Vibration Fatigue Fracture Mechanism of e-Type Clip Under Rail Corrugation Excitation

-

摘要:

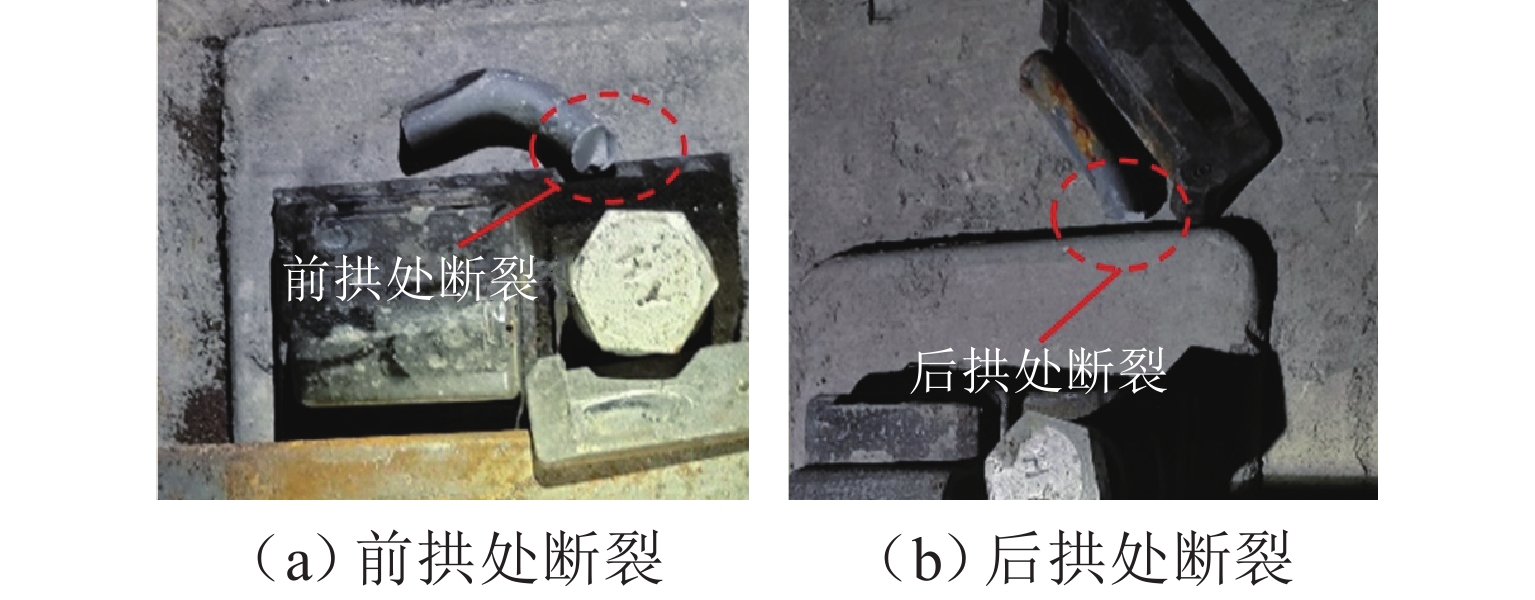

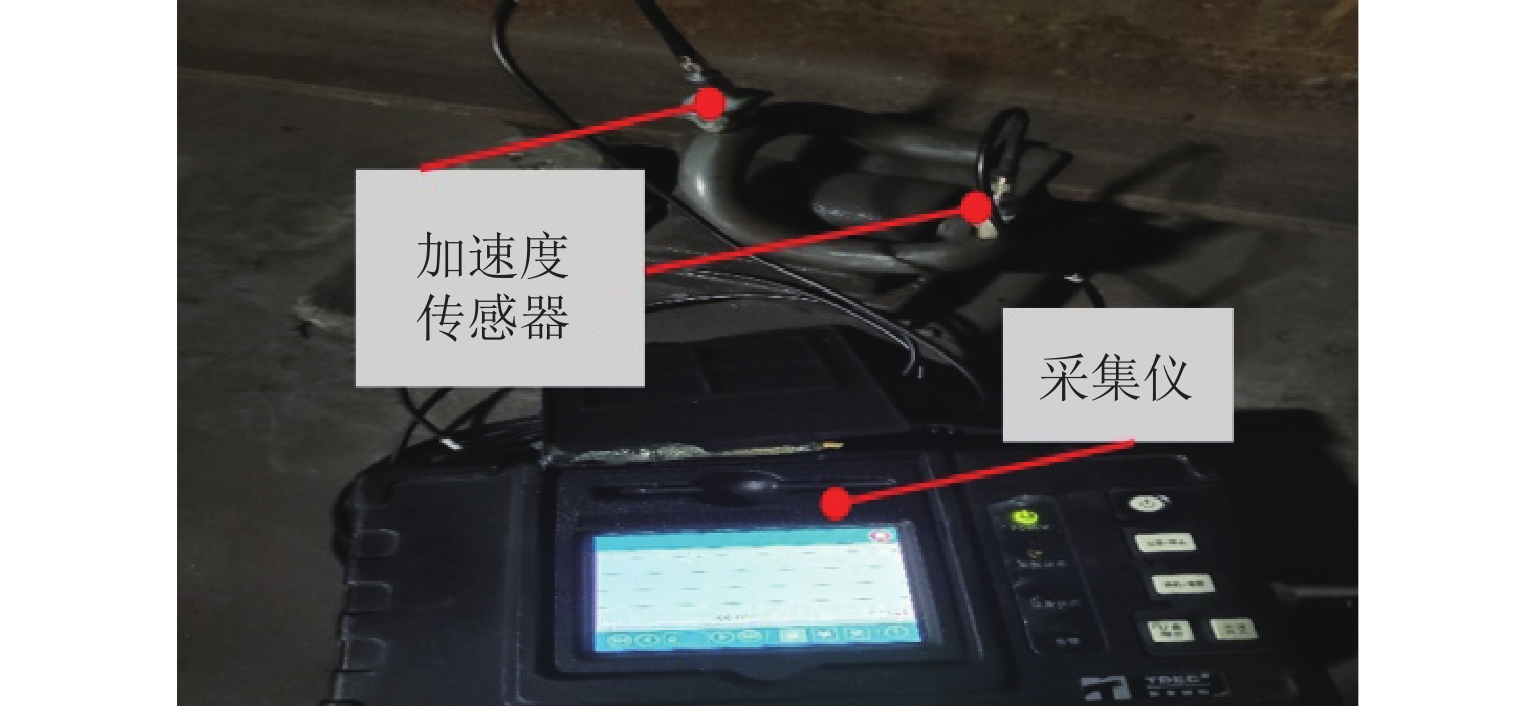

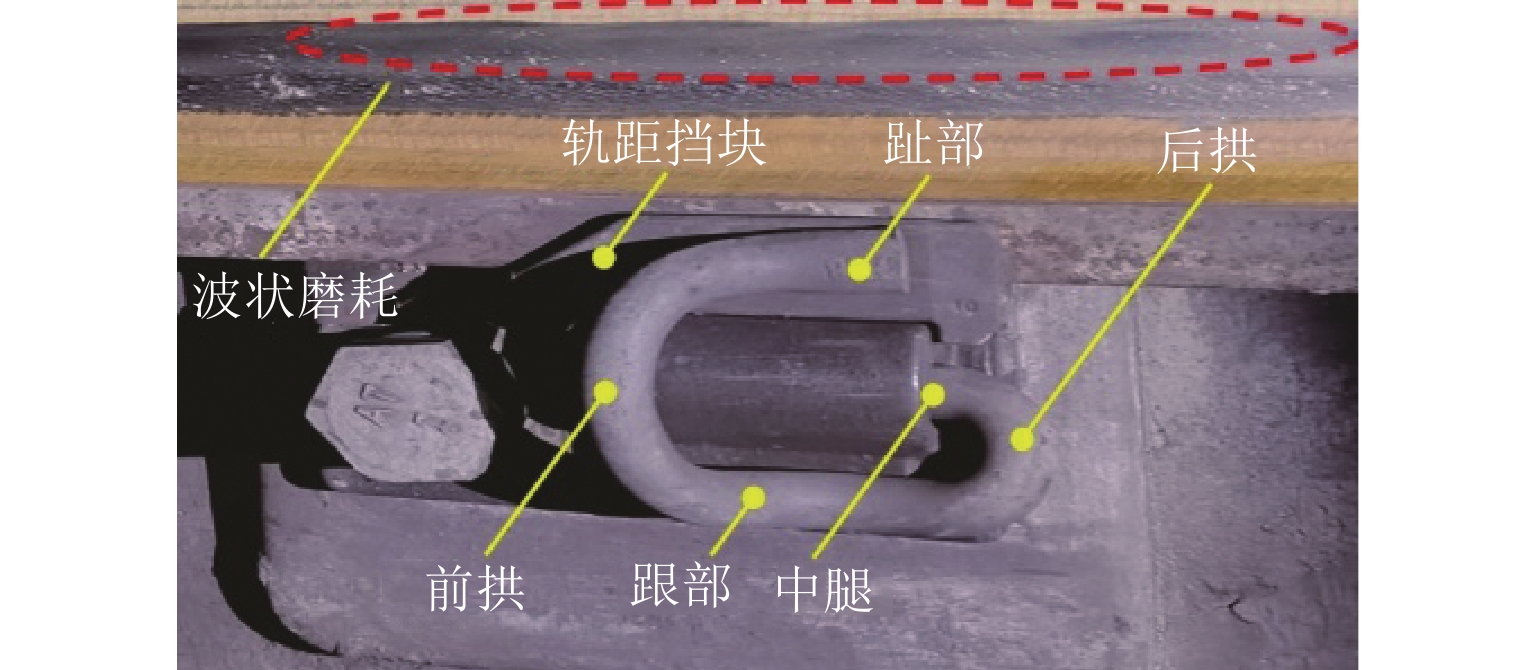

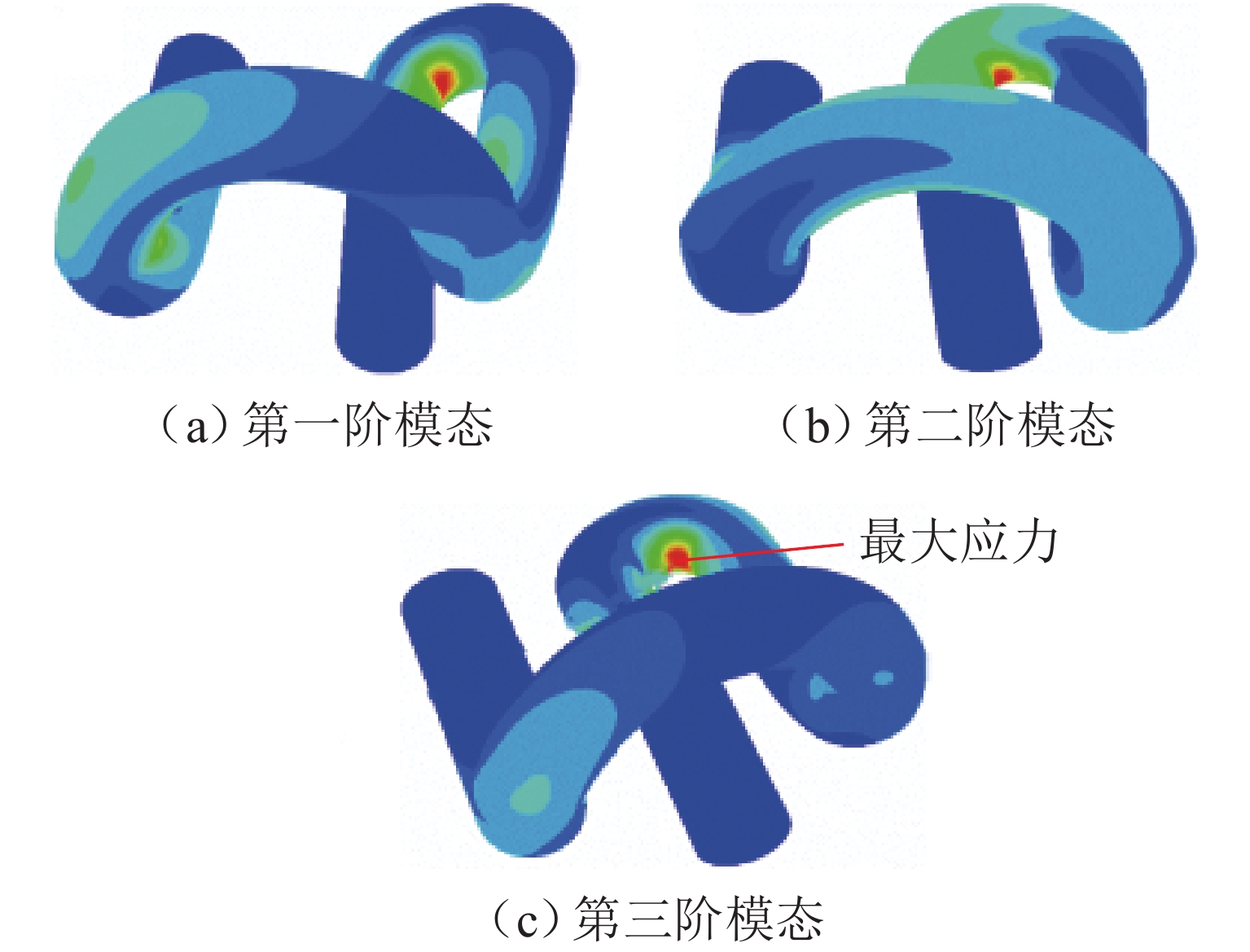

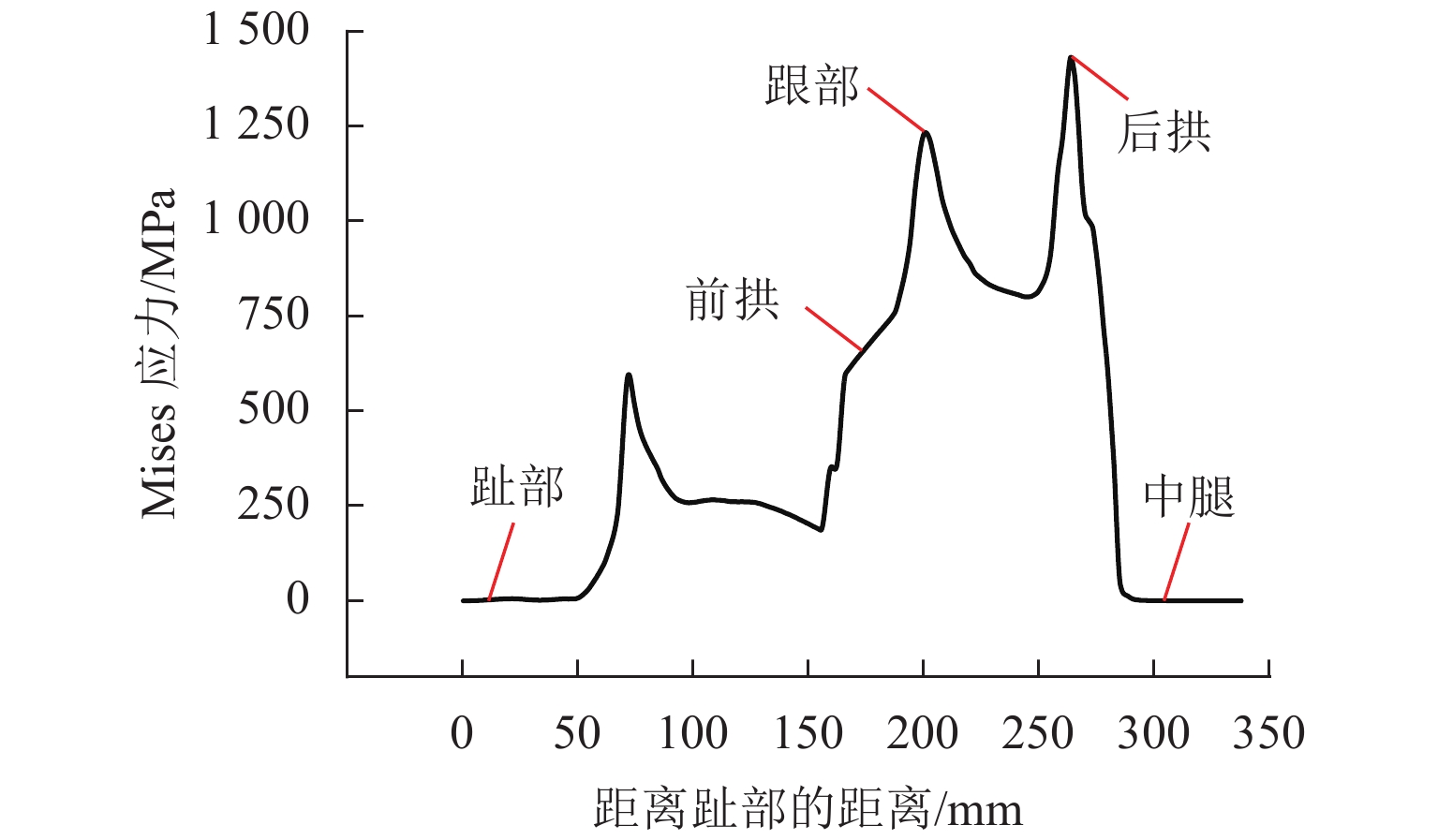

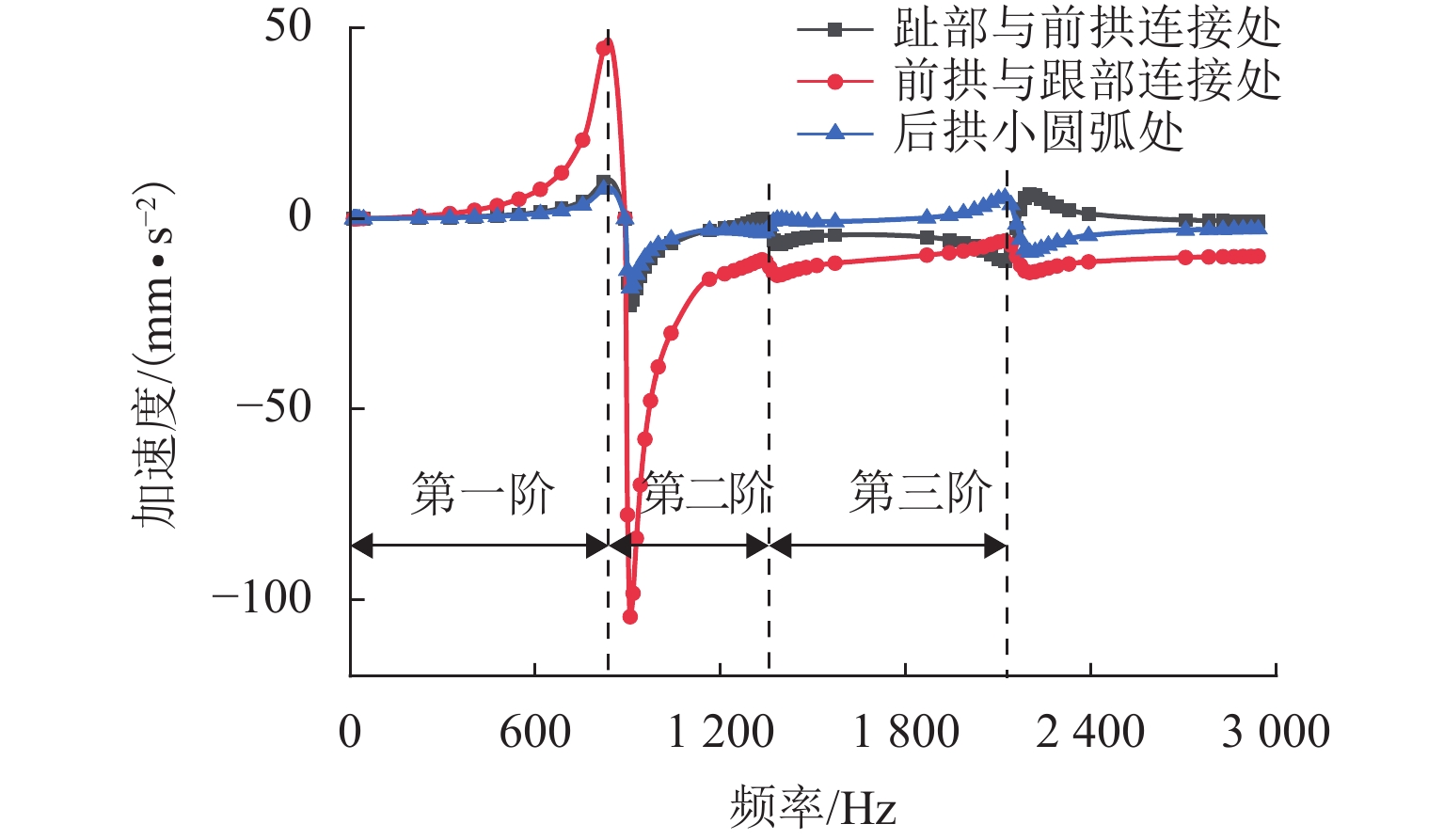

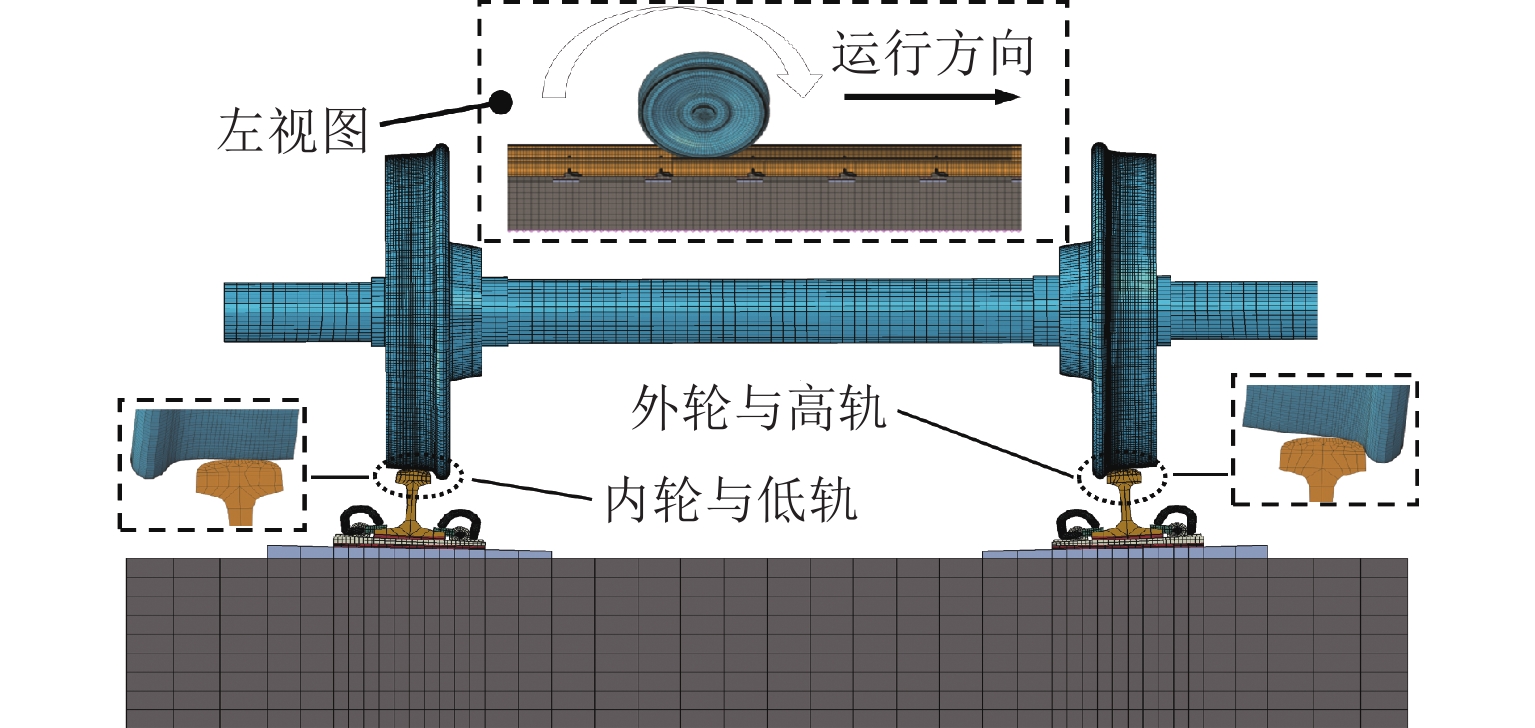

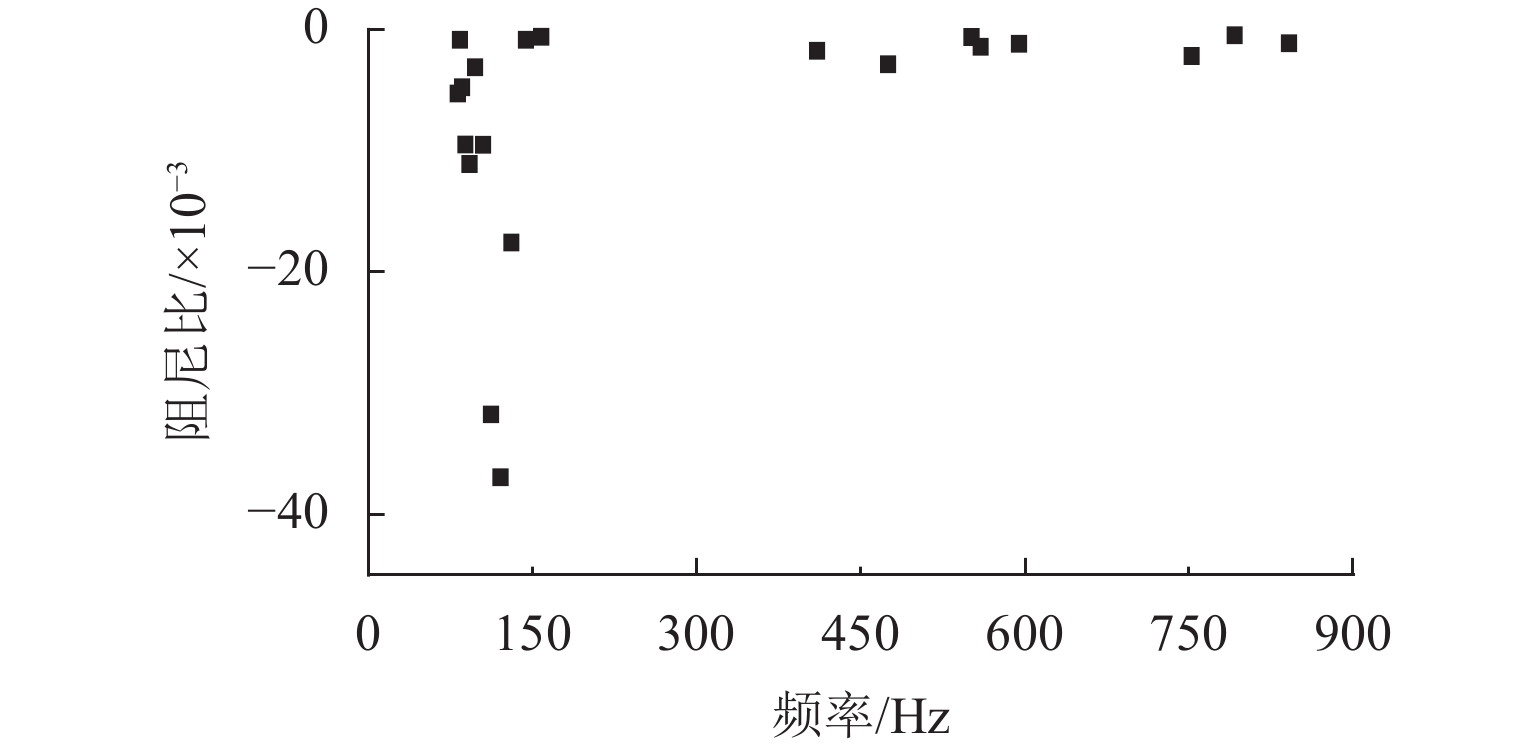

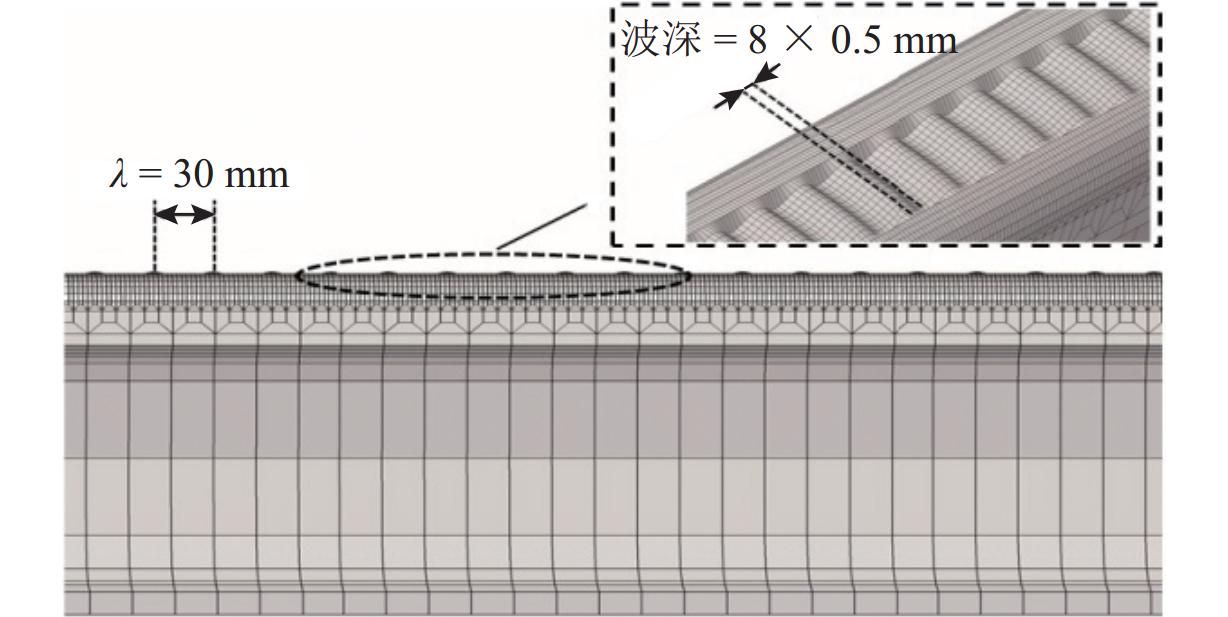

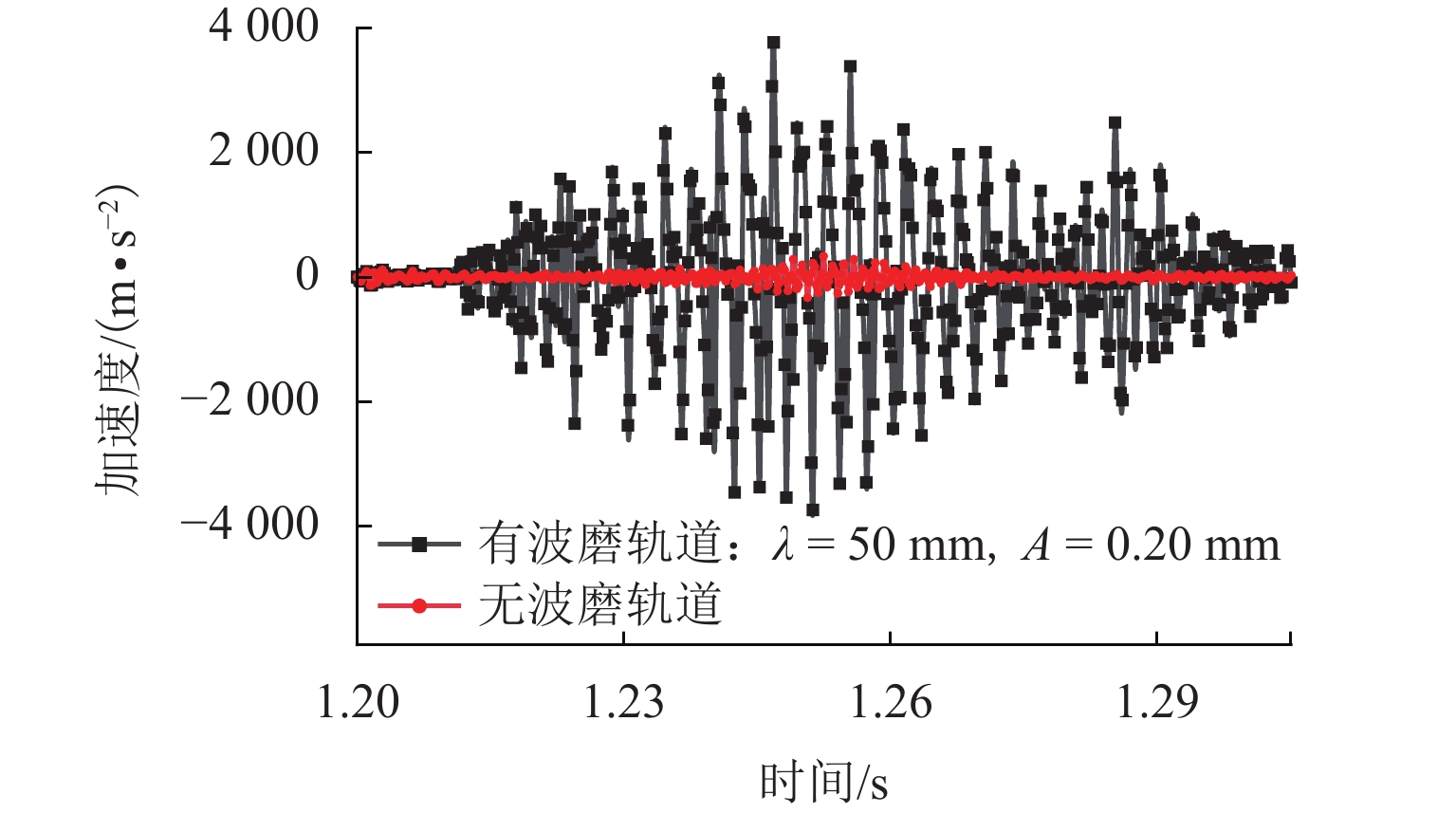

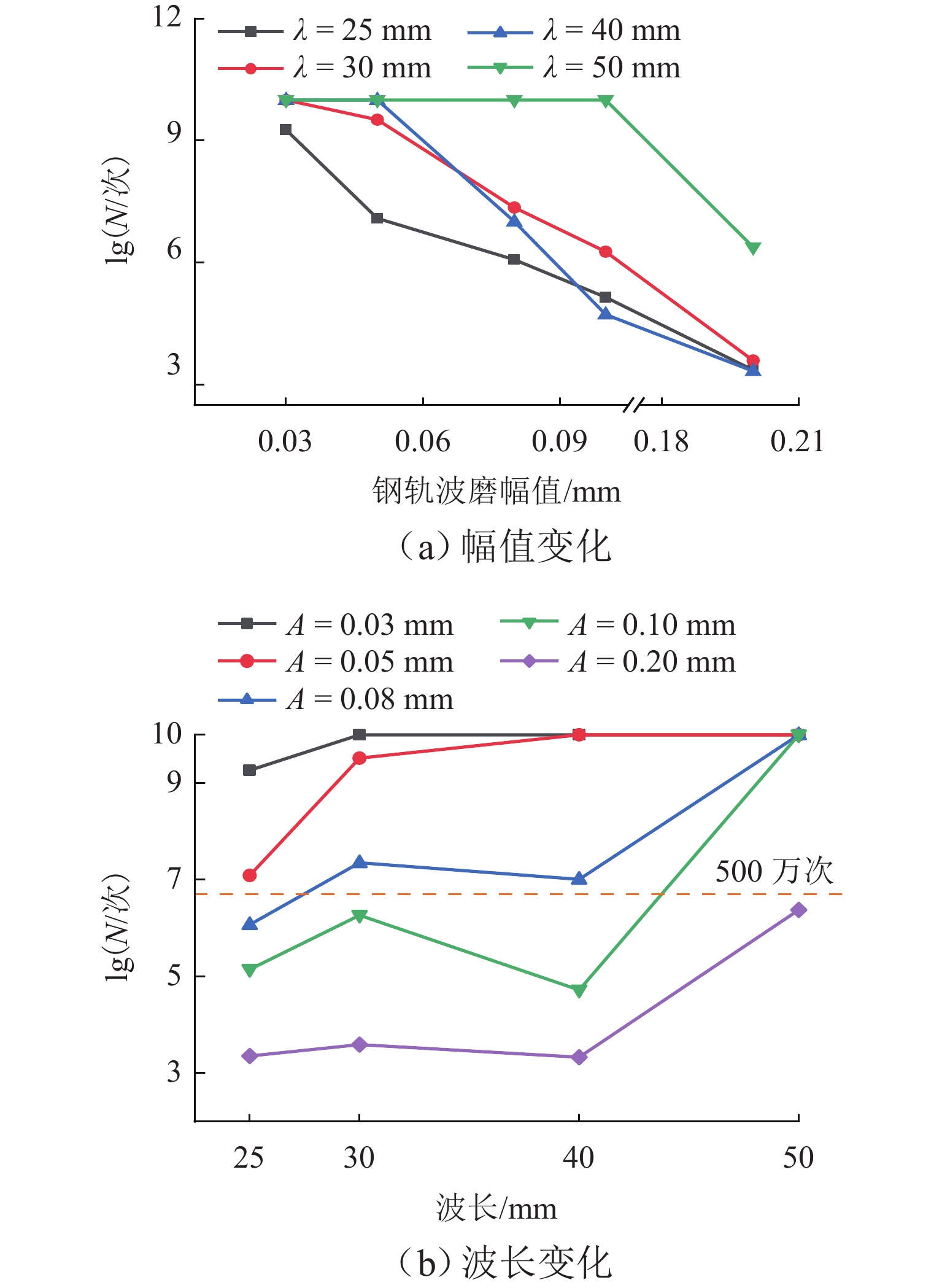

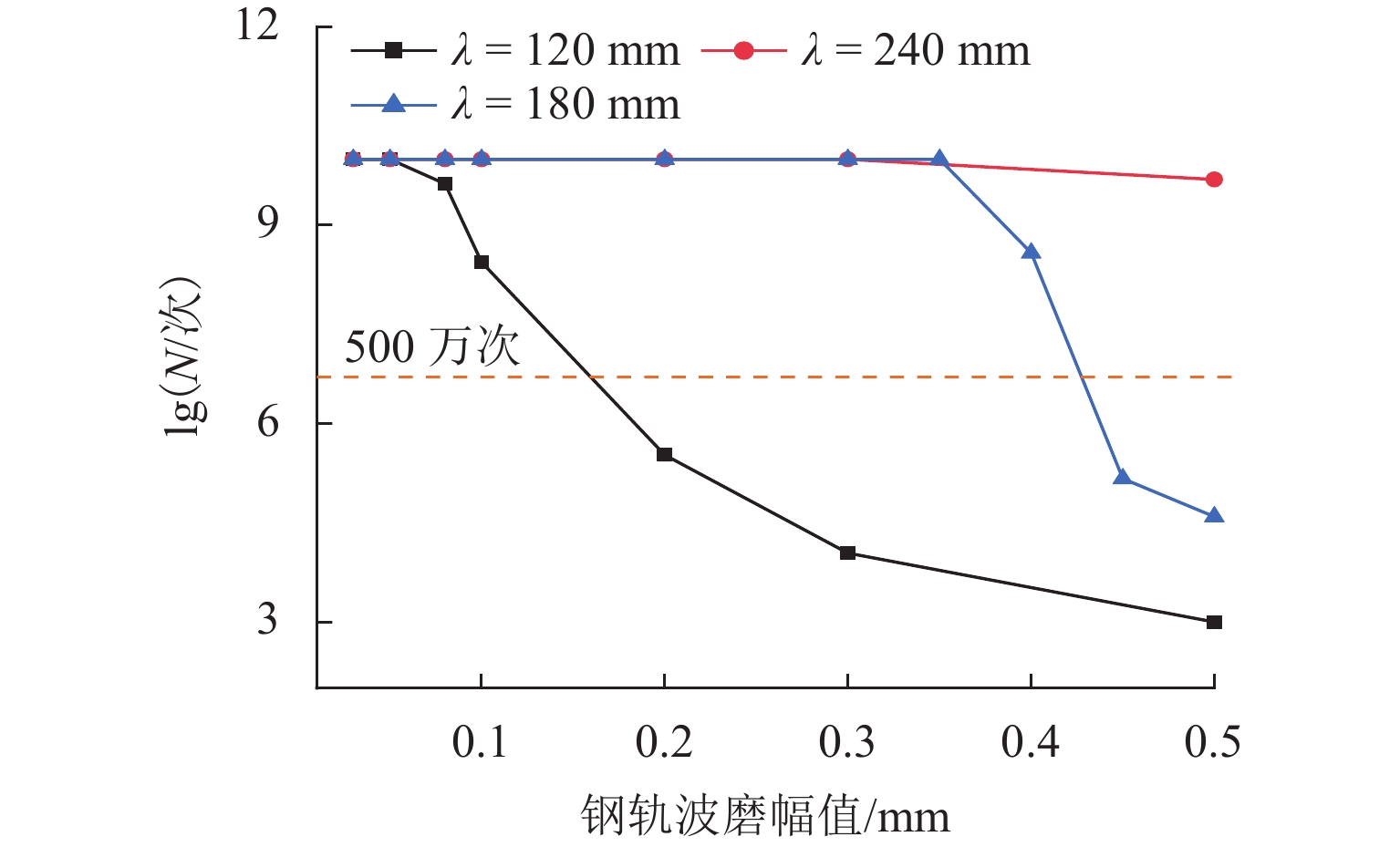

为研究地铁小半径曲线轨道上e型弹条异常断裂的原因,通过长期跟踪和测量成都地铁X号线钢轨波磨的发展情况,并基于摩擦自激振动理论,建立轮对-轨道-扣件系统的全实体单元有限元模型;采用隐式动态分析方法和谐响应分析方法,研究短波长波磨、长波长波磨对e型弹条振动疲劳寿命的影响. 研究表明:这2种类型的钢轨波磨都会导致地铁e型弹条振动疲劳寿命减小;波磨幅值越大,导致弹条振动疲劳寿命越小;钢轨波磨不仅能够引起e型弹条产生与钢轨波磨“同频”的受迫振动,还容易激发弹条产生该频率的倍频振动;对于短波长波磨而言,由于2倍频的存在,在相同波深幅值的短波长波磨影响下,25 mm 和40 mm波长的钢轨波磨最容易导致e型弹条产生振动疲劳断裂;波长为120 mm的长波长波磨的波深幅值较大时,激发出的6倍频振动导致弹条振动疲劳寿命急剧减小;由于振动强度的减弱,波长为240 mm的长波长波磨对弹条振动疲劳寿命的影响有限.

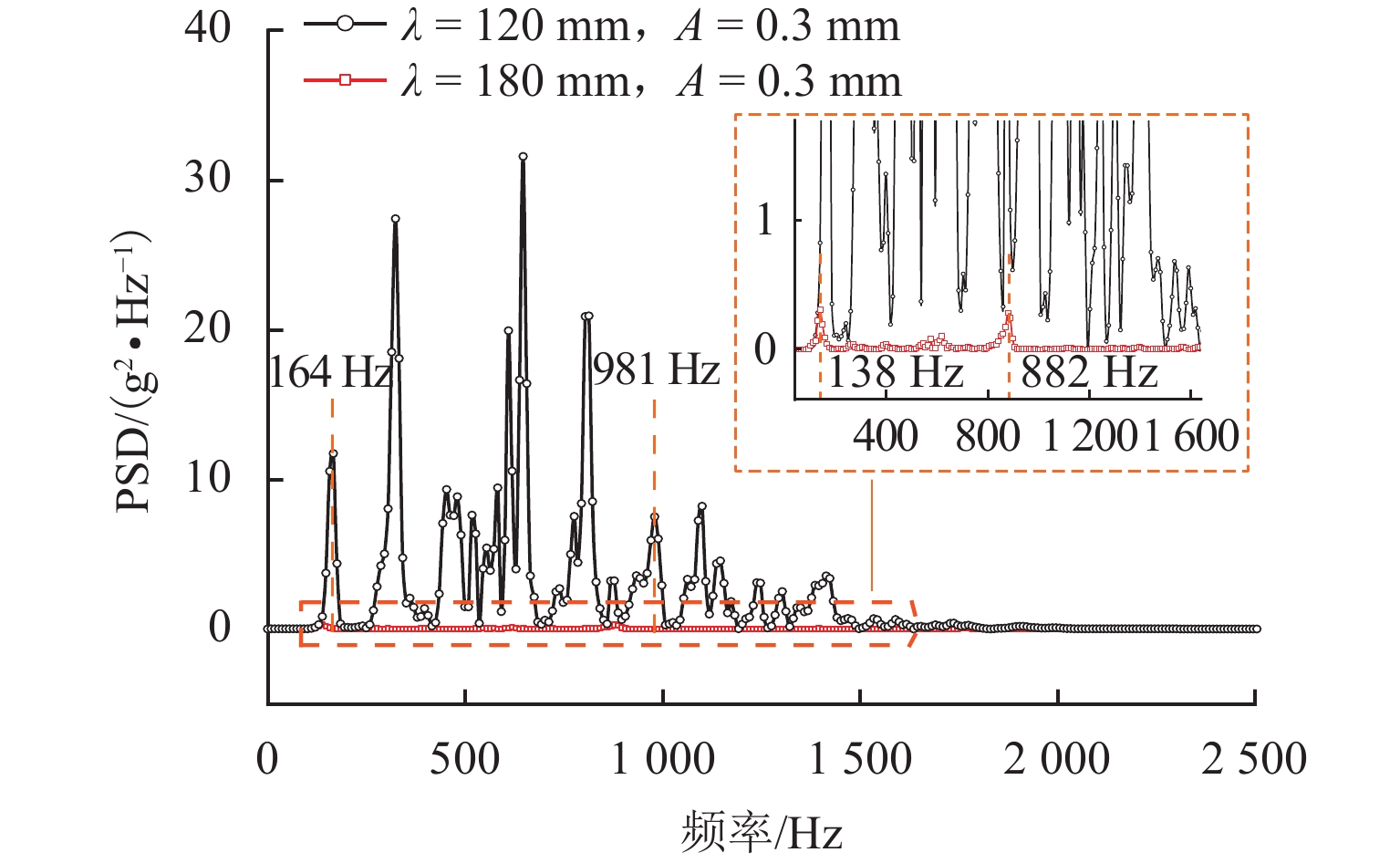

Abstract:To study the reason for the abnormal fracture of e-type clips on small-radius curved subway tracks, the development of rail corrugation on Line X of the Chengdu Metro over an extended period was monitored and measured. Based on the theory of friction-induced self-excited vibration, a comprehensive solid finite element model of the wheelset−rail−fastening system was established. The effects of short-pitch rail corrugation and long-pitch rail corrugation on the vibration fatigue life of e-type clips were studied by means of implicit dynamic analysis and harmonic response analysis. The study reveals that both types of rail corrugation result in a decrease in the vibration fatigue life of the e-type clips. Greater amplitude of rail corrugation indicates shorter vibration fatigue life of the clips. Rail corrugation can not only induce the e-type clip to generate forced vibrations at the frequency matching that of the rail corrugation but also easily trigger vibrations at multiples of this frequency in the e-type clips. For short-pitch rail corrugation, due to the existence of a frequency twice that of the rail corrugation, the rail corrugation with wavelengths of 25 mm and 40 mm is most likely to lead to vibration fatigue failure of the e-type clips under the influence of short-pitch and long-pitch rail corrugation with the same wave depth amplitude. When the wave depth amplitude of long-pitch rail corrugation with a wavelength of 120 mm is large, the vibration fatigue life of the clips decreases sharply due to the excited 6-fold vibration. However, the long-pitch rail corrugation with a wavelength of 240 mm has only a limited impact on the vibration fatigue life of the clips due to the attenuation of vibration intensity.

-

表 1 2段曲线轨道的线路参数

Table 1. Line parameters of two curved tracks

位置 缓和曲线

长度/m超高/

mm曲线

半径/m曲线

长度/m第 1 段 70 85 500 199.280 第 2 段 60 115 350 651.031 表 2 发生在弯轨上的钢轨波磨的位置信息及类型

Table 2. Types and location information of rail corrugation at curved tracks

区段 第 1 次观测

(开通前)第 2 次观测

(空载试运营)第 3 次观测

(开通后2个月)第 4 次观测

(开通后1年)R = 350 m 的曲线轨道低轨 无波磨 短波:

22~25 mm短波:

22~30 mm短波:22~30、40~50 mm,

长波:120~250 mmR = 350 m 的曲线轨道高轨 无波磨 无波磨 无波磨 无波磨 R = 500 m 的曲线轨道高轨和低轨 无波磨 无波磨 无波磨 无波磨 直线轨道 无波磨 无波磨 无波磨 无波磨 表 3 扣件系统的材料参数

Table 3. Material parameters of fastening system

部件 密度/

(g·cm−3)弹性模量/

MPa泊松比 轨距挡块 1.57 8500 0.40 弹条 7.80 2.06 × 105 0.30 铁垫板 7.80 1.73 × 105 0.26 表 4 不同“低通信号”下的e型弹条振动疲劳寿命

Table 4. Vibration fatigue life of e-type clips under influence of different “low-pass signals”

信号 振动疲劳寿命/(×106 次) 完整信号 1.180 2.0 kHz“低通” 1.185 1.2 kHz“低通” 2.637 -

[1] COLLETTE C, VANHONACKER P, BASTAITS R, et al. Comparison between time and frequency studies of a corrugated curve of RER Paris network[J]. Wear, 2008, 265(9): 1249-1258. [2] TORSTENSSON P T, NIELSEN J C O. Monitoring of rail corrugation growth due to irregular wear on a railway metro curve[J]. Wear, 2009, 267(1/2/3/4): 556-561. [3] CARLBERGER A, TORSTENSSON P T, NIELSEN J C, et al. An iterative methodology for the prediction of dynamic vehicle–track interaction and long-term periodic rail wear[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2018, 232(6): 1718-1730. doi: 10.1177/0954409717747127 [4] 陈光雄. 钢轨波磨预测模型验证工况的研究[J]. 西南交通大学学报, 2022, 57(5): 1017-1023, 1054.CHEN Guangxiong. Study on validation conditions of rail corrugation prediction models[J]. Journal of Southwest Jiaotong University, 2022, 57(5): 1017-1023, 1054. [5] ZHANG H G, LIU W N, LIU W F, et al. Study on the cause and treatment of rail corrugation for Beijing metro[J]. Wear, 2014, 317(1/2): 120-128. [6] GRASSIE S L, KALOUSEK J. Rail corrugation: characteristics, causes and treatments[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 1993, 207(1): 57-68. doi: 10.1243/PIME_PROC_1993_207_227_02 [7] GRASSIE S L. Rail corrugation: characteristics, causes, and treatments[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2009, 223(6): 581-596. doi: 10.1243/09544097JRRT264 [8] OOSTERMEIJER K H. Review on short pitch rail corrugation studies[J]. Wear, 2008, 265(9/10): 1231-1237. [9] VALEHRACH J, GUZIUR P, RIHA T, et al. Assessment of rail long-pitch corrugation[J]. IOP Conference Series: Materials Science and Engineering, 2017, 236: 012048.1-012048.8. [10] 杜茂金. 南京地铁DT Ⅵ2型扣件弹条折断原因分析[J]. 城市轨道交通研究, 2009, 12(7): 40-42.DU Maojin. Analysis of DT Ⅵ2 type fastener broken shells in Nanjing metro[J]. Urban Mass Transit, 2009, 12(7): 40-42. [11] 肖宏, 马春生, 郭骁, 等. e型扣件弹条断裂原因频谱分析[J]. 同济大学学报(自然科学版), 2017, 45(7): 1000-1008.XIAO Hong, MA Chunsheng, GUO Xiao, et al. Fractures of e-type fastening clip by spectral analysis method[J]. Journal of Tongji University (Natural Science), 2017, 45(7): 1000-1008. [12] LING L, LI W, SHANG H X, et al. Experimental and numerical investigation of the effect of rail corrugation on the behaviour of rail fastenings[J]. Vehicle System Dynamics, 2014, 52(9): 1211-1231. doi: 10.1080/00423114.2014.934844 [13] WANG P, LU J, ZHAO C Y, et al. Numerical investigation of the fatigue performance of elastic rail clips considering rail corrugation and dynamic axle load[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2020, 235(3): 339-352. [14] XIAO H, WANG J B, ZHANG Y R. The fractures of e-type fastening clips used in the subway: theory and experiment[J]. Engineering Failure Analysis, 2017, 81: 57-68. doi: 10.1016/j.engfailanal.2017.07.006 [15] XIAO H, GUO X, WANG H Y, et al. Fatigue damage analysis and life prediction of e-clip in railway fasteners based on ABAQUS and FE-SAFE[J]. Advances in Mechanical Engineering, 2018, 10(3): 1-12. [16] MA D K, SHI J, YAN Z Q, et al. Experimental and numerical investigation of the effect of the assembled state on the static-dynamic characteristics and fatigue performance of railway fastening clips[J]. Structures, 2022, 46: 1808-1822. doi: 10.1016/j.istruc.2022.11.038 [17] HASAP A, PAITEKUL P, NORAPHAIPHIPAKSA N, et al. Influence of toe load on the fatigue resistance of elastic rail clips[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2018, 232(4): 1078-1087. doi: 10.1177/0954409717707834 [18] HASAP A, PAITEKUL P, NORAPHAIPHIPAKSA N, et al. Analysis of the fatigue performance of elastic rail clip[J]. Engineering Failure Analysis, 2018, 92: 195-204. doi: 10.1016/j.engfailanal.2018.05.013 [19] 崔晓璐, 彭双千, 徐佳, 等. 钢轨波磨区段科隆蛋扣件弹条断裂机理[J]. 西南交通大学学报, 2025, 60(1): 205-213.CUI Xiaolu, PENG Shuangqian, XU Jia, et al. Fracture mechanism of cologne-egg fastener clips in rail corrugation sections[J]. Journal of Southwest Jiaotong University, 2025, 60(1): 205-213. [20] SADEGHI J, SEYEDKAZEMI M, KHAJEHDEZFULY A. Nonlinear simulation of vertical behavior of railway fastening system[J]. Engineering Structures, 2020, 209(C): 110340.13-110340.13. [21] 徐井芒, 梁新缘, 王凯, 等. 扣件刚度非线性对波磨区轮轨瞬态滚动接触行为影响研究[J]. 西南交通大学学报, 2024, 59(2): 1-8.XU Jingmang, LIANG Xinyuan, WANG Kai, et al. Influence of fastener stiffness nonlinearity on wheel-rail transient rolling contact behavior in corrugated area[J]. Journal of Southwest Jiaotong University, 2024, 59(2): 1-8. [22] WANG Z Q, LEI Z Y, ZHAO Y, et al. Rail corrugation characteristics of cologne egg fastener section in small radius curve[J]. Shock and Vibration, 2020, 2020: 1-12. [23] LIU X G, WANG P. Investigation of the generation mechanism of rail corrugation based on friction induced torsional vibration[J]. Wear, 2021, 468/469: 203593. [24] GRASSIE S L. Rail corrugation: a problem solved?[J]. Wear, 2023, 530/531(9/10): 1-8. [25] DONG B J, CHEN G X, SONG Q F, et al. Study on long-term tracking of rail corrugation and the influence of parameters[J]. Wear, 2023, 523(1-2): 1-13. [26] SUN L L, YAN Z Q, XIAO J H, et al. Experimental analysis of the modal characteristics of rail fastening clips[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2019, 234(2): 134-141. [27] OREGUI M, LI Z, DOLLEVOET R. Identification of characteristic frequencies of damaged railway tracks using field hammer test measurements[J]. Mechanical Systems and Signal Processing, 2015, 54/55: 224-242. doi: 10.1016/j.ymssp.2014.08.024 [28] KINKAID N, O’REILLY O, PAPADOPOULOS P. Automotive disc brake squeal[J]. Journal of Sound and Vibration, 2003, 267(1): 105-166. doi: 10.1016/S0022-460X(02)01573-0 [29] 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 弹簧钢: GB/T 1222—2016[S]. 北京: 中国标准出版社, 2016. [30] CUI X L, BAO P Y, LI Tong, et al. Research on the failure mechanism of elastic strip fracture in corrugated sections of metros[J]. Engineering Failure Analysis, 2023, 143: 1-12. -

下载:

下载: