Influence of Braking Conditions on Residual Stress and Warping Deformation of Brake Discs of High-Speed Trains

-

摘要:

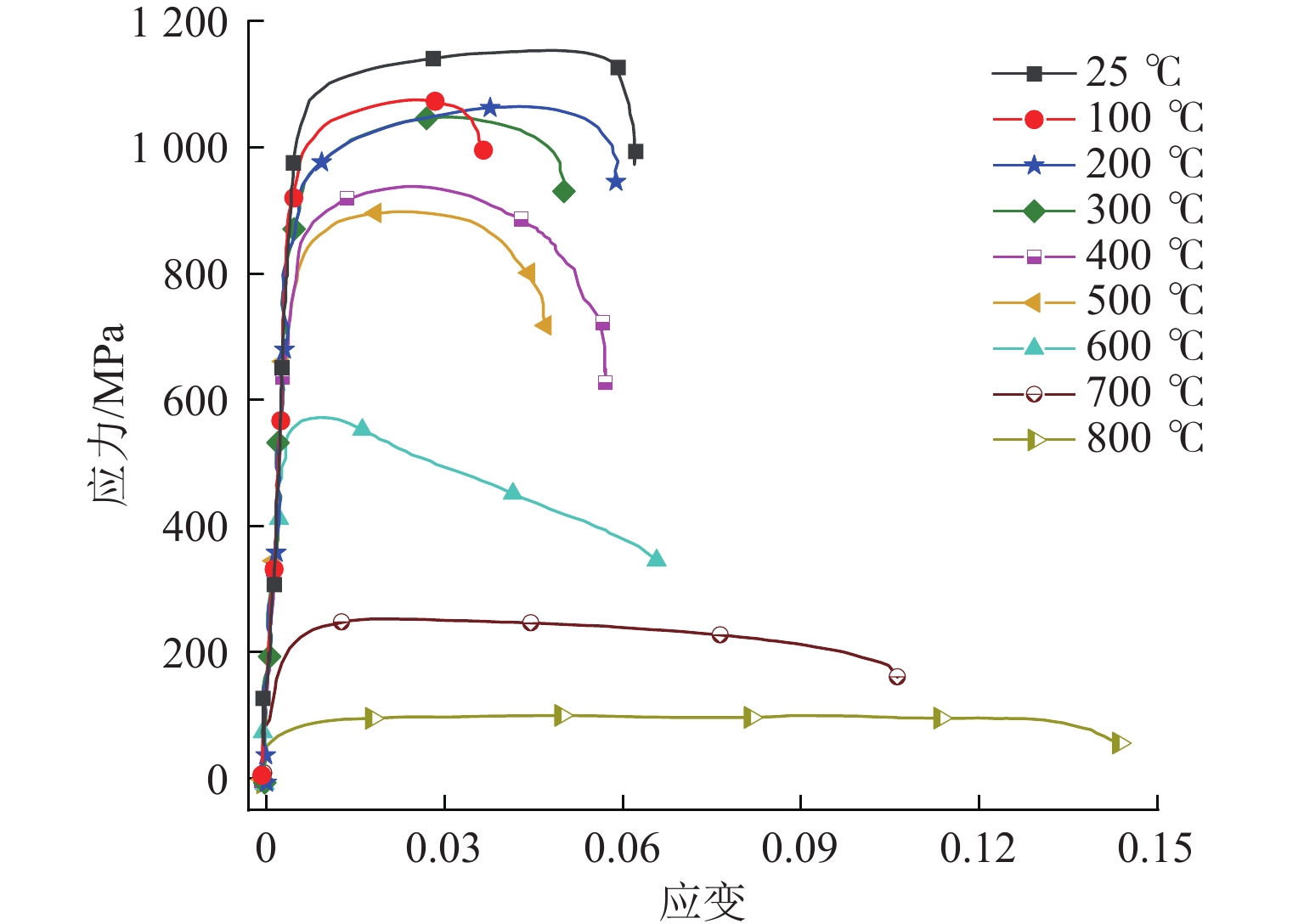

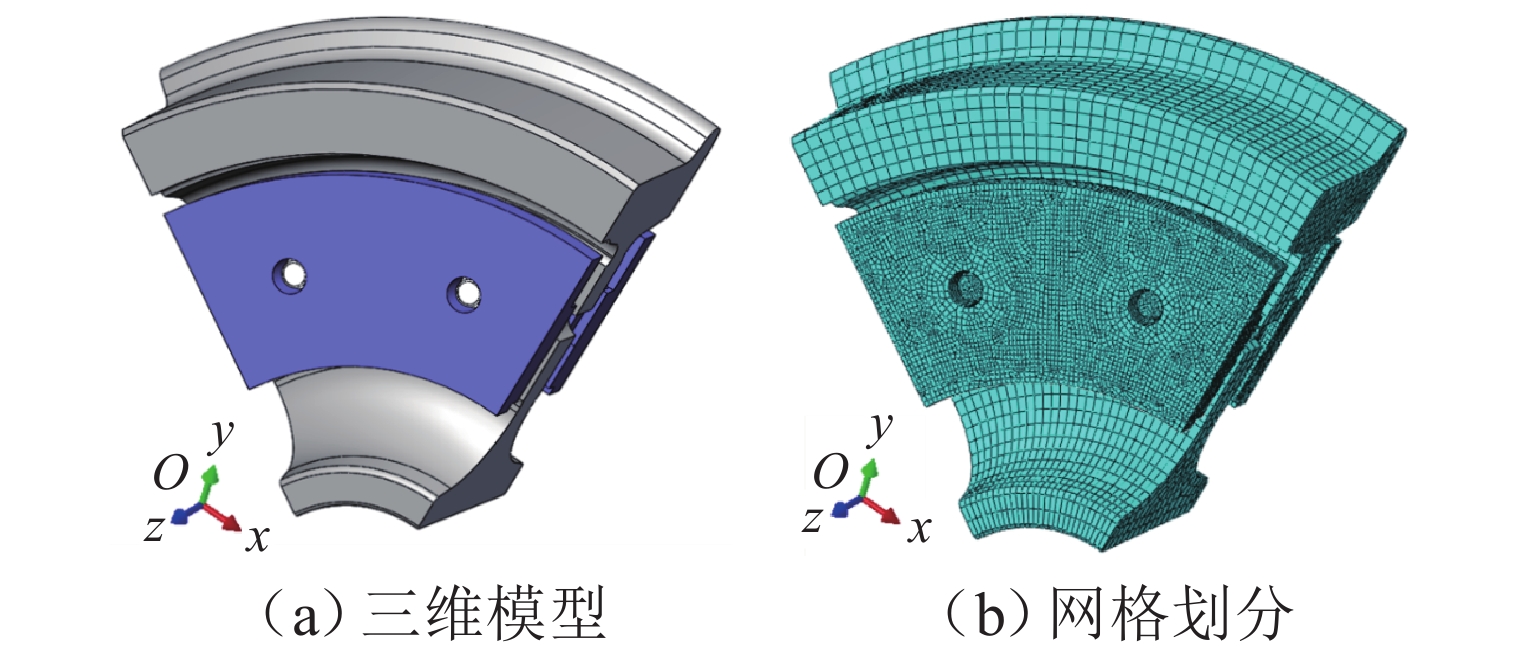

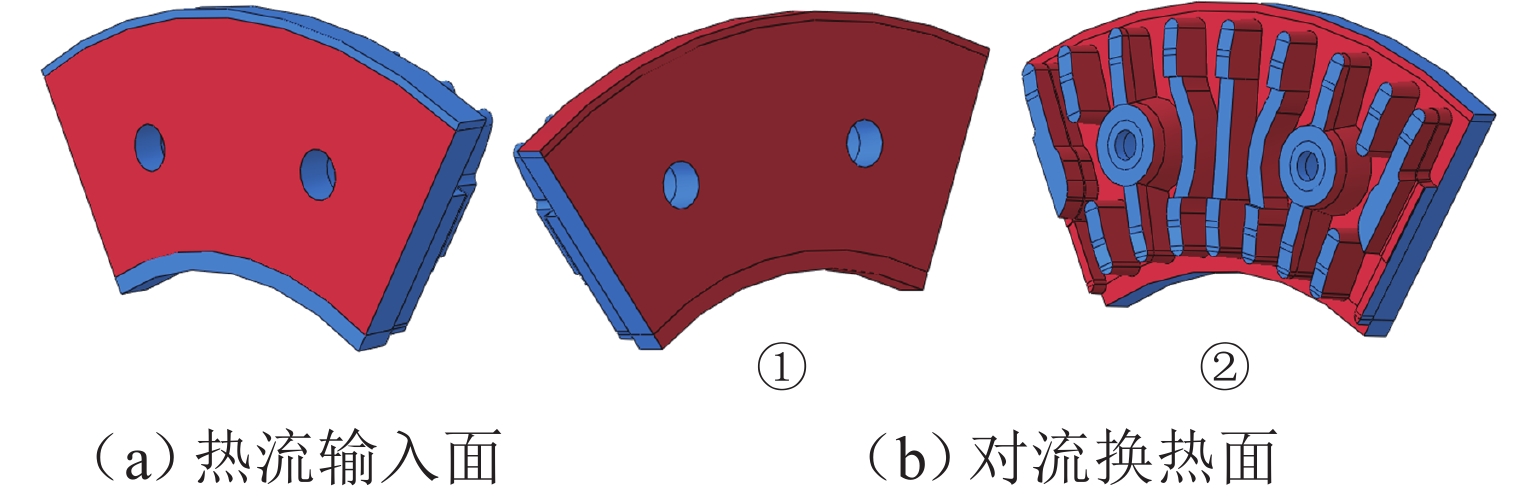

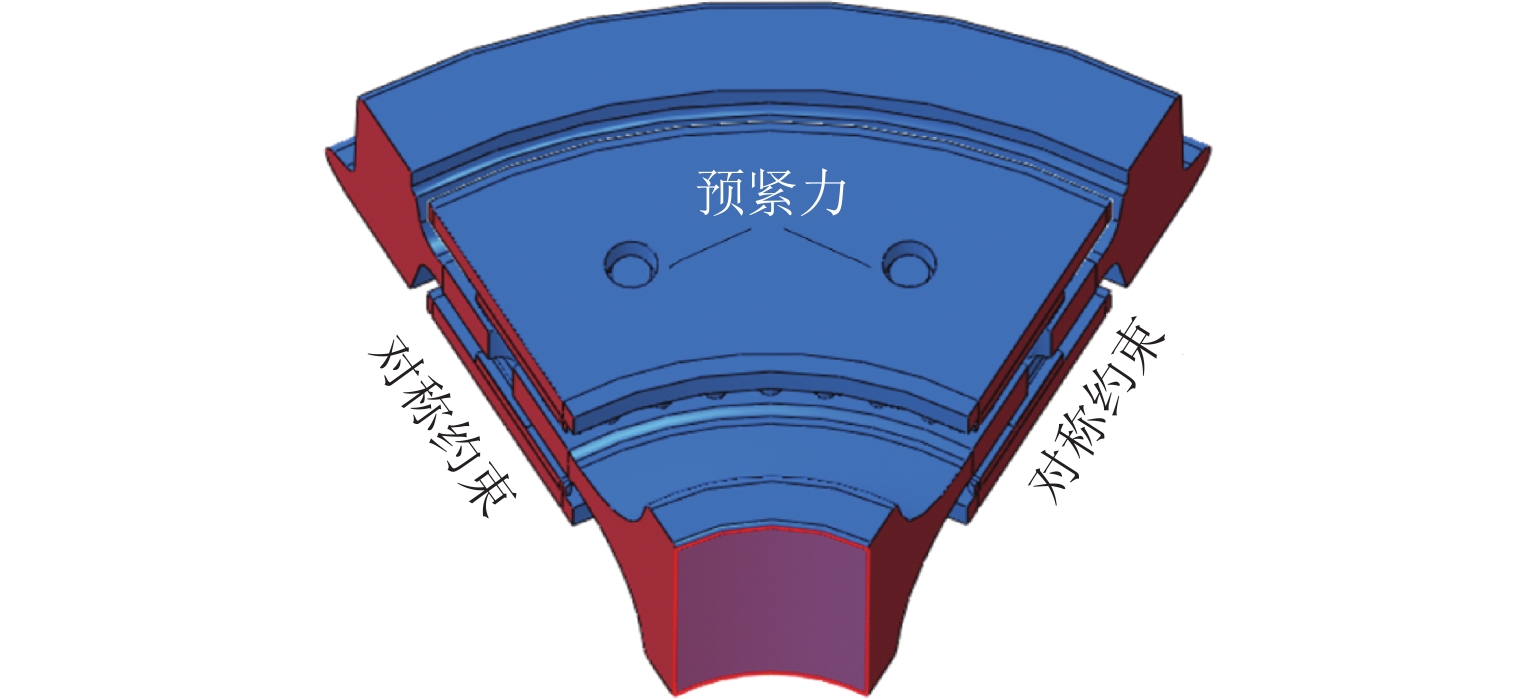

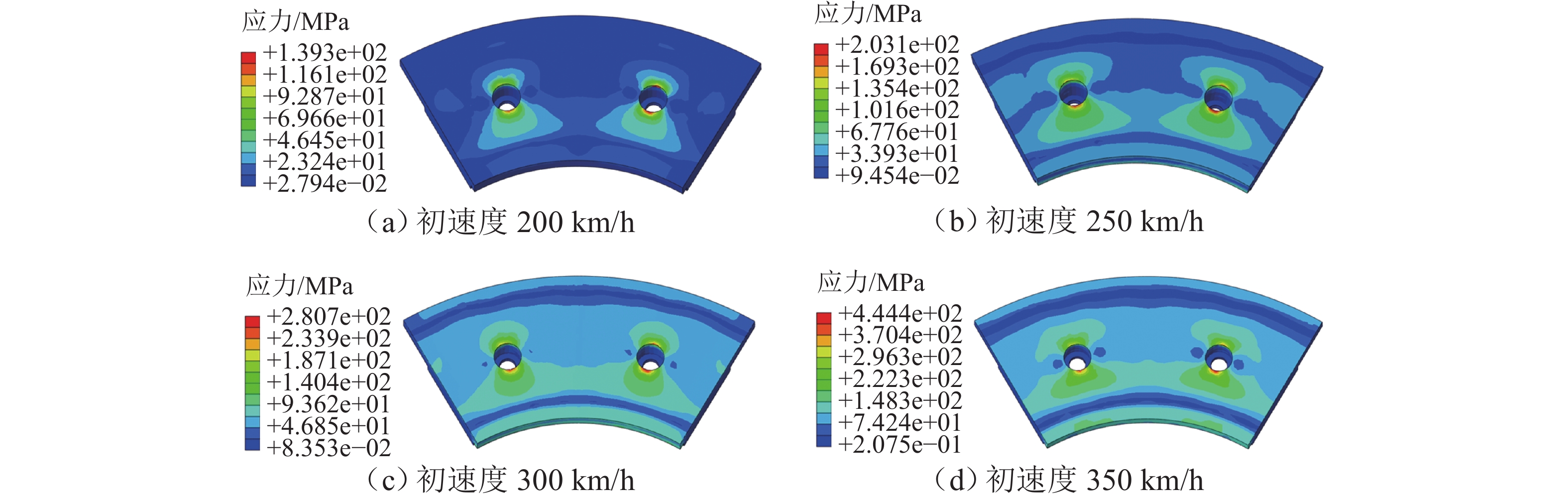

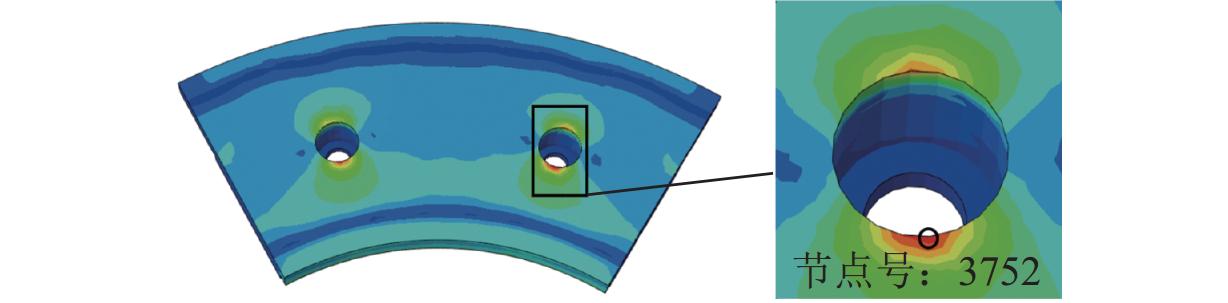

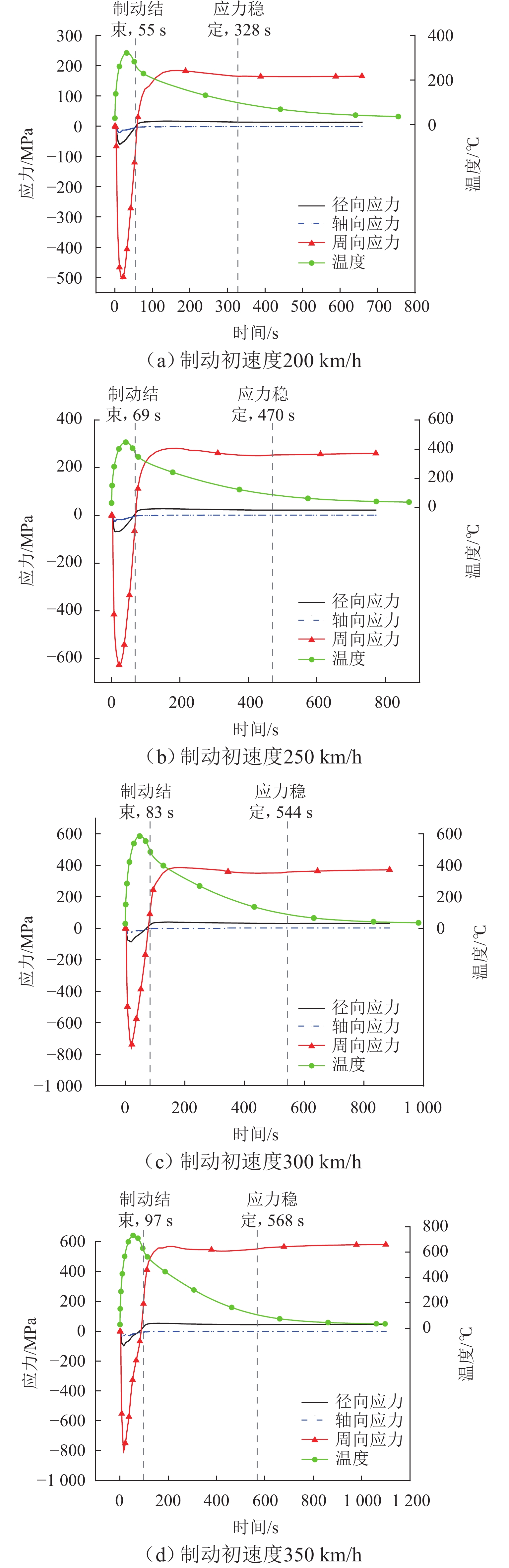

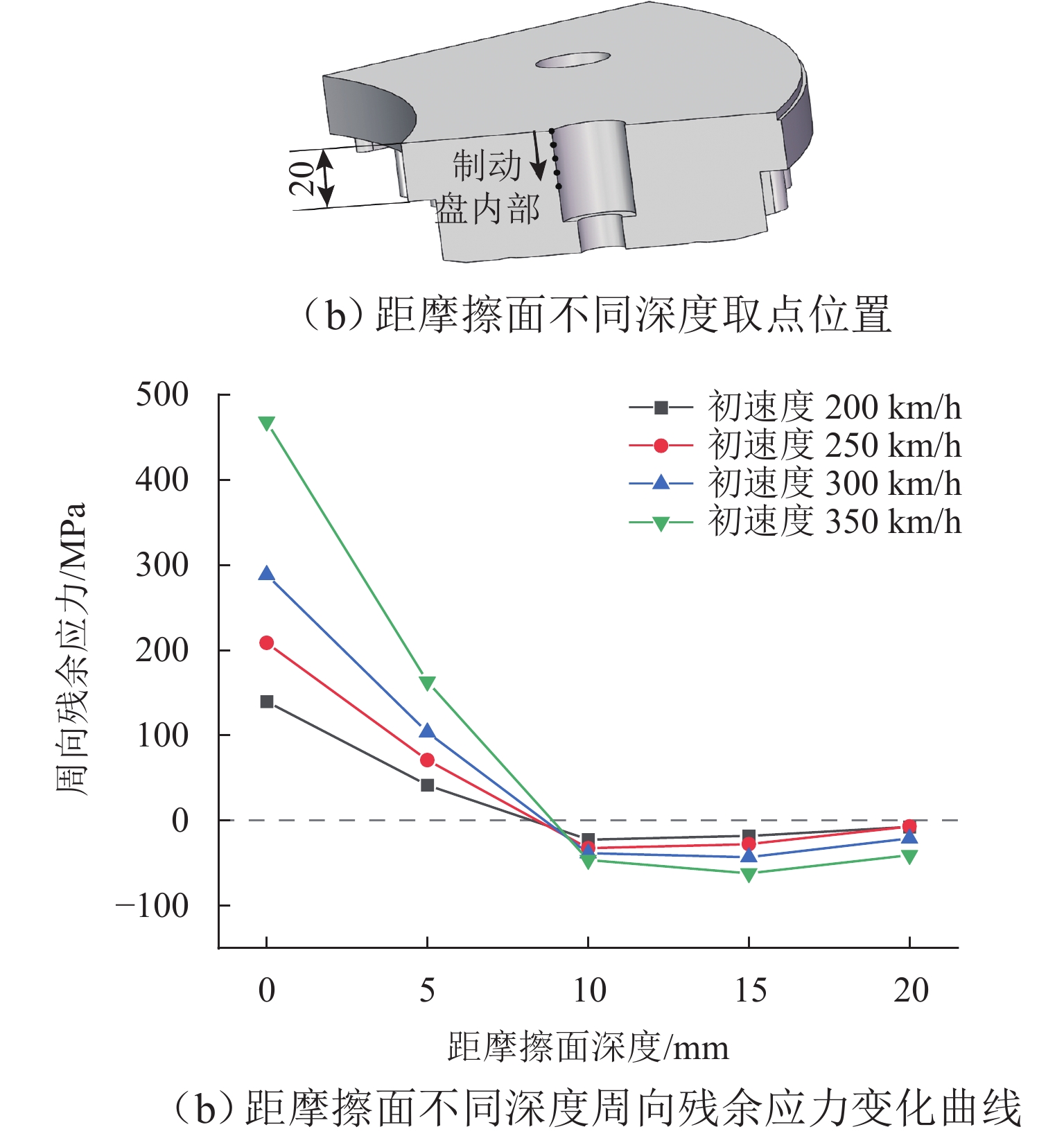

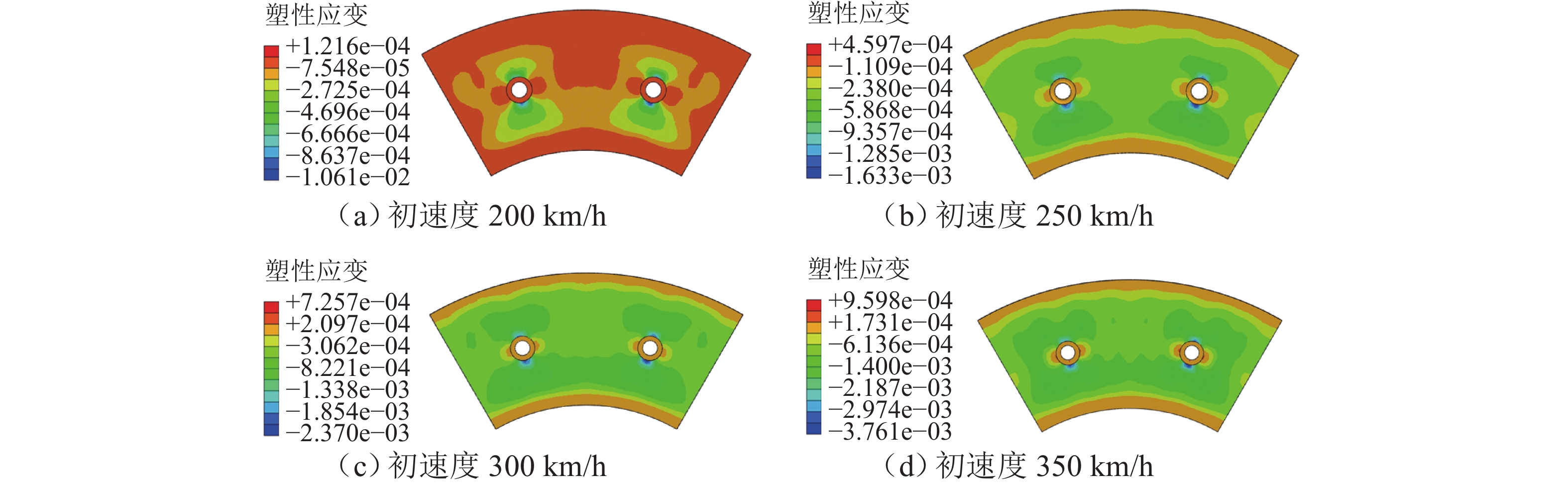

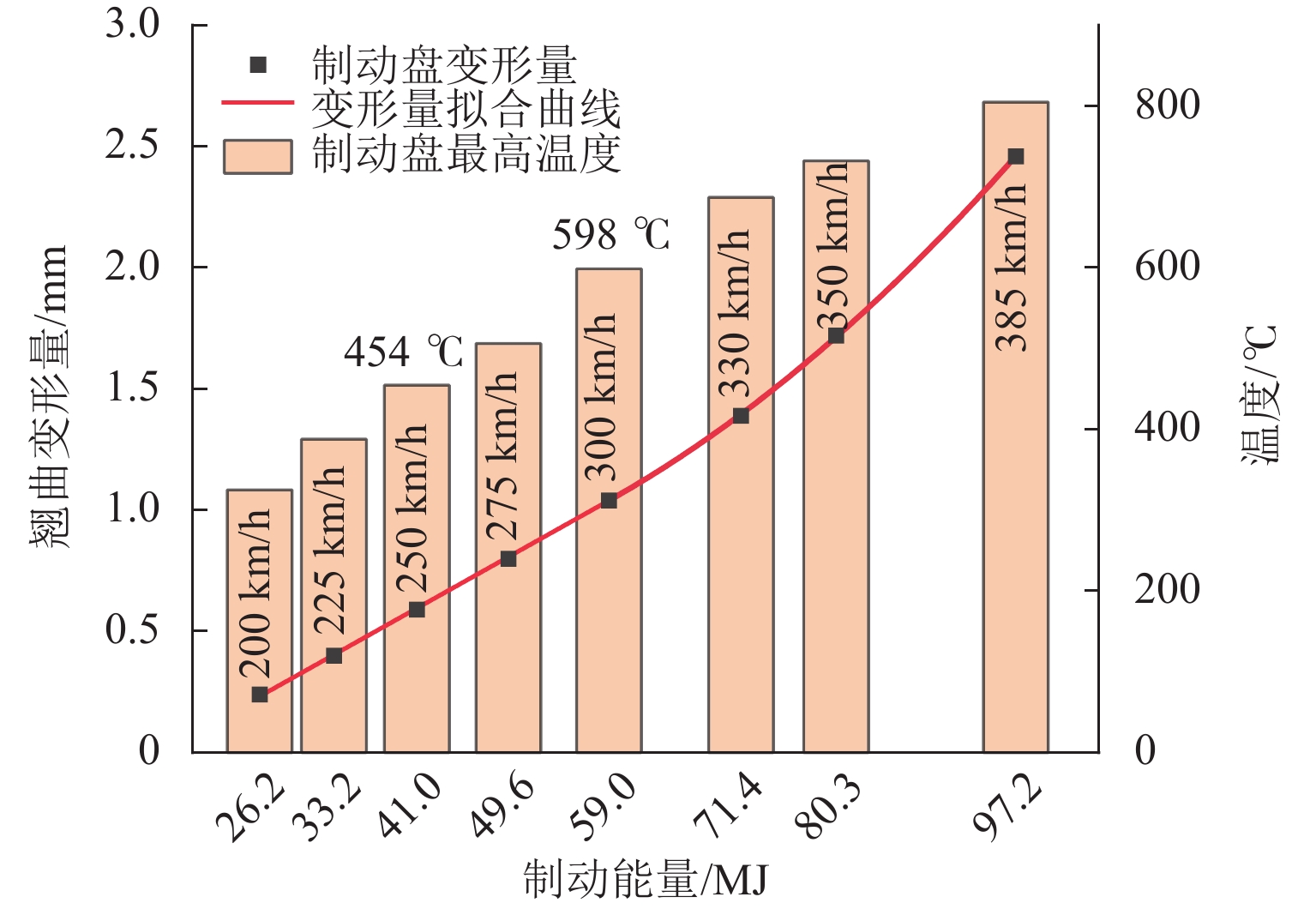

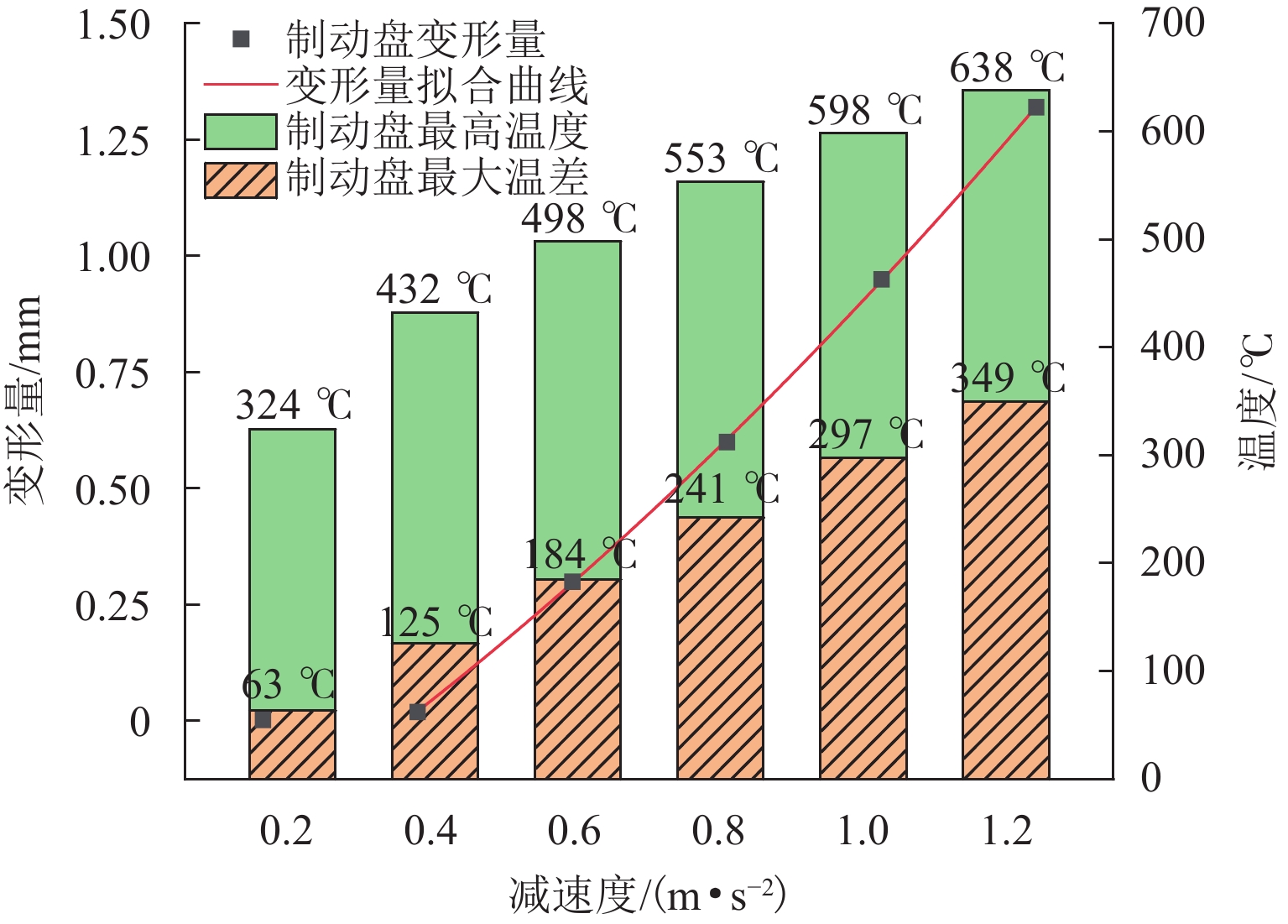

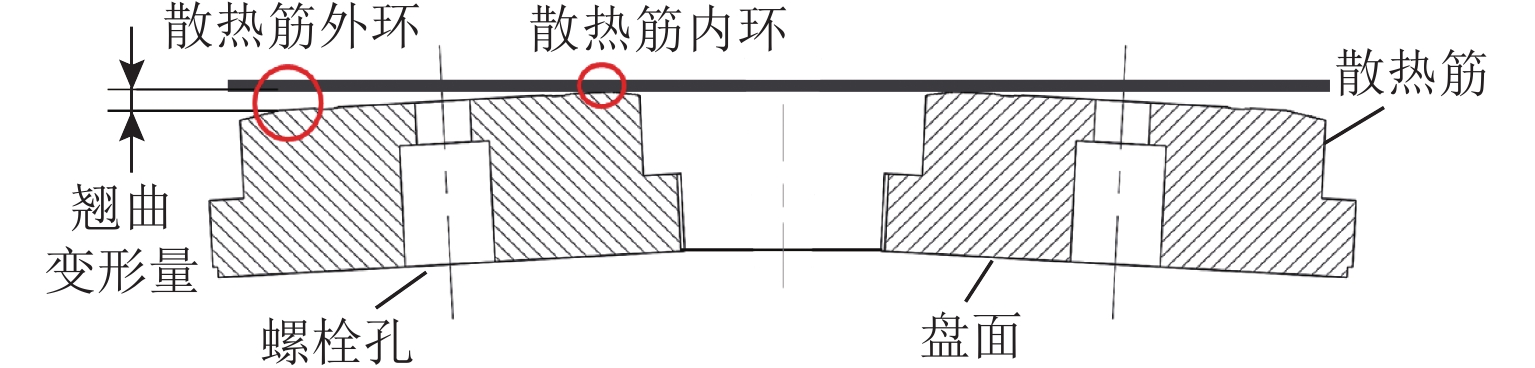

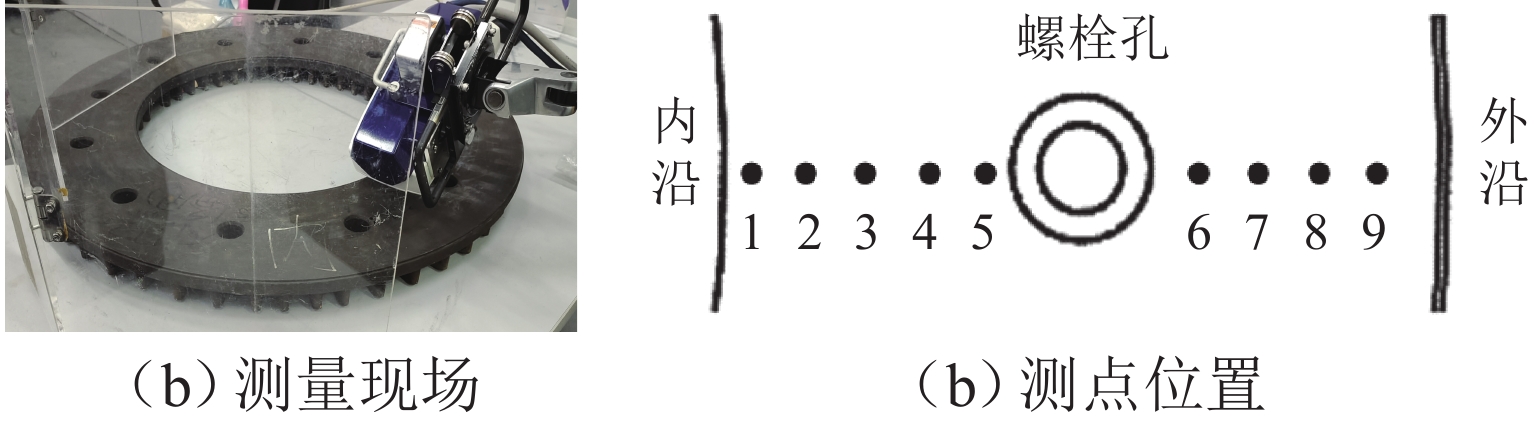

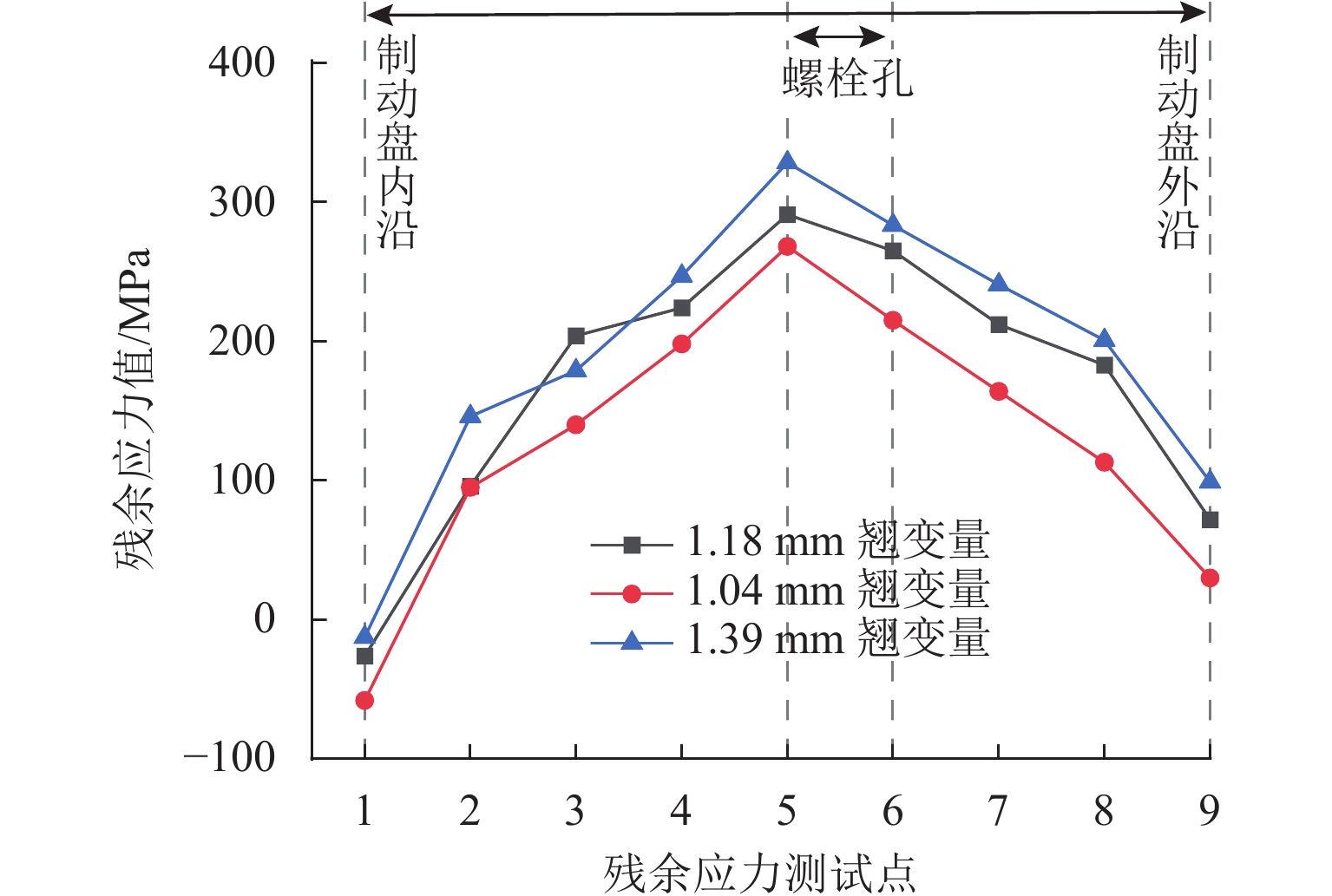

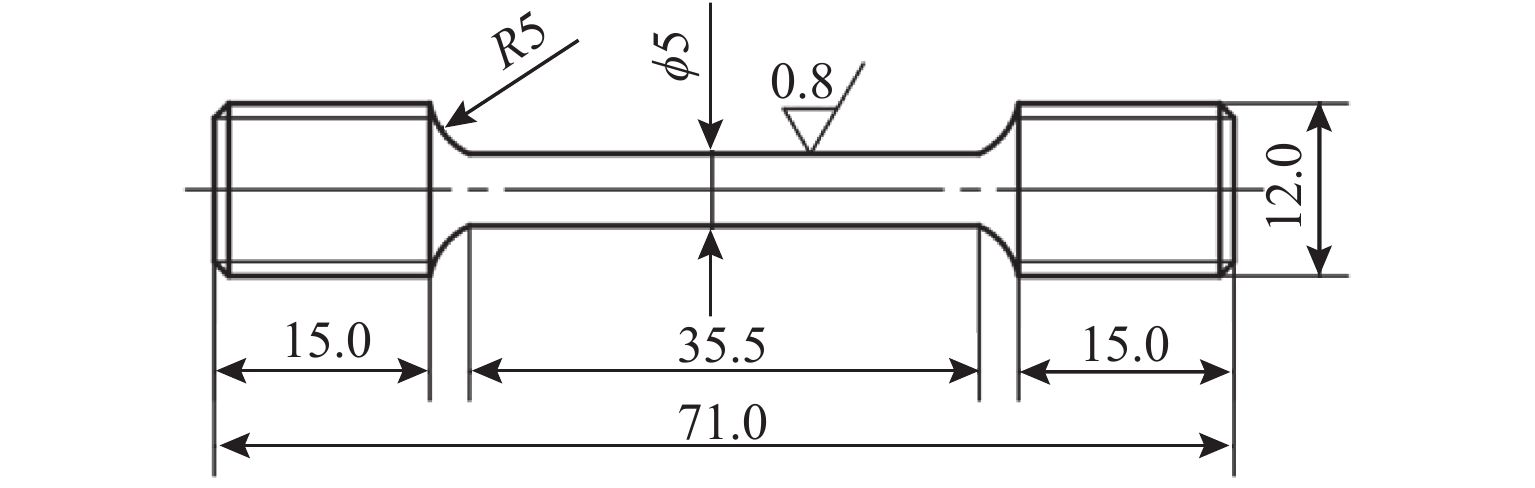

动车组制动盘在长期服役过程中会形成复杂的残余应力,进而使盘体在拆解后形成不可恢复的翘曲变形,为探究残余应力与翘曲变形对制动盘后续维修和重复利用可行性的影响,首先,通过测试动车组轮装铸钢制动盘材料不同温度下的拉伸应力-应变数据,构建对应的材料Ramberg-Osgood本构模型,在有限元软件中建立制动盘循环对称三维瞬态仿真模型;其次,针对列车不同制动初速度、不同平均减速度等制动工况,采用间接耦合方法分析制动盘表层与心部残余应力的形成与平衡过程,研究制动盘结构约束释放后的翘曲变形量变化,采用分段函数与多项式拟合制动盘变形量与制动能量、热输入功率的函数关系;最后,通过对服役后的制动盘进行翘曲变形量测量与X射线残余应力测试,对比分析了对应仿真条件时制动盘摩擦面残余应力分布规律,发现仿真结果与实测数据具有较好的数据和趋势一致性. 研究表明:制动盘翘曲变形量与制动能量、制动减速度呈正相关关系,制动工况越严苛制动盘翘曲变形量越大;仿真与实测均表明高残余拉应力位于摩擦面中部螺栓孔附近,且制动工况越严苛残余拉应力值越大.

Abstract:The brake disc of electric multiple units (EMUs) will form complex residual stress during long-term service, which will lead to irreversible warping deformation after disassembly. In order to investigate the influence of residual stress and warping deformation on the feasibility of subsequent maintenance and reuse of brake discs, firstly, the Ramberg-Osgood constitutive model of corresponding materials was constructed by testing the tensile stress-strain data of cast steel for wheel-mounted brake discs of EMUs at different temperatures. A cyclically symmetric three-dimensional transient numerical simulation model of brake discs was established in finite element software. Secondly, the formation and balance process of residual stress in the surface and center of the brake disc were analyzed by indirect coupling method for different braking conditions considering different initial braking speeds and different average decelerations of the train. The change in warping deformation of the brake disc after structural constraint release was studied. The functional relationship between brake disc deformation and braking energy and heat input power was fitted by piecewise function and polynomial. Finally, by measuring the warping deformation and testing the X-ray residual stress of the brake disc after service, the residual stress distribution law on the friction surface of the brake disc under the corresponding simulation condition was compared. The simulation results had good data and trend consistency with the measured data. The study reveals that the warping deformation of the brake disc is positively correlated with braking energy and braking deceleration. More severe braking condition indicates greater warping deformation of the brake disc. The simulation and measurement show that the high residual tensile stress is located in the middle of the friction surface and close to the bolt holes. The high residual tensile stress value is higher when the braking condition becomes more severe.

-

Key words:

- brake disc /

- residual stress /

- warping deformation /

- numerical simulation /

- test verification

-

表 1 制动盘材料不同温度下的力学性能参数

Table 1. Mechanical properties of brake disc material at different temperatures

温度/℃ σ0.2/MPa σb/MPa E/GPa n 25 1055 1142 214 37.893 100 1007 1095 202 33.306 400 843 948 191 19.766 600 547 568 159 13.252 800 77 102 59 12.593 表 2 制动盘翘曲变形量测试结果

Table 2. Test results of warping deformation of brake disc

螺栓孔编号 1 2 3 4 5 6 7 8 9 10 11 12 变形量/mm 1.20 1.24 1.18 1.20 1.16 1.20 1.16 1.20 1.16 1.20 1.18 1.18 -

[1] 周素霞, 孙晨龙, 赵兴晗, 等. 城际快速列车铸钢制动盘三维瞬态温度场和应力场仿真分析[J]. 铁道学报, 2017, 39(8): 33-38. doi: 10.3969/j.issn.1001-8360.2017.08.005ZHOU Suxia, SUN Chenlong, ZHAO Xinghan, et al. Simulation and analysis of 3D transient temperature field and stress field of cast steel brake disc of intercity trains[J]. Journal of the China Railway Society, 2017, 39(8): 33-38. doi: 10.3969/j.issn.1001-8360.2017.08.005 [2] 杨智勇, 李志强, 李卫京, 等. 制动盘摩擦面热损伤的形成机理分析[J]. 铁道机车车辆, 2012, 32(3): 14-19. doi: 10.3969/j.issn.1008-7842.2012.03.004YANG Zhiyong, LI Zhiqiang, LI Weijing, et al. Research on forming mechanism of thermal damages of brake disc in service[J]. Railway Locomotive & Car, 2012, 32(3): 14-19. doi: 10.3969/j.issn.1008-7842.2012.03.004 [3] 李继山, 韩晓辉, 范荣巍. 高速列车制动盘残余应力数值仿真及试验验证[J]. 铁道机车车辆, 2010, 30(6): 8-10, 85. doi: 10.3969/j.issn.1008-7842.2010.06.003LI Jishan, HAN Xiaohui, FAN Rongwei. Numerical simulation and test of brake disc residual stress on high-speed train[J]. Railway Locomotive & Car, 2010, 30(6): 8-10, 85. doi: 10.3969/j.issn.1008-7842.2010.06.003 [4] 石晓玲, 李强, 赵方伟. 高速列车制动盘在不同制动工况下的残余热应力分布研究[J]. 铁道机车车辆, 2015, 35(4): 7-10, 49. doi: 10.3969/j.issn.1008-7842.2015.04.02SHI Xiaoling, LI Qiang, ZHAO Fangwei. Research on residual thermal stress of high speed train brake disk under different braking conditions[J]. Railway Locomotive & Car, 2015, 35(4): 7-10, 49. doi: 10.3969/j.issn.1008-7842.2015.04.02 [5] 高悦, 陈明峰, 梁宗敏. 残余应力对构件受力性能的影响[C]// 北京力学会第十六届学术年会论文集. 北京: [出版者不详], 2010: 455-456. [6] WANG J B, GAO G J, ZHANG Y, et al. Anti-snow performance of snow shields designed for brake calipers of a high-speed train[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2019, 233(2): 121-140. doi: 10.1177/0954409718783327 [7] 钱坤才, 吴射章, 乔青锋, 等. 高寒雨雪气候下高速动车组盘片摩擦副摩擦性能[J]. 西南交通大学学报, 2017, 52(6): 1188-1192. doi: 10.3969/j.issn.0258-2724.2017.06.020QIAN Kuncai, WU Shezhang, QIAO Qingfeng, et al. Friction performance of brake disks and blocks for high-speed EMU trains in cold, rainy, and snowy weather[J]. Journal of Southwest Jiaotong University, 2017, 52(6): 1188-1192. doi: 10.3969/j.issn.0258-2724.2017.06.020 [8] 韩俊臣, 宋春元, 徐芳, 等. 基于离散相的高速动车组转向架区域积雪问题研究[J]. 铁道科学与工程学报, 2020, 17(2): 280-287.HAN Junchen, SONG Chunyuan, XU Fang, et al. Study on the snow issue in the bogie regions of the standard EMU with three cars based on DPM method[J]. Journal of Railway Science and Engineering, 2020, 17(2): 280-287. [9] WANG J N, ZAFAR M Q, CHEN Y B, et al. Tribological properties of brake disc material for a high-speed train and the evolution of debris[J]. Lubricants, 2022, 10(8): 168.1-168.17. [10] 童欣. 基于相变储热原理的高速列车制动盘散热研究[D]. 北京: 北京建筑大学, 2022. [11] LUO J, LIU J Z, YOU Z Y, et al. Fatigue life prediction of brake discs for high-speed trains via thermal stress[J]. Science Progress, 2022, 105(2): 368504221102742.1-368504221102742.25. [12] 王东伟, 吴霄, 项载毓, 等. 高速列车盘形制动系统热机耦合特性分析[J]. 西南交通大学学报, 2021, 56(2): 428-436.WANG Dongwei, WU Xiao, XIANG Zaiyu, et al. Investigation on thermo-mechanical coupling characteristics of disc brake system of high-speed train[J]. Journal of Southwest Jiaotong University, 2021, 56(2): 428-436. [13] WU S C, ZHANG S Q, XU Z W. Thermal crack growth-based fatigue life prediction due to braking for a high-speed railway brake disc[J]. International Journal of Fatigue, 2016, 87: 359-369. doi: 10.1016/j.ijfatigue.2016.02.024 [14] 石晓玲, 李强, 薛海, 等. 高速列车锻钢制动盘多裂纹间作用机制研究[J]. 铁道学报, 2016, 38(3): 36-41. doi: 10.3969/j.issn.1001-8360.2016.03.005SHI Xiaoling, LI Qiang, XUE Hai, et al. Study on interaction mechanism between cracks at forged steel brake disc for high speed train[J]. Journal of the China Railway Society, 2016, 38(3): 36-41. doi: 10.3969/j.issn.1001-8360.2016.03.005 [15] XIE X D, LI Z Q, DOMBLESKY J P, et al. Analysis of deep crack formation and propagation in railway brake discs[J]. Engineering Failure Analysis, 2021, 128: 105600.1-105600.16. [16] BELHOCINE A, ABDULLAH O I. Thermomechanical model for the analysis of disc brake using the finite element method in frictional contact[J]. Multiscale Science and Engineering, 2020, 2(1): 27-41. doi: 10.1007/s42493-020-00033-6 [17] SAGA S I, TOYOSAKI Y. Measurement and evaluation method of dynamic deformation of brake disc[J]. Quarterly Report of RTRI, 2018, 59(4): 255-261. [18] 石晓玲, 李强, 宋占勋, 等. 高速列车锻钢制动盘热疲劳裂纹耦合扩展特性研究[J]. 机械工程学报, 2016, 52(10): 126-132. doi: 10.3901/JME.2016.10.126SHI Xiaoling, LI Qiang, SONG Zhanxun, et al. Research on coupled extension characteristic of thermal fatigue cracks at forged brake disc for high speed train[J]. Journal of Mechanical Engineering, 2016, 52(10): 126-132. doi: 10.3901/JME.2016.10.126 [19] 全国钢标准化技术委员会. 金属材料弹性模量和泊松比试验方法: GB/T 22315—2008[S]. 北京: 中国标准出版社, 2008. [20] RAMBERG W, OSGOOD W. Description of stress-strain curves by three parameters[J]. National Advisory Committee for Aeronautics Technical Note, 1943: 902.1-902.31. [21] 李志强. 高速列车制动盘热斑特征及裂纹萌生扩展机制研究[D]. 北京: 北京交通大学, 2016. [22] 中国铁路总公司. 中国标准动车组暂行技术条件: TL/CL 342—2014[S]. 北京: [出版者不详], 2014. [23] 王辰辰. 残余应力测试与校准方法研究现状与展望[J]. 计测技术, 2021, 41(2): 56-63.WANG Chenchen. Review on measurement and metrology methods of residual stress[J]. Metrology & Measurement Technology, 2021, 41(2): 56-63. -

下载:

下载: