Safety Limit for Periodic Short-Wave Irregularity of Wheel and Rail for High-Speed Railways at 400 km/h

-

摘要:

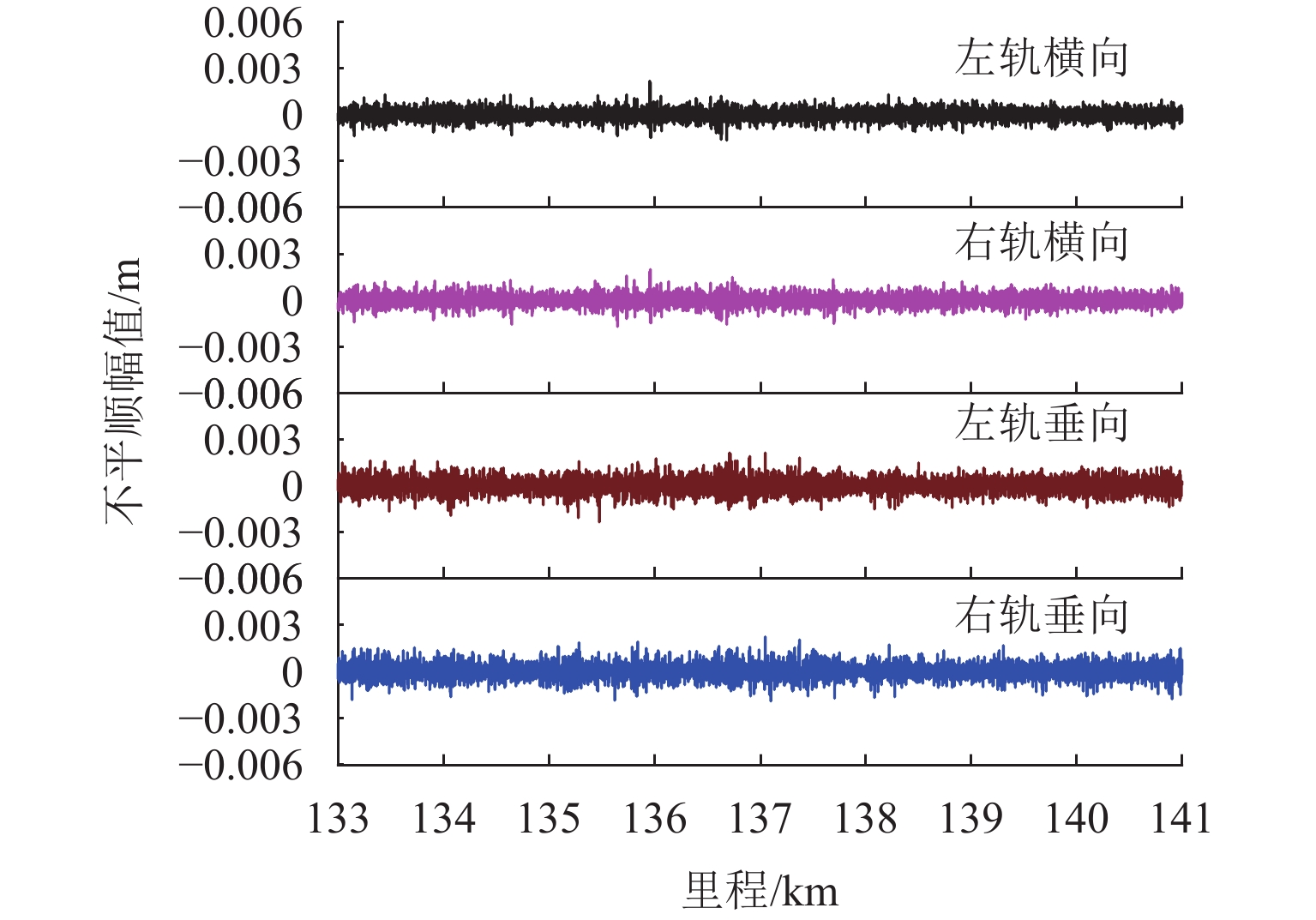

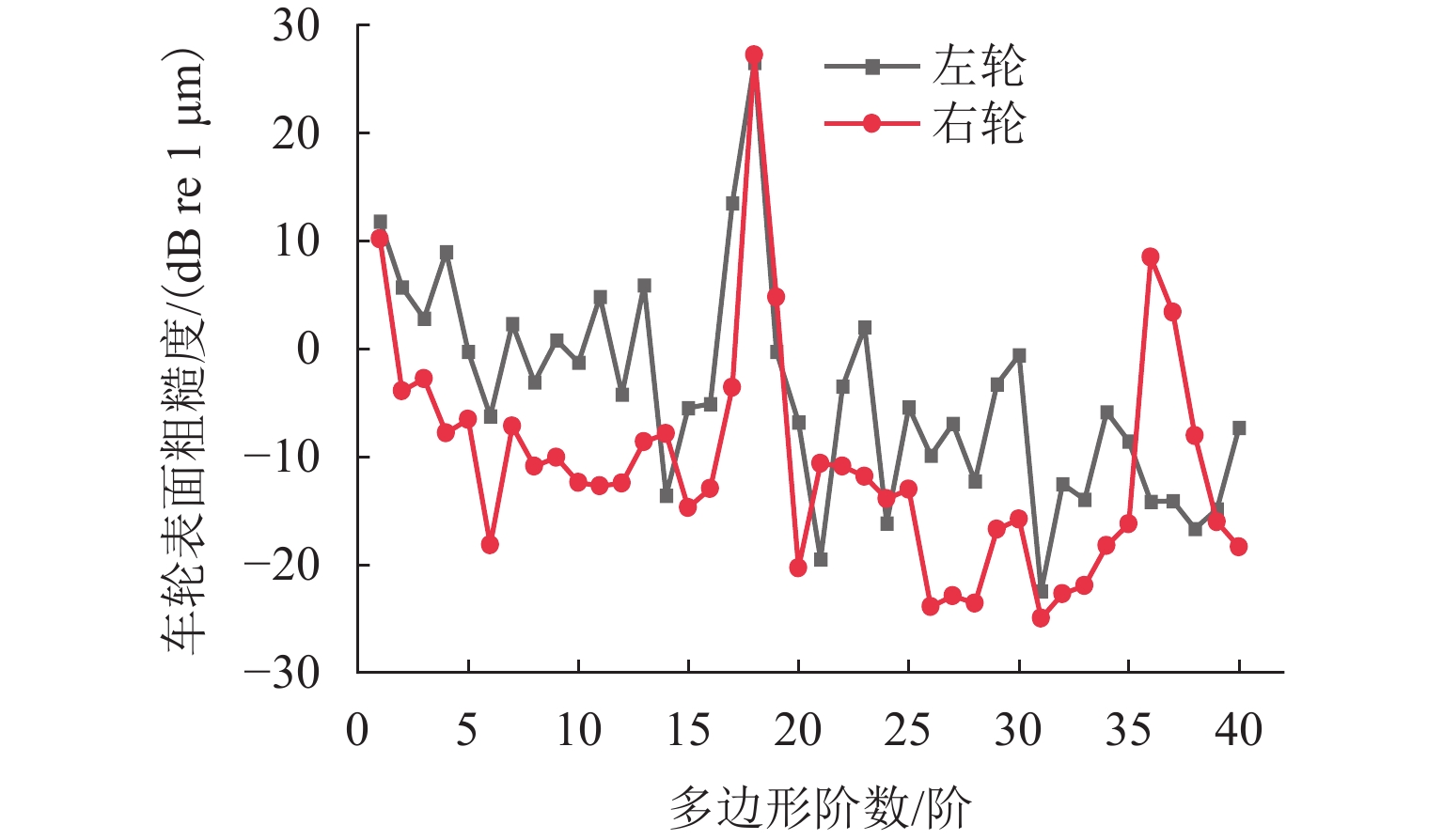

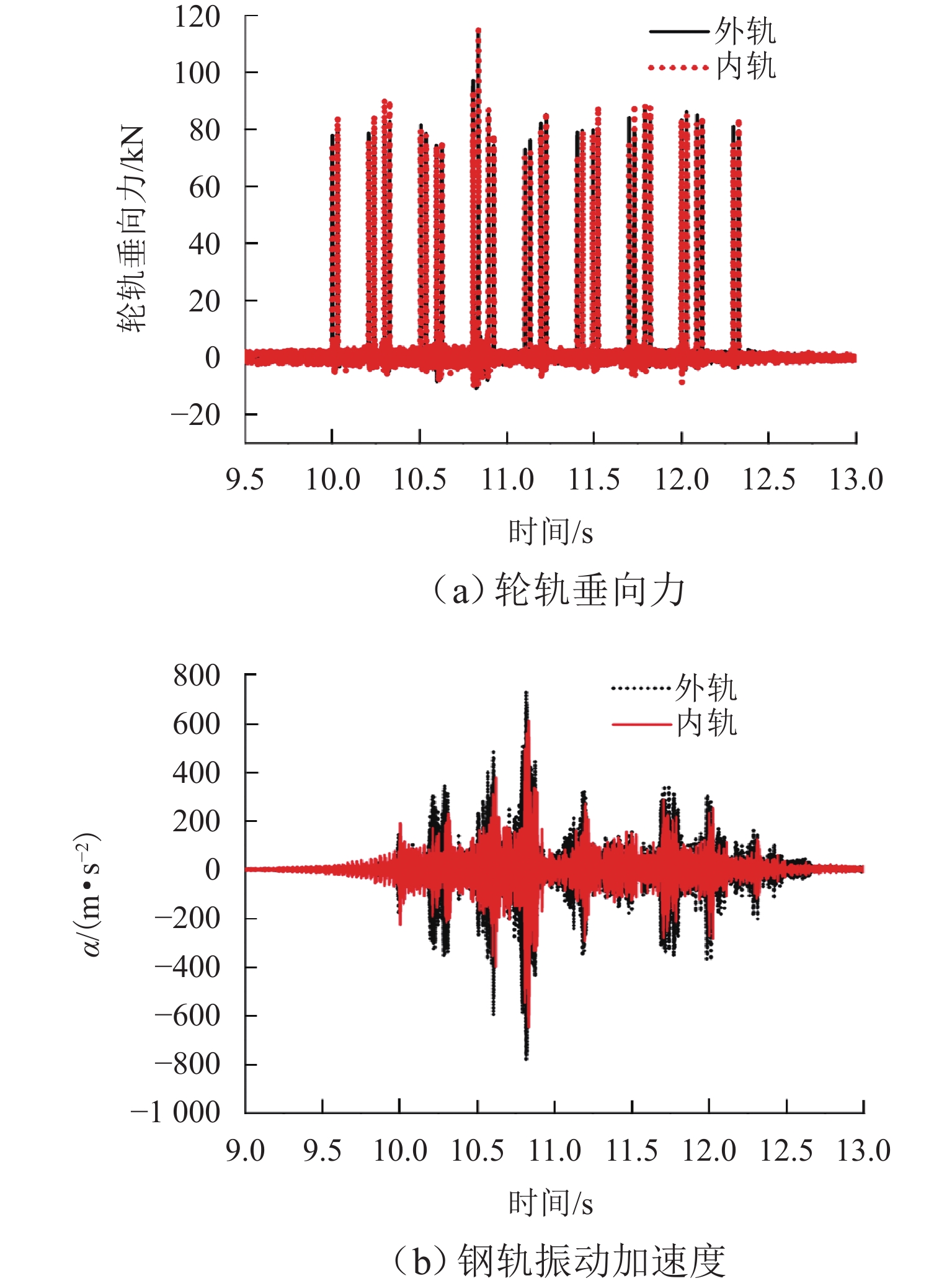

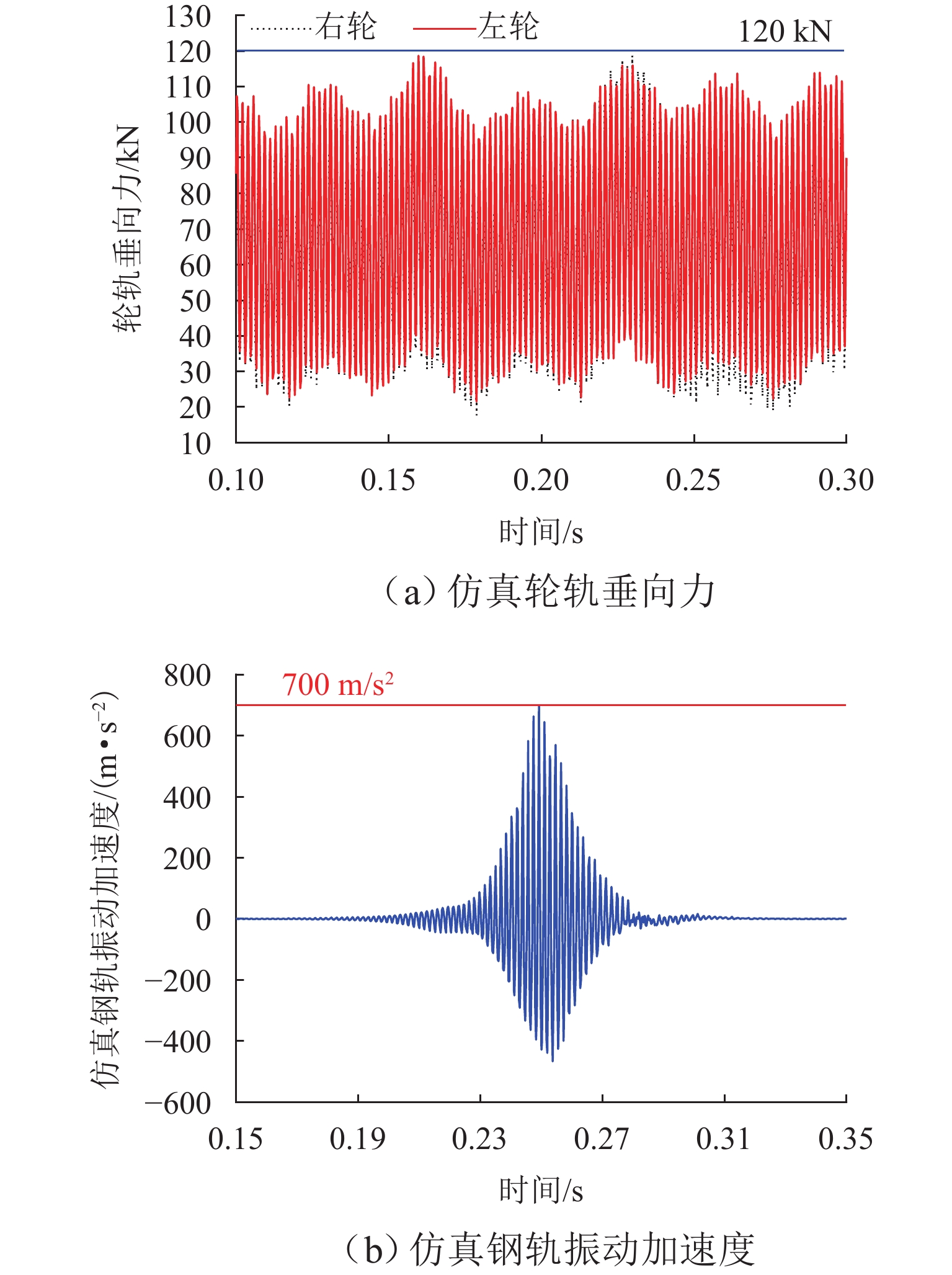

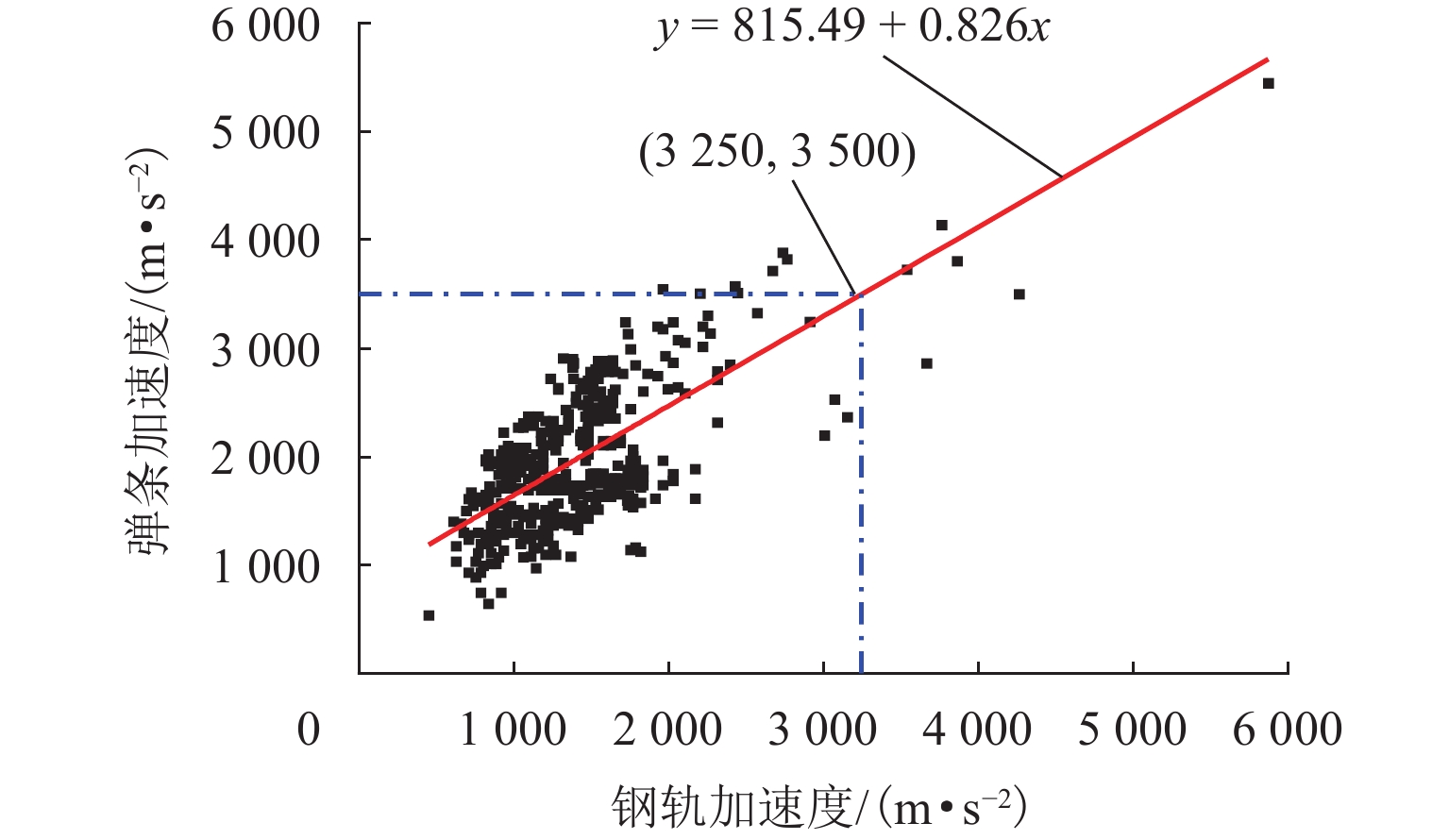

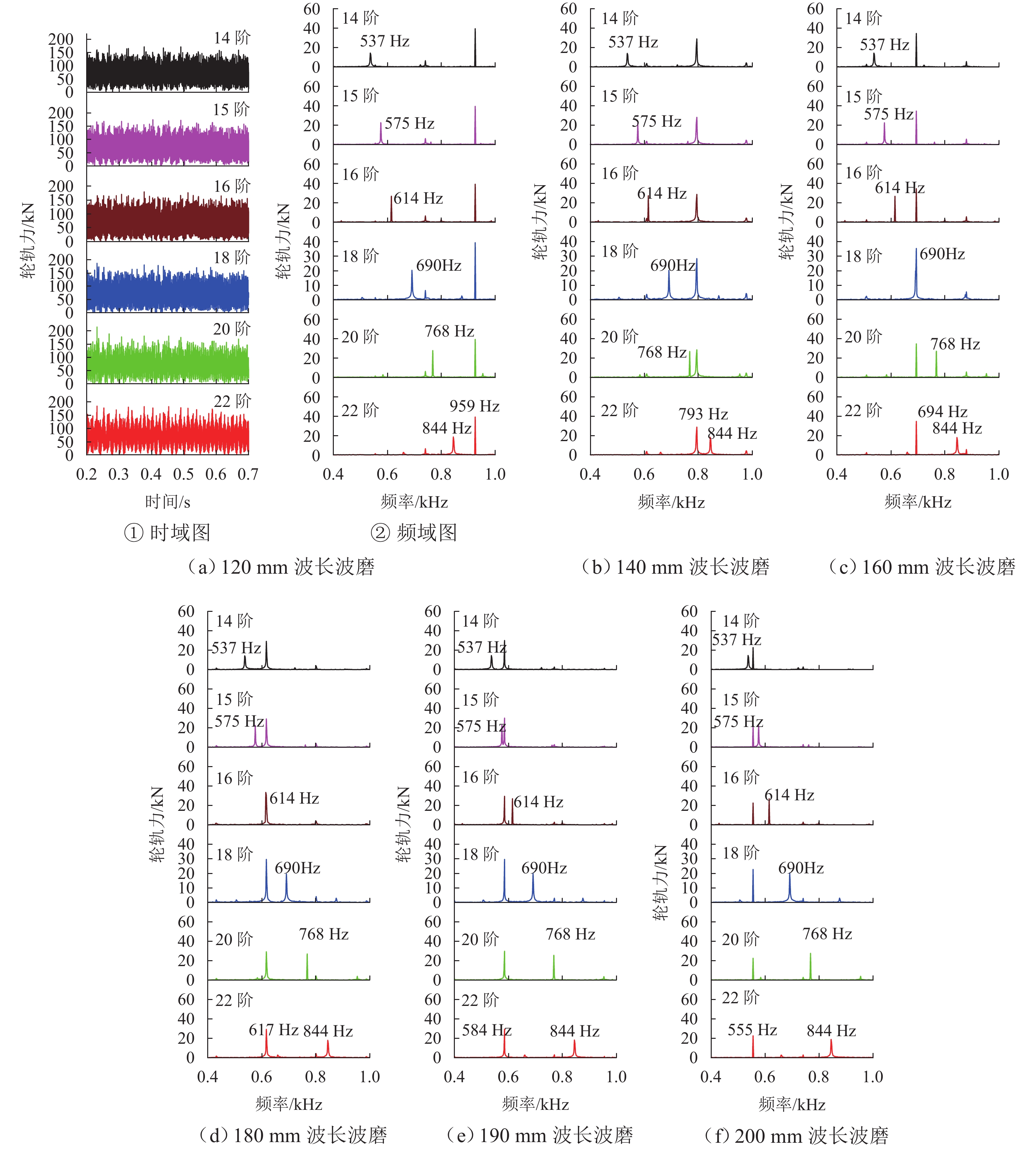

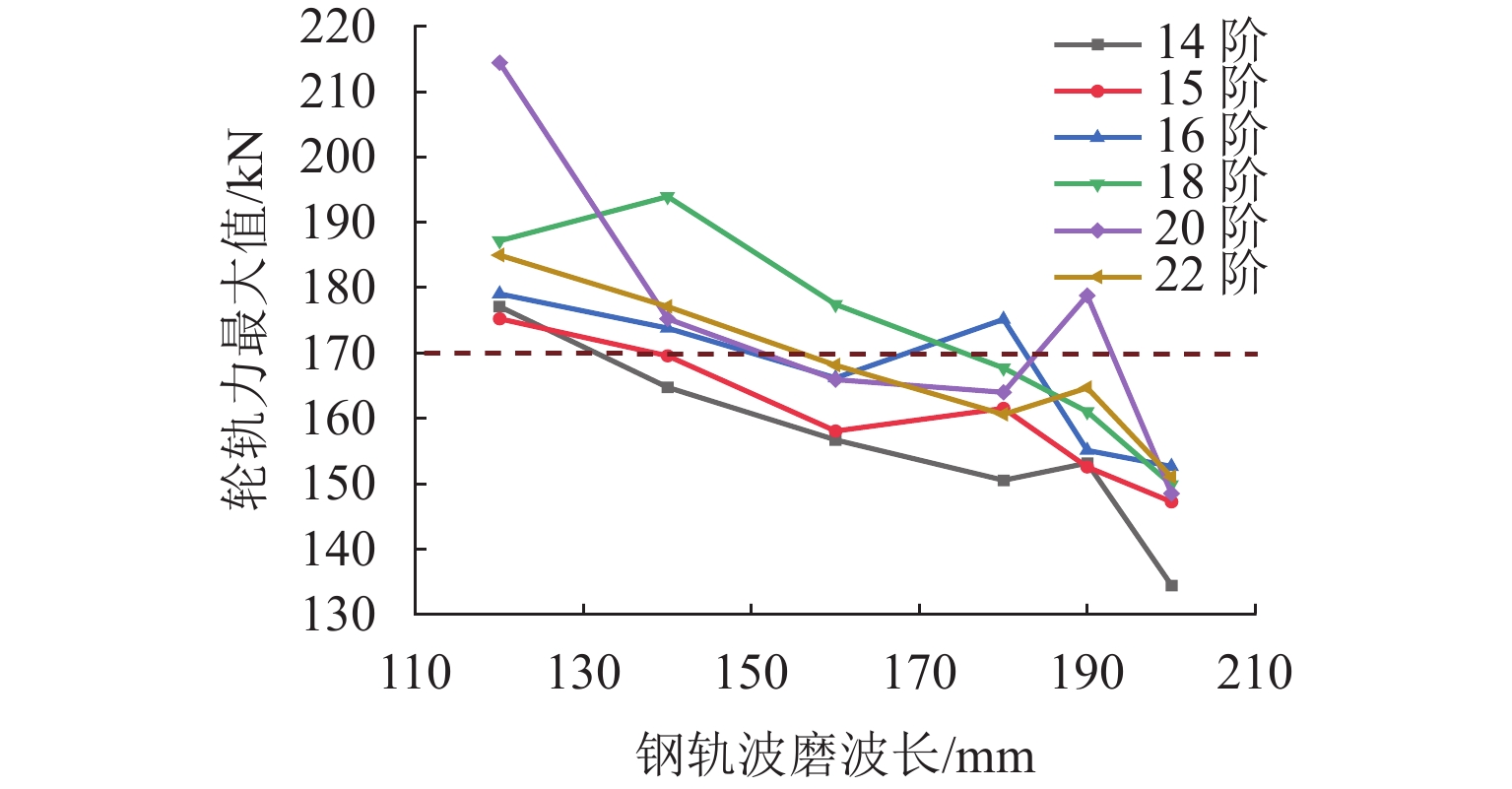

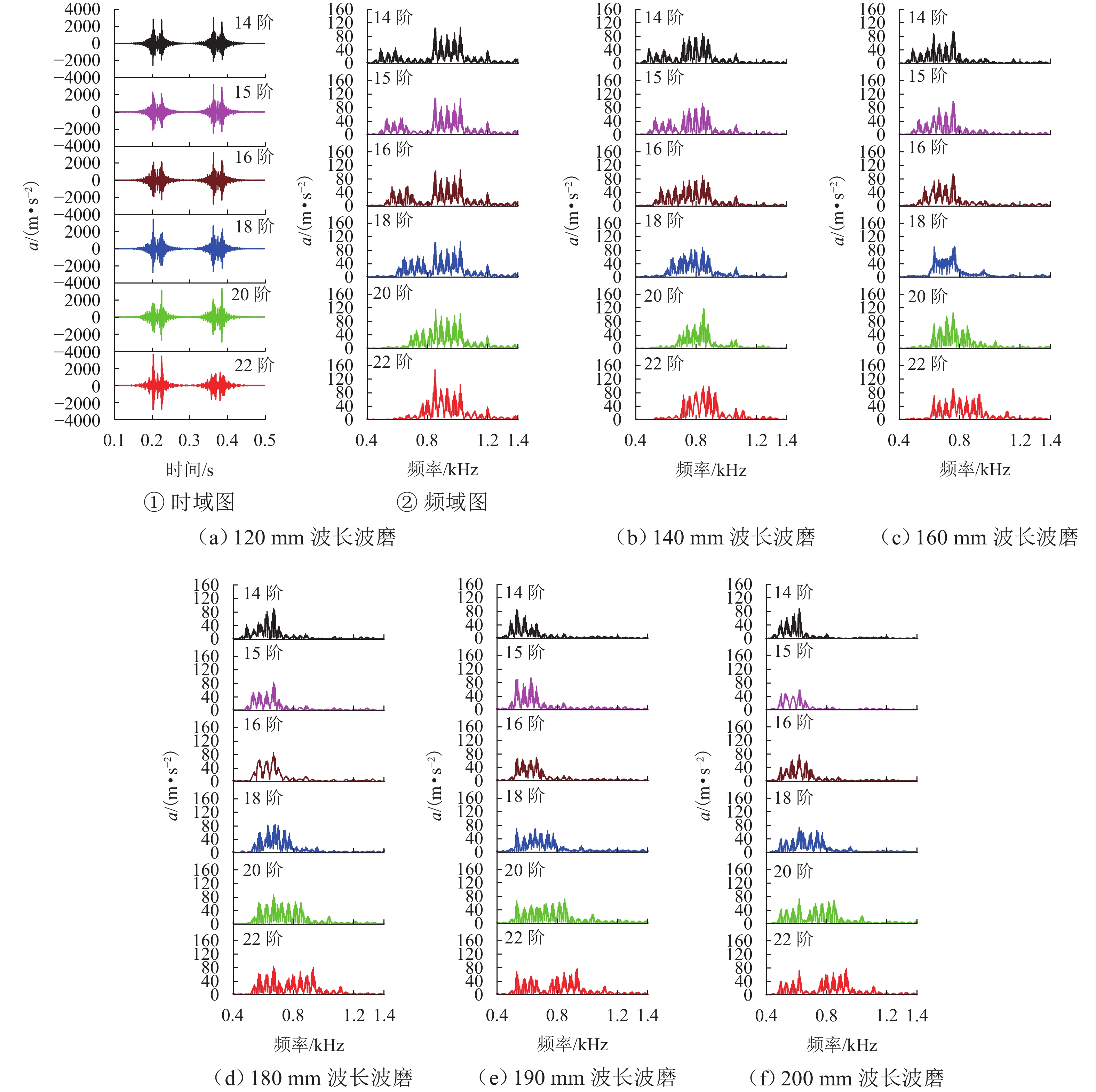

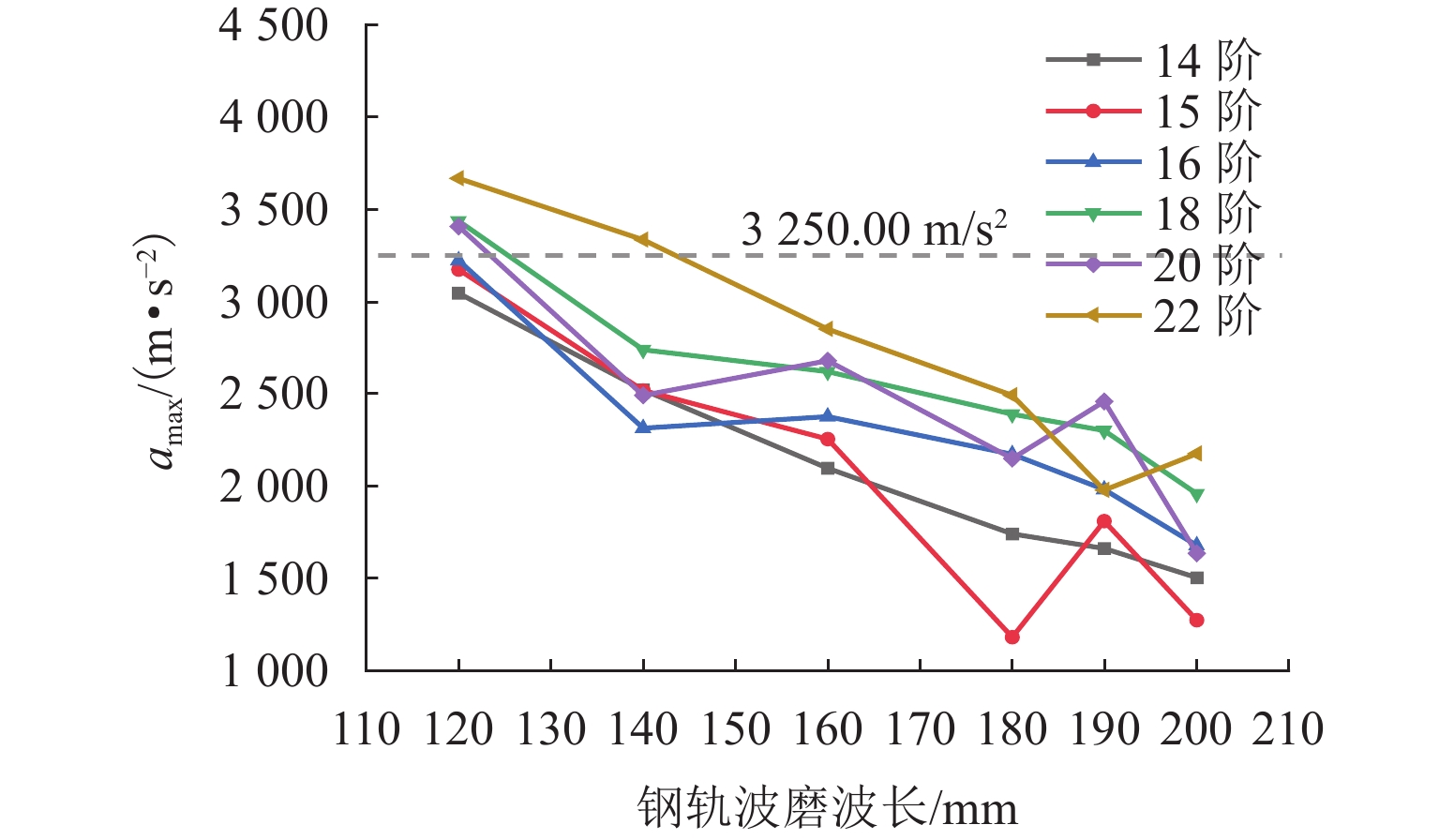

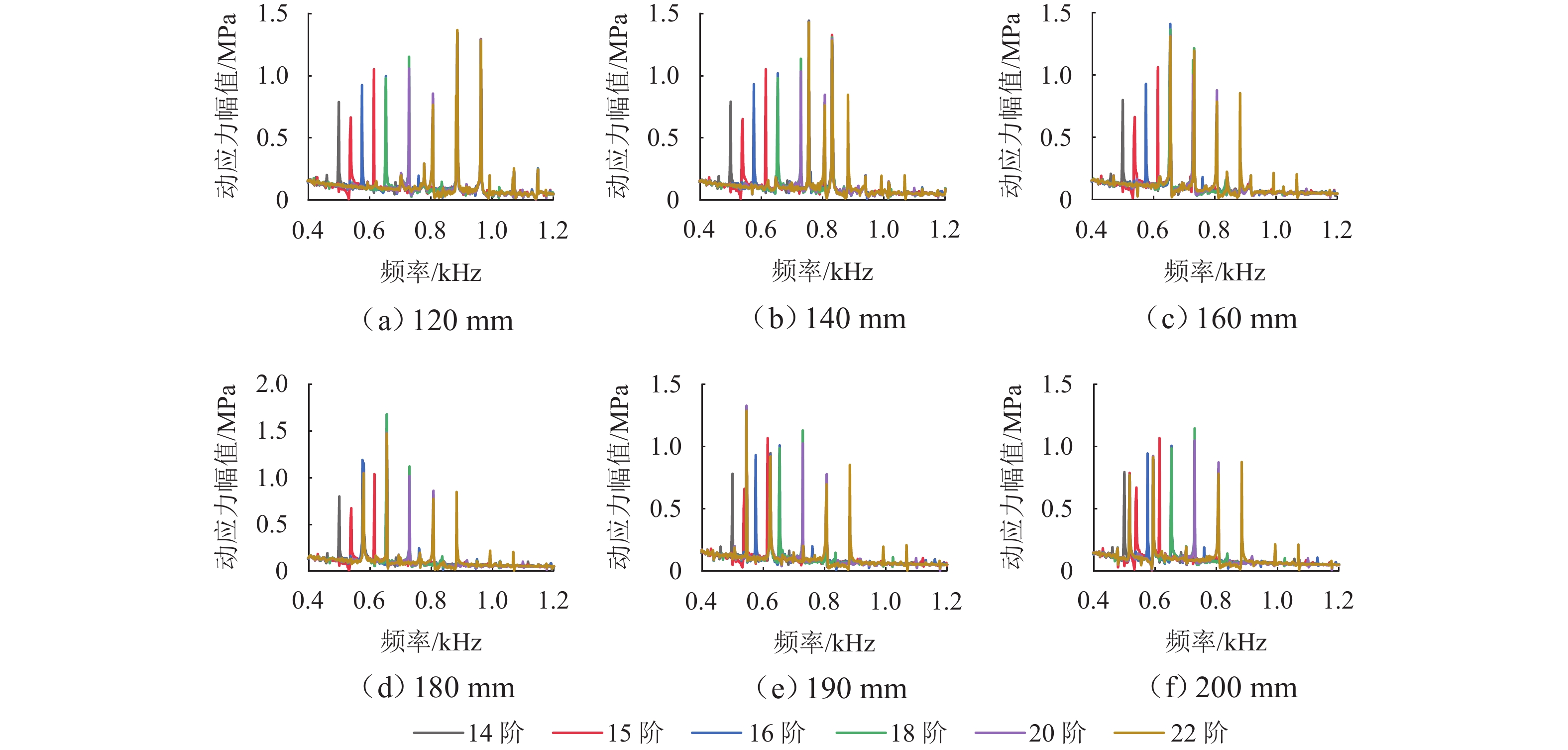

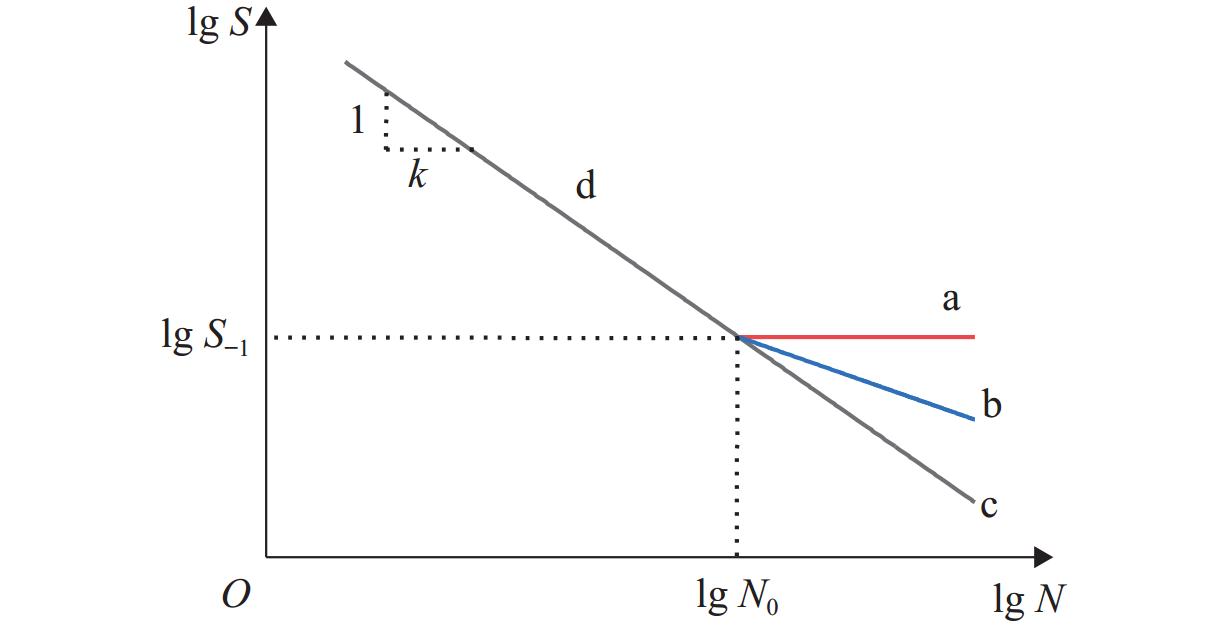

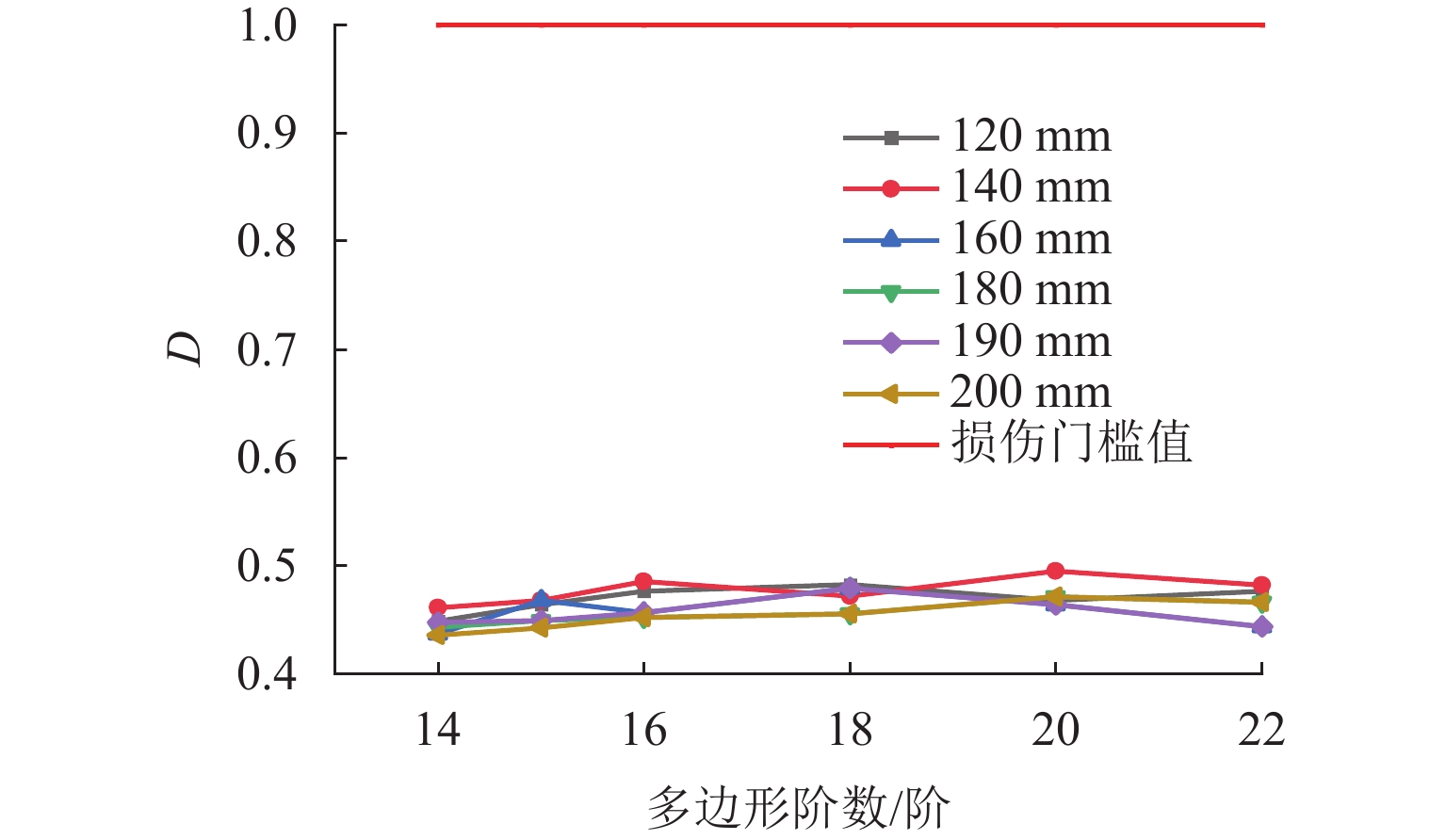

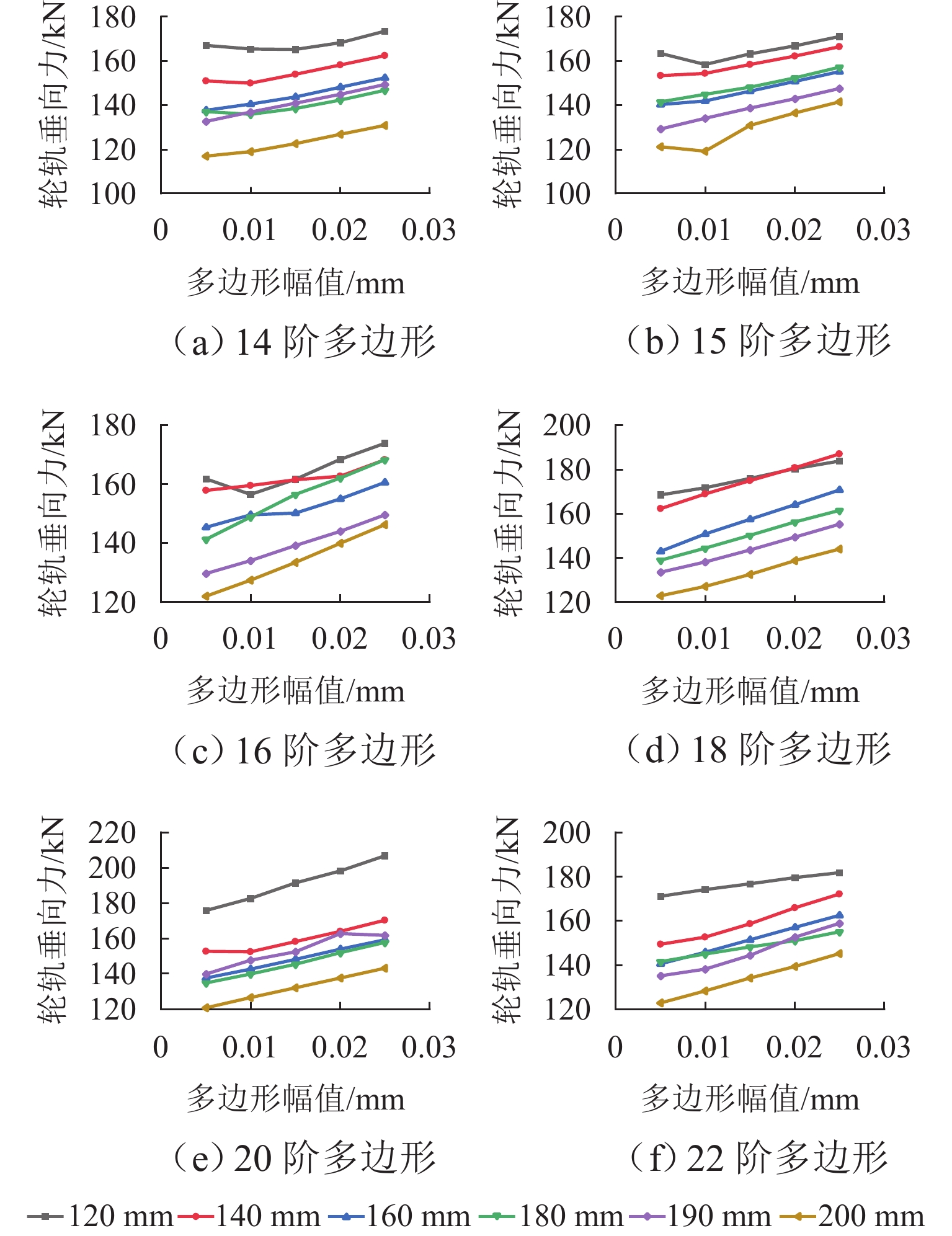

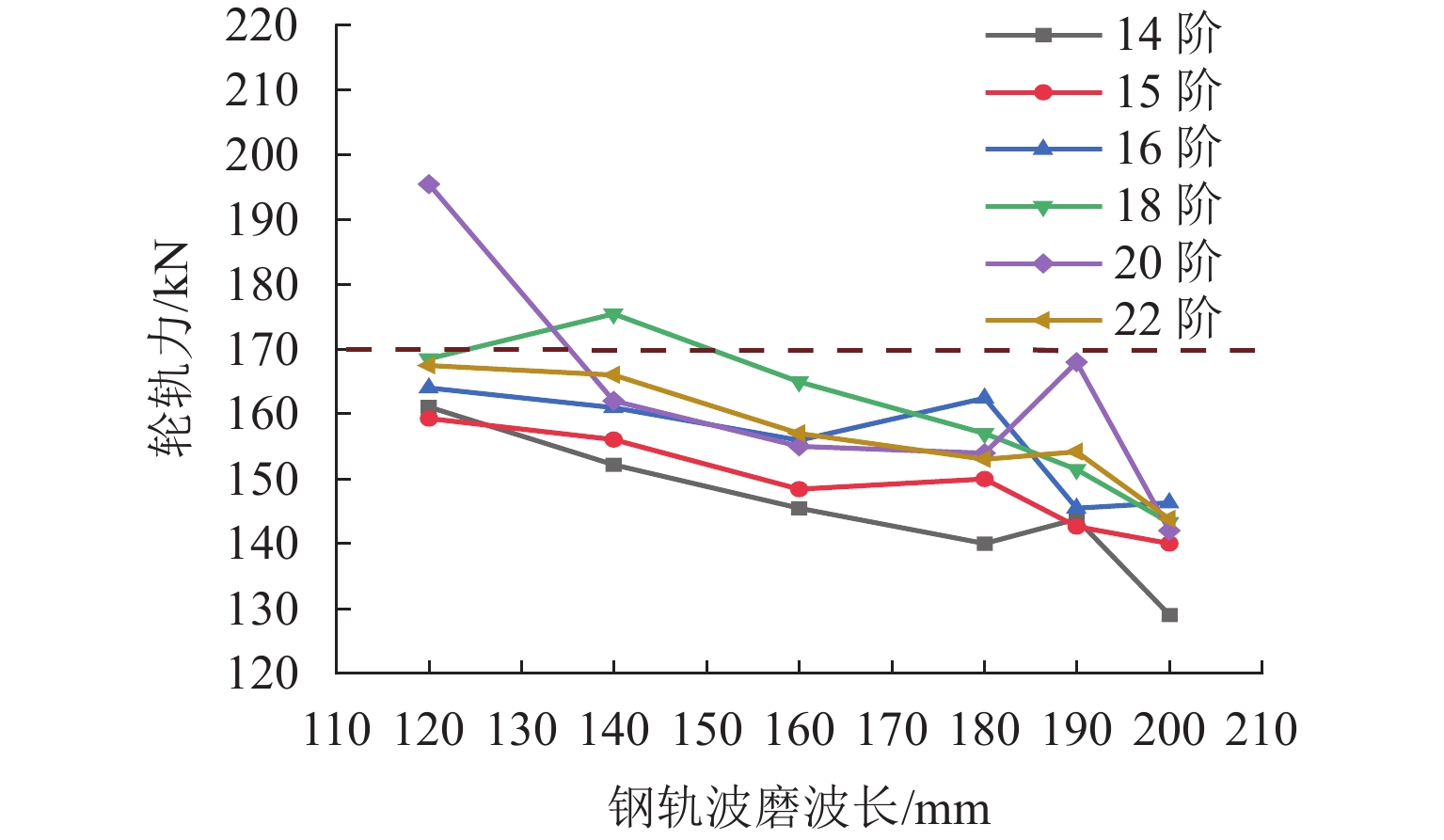

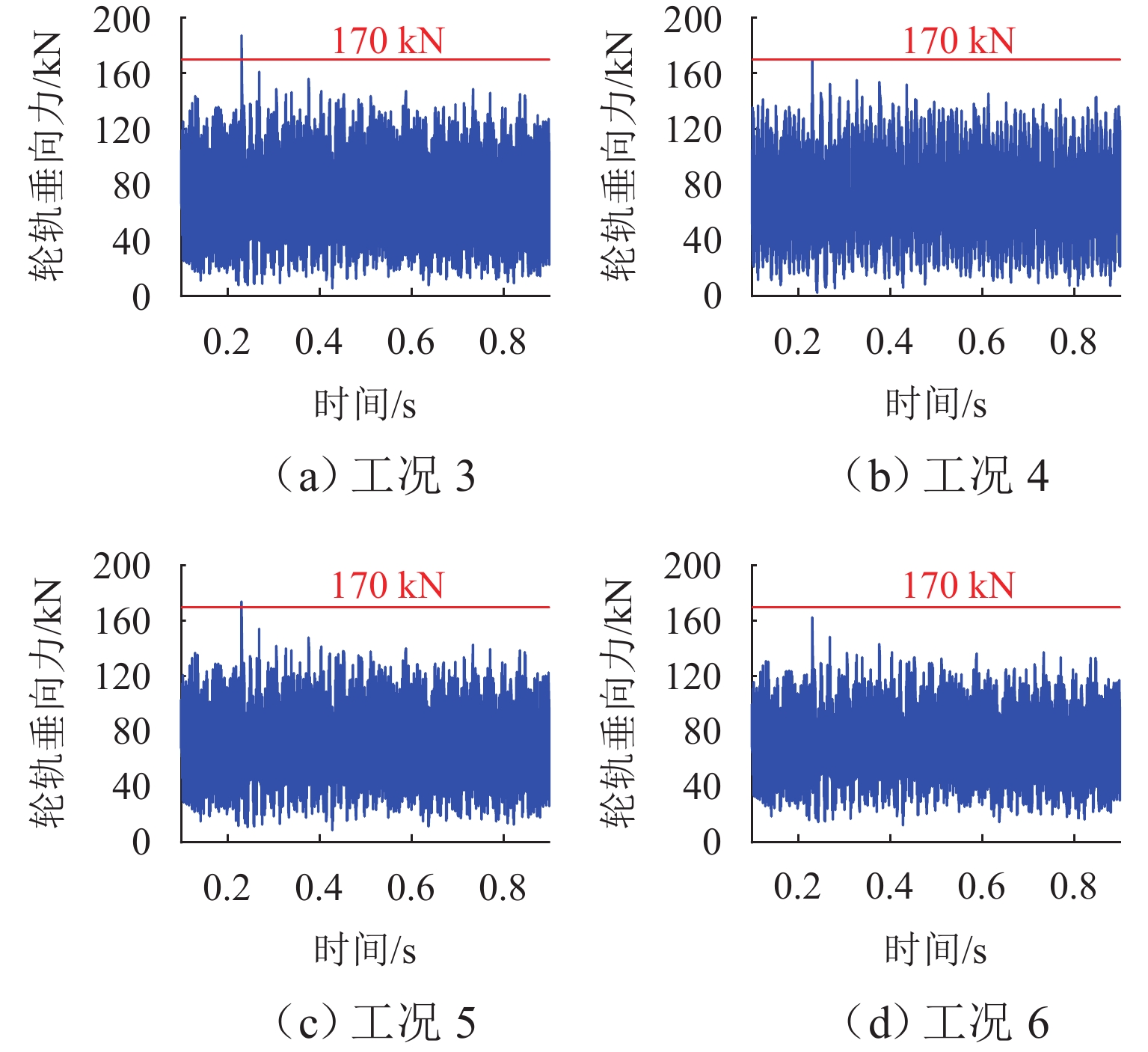

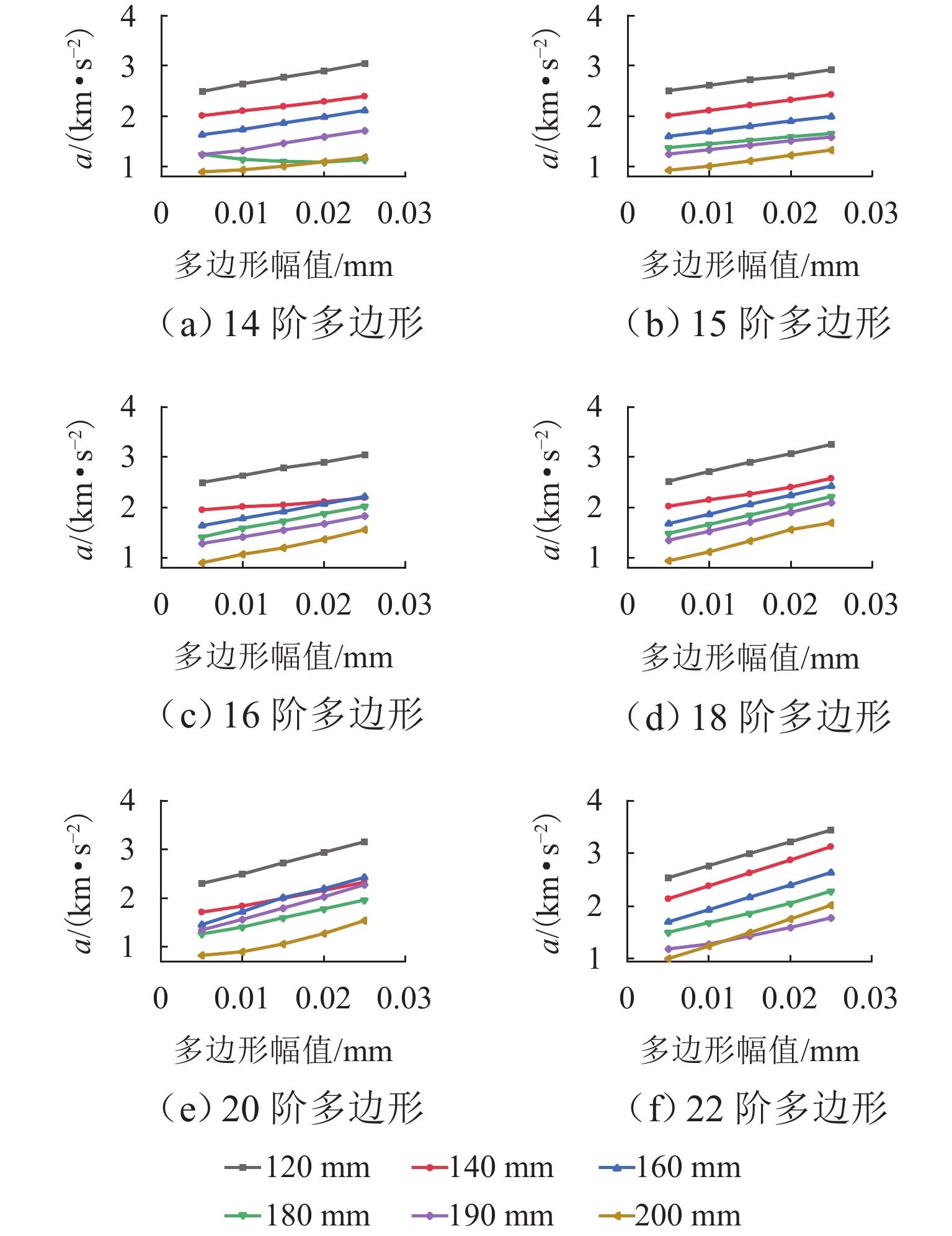

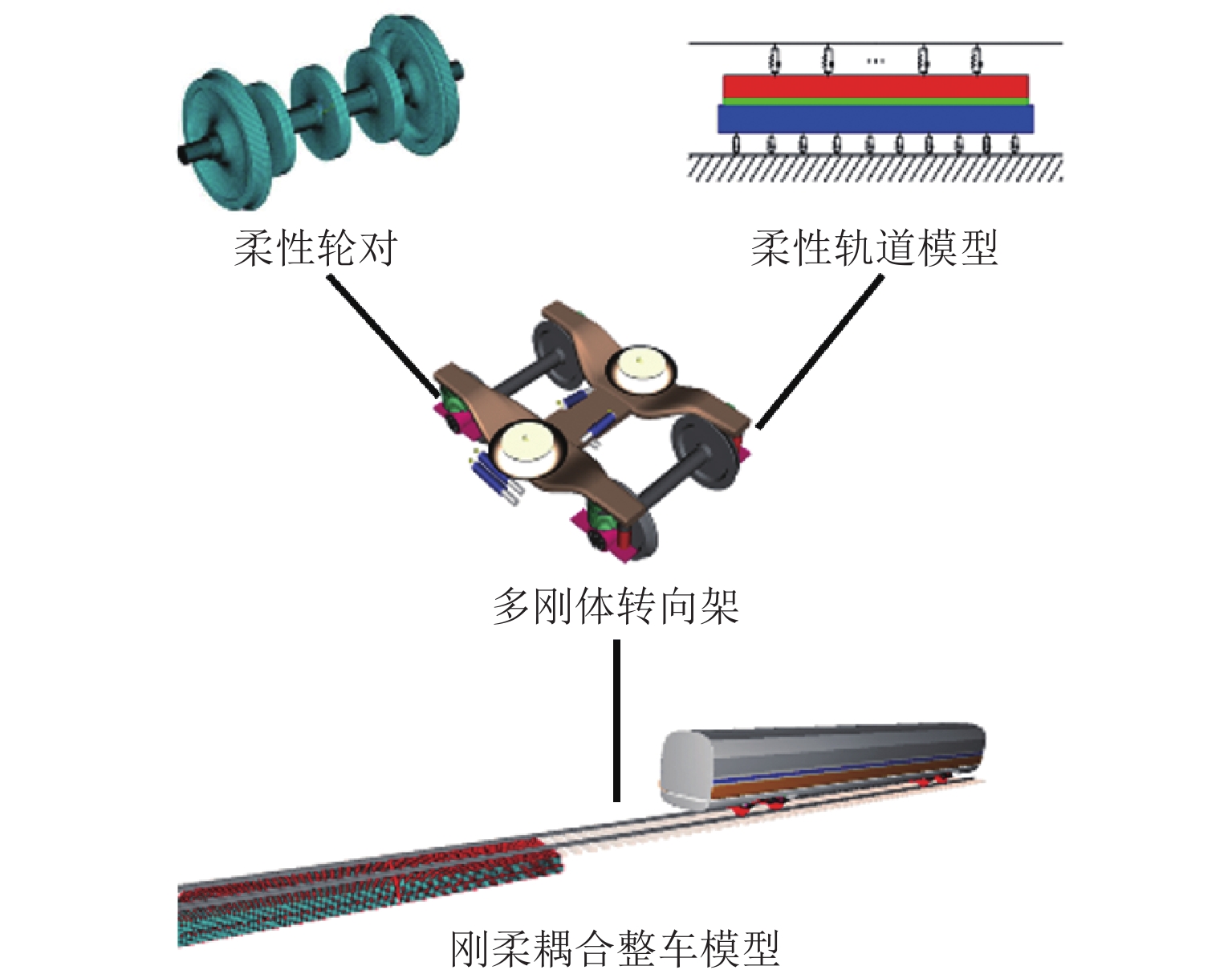

针对400 km/h速度等级高速铁路车轮多边形和钢轨波磨安全限值缺乏的问题,提出确定轮轨周期性短波不平顺安全限值的3个原则:基于《TB 10761—2013高速铁路工程动态验收技术规范》规定的轮轨垂向力不超过170.00 kN、基于由武广线实测数据拟合得到的弹条与钢轨振动加速度关系以及弹条共振疲劳断裂时由弹条加速度确定的钢轨振动加速度小于3 250.00 m/s2、基于轮轴至少服役30年换算确定的轮轴疲劳损伤寿命超过1 200万公里. 依据以上3个原则建立CR400BF型高速动车组的车辆-轨道刚柔耦合动力学模型,开展CR400BF动车组受大幅值轮轨周期性短波不平顺耦合激励时的轮轨力、钢轨振动加速度、轮轴疲劳损伤寿命计算;在此基础上,研究时速400公里高速铁路轮轨周期性短波不平顺的安全限值. 结果表明:120~200 mm波长、0.020 mm幅值的钢轨波磨与0.025 mm幅值的14~22阶多边形耦合激励时,轮轨力不超过170.00 kN;120~200 mm波长、0.040 mm幅值的钢轨波磨与0.020 mm幅值的14~22阶多边形耦合激励时,钢轨振动加速度不超过3 250.00 m/s2;在120~200 mm波长、0.040 mm幅值的钢轨波磨与0.030 mm幅值的14~22阶多边形耦合激励时,轮轴疲劳损伤寿命超过1 200万公里. 因此,建议将时速400 公里高速铁路的轮轨周期性短波不平顺的安全限值定为0.020 mm,与时速350公里限值一致.

Abstract:In response to the lack of safety limits for wheel polygon and rail corrugation on high-speed railways operating at 400 km/h, three principles for determining the safety limits of periodic short-wave irregularities between wheel and rail were proposed: According to the

Technical Regulations for Dynamic Acceptance for High-Speed Railways Construction (TB 10761—2013), the wheel–rail vertical force should not exceed 170.00 kN; based on the relationship between the acceleration of elastic rail clips and rail acceleration fitted from measured data on the Wuhan–Guangzhou line and the rail acceleration corresponding to the fatigue fracture of the elastic rail clips caused by resonance, the rail acceleration should be less than 3 250.00 m/s2; according to a service life of at least 30 years, the fatigue damage life of wheel axles should exceed 12 million km. Based on these three principles, a rigid and flexible coupled dynamic model of the vehicle–track system for CR400BF high-speed electrical multiple units (EMUs) was established to calculate the wheel–rail force, rail vibration acceleration, and fatigue damage life of wheel axles under the coupled excitation of large-amplitude periodic short-wave irregularities of wheel and rail for CR400BF EMUs. On this basis, the safety limit of periodic short-wave irregularities between the wheel and rail of high-speed railway at 400 km/h was studied. The results show that under the coupled excitation of rail corrugation with a wavelength of 120–200 mm and an amplitude of 0.020 mm and a 14th–22nd order polygon with an amplitude of 0.025 mm, the wheel–rail force does not exceed 170.00 kN. Under the coupled excitation of rail corrugation with a wavelength of 120–200 mm and an amplitude of 0.040 mm, and a 14th–22nd order polygon with an amplitude of 0.020 mm, the rail acceleration does not exceed 3 250.00 m/s2. Under the coupled excitation of rail corrugation with a wavelength of 120–200 mm and an amplitude of 0.040 mm, and a 14th–22nd order polygon with an amplitude of 0.030 mm, the fatigue damage life of the wheel axle exceeds 12 million km. Therefore, it is recommended to set the safety limit for the periodic short-wave irregularities of wheel and rail for 400 km/h high-speed railways at 0.020 mm, which is consistent with the limit for 350 km/h lines. -

表 1 CR400BF动车组主要动力学参数

Table 1. Main dynamic parameters of CR400BF EMUs

名称 参数取值 车辆定距/m 17.8 轴距/m 2.5 轴重/t ≤17 车轮直径/mm 850~920 车轮型面 LMB10 轮对质量/t 1.517 轴箱质量/kg 100 一系钢簧纵向/垂向刚度/(kN•m−1) 919.8/886.0 二系横向减振器节点刚度/(MN•m−1) 8.5 表 2 轨道模型的基本参数

Table 2. Basic parameters of track model

部位 参数 数值 钢轨 弹性模量/GPa 210 密度/(kg•m−3) 7800 泊松比 0.3 扣件 垂向刚度/(MN•m−1) 23 横向刚度/(MN•m−1) 30 间距/m 0.6 轨道板 弹性模量/GPa 36 密度/(kg•m−3) 2500 泊松比 0.2 水泥沥青砂浆层 弹性模量/GPa 0.2 密度/(kg•m−3) 2000 泊松比 0.2 底座版 弹性模量/GPa 33 密度/(kg•m−3) 2500 泊松比 0.2 表 3 不同工况对应参数

Table 3. Parameters corresponding to different working conditions

工况 波磨 多边形 幅值/mm 波长/mm 幅值/mm 阶数/阶 1 0.030 120 0.030 18 2 0.030 140 0.030 20 3 0.025 120 0.030 18 4 0.025 140 0.030 20 5 0.020 120 0.030 20 6 0.020 120 0.025 20 -

[1] 吴越. 高速列车车轮多边形磨耗机理及其影响研究[D]. 成都: 西南交通大学, 2023. [2] 姜子清, 司道林, 李伟, 等. 高速铁路钢轨波磨研究[J]. 中国铁道科学, 2014, 35(4): 9-14.JIANG Ziqing, SI Daolin, LI Wei, et al. On rail corrugation of high speed railway[J]. China Railway Science, 2014, 35(4): 9-14. [3] LI G F, WANG H B, ZHOU Y B, et al. Research on the evolution of the wheel polygon based on the iterative model of long-term wear on both sides of the wheelset[J]. Vehicle System Dynamics, 2023, 61(10): 2570-2597. doi: 10.1080/00423114.2022.2120024 [4] JOHANSSON A, NIELSEN J O. Out-of-round railway wheels—wheel-rail contact forces and track response derived from field tests and numerical simulations[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2003, 217(2): 135-146. doi: 10.1243/095440903765762878 [5] LEWIS R, OLOFSSON U. Wheel-rail interface handbook[M]. Boca Raton: CRC Press, 2009. [6] CLARK R A, DEAN P A, ELKINS J A, et al. An investigation into the dynamic effects of railway vehicles running on corrugated rails[J]. Journal of Mechanical Engineering Science, 1982, 24(2): 65-76. doi: 10.1243/JMES_JOUR_1982_024_015_02 [7] NIELSEN J O, EKBERG A, LUNDÉN R. Influence of short-pitch wheel/rail corrugation on rolling contact fatigue of railway wheels[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2005, 219(3): 177-187. doi: 10.1243/095440905X8871 [8] EKBERG A, KABO E, NIELSEN J C O, et al. Subsurface initiated rolling contact fatigue of railway wheels as generated by rail corrugation[J]. International Journal of Solids and Structures, 2007, 44(24): 7975-7987. doi: 10.1016/j.ijsolstr.2007.05.022 [9] 王远, 佟岩. 高速动车组车轮多边形对车内噪声的影响[J]. 噪声与振动控制, 2018, 38(1): 147-150.WANG Yuan, TONG Yan. Influence of polygonal wheels on interior noise of high-speed trains[J]. Noise and Vibration Control, 2018, 38(1): 147-150. [10] 高闯, 孙守光, 任尊松, 等. 车轮多边形对高速列车车轴疲劳强度影响研究[J]. 机械工程学报, 2023, 59(6): 185-193. doi: 10.3901/JME.2023.06.185GAO Chuang, SUN Shouguang, REN Zunsong, et al. Study on the influence of wheel polygon on the fatigue strength of high-speed train axle[J]. Journal of Mechanical Engineering, 2023, 59(6): 185-193. doi: 10.3901/JME.2023.06.185 [11] 胡晓依, 侯银庆, 宋志坤, 等. 基于柔性轮轨模型的车轮谐波磨耗对高速轮轨系统振动影响的仿真研究[J]. 中国铁道科学, 2018, 39(6): 81-89.HU Xiaoyi, HOU Yinqing, SONG Zhikun, et al. Simulation study on influence of harmonic wear of wheel on vibration of high-speed wheel-rail system based on flexible wheel-rail model[J]. China Railway Science, 2018, 39(6): 81-89. [12] 刘玉涛. 钢轨波磨下扣件弹条疲劳断裂机理研究[D]. 成都: 西南交通大学, 2017. [13] 李谷, 张志超, 祖宏林, 等. 高速铁路典型轨道病害下轮轨力响应特性试验研究[J]. 中国铁道科学, 2019, 40(6): 30-36.LI Gu, ZHANG Zhichao, ZU Honglin, et al. Experimental study on wheel-rail force response characteristics under typical track defects of high speed railway[J]. China Railway Science, 2019, 40(6): 30-36. [14] 王忆佳. 车轮踏面伤损对高速列车动力学行为的影响[D]. 成都: 西南交通大学, 2014. [15] 刘国云. 关键部件性能演变的高速列车动力学性能分析及评估[D]. 成都: 西南交通大学, 2018. [16] 陈伟, 戴焕云, 罗仁. 高速列车车轮高阶多边形对车辆动力学性能的影响[J]. 铁道车辆, 2014, 52(12): 4-9.CHEN Wei, DAI Huanyun LUO Ren. Effect of high order polygons of wheels for high speed trains on dynamics performance of vehicles[J]. Rolling Stock, 2014, 52(12): 4-9. [17] 尹振坤, 吴越, 韩健. 高速列车车轮多边形磨耗对轮轨垂向力的影响[J]. 铁道学报, 2017, 39(10): 26-32.YIN Zhenkun, WU Yue, HAN Jian. Effect of polygonal wear of high-speed train wheels on vertical force between wheel and rail[J]. Journal of the China Railway Society, 2017, 39(10): 26-32. [18] 张富兵, 邬平波, 吴兴文, 等. 高速列车车轮多边形磨耗安全限值研究[J]. 铁道学报, 2021, 43(3): 42-51.ZHANG Fubing, WU Pingbo, WU Xingwen, et al. Research on safety limit of wheel polygonalization of high-speed train[J]. Journal of the China Railway Society, 2021, 43(3): 42-51. [19] NIELSEN J C O, EKBERG A. Acceptance criterion for rail roughness level spectrum based on assessment of rolling contact fatigue and rolling noise[J]. Wear, 2011, 271(1/2): 319-327. [20] 中国国家铁路集团有限公司机辆部. 动车组车轮等效锥度、多边形、径跳运用标准: 机辆动客函[2021]36号[S]. 北京: 中国国家铁路集团有限公司, 2021. [21] 中国铁路总公司. 高速铁路钢轨打磨管理办法: 铁总运[2014]357号[S]. 北京: 中国铁路总公司, 2014. [22] 中国国家铁路集团有限公司. 动车组总体技术条件(暂行): TJ/CJ 591—2022 CR450[S]. 北京: 中国国家铁路集团有限公司, 2022. [23] 胡晓依, 成棣, 闫子权, 等. 时速400公里速度级轮轨关系关键技术研究[R]. 北京: 中国铁道科学研究院集团有限公司, 2022. [24] 金学松, 吴越, 梁树林, 等. 高速列车车轮多边形磨耗、机理、影响和对策分析[J]. 机械工程学报, 2020, 56(16): 118-136. doi: 10.3901/JME.2020.16.118JIN Xuesong, WU Yue, LIANG Shulin, et al. Characteristics, mechanism, influences and countermeasures of polygonal wear of high-speed train wheels[J]. Journal of Mechanical Engineering, 2020, 56(16): 118-136. doi: 10.3901/JME.2020.16.118 [25] 常崇义, 胡晓依, 刘丰收, 等. 高速铁路轮轨关系深化研究调研总报告[R]. 北京: 中国铁道科学研究院, 2016. [26] 中国铁道科学研究院 高速铁路工程动态验收技术规范: TB 10716—2013[S]. 北京: 中国铁道出版社, 2013. [27] ZHANG F B, WANG Q S, ZHANG Z Q, et al. Research on the influence of wheel polygonization on axle stress[J]. Shock and Vibration, 2021, 2021(1): 1-12. [28] MINER M A. Cumulative damage in fatigue[J]. Journal of Applied Mechanics, 1945, 12(3): 159-164. doi: 10.1115/1.4009458 -

下载:

下载: