Study on Uniaxial Tensile Test and Constitutive Model of Steel Structure Coating

-

摘要:

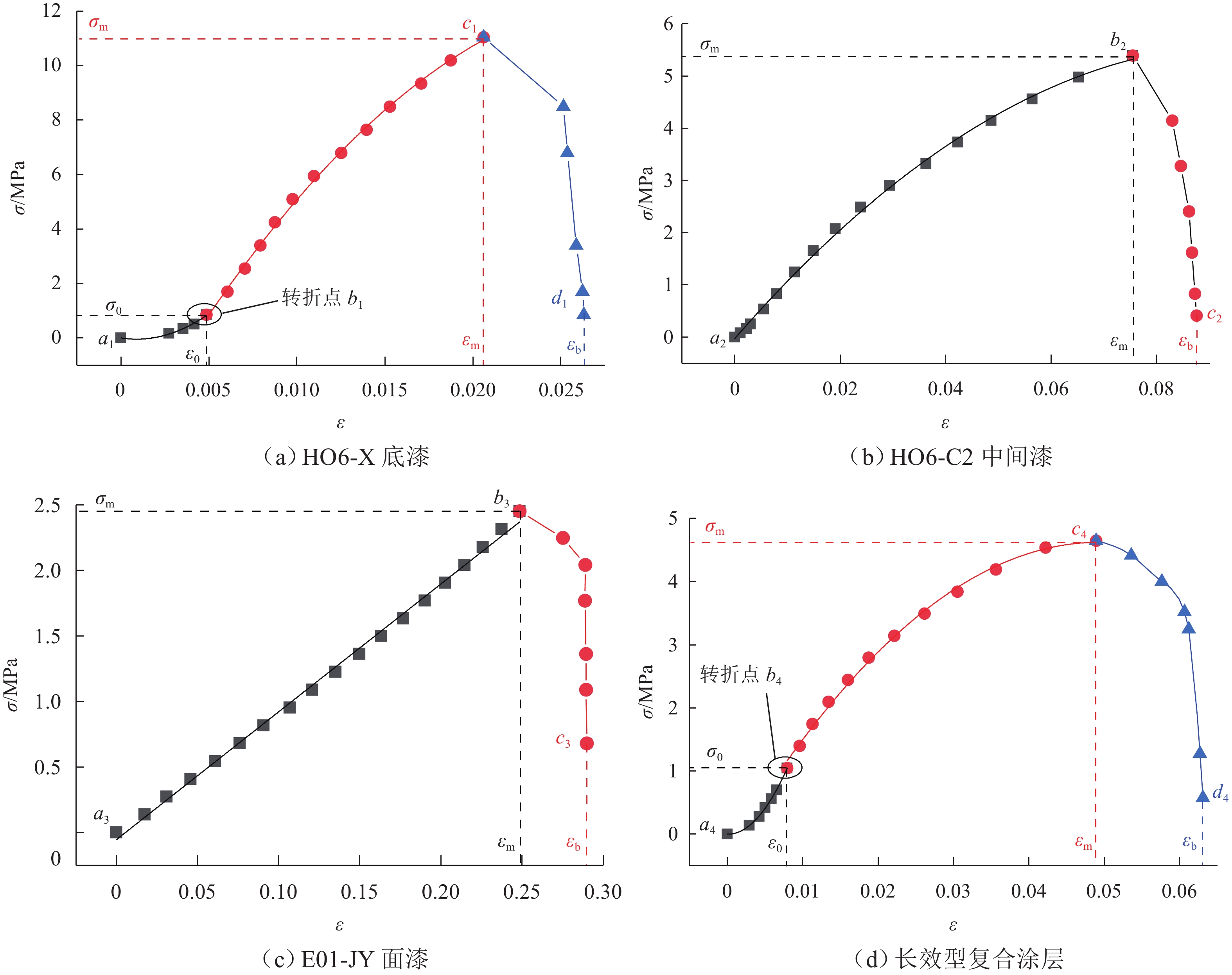

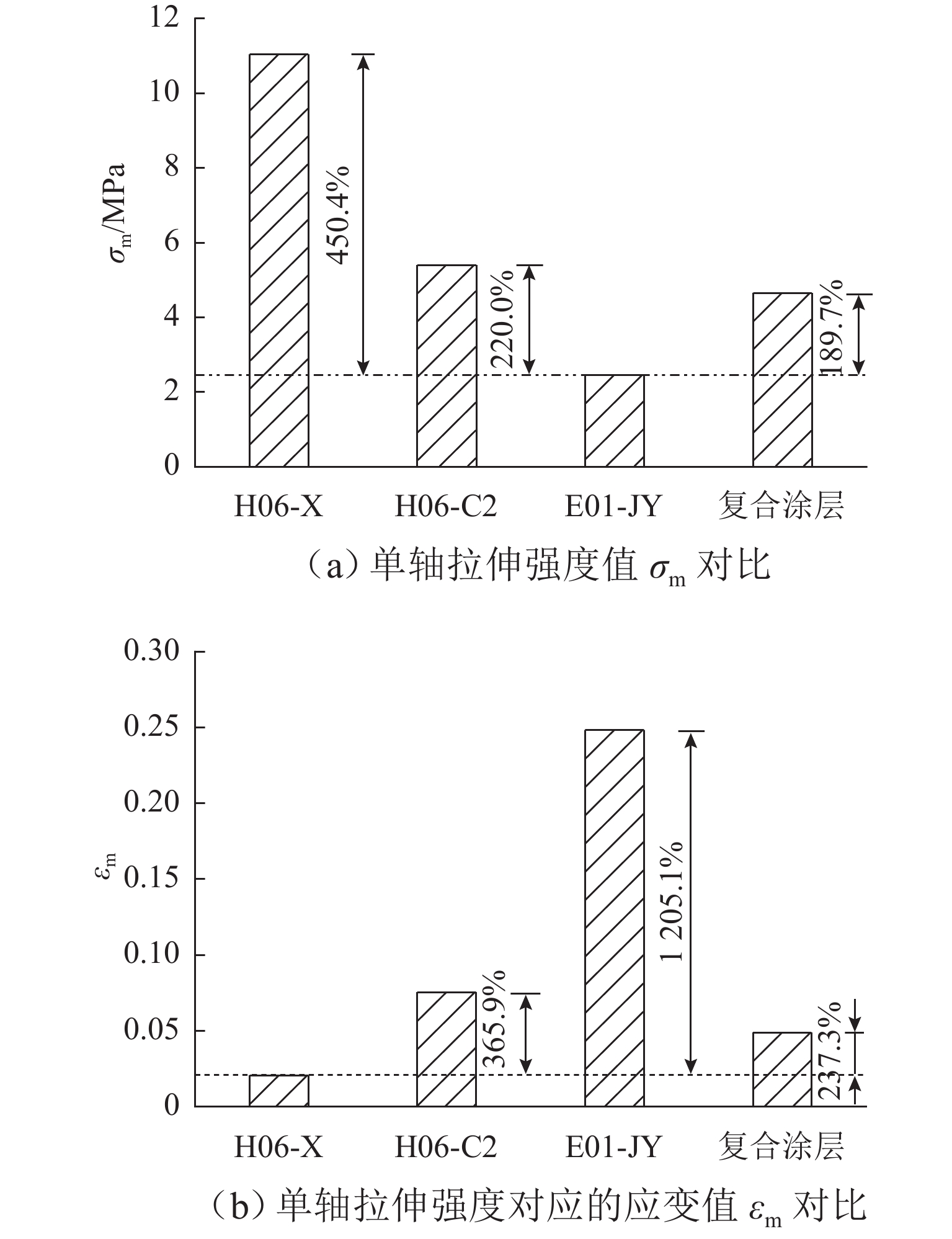

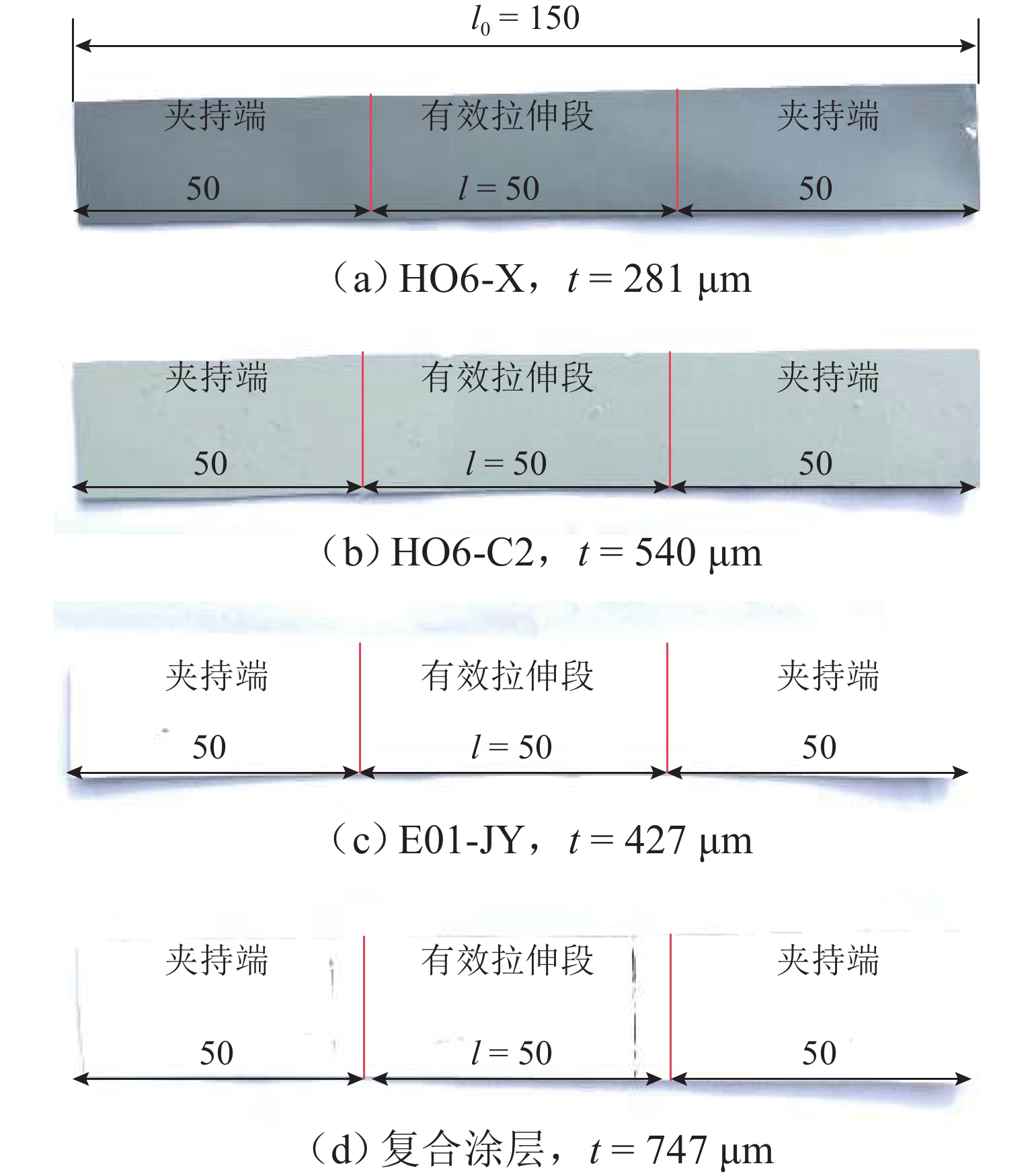

为研究钢结构桥梁涂装层的力学本构模型,以长效型涂装体系为试验对象对其分别进行单轴拉伸试验,得出面漆、中间漆、底漆和复合涂层的应力-应变曲线;通过无量纲化处理获得长效型涂装体系上升段本构方程的统一表达形式,并针对每种漆膜适用条件给出相应的本构方程. 研究结果表明:1) H06-X环氧富锌底漆(含锌量80%)和长效型复合涂层的应力-应变曲线分为弹塑型阶段、应变强化阶段和破坏阶段;H06-C2环氧厚浆云母氧化铁中间漆的应力-应变曲线分为应变强化阶段和破坏阶段;E01-JY氟碳面漆的应力-应变曲线分为近似线弹性阶段和破坏阶段. 2) 依据应力-应变曲线得出了底漆、中间漆、面漆和复合涂层的弹性模量、泊松比、剪切模量、单轴拉伸强度、拉伸断裂应变等力学性能特征参数;底漆的单轴拉伸强度最强,中间漆次之,面漆最差;面漆的变形性能最佳,中间漆次之,底漆最差.

Abstract:To study the mechanical constitutive model of steel bridge coating, uniaxial tensile tests were carried out on the long-lasting coating system, obtaining the stress–strain curves for the topcoat, intermediate coat, primer, and composite coating. The unified expression for the constitutive equation of the ascending segment of the long-lasting coating system was obtained through dimensionless processing, with corresponding constitutive equations provided for each coating film. The results are as follows. 1) The stress–strain curve for H06-X epoxy zinc-rich primer (80% zinc content) and long-lasting composite coating consists of an elastic and plastic stage, a strain-hardening stage, and a failure stage; the stress–strain curve for H06-C2 epoxy thick mica ferric oxide intermediate coat consists of a strain-hardening stage and a failure stage; the stress–strain curve for E01-JY fluorocarbon topcoat consists of an approximate linear elastic stage and a failure stage. 2) Based on the stress–strain curves, the mechanical property parameters of the primer, intermediate coat, topcoat, and composite coating, such as the elastic modulus, Poisson’s ratio, shear modulus, uniaxial tensile strength, and tensile fracture strain, are obtained. The primer shows the highest uniaxial tensile strength, followed by the intermediate paint, with the topcoat being the weakest. In contrast, the topcoat exhibits the best deformability, followed by the intermediate coat, with the primer showing the worst.

-

表 1 钢结构桥梁长效型涂装体系组分及配比

Table 1. Components and ratios of long-lasting coating system for steel bridge

对象 A组分 B组分 比例 底漆 H06-X环氧富锌底漆

(含锌量80%)H06-X固化剂 12.8∶1 中间漆 H06-C2环氧厚浆云母

氧化铁中间漆H06-C2固化剂 13.5∶1 面漆 E01-JY氟碳面漆 E01-JY固化剂 10∶1 表 2 涂层力学性能参数

Table 2. Mechanical property parameters for coatings

涂层种类 E/MPa υ G/MPa σm /MPa εm εb H06-X底漆 535.7 0.20 223.2 11.0 0.021 0.026 H06-C2中间漆 71.5 0.06 33.8 5.4 0.075 0.086 E01-JY面漆 9.9 0.03 4.8 2.5 0.248 0.289 复合涂层 95.1 0.13 41.9 4.7 0.049 0.062 -

[1] KAMANI P K. Corrosion management & coatings[J]. Paintindia, 2016, 1: 100-105. [2] 戴润达. 钢桥梁的长效防腐涂装[J]. 涂料工业,2018,48(12): 74-79. doi: 10.12020/j.issn.0253-4312.2018.12.74DAI Runda. Research on long-lasting anticorrosive coating of steel bridge[J]. Paint & Coatings Industry, 2018, 48(12): 74-79. doi: 10.12020/j.issn.0253-4312.2018.12.74 [3] TOUBIA E A, EMAMI S. Experimental evaluation of structural steel coating systems[J]. Journal of Materials in Civil Engineering, 2016, 28(12): 4016147.1-4016147.10. [4] 蔺鹏臻,魏亚鹏,乔叶伟. 风沙冲蚀下钢结构涂层的界面应力与破坏准则[J]. 西南交通大学学报,2023,58(1): 236-243. doi: 10.3969/j.issn.0258-2724.20210189LIN Pengzhen, WEI Yapeng, QIAO Yewei. Interfacial stress and failure criteria of steel structure coatings under wind-sand erosion[J]. Journal of Southwest Jiaotong University, 2023, 58(1): 236-243. doi: 10.3969/j.issn.0258-2724.20210189 [5] HIROKAZU M. A multi-step linear approximation method for nonlinear analysis of stress and deformation of coated plain-weave fabric[J]. Journal of Textile Engineering, 2006, 52(5): 189-195. doi: 10.4188/jte.52.189 [6] BOGNER B H. The mechanical behaviour of coated fabrics used in prestressing textile engineering structures: theory, simulation and numerical analysis to be used in a fem-model[J]. Journal of the International Association for Shell and Spatial Structures, 2008, 49(1): 39-47. [7] 许荔,江晓禹,钱林茂. 树脂基纳米涂层复合材料力学性能试验研究[J]. 西南交通大学学报,2005,40(3): 347-350. doi: 10.3969/j.issn.0258-2724.2005.03.014XU Li, JIANG Xiaoyu, QIAN Linmao. Experimental study on mechanical properties of resin matrix nano-coating composites[J]. Journal of Southwest Jiaotong University, 2005, 40(3): 347-350. doi: 10.3969/j.issn.0258-2724.2005.03.014 [8] 陈辉,苟国庆,刘艳,等. 等离子喷涂WC-17Co纳米涂层形成及强韧化机理[J]. 西南交通大学学报,2008,43(5): 633-637. doi: 10.3969/j.issn.0258-2724.2008.05.015 [9] CHEN Hui, GOU Guoqing, LIU Yan, et al. Formation and strengthening mechanisms of plasma sprayed nanostructured WC-Co coating[J]. Journal of Southwest Jiaotong University, 2008, 43(5): 633-637. [10] 易洪雷,丁辛,陈守辉. PES/PVC膜材料拉伸性能的各向异性及破坏准则[J]. 复合材料学报,2005,22(6): 98-102. doi: 10.3321/j.issn:1000-3851.2005.06.017YI Honglei, DING Xin, CHEN Shouhui. Orthotropic behavior and strength criterion of pes/pvc membrane materials under tensile loading[J]. Acta Materiae Compositae Sinica, 2005, 22(6): 98-102. doi: 10.3321/j.issn:1000-3851.2005.06.017 [11] 刘平,吴刚,唐柏鉴,等. PVDF涂层织物拉伸力学性能试验研究[J]. 东南大学学报(自然科学版),2017,47(6): 1195-1200.LIU Ping, WU Gang, TANG Baijian, et al. Experimental study on mechanical properties of PVDF textile[J]. Journal of Southeast University (Natural Science Edition), 2017, 47(6): 1195-1200. [12] 于沁灵,龚景海,郭晓,等. 涂层织物类膜材的拉伸试验及力学参数研究[J]. 空间结构,2020,26(4): 64-69.YU Qinling, GONG Jinghai, GUO Xiao, et al. Tensile test and mechanical parameters of coated fabric membrane[J]. Spatial Structures, 2020, 26(4): 64-69. [13] 王利钢,陈务军,高成军. 聚酯纤维机织物-聚氯乙烯-聚偏氟乙烯膜材双轴剪切力学性能试验[J]. 复合材料学报,2015,32(4): 1118-1124.WANG Ligang, CHEN Wujun, GAO Chengjun. Test on biaxial shear mechanical performance of polyester fabric-polyvinyl chloride-polyvinylidene fluoride membrane[J]. Acta Materiae Compositae Sinica, 2015, 32(4): 1118-1124. [14] 李阳. 建筑膜材料和膜结构的力学性能研究与应用[D]. 上海:同济大学,2007.LI Yang. Study and Applications on Mechanical Properties of Membrane Materials and Structures[D]. Shanghai: Tongji University, 2007. [15] 许珊珊,张营营,徐俊豪,等. PVC涂层织物膜材的非线性各向异性本构关系模型[J]. 建筑材料学报,2020,23(5): 1098-1103. doi: 10.3969/j.issn.1007-9629.2020.05.015XU Shanshan, ZHANG Yingying, XU Junhao, et al. Nonlinear anisotropic constitutive model of PVC coated fabric membrane[J]. Journal of Building Materials, 2020, 23(5): 1098-1103. doi: 10.3969/j.issn.1007-9629.2020.05.015 [16] 张营营,徐俊豪,曹原,等. PTFE膜材料的偏轴拉伸性能及破坏机理[J]. 哈尔滨工业大学学报,2016,48(12): 135-141,164.ZHANG Yingying, XU Junhao, CAO Yuan, et al. Off-axial tensile behaviors and failure mechanisms of PTFE coated fabrics[J]. Journal of Harbin Institute of Technology, 2016, 48(12): 135-141,164. [17] European Committee for Standardization. Plastics determination of Tensile Properties: ISO 527 -3-2018[S]. Belgium Brusse: European Committee for Standardization, 2018. [18] 何平笙. 高聚物的力学性能[M]. 第3版. 合肥:中国科学技术大学出版社,2021:218. [19] 束德林. 工程材料力学性能[M]. 第3版. 北京:机械工业出版社,2016:192-195. -

下载:

下载: