Cause of Rail Corrugation on Ladder Sleeper Track

-

摘要:

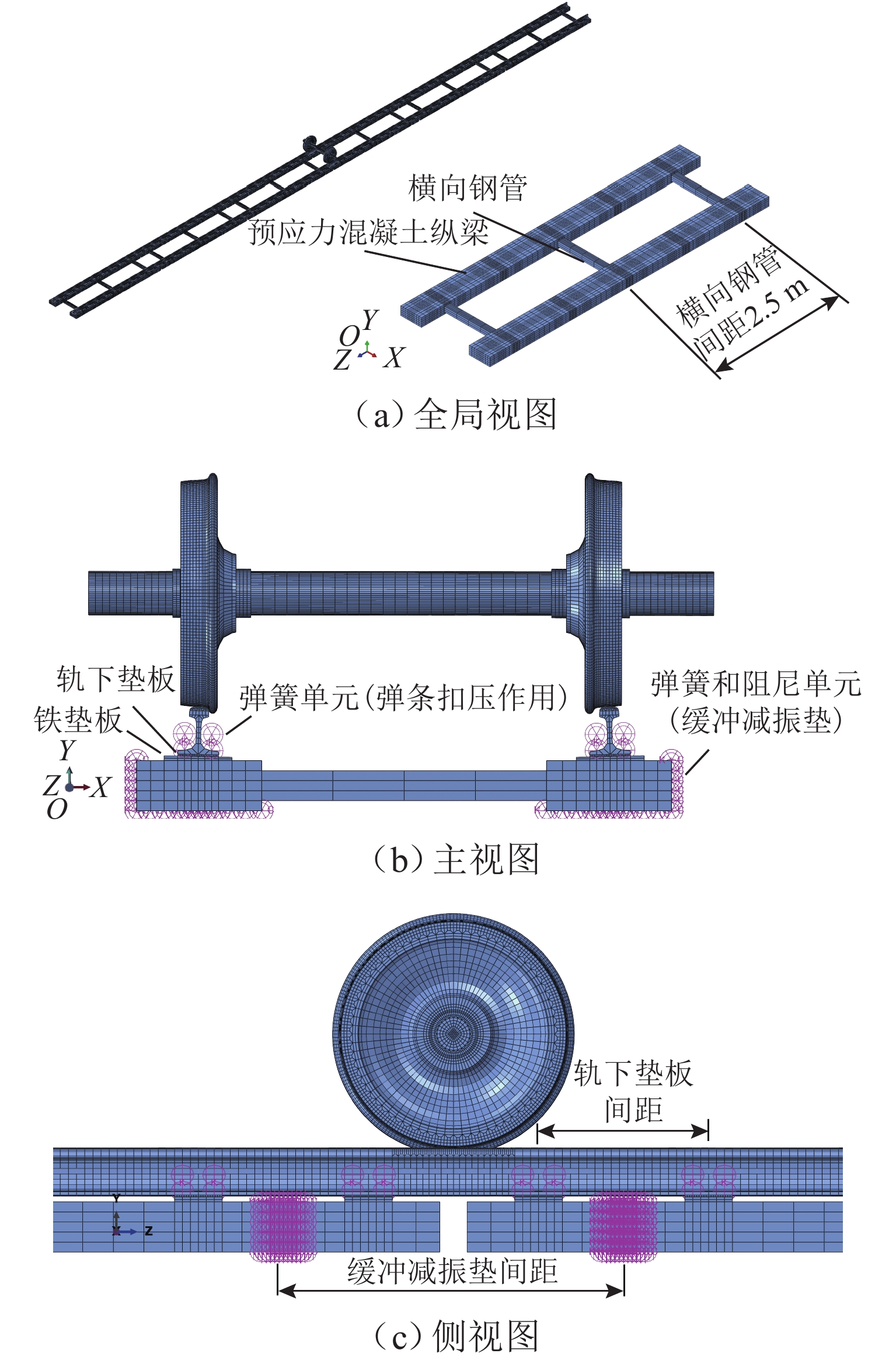

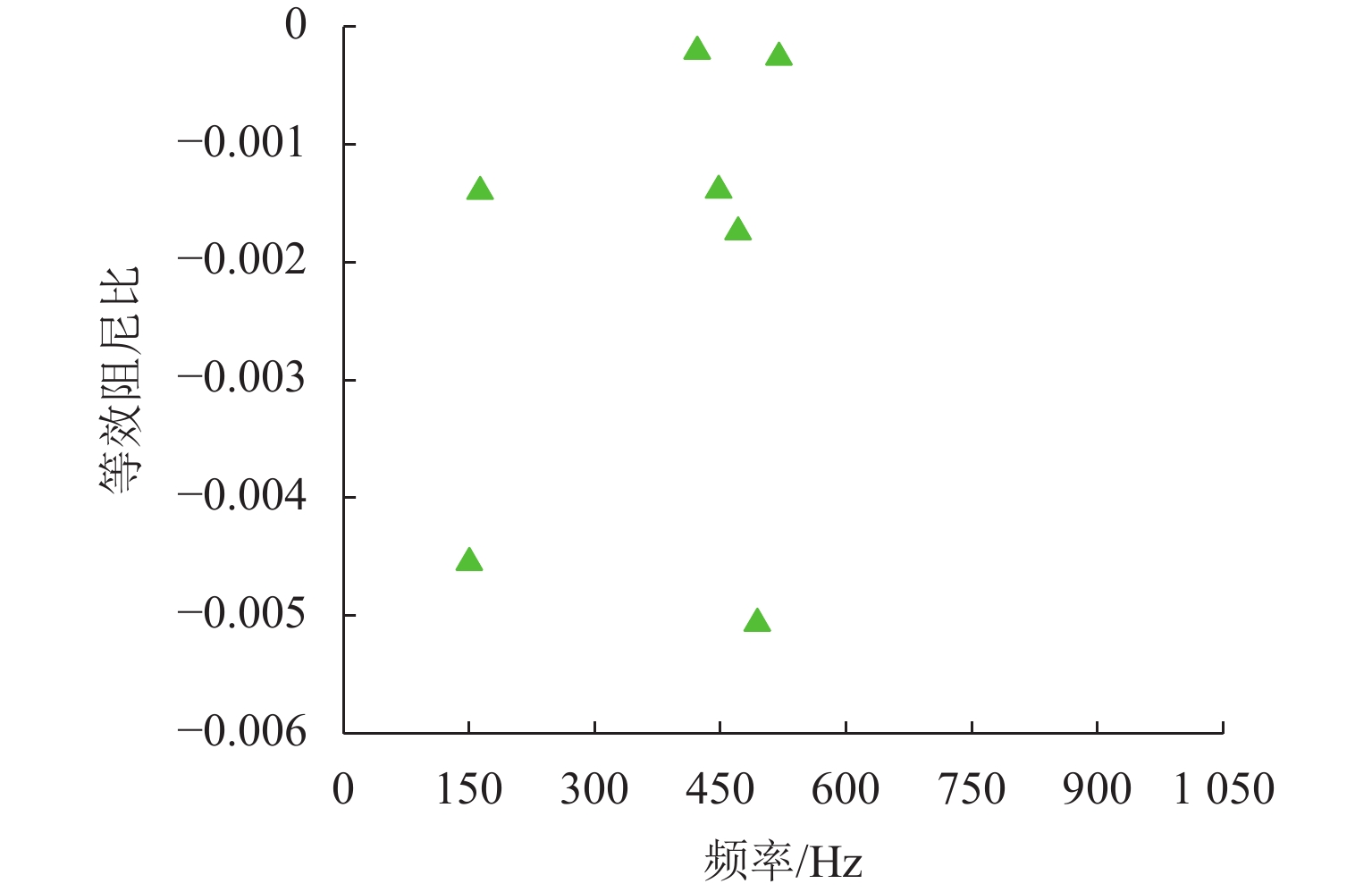

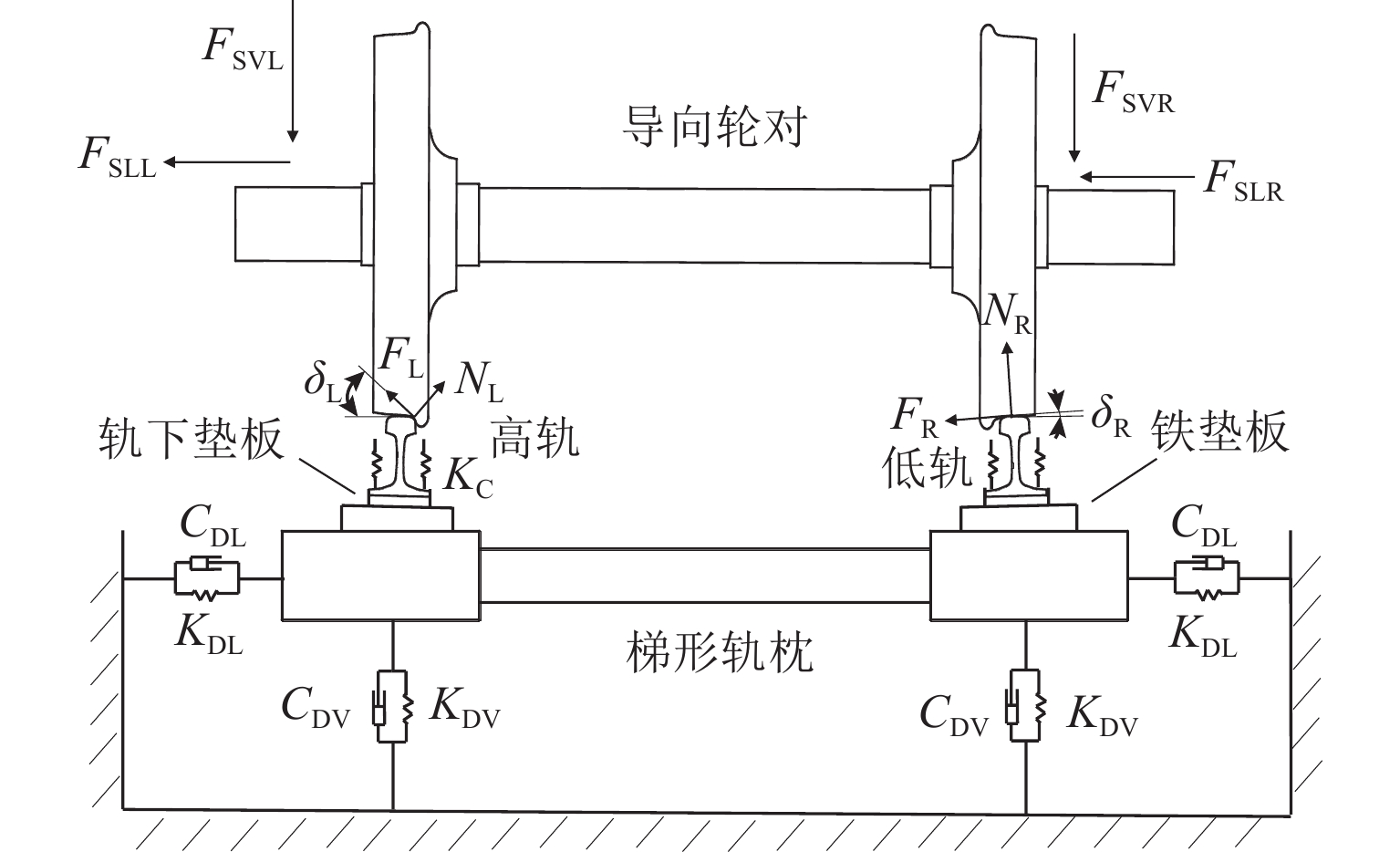

为研究地铁小半径曲线段梯形轨枕轨道上内轨波磨的形成机理,基于饱和轮轨蠕滑力引发的摩擦自激振动导致钢轨波磨的理论,建立导向轮对-梯形轨枕轨道系统有限元模型,模型中采用实体单元对扣件系统进行建模;应用复特征值分析和瞬时动态分析分别求解轮轨系统的运动稳定性和时域动态响应;研究了缓冲减振垫参数和梯形轨枕结构对轮轨系统摩擦自激振动的影响. 研究结果表明:饱和轮轨蠕滑力引发的频率为150 Hz的摩擦自激振动是小半径曲线段梯形轨枕轨道上内轨波磨的成因,预测得到的波磨波长约为69 mm,与实测结果很接近;参数敏感性分析表明,增大侧向缓冲垫阻尼及铺设横向钢管间距为1.25 m的梯形轨枕可以在一定程度上抑制梯形轨枕轨道上的钢轨波磨.

Abstract:To study the formation mechanism of inner rail corrugation on the ladder sleeper track in the small-radius curve, a finite element model of the leading wheelset–ladder sleeper track system was developed based on the theory that self-excited frictional vibration triggered by saturated wheel-rail creep force causes rail corrugation. In this model, solid elements were used to model the fastening system. Complex eigenvalue analysis and transient dynamic analysis were applied to solve the motion stability and dynamic time-domain response of the wheel-rail system, respectively. Furthermore, the effects of the parameters of the cushioning pad and ladder sleeper structure on the self-excited frictional vibration of the wheel-rail system were studied. The results show that the self-excited frictional vibration with a frequency of 150 Hz caused by the saturated wheel-rail creep force is the cause of inner rail corrugation on the ladder sleeper track in the small-radius curve section. The predicted corrugation wavelength is 69 mm, which agrees well with the measured wavelength. Parameter sensitivity analysis shows that increasing the damping of the lateral cushioning pad and laying ladder sleepers with a spacing of 1.25 m between lateral steel pipes can suppress rail corrugation on the ladder sleeper track to a certain extent.

-

表 1 材料参数

Table 1. Material parameters

部件 密度/

(×103 kg·m−3)弹性模量/MPa 泊松比 钢轨/轮对 7.80 210000 0.30 轨下垫板 1.19 12 0.45 铁垫板 7.80 173000 0.30 横向钢管 7.80 210000 0.30 混凝土纵梁 2.50 36000 0.20 -

[1] CUI X L, CHEN G X, OUYANG H J. Study on the effect of track curve radius on friction-induced oscillation of a wheelset–track system[J]. Tribology Transactions, 2019, 62(4): 688-700. doi: 10.1080/10402004.2019.1601317 [2] 陈光雄. 钢轨波磨预测模型验证工况的研究[J]. 西南交通大学学报,2022,57(5): 1017-1023,1054. doi: 10.3969/j.issn.0258-2724.20200842CHEN Guangxiong. Study on validation conditions of rail corrugation prediction models[J]. Journal of Southwest Jiaotong University, 2022, 57(5): 1017-1023,1054. doi: 10.3969/j.issn.0258-2724.20200842 [3] WANG P, LU J, ZHAO C Y, et al. Numerical investigation of the fatigue performance of elastic rail clips considering rail corrugation and dynamic axle load[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2021, 235(3): 339-352. doi: 10.1177/0954409720926016 [4] 关庆华,张斌,熊嘉阳,等. 地铁钢轨波磨的基本特征、形成机理和治理措施综述[J]. 交通运输工程学报,2021,21(1): 316-337.GUAN Qinghua, ZHANG Bin, XIONG Jiayang, et al. Review on basic characteristics, formation mechanisms, and treatment measures of rail corrugation in metro systems[J]. Journal of Traffic and Transportation Engineering, 2021, 21(1): 316-337. [5] TORSTENSSON P T, SCHILKE M. Rail corrugation growth on small radius curves—measurements and validation of a numerical prediction model[J]. Wear, 2013, 303(1/2): 381-396. [6] HIENSCH M, NIELSEN J C O, VERHEIJEN E. Rail corrugation in The Netherlands—measurements and simulations[J]. Wear, 2002, 253(1/2): 140-149. [7] SHENG X, THOMPSON D J, JONES C J C, et al. Simulations of roughness initiation and growth on railway rails[J]. Journal of Sound and Vibration, 2006, 293(3/4/5): 819-829. [8] ROBLES R, CORREA N, VADILLO E G, et al. Comprehensive efficient vertical and lateral track dynamic model to study the evolution of rail corrugation in sharp curves[J]. Journal of Sound and Vibration, 2023, 545: 117448. 1-117448.18. [9] WU T X, THOMPSON D J. An investigation into rail corrugation due to micro-slip under multiple wheel/rail interactions[J]. Wear, 2005, 258(7/8): 1115-1125. [10] JIN X S, WEN Z F, WANG K Y, et al. Three-dimensional train–track model for study of rail corrugation[J]. Journal of Sound and Vibration, 2006, 293(3/4/5): 830-855. [11] EADIE D T, KALOUSEK J, CHIDDICK K C. The role of high positive friction (HPF) modifier in the control of short pitch corrugations and related phenomena[J]. Wear, 2002, 253(1/2): 185-192. [12] SUN Y Q, SIMSON S. Wagon–track modelling and parametric study on rail corrugation initiation due to wheel stick-slip process on curved track[J]. Wear, 2008, 265(9/10): 1193-1201. [13] LIU X G, WANG P. Investigation of the generation mechanism of rail corrugation based on friction induced torsional vibration[J]. Wear, 2021, 468/469: 203593.1-203593.9. [14] CHEN G X, ZHANG S, WU B W, et al. Field measurement and model prediction of rail corrugation[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2020, 234(4): 381-392. doi: 10.1177/0954409719877318 [15] CHEN G X, ZHOU Z R, OUYANG H, et al. A finite element study on rail corrugation based on saturated creep force-induced self-excited vibration of a wheelset–track system[J]. Journal of Sound and Vibration, 2010, 329(22): 4643-4655. doi: 10.1016/j.jsv.2010.05.011 [16] QIAN W J, CHEN G X, OUYANG H, et al. A transient dynamic study of the self-excited vibration of a railway wheel set–track system induced by saturated creep forces[J]. Vehicle System Dynamics, 2014, 52(9): 1115-1138. doi: 10.1080/00423114.2014.924629 [17] QIAN W J, HUANG Z Q, OUYANG H, et al. Numerical investigation of the effects of rail vibration absorbers on wear behaviour of rail surface[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2019, 233(3): 424-438. doi: 10.1177/1350650118785061 [18] CUI X L, CHEN G X, YANG H G, et al. Effect of the wheel/rail contact angle and the direction of the saturated creep force on rail corrugation[J]. Wear, 2015, 330/331: 554-562. doi: 10.1016/j.wear.2014.12.046 [19] 吴波文,陈光雄,赵晓男,等. 地铁先锋扣件地段钢轨波磨成因[J]. 西南交通大学学报,2020,55(3): 650-657. doi: 10.3969/j.issn.0258-2724.20180371WU Bowen, CHEN Guangxiong, ZHAO Xiaonan, et al. Formation mechanisim of rail corrugation occurring on tight curved track with vanguard fasteners[J]. Journal of Southwest Jiaotong University, 2020, 55(3): 650-657. doi: 10.3969/j.issn.0258-2724.20180371 [20] WANG Z Q, LEI Z Y. Analysis of influence factors of rail corrugation in small radius curve track[J]. Mechanical Sciences, 2021, 12(1): 31-40. doi: 10.5194/ms-12-31-2021 [21] WANG Y, XIAO H, NADAKATTI M M, et al. Mechanism of rail corrugation combined with friction self-excited vibration and wheel-track resonance[J]. Construction and Building Materials, 2023, 400: 132782.1-132782.16. [22] EL BESHBICHI O, WAN C, BRUNI S, et al. Complex eigenvalue analysis and parameters analysis to investigate the formation of railhead corrugation in sharp curves[J]. Wear, 2020, 450/451: 203150.1-203150.10. [23] FOURIE D, FRÖHLING R, HEYNS S. Railhead corrugation resulting from mode-coupling instability in the presence of veering modes[J]. Tribology International, 2020, 152: 106499.1-106499.12. [24] 李响,任尊松,王子. 基于梯形轨枕轨道振动特性的钢轨波磨研究[J]. 铁道学报,2020,42(10): 38-44. doi: 10.3969/j.issn.1001-8360.2020.10.006LI Xiang, REN Zunsong, WANG Zi. Study on rail corrugation of ladder-type sleeper track based on vibration characteristics[J]. Journal of the China Railway Society, 2020, 42(10): 38-44. doi: 10.3969/j.issn.1001-8360.2020.10.006 [25] YAN Z Q, MARKINE V, GU A J, et al. Optimisation of the dynamic properties of ladder track to minimise the chance of rail corrugation[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2014, 228(3): 285-297. doi: 10.1177/0954409712472329 [26] OREGUI M, LI Z, DOLLEVOET R. An investigation into the modeling of railway fastening[J]. International Journal of Mechanical Sciences, 2015, 92: 1-11. doi: 10.1016/j.ijmecsci.2014.11.019 [27] LI W, WANG H Y, WEN Z F, et al. An investigation into the mechanism of metro rail corrugation using experimental and theoretical methods[J]. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 2016, 230(4): 1025-1039. doi: 10.1177/0954409715596182 [28] 崔晓璐,唐传平,包鹏羽,等. 高速列车制动区段钢轨波磨抑制方法[J]. 西南交通大学学报,2023,58(3): 656-664. doi: 10.3969/j.issn.0258-2724.20220256CUI Xiaolu, TANG Chuanping, BAO Pengyu, et al. Rail corrugation suppressing method on braking sections of high-speed trains[J]. Journal of Southwest Jiaotong University, 2023, 58(3): 656-664. doi: 10.3969/j.issn.0258-2724.20220256 [29] CUI X L, CHENG Z, YANG Z C, et al. Study on the phenomenon of rail corrugation on high-speed rail based on the friction-induced vibration and feedback vibration[J]. Vehicle System Dynamics, 2022, 60(2): 413-432. doi: 10.1080/00423114.2020.1817507 -

下载:

下载: