Modeling and Dynamics Analysis of High-Temperature Magnetic Bearing-Rotor System

-

摘要:

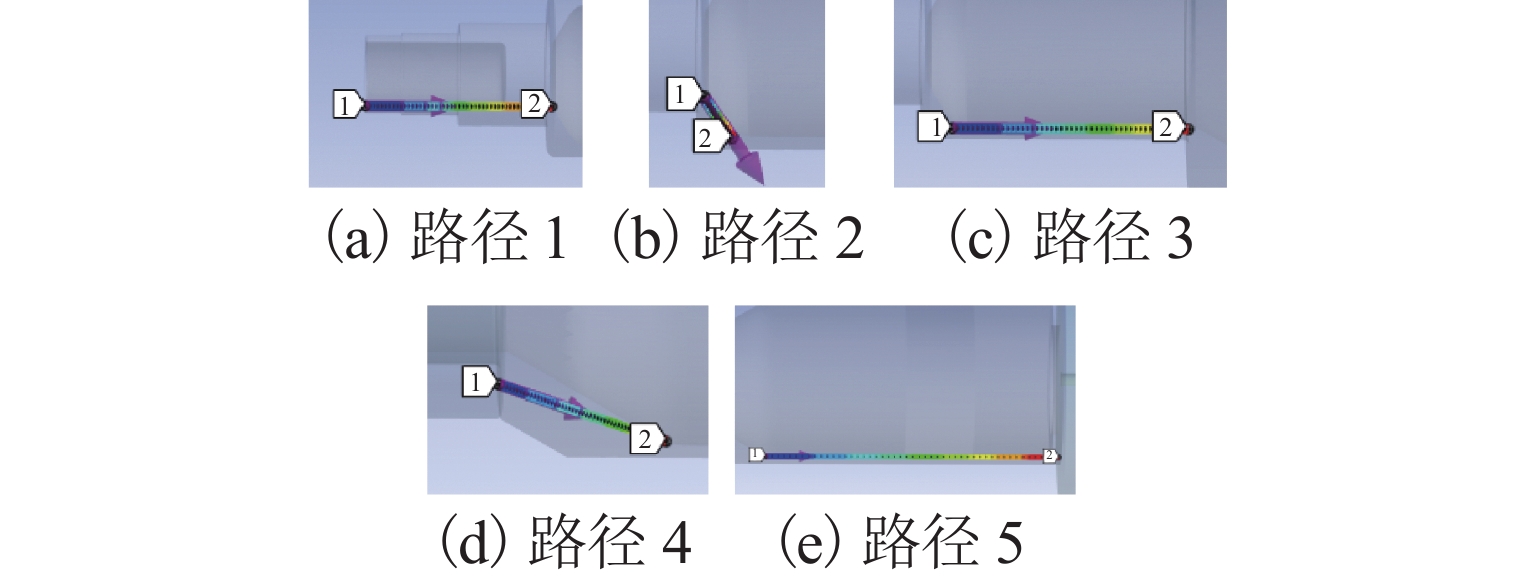

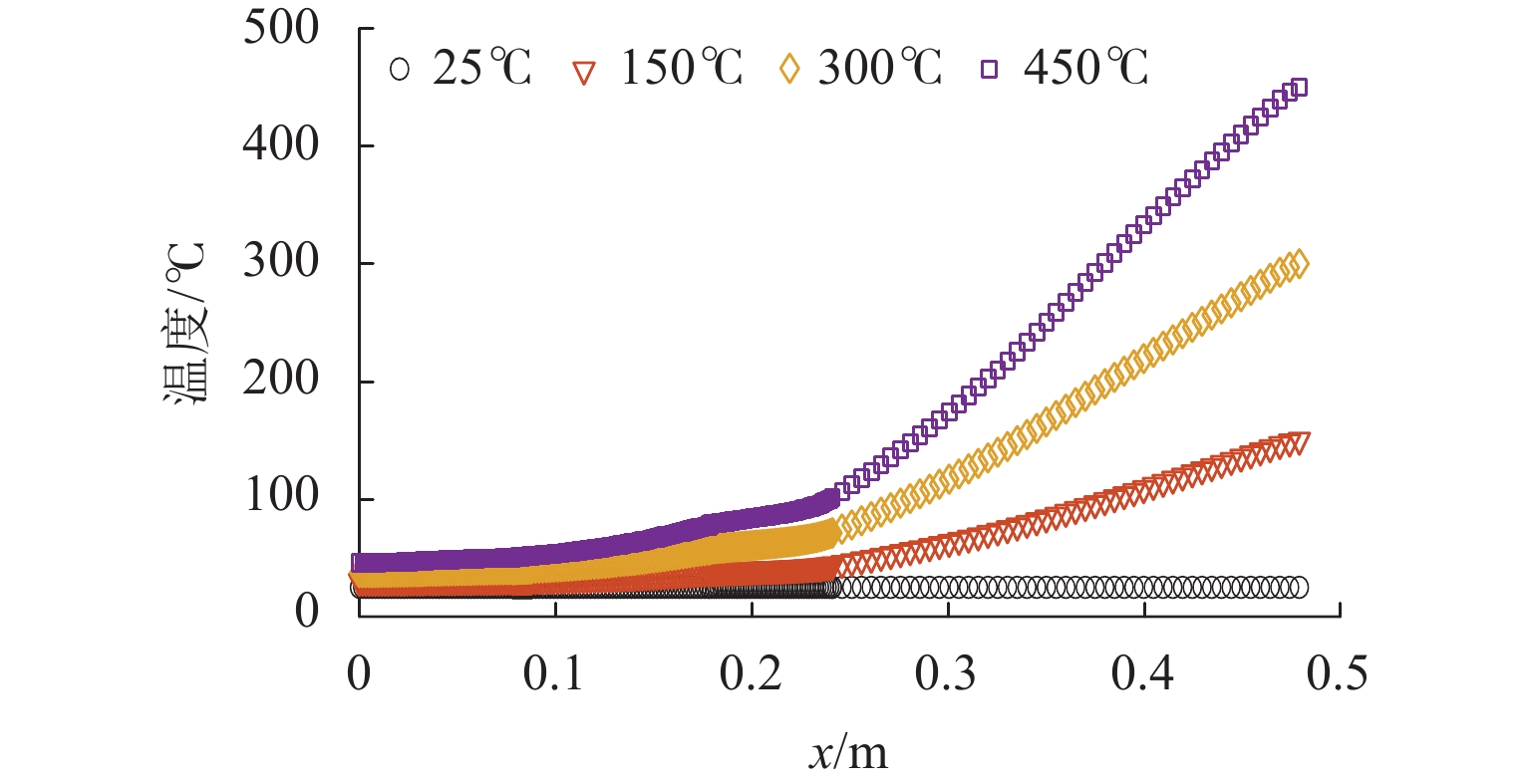

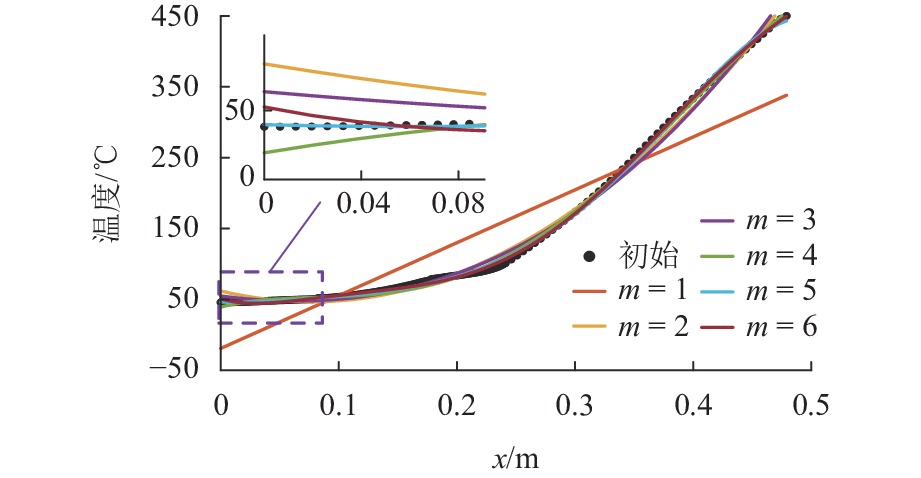

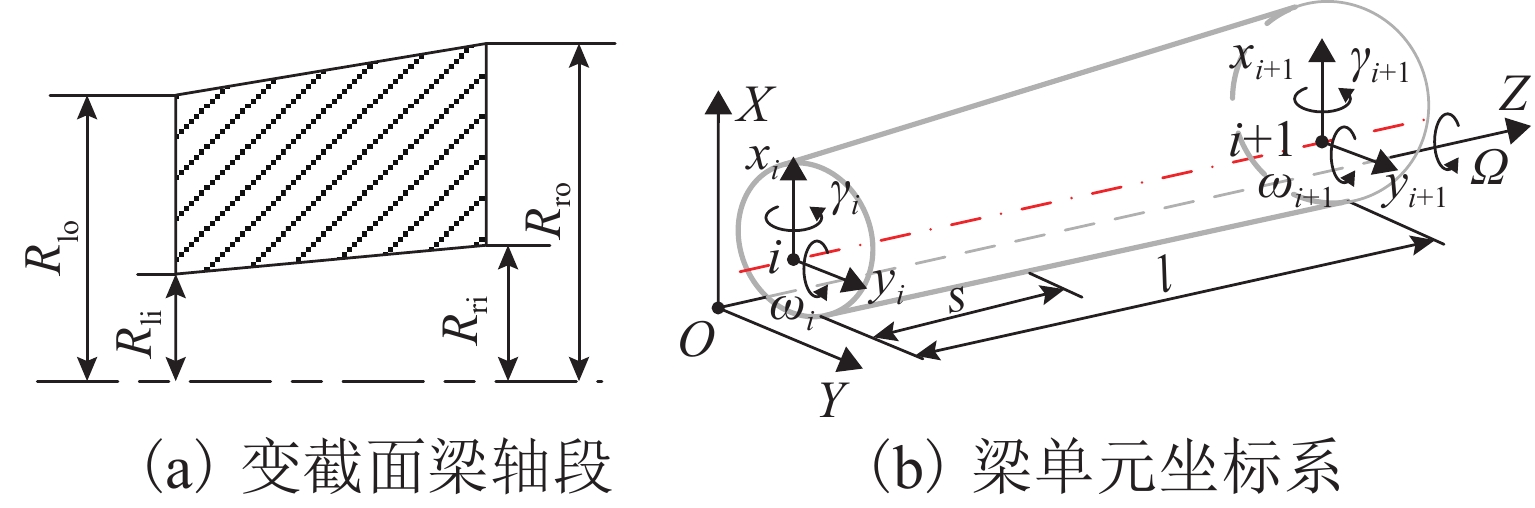

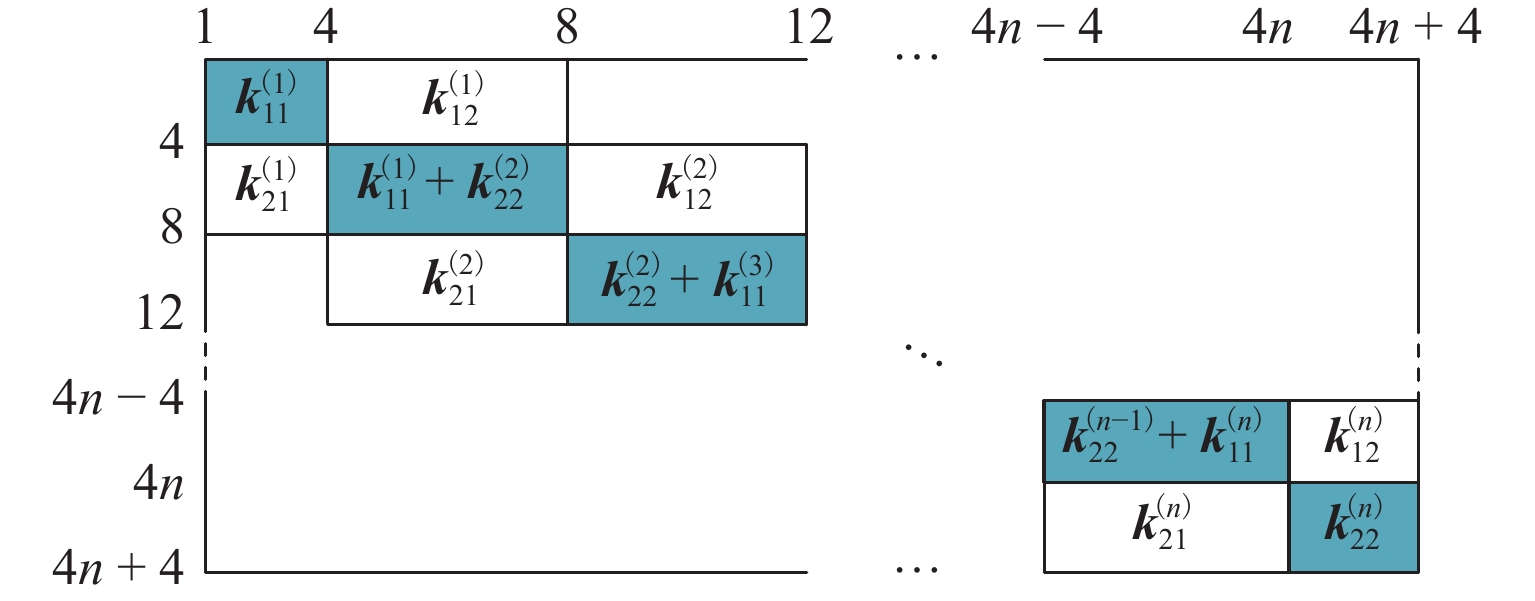

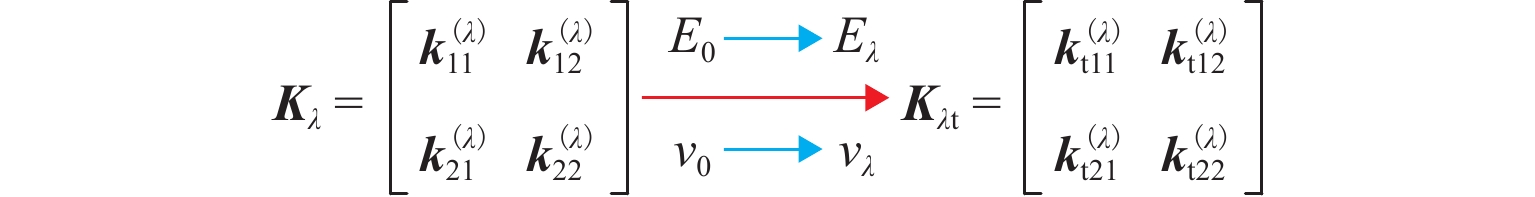

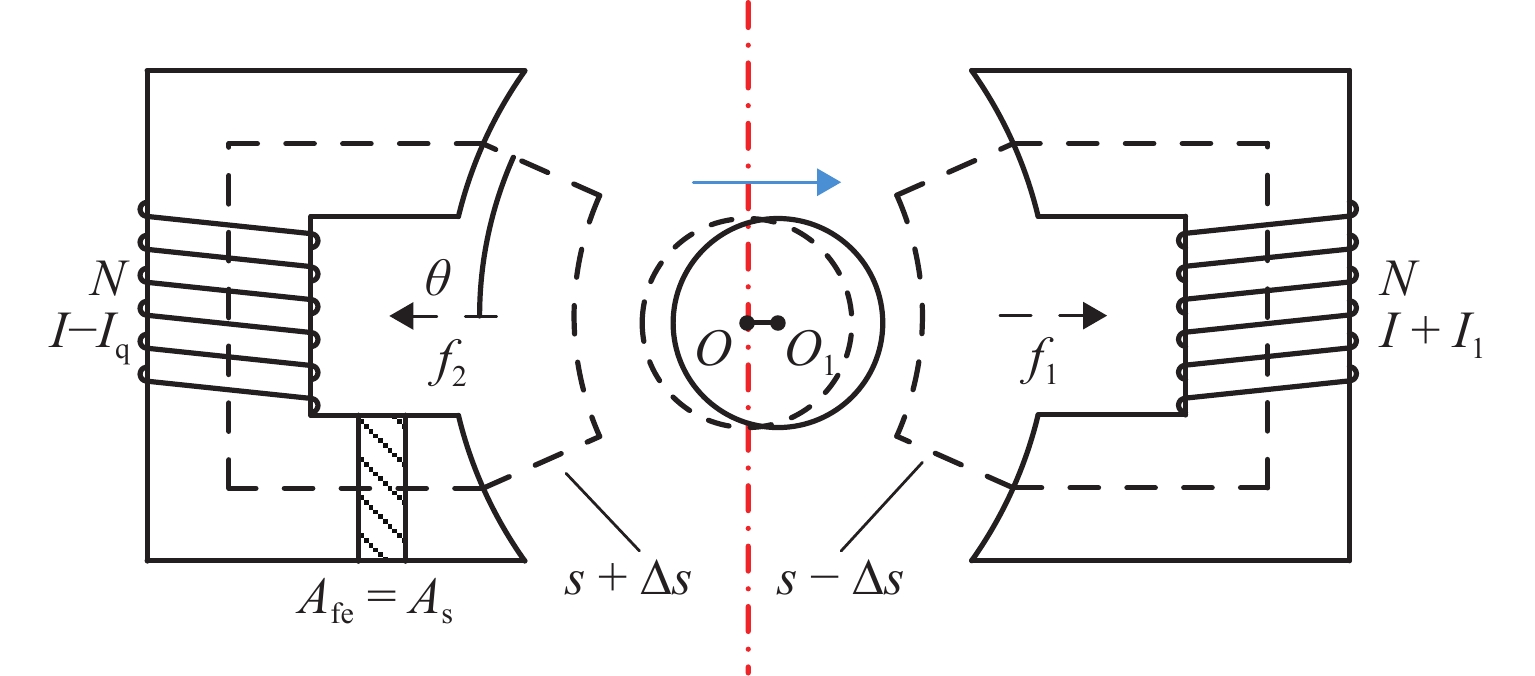

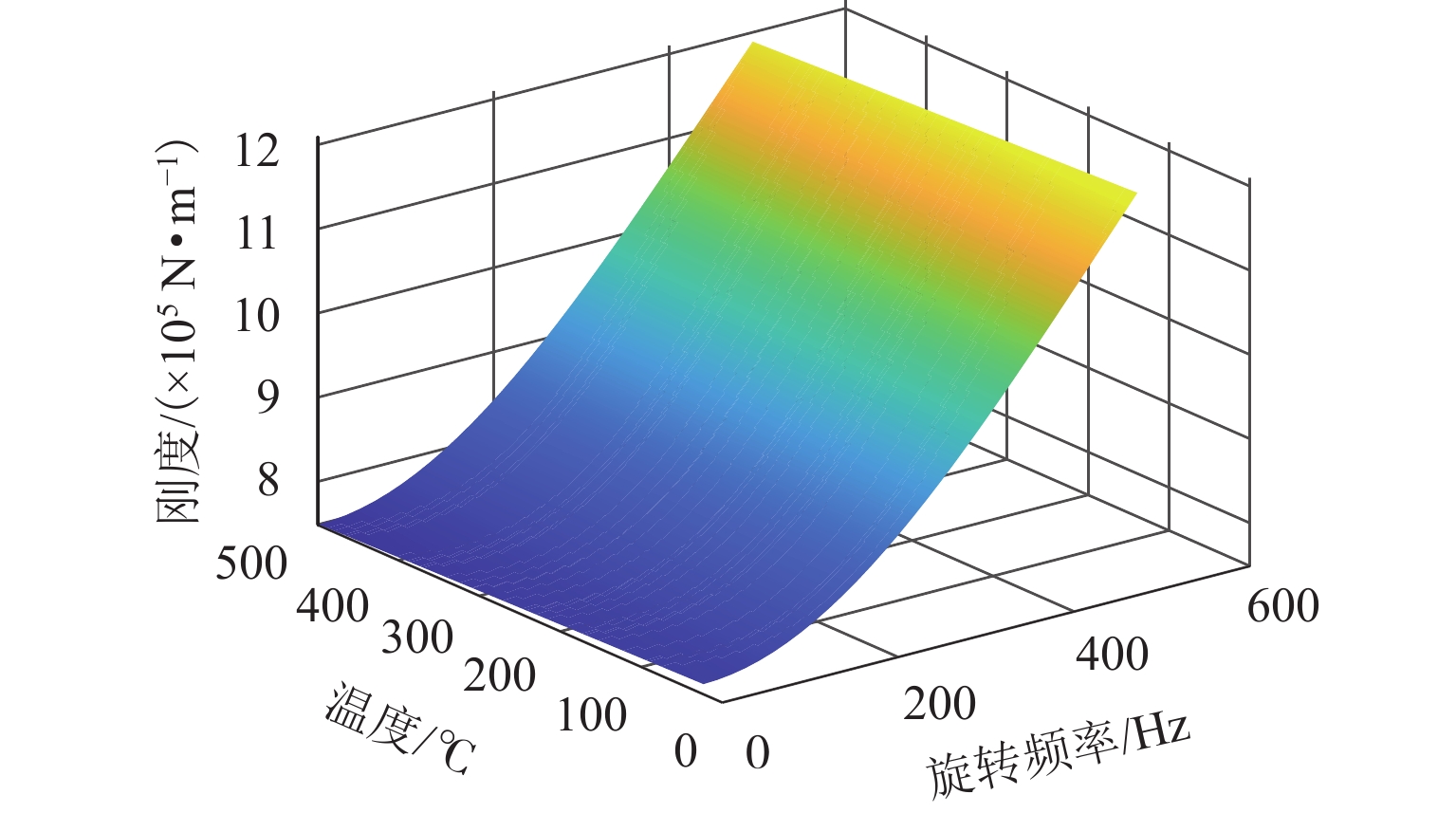

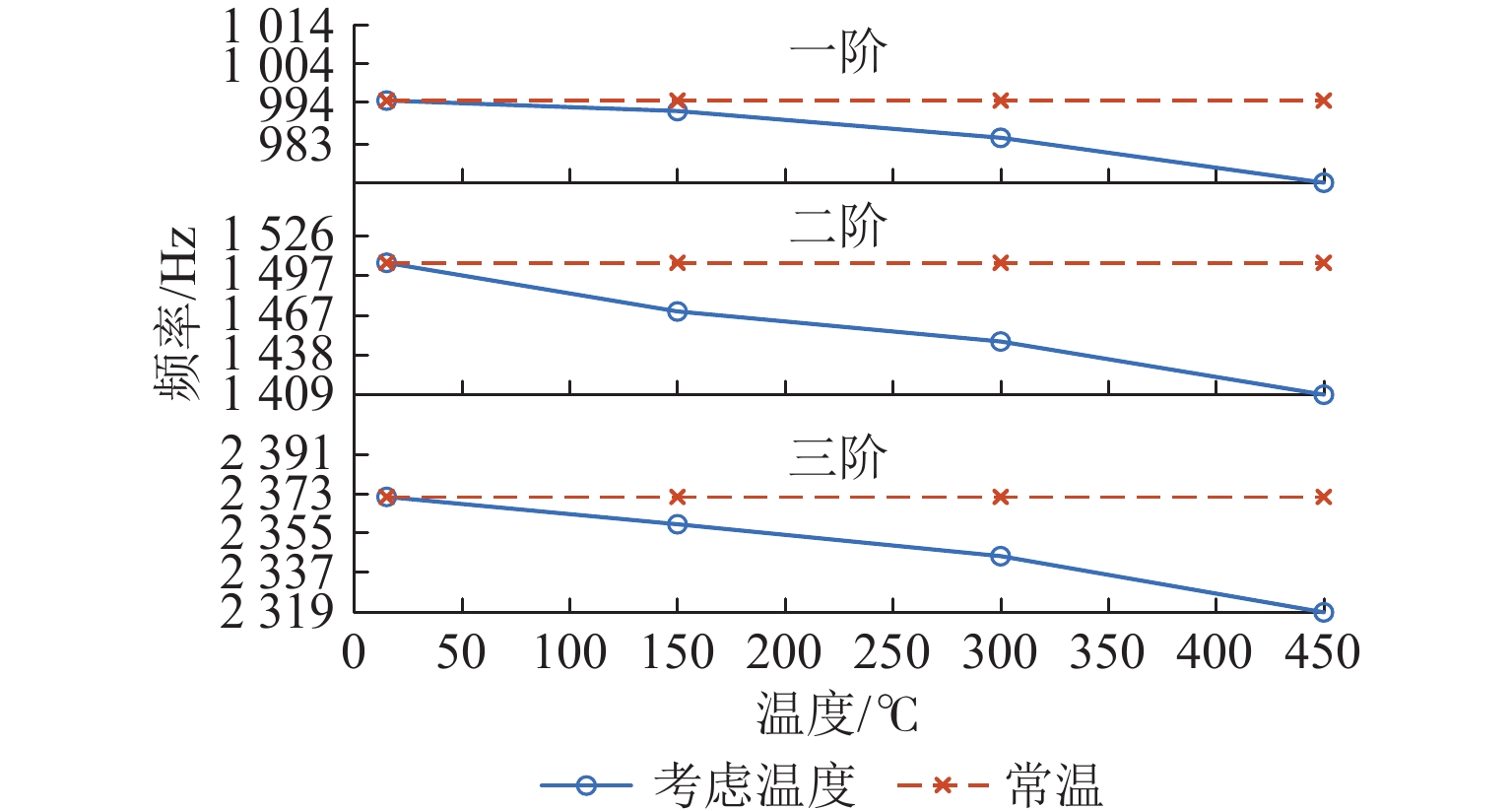

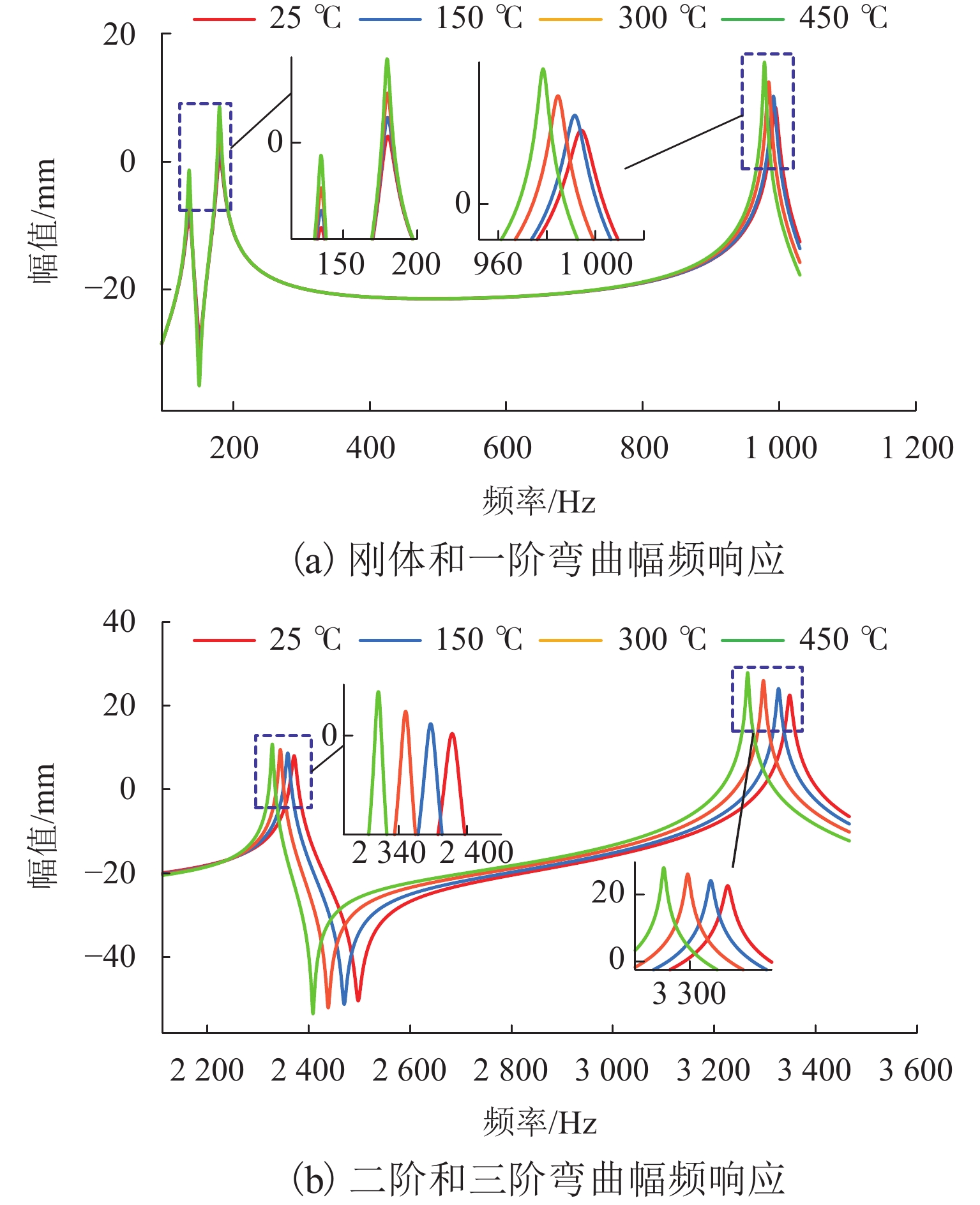

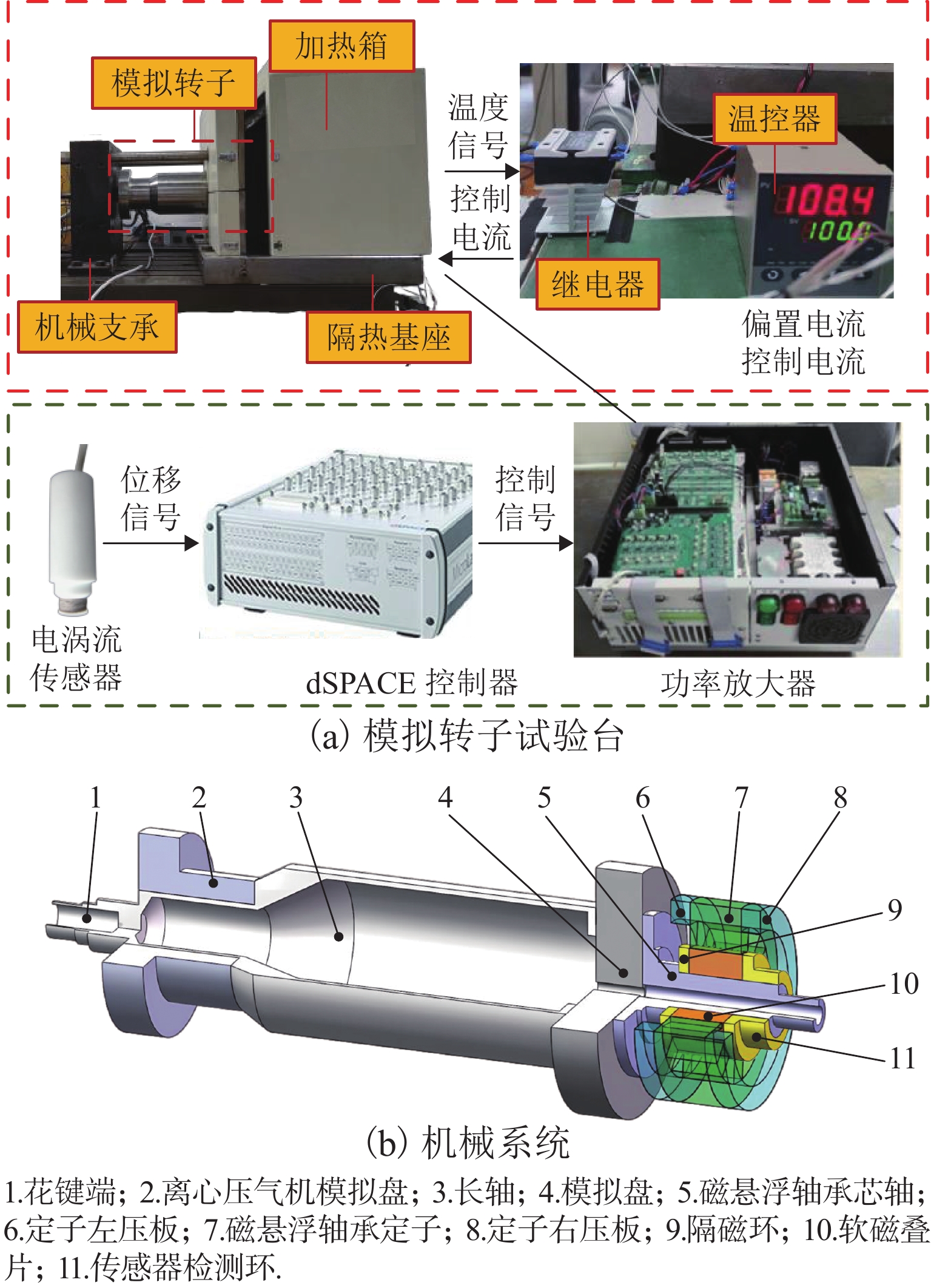

在多电航空发动机中,主动磁悬浮轴承因其耐高温、非接触等特性可以突破温度对支承部位的限制,使支承部位能够更靠近燃烧室. 为探究温度对磁悬浮轴承转子系统动态特性的影响规律,提出一种高温磁悬浮轴承转子系统动力学建模方法. 通过仿真得到转子在不同温度下的温度分布,并使用多项式拟合转子轴向温度分布;基于有限元方法推导柔性转子单元的动力学模型,引入温度影响,建立考虑温度影响的磁悬浮轴承转子系统整体动力学模型,并通过模态试验验证模型的准确性;基于理论动力学模型分析系统的动态特性. 结果表明:温度升高会导致转子的前三阶支承模态频率下降,增大各阶幅频响应幅值;当温度从常温升至450 ℃时,转子的前三阶弯曲支承模态频率分别降低了3.818%、5.670%、3.183%,前三阶弯曲模态幅频响应幅值分别升高了83.4%、34.4%、24.1%.

Abstract:In the multi-electric aircraft engine, an active magnetic bearing can break through the limitation of temperature on the support part due to its high temperature resistance and non-contact characteristics, which enables its support part to be closer to the combustion chamber. In order to investigate the influence of temperature on the dynamic characteristics of the magnetic bearing-rotor system, a dynamics modeling method for a high-temperature magnetic bearing-rotor system was proposed. The temperature distributions of the rotor at different temperatures were obtained through simulation, and the axial temperature distribution of the rotor was fitted using polynomials. Based on the finite element method, the dynamics model of the flexible rotor unit was derived. The temperature influence was introduced, and the overall dynamics model of the magnetic bearing- rotor system considering the temperature influence was established. The accuracy of the model was verified by a modal test. The dynamic characteristics of the system were analyzed based on the theoretical dynamics model, and the results show that an increase in temperature leads to a decrease in the first three orders of the support modal frequency of the rotor and an increase in the amplitude of the amplitude frequency response of each order. When the temperature increases from room temperature to 450 ℃, the first three orders of the bending support modal frequency of the rotor decrease by 3.818%, 5.670%, and 3.183%, respectively, and the amplitudes of the first three orders of the bending modal amplitude frequency response increase by 83.4%, 34.4%, and 24.1%, respectively.

-

表 1 机械系统所使用的材料

Table 1. Materials used in mechanical systems

序号 所用材料 1,2,3,4,6,8 1Cr11Ni2W2MoV 5 GH4169 7,10 高温软磁合金(1J22) 9,11 38 黄铜 表 2 数学模型拟合的R2值

Table 2. R2 by mathematical model fitting

m 150 ℃ 300 ℃ 450 ℃ 1 0.799 123 0.815 718 0.824 486 2 0.993 046 0.993 757 0.993 782 3 0.996 804 0.995 234 0.994 565 4 0.998 708 0.998 45 0.998 344 5 0.999 406 0.999 188 0.999 120 6 0.999 495 0.999 374 0.999 328 表 3 磁悬浮轴承的结构参数和电控参数

Table 3. Structural parameters and electrical control parameters of magnetic bearing

参数 取值 参数 取值 转子半径/mm 89.4 比例系数 kp 1 磁极面积 As/mm2 200 积分系数 ki 1 磁极夹角 θ/(°) 22.5 微分系数 kd 0.0 005 单边气隙 sa/mm 0.3 偏置电流 I/A 2 定子齿数 8 线圈匝数 N/匝 240 表 4 支承模态频率对比

Table 4. Comparison of support modal frequency

温度/℃ 阶次 计算频率/Hz 试验频率/Hz 误差/% 25 1 994.490 994.375 0.0 115 2 1506.200 1506.250 0.0 033 3 2437.090 2494.380 2.2 960 150 1 990.606 983.750 0.6 900 2 1471.570 1496.880 0.0 169 3 2421.910 2477.610 2.3 000 300 1 982.417 976.250 0.6 300 2 1450.280 1450.990 0.0 493 3 2404.800 2460.590 2.2 320 450 1 968.743 958.750 1.0 000 2 1412.160 1413.460 0.0 922 3 2374.860 2391.080 2.6 830 -

[1] 吴志琨,李军,时瑞军. 多电航空发动机研究现况及关键技术[J]. 航空工程进展,2012,3(4): 463-467. doi: 10.3969/j.issn.1674-8190.2012.04.015WU Zhikun, LI Jun, SHI Ruijun. Current research status and key technologies of more-electric aeroengine[J]. Advances in Aeronautical Science and Engineering, 2012, 3(4): 463-467. doi: 10.3969/j.issn.1674-8190.2012.04.015 [2] 刘程子,湛江,杨艳,等. 主动磁悬浮轴承–柔性转子的研究和发展综述[J]. 中国电机工程学报,2020,40(14): 4602-4614,4739.LIU Chengzi, ZHAN Jiang, YANG Yan, et al. Review of research status and development of flexible rotor-magnetic bearing[J]. Proceedings of the CSEE, 2020, 40(14): 4602-4614,4739. [3] 金超武. 高温磁悬浮轴承若干关键技术研究[D]. 南京:南京航空航天大学,2011. [4] ZIAEI-RAD S, KOUCHAKI E, IMREGUN M. Thermoelastic mdeling of rotor response with shaft rub[J]. Journal of Applied Mechanics, 2010, 77(6): 061010.1-061010.1. [5] 朱向哲,贺威,袁惠群. 稳态温度场对转子系统振动特性的影响[J]. 东北大学学报(自然科学版),2008,29(1): 113-116.ZHU Xiangzhe, HE Wei, YUAN Huiqun. Effects of steady temperature field on vibrational characteristics of a rotor system[J]. Journal of Northeastern University (Natural Science), 2008, 29(1): 113-116. [6] 何鹏,刘占生,刘镇星. 考虑杨氏模量随轴向温度分布变化的转子有限元建模方法研究[J]. 振动与冲击,2012,31(14): 22-26,55. doi: 10.3969/j.issn.1000-3835.2012.14.005HE Peng, LIU Zhansheng, LIU Zhenxing. Finite element modelling of rotor considering the variation of Yang’s modulus with axial temperature distribution[J]. Journal of Vibration and Shock, 2012, 31(14): 22-26,55. doi: 10.3969/j.issn.1000-3835.2012.14.005 [7] GOU X F, ZHU L Y, QI C J. Nonlinear dynamic model of a gear-rotor-bearing system considering the flash temperature[J]. Journal of Sound and Vibration, 2017, 410: 187-208. [8] XIANG F G, CHEN X, ZHANG B, et al. Simulation method of rotor dynamic characteristics considering temperature distribution and aerodynamic load[C]//Proceedings of ASME Turbo Expo 2022:Turbomachinery Technical Conference and Exposition. Rotterdam:ASME, 2022:13-17. [9] DU T C, SUN Y H, GENG H P, et al. Dynamic Analysis on Rotor System Supported by Active Magnetic Bearings based on Sliding Mode Control[C]//2018 IEEE International Conference on Mechatronics and Automation (ICMA). Changchun:IEEE, 2018:1960-1965. [10] MUSHI S E, LIN Z L, ALLAIRE P E. Design, construction, and modeling of a flexible rotor active magnetic bearing test rig[J]. ASME Transactions on Mechatronics, 2012, 17(6): 1170-1182. [11] XU Y P, ZHOU J, LIN Z L, et al. Identification of dynamic parameters of active magnetic bearings in a flexible rotor system considering residual unbalances[J]. Mechatronics, 2018, 49: 46-55. [12] 沈权,周瑾,马彦超,等. 基础激励下磁悬浮转子系统动力学建模与分析[J]. 振动与冲击,2022,41(17): 35-47,72.SHEN Quan, ZHOU Jin, MA Yanchao, et al. Dynamic modeling and analysis of maglev rotor system under base excitation[J]. Journal of Vibration and Shock, 2022, 41(17): 35-47,72. [13] WU C, SU Z Z, WANG D, et al. Dynamic modeling method for active magnetic bearings-rotor system of steam turbines[J]. Journal of Mechanical Science and Technology, 2023, 37(4): 1665-1673. [14] 王戈一. 磁悬浮多电发动机的研究[J]. 燃气涡轮试验与研究,2007,20(4): 15-18,35. doi: 10.3969/j.issn.1672-2620.2007.04.003WANG Geyi. Study of a more-electric engine with active magnetic bearings[J]. Gas Turbine Experiment and Research, 2007, 20(4): 15-18,35. doi: 10.3969/j.issn.1672-2620.2007.04.003 [15] BURDET L. Active magnetic bearing design and characterization for high temperature applications[R]. Swiss:Federal Institute of Technology in Lausanne, 2006. [16] MONTAGUE G T, JANSEN M J, PROVENZA A, et al. Experimental high temperature characterization of a magnetic bearing for turbomachinery[C]//59th Annual Forum and Technology Display. Phoenix:Vertical Flight Society, 2003:1-18. [17] SHI Z, SUN X D, LEI G, et al. Multiobjective optimization of a five-phase bearingless permanent magnet motor considering winding area[J]. IEEE/ASME Transactions on Mechatronics, 2022, 27(5): 2657-2666. [18] 周扬,周瑾,张越,等. 基于RBF近似模型的磁悬浮轴承结构优化设计[J]. 西南交通大学学报,2022,57(3): 682-692. doi: 10.3969/j.issn.0258-2724.20210766ZHOU Yang, ZHOU Jin, ZHANG Yue, et al. Optimum structural design of active magnetic bearing based on RBF approximation model[J]. Journal of Southwest Jiaotong University, 2022, 57(3): 682-692. doi: 10.3969/j.issn.0258-2724.20210766 [19] 徐园平. 柔性转子磁悬浮轴承支承特性辨识[D]. 南京:南京航空航天大学,2018. -

下载:

下载: