi: 10.3969/j.issn.1009-5624.2022.6.xxjlcl202206003 [5] ZHANG R, SHEN X, ZHANG Y T, et al. Dead lithium formation in lithium metal batteries: a phase field model[J]. Journal of Energy Chemistry, 2022, 71: 29-35. doi: 10.1016/j.jechem.2021.12.020 [6] CHENG X B, ZHANG R, ZHAO C Z, et al. Toward safe lithium metal anode in rechargeable batteries: a review[J]. Chemical Reviews, 2017, 117(15): 10403-10473. doi: 10.1021/acs.chemrev.7b00115 [7] ARGUELLO M E, LABANDA N A, CALO V M, et al. Dendrite formation in rechargeable lithium-metal batteries: phase-field modeling using open-source finite element library[J]. Journal of Energy Storage, 2022, 53: 104892.1-104892.21. [8] 李志强, 刘媛, 李彬, 等. 一种面向浮充工况的锂离子电池组早期内短路快速定量诊断方法[J/OL]. 西南交通大学学报, 1-8[2025-02-17]. http: //kns.cnki.net/kcms/detail/51.1277.U.20240614.1318.006.html. [9] RAMASUBRAMANIAN A, YURKIV V, FOROOZAN T, et al. Lithium diffusion mechanism through solid–electrolyte interphase in rechargeable lithium batteries[J]. The Journal of Physical Chemistry C, 2019, 123(16): 10237-10245. doi: 10.1021/acs.jpcc.9b00436 [10] MU W Y, LIU X L, WEN Z, et al. Numerical simulation of the factors affecting the growth of lithium dendrites[J]. Journal of Energy Storage, 2019, 26: 100921.1-100921.10. [11] VERMA P, PURAVANKARA S, NANDANWAR M N, et al. Insights into the morphological evolution of mossy dendrites in lithium metal symmetric and full cell: a modelling study[J]. Journal of the Electrochemical Society, 2023, 170(3): 030529.1-030529.11. [12] CHENG F, HU Y, ZHAO L X. Analysis of weak solutions for the phase-field model for lithium-ion batteries[J]. Applied Mathematical Modelling, 2020, 78: 185-199. doi: 10.1016/j.apm.2019.09.048 [13] REN Y, ZHOU Y, CAO Y. Inhibit of lithium dendrite growth in solid composite electrolyte by phase-field modeling[J]. The Journal of Physical Chemistry C, 2020, 124(23): 12195-12204. doi: 10.1021/acs.jpcc.0c01116 [14] ARGUELLO M E, GUMULYA M, DERKSEN J, et al. Phase-field modeling of planar interface electrodeposition in lithium-metal batteries[J]. Journal of Energy Storage, 2022, 50: 104627.1-104627.13. [15] JING H X, XING H, DONG X L, et al. Nonlinear phase-field modeling of lithium dendritic growth during electrodeposition[J]. Journal of the Electrochemical Society, 2022, 169(3): 032511.1-032511.6. [16] MONROE C, NEWMAN J. Dendrite growth in lithium/polymer systems: a propagation model for liquid electrolytes under galvanostatic conditions[J]. Journal of the Electrochemical Society, 2003, 150(10): A1377.1-A1377.8. [17] GUYER J E, BOETTINGER W J, WARREN J A, et al. Phase field modeling of electrochemistry Ⅰ: equilibrium[J]. Physical Review E, 2004, 69(2): 021603.1-021603.13. [18] CHEN L, ZHANG H W, LIANG L Y, et al. Modulation of dendritic patterns during electrodeposition: a nonlinear phase-field model[J]. Journal of Power Sources, 2015, 300: 376-385. doi: 10.1016/j.jpowsour.2015.09.055 [19] ZHANG R, SHEN X, CHENG X B, et al. The dendrite growth in 3D structured lithium metal anodes: electron or ion transfer limitation?[J]. Energy Storage Materials, 2019, 23: 556-565. doi: 10.1016/j.ensm.2019.03.029 [20] MCDOWELL M T, CORTES F J Q, THENUWARA A C, et al. Toward high-capacity battery anode materials: chemistry and mechanics intertwined[J]. Chemistry of Materials, 2020, 32(20): 8755-8771. doi: 10.1021/acs.chemmater.0c02981 [21] TANG Y F, ZHANG L Q, CHEN J Z, et al. Electro-chemo-mechanics of lithium in solid state lithium metal batteries[J]. Energy & Environmental Science, 2021, 14(2): 602-642. [22] WANG M J, KAZYAK E, DASGUPTA N P, et al. Transitioning solid-state batteries from lab to market: linking electro-chemo-mechanics with practical considerations[J]. Joule, 2021, 5(6): 1371-1390. doi: 10.1016/j.joule.2021.04.001 [23] 朱迎迎, 王勇, 徐淼, 等. 追踪锂金属负极的压力与形貌变化[J]. 物理化学学报, 2023, 39(1): 77-84.ZHU Yingying, WANG Yong, XU Miao, et al. Tracking pressure changes and morphology evolution of lithium metal anodes[J]. Acta Physico-Chimica Sinica, 2023, 39(1): 77-84. [24] SHEN X, ZHANG R, SHI P, et al. How does external pressure shape Li dendrites in Li metal batteries?[J]. Advanced Energy Materials, 2021, 11(10): 2003416.1-2003416.9. [25] ZHANG X, WANG Q J, HARRISON K L, et al. Pressure-driven interface evolution in solid-state lithium metal batteries[J]. Cell Reports Physical Science, 2020, 1(2): 100012.1-100012.19. [26] 罗崇亮, 余云燕, 张璟, 等. 硫酸盐渍土热-质迁移试验与耦合模型[J]. 西南交通大学学报, 2023, 58(2): 470-478.LUO Chongliang, YU Yunyan, ZHANG Jing, et al. Heat-mass transfer test and coupling model of sulfate saline soil[J]. Journal of Southwest Jiaotong University, 2023, 58(2): 470-478. -

下载:

下载: