Cutter Layout on Special-Shaped Cutterhead for Shaft Boring Machine

-

摘要:

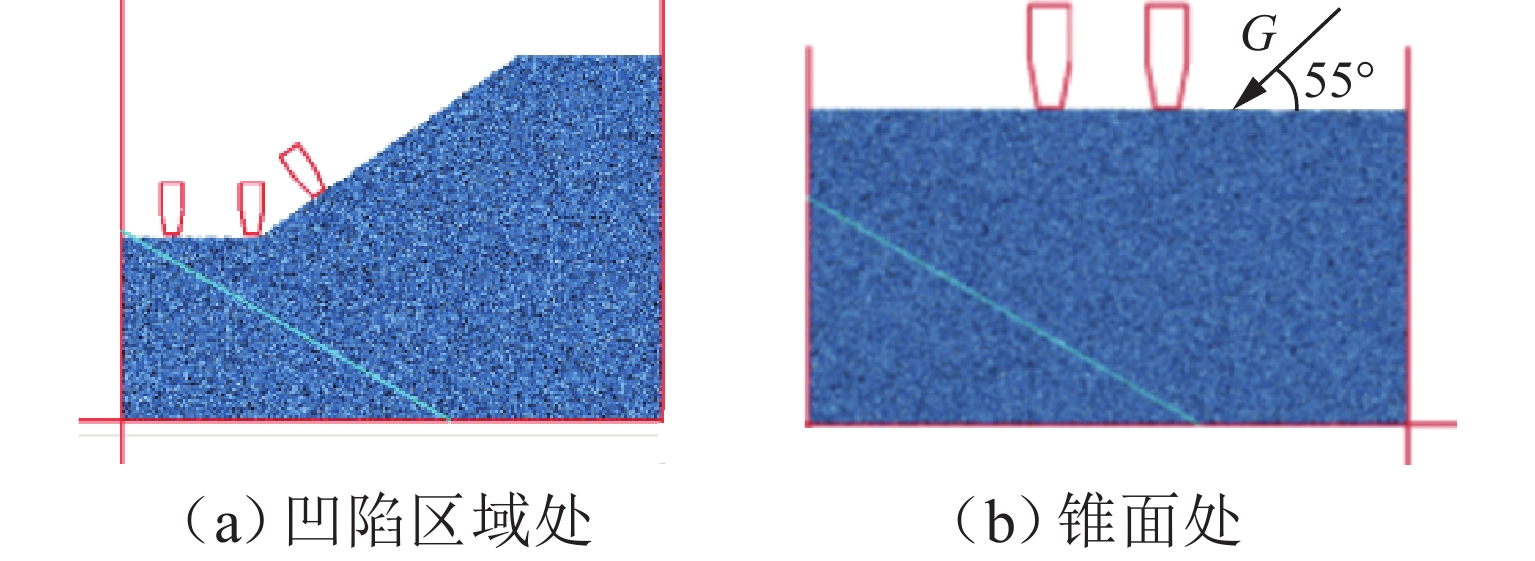

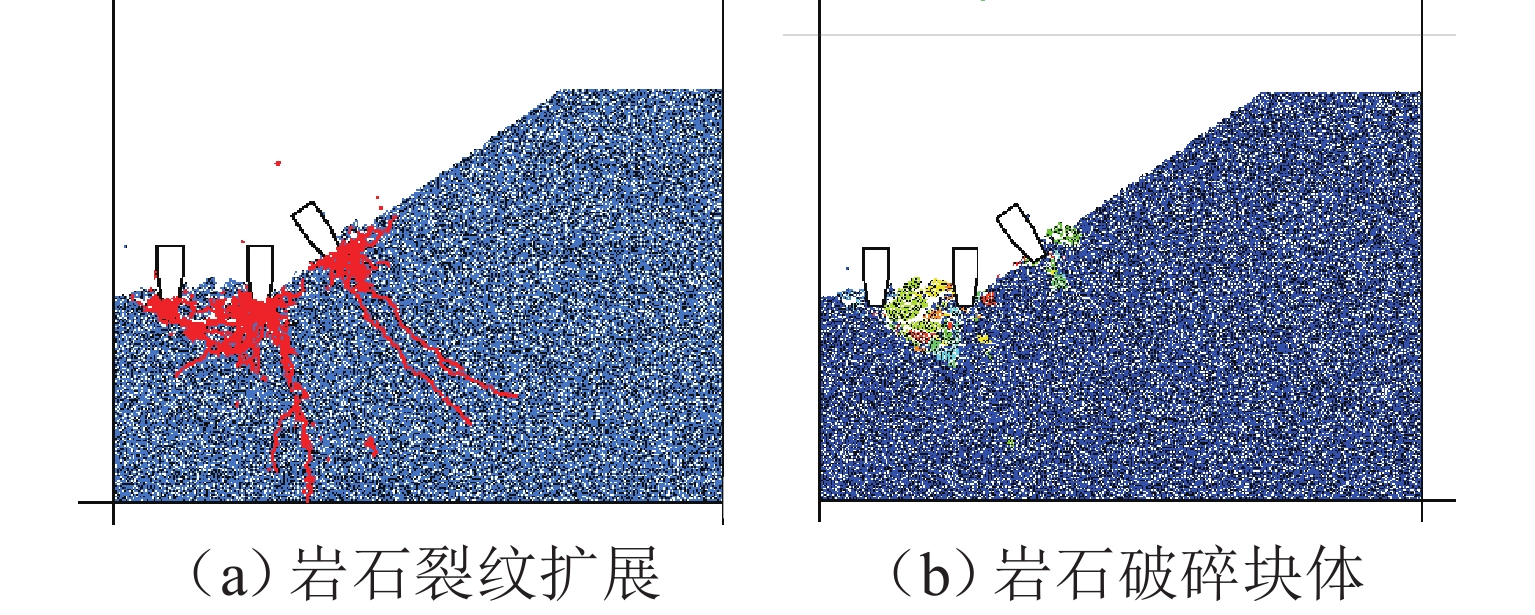

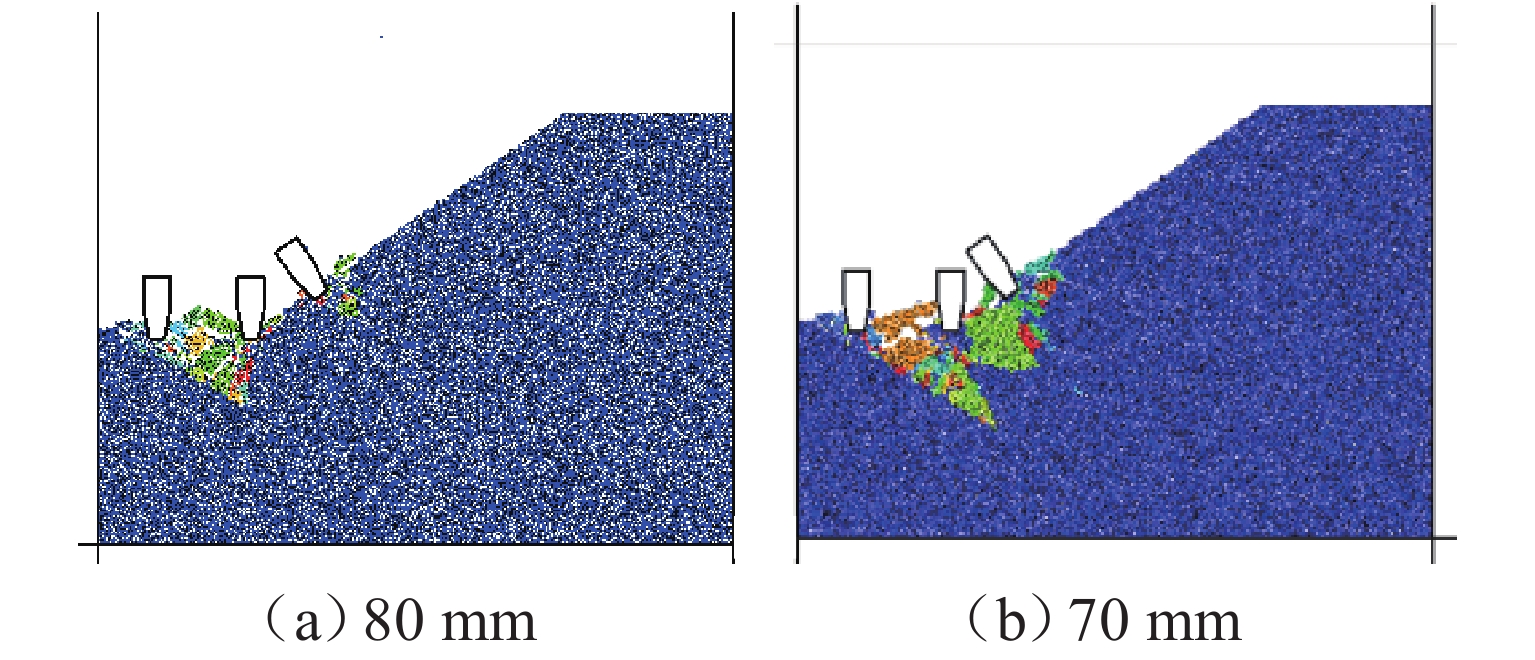

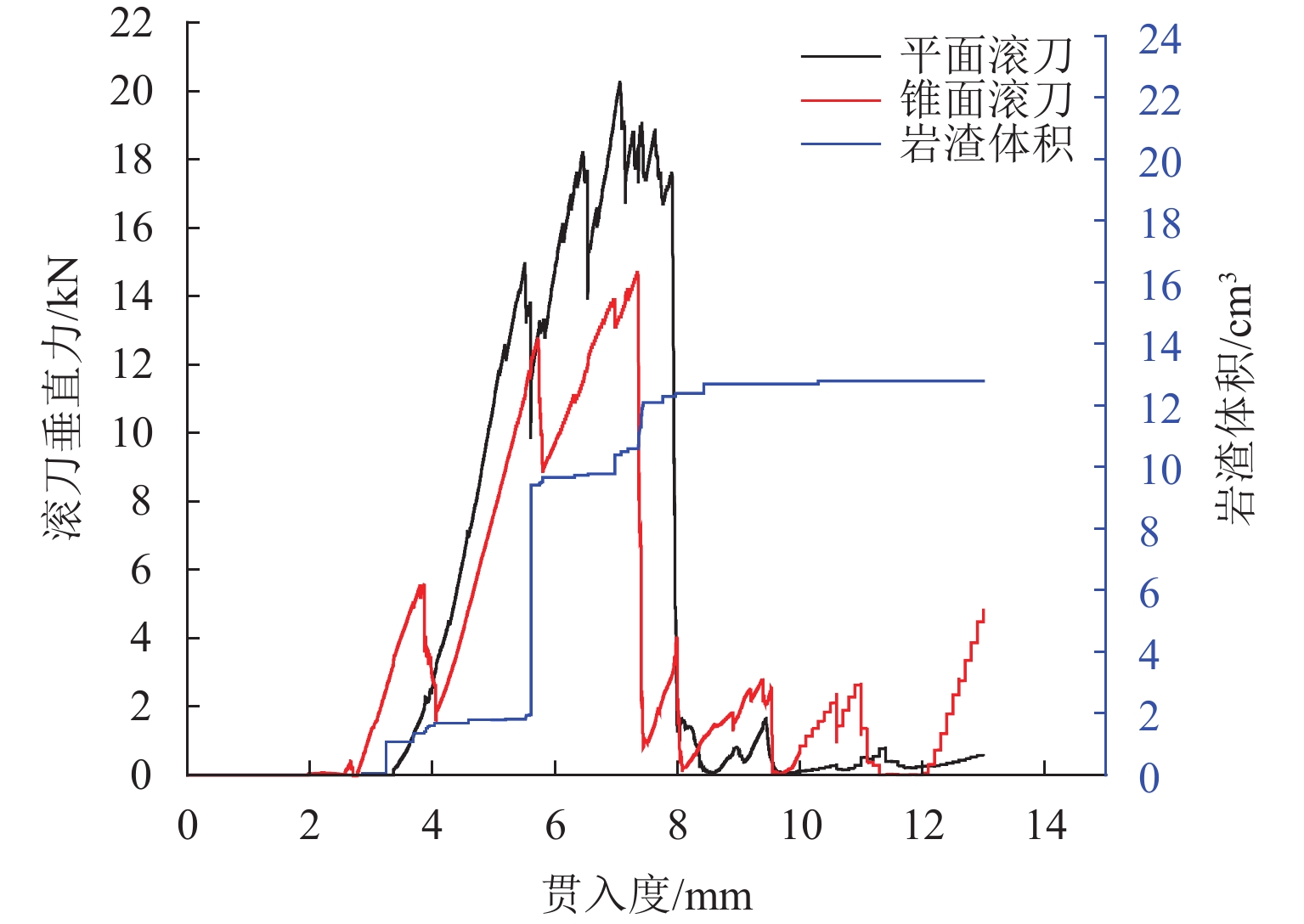

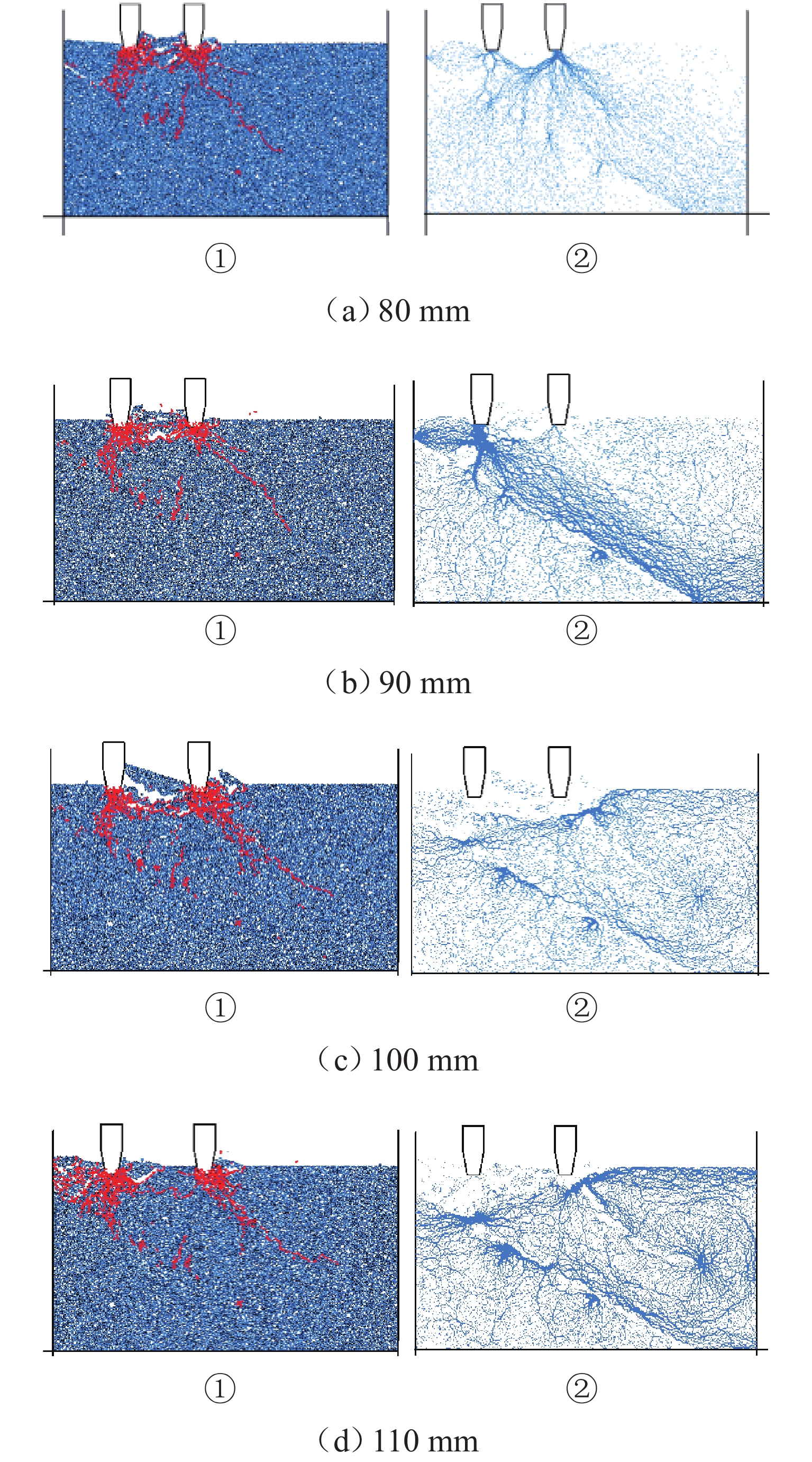

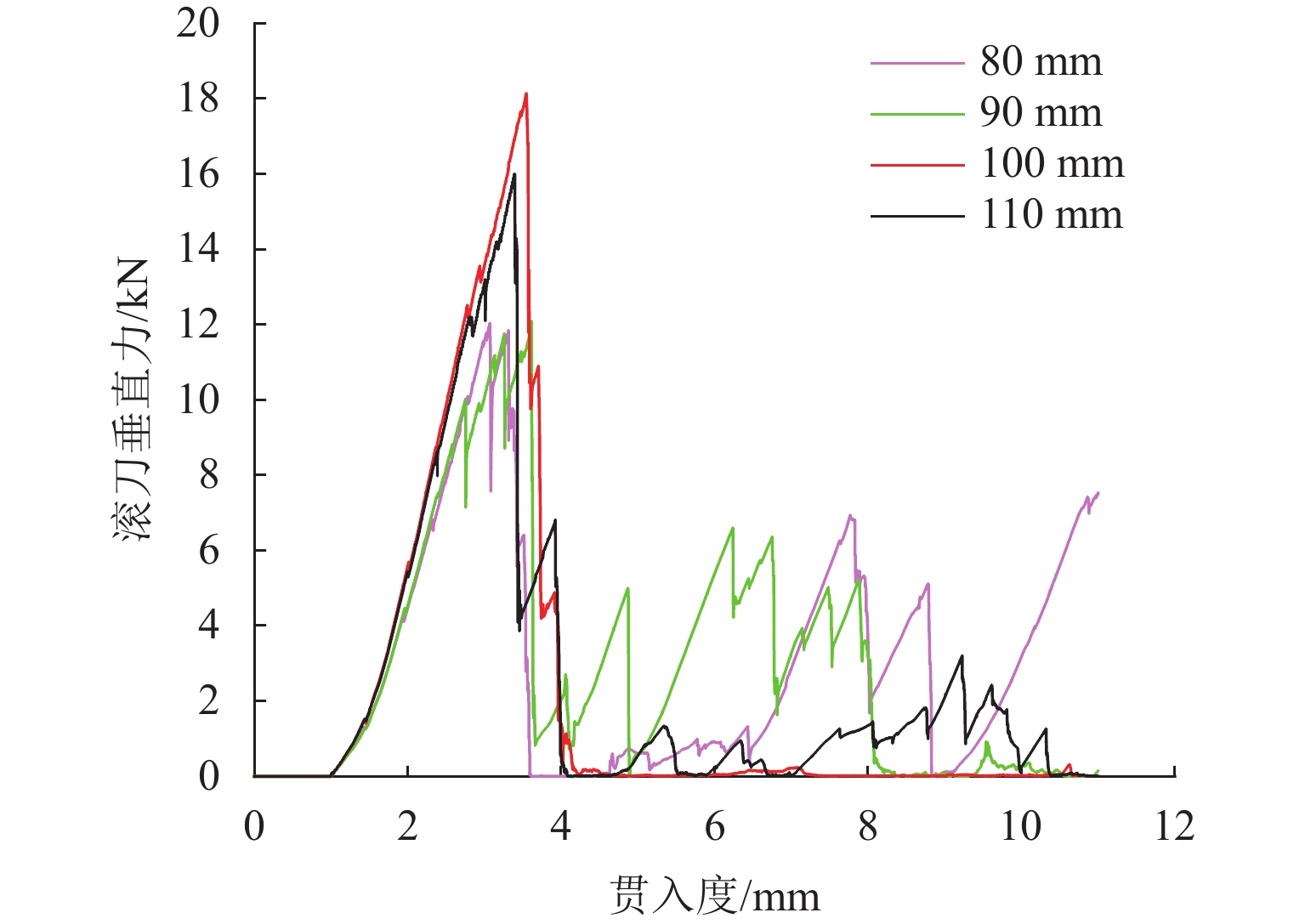

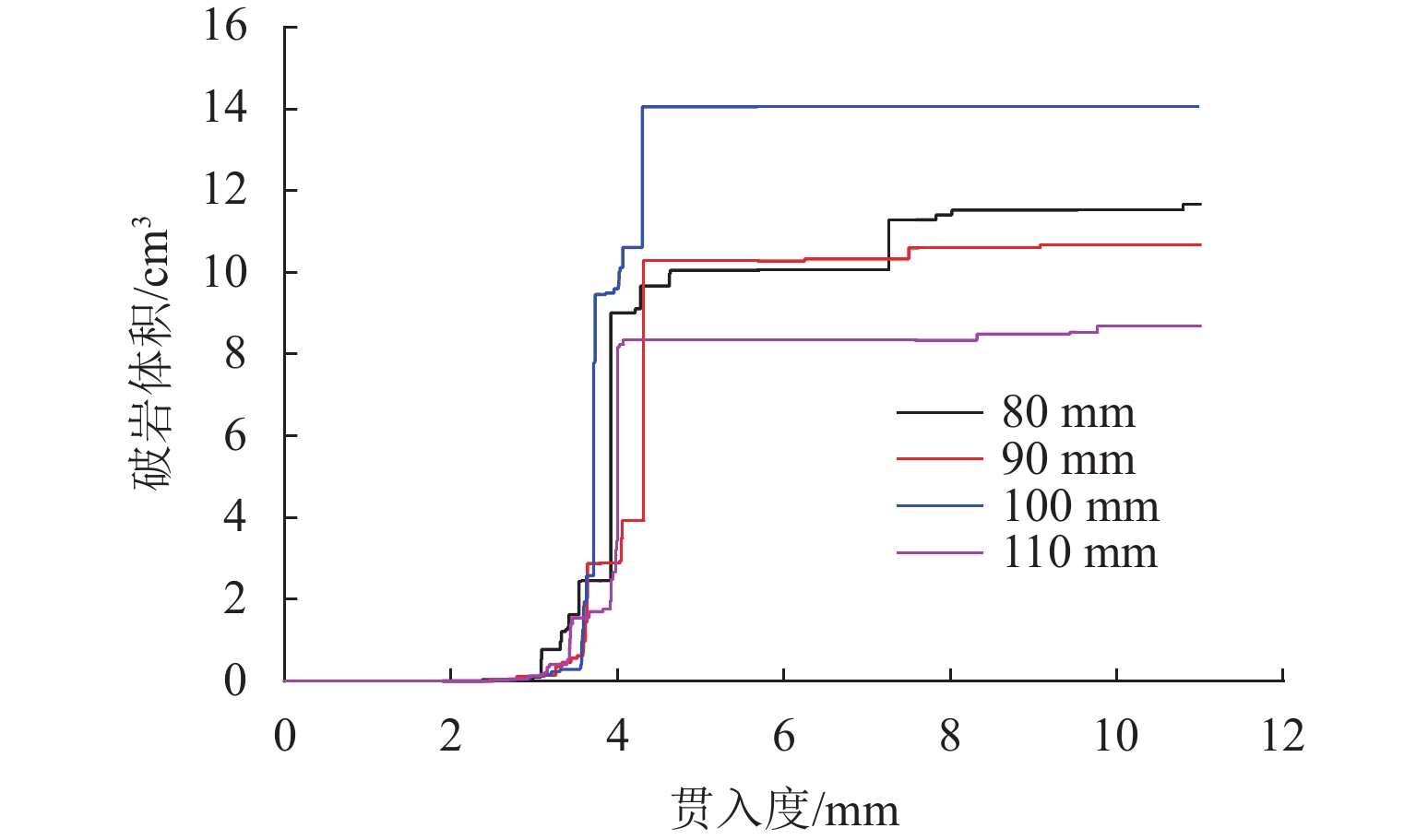

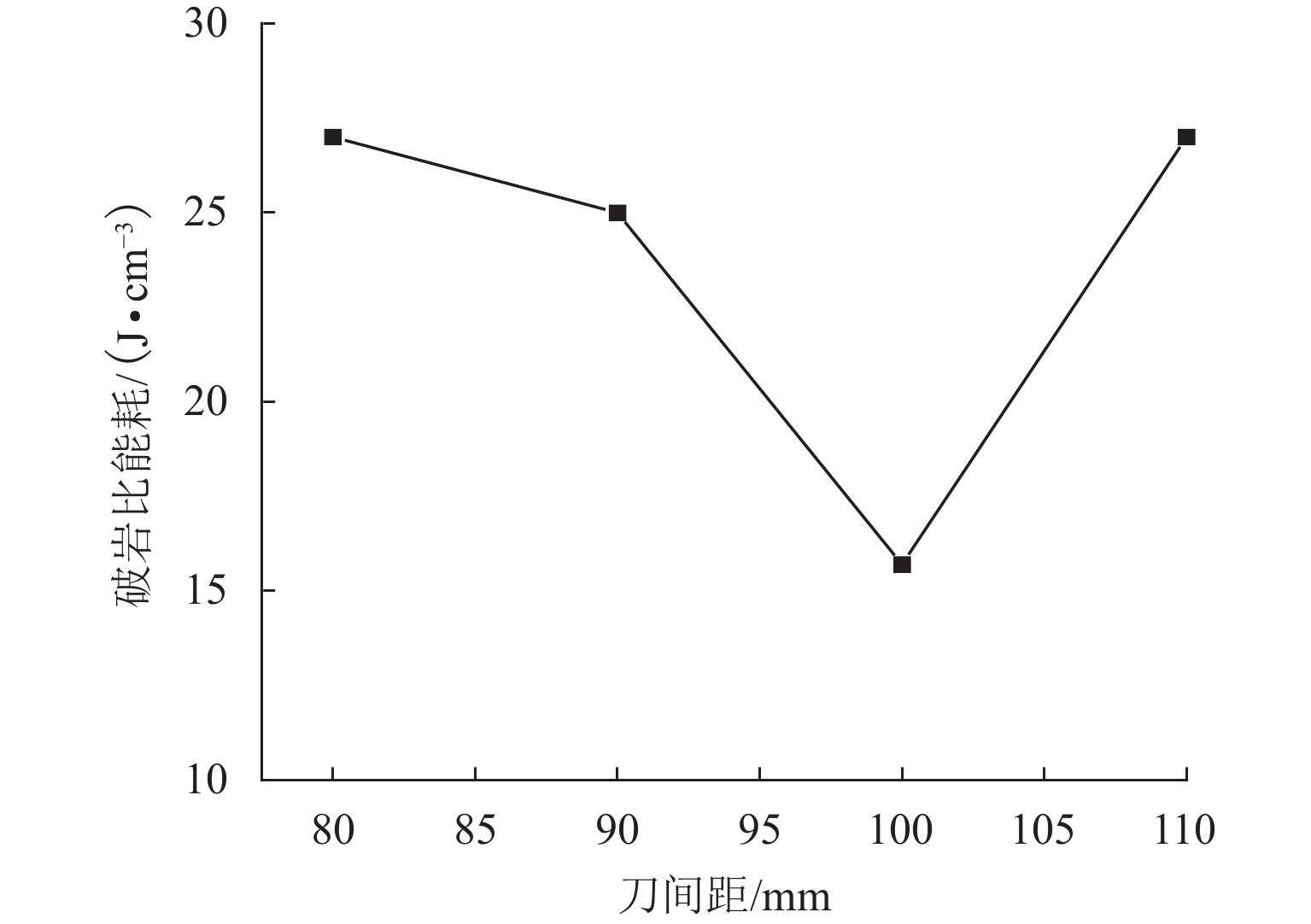

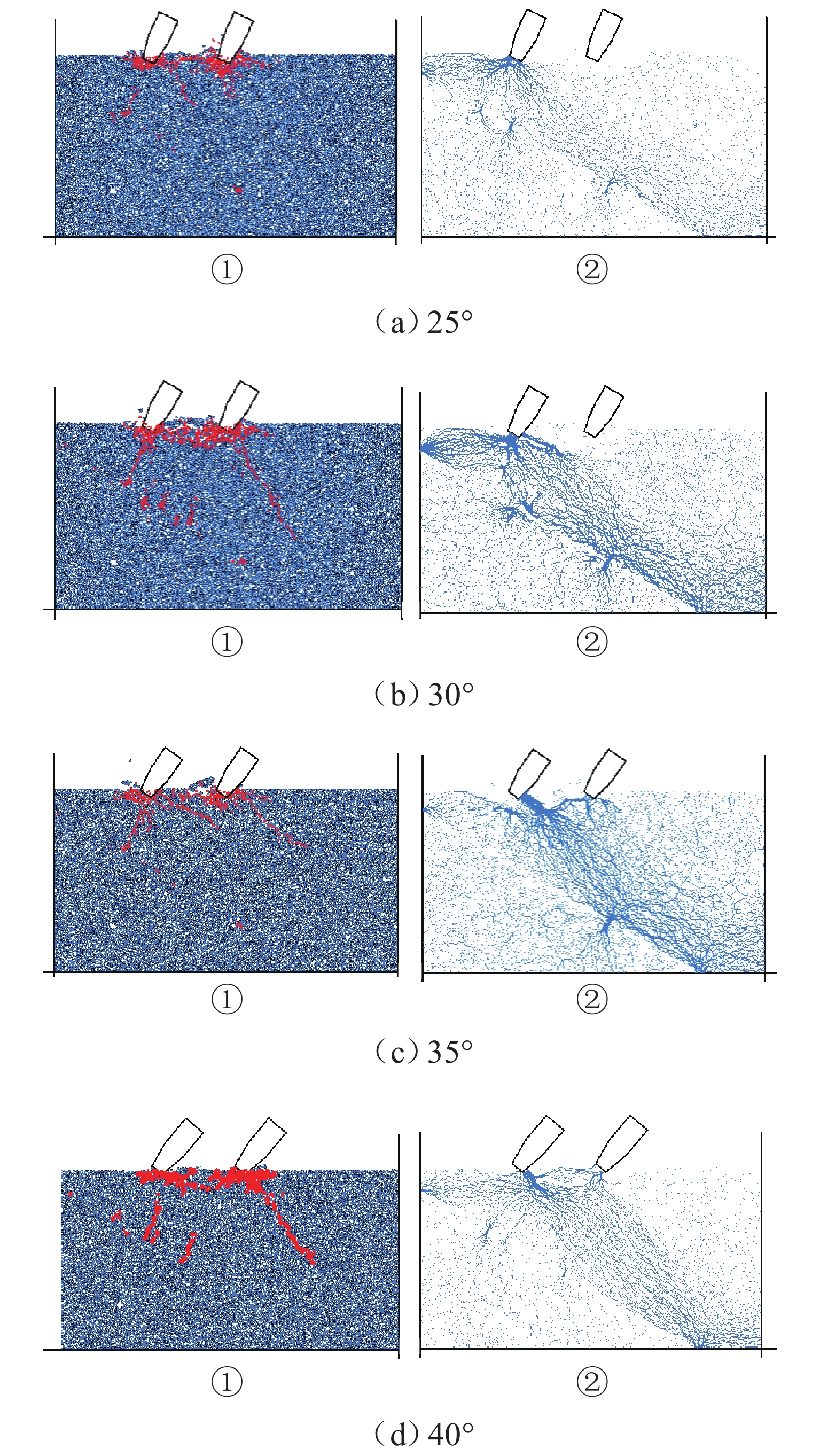

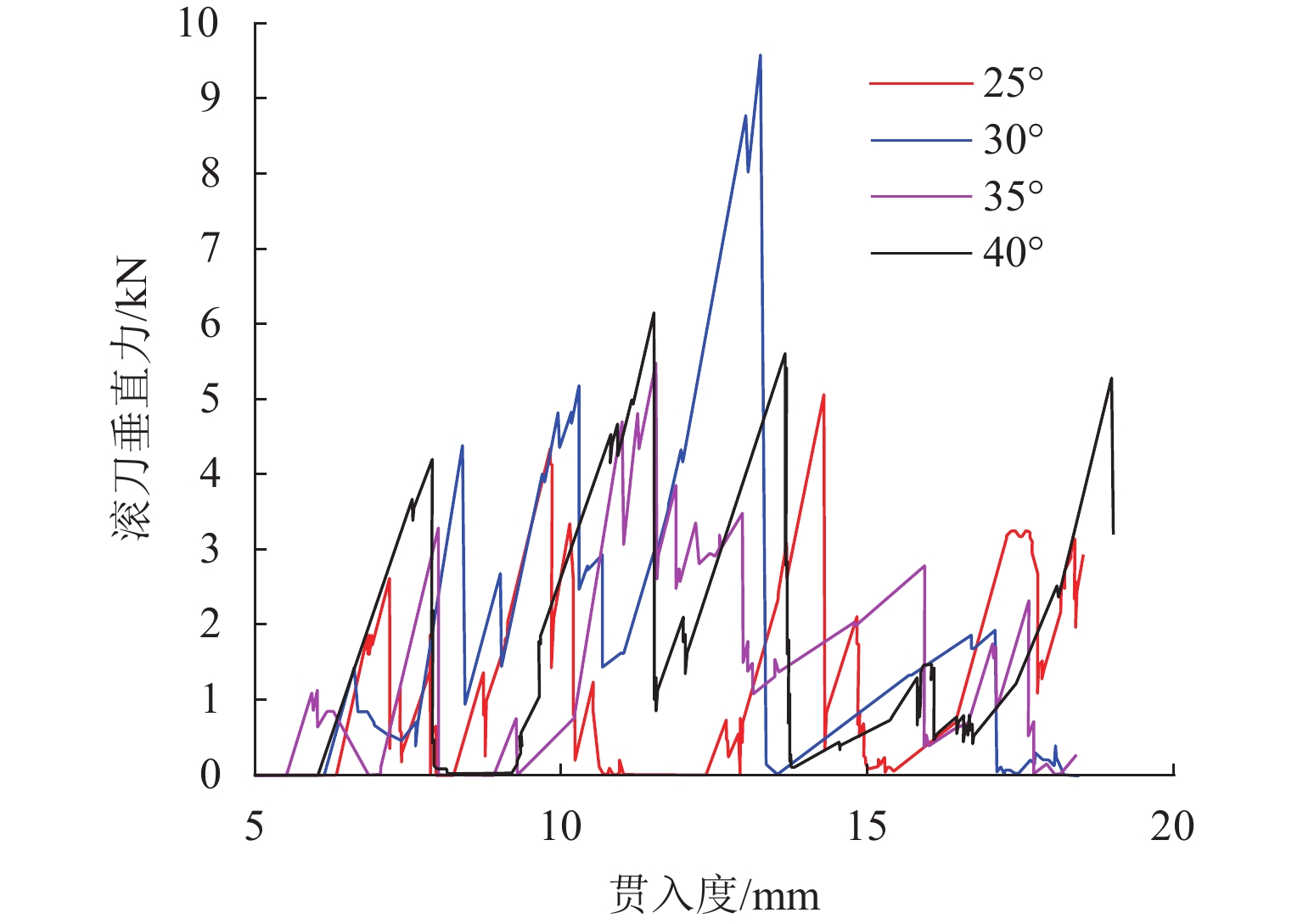

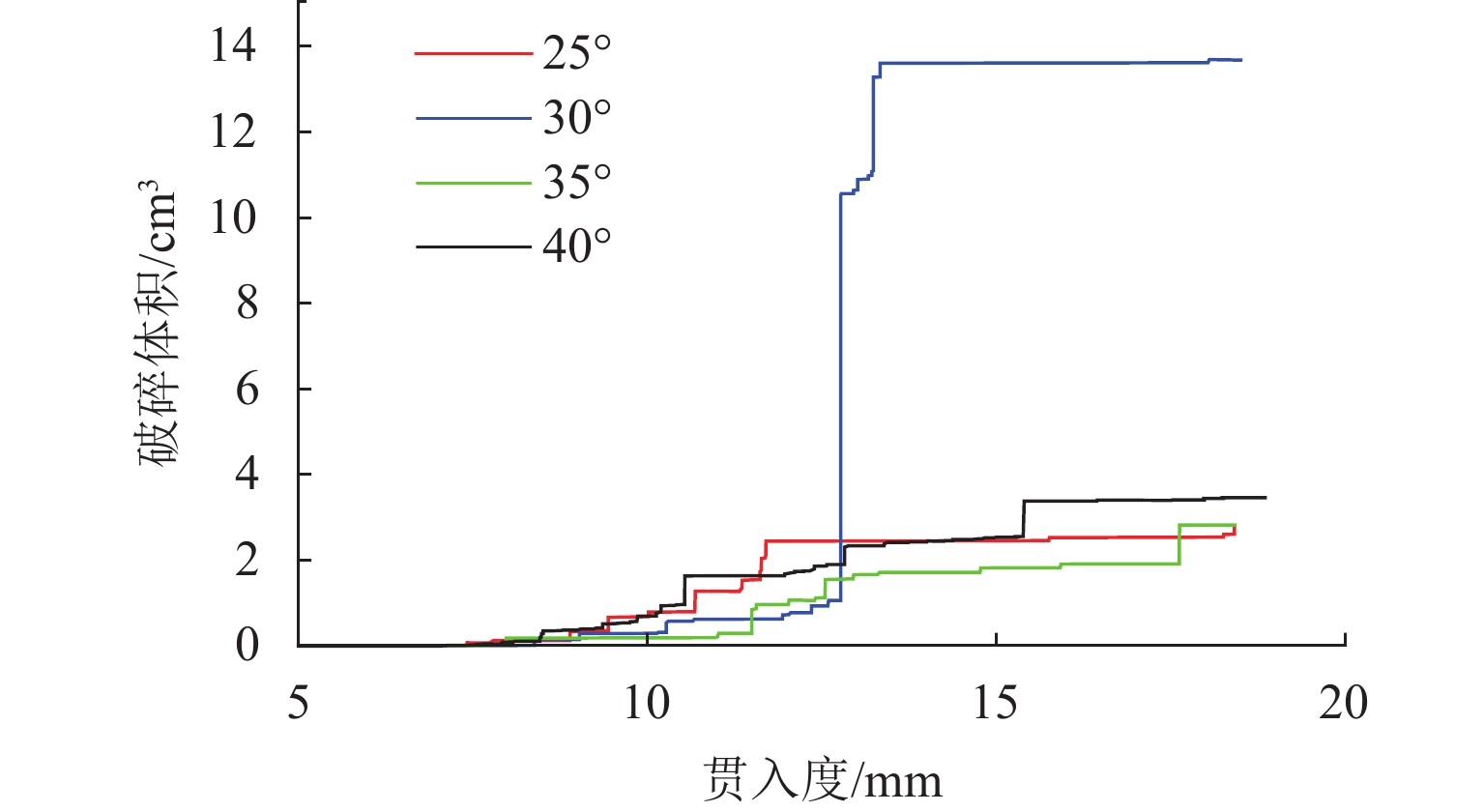

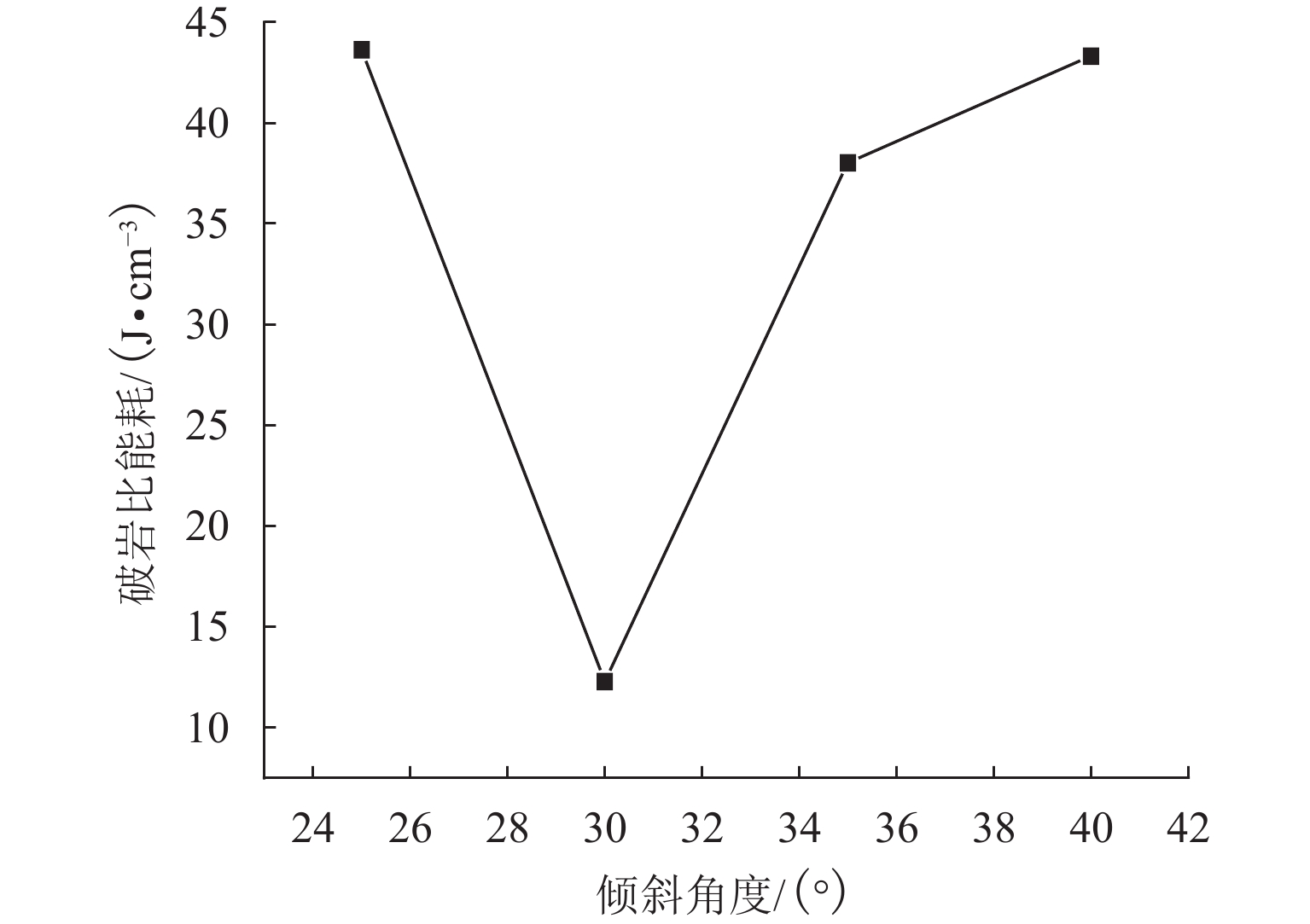

为解决竖井全断面掘进机类“W”型刀盘滚刀布局困难的问题,基于离散元法研究滚刀安装排布参数对滚刀破岩效果的影响规律,通过粒子群优化算法得到滚刀整体布局优化方案. 首先,分别建立掌子面凹陷区域处和锥面处滚刀组协同破岩的二维离散元模型;然后,研究不同布刀间距的凹陷区域处滚刀组协同破岩效果,揭示锥面处滚刀刀间距及安装倾角对岩石破碎情况、滚刀载荷和破岩效率的影响规律,以破岩比能为指标得到合理的锥面处滚刀刀间距和安装倾角;最后,分析确定星型布局方式是适合异型刀盘上滚刀的布局方式,并利用粒子群算法优化滚刀布局方案. 研究结果表明:千枚岩地层中凹陷区域处应该缩小滚刀组的布刀间距;锥面处异型刀盘的滚刀采用垂直锥面安装方式时,岩石破碎效率更高;滚刀布局优化后的异型刀盘径向载荷减小24.07%,刀盘合力矩减少40.83%. 研究成果可为竖井工程中异型刀盘的滚刀布局提供参考.

Abstract:In order to solve the problem of difficult cutter layout on a W-shaped cutterhead for a shaft boring machine, the influence of cutter installation and arrangement parameters on the rock breaking effect of cutters was studied based on the discrete element method, and the overall layout optimization scheme of cutters was obtained by particle swarm optimization algorithm. Firstly, the two-dimensional discrete element model of the cooperative rock breaking of cutters at the depression area and the conical surface of the tunnel face was established, respectively. Then, the cooperative rock breaking effect of cutters with different cutter spacing at the depression area was studied, and the influence of different cutter spacing and tilt angles at the conical surface on the rock breaking condition, cutter load, and rock breaking efficiency was revealed. The reasonable cutter spacing and tilt angle at the conical surface were obtained by taking the specific energy of rock breaking as the index. Finally, it was found that the star-shaped layout was suitable for cutters on the special-shaped cutterhead, and the particle swarm optimization algorithm was used to optimize the cutter layout scheme. The results show that cutter spacing of cutters should be reduced at the depression area of the phyllite strata. When cutters on the special-shaped cutterhead at the conical surface adopt the vertical conical installation method, the rock breaking efficiency is higher. After the optimization of the cutter layout, the radial load of the special-shaped cutterhead is reduced by 24.07%, and the resultant moment of the cutterhead is reduced by 40.83%. The research results can provide a reference for cutter layout on the special-shaped cutterhead in shaft engineering.

-

表 1 各地层岩石力学参数

Table 1. Rock mechanics parameters of each stratum

深度/m 地层 承载力/kPa 抗压强度/MPa 内摩擦角/(°) 凝聚力/MPa 密度/(g·cm−3) 2~4 粉质黏土 150 0.16 23.9 0.04 1.95 16~37 强风化石英岩 600 48.50 38.2 1.30 2.70 48~50 中风化石英岩 2500 63.50 5.2 4.50 2.90 60~79 微风化石英岩 5000 87.10 34.8 5.20 2.90 90~702 千枚岩 3500 78.50 24.8 9.93 2.70 表 2 千枚岩体模型的细观参数

Table 2. Meso-parameters of phyllite model

参数 取值 有效模量/GPa 9.95 刚度比 1.5 胶结有效模量/GPa 9.95 胶结刚度比 1.5 内聚力/MPa 8.0 摩擦角/(°) 38.5 摩擦系数 0.6 表 3 未优化的部分刀具布局参数

Table 3. Partial cutter layout parameters not involved in optimization

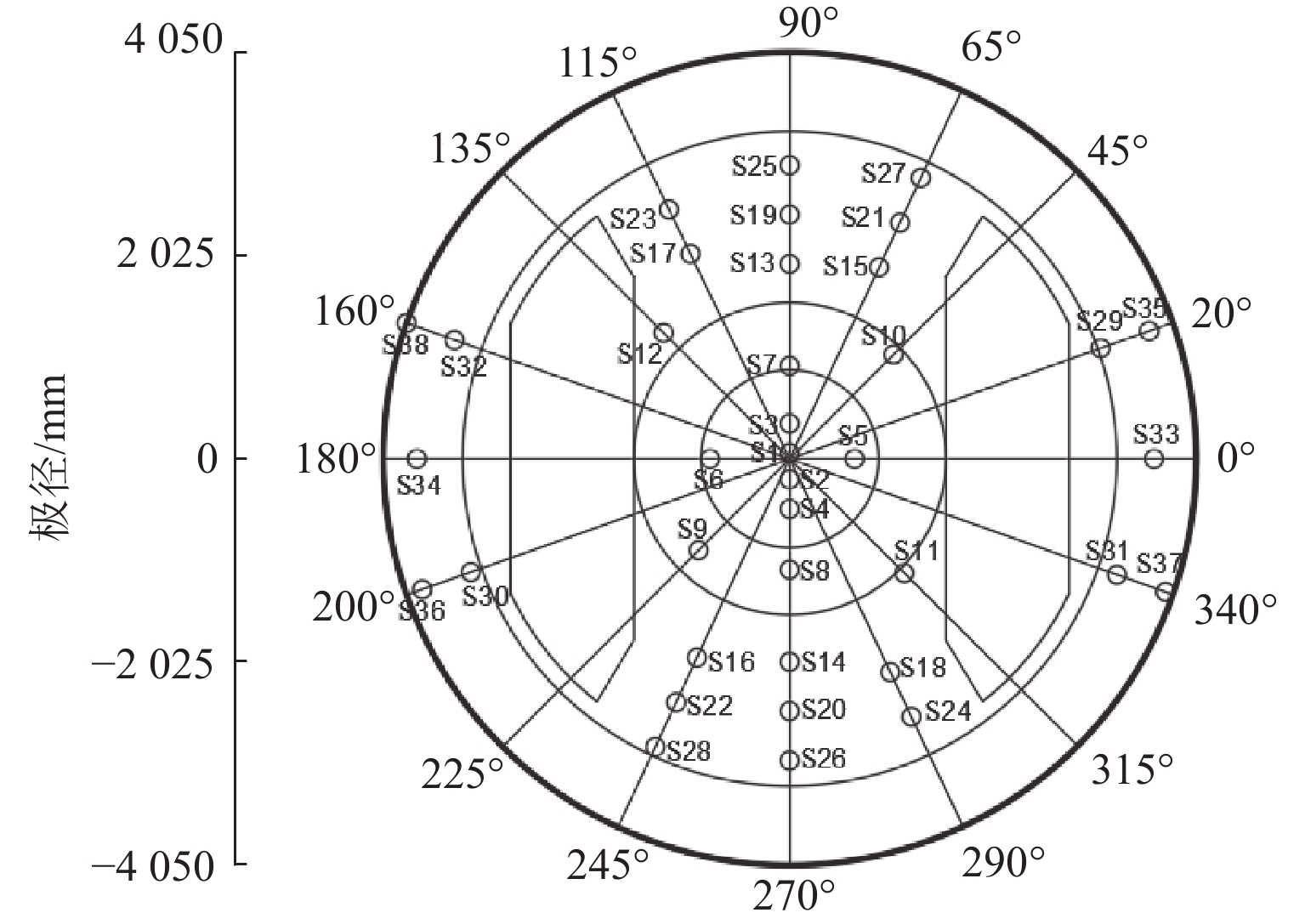

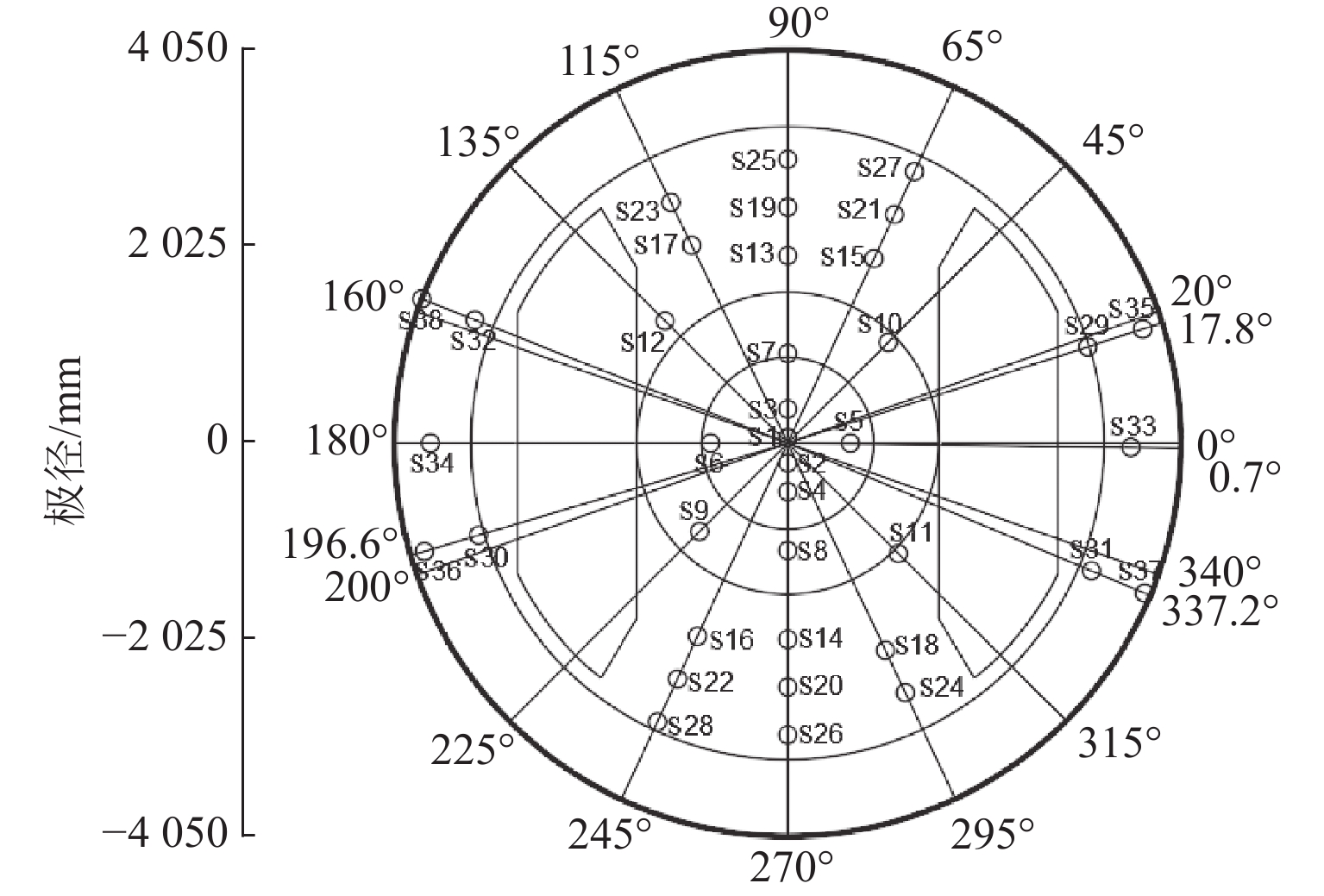

滚刀刀号 极径/mm 极角/(°) S1 57.34、130.66 90.0 S2 204.38、278.10 270.0 S3 351.82、425.54 90.0 S4 499.26、572.98 270.0 S5 646.70、720.42 0 S6 794.14、867.86 180.0 S7 925.20、 1015.20 90.0 S8 1105.20 、1195.20 270.0 S9 1285.20 、1375.20 225.0 S10 1465.20 、1555.20 45.0 表 5 优化前后各目标函数的对比

Table 5. Comparison of objective functions before and after optimization

目标函数 径向载荷/N 刀盘合力矩/

(×109 N•m)破岩量方差/

(×105 mm3)原刀盘 446.19 3.5 333.73 优化后 338.88 2.1 333.68 表 4 优化前、后滚刀布局参数

Table 4. Partial cutter layout parameters before and after optimization

滚刀刀号 优化前 优化后 极径/mm 极角/

(°)极径/mm 极角/

(°)S11 1612.54 、1694.46 315.0 1609.30 、1695.90 315.0 S12 1776.38 、1858.30 135.0 1781.80 、1859.30 135.0 S13 1940.22 90.0 1932.80 90.0 S14 2022.14 270.0 2021.10 270.0 S15 2104.06 65.0 2098.50 65.0 S16 2185.98 245.0 2194.50 245.0 S17 2267.90 115.0 2265.10 115.0 S18 2349.82 295.0 2357.60 295.0 S19 2431.74 90.0 2432.20 90.0 S20 2513.66 270.0 2511.30 270.0 S21 2595.58 65.0 2599.70 65.0 S22 2677.50 245.0 2680.50 245.0 S23 2759.42 115.0 2755.90 115.0 S24 2841.34 295.0 2845.40 295.0 S25 2923.26 90.0 2924.40 90.0 S26 3005.18 270.0 3008.80 270.0 S27 3087.10 65.0 3085.50 65.0 S28 3169.02 245.0 3171.00 245.0 S29 3242.74 20.0 3245.20 17.8 S30 3316.46 200.0 3318.40 196.6 S31 3390.18 340.0 3392.80 337.2 S32 3463.90 160.0 3460.00 158.5 S33 3537.62 (3611.34 )0 3535.50 (3611.30 )−0.7 S34 3685.06 (3758.78 )180.0 3678.30 (3751.20 )180.0 S35 3832.50 20.0 3839.80 17.8 S36 3906.22 200.0 3903.50 196.6 S37 3979.94 340.0 3985.80 337.2 S38 4050.00 160.0 4050.00 158.5 -

[1] 徐辉东,刘林林,付新鹏. 竖井全断面机械破岩装备技术现状及发展方向[J]. 建井技术,2020,41(6): 51-57.XU Huidong, LIU Linlin, FU Xinpeng. Technology status and development of vertical shaft full-face mechanical rock cutting equipment[J]. Mine Construction Technology, 2020, 41(6): 51-57. [2] 刘志强,宋朝阳,程守业,等. 千米级竖井全断面科学钻进装备与关键技术分析[J]. 煤炭学报,2020,45(11): 3645-3656.LIU Zhiqiang, SONG Zhao Yang, CHENG Shouye, et al. Equipment and key technologies for full-section scientifically drilling of kilometer-level vertical shafts[J]. Journal of China Coal Society, 2020, 45(11): 3645-3656. [3] 刘志强. 竖井掘进机凿井技术[M]. 北京:煤炭工业出版社,2018:52-60. [4] KANG Y Q, YANG R S, YANG L Y, et al. Theoretical and numerical studies of rock breaking mechanism by double disc cutters[J]. International Journal of Mining Science and Technology, 2023, 33(7): 815-828. doi: 10.1016/j.ijmst.2023.03.006 [5] 刘立鹏,刘海舰,傅睿智,等. TBM双滚刀间距及入岩次序对破岩效果影响研究[J]. 水利水电技术,2018,49(4): 56-62.LIU Lipeng, LIU Haijian, FU Ruizhi, et al. Study on influencesfrom spacing between dual-disc cutters and rock-penetrating sequence of TBM on rock-breaking effect[J]. Water Resources and Hydropower Engineering, 2018, 49(4): 56-62. [6] ZHANG Z Q, ZHANG K J, DONG W J, et al. Study of rock-cutting process by disc cutters in mixed ground based on three-dimensional particle flow model[J]. Rock Mechanics and Rock Engineering, 2020, 53(8): 3485-3506. doi: 10.1007/s00603-020-02118-y [7] CHO J W, JEON S, JEONG H Y, et al. Evaluation of cutting efficiency during TBM disc cutter excavation within a Korean granitic rock using linear-cutting-machine testing and photogrammetric measurement[J]. Tunnelling and Underground Space Technology Incorporating Trenchless Technology Research, 2013, 35: 37-54. [8] CHANG S H, CHOI S W, BAE G J, et al. Performance prediction of TBM disc cutting on granitic rock by the linear cutting test[J]. Tunnelling and Underground Space Technology, 2006, 21(3/4): 271-271. [9] 宁向可,耿麒,卢智勇,等. 全断面隧道掘进机锥面刀盘滚刀破岩机制研究[J]. 现代隧道技术,2023,60(2): 73-83.NING Xiangke, GENG Qi, LU Zhiyong, et al. A study on the rock-breaking mechanism of disc cutters on cone cutterhead of full-face tunnel boring machines[J]. Modern Tunnelling Technology, 2023, 60(2): 73-83. [10] 薛亚东,周杰,赵丰,等. 基于MatDEM的TBM滚刀破岩机理研究[J]. 岩土力学,2020,41(增1): 337-346.XUE Yadong, ZHOU Jie, ZHAO Feng, et al. Study on rock breaking mechanism of TBM hob based on MatDEM[J]. Rock and Soil Mechanics, 2020, 41(S1): 337-346. [11] 张蒙祺,王一博,章龙管,等. 不同岩石和围压下刃形对滚刀破岩性能的影响[J]. 西南交通大学学报,2023,58(2): 332-339.ZHANG Mengqi, WANG Yibo, ZHANG Longguan, et al. Effects of TBM cutter profile on rock fragmentation under different rock type and confining pressure conditions[J]. Journal of Southwest Jiaotong University, 2023, 58(2): 332-339. [12] 吴永胜,谭忠盛,喻渝,等. 川西北茂县群千枚岩各向异性力学特性[J]. 岩土力学,2018,39(1): 207-215.WU Yongsheng, TAN Zhongsheng, YU Yu, et al. Anisotropically mechanical characteristics of Maoxian Group phyllite in northwest of Sichuan Province[J]. Rock and Soil Mechanics, 2018, 39(1): 207-215. [13] 帅攀,赵伟华,周怡劼. 千枚岩倾倒变形岩体饱水软化效应试验研究[J]. 地下水,2023,45(2): 8-12. [14] 管会生. 工程机械理论与设计[M]. 成都:西南交通大学出版社,2020:12-13. [15] 宋纯宁. 基于对称与不对称刀具下的TBM刀盘力学性能分析[D]. 北京:华北电力大学,2020. [16] 冯欢欢,陈馈,周建军,等. 掘进机滚刀最优破岩刀间距的分析与计算[J]. 现代隧道技术,2014,51(3): 124-130,137.FENG Huanhuan, CHEN Kui, ZHOU Jianjun, et al. Analysis and calculation of optimum TBM disc cutter spacing[J]. Modern Tunnelling Technology, 2014, 51(3): 124-130,137. [17] 徐飞. 炭质千枚岩隧道围岩流变机制与让抗耦合支护结构研发及工程应用[D]. 济南:山东大学,2017. [18] 黄薇,闫治涛,孙峰,等. 层状页岩巴西劈裂破坏特征颗粒流模拟研究[J]. 山东科技大学学报(自然科学版),2022,41(6): 74-82.HUANG Wei, YAN Zhitao, SUN Feng, et al. Particle flow simulation of Brazilian splitting failure characteristics of layered shale[J]. Journal of Shandong University of Science and Technology (Natural Science), 2022, 41(6): 74-82. [19] 孔晓璇,刘泉声,赵怡凡,等. 节理倾角对岩石隧道掘进机破岩特性影响的数值研究[J]. 煤炭学报,2015,40(6): 1257-1262.KONG Xiaoxuan, LIU Quansheng, ZHAO Yifan, et al. Numerical simulation on the effect of joint orientation on rock fragmentation by TBM disc cutters[J]. Journal of China Coal Society, 2015, 40(6): 1257-1262. [20] ROSTAMI J, OZDEMIR L. A new model for performance prediction of hard rock TBMs[C]// Proceedomgs of Rapid Excavation and Tunneling Conference (RETC). Boston: [s.n.], 1993: 793-809. [21] 张宏图,杨耀浦,刘勇,等. 低压磨料空气射流切槽辅助TBM滚刀破岩规律研究[J]. 煤炭学报,2023,11(12): 1-12. [22] 王鹏. 岩石脆性对镐型截齿破岩比能耗的影响[J]. 价值工程,2017,36(21): 155-156.WANG Peng. Effects of rock brittleness on specific energy of rock cutting using the conical pick[J]. Value Engineering, 2017, 36(21): 155-156. [23] 张照煌,乔永立. 全断面岩石掘进机盘形滚刀布置规律研究[J]. 工程力学,2011,28(5): 172-177.ZHANG Zhaohuang, QIAO Yongli. Research on the layout of tbm disc cutter[J]. Engineering Mechanics, 2011, 28(5): 172-177. [24] SHI Y, EBERHART R. A modified particle swarm optimizer[C]//1998 IEEE International Conference on Evolutionary Computation Proceedings. IEEE World Congress on Computational Intelligence (Cat. No. 98TH8360). Anchorage: IEEE, 2002: 69-73. [25] SUN H Y, GUO W, LIU J Q, et al. Layout design for disc cutters based on analysis of TBM cutter-head structure[J]. Journal of Central South University, 2018, 25(4): 812-830. doi: 10.1007/s11771-018-3786-8 [26] 乔金丽,孟秋杰,刘建琴,等. 基于等摩擦耗能的滚刀多目标优化布局[J]. 地下空间与工程学报,2020,16(2): 531-539.QIAO Jinli, MENG Qiujie, LIU Jianqin, et al. Multi-objective optimization design of disc cutter layout based on balanced friction energy consumption[J]. Chinese Journal of Underground Space and Engineering, 2020, 16(2): 531-539. -

下载:

下载: